Nano-modified epoxy resin and preparation method thereof

A technology of epoxy resin and nano-modification, which is applied in the direction of epoxy resin coating, coating, etc., can solve the problems of difficult polymerization of nano-materials and epoxy resin, and achieve the effect of superior performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

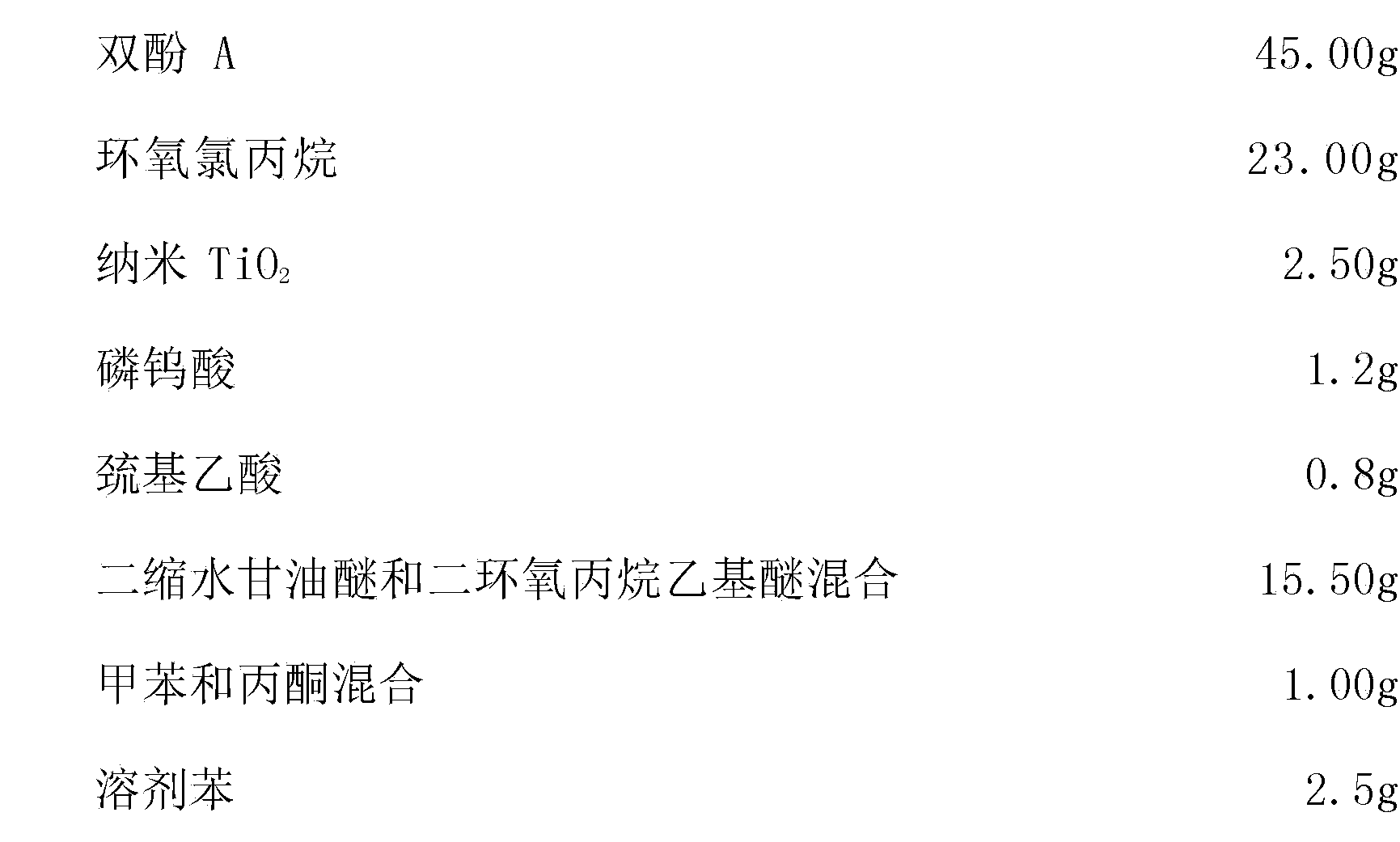

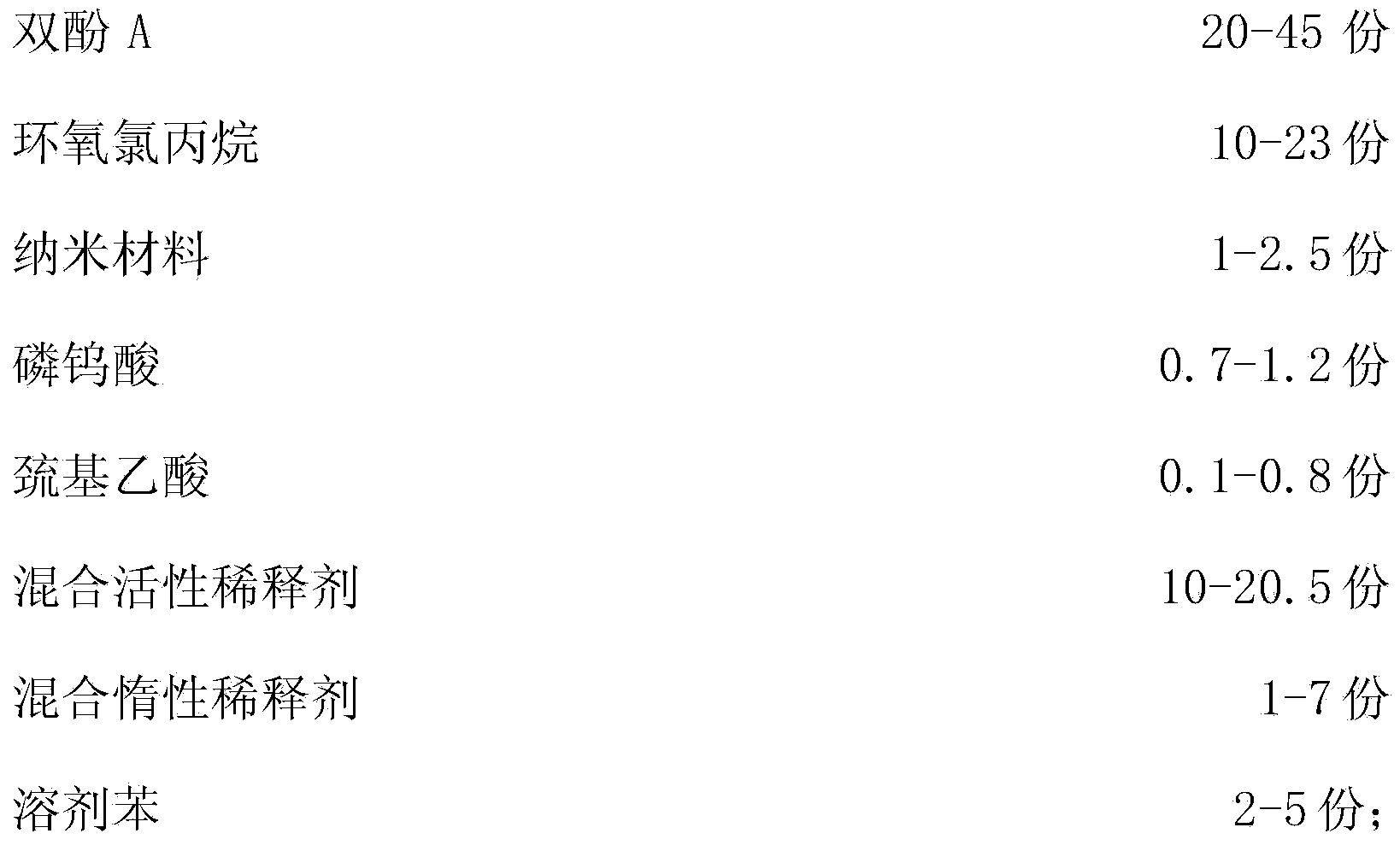

[0020] Embodiment 1: Nano TiO 2 Modified epoxy resin

[0021]

[0022] Mix 45.00g bisphenol A, 23.00g epichlorohydrin, 1.20 phosphotungstic acid, 0.80 mercaptoacetic acid, 15.50g mixed reactive diluent (diglycidyl ether and dioxypropylene ethyl ether mixed) and 1.00g mixed inert diluent Agent (mixed with toluene and acetone) was mixed under stirring to dissolve bisphenol A.

[0023] Add 0.85g of benzene dropwise to the mixed solution in the previous step, and control the temperature at 62°C. After the dropwise addition, raise the temperature to 90°C, and then sieve in 1.70g of nanomaterials to maintain the reaction. After the reaction is completed, recover epichlorohydrin; Add 0.85g of benzene dropwise to the reaction solution, and at the same time sieve in the remaining 0.80g of nanomaterials, keep warm to maintain the reaction; finally add the remaining 0.8g of benzene dropwise to dissolve the resin, stir and let stand to separate layers.

[0024] Put the resin liquid i...

Embodiment 2

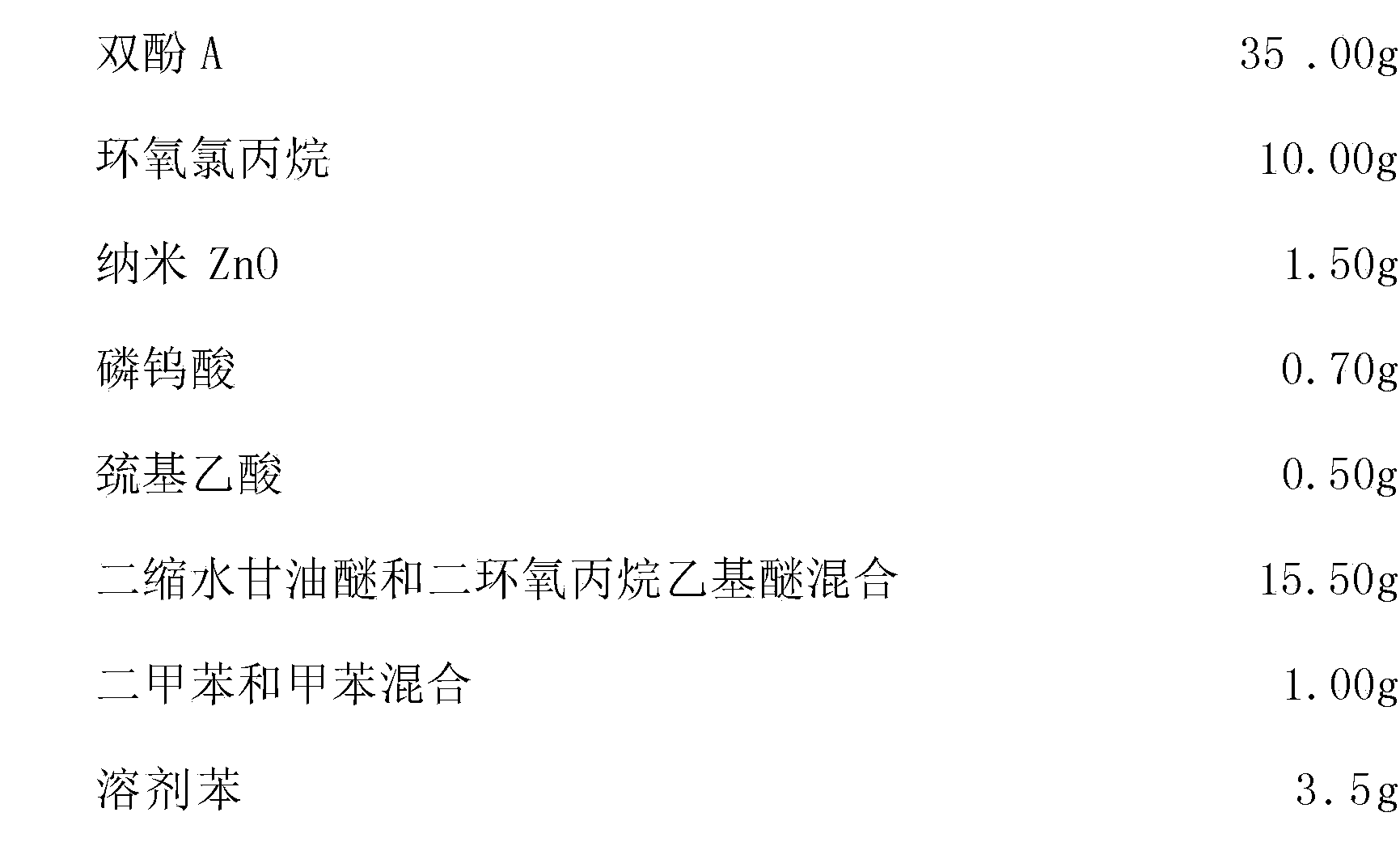

[0025] Embodiment 2: Nano ZnO modified epoxy resin

[0026]

[0027] The production process steps are the same as in Example 1.

Embodiment 3

[0028] Embodiment 3: Nano-CaCO 3 Modified epoxy resin

[0029] The production process steps are the same as in Example 1.

[0030] Embodiment 1-3 gained product performance test parameter is as shown in 1:

[0031]

[0032] Table 1

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com