Highly-anticorrosive and chromium-free anti-fingerprint coating and preparation method thereof

A fingerprint-resistant and high-corrosion-resistant technology, applied in the field of coatings, can solve problems such as poor corrosion resistance and solvent resistance, high-temperature yellowing, and environmental pollution, and achieve the effects of good fingerprint resistance, improved adhesion, and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

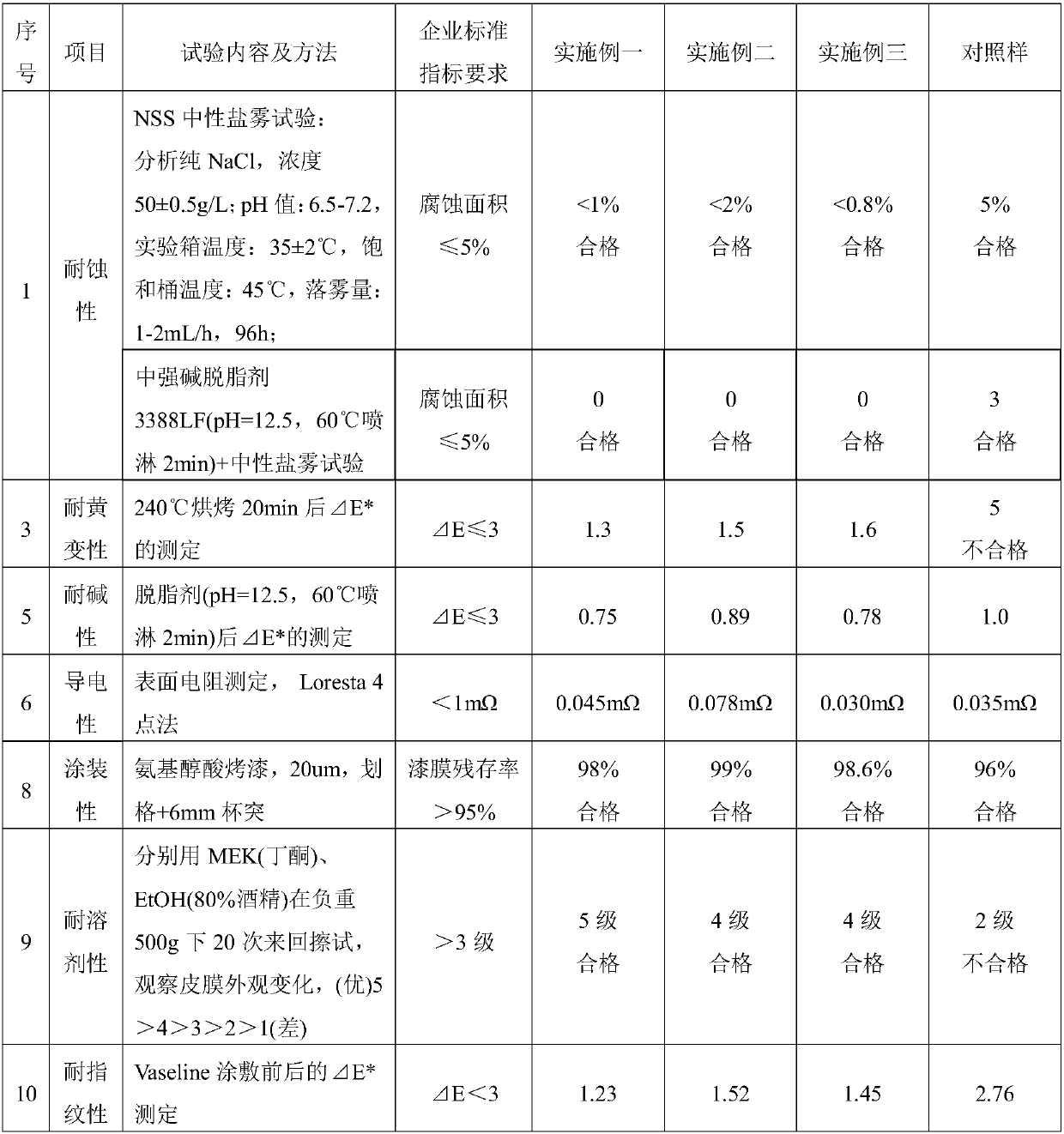

Examples

preparation example Construction

[0026] A kind of preparation method of high corrosion-resistant chrome-free anti-fingerprint coating of the present invention, comprises the following steps:

[0027] 1) Take deionized water, stir, and under stirring conditions, add epoxy acrylic resin, continue stirring to obtain mixture A;

[0028] 2) Under stirring conditions, slowly add silica sol and alkoxysilane to the mixture A obtained in step 1), and continue stirring to obtain mixture B;

[0029] 3) Under stirring conditions, add ethylene glycol, polytetrafluoroethylene wax, anti-corrosion additives, wetting agent and defoamer in sequence to the mixture B obtained in step 2), and continue stirring to obtain mixture C; 4) while Stirring, while filling, get anti-fingerprint paint.

[0030] Preferably, the stirring speeds in the step 1), the step 2), the step 3) and the step 4) are all 30-50r / min.

[0031] Further, the time for stirring in step 1) is 10-20 min, the time for stirring in step 2) is 20-60 min, and the ti...

Embodiment 1

[0033] A kind of preparation method of high corrosion-resistant chrome-free anti-fingerprint coating of the present invention, comprises the following steps:

[0034] 1) Take 110Kg of deionized water, add it to the stirring tank, start stirring, the stirring speed is 30r / min, under stirring condition, add 123Kg of silicone modified epoxy acrylate, continue stirring, the stirring speed is 30r / min, stir Time is 10min, obtains mixture A;

[0035] 2) Under the condition of stirring at a stirring speed of 30r / min, slowly add 80Kg of silica sol and 20Kg of alkoxysilane with a particle size of 10nm in the mixture A obtained in step 1), and continue stirring at a stirring speed of 30r / min. Stirring time was 20min to obtain mixture B;

[0036] 3) Under the stirring condition that the stirring speed is 30r / min, add ethylene glycol 20Kg, polytetrafluoroethylene wax 671 40Kg, anti-corrosion additive sodium molybdate 5Kg, wetting agent OP to the mixture B obtained in step 2). -91Kg and d...

Embodiment 2

[0039] A kind of preparation method of high corrosion-resistant chrome-free anti-fingerprint coating of the present invention, comprises the following steps:

[0040] 1) Take 305.2Kg of deionized water, add it to the stirring tank, start stirring, the stirring speed is 40r / min, under the stirring condition, add 40Kg of epoxy acrylic resin, continue stirring, the stirring speed is 40r / min, and the stirring time is 15min , to get mixture A;

[0041] 2) Under the condition of stirring at a stirring speed of 40r / min, slowly add 32Kg of silica sol and 4Kg of alkoxysilane to the mixture A obtained in step 1), and continue stirring at a stirring speed of 40r / min and a stirring time of 40min to obtain mixture B;

[0042] 3) Under the stirring condition that the stirring speed is 40r / min, add 4Kg of ethylene glycol, 12Kg of polytetrafluoroethylene wax, 2Kg of ammonium molybdate of anti-corrosion additive, wetting agent NP- 10 0.4Kg and defoamer SN-154 0.4Kg, continue to stir, the sti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com