Fluorocarbon coating and method for preparing colored aluminum profiles from fluorocarbon coating

A technology of fluorocarbon coatings and aluminum profiles, applied in polyester coatings, epoxy resin coatings, polyurea/polyurethane coatings, etc., can solve low production efficiency, UV fluorocarbon coatings cannot be cured, and fluorocarbon coatings have a long curing time, etc. problems, to achieve the effect of high production efficiency, rich paint film color, and small production site

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

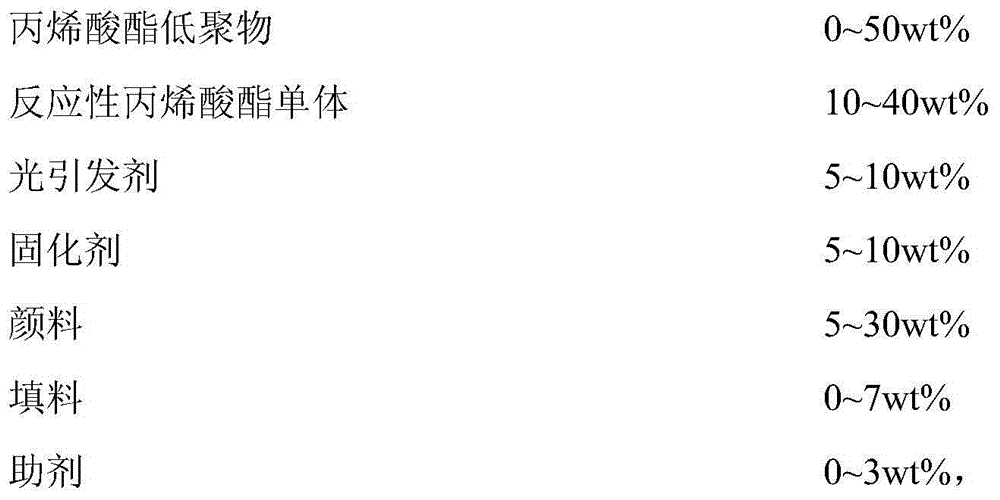

Method used

Image

Examples

Embodiment 1

[0027] Example 1: White high-gloss aluminum profile

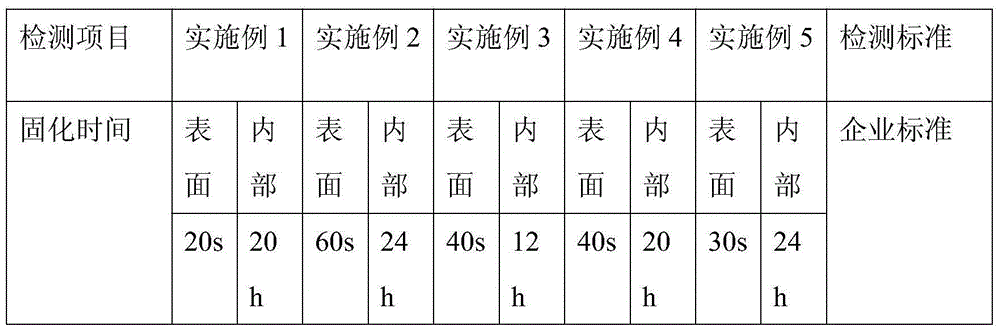

[0028] Soak the aluminum profile in 5% lye for 5 minutes, then clean the oil stain with water, dry it in an oven, and spray the double-cured white fluorocarbon coating with ultraviolet light and natural curing on the aluminum profile by air spraying method, 80 ℃ infrared Leveling for 1 minute, enter a 17.6KW high-pressure mercury lamp, a 17.6KW gallium lamp and a 17.6KW iron lamp for curing, and place it in a natural state for 20 hours. After the internal coating of the aluminum profile is cured, After passing the inspection and reaching the standard, stick a protective film and pack it to get a white high-gloss aluminum profile.

[0029] The weight percent of UV and natural curing dual curing white fluorocarbon coating is composed of: fluorine-containing polyurethane acrylate 30%, epoxy acrylate 10%, hydroxyethyl methacrylate 10%, Ciba 11735%, HDI 5%, titanium White powder 30%, talcum powder 7%, wetting and dispersing age...

Embodiment 2

[0030] Example 2: Black matte aluminum profile

[0031] Soak the aluminum profile in 10% lye for 2 minutes, then clean the oil stain with water, dry it in an oven, mix the components AB of the dual-curing black fluorocarbon coating with ultraviolet light and natural curing, and use vacuum spraying to mix well The paint is sprayed on the aluminum profile, 80 ℃ infrared leveling for 30 seconds, put into two 17.6KW high-pressure mercury lamps, two 17.6KW gallium lamps and one 17.6KW iron lamp to cure, and put it in the natural state After 24 hours, after the internal coating film of the aluminum profile is cured, it passes the inspection and reaches the standard, and then the protective film is attached and packaged, and the black matte aluminum profile is obtained.

[0032] The weight percent of UV and natural curing dual curing black fluorocarbon coating is composed of: A component: fluorine-containing epoxy acrylate 70%, Ciba TPO 5%, carbon black 5%, matting powder 2%, wetting...

Embodiment 3

[0033] Example 3: Gray matte aluminum profile

[0034] Soak the aluminum profile in 7% lye for 2 minutes, then clean the oil stain with water, dry it in an oven, and spray the dual-curing gray fluorocarbon coating with ultraviolet light and natural curing on the aluminum profile by electrostatic spraying method, 80 ℃ infrared Leveling for 50 seconds, curing in two 17.6KW high-pressure mercury lamps, one 17.6KW gallium lamp and one 17.6KW iron lamp, natural curing for 12 hours, after the internal coating of the aluminum profile is cured, it is inspected Qualified up to the standard, affix a protective film, package, that is, gray matte aluminum profile.

[0035] The weight percentage of UV and natural curing dual curing gray fluorocarbon coating is composed of: 30% fluorine-containing polyester acrylate containing hydroxyl, 40% trimethylol propane triacrylate, Ciba 1845%, IPDI 10%, titanium dioxide 10%, carbon black 2%, matting powder 2%, wetting and dispersing agent 2%, level...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com