Outdoor display screen unit board and manufacturing method thereof

The technology of an outdoor display screen and its manufacturing method is applied in the direction of electrical components, semi-conductor devices of light-emitting components, lighting and heating equipment, etc. It can solve the problems of lifespan not as good as that of straight lamps, color separation treatment, high price, etc., and achieve good moisture-proof and waterproof Anti-collision function, simple manufacturing requirements, and low price and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

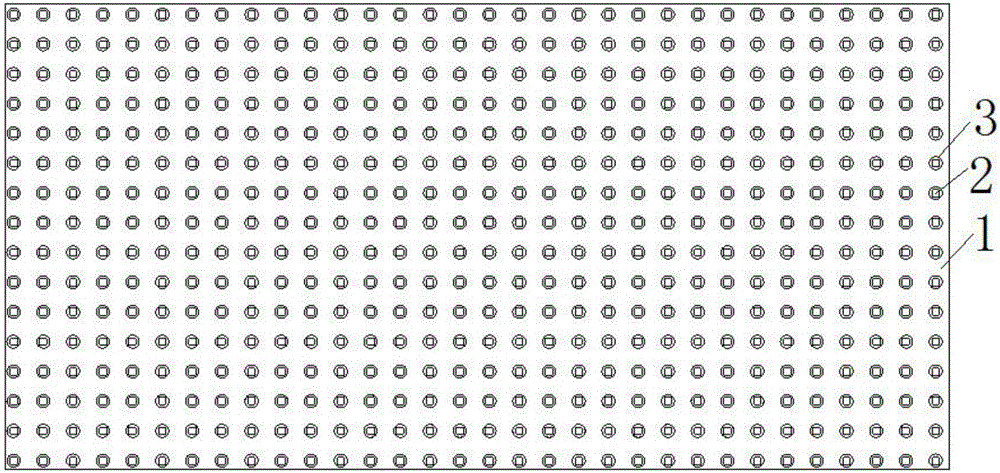

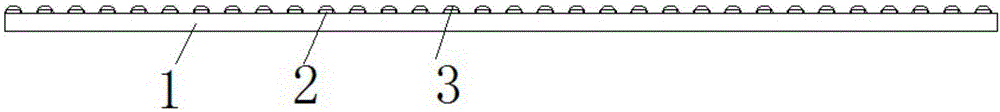

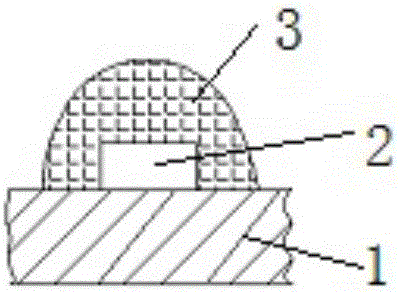

[0021] Such as Figure 1-Figure 5 As shown, the present invention includes a PCB board 1 (printed circuit board), and multiple rows and columns of SMD lamps 2 are arranged on the PCB board 1, and the SMD lamps 2 are fixed on the PCB board by patching, each The outer surface of each SMD lamp 2 is all provided with waterproof member 3; Wherein, described SMD lamp 2 comprises one or more LED chip 21, package 22 and pin 23, and described package 22 is arranged on described LED chip 21 Around, one end of the pin 23 extends out of the package 22 and is connected to the circuit on the PCB 1 .

[0022] The present invention absorbs the advantages of the two methods of SMD lamp and COB lamp on the display screen in the prior art, and overcomes the shortcomings of the two methods, so the price is low (compared to the above two methods), the quality is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com