LCD screen hardness test method

A hardness test and screen technology, applied in the field of LCD screen testing, can solve problems such as affecting the normal use and work of LCD, impact of flying sand and stone, cracking of LCD glass substrate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

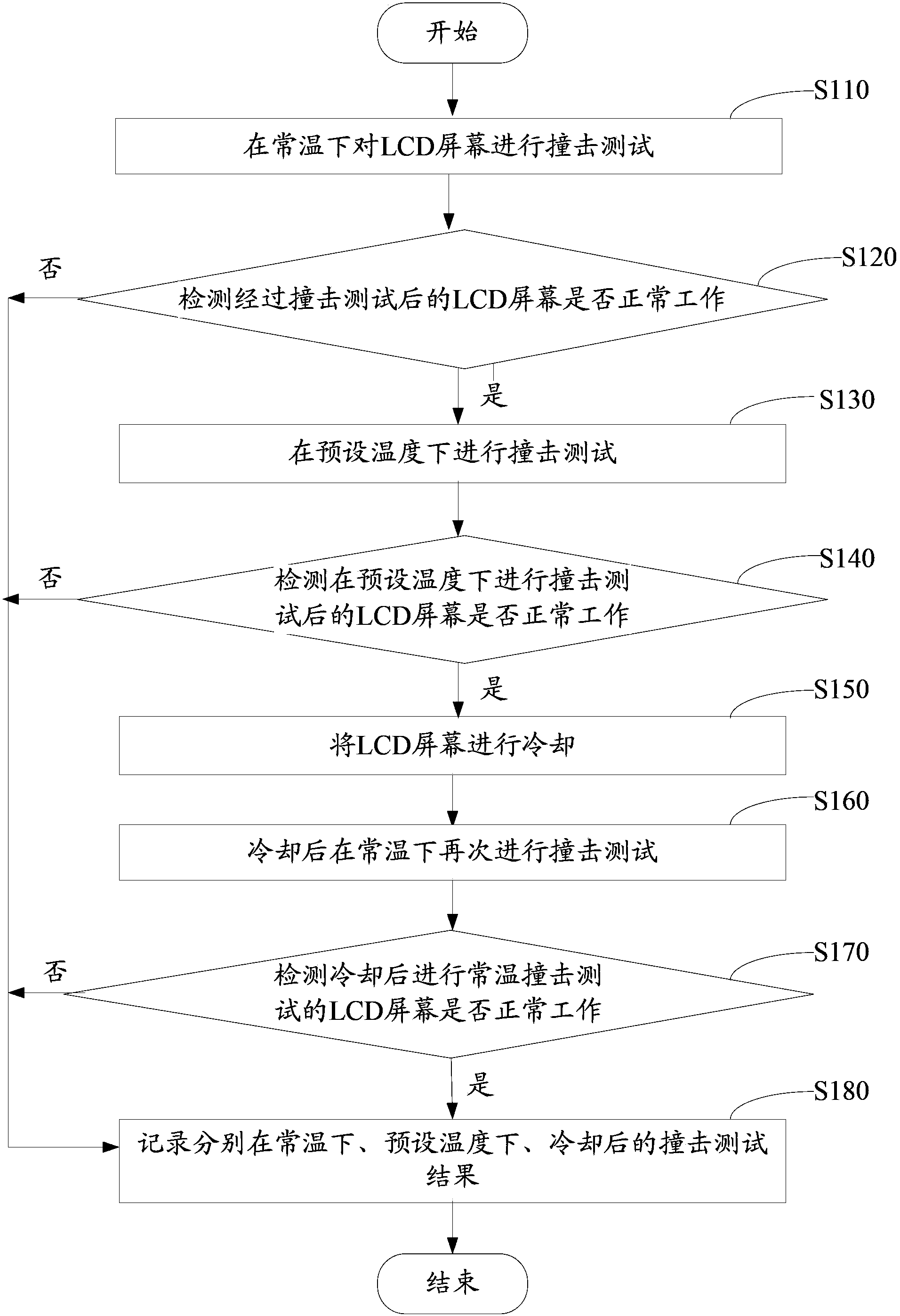

[0026] Such as figure 1 Shown is a flow chart of the LCD screen hardness test method.

[0027] Generally, 5 LCD screen prototypes to be tested will be selected. Before using the LCD screen hardness test method, the surface of the LCD screen must be free from abnormal phenomena such as dirt, missing corners, and cracks, and the LCD screen prototype should be connected to the power supply and signal for regular screen display. Quality inspection is normal. Usually, the above-mentioned routine quality inspection is performed to confirm the quality of the LCD screen prototype and ensure the validity of subsequent tests.

[0028] In particular, the test environment illumination is 200±10Lux.

[0029] A method for testing the hardness of an LCD screen, comprising the following steps:

[0030] In step S110, an impact test is performed on the LCD screen at room temperature.

[0031] Specifically include the following steps:

[0032] ① Place the LCD screen to be tested horizontall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com