Modified polypropylene material and preparation method thereof

A polypropylene material and modification technology, applied in the field of plastic products, can solve the problems of poor environmental stress cracking resistance, brittle cracking, poor toughness of polypropylene materials, etc., and achieve the effects of superior aging resistance, good toughness and rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

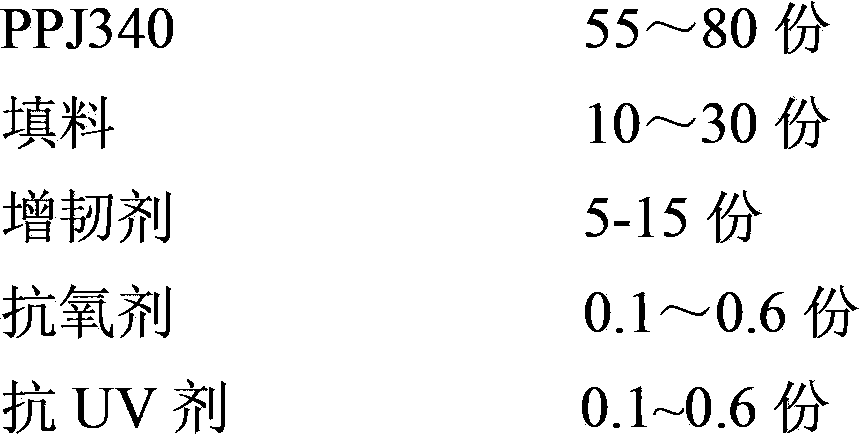

[0021] formula:

[0022]

[0023] The molecular weight of PPJ340 is 300,000-500,000, and it is a product of J340 produced by Sinopec Yangzi Petrochemical Company;

[0024] The toughening agent is an elastomer, and the 8150 of DuPont Company of the United States is used;

[0025] The filler is 5000-mesh calcium carbonate from Hangzhou Advanced Calcium Industry Co., Ltd.;

[0026] Antioxidant is the composite antioxidant of 1010 and 168 of Jinhai Yabao Company, and the weight ratio of the two is 1: 2;

[0027] Anti-UV agent can adopt Ciba's 531.

[0028] Manufacturing process:

[0029] According to the proportion, each component was first mixed in a high-speed mixer for 5 minutes, and then blended and extruded in a screw extruder at a blending temperature of 220°C to obtain the modified polypropylene material of the present invention.

Embodiment 1

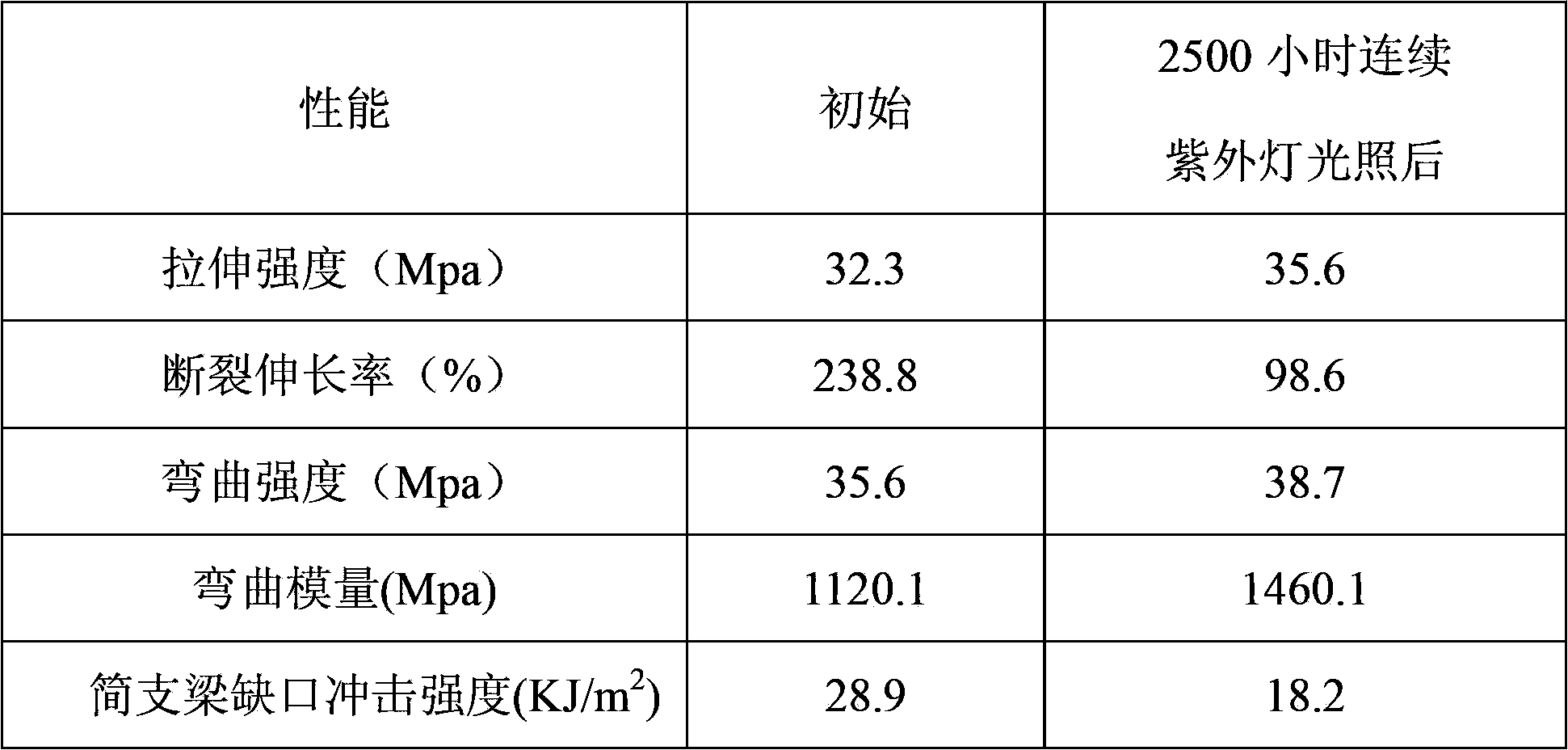

[0030] The polypropylene material of embodiment 1 adopts ASTM standard test, and test result is as table 1:

[0031] Table 1: The performance test result of the polypropylene material of embodiment 1

[0032]

[0033]

example 2

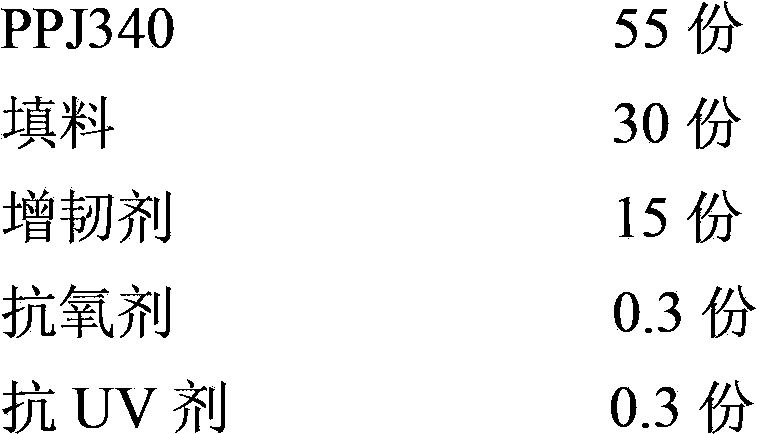

[0035] formula:

[0036]

[0037] The molecular weight of PPJ340 is 300,000-500,000, and it is a product of J340 produced by Sinopec Yangzi Petrochemical Company;

[0038] The toughening agent is an elastomer, and the 8150 of DuPont Company of the United States is used;

[0039] The filler is calcium carbonate above 5000 mesh from Hangzhou Advanced Calcium Industry Co., Ltd.;

[0040] Antioxidant is the composite antioxidant of 1010 and 168 of Jinhai Yabao Company, and the weight ratio of the two is 1: 3;

[0041] The anti-UV agent can adopt Ciba 770.

[0042] Manufacturing process:

[0043] According to the proportion, each component was first mixed in a high-speed mixer for 4 minutes, and then blended and extruded in a screw extruder at a blending temperature of 200°C to obtain the modified polypropylene material of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com