Patents

Literature

43results about How to "Increase the radius of rotation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

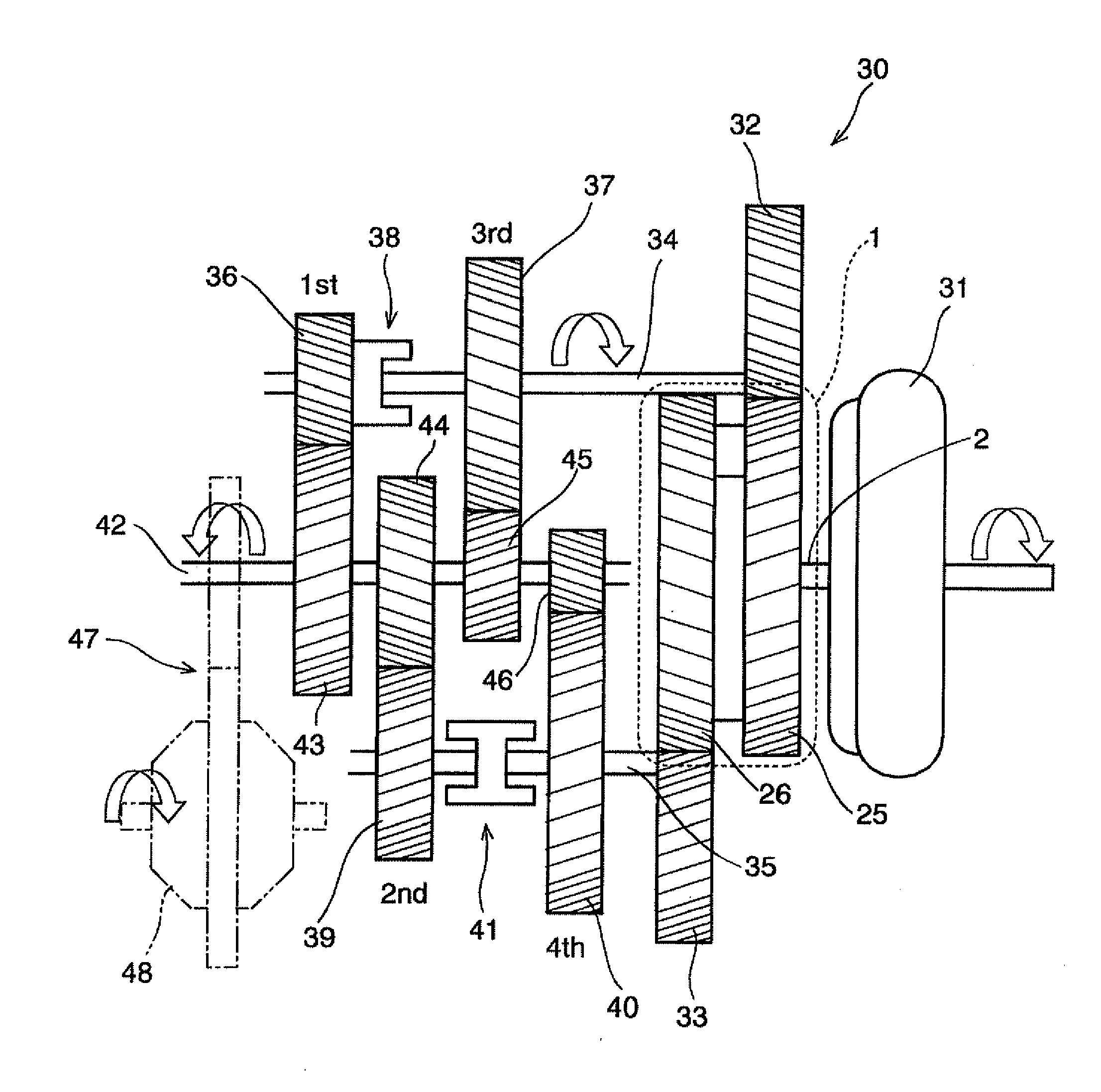

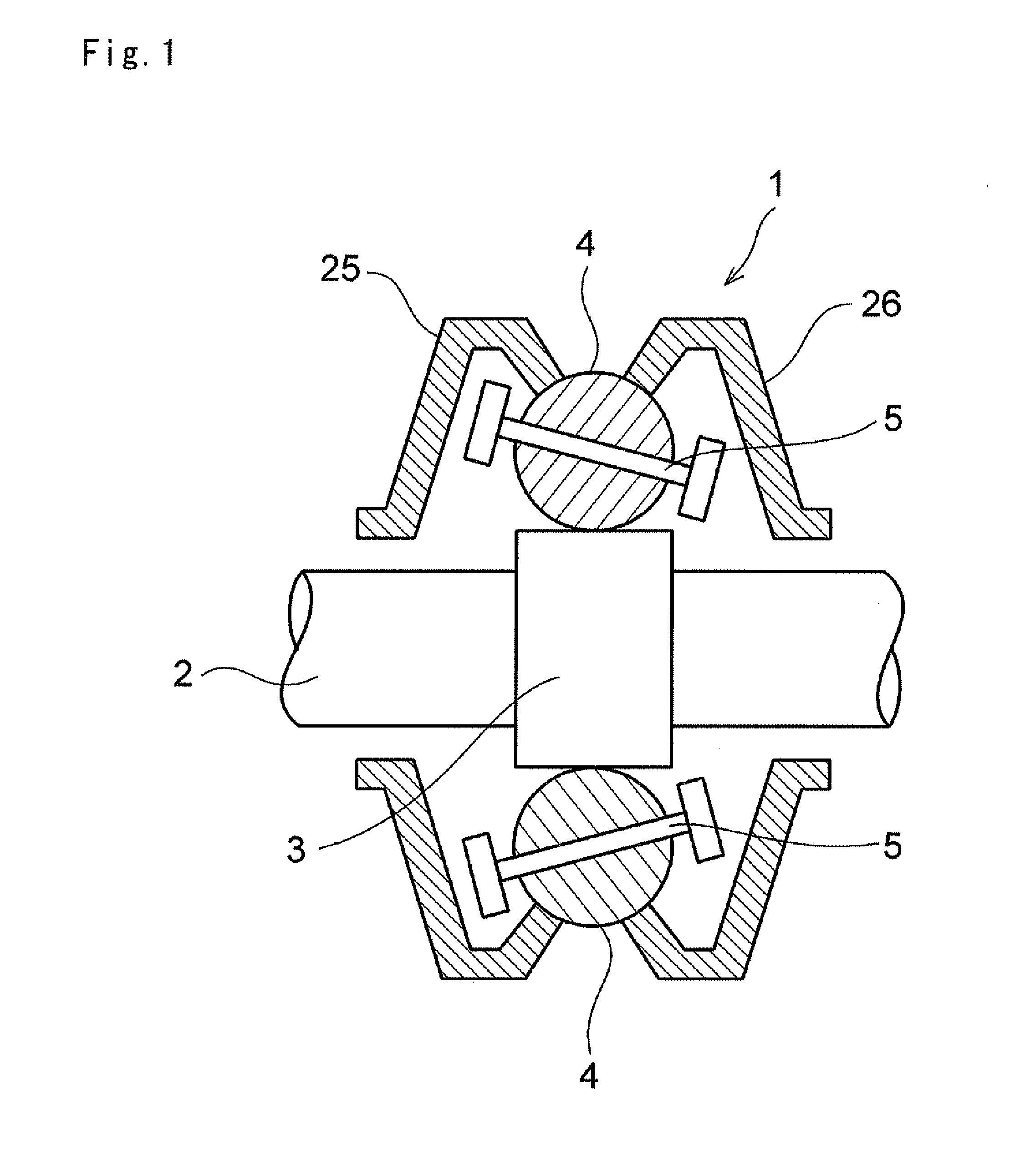

Continuously variable transmission mechanism and transmission using the same

InactiveUS20110319222A1Increase rotation speedRotational radiusFriction gearingsRotation velocityControl theory

A continuously variable transmission adapted to set a speed change ratio in accordance with a tilt angle of a rolling member mediating a torque being transmitted, and to transmit a torque among three elements. The transmission mechanism is provided with a rolling member having a smooth outer face and capable of tilting a rotational center axis thereof, and a rotary member arranged to be contacted with a predetermined portion of the outer face of the rolling member in a torque transmittable manner. Specifically, the continuously variable transmission mechanism is configured to vary a rotational speed of the rotary member by changing a rotation radius of a contact point between the rolling member and the rotary member by tilting the rotational center axis of the rolling member.

Owner:TOYOTA JIDOSHA KK

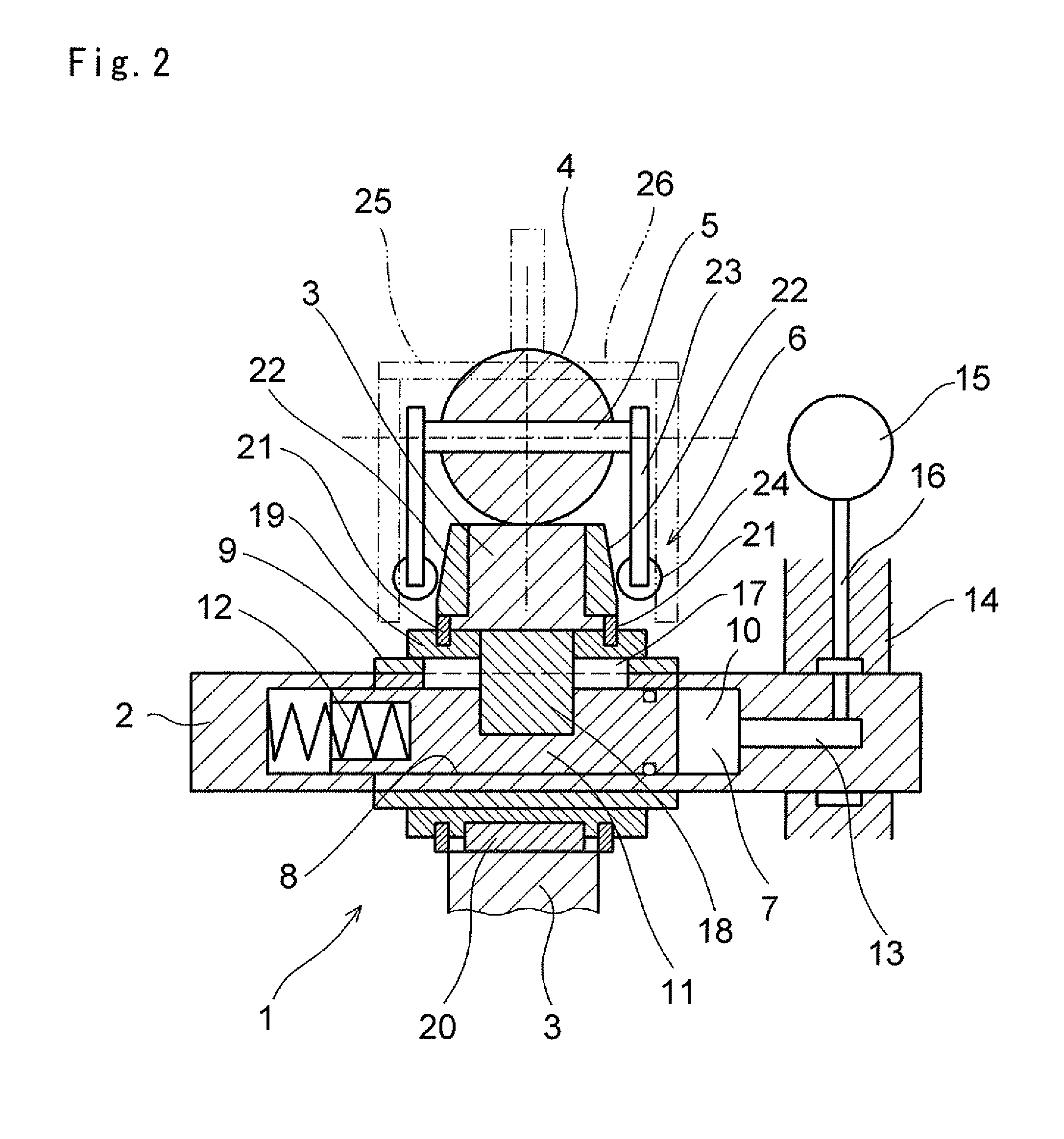

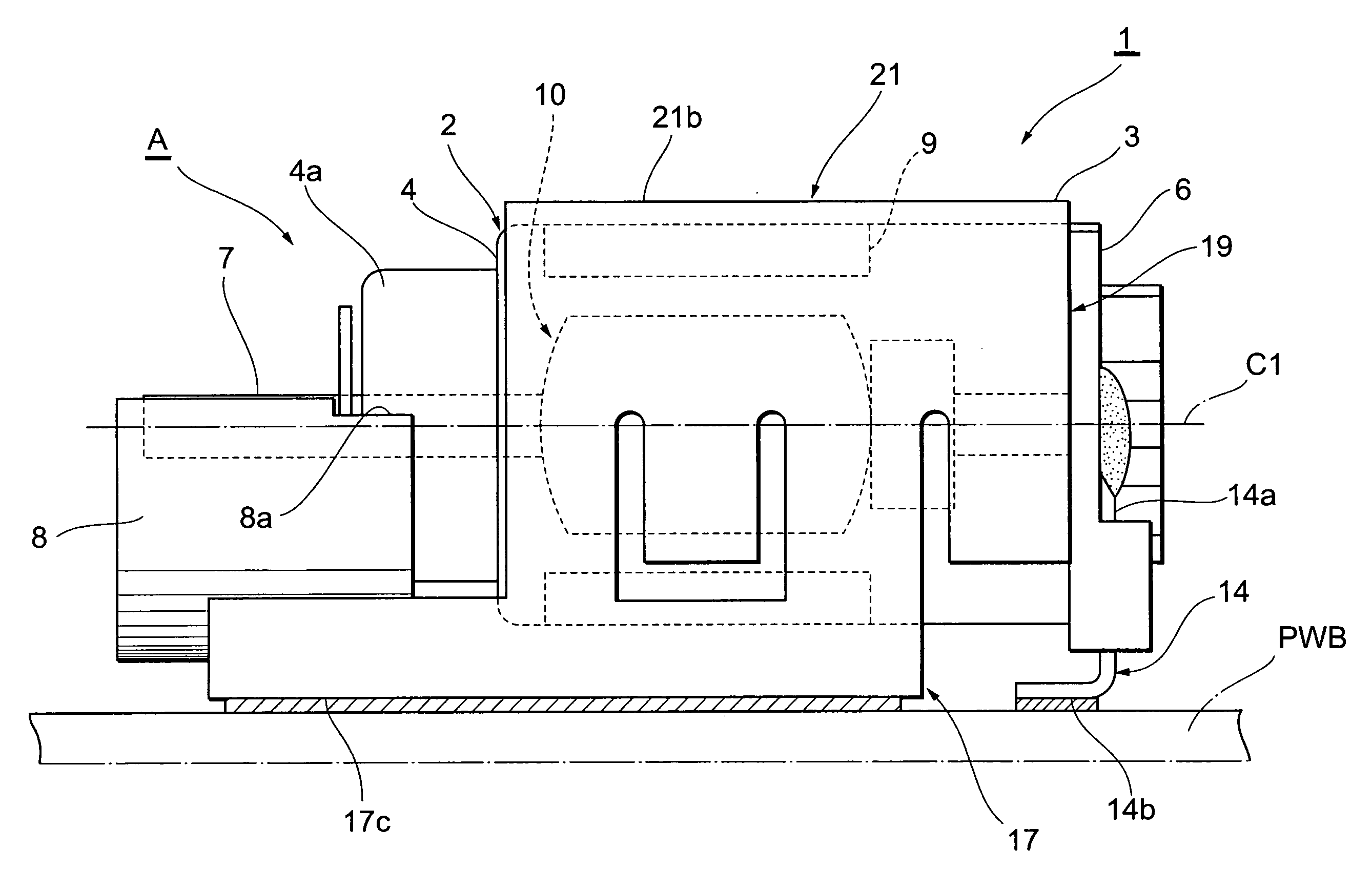

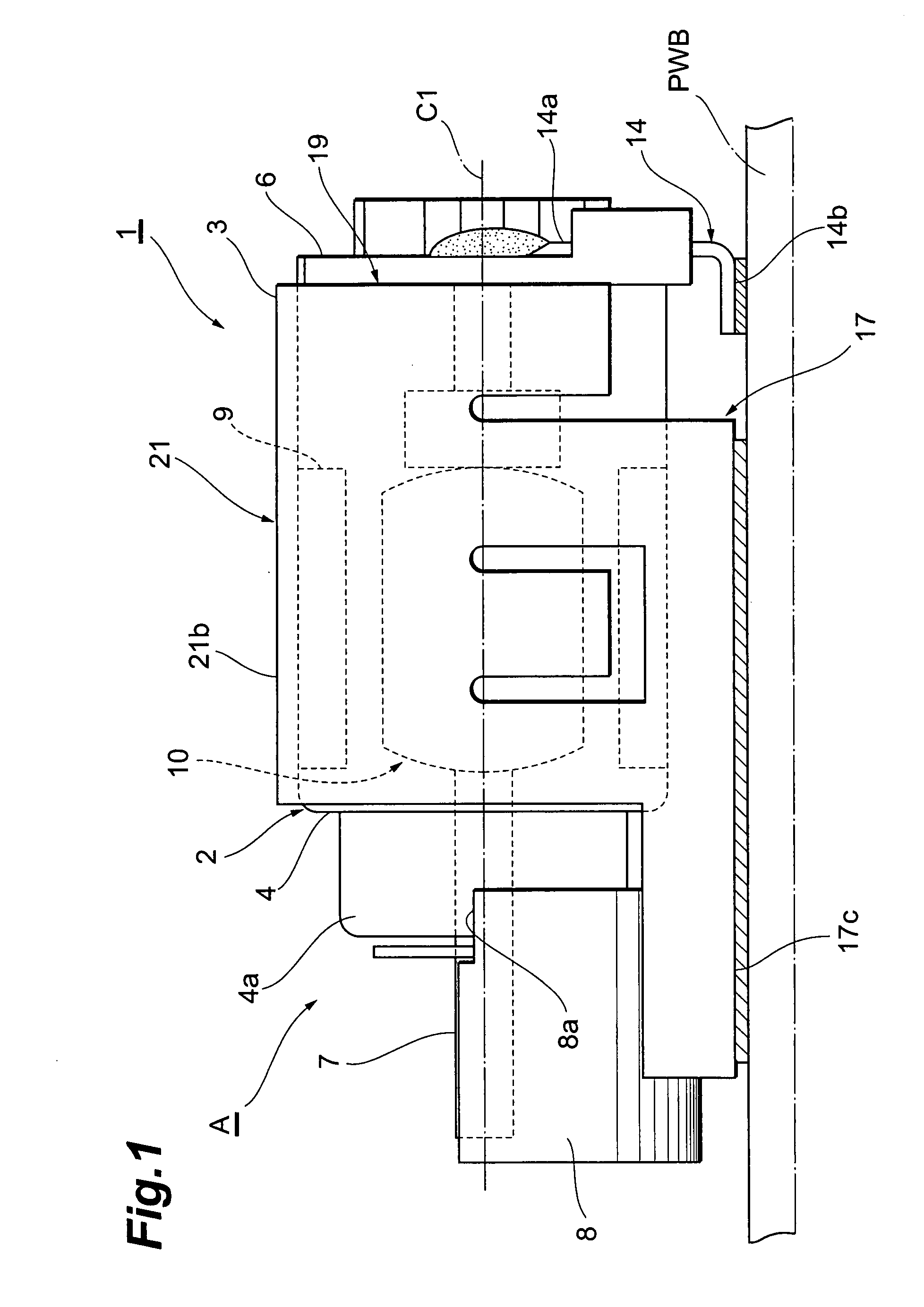

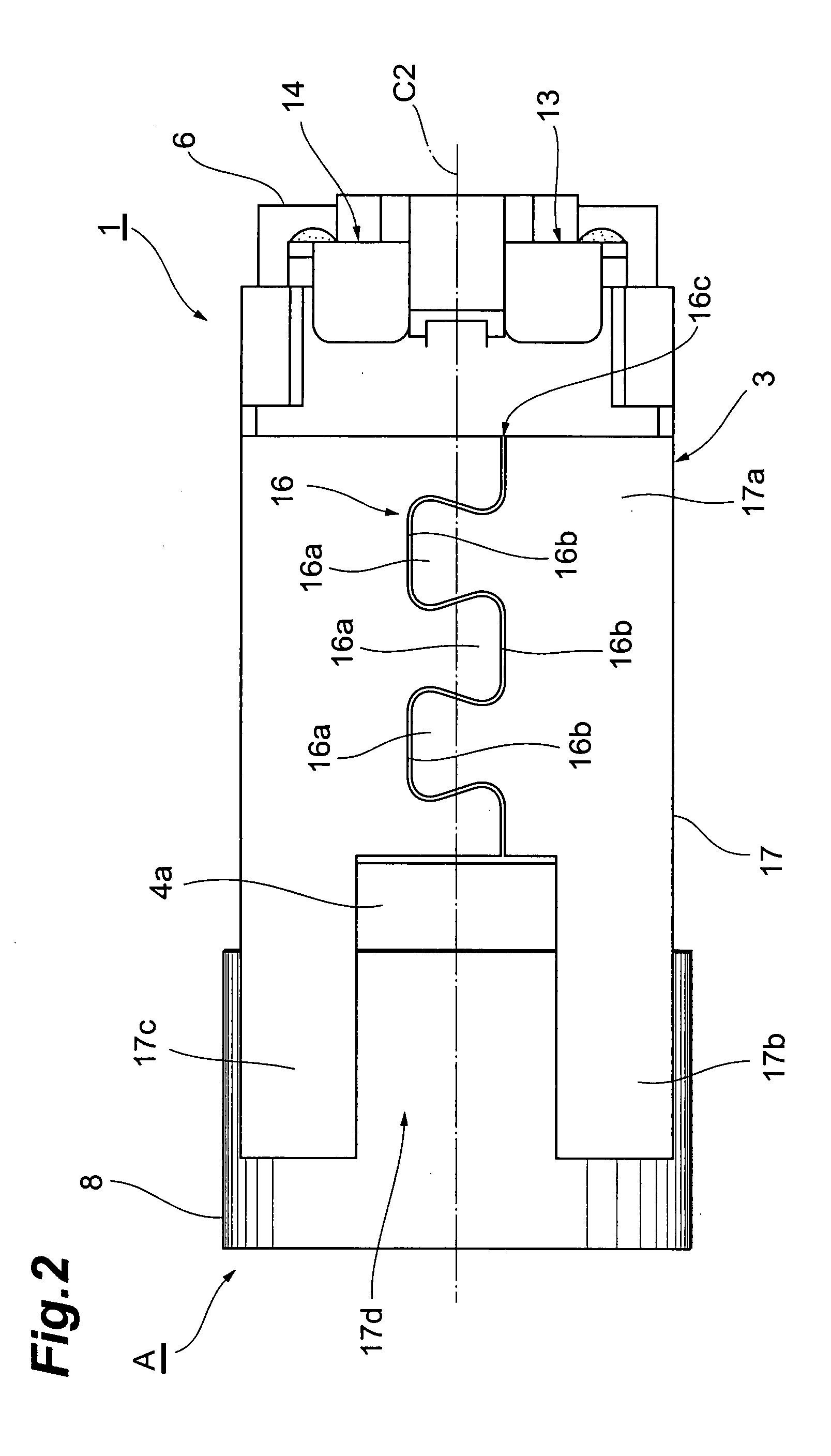

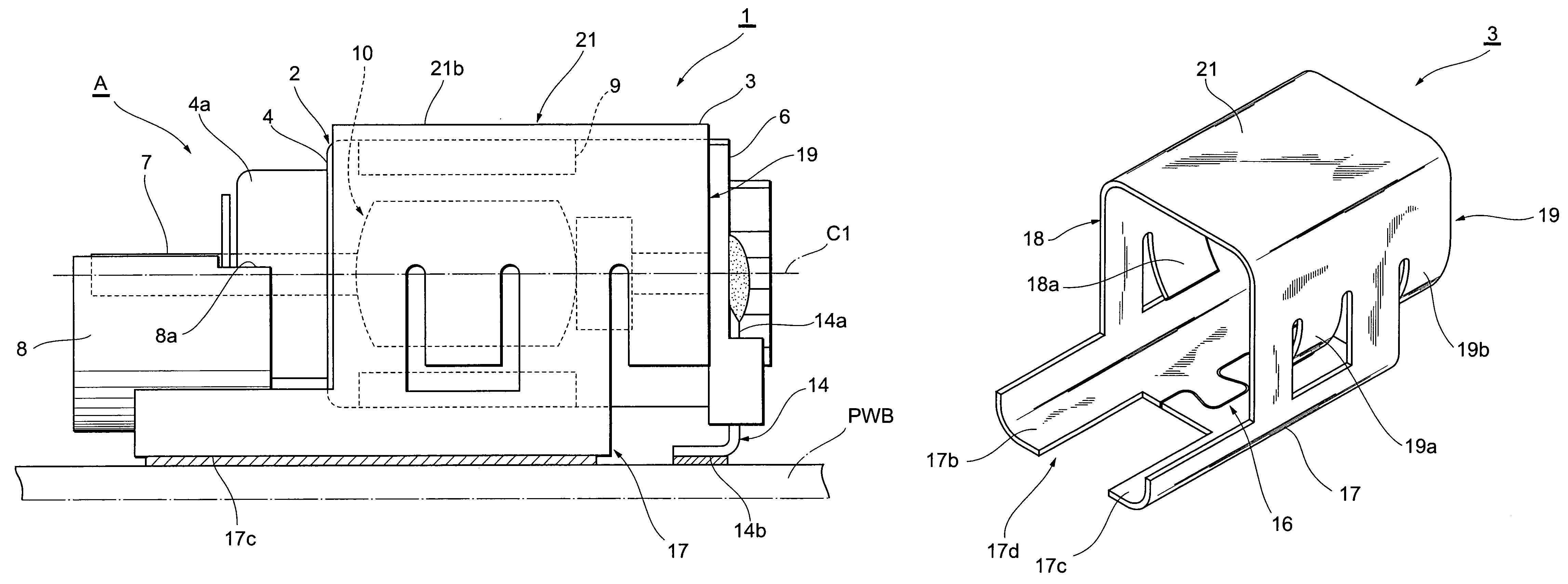

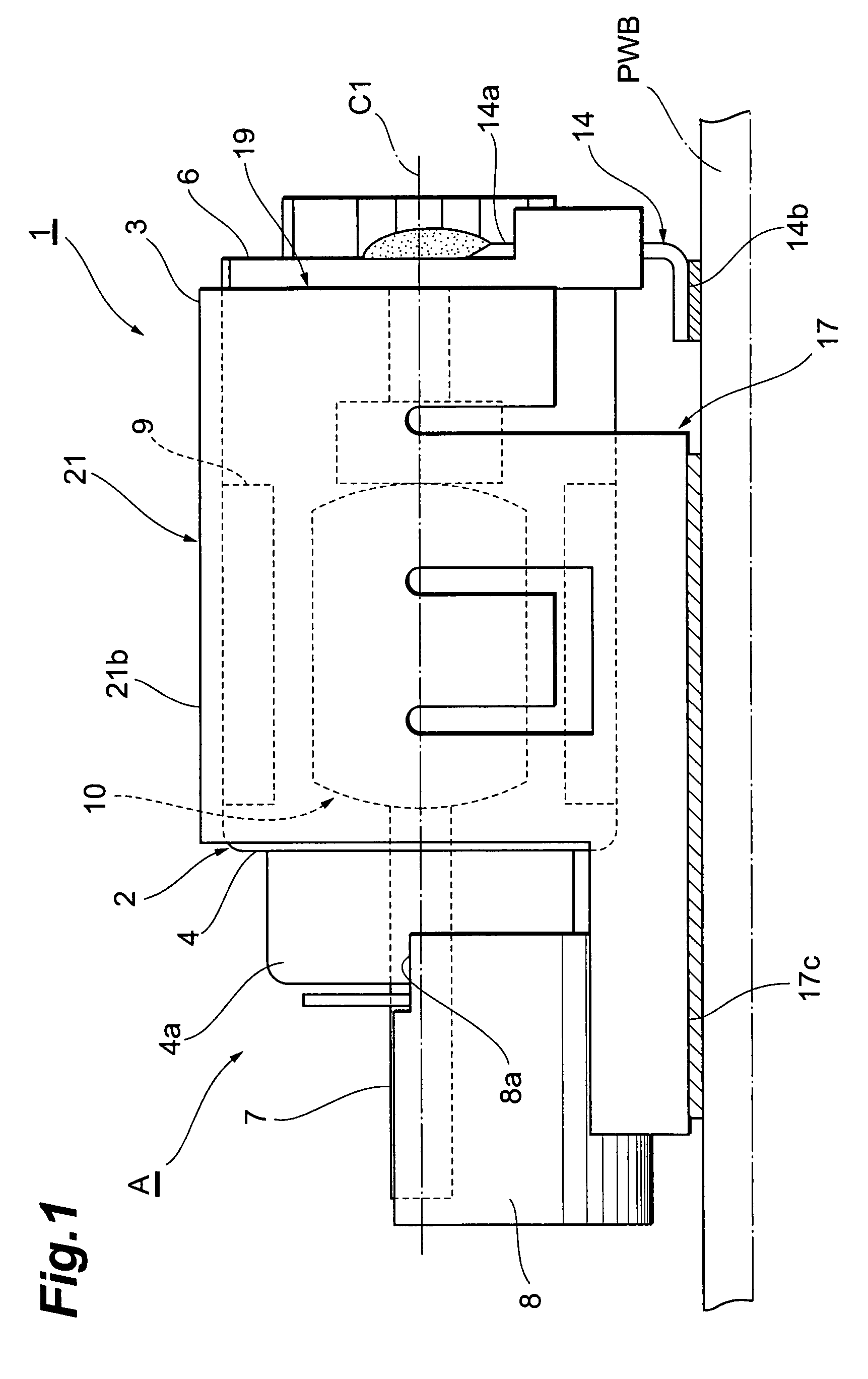

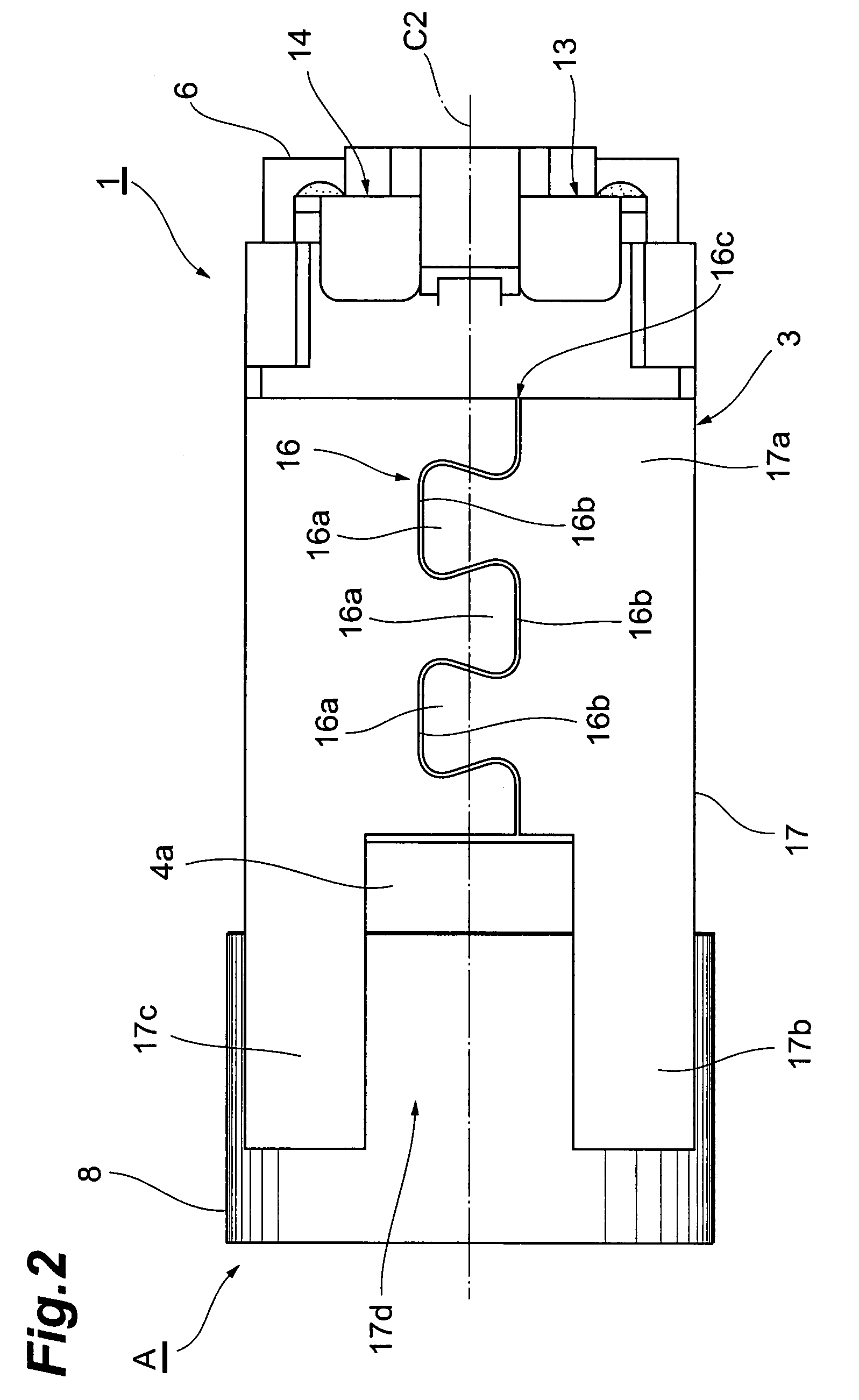

Vibration motor

InactiveUS20070241626A1Upsizing of the weightIncrease the radius of rotationMechanical energy handlingStructural associationSurface mountingEngineering

A vibration motor having a tubular case, a shaft protruding from a front end of the case, a weight eccentrically fixed to an end of the shaft, and a metallic holder surrounding the case, the holder being surface-mounted on a wiring board by reflow-soldering, wherein the holder has a planate bottom placed on the wiring board, a pair of forward tilting prevention portions that extends up to a position facing the weight is formed at the bottom, a notch is provided on a center line extending along the bottom between the forward tilting prevention portions, and the notch extends from the front end of the forward tilting prevention portions beyond the position facing the weight.

Owner:COPAL CO LTD

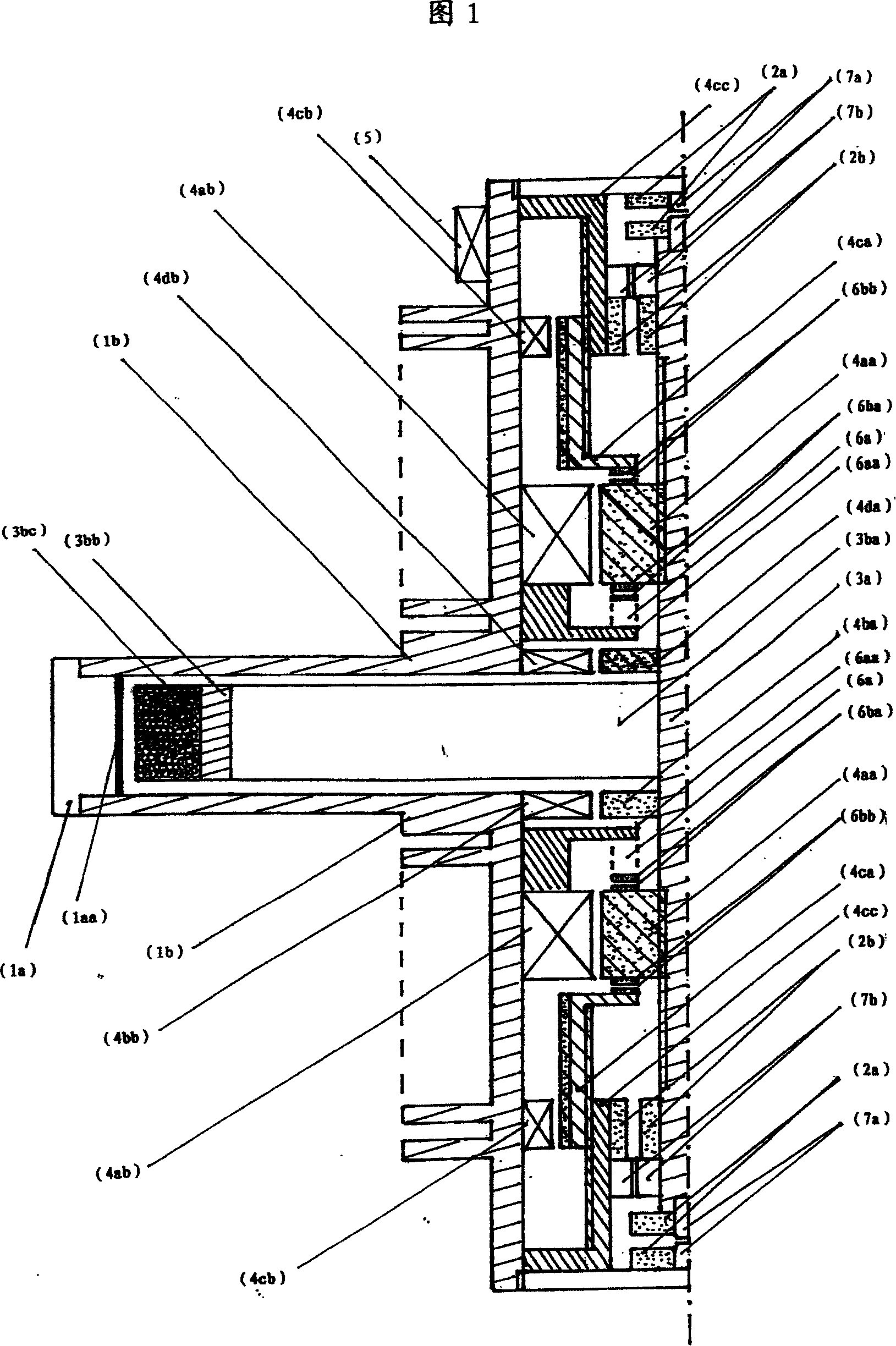

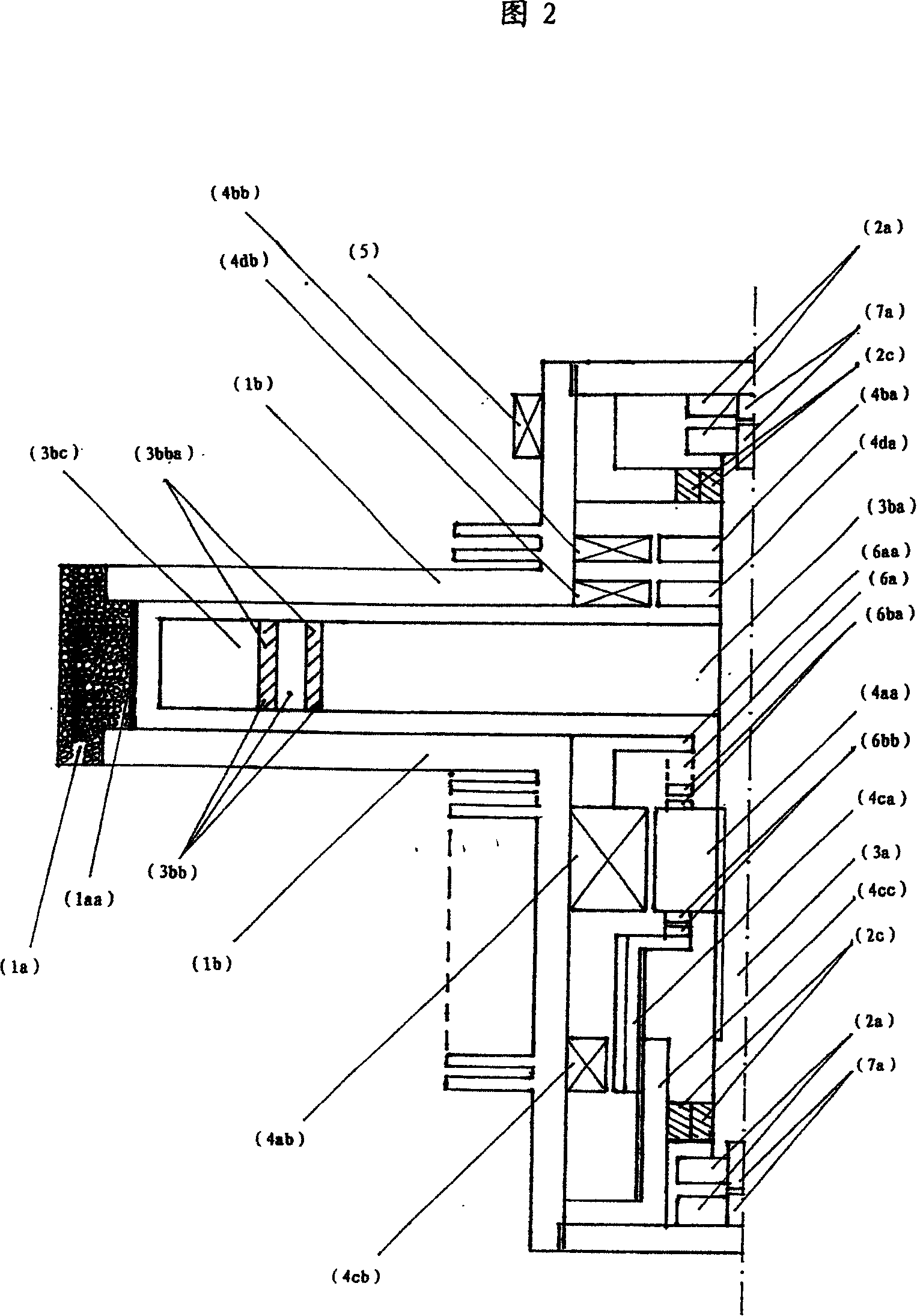

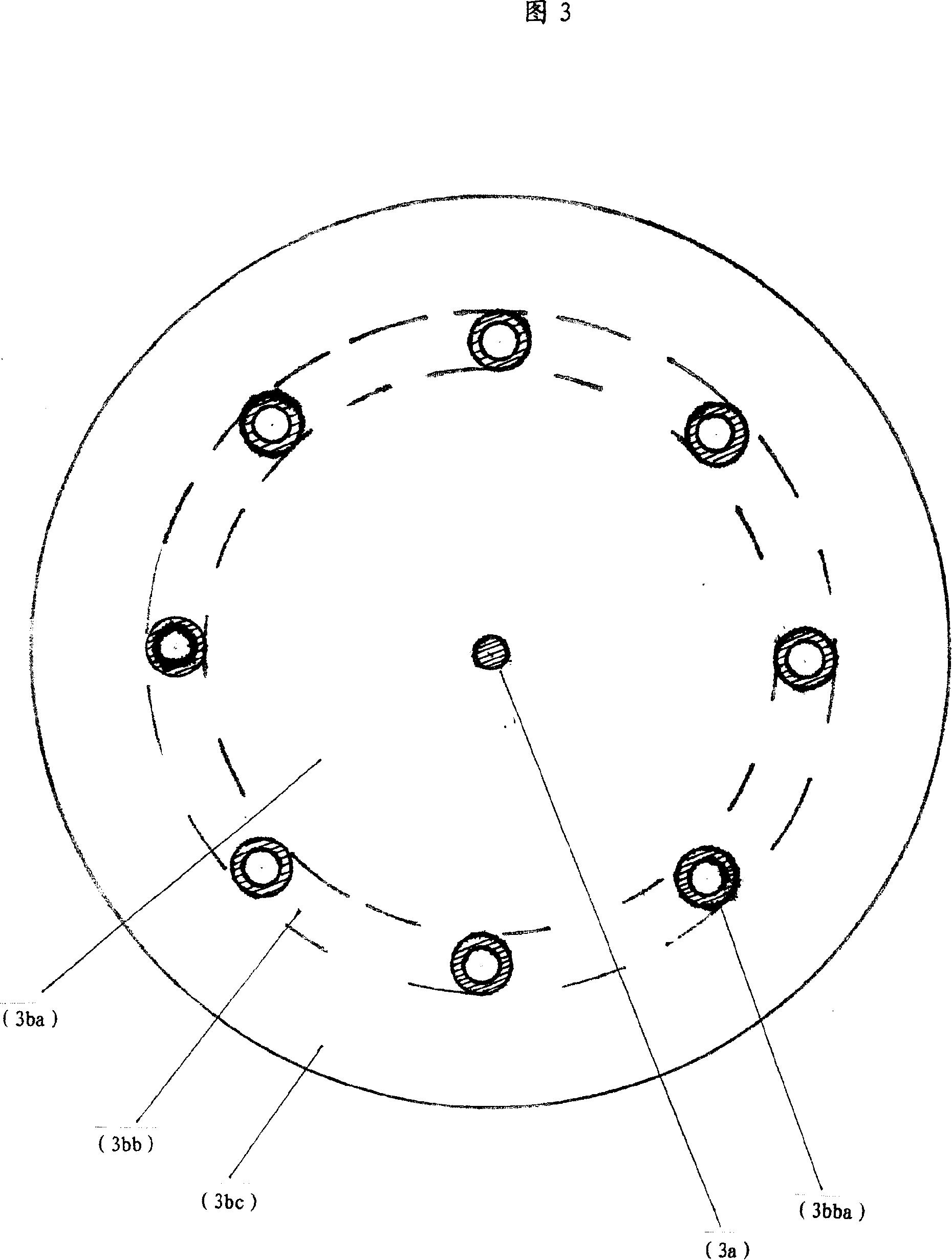

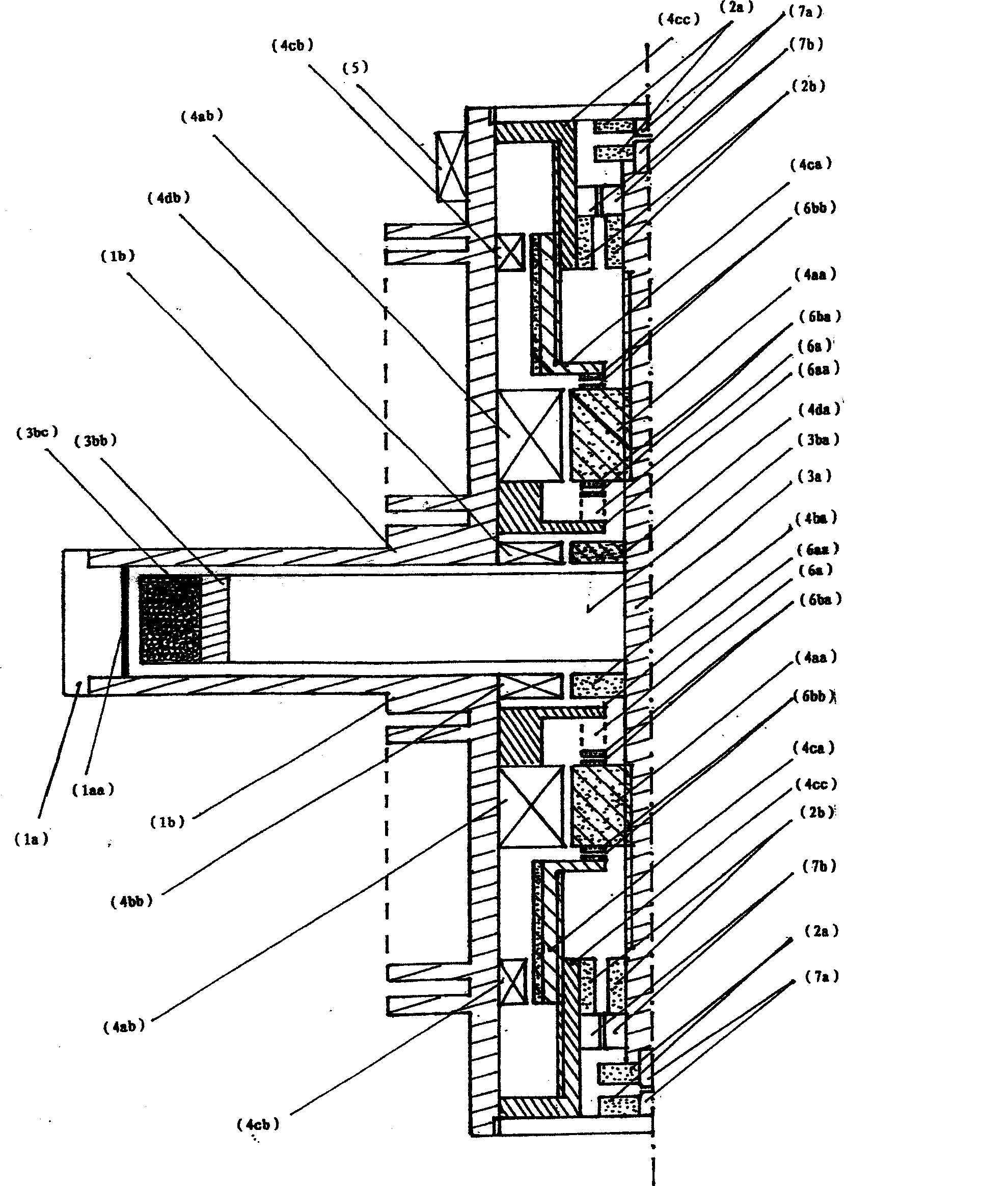

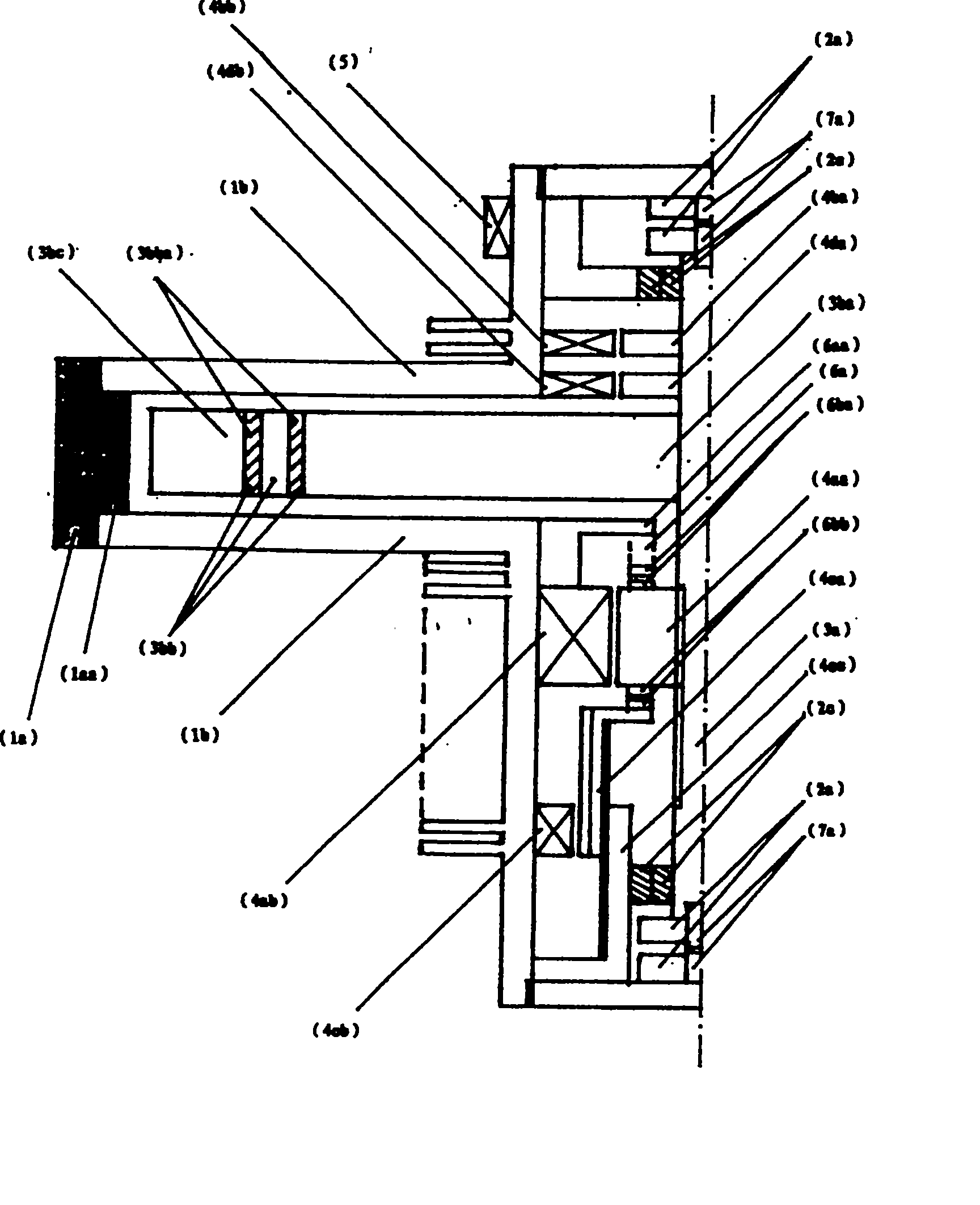

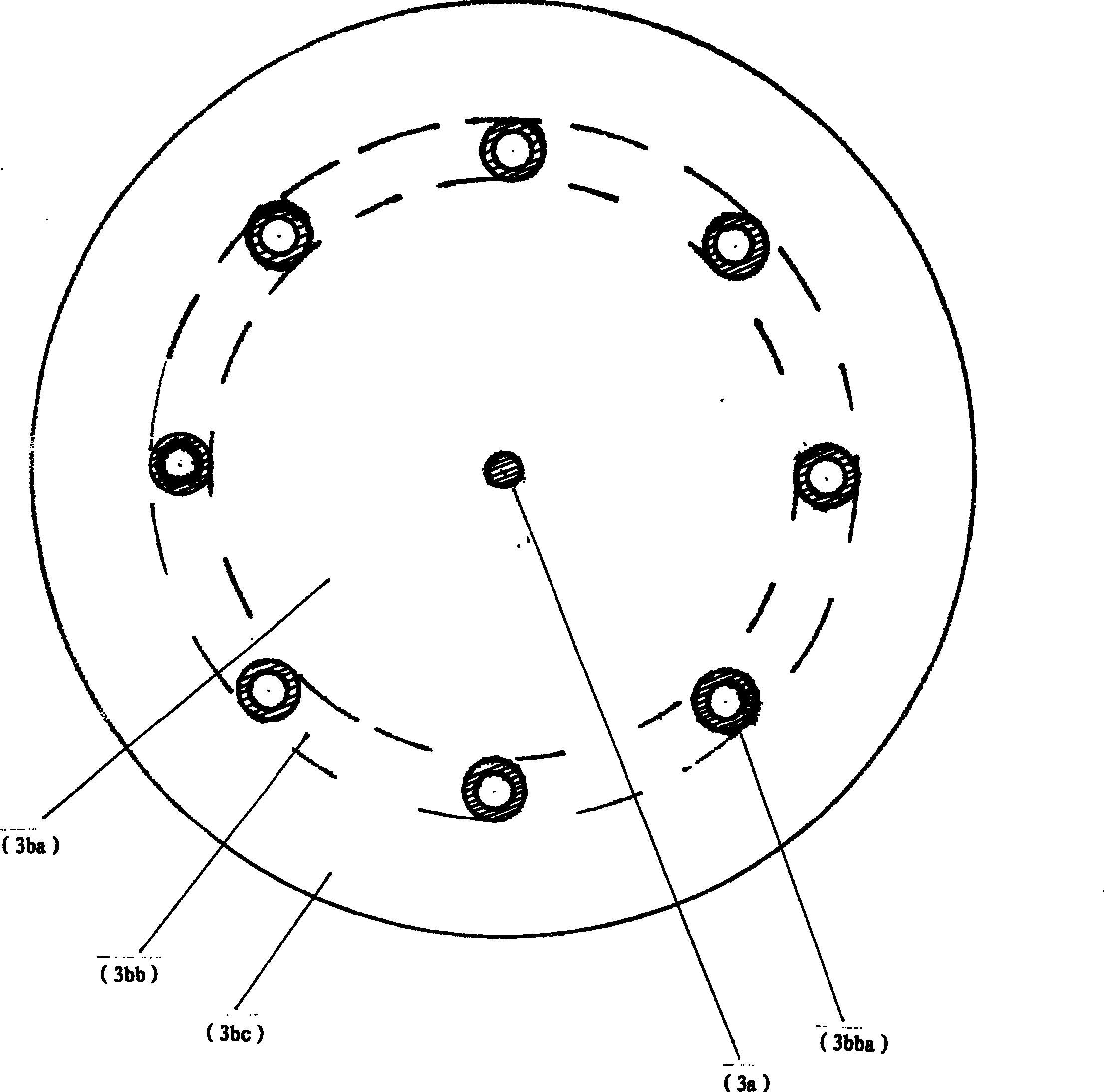

Energy storage system for magnetic floating flywheel

InactiveCN101127465AReduce weightLight weightFlywheelsMechanical energy handlingElectricityLevitation

The utility model discloses a magnetic levitation flywheel energy accumulation system, which has the advantages of small deadweight, large electricity storage, low manufacturing cost, mobile usage, free adjustment of the real-time discharge quantity value to the outside, and quick charge or large real-time discharge; wherein, the axial component of ''the high-vacuum enclosed housing'' is made of materials of low specific gravity. No permanent magnetic material components are positioned on the ''Flywheel'' and the ''Wheel Disk'' is divided into three rings. Four ''Permanent Magnetic Rotating Motor Devices'' are arranged. The ''Magnet bearing'' is ''all magnetic levitation bearing'' or ''semimagnetic levitation bearing''. The utility model is also provided with a device to guarantee the reliability of the mobile usage of the ''Magnet Bearing''.

Owner:严密 +1

Vibration motor

InactiveUS7619335B2Upsizing of the weightIncrease the radius of rotationMagnetic circuit stationary partsMechanical vibrations separationSurface mountingEngineering

A vibration motor having a tubular case, a shaft protruding from a front end of the case, a weight eccentrically fixed to an end of the shaft, and a metallic holder surrounding the case, the holder being surface-mounted on a wiring board by reflow-soldering, wherein the holder has a planate bottom placed on the wiring board, a pair of forward tilting prevention portions that extends up to a position facing the weight is formed at the bottom, a notch is provided on a center line extending along the bottom between the forward tilting prevention portions, and the notch extends from the front end of the forward tilting prevention portions beyond the position facing the weight.

Owner:COPAL CO LTD

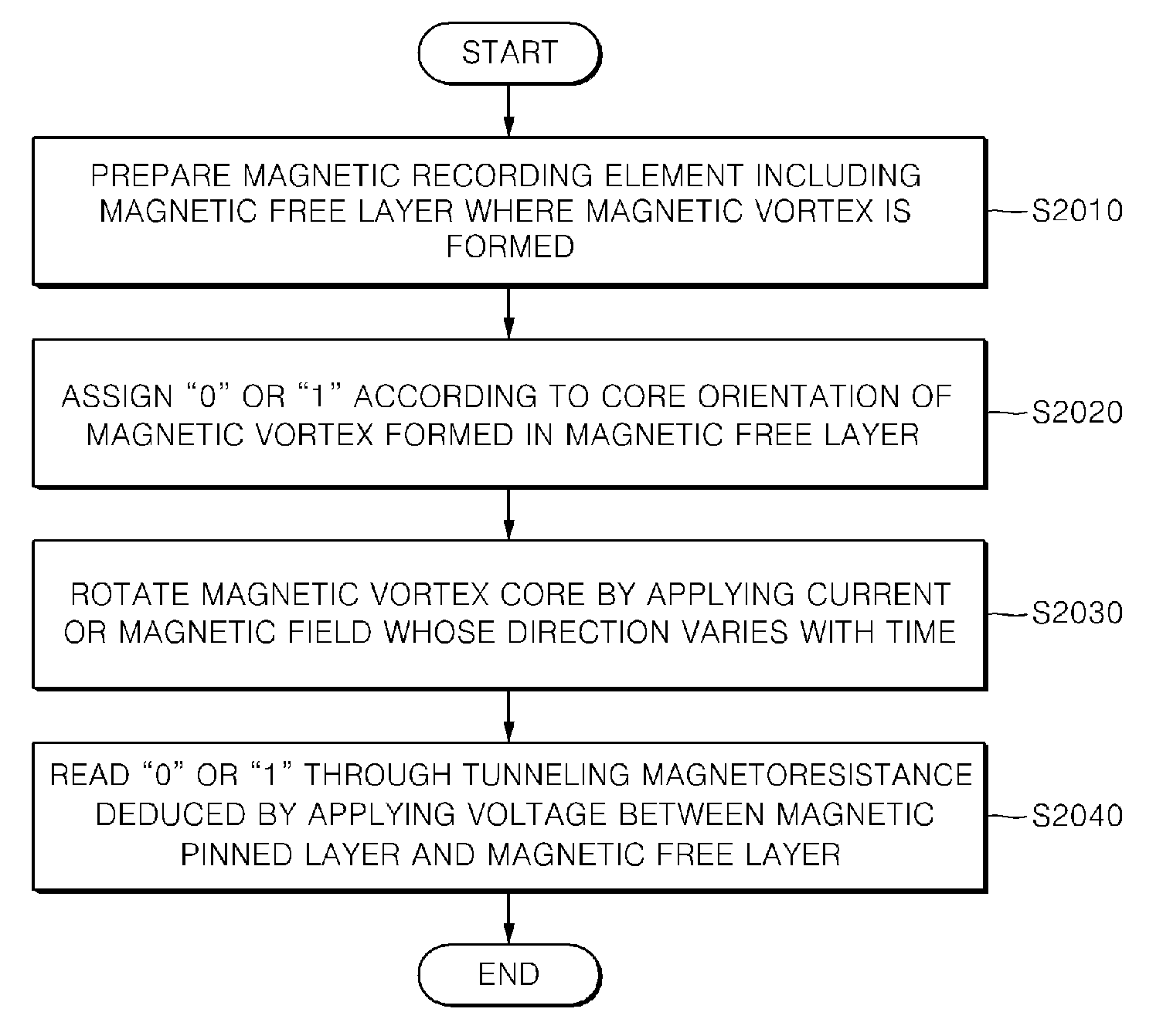

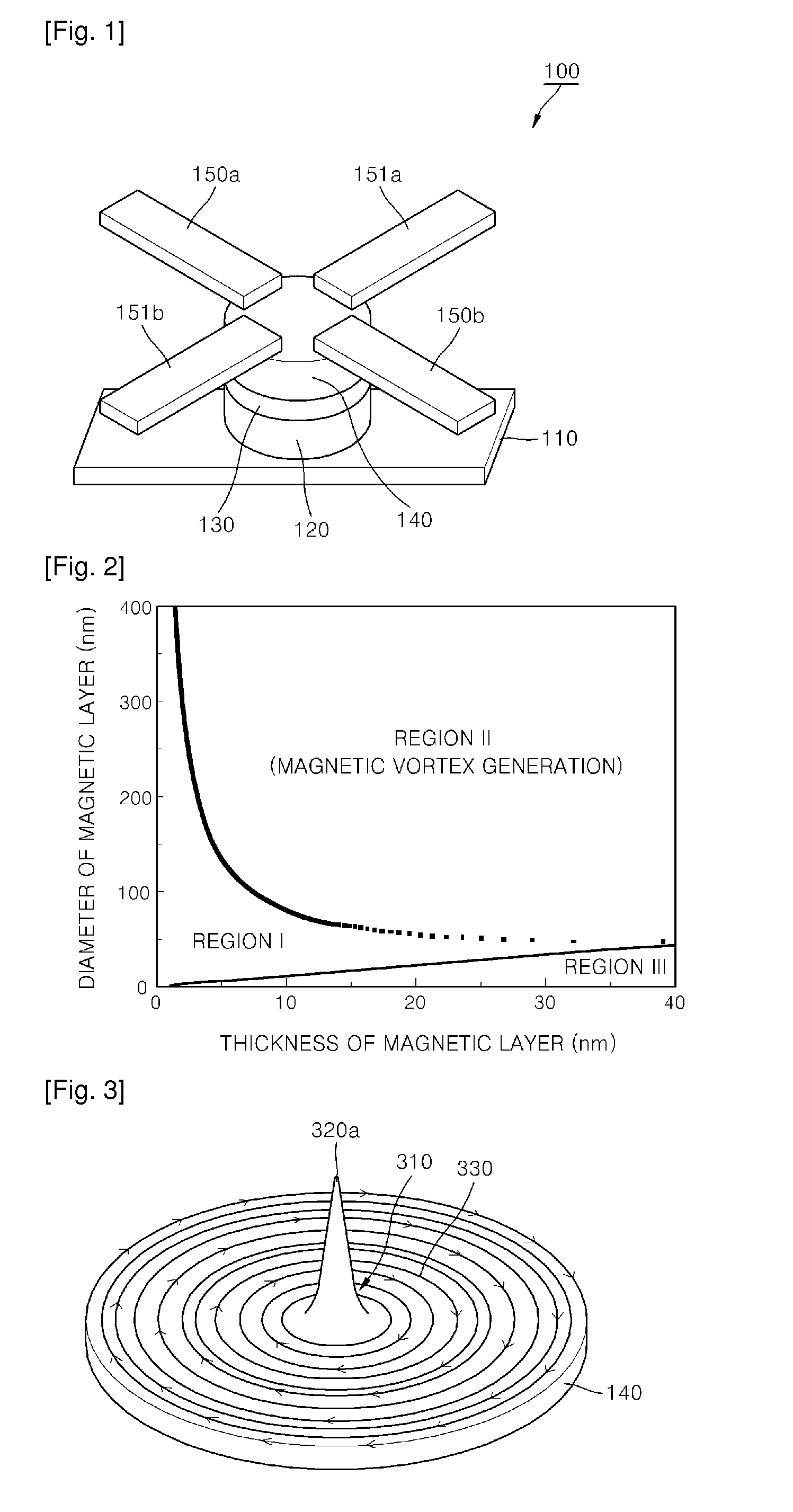

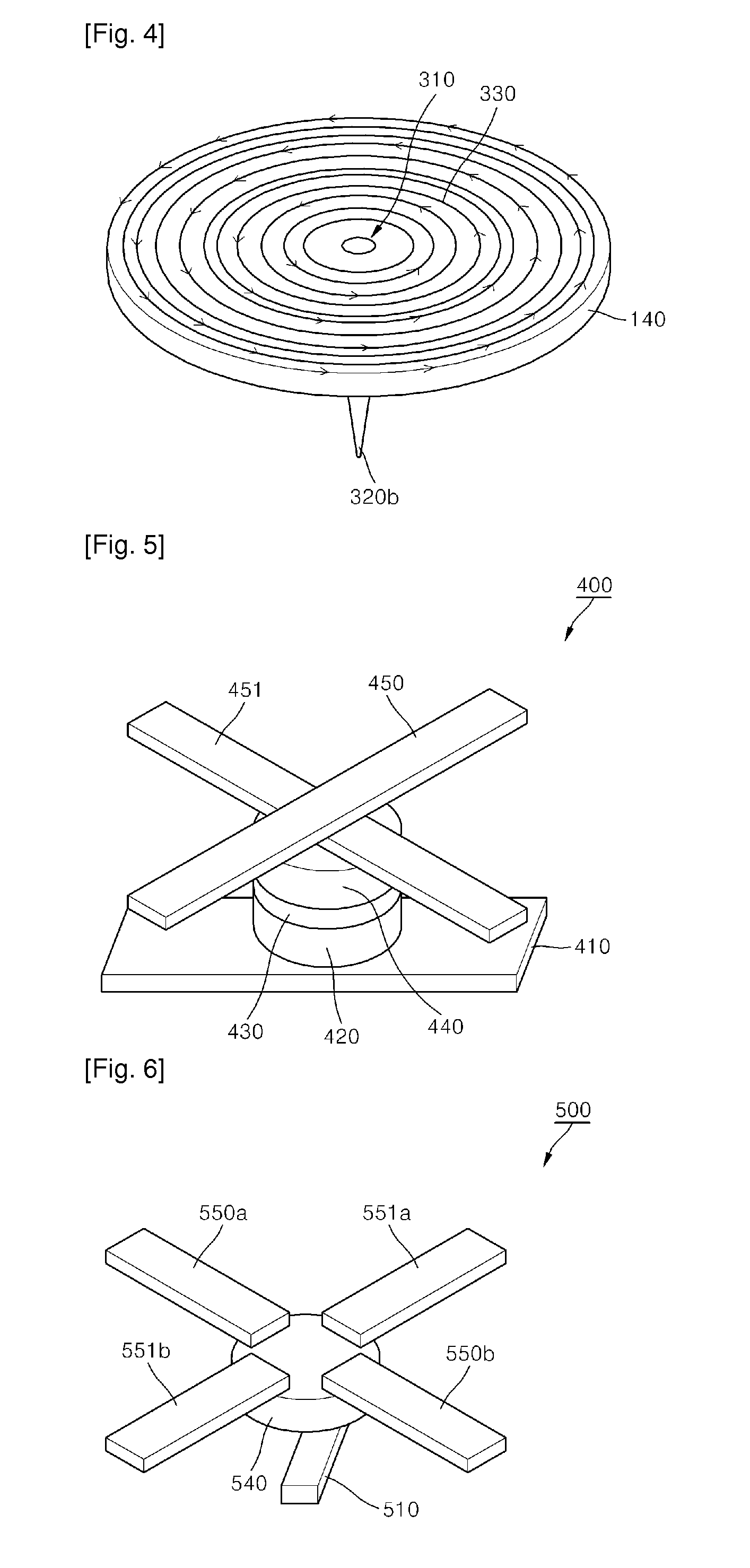

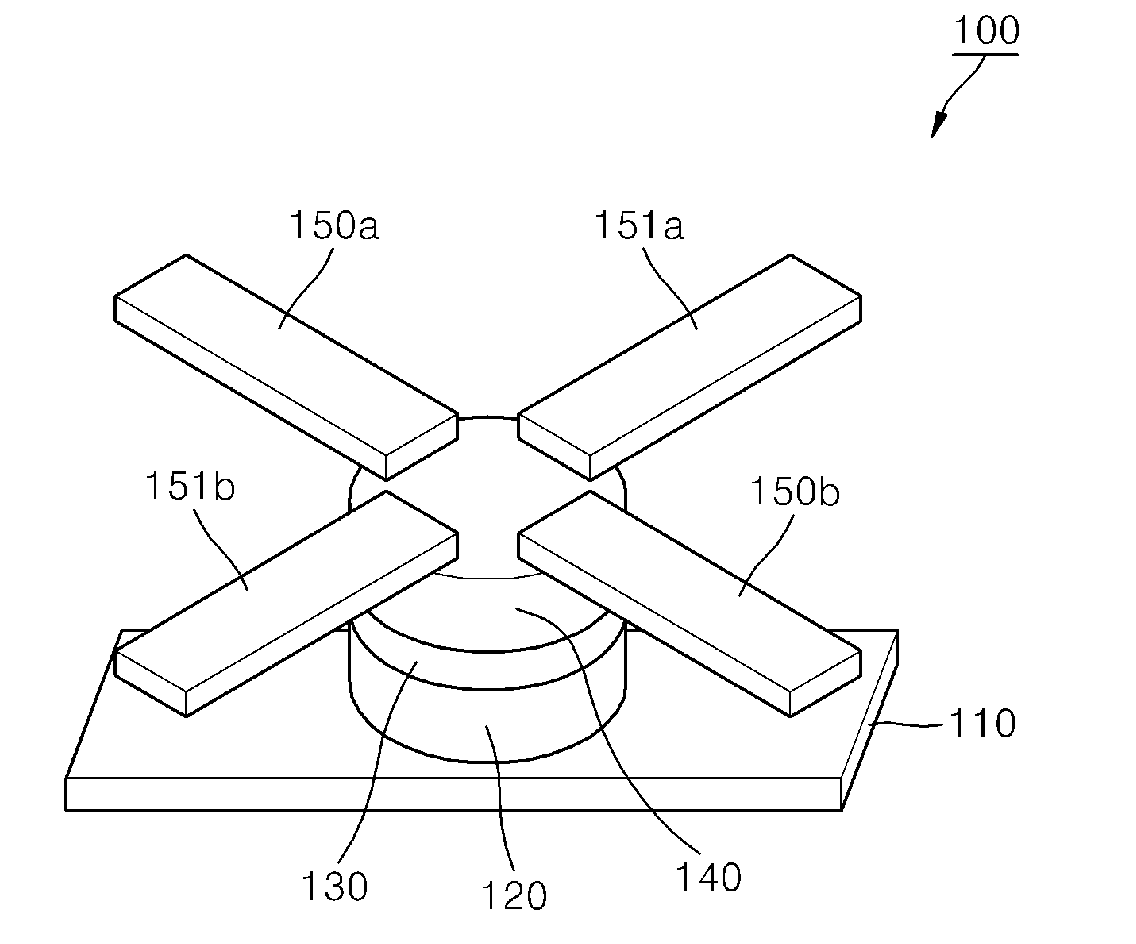

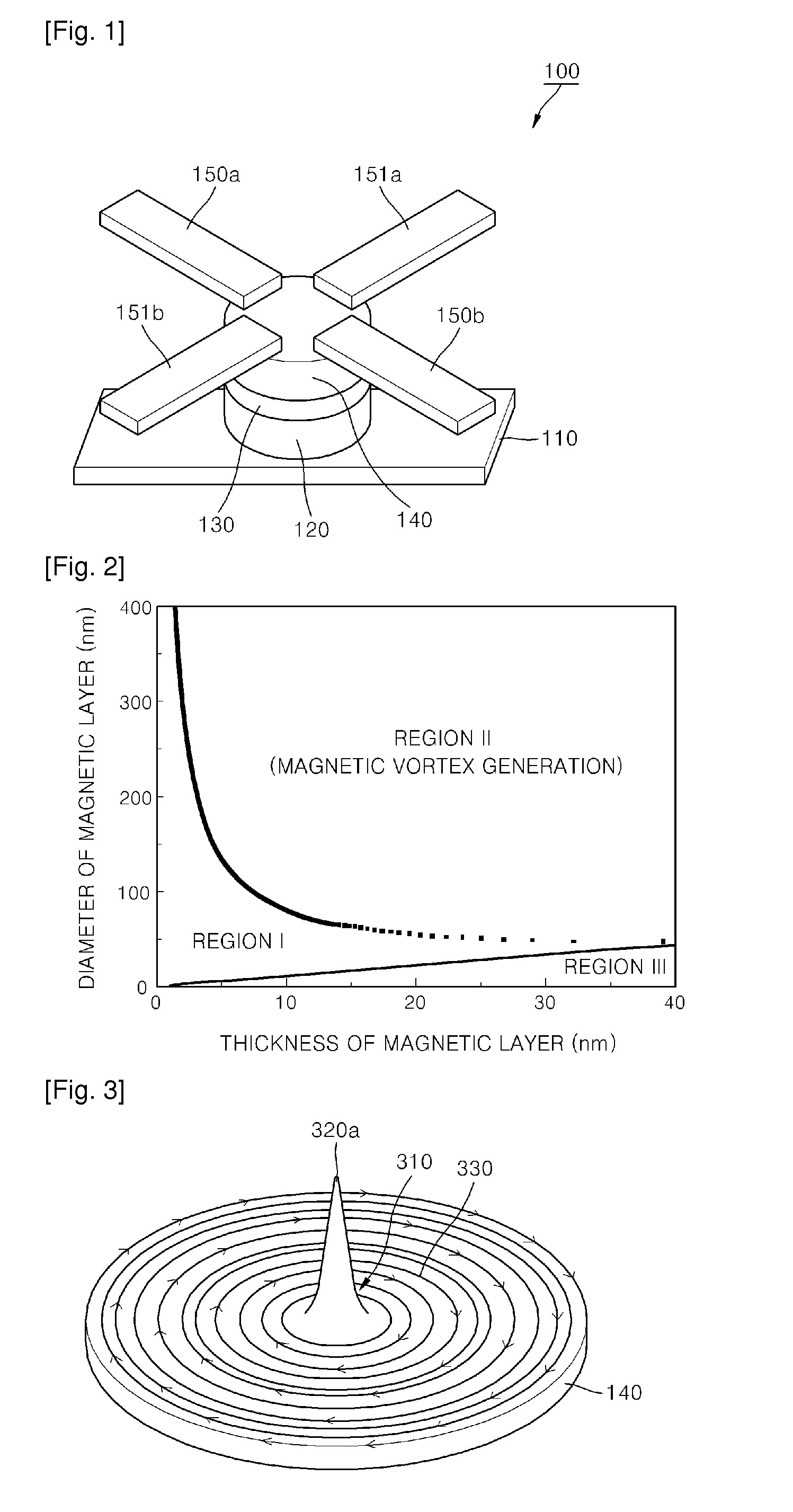

Method for read-out of information in magnetic recording element and method for read-out of information in magnetic random access memory

ActiveUS8094487B2Low powerIncrease the radius of rotationRecord information storageRecording/reproducing/erasing methodsStatic random-access memoryMagnetic vortex

Provided are a method for read-out of information in a magnetic recording element and a method for read-out of information in a magnetic random access memory. In the method, a magnetic recording element including a magnetic free layer where a magnetic vortex is formed is prepared, and “0” or “1” is assigned according to a core orientation of a magnetic vortex formed in the magnetic free layer. The magnetic vortex core formed in the magnetic free layer rotates on the magnetic free layer by applying a current or magnetic field, of which a direction varies with time, to the magnetic free layer with the magnetic vortex formed. “0” or “1” assigned according to the core orientation of the magnetic vortex formed in the magnetic free layer is read out by measuring a characteristic caused by a difference in a rotation radius of the magnetic vortex core. Herein, the rotation radius of the magnetic vortex core, which is formed in the magnetic free layer and rotates by the applied current or magnetic field, varies with the core orientation of the magnetic vortex formed in the magnetic free layer.

Owner:SEOUL NAT UNIV R&DB FOUND

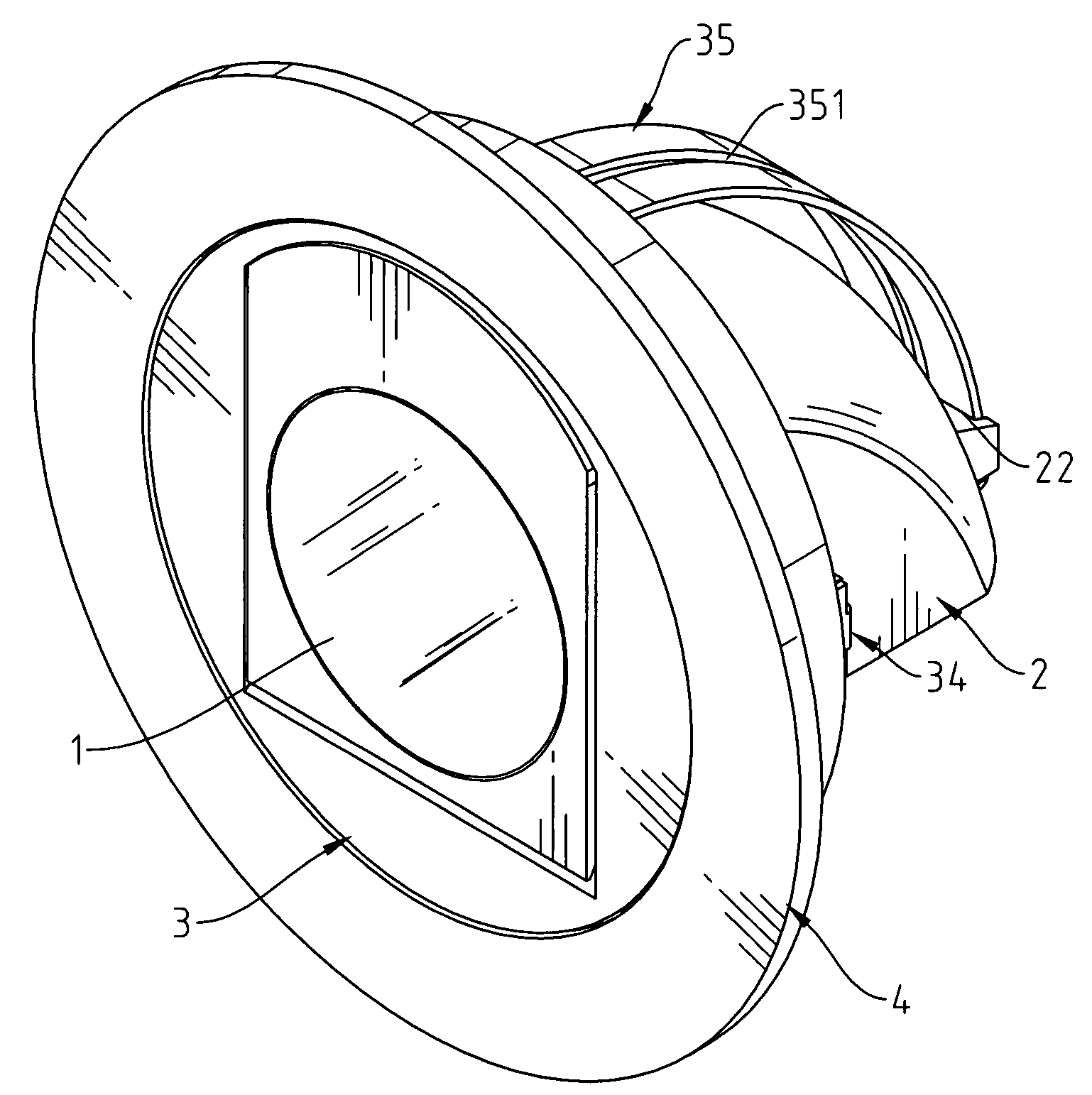

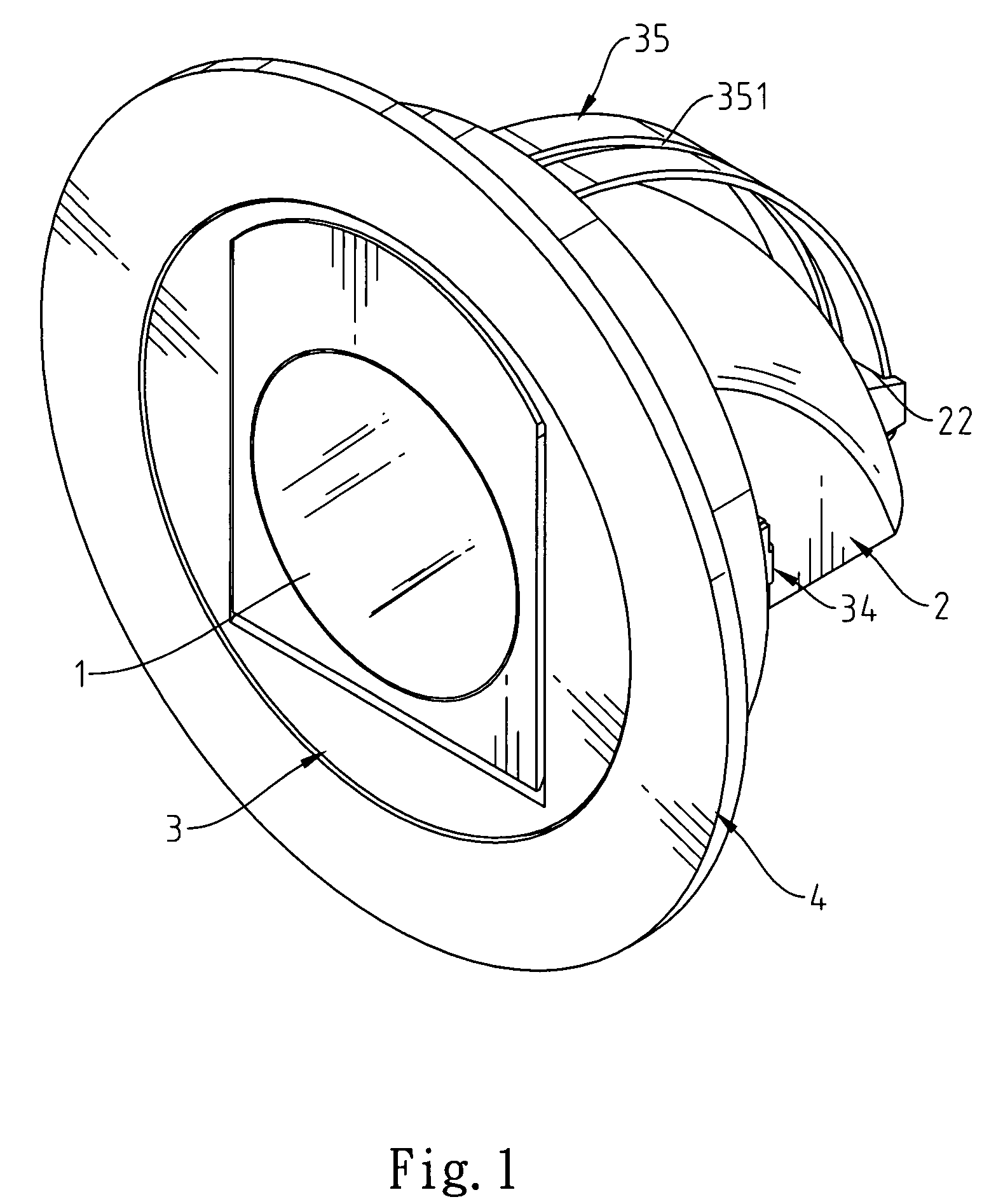

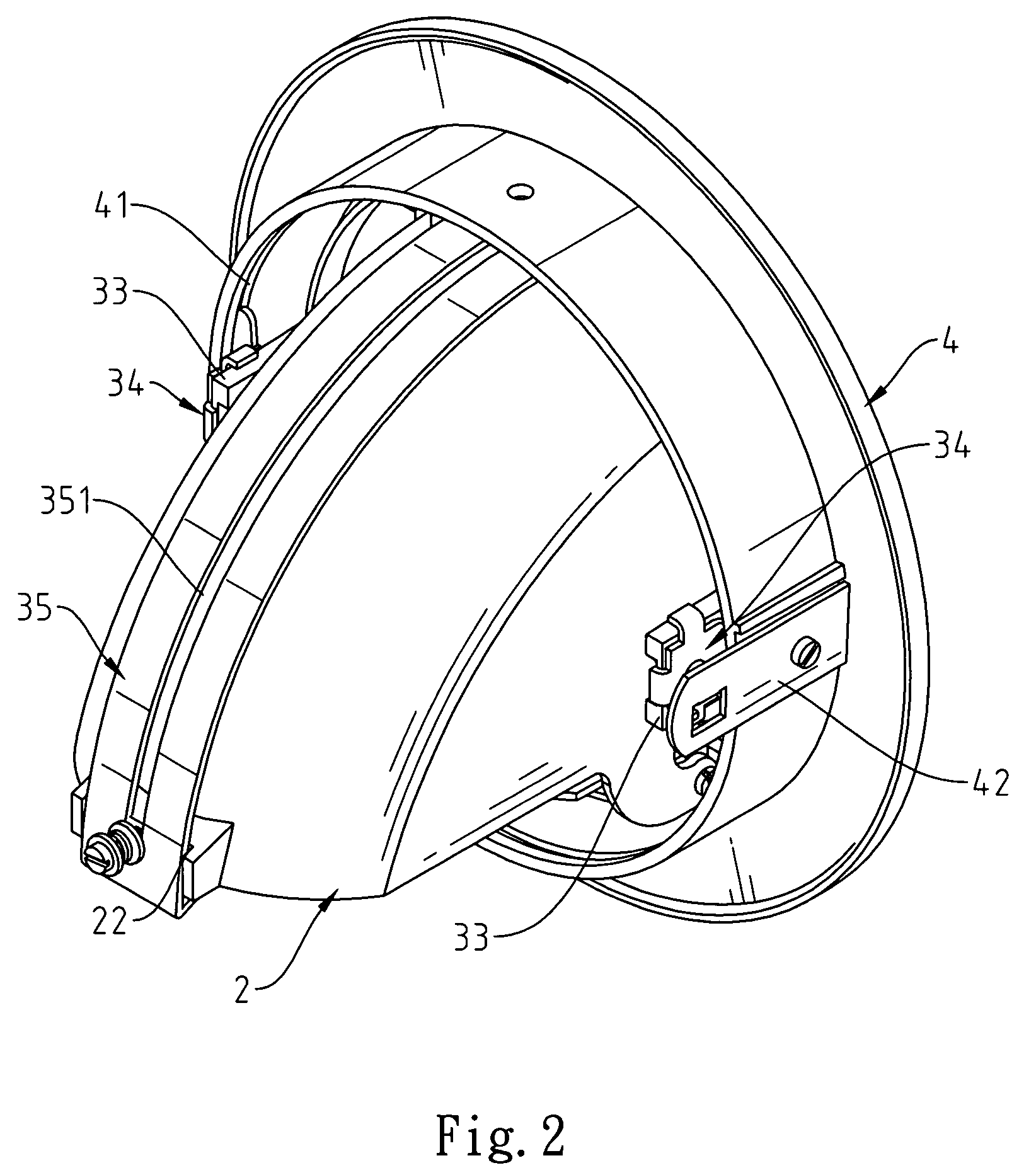

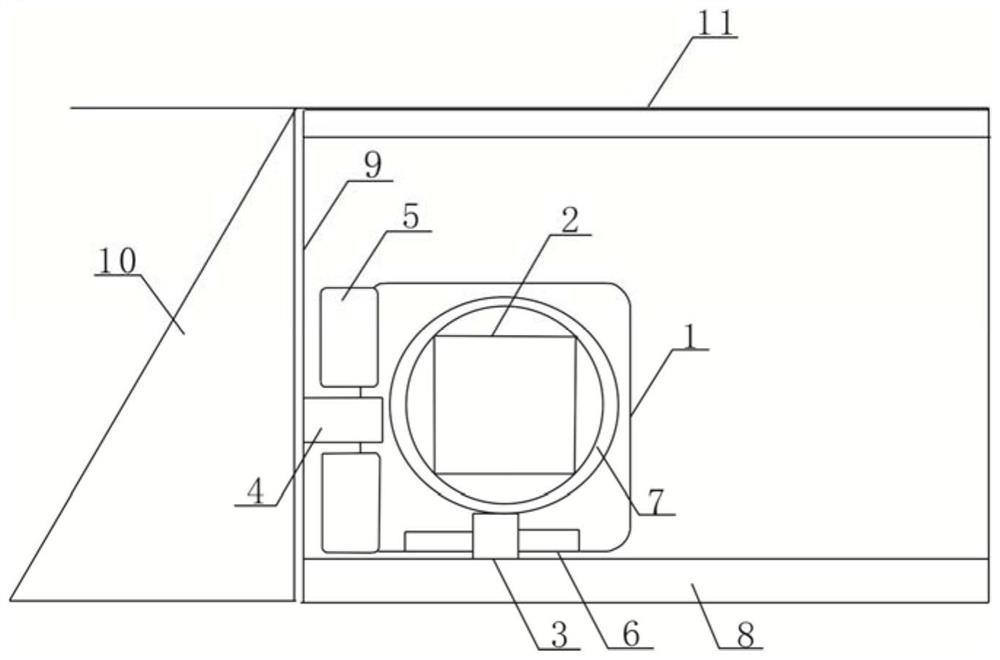

Recessed lamp structure

InactiveUS7600899B2Increase the radius of rotationEffective lightingLighting support devicesVehicle interior lightingEngineeringMechanical engineering

A recessed lamp structure comprises: a lamp bulb, a lamp holder, a rotatory carrier and an outer mounting base. The rotatory carrier is securely screwed onto a track frame, which has a hollow sliding slot on the center of the bended body thereof. The track frame is securely positioned on the axially connecting base of the rotatory carrier via two axial plates that locate on the rearward of the track frame. The lamp holder is rotatably coupled with the rotatory carrier by two bolts. The bolts are mounted in the limited connection space between the lamp holder and the rotatory carrier. Besides, the lamp holder is shiftable along the sliding slot for adjusting the lighting angle within approximate 70 degrees. Consequently, the recessed lamp structure of the present invention has simplified components and is easy to practice.

Owner:CHEN YEN CHANG

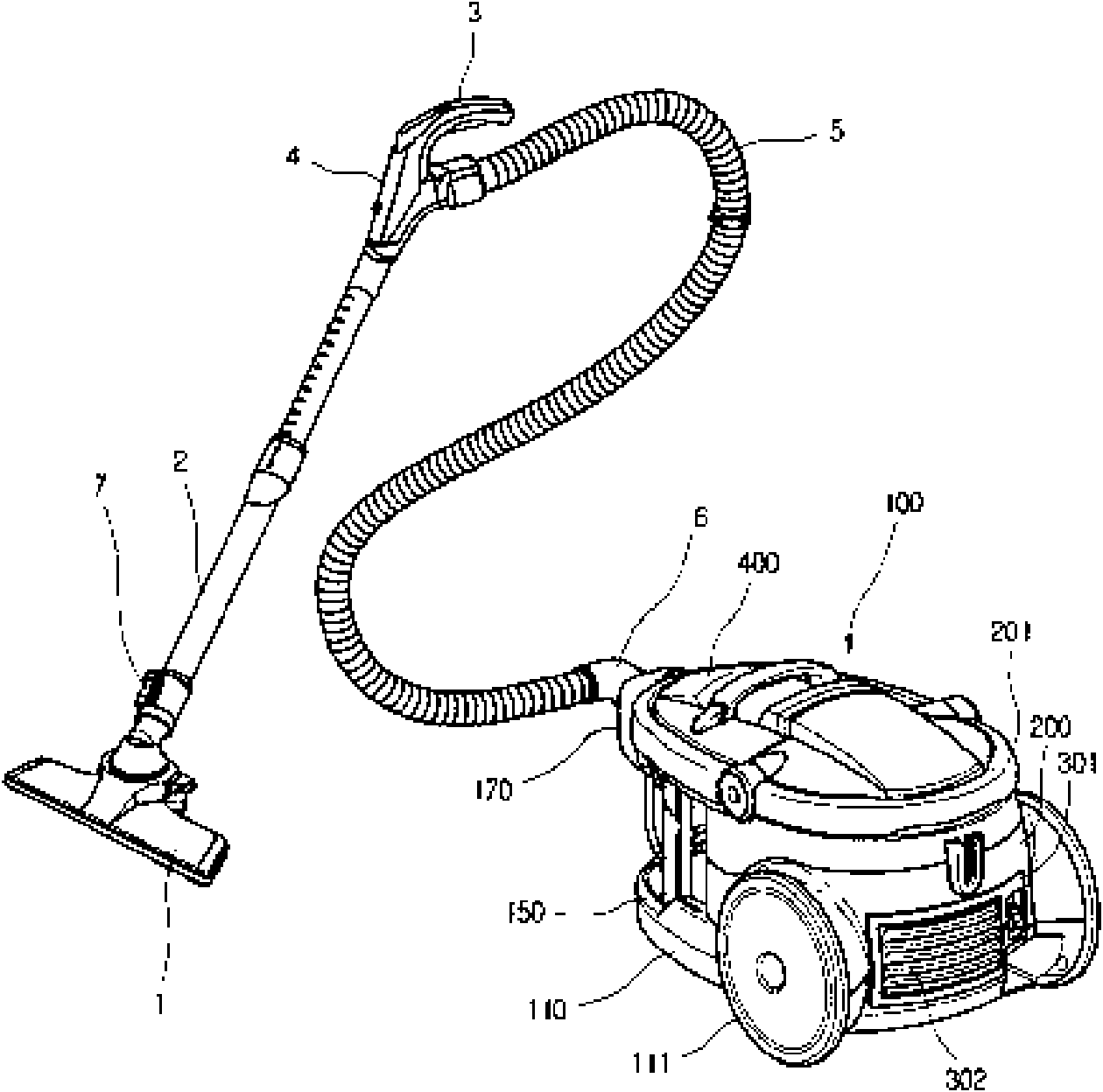

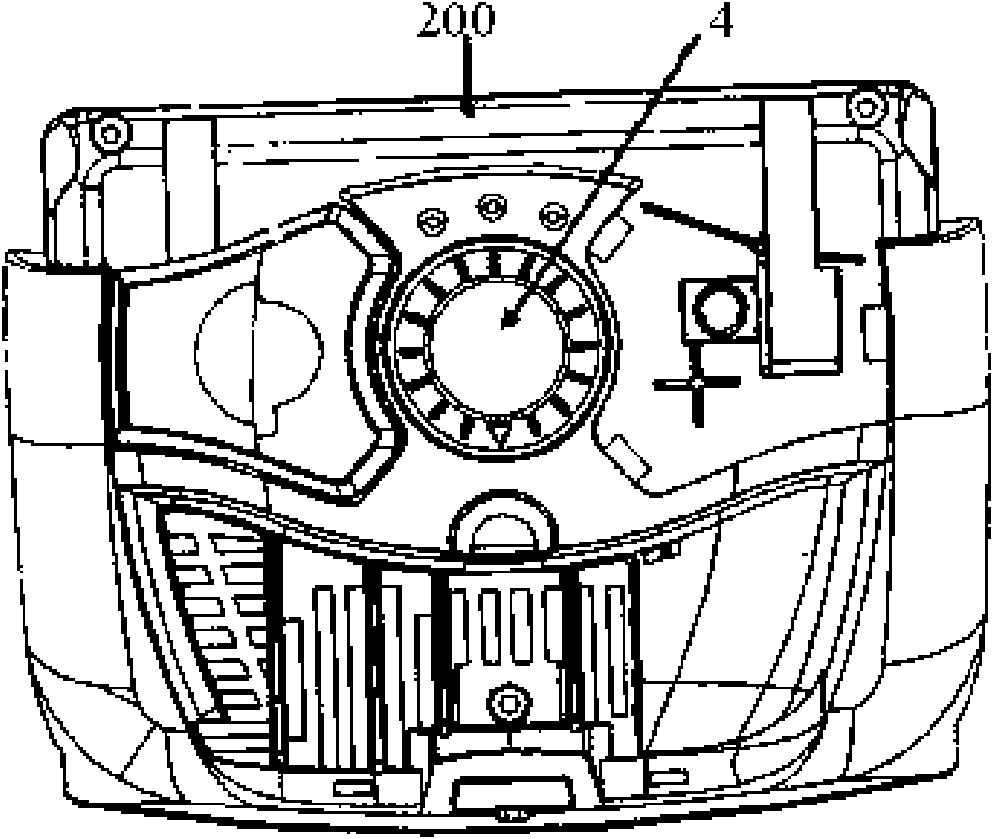

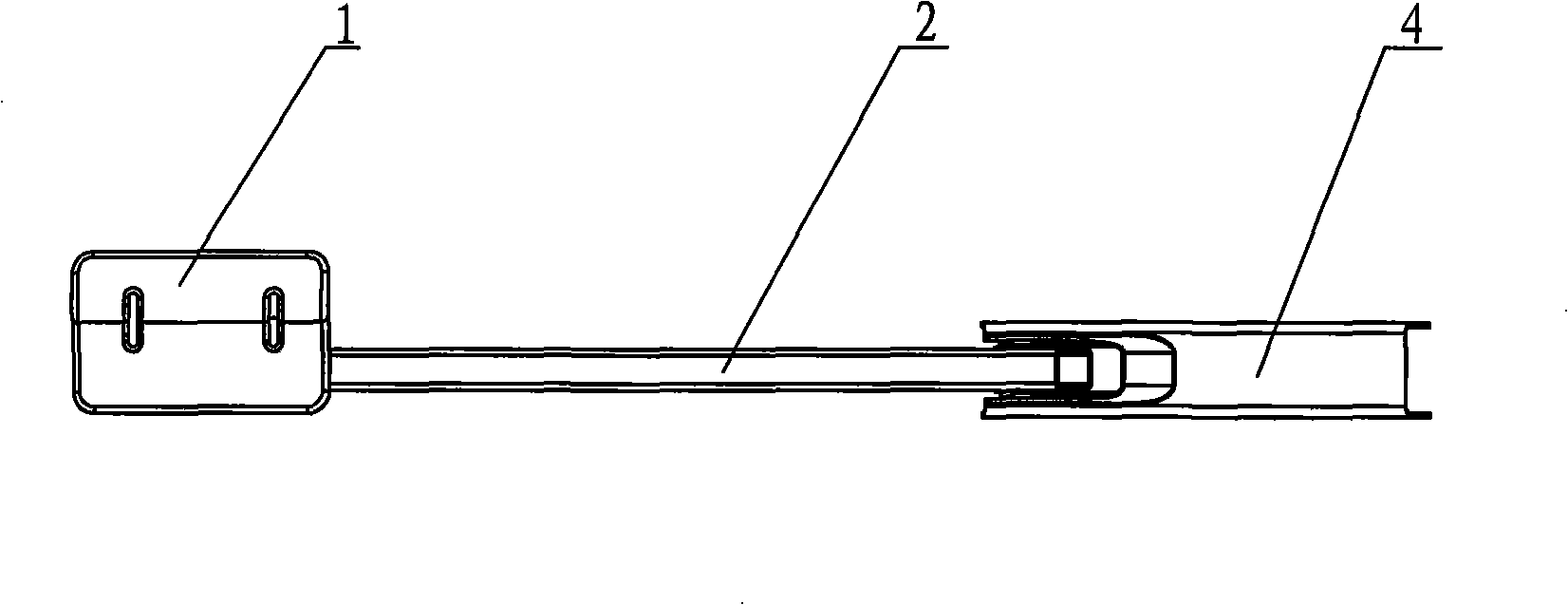

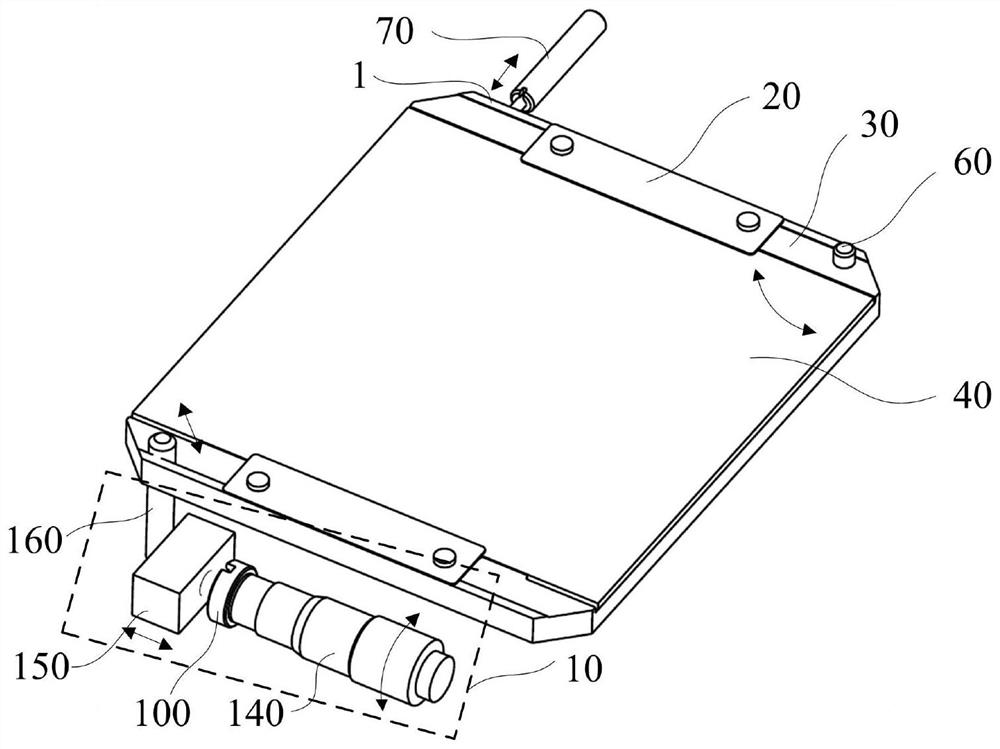

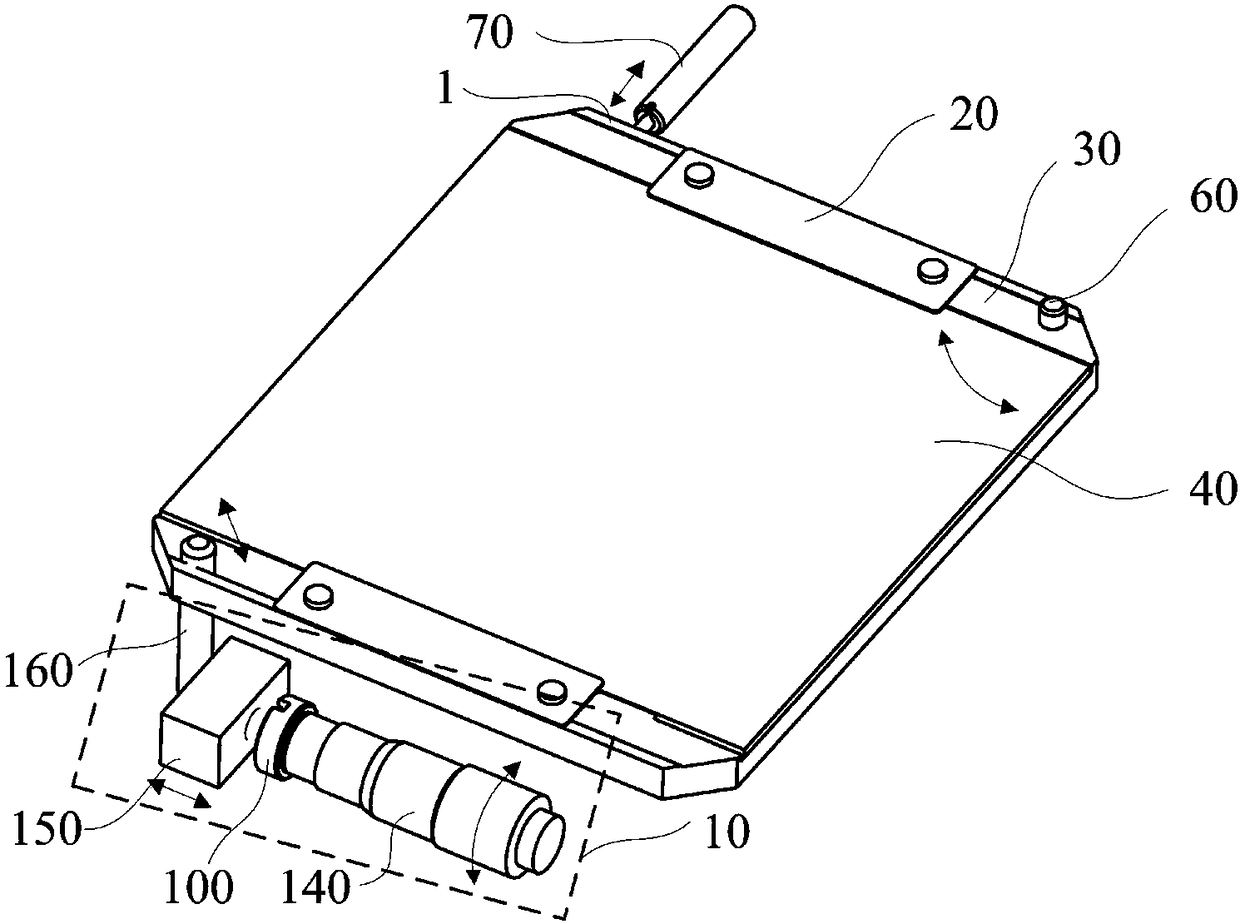

Power adjusting device for dust collector

InactiveCN101884513AIncrease the radius of rotationChange powerElectric equipment installationSuction forceEngineering

The invention discloses a power adjusting device for a dust collector, which is used for adjusting the power of the dust collector to meet the requirements of different occasions on suction. The power adjusting device consists of a knob, a knob bracket and a rheostat connected with the knob, wherein the power adjusting device is arranged on the side part of a dust collector body; and only a part of the knob is exposed outside the dust collector body. The power adjusting device can allow a user to optionally, conveniently and continuously change the power of the dust collector so as to meet the requirements of different places on the suction of the dust collector, and reduces a needed space, enhances touch effect, improves use convenience, simultaneously increases the rotation radius of the knob and enhances use safety.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

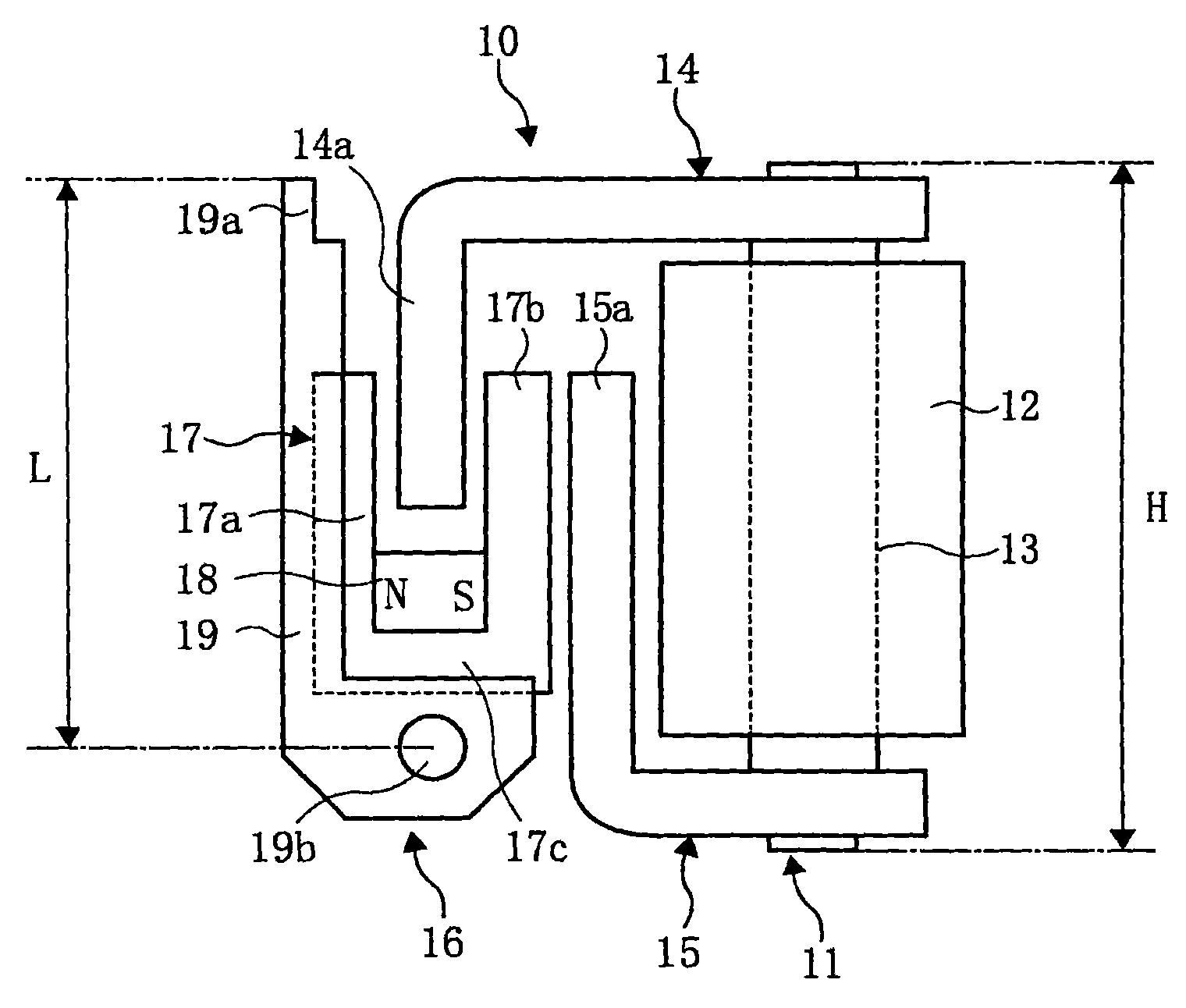

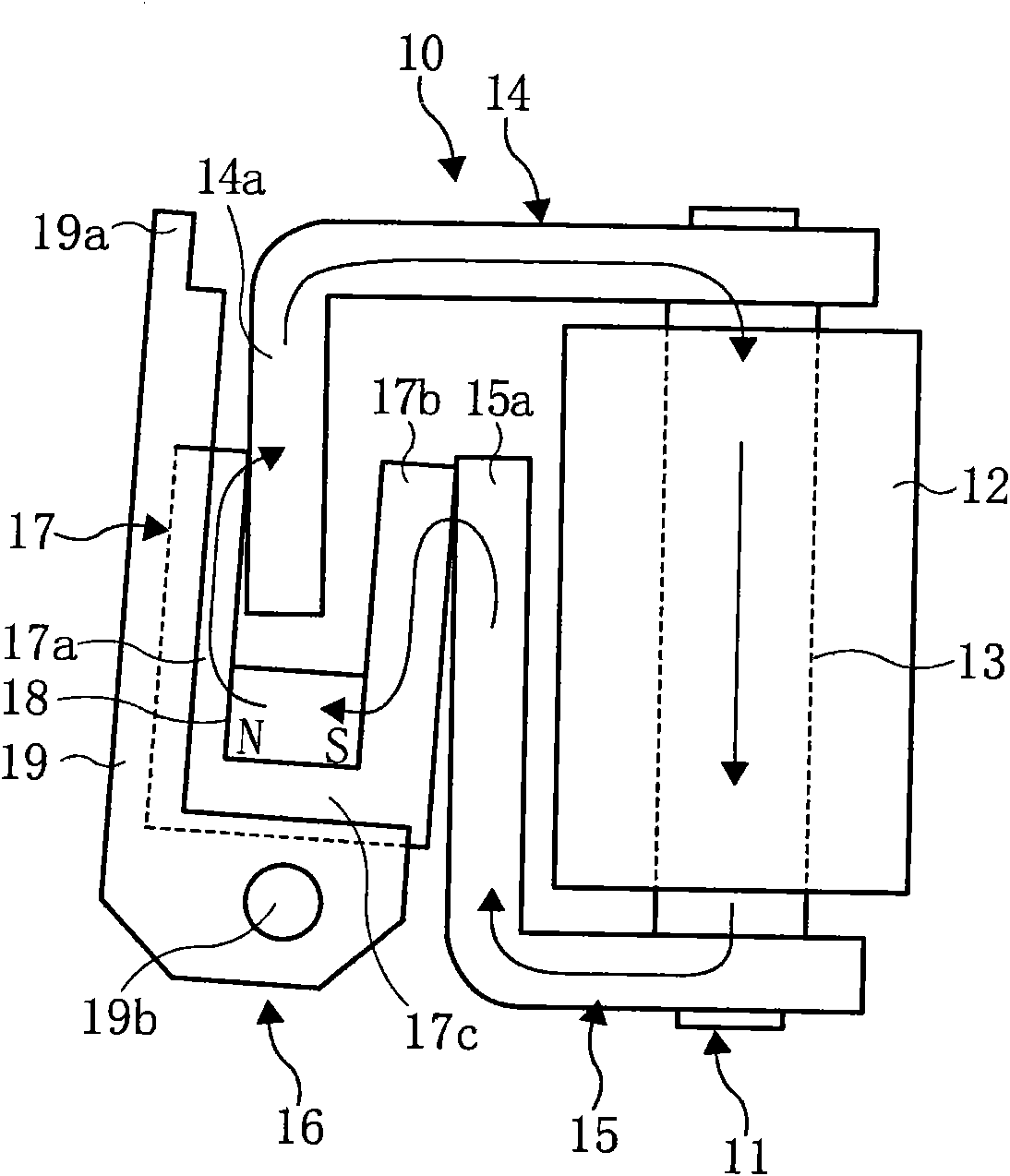

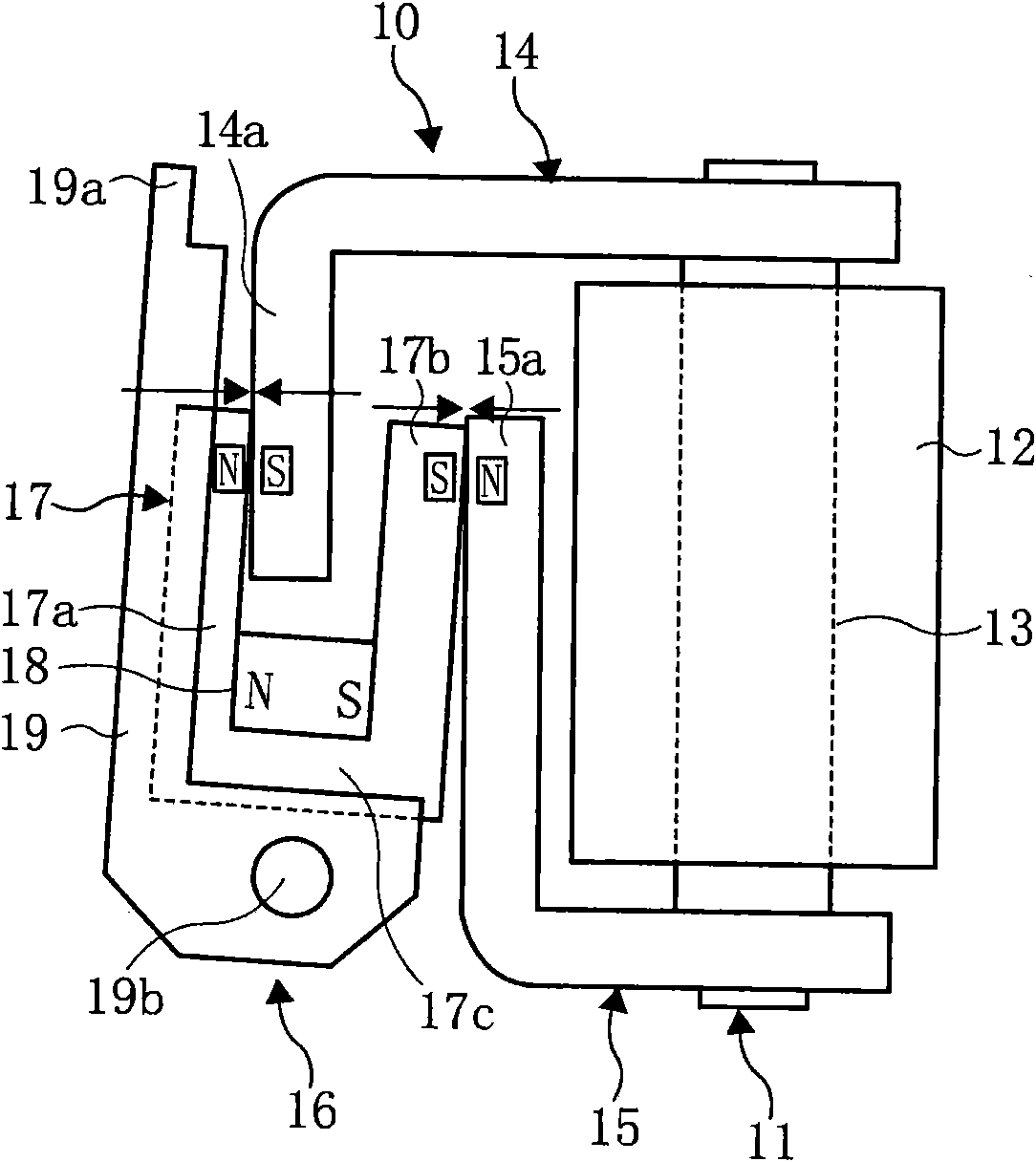

Electromagnet device and electromagnetic relay

InactiveCN102117716AIncrease rotational driveIncrease the radius of rotationElectromagnetic relay detailsElectromagnetRelay

The invention provides an electromagnet device capable of increasing the driving force and the linear driving distance and an electromagnetic relay capable of increasing the distance between the switch contact points. The movable iron core of a movable iron core part is formed by the u-shaped iron core of a built-in permanent magnet and the movable iron core part is driven by an electromagnet. The yokes of the movable iron core and the electromagnet are inserted into each other to be assembled, so that one of the core pins parallel to the movable iron core is inserted between the front ends of two parallel yokes of the electromagnet. Meanwhile, the front end of one of the yokes is inserted between the two parallel core pins of the movable iron core. In addition, the lower end of the movable iron core part is rotatably supported.

Owner:FUJI ELECTRIC FA COMPONENTS & SYST CO LTD

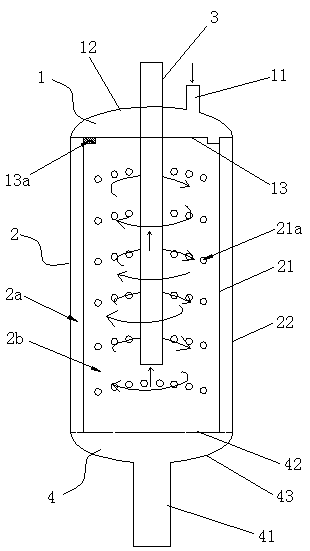

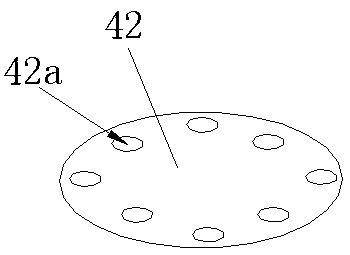

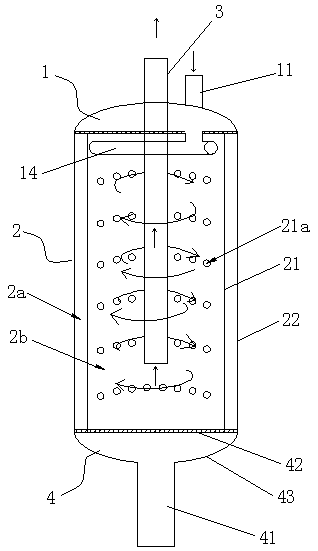

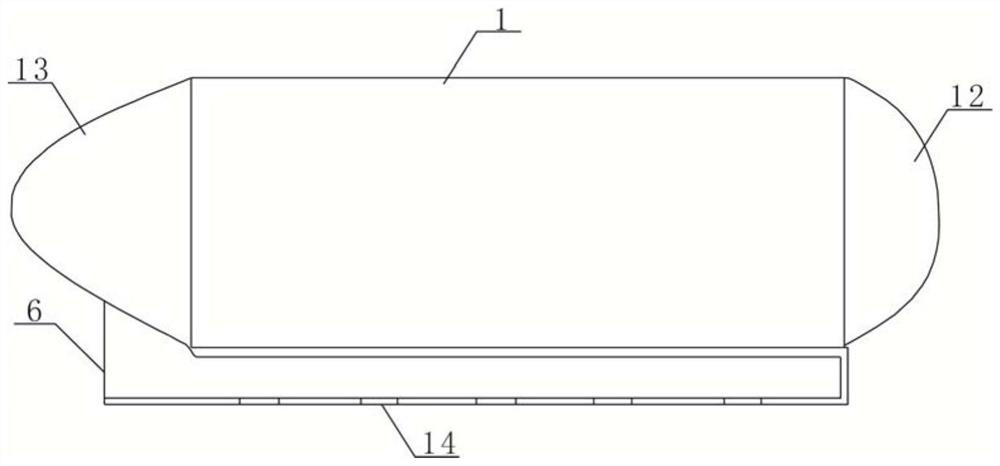

Gas and liquid separator

PendingCN110064251AEasy to separateSimple structureGas treatmentDispersed particle separationVapor–liquid separatorEngineering

The invention discloses a gas and liquid separator which comprises a separator body. A steam chamber is arranged at the upper portion of the separator body. A gas inlet pipe is arranged on the steam chamber, a jacket of the cylindrical structure is arranged below the steam chamber, a water collecting channel is formed between an inner layer plate and an outer layer plate of the jacket, a cylindercavity is formed inside an inner layer plate of the jacket at the middle of the separator body, a gas outlet pipe is arranged in the center of the cylinder cavity, and the upper end of the gas outletpipe stretches out of the separator body; a water outlet is formed in the inner layer plate of the jacket, a water collecting chamber is arranged below the jacket and communicated with the water collecting channel, a gas inlet is formed in the portion, at the inner side of the inner layer plate, of the outer edge of the steam chamber, and the gas inlet is formed in the tangent direction. The gas and liquid separator has the advantages of being simple in structure, high in separating efficiency and good in separating effect.

Owner:宁波金名片能源科技有限公司

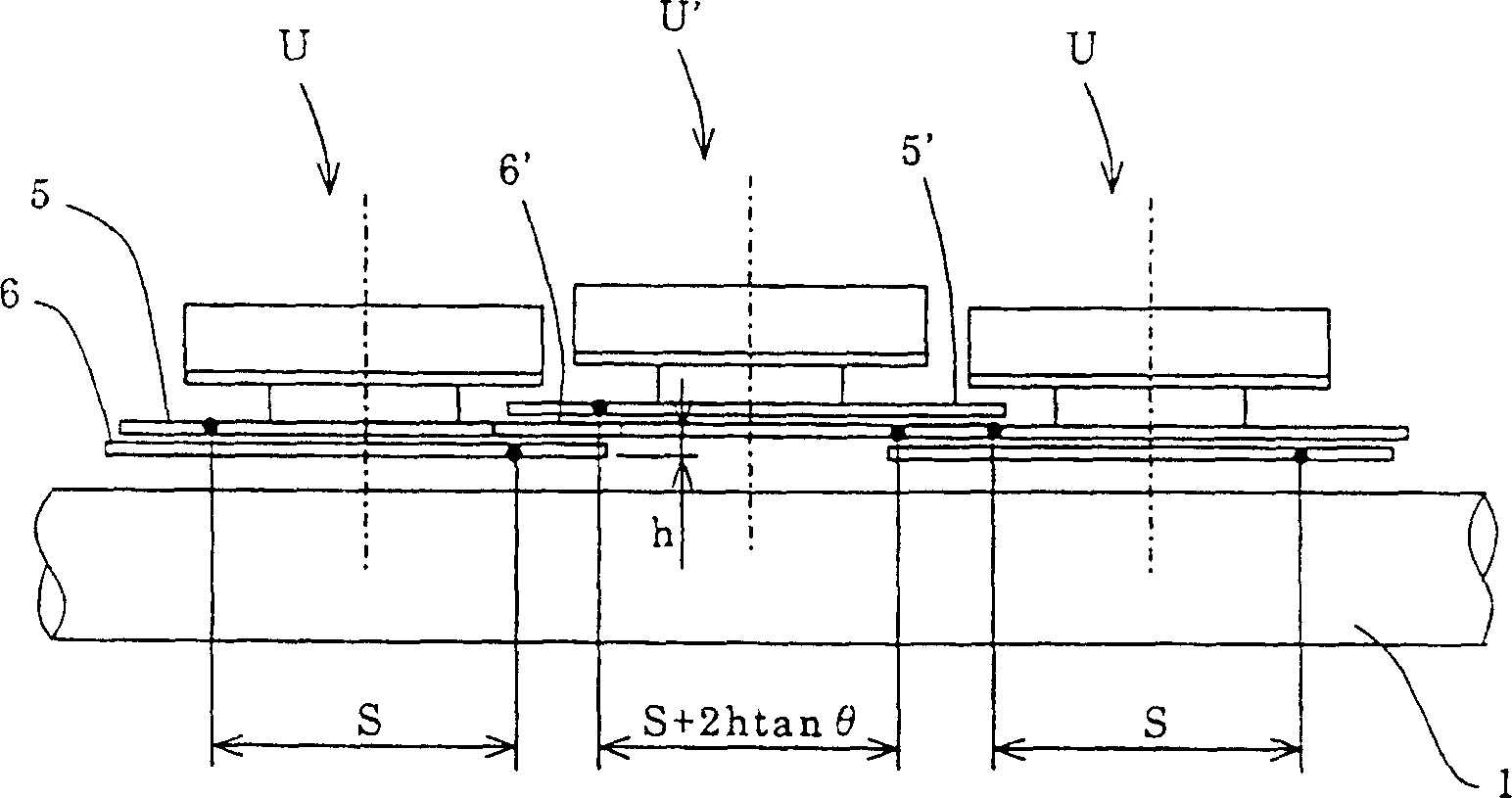

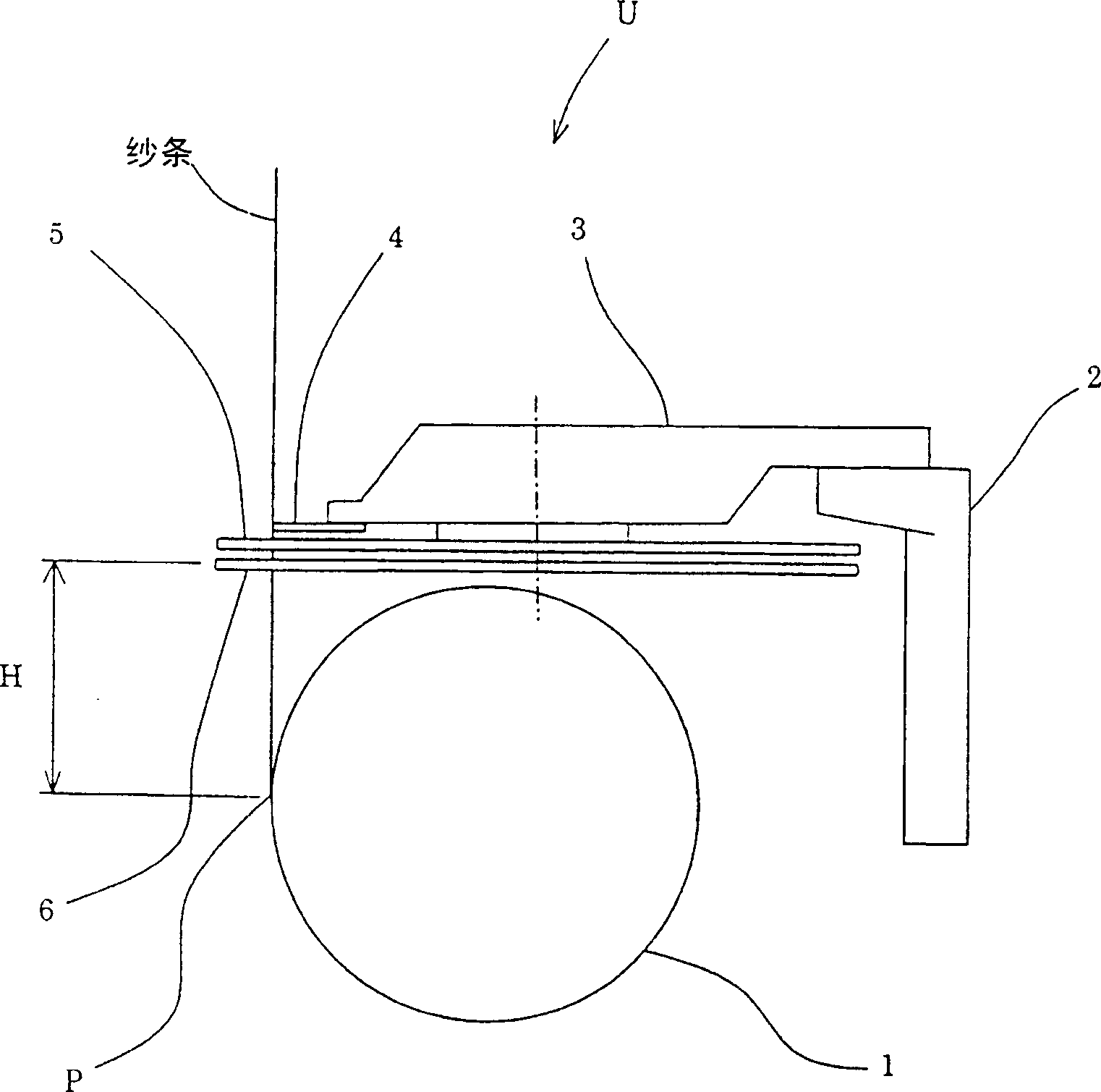

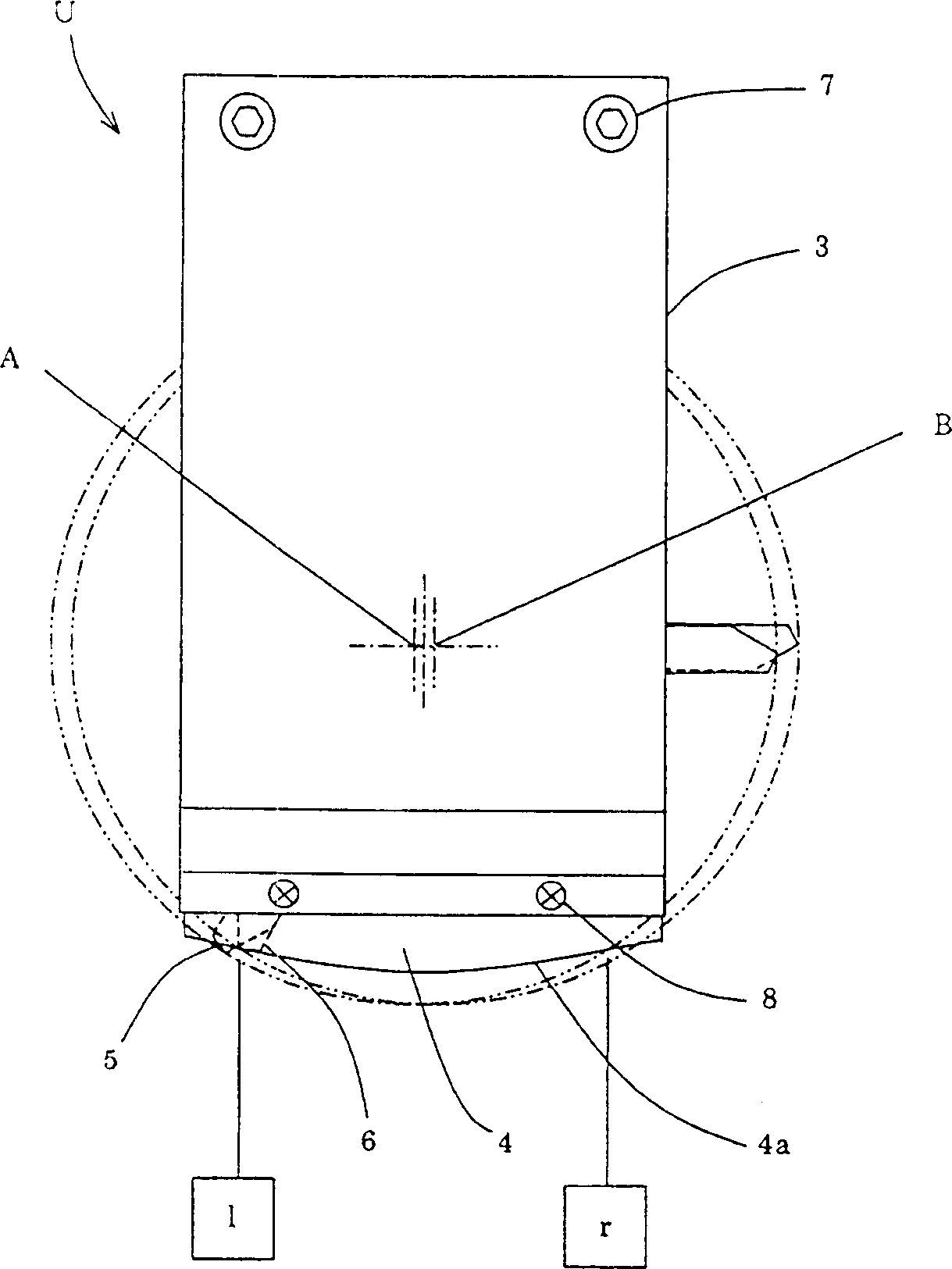

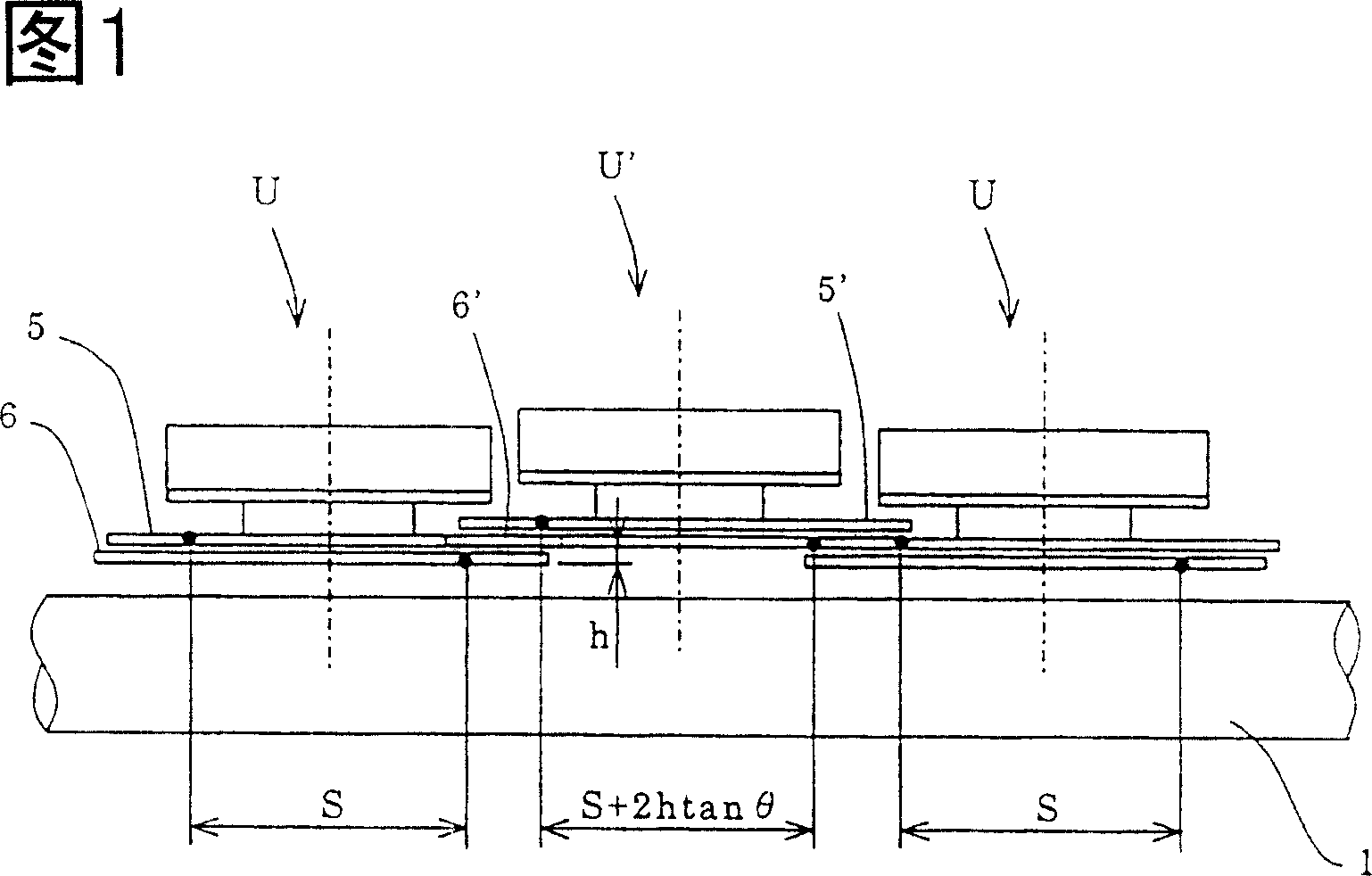

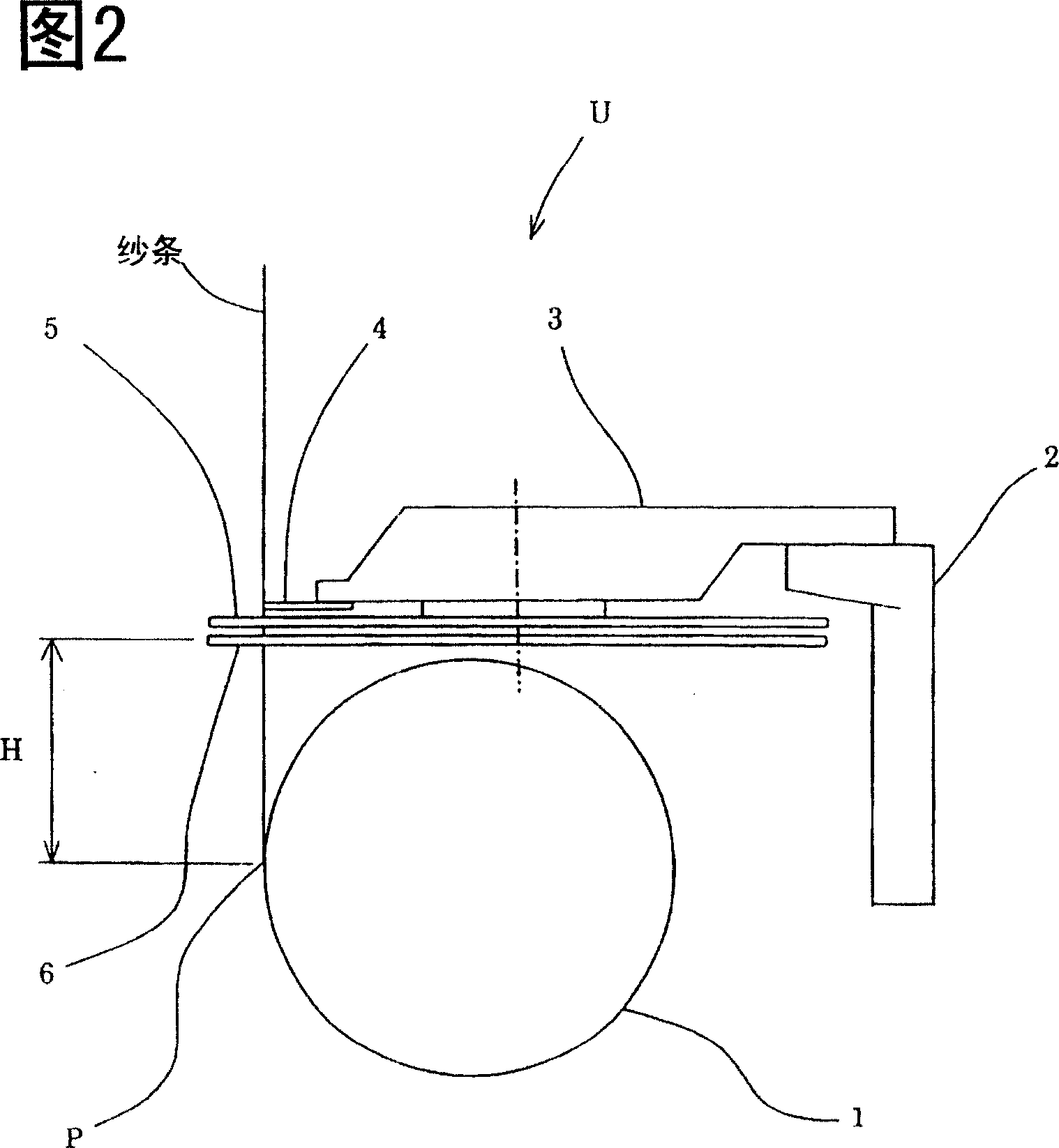

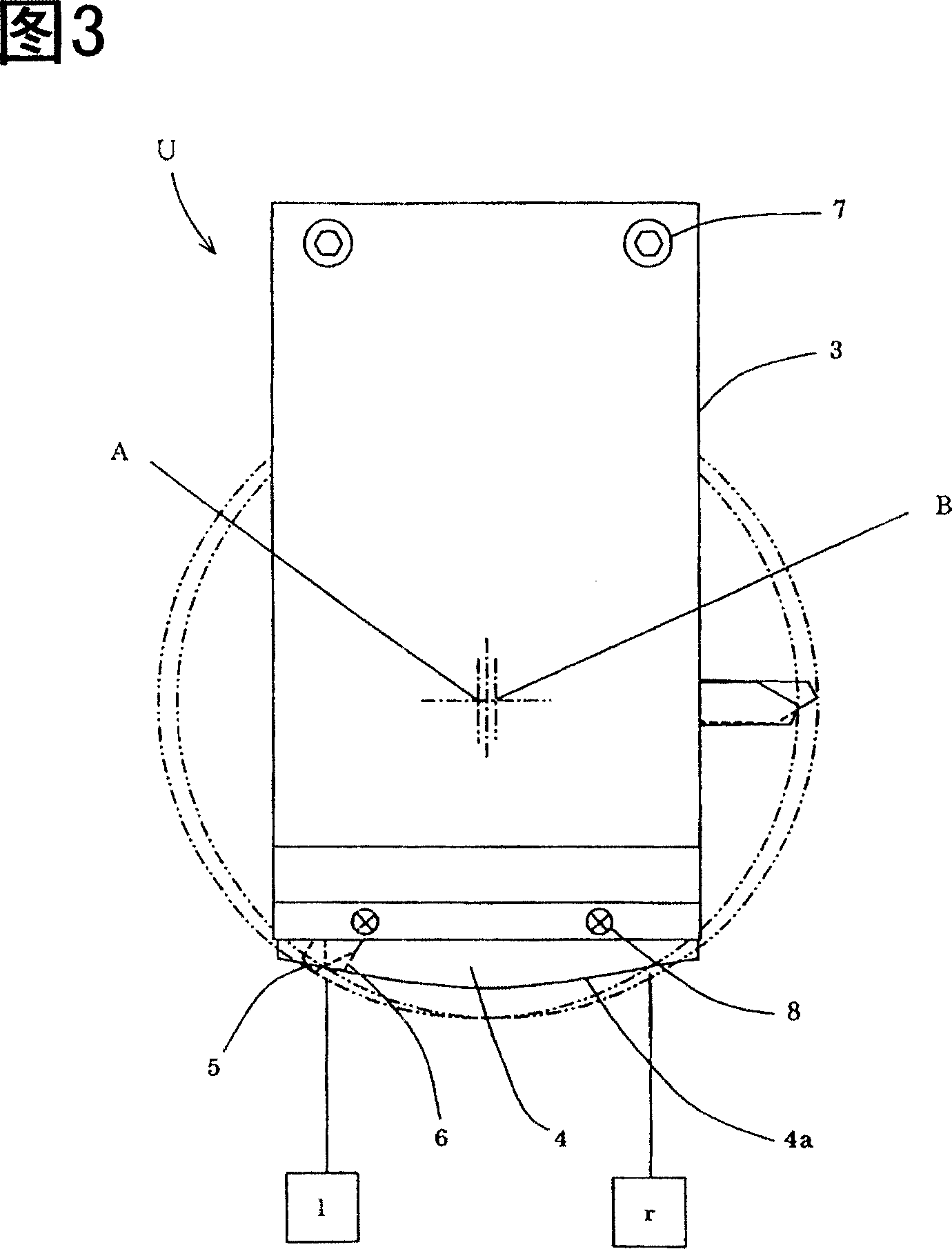

Yarn Winder

InactiveCN1406854AUniform roll widthIncrease the radius of rotationFilament handlingFolding thin materialsYarnBobbin

Provide is a yarn winding device capable of providing a package with a uniform winding width even when a distance between a rotary vane and a point where the yarn contacts a contact roller, that is a free length, is different when the yarn is released from the rotary vane between adjoining vane traverse devices. This yarn winding device comprises the traverse devices for traversing the yarn along a guide rail by an upper and lower pair of the rotary vanes rotating in the opposite directions for at least two respective adjoining bobbins for winding the yarn and the contact roller arranged in upstream of the bobbins for a yarn traveling yarn guide and has different free length between the adjoining traverse devices. By making different rotational radii formed by tips of the rotary vanes between the traverse devices, the winding width of each package wound between the traverse devices is uniformized.

Owner:TSTM CO LTD

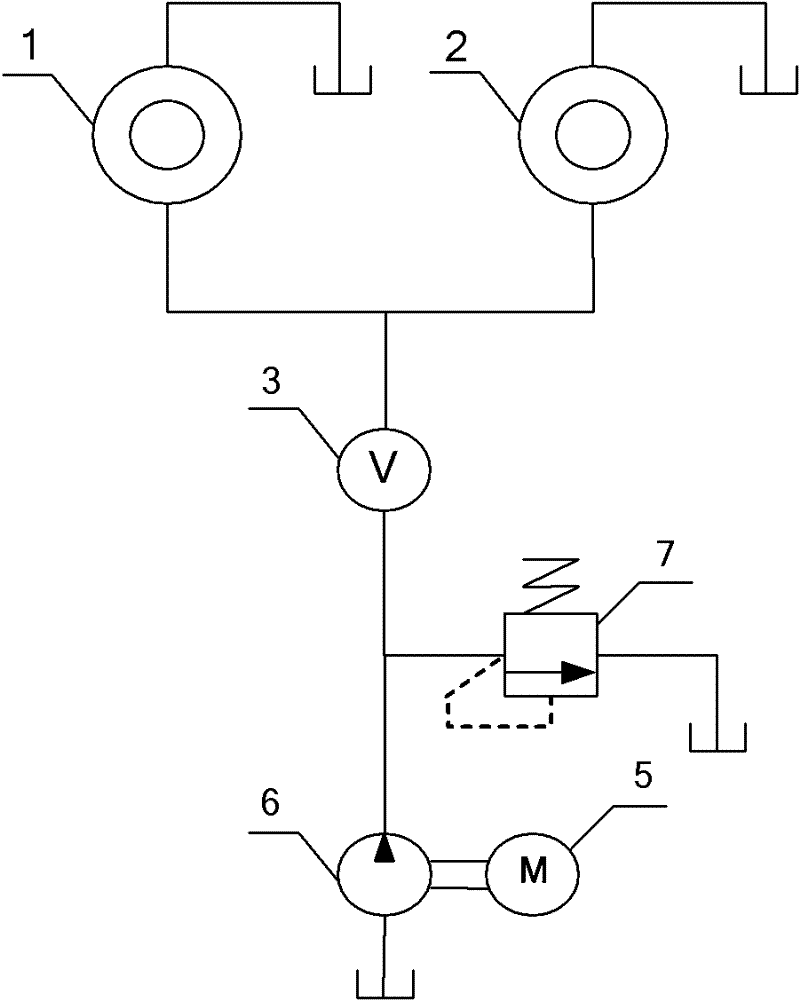

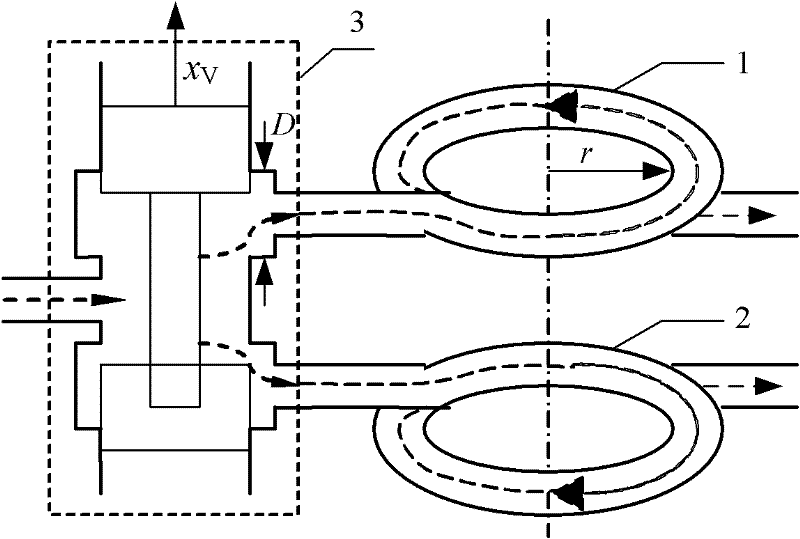

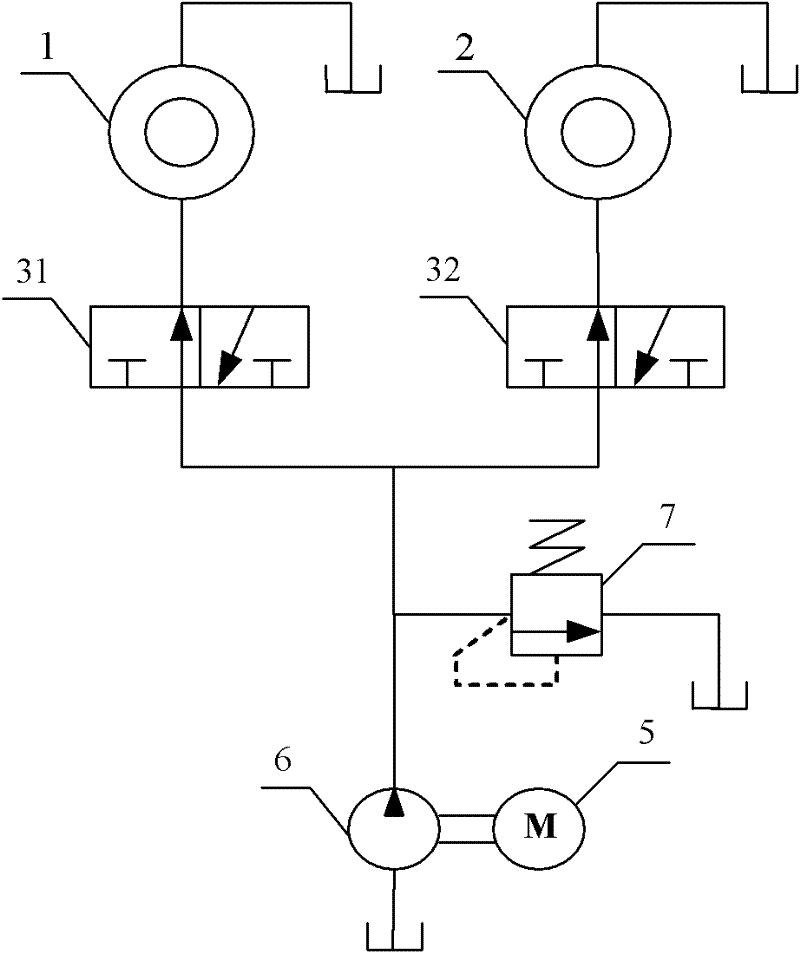

Device and method for controlling satellite attitudes through liquid circuit valve

InactiveCN102303708AIncrease the radius of rotationPower consumption advantageSpacecraft guiding apparatusLoop controlMomentum

The invention relates to a device and method for controlling satellite attitudes through a liquid circuit valve, relating to the device and method for controlling satellite attitudes, and solving the problem of bad effect of control of satellite attitudes caused by serious bearing abrasion and poor heat radiation and lubrication in the traditional device adopting flywheel-type momentum interchange to control the satellite attitudes. In the device provided by the invention, a group of satellite attitude control units are respectively installed in the directions of three axles of a satellite body. The method provided by the invention comprises a step of controlling the quantity of flow entering a forward circuit and a backward circuit through a circuit control valve or a forward / reverse control valve so as to realize the control of the satellite attitudes. The device and method provided by the invention are suitable for the control of the satellite attitudes.

Owner:HARBIN INST OF TECH

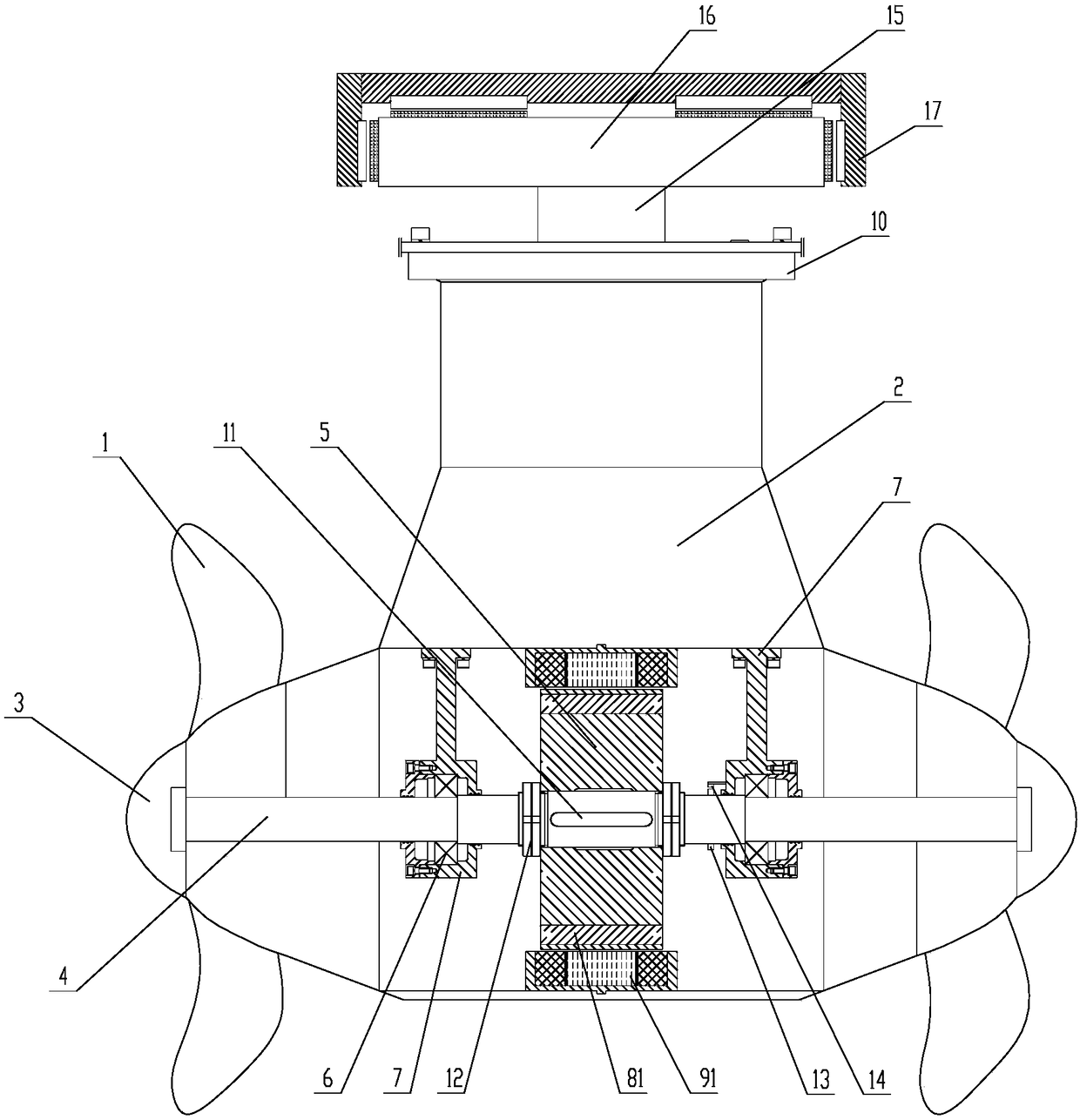

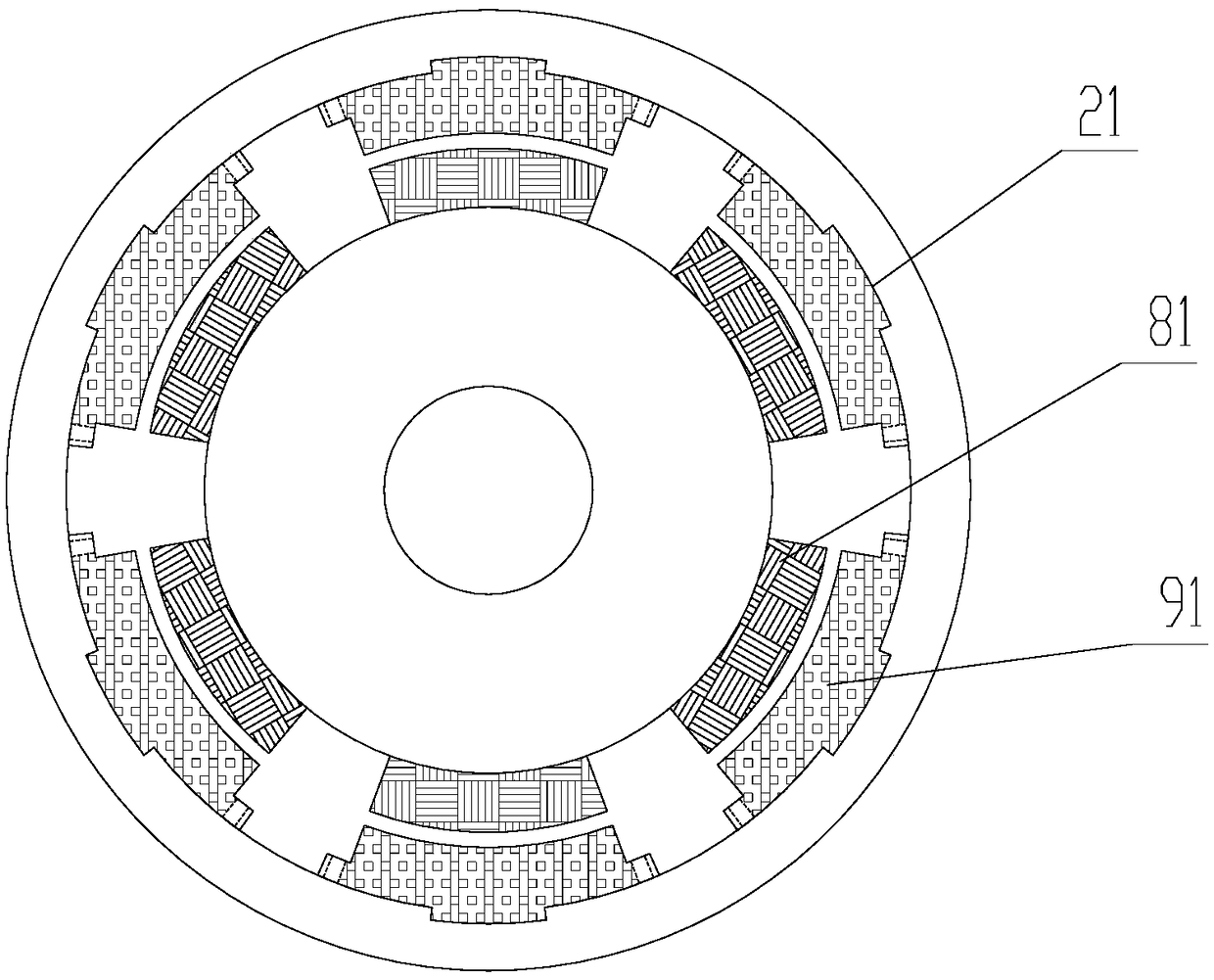

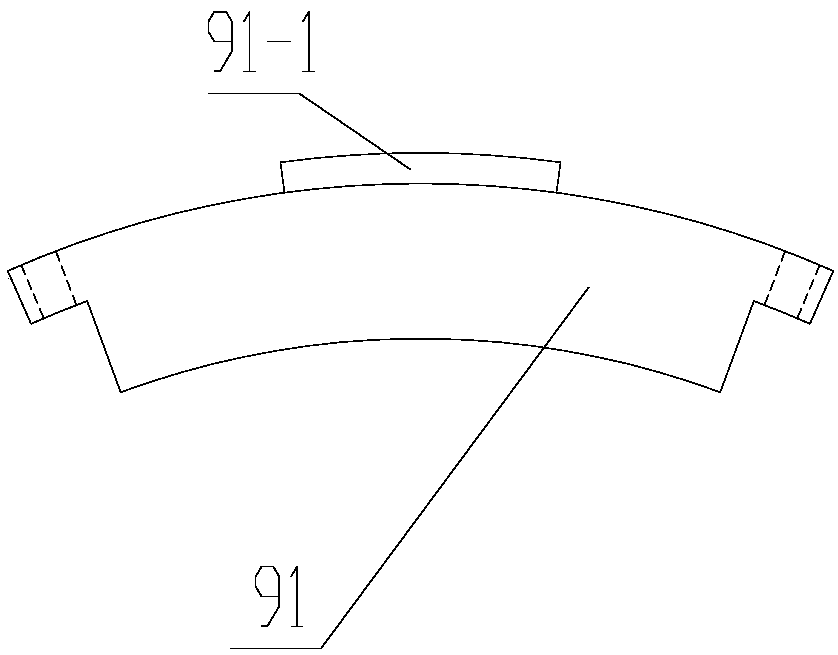

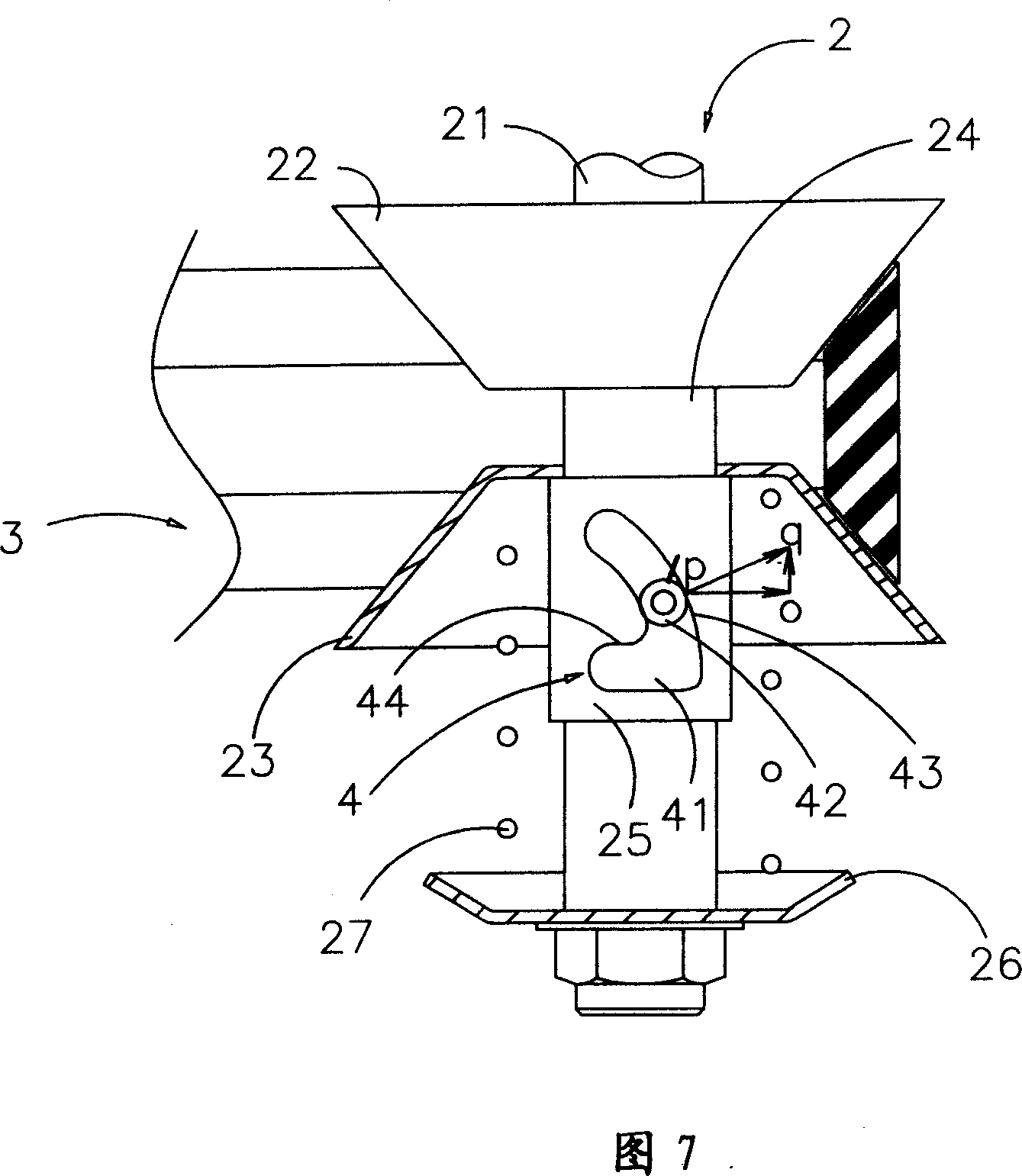

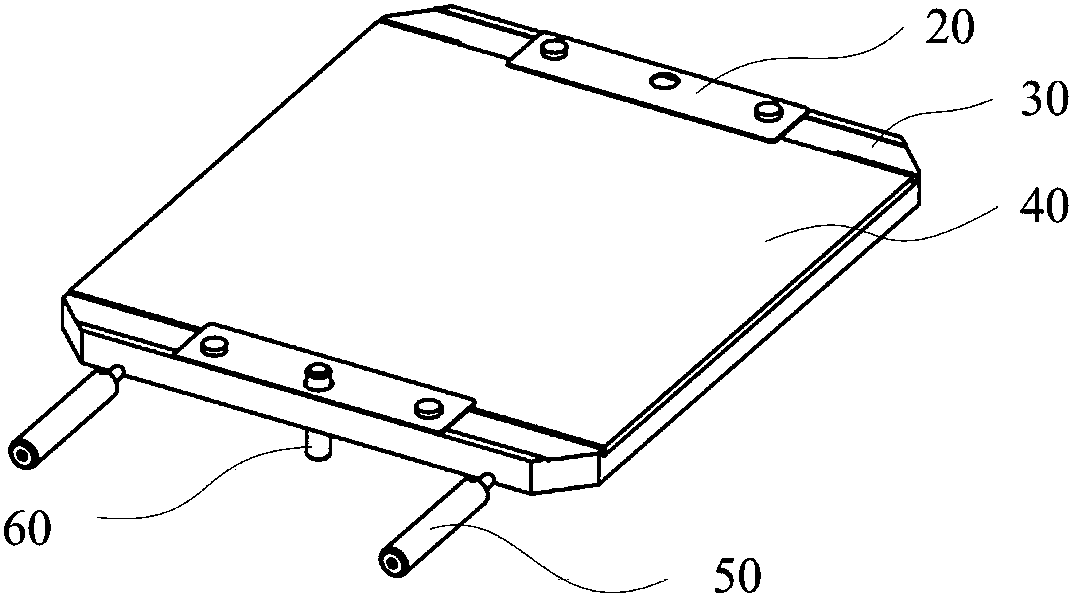

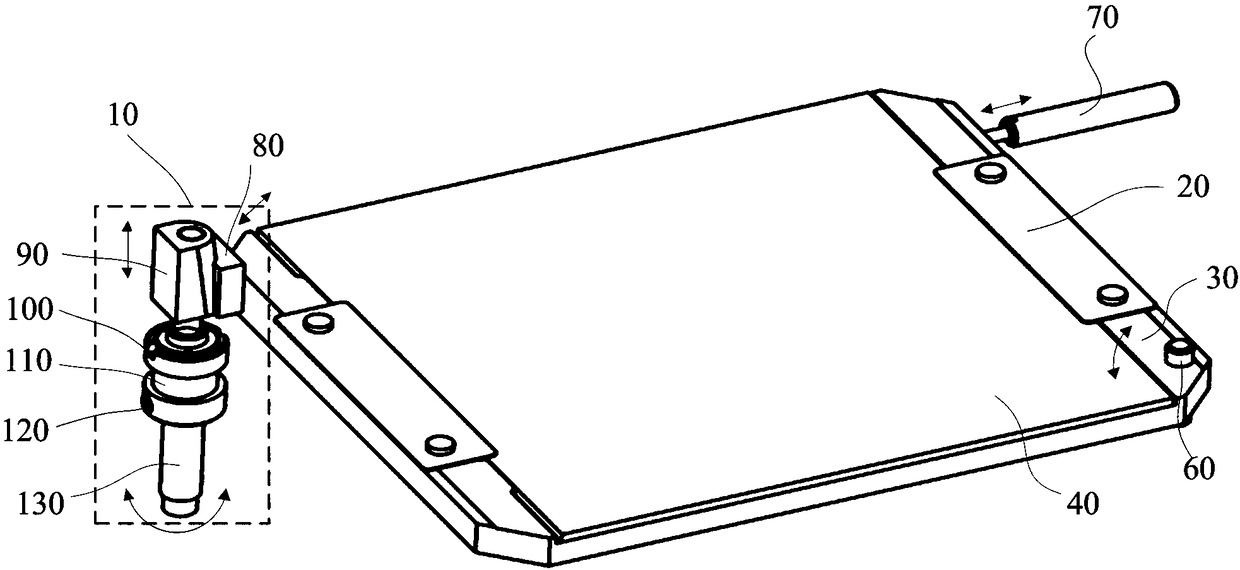

Ship pod type propeller

PendingCN109436268AAchieve angular deflectionIncrease moment radiusPropulsion power plantsOutboard propulsion unitsSynchronous motorPropeller

The invention discloses a ship pod type propeller which comprises a pod housing, a propeller body and a propeller shaft. The pod housing is installed on a ship body through a rotating bearing. The propeller shaft is fixedly installed on a bearing pedestal of an inner cavity of the pod housing through a bearing in the pod housing. The propeller body outside the pod housing is installed at one end of the propeller shaft. The propeller shaft is driven by a permanent magnetic synchronous motor. Modularized design is adopted, the ship pod type propeller is convenient to manufacture, high in installation precision and large in output power, and a driving device is small in size.

Owner:HUBEI HUANYEE ELECTROMAGNETIC EQUIP ENG TECH CO LTD

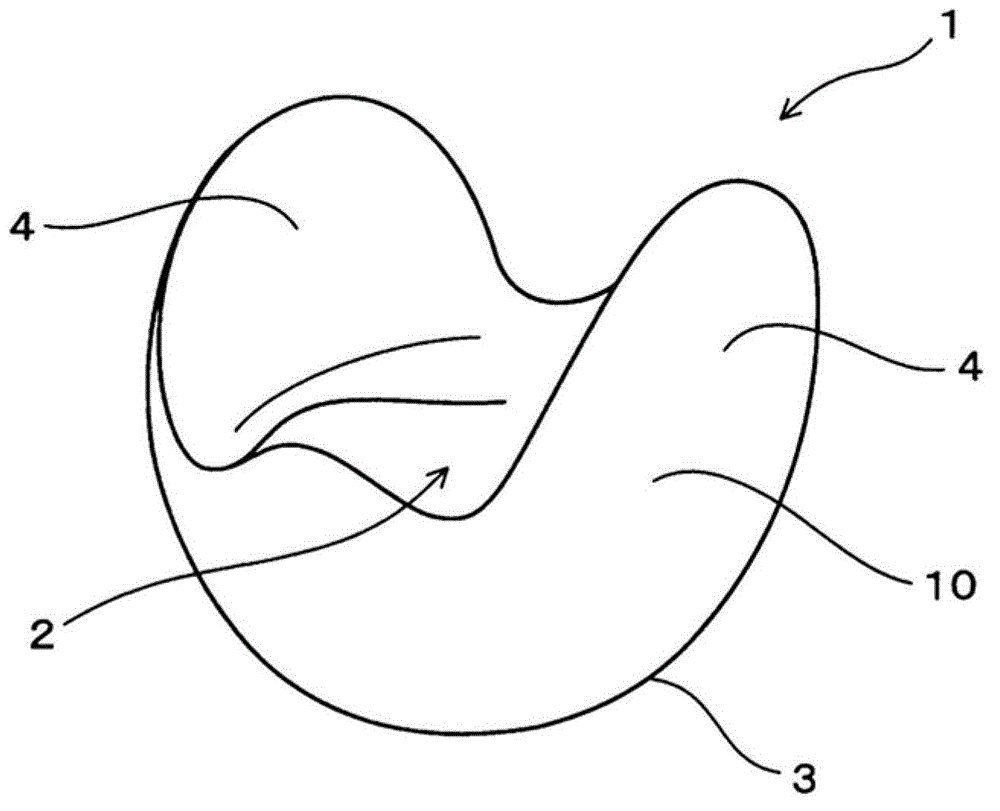

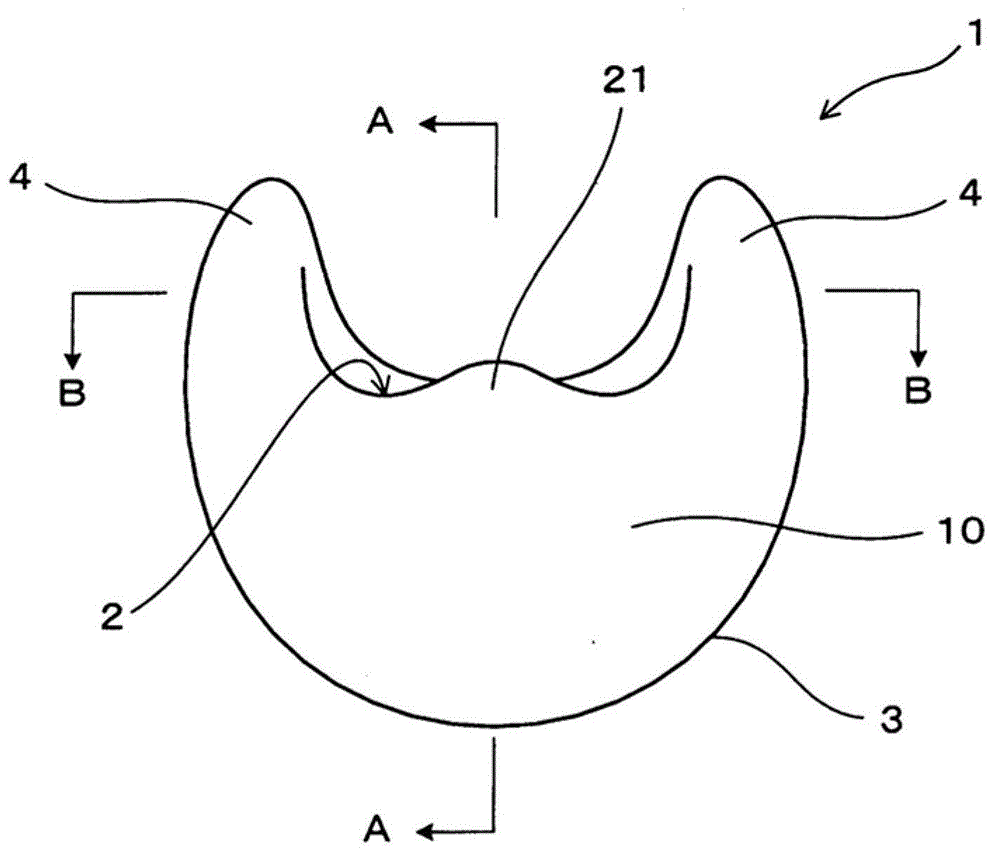

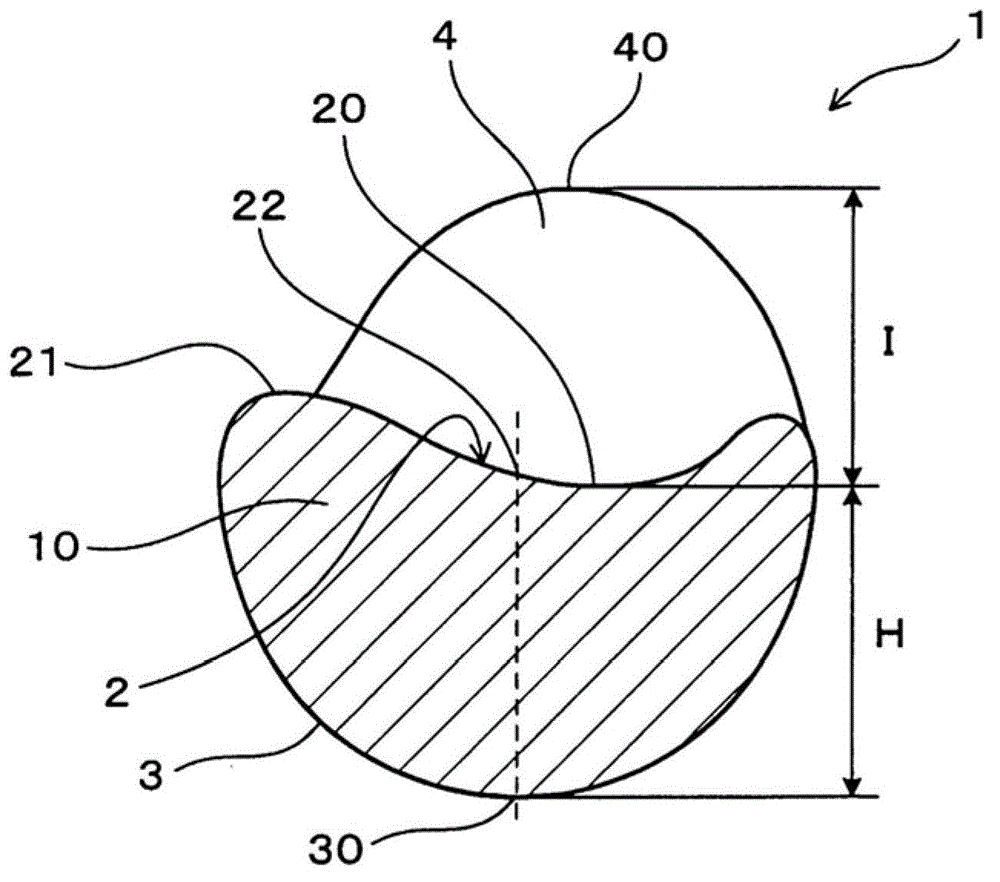

Exercise assisting apparatus

An exercise assisting apparatus (1) has a main body (10). The main body portion is provided with a seat surface (2) for a user to be seated in, and a substantially spherical bottom surface (3). The height H of the lowest point of the seat surface (2) is in the range of 100 ~ 450mm, and the seat surface has a restriction unit which restrains the user's buttocks from deviating the seat surface (2). The exercise assisting apparatus (1), in the state of the user is seated in the seat surface, allows the seat surface (2) to incline in all directions while maintaining the bottom surface (3) in a state of touching the ground.

Owner:MTG CO LTD

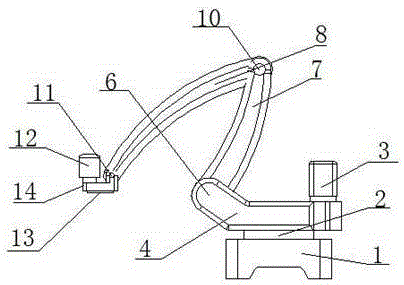

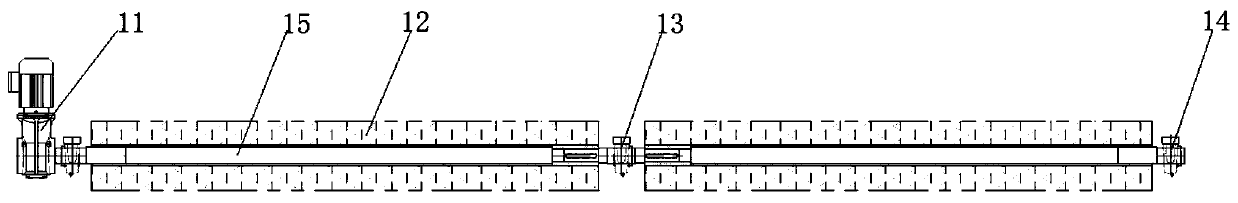

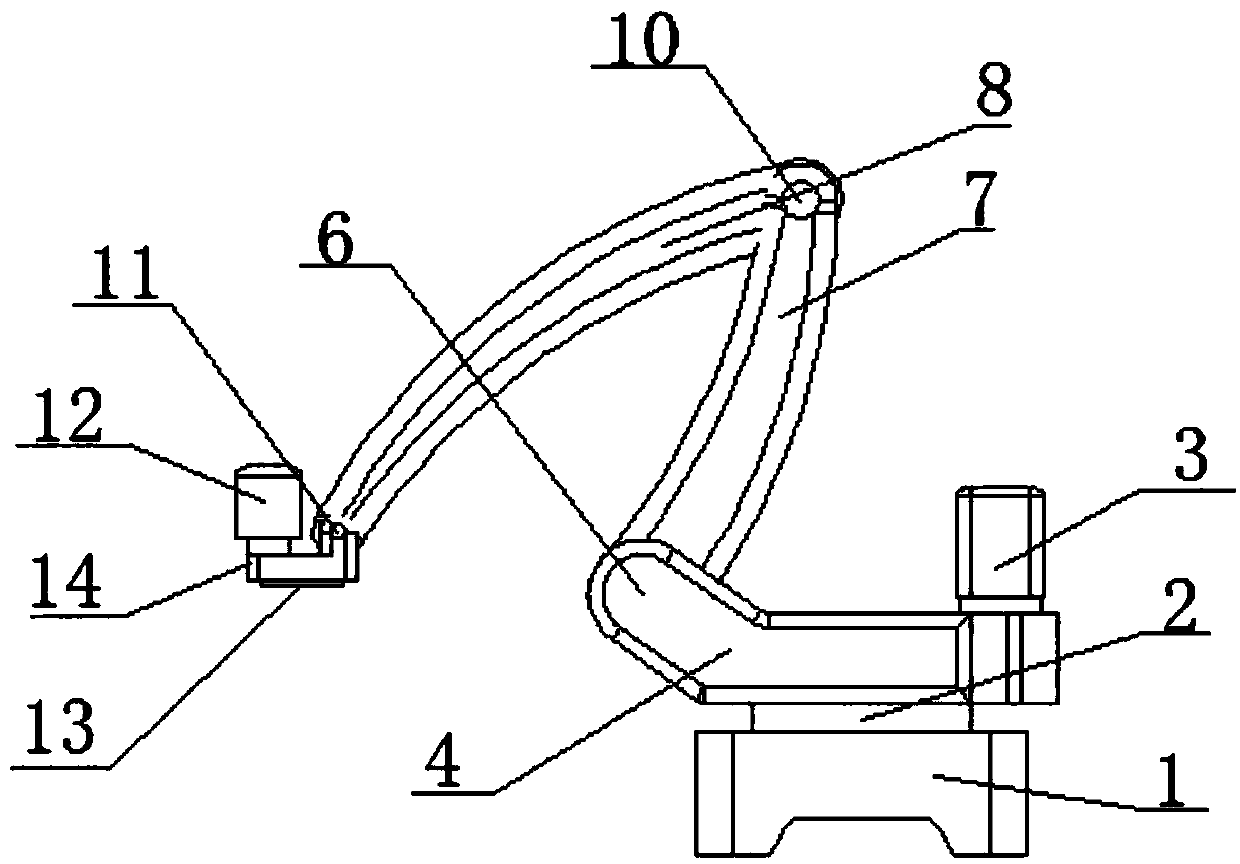

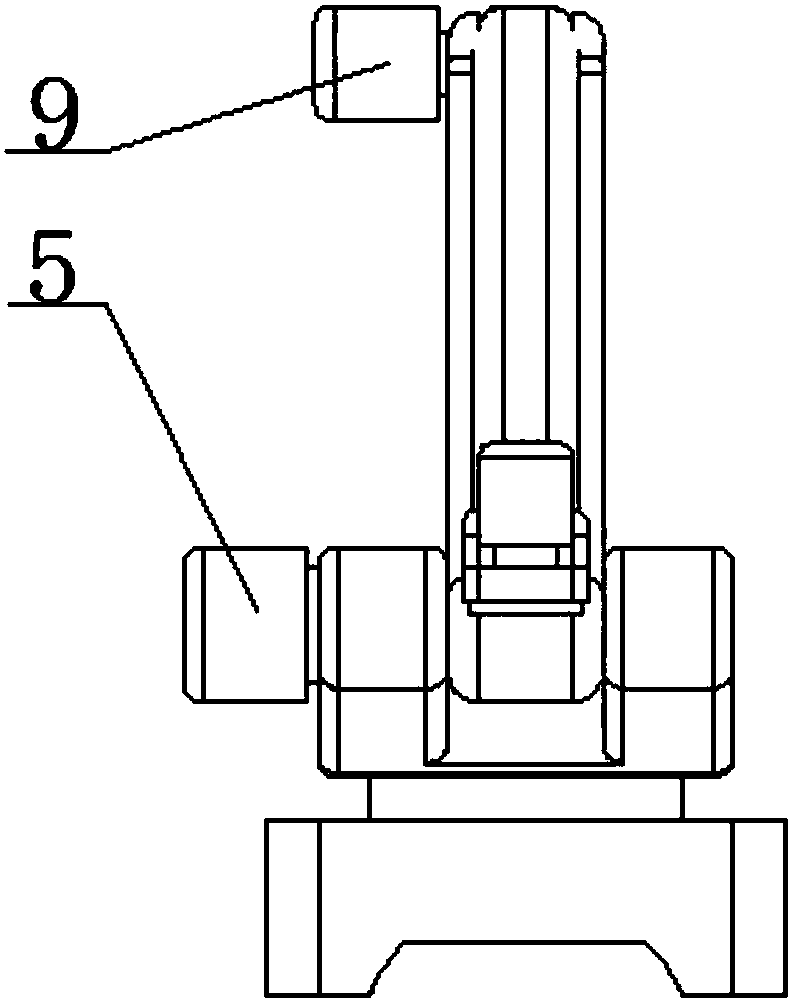

Mechanical hand system

InactiveCN106514613ALow costReduce computationProgramme-controlled manipulatorEngineeringManipulator system

The invention relates to a mechanical hand system comprising a base and a rotation base installed on the upper end face of the base through a first rotating shaft. The rotation base is connected with a first arm through a second rotating shaft. The first arm is connected with a second arm through a third rotating shaft. The second arm is connected with a connection device through a fourth rotating shaft. A first stepping motor for driving the first rotating shaft to rotate is arranged on the rotation base. A second stepping motor for driving the first arm to move is installed at one end of the second rotating shaft. A third stepping motor for driving the second arm to move is installed at one end of the third rotating shaft. A fourth stepping motor for driving the connection device to move is arranged on the upper end face of the connection device. The first arm and the second arm are arc-shaped bent arms with radian correspondingly. The mechanical hand system does not rely on a servo-driven control module, the control module executes a command mentioned above, the computation of a program is omitted, and the program control cost is saved; and meanwhile, the bent arm design is adopted for the mechanical arms, the rotation radius is large, the volume of the mechanical hand system is effectively reduced, and the mechanical hand system can be more convenient and reasonable during use.

Owner:XIAN YUEJIE ENVIRONMENTAL PROTECTION TECH CO LTD

Method for read-out of information in magnetic recording element and method for read-out of information in magnetic random access memory

ActiveUS20100271728A1Low powerIncrease the radius of rotationRecord information storageRecording/reproducing/erasing methodsMagnetic vortexRandom access memory

Provided are a method for read-out of information in a magnetic recording element and a method for read-out of information in a magnetic random access memory. In the method, a magnetic recording element including a magnetic free layer where a magnetic vortex is formed is prepared, and “0” or “1” is assigned according to a core orientation of a magnetic vortex formed in the magnetic free layer. The magnetic vortex core formed in the magnetic free layer rotates on the magnetic free layer by applying a current or magnetic field, of which a direction varies with time, to the magnetic free layer with the magnetic vortex formed. “0” or “1” assigned according to the core orientation of the magnetic vortex formed in the magnetic free layer is read out by measuring a characteristic caused by a difference in a rotation radius of the magnetic vortex core. Herein, the rotation radius of the magnetic vortex core, which is formed in the magnetic free layer and rotates by the applied current or magnetic field, varies with the core orientation of the magnetic vortex formed in the magnetic free layer.

Owner:SEOUL NAT UNIV R&DB FOUND

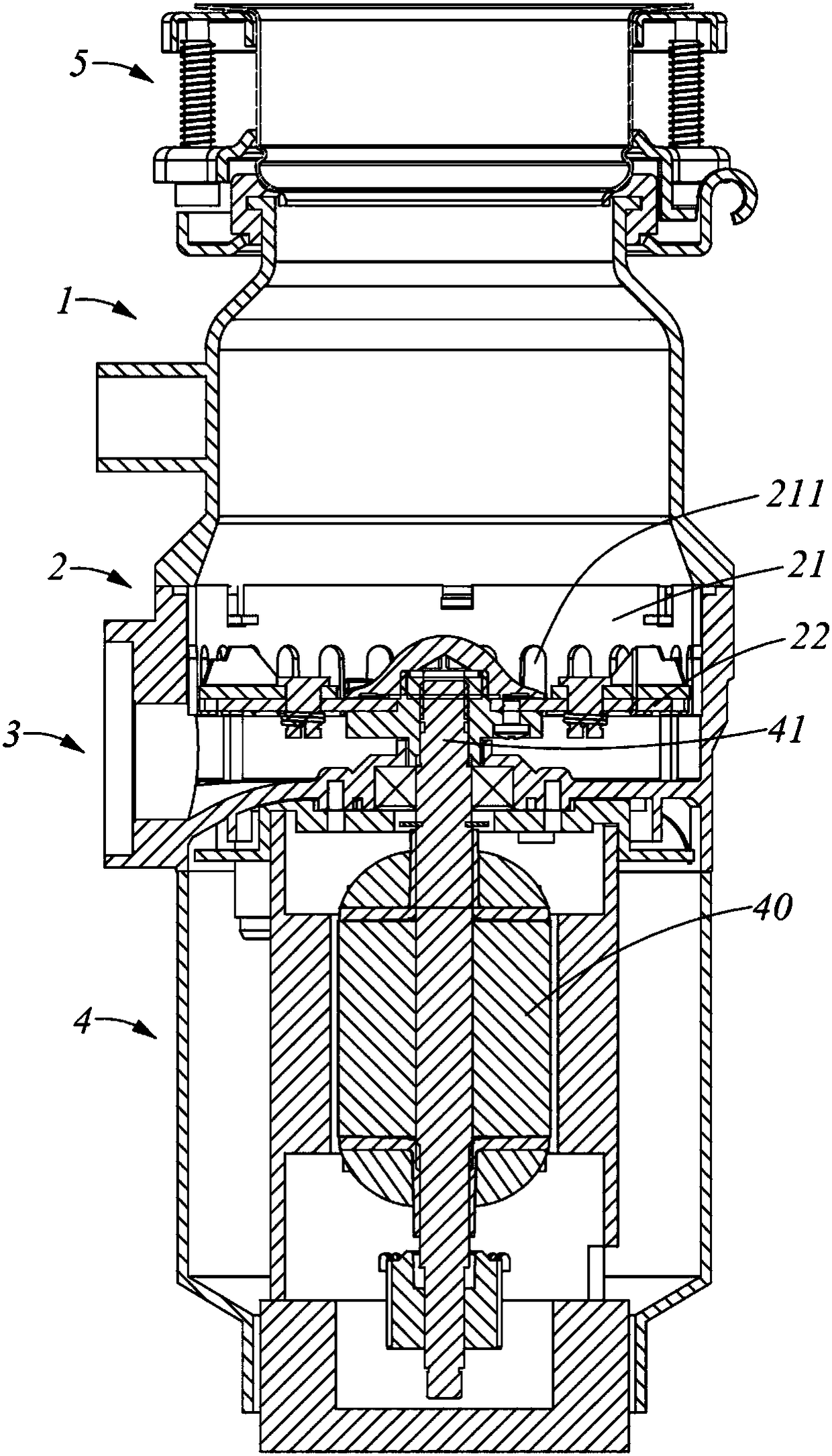

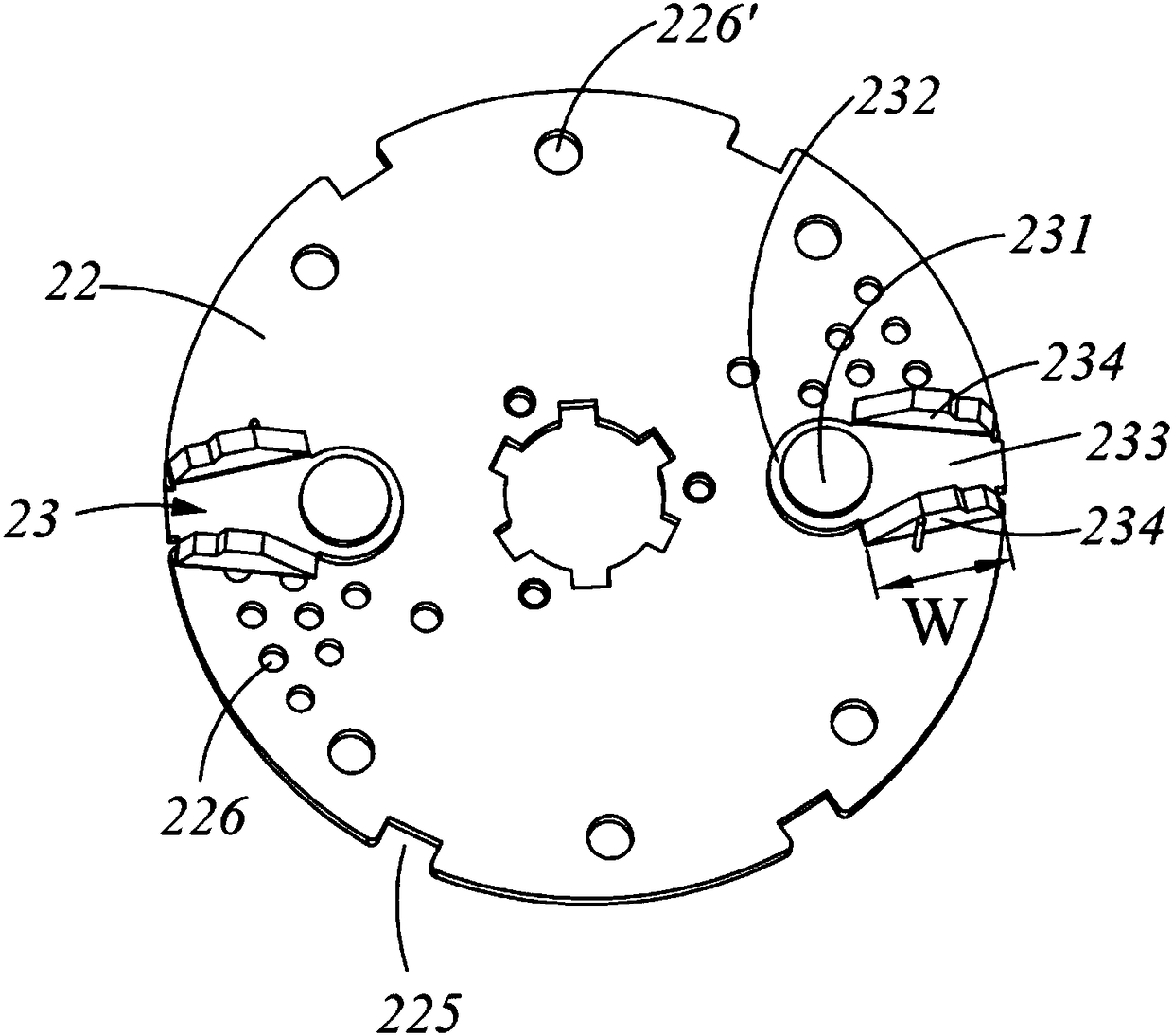

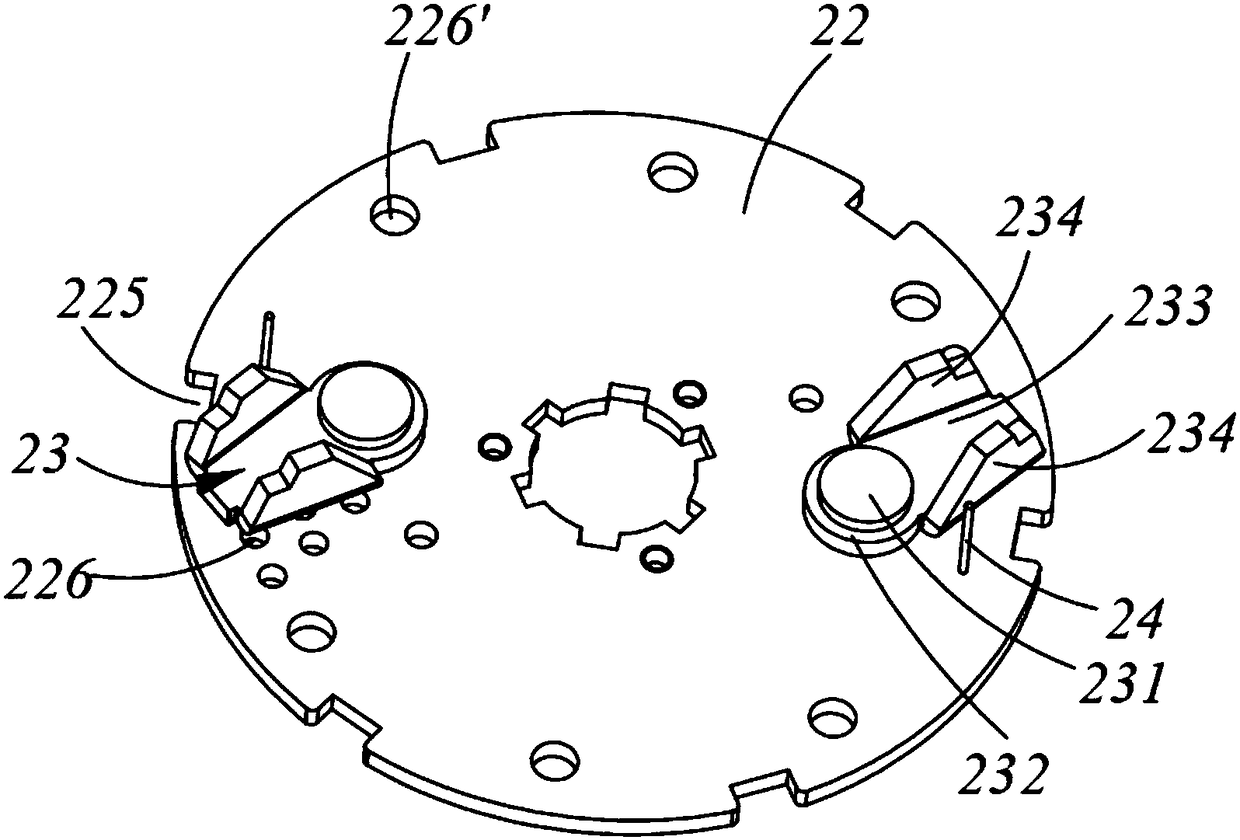

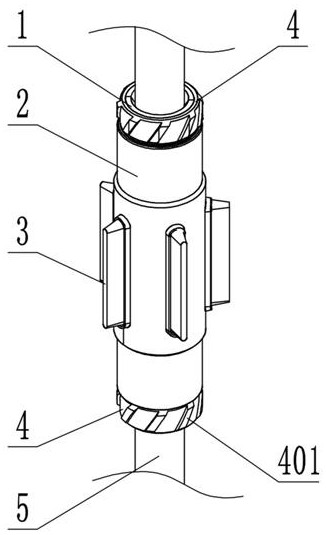

Food waste treating device

InactiveCN108187843AEasy to throw awayReduce frictionDomestic plumbingGrain treatmentsDrive shaftEngineering

The invention provides a food waste treating device. The device comprises a grinding crushing part and a motor part which are arranged from top to bottom, wherein the grinding crushing part comprisesa grinding crushing mechanism; the grinding crushing mechanism comprises a static grinding crushing ring and a rotary crushing assembly; the rotary crushing assembly comprises a grinding plate which is provided with one or a plurality of protruding blocks; a motor of the motor part is capable of driving the grinding plate to rotate through a driving shaft; a protruded part with a crest shaped section is arranged in the middle part of the grinding plate. According to the food waste treating device, the protruded part is arranged in the middle part of the grinding disc, and the section of the protruded part is of a crest structure, so that food wastes entering a grinding chamber are difficultly accumulated in the middle of the grinding plate, and moreover, the frictional force relative to the grinding plate can be reduced, the rotating radius can be increased, the centrifugal force can be improved, and as a result, foods are more easily thrown to the surrounding to be cut and ground, andthe working efficiency is improved.

Owner:SKYBEST ELECTRIC APPLIANCE SUZHOU CO LTD

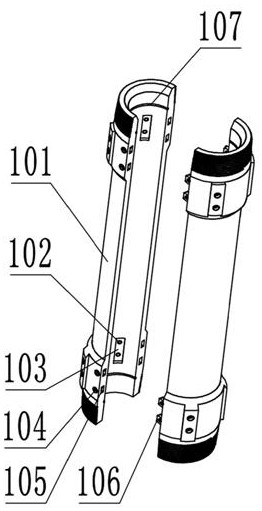

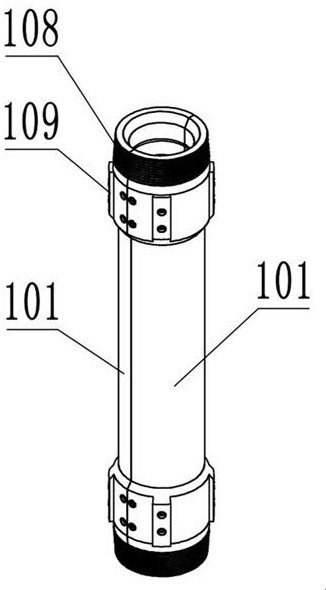

Annular speed-increasing cyclone for vertical well

The invention discloses an annular speed-increasing cyclone for a vertical well. The annular speed-increasing cyclone comprises an inner barrel, a rubber impeller and an outer barrel, wherein the inner barrel is formed by splicing two half barrels which are detachably connected; a rubber barrel groove is formed in the middle of the inner barrel; external thread parts are arranged at the upper end and the lower end of the inner barrel; the external thread parts at the two ends are in threaded connection with locking nuts; a group of tong tooth grooves are formed in the inner wall of the inner barrel; matched tong teeth are placed in the tong tooth grooves; the rubber impeller comprises a rubber barrel and a group of blades which are radially connected to the periphery of the rubber barrel; the rubber barrel is sleeved in the rubber barrel groove; the outer barrel is sleeved on the outer side of the inner barrel; the outer barrel and the inner barrel are fixed through the locking nuts; the outer barrel is provided with a group of blade grooves for the blades to extend out; and movable gaps are reserved between the blade grooves and the blades. According to the annular speed-increasing cyclone, transverse shear stress is applied to drilling fluid at an underground annular position by utilizing the rotation of the rubber impeller, and the flow velocity of the drilling fluid is increased, so that an effect of clearing rock debris falling blocks accumulated and retained in a borehole is achieved.

Owner:王树永

Back action mechanism of belt type stepless gear

The invention relates to a kind of back action mechanism of draper-type non segment speed changer. The invention is used to transfer dynamic force of positive-reverse direction, reach the different speed reducing ratio, and suit automotive vehicle drive components of different power equipment. It includes front draper wheel, source of power, back draper wheel, and twisting force cam set fitted over the front draper wheel and after draper wheel with ring. The front draper wheel and the source of the power is set on the front rotating shaft; the front draper wheel is made up of front active semi-wheel set on the front rotating shaft by slip cap and front fixed semi-wheel fixedly set on the front rotating shaft; the after draper wheel is made up of the back fixed semi-wheel and back active semi-wheel which are fitted over the back-shaft.; the twisting force cam set includes cam guide slot set on the active semi-wheel and corresponding cam pin in the cam guide slot; the clockwise rotation cam guide rail and the anticlockwise rotation cam guide rail are set on the inner wall of the cam guide slot; one end of the cam pin is set in the fixed semi-wheel, the other end is set in the cam guide slot and contacted to the opposite rotation cam guide rail and the reverse rotation cam guide rail.

Owner:IND TECH RES INST

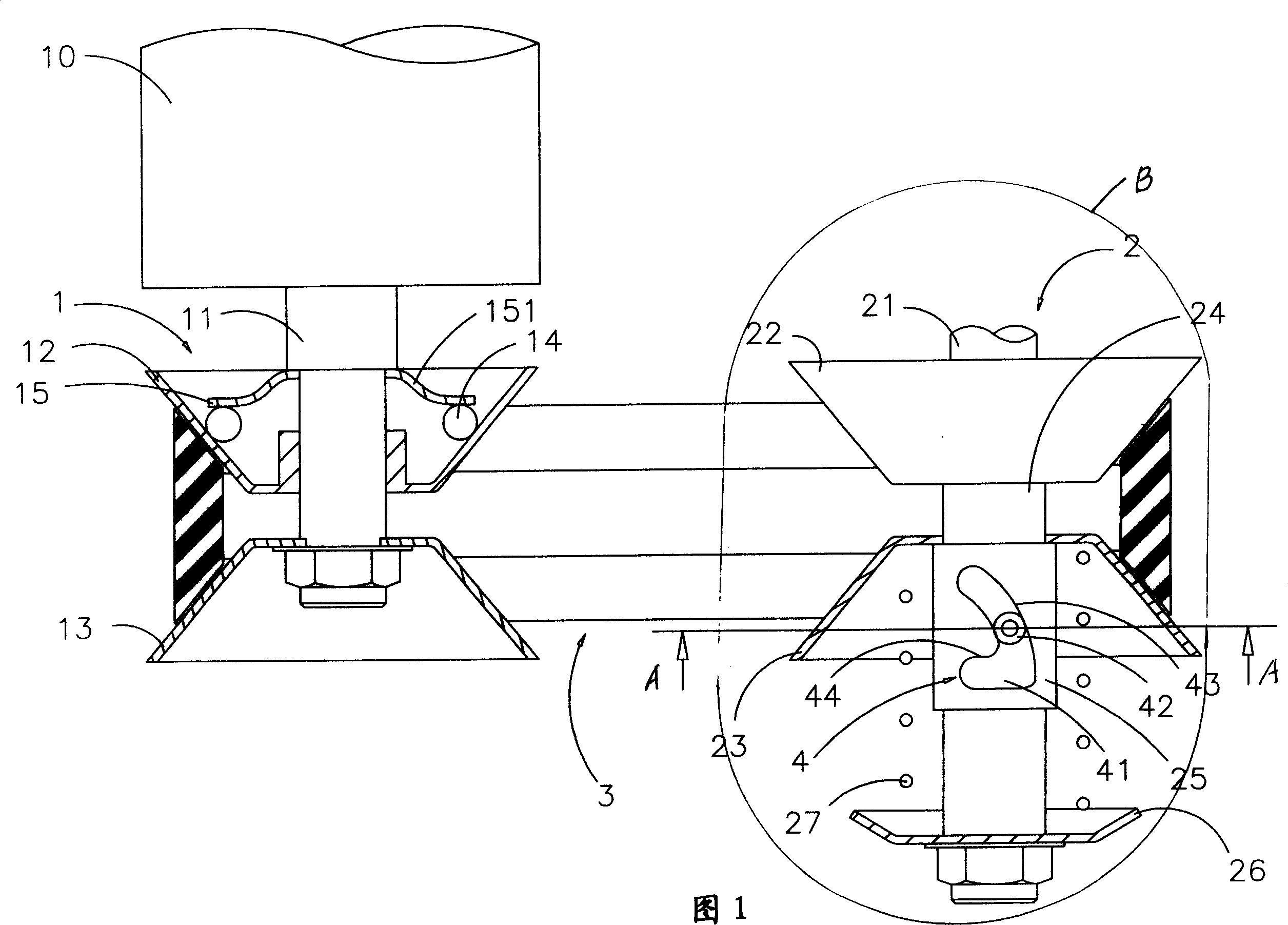

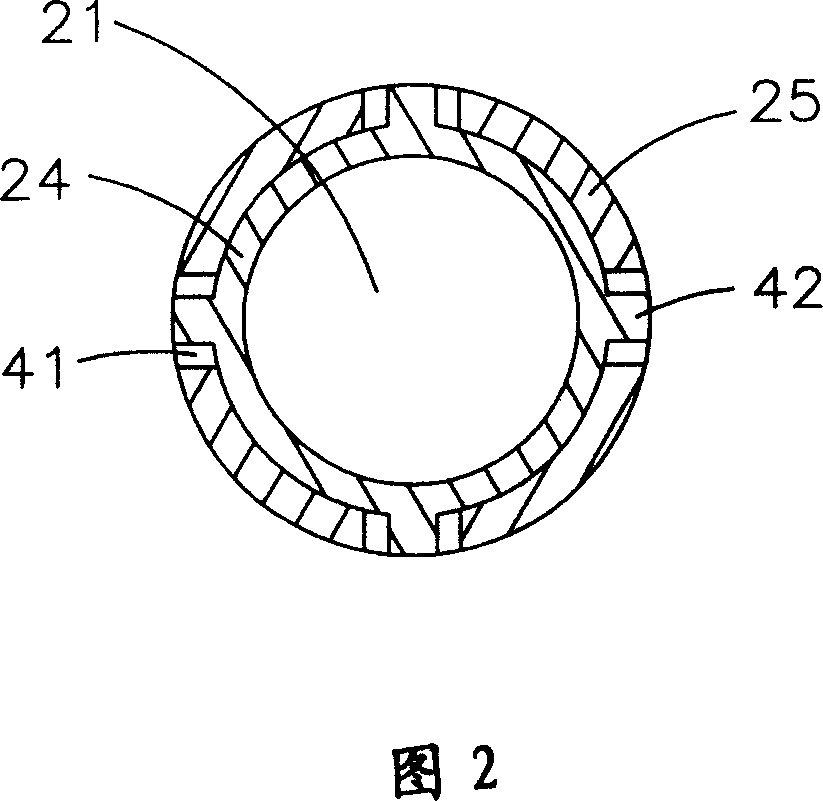

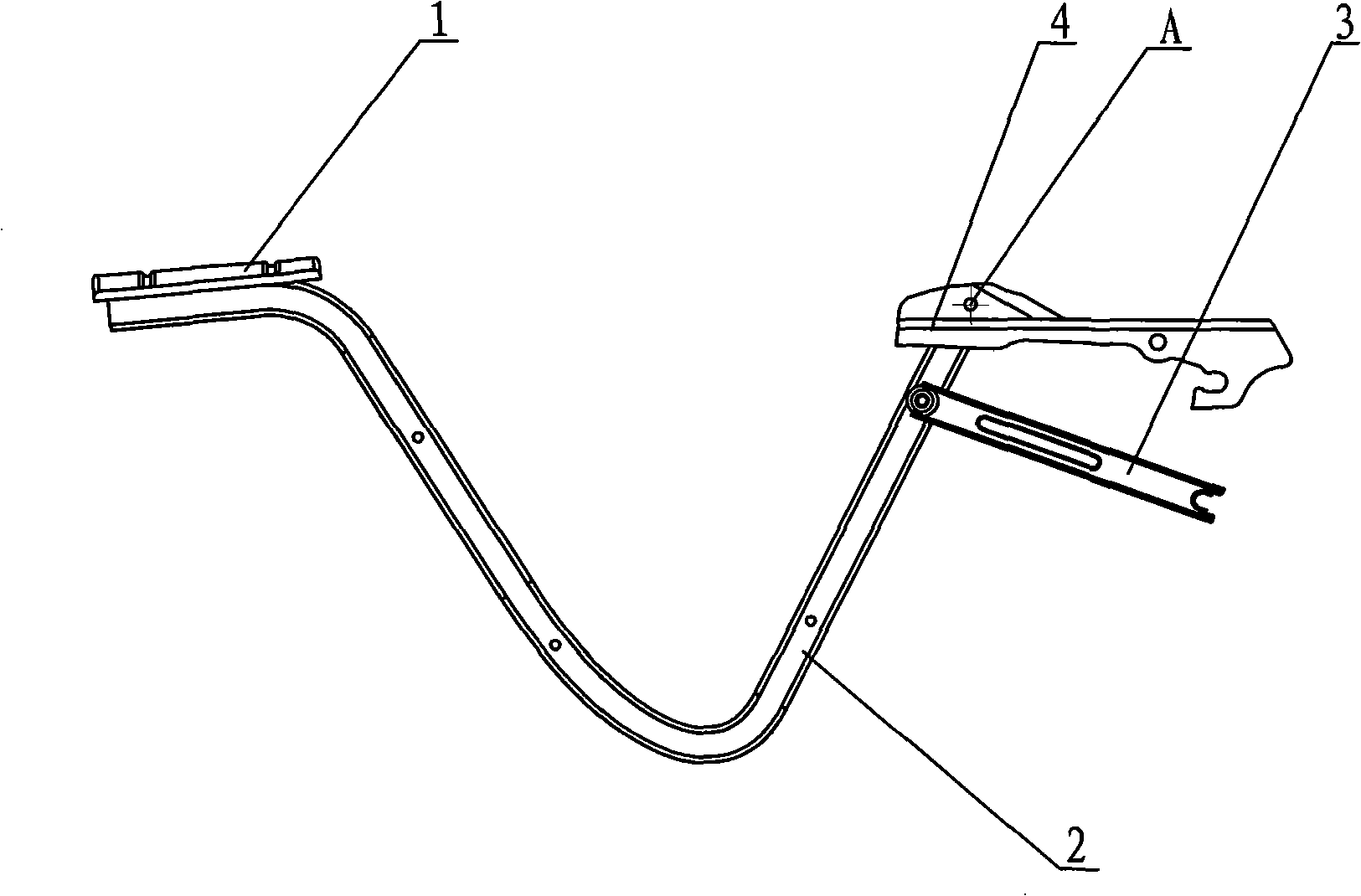

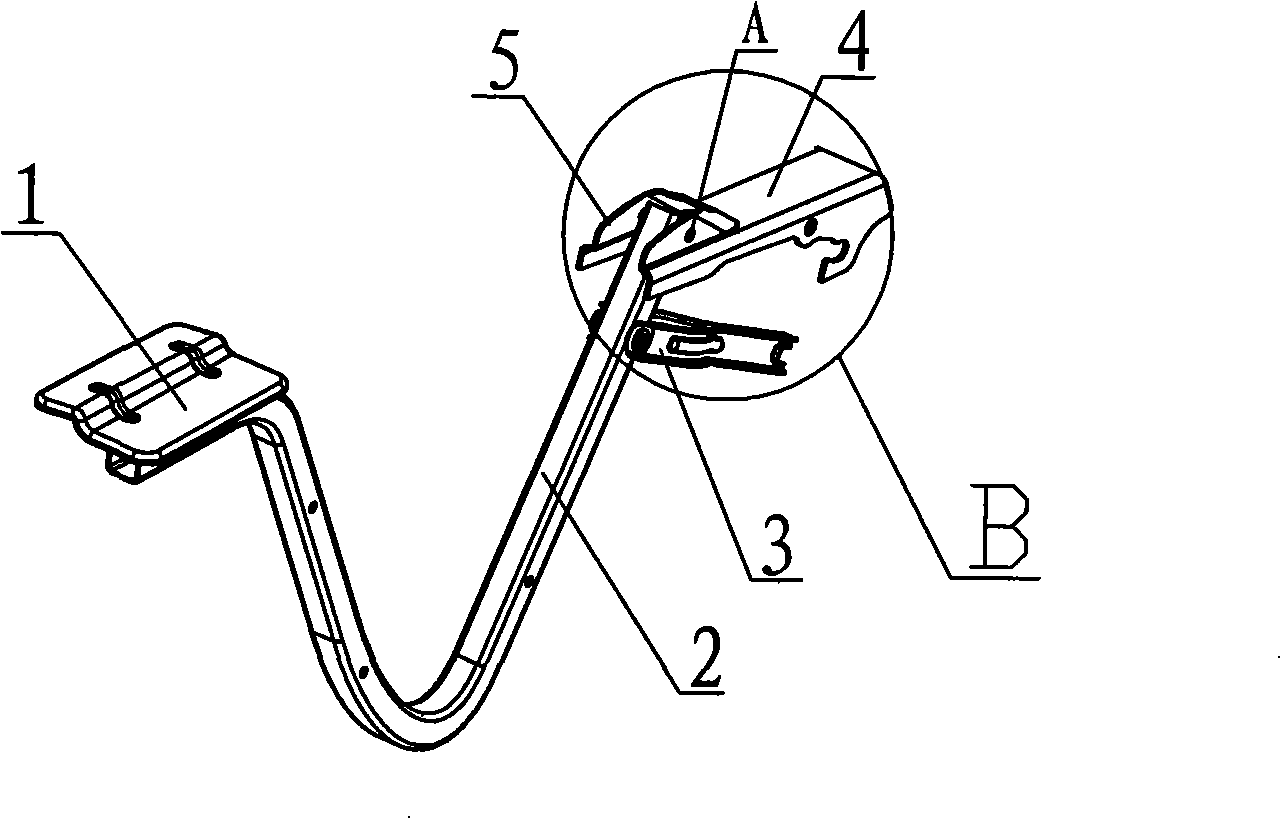

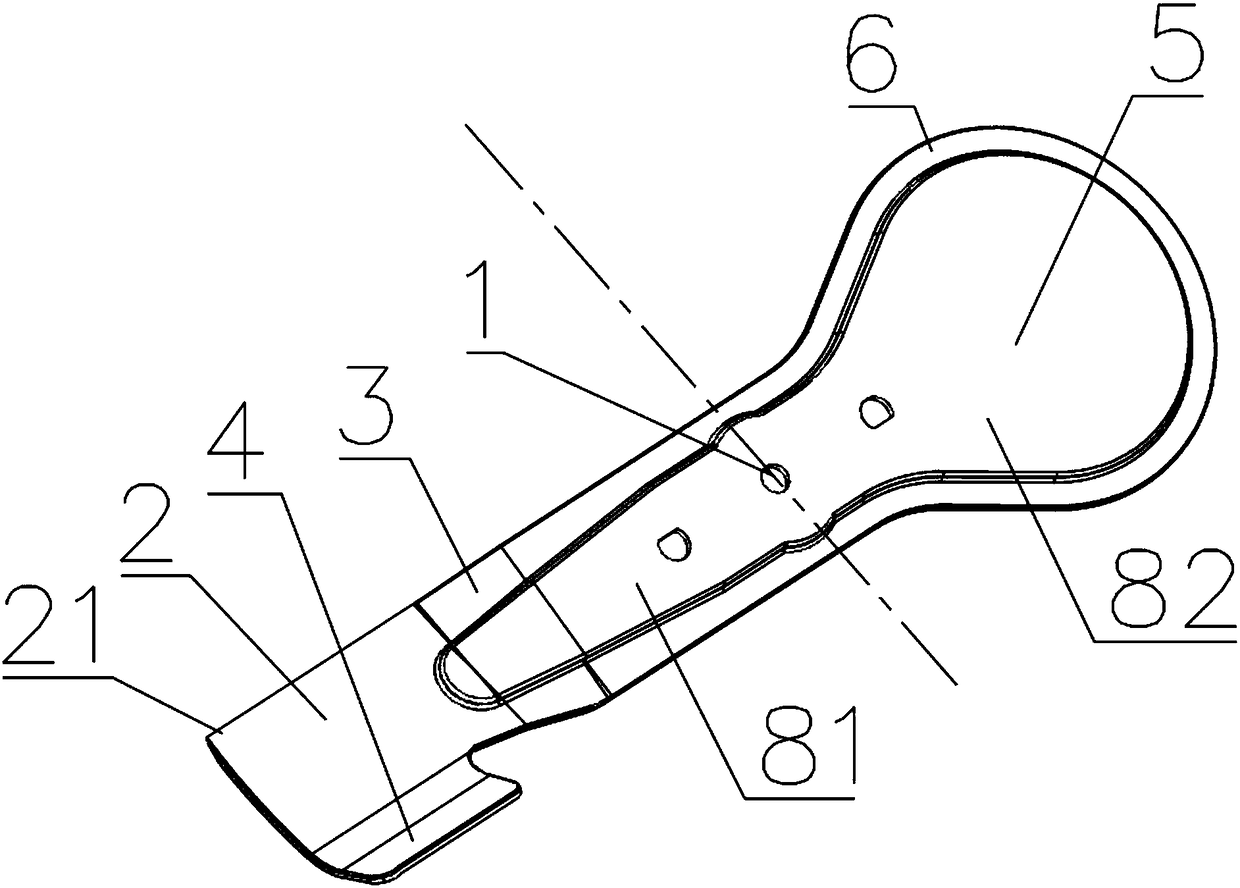

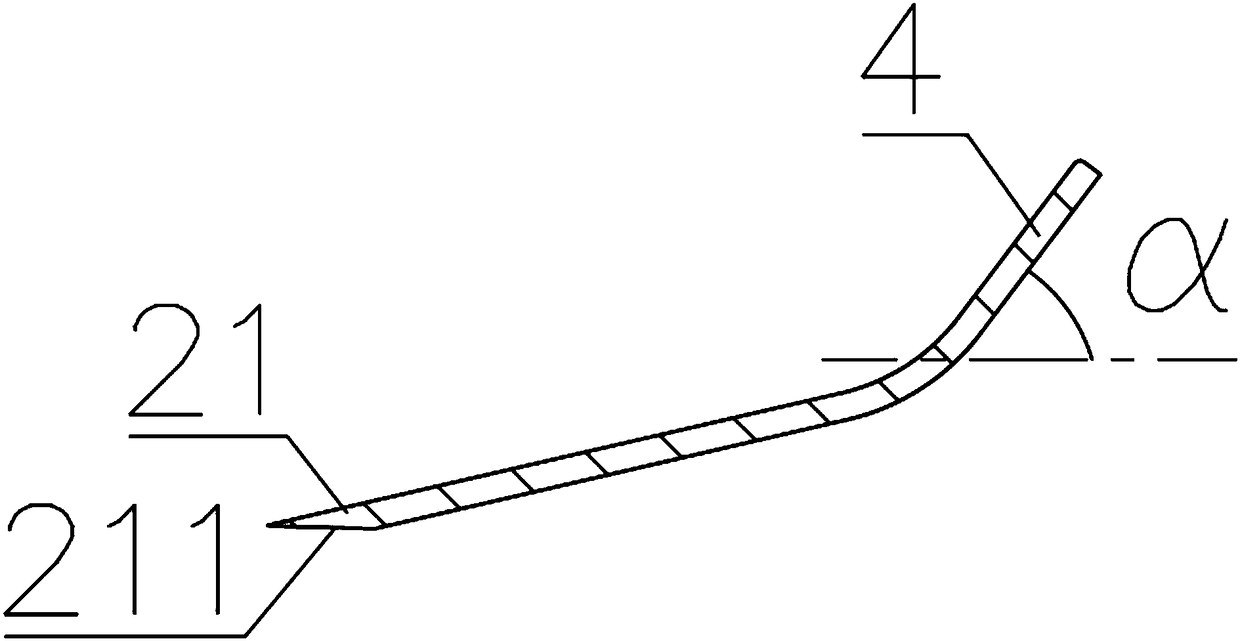

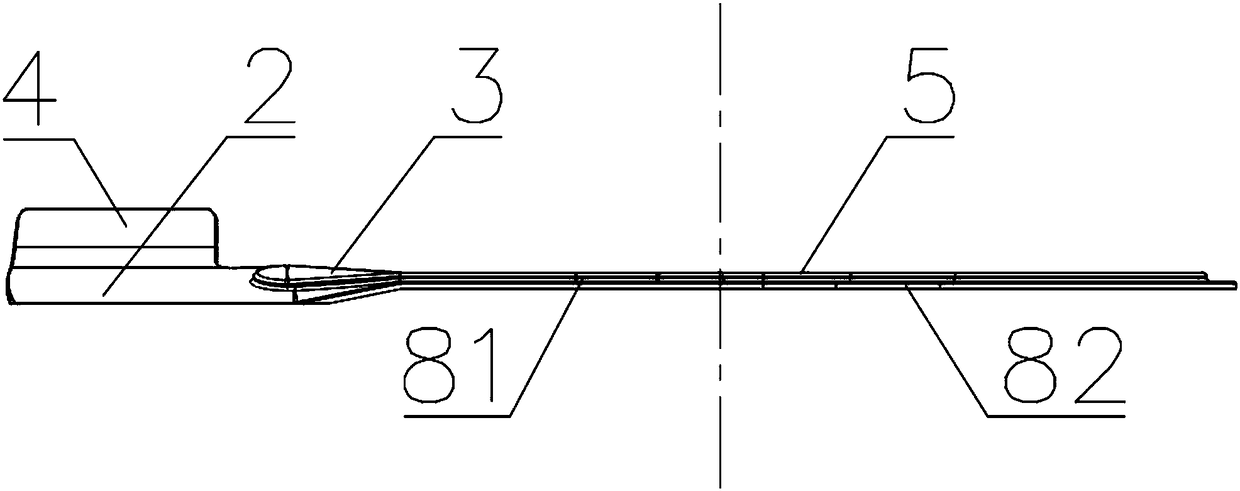

Automobile luggage case link connection mechanism

InactiveCN101314366AIncrease the radius of rotationLarge space arrangementSuperstructure subunitsPinless hingesPipe supportHinge joint

The invention discloses a vehicle boot hinge joint structure, which comprises a boot inner plate support (1), a bend pipe (2), a bend pipe connecting rod (3) and a bend pipe support (4), wherein one end of the bend pipe (2) extends along the horizontal direction, and the boot inner plate support (1) is connected above the bent pipe (2); the other end of the bend pipe (2) is articulated with the end head of the bend pipe support (4), and the bend pipe connecting rod (3) is articulated under the bent pipe (2); the bend pipe (2) is V-shaped, and the distance between the middle point of the section of the bend pipe extending along horizontal direction and a hinge point (A) of the bend pipe (2) and the bend pipe support (4) is between 711 and 869mm; the maximum angle at which the bend pipe (2) rotates around the hinge point is between 58 and 65.5 degrees; the joint of the bend pipe support (4) and the end head of the bend pipe (2) is provided with a U-shaped gap (5); and the end head of the bend pipe (2) is clamped inside the gap. The vehicle boot hinge joint structure has more reasonable design and effectively enlarges the use space of a boot, thereby increasing use value; moreover, the structure is more suitable for a large-boot car model.

Owner:力帆科技(集团)股份有限公司

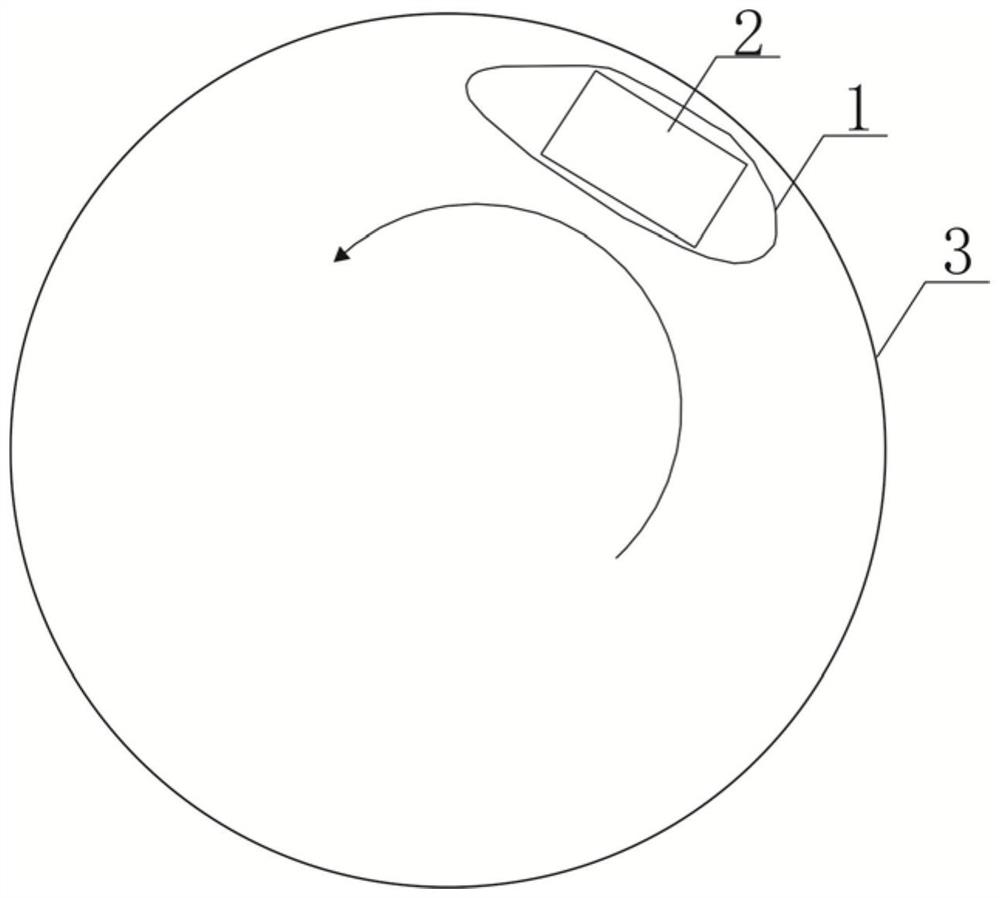

Ring type eccentric dish washing machine

InactiveCN110881928AIncrease the radius of rotationExpand the spraying rangeTableware washing/rinsing machine detailsAutomatic washing/rinsing machine detectionClean waterPhysics

The invention relates to a nozzle assembly of a dish-washing machine, in particular to the nozzle assembly capable of spraying cleaning water and a dish-washing machine with the nozzle assembly. The dish washing machine comprises a machine shell, dish collecting baskets, a heater, a water collecting pool, a water supply pipe, a self-rotating device and a spraying device. One end of the self-rotating device is connected with the water supply pipe, and the self-rotating device comprises a connecting piece, a connecting sleeve, a rotating shaft, a connecting shaft and a sliding block, wherein theconnecting piece is a circular flange piece; the connecting sleeve is in a thick-skin cylinder shape. One end is coaxially connected with the connecting sheet; an annular through hole penetrating through the inner wall of the connecting sleeve is formed in the inner wall, connected with the connecting sheet, of the upper end of the connecting sleeve; the rotating shaft is arranged at the eccentric position in the connecting sleeve, the connecting shaft is transversely arranged in the connecting sleeve and perpendicularly connected with one end of the rotating shaft, the sliding blocks are arranged in the annular through hole in a spherical mode, the two sliding blocks are arranged at the two ends of the connecting shaft, and the spraying range of clean water is enlarged by increasing therotating radius of the rotating arm through the self-rotating device.

Owner:安徽冠东科技有限公司

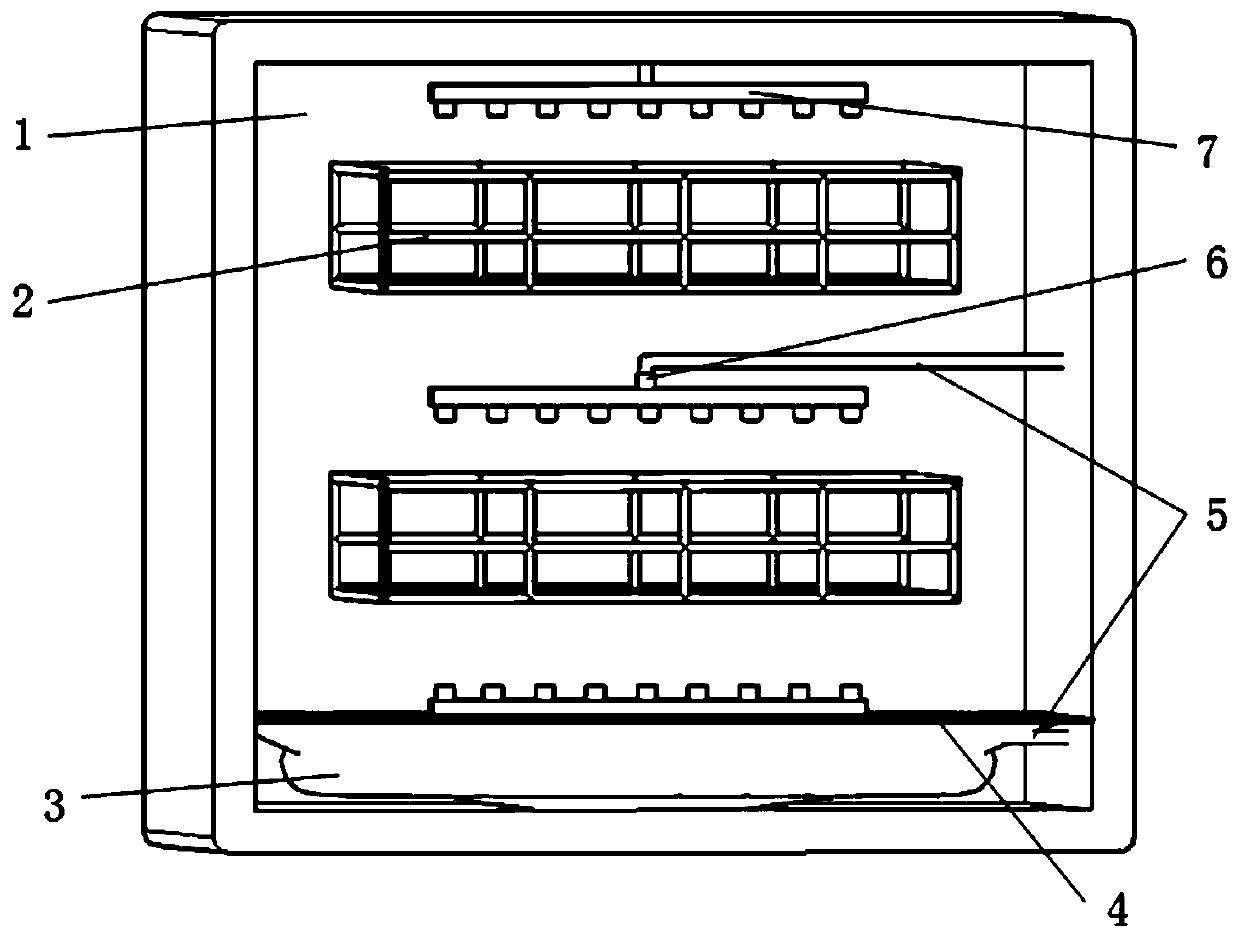

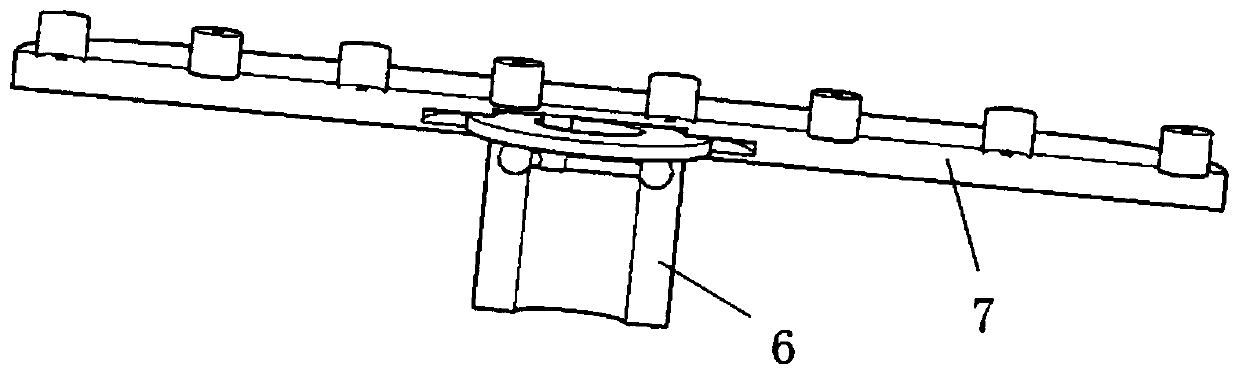

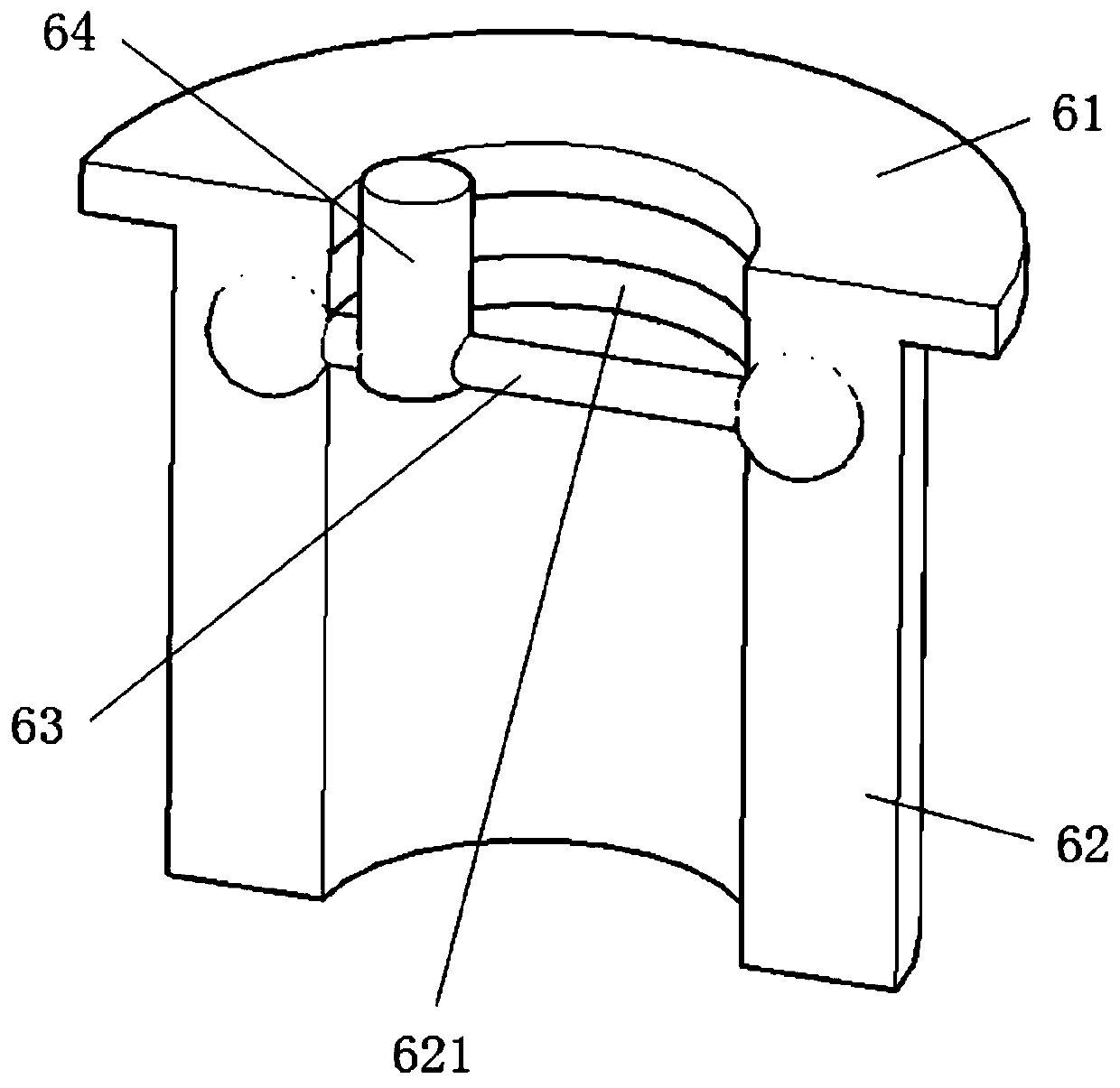

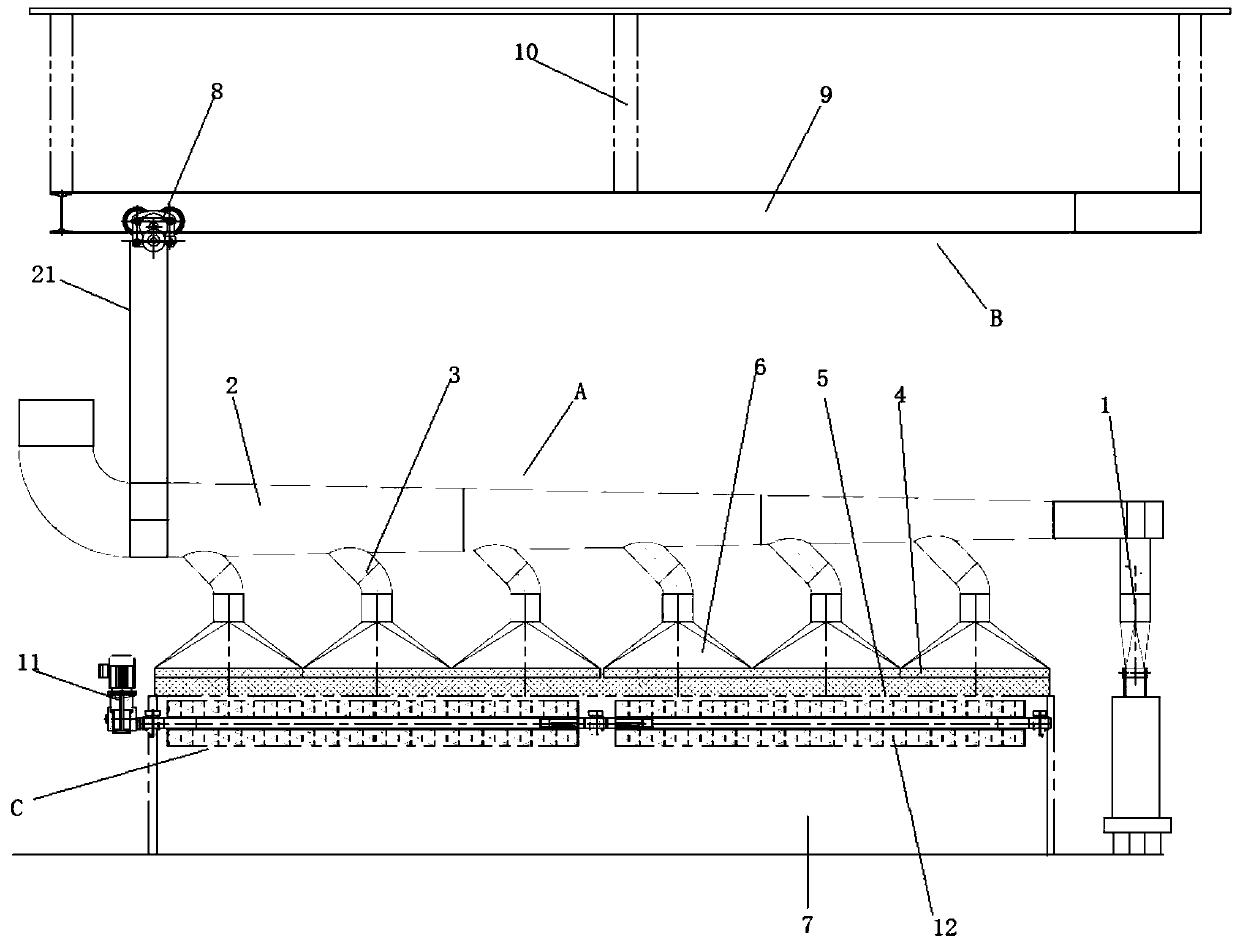

Convenient-to-move diameter-variable flat-mouth suction pipe cover equipment for efficient dust collection

PendingCN110560444AIncrease the radius of rotationDoes not affect production runsDirt cleaningCleaning using toolsDrinking strawKiln

The invention belongs to the technical field of dust collection and dust removal in industrial production and discloses convenient-to-move diameter-variable flat-mouth suction pipe cover equipment forefficient dust collection. The equipment comprises a diameter-variable flat-mouth suction pipe cover, a suction cover hanging walking rail, an electric rolling brush and a kiln car, wherein the diameter-variable flat-mouth suction pipe cover comprises a movable rotary seat, a diameter-variable suction opening pipe, suction cover bent pipes, a suction cover flat suction mouth and suction covers; the right end of the diameter-variable suction opening pipe is rotatably mounted on the movable rotary seat; a rotary movable rail is arranged just above the diameter-variable flat-mouth suction pipe cover through a rail fixed bracket in a hoisting manner; the diameter-variable flat-mouth suction pipe cover covers the kiln car; and the electric rolling bush is mounted on the kiln car. By mounting and using the convenient-to-move diameter-variable flat-mouth suction pipe cover equipment for efficient dust collection, the production work is facilitated and the operation of production operation planes of enterprises is not influenced; the diameter-variable flat-mouth suction pipe cover can move at any time by means of the movable rotary seat and the suction cover hanging walking rail; the movable rotary seat and other parts of the suction covers are protected from damages; the labor cost and the potential safety hazards are reduced; and the dust collection area of the suction cover is enlarged and the operation service life of a long-distance suction pipe is prolonged.

Owner:溧阳中民环保设备有限公司

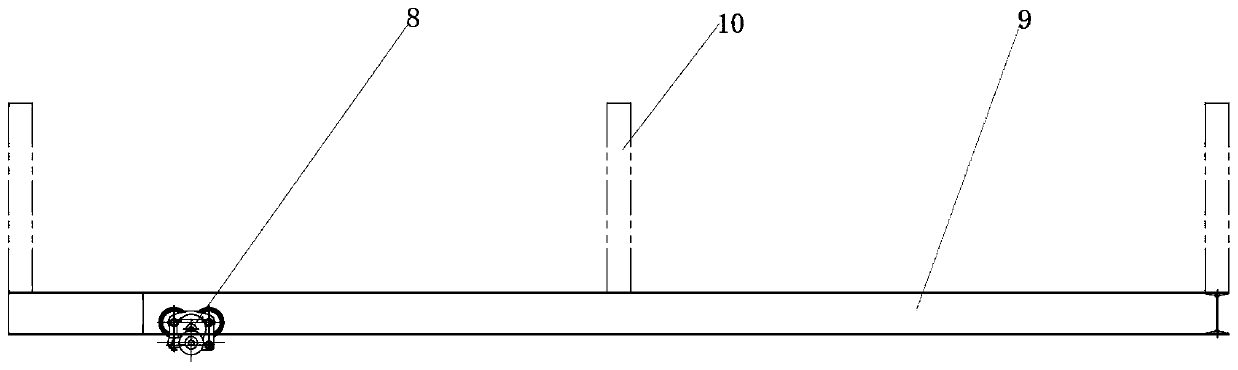

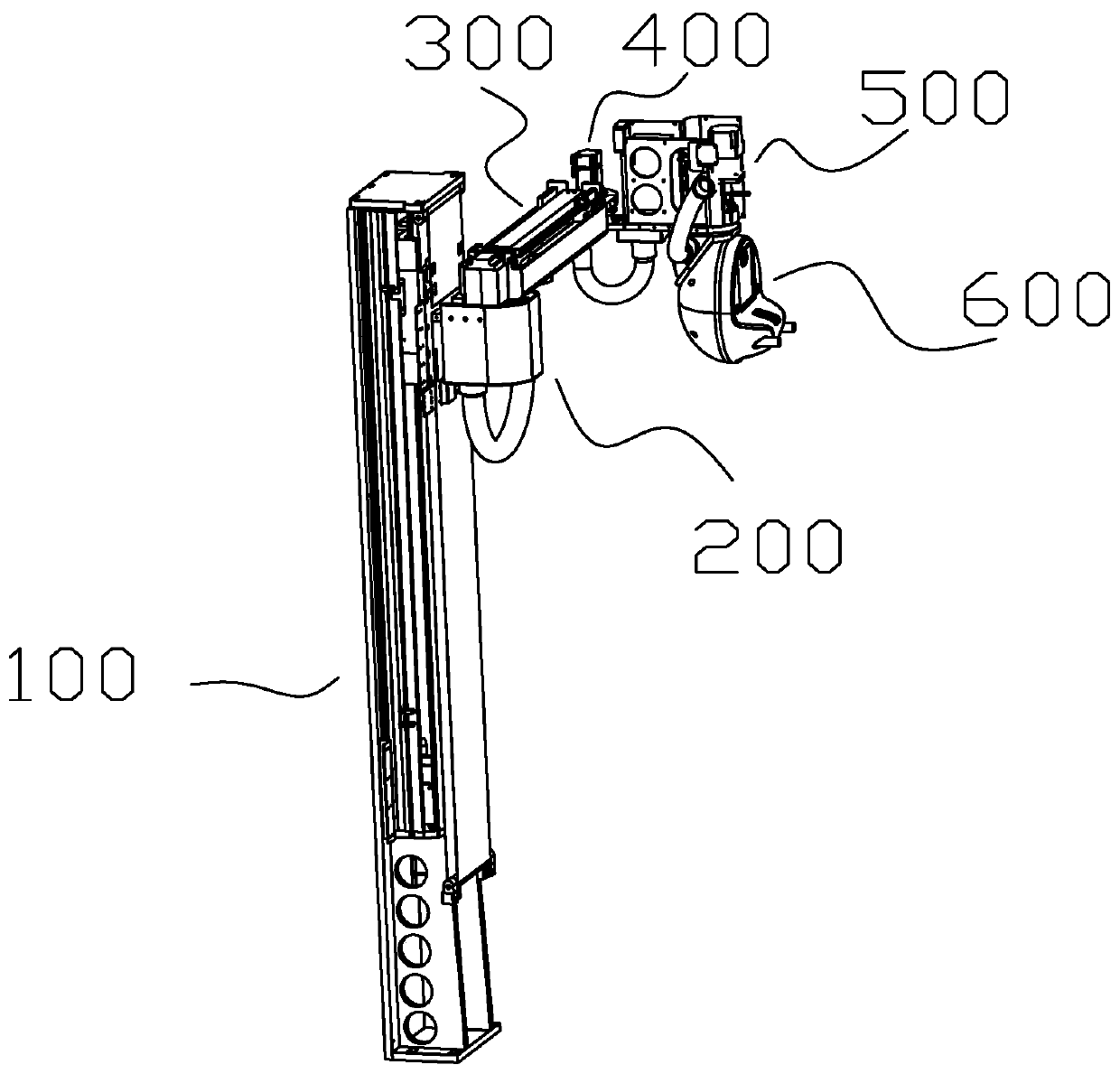

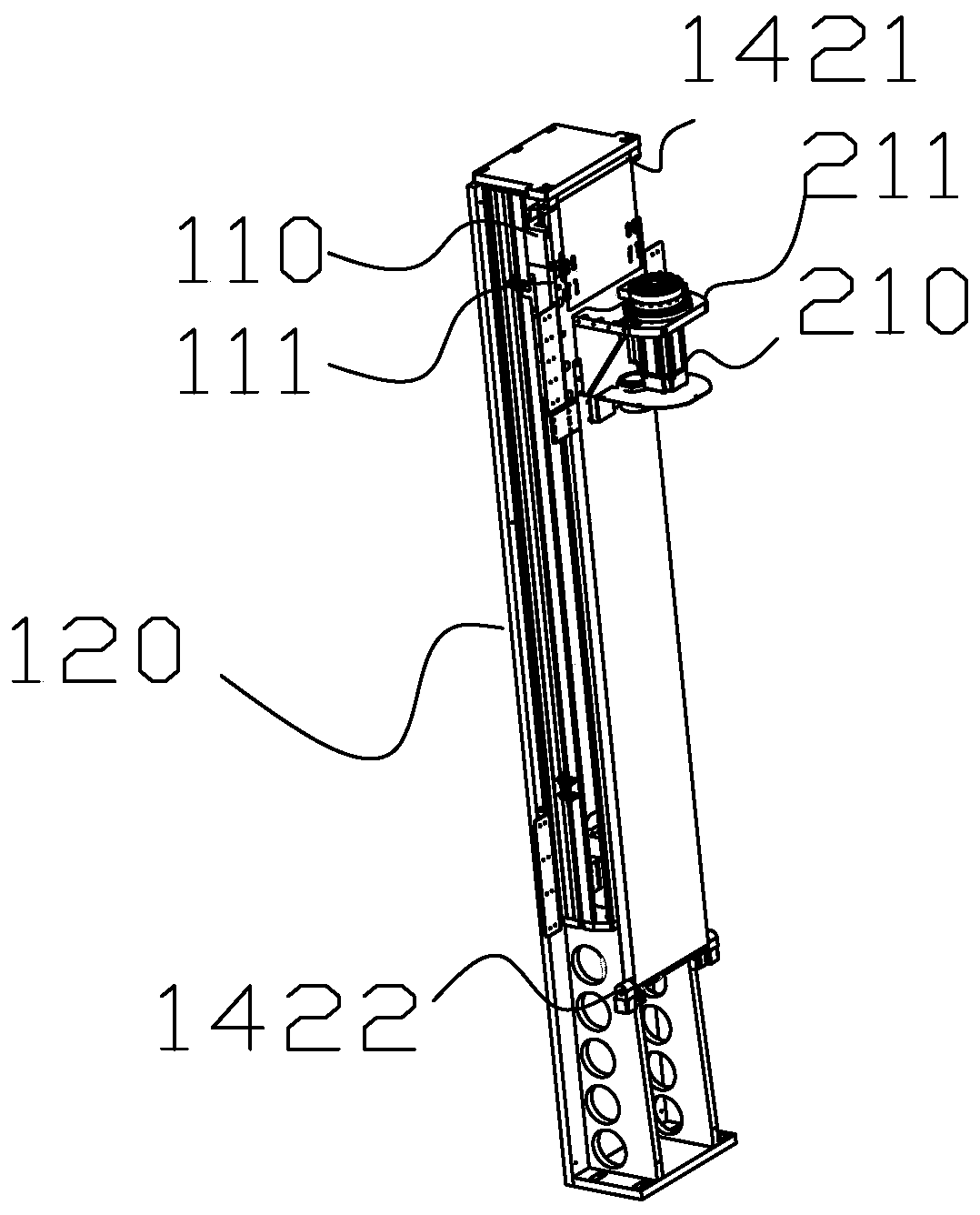

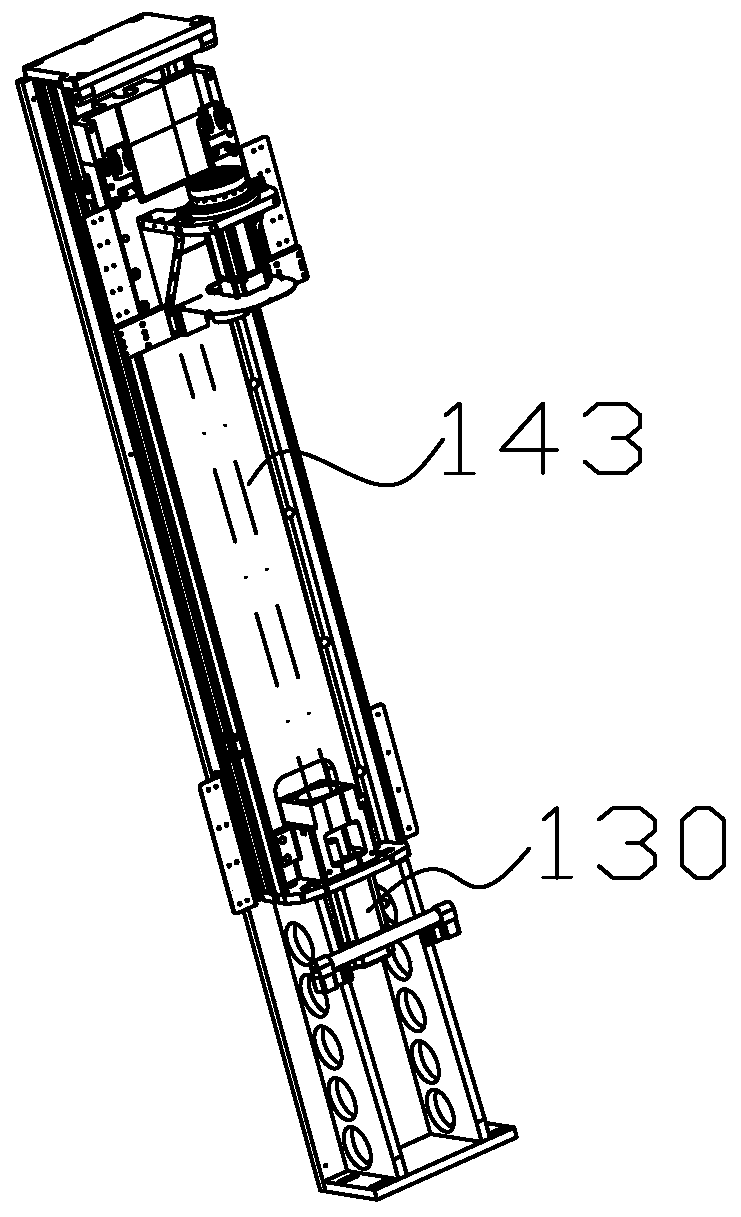

Five-axis mechanical arm used for passage verification

PendingCN111531554AIncrease the radius of rotationIncrease verification timeProgramme-controlled manipulatorCharacter and pattern recognitionEngineeringPower apparatus

The invention discloses a five-axis mechanical arm used for passage verification. The five-axis mechanical arm used for passage verification comprises a first moving shaft which can move up and down,a second moving shaft which is connected with the first moving shaft through a first connecting piece on the first moving shaft and can rotate freely, and a third moving shaft which can move horizontally through a second connecting piece on the second moving shaft; a third connecting piece is arranged at one end, far away from an output end of a second power device, of the third moving shaft; a power device of a fourth moving shaft is positioned on the third connecting piece; an output shaft of the fourth power device is connected with a fourth connecting piece; and one end, far away from theoutput end of the fourth power device, of the fourth connecting piece is connected with a fifth moving shaft. According to the five-axis mechanical arm used for passage verification, related technicalparameters of the mechanical arm can be determined, wherein the rotating arm spread is in the variable rotating radius of 600 to 900 mm, an up-down height stroke is the linear movement stroke of 800mm, and the fastest full stroke is 3 seconds; the rotating radius of the mechanical arm is increased by a telescopic arm; and the verification of tourist information can be performed within a relatively large range.

Owner:SHENZHEN HUAZHENGLIAN INDAL +1

Robot

The invention relates to a robot. The robot comprises a base and a rotating seat; the rotating seat is mounted on the upper end surface of the base by means of a first rotating shaft; the rotating seat is connected with a first arm by means of a second rotating shaft; the first arm is connected with a second arm by means of a third rotating shaft; the second arm is connected with a connecting device by means of a fourth rotating shaft; a first stepping motor used for driving the first rotating shaft to rotate is arranged on the rotating shaft; a second stepping motor used for driving the firstarm to move is mounted at one end of the second rotating shaft; a third stepping motor used for driving the second arm to rotate is mounted at one end of the third rotating shaft; a fourth stepping motor used for driving the connecting device to move is arranged on the upper end surface of the connecting device; and the first arm and the second arm are corresponding arc-shaped bent arms with radians. The robot does not dependent on a servo-driven control module, the control module executes commands, the computation amount of a program is omitted, the cost of the control program is reduced, meanwhile, a mechanical arm adopts bent arm design, the turning radius is larger, the size of the robot is effectively reduced, and the robot is more convenient and reasonable during use.

Owner:西安北辰星信息技术有限公司

Yarn Winder

InactiveCN100369797CUniform roll widthIncrease the radius of rotationFilament handlingFolding thin materialsYarnBobbin

Provide is a yarn winding device capable of providing a package with a uniform winding width even when a distance between a rotary vane and a point where the yarn contacts a contact roller, that is a free length, is different when the yarn is released from the rotary vane between adjoining vane traverse devices. This yarn winding device comprises the traverse devices for traversing the yarn along a guide rail by an upper and lower pair of the rotary vanes rotating in the opposite directions for at least two respective adjoining bobbins for winding the yarn and the contact roller arranged in upstream of the bobbins for a yarn traveling yarn guide and has different free length between the adjoining traverse devices. By making different rotational radii formed by tips of the rotary vanes between the traverse devices, the winding width of each package wound between the traverse devices is uniformized.

Owner:TSTM CO LTD

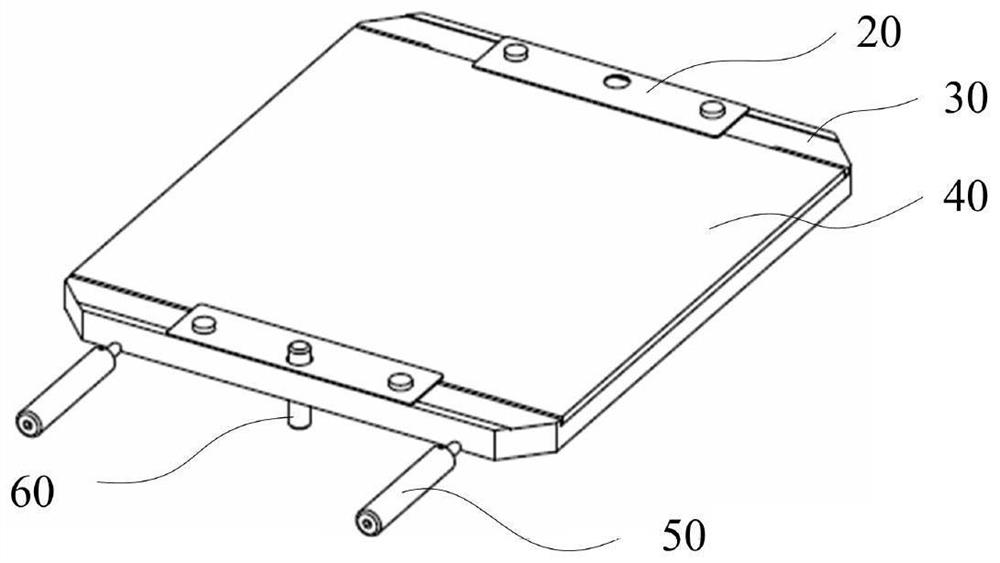

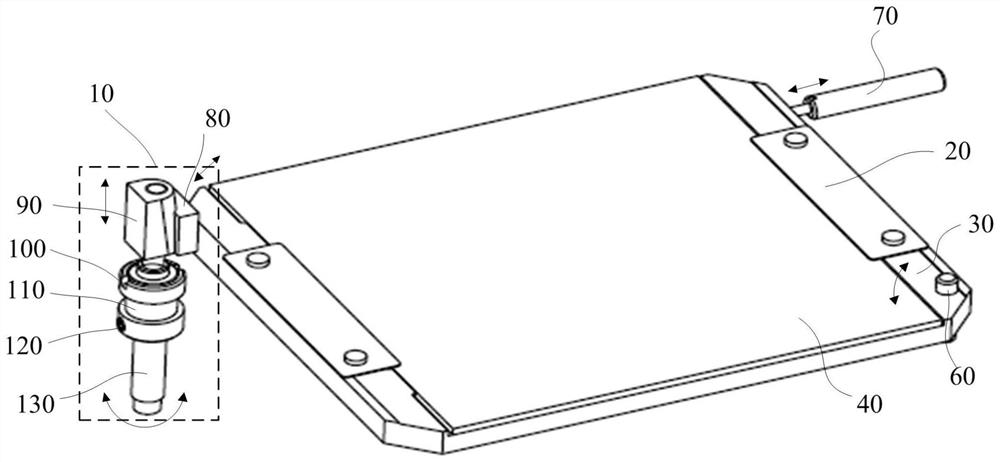

A polarizing device and an optical alignment device

ActiveCN109212648BIncrease the radius of rotationHigh-resolutionPolarising elementsNon-linear opticsRotational axisWire grid

The present invention provides a polarizing device and an optical alignment device, including a polarizing unit and a mounting frame, and the polarizing unit includes a polarizing wire grid, a wire grid frame plate, and a wire grid adjustment unit. The wire grid frame plate is used to support the polarized wire grid, and the wire grid frame plate is rotated and installed on the installation frame with the normal direction of the polarized wire grid as the rotation axis, and the wire grid adjustment unit is The rotation of the wire grid frame plate provides the driving force, the rotation axis of the wire grid frame plate and the driving force point of the wire grid adjustment unit are located on a pair of opposite corners of the wire grid plane of the polarizing wire grid, solving The problem that the adjustment resolution of the existing polarizing device cannot meet the needs of actual use is solved.

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

Cutting blade of spiral cutter type lawn mower and spiral cutter type lawn mower

The invention provides a cutting blade of a spiral cutter type lawn mower and the spiral cutter type lawn mower. The cutting blade is in a platy shape and rotates around the rotating center. The cutting blade comprises a first section and a second section. A cutting part is arranged on the cutting blade and is only arranged at one end of the first section. A balance weight part is further arrangedon the cutting blade. The cutting part comprises a cutting edge at the front end of the cutting part. The cutting edge comprises a cutting inclined face facing downwards. The cutting blade is low invibration noise, long in service life and good in mowing effect.

Owner:ZHEJIANG YAT ELECTRICAL APPLIANCE CO LTD

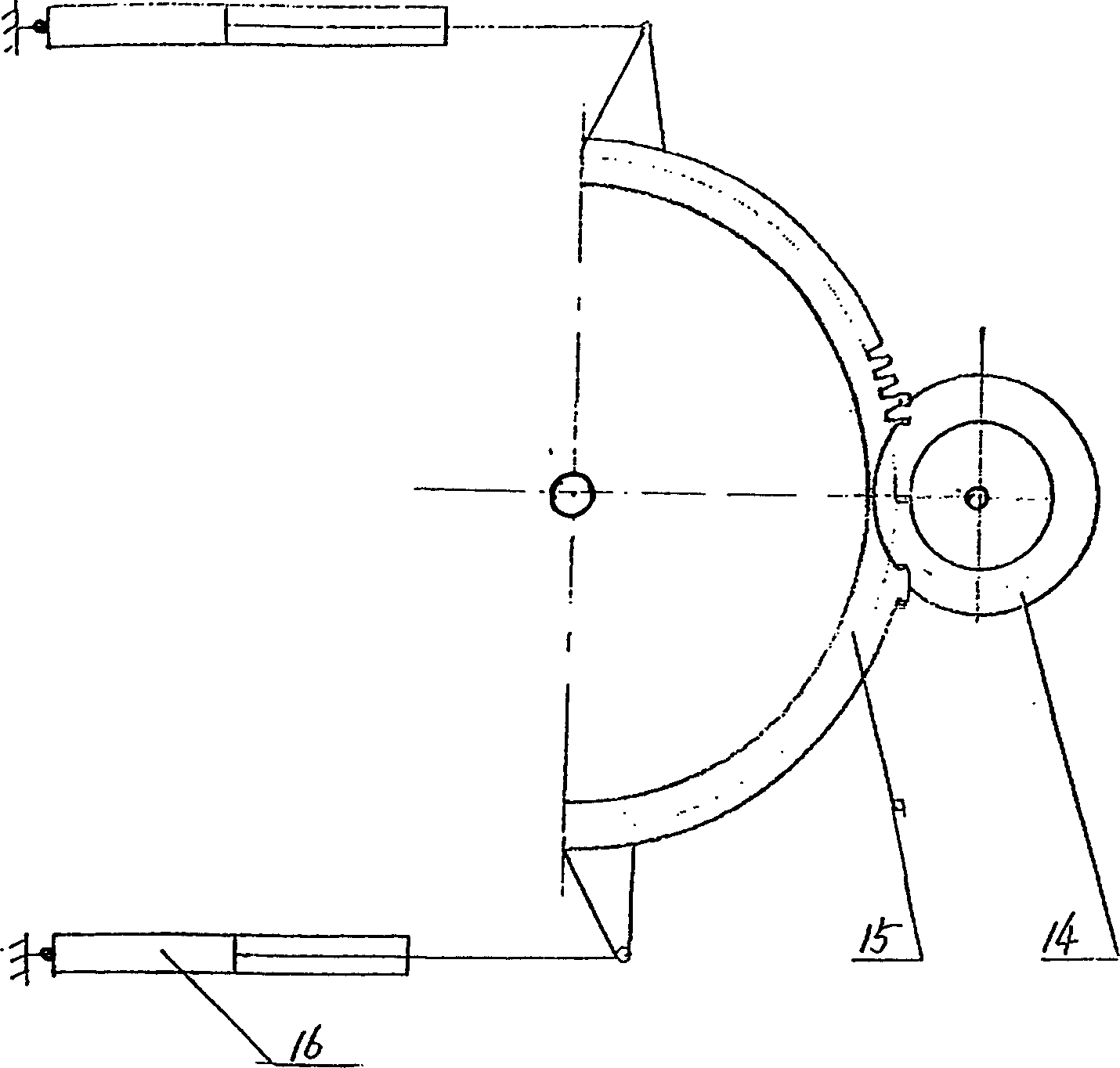

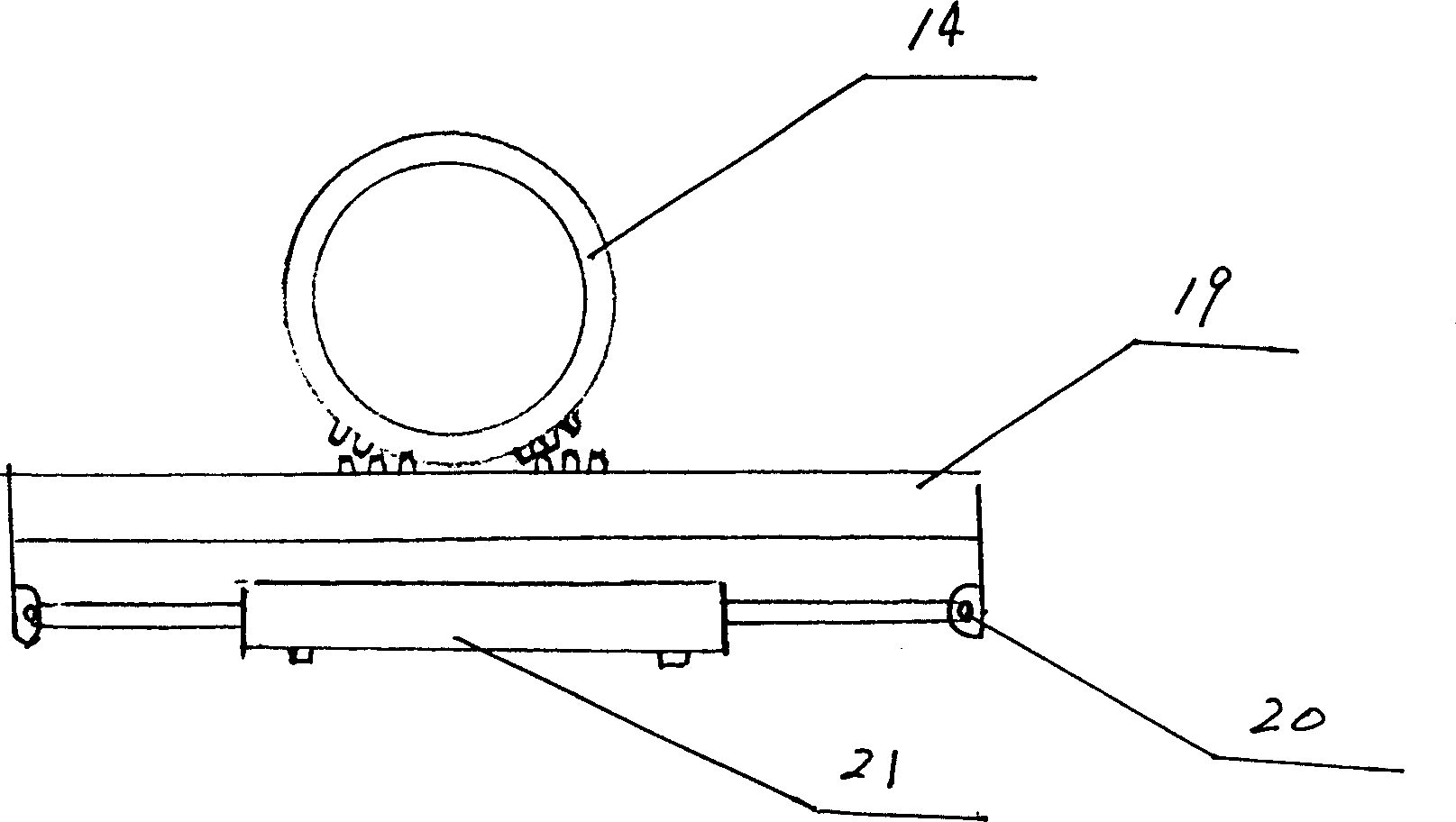

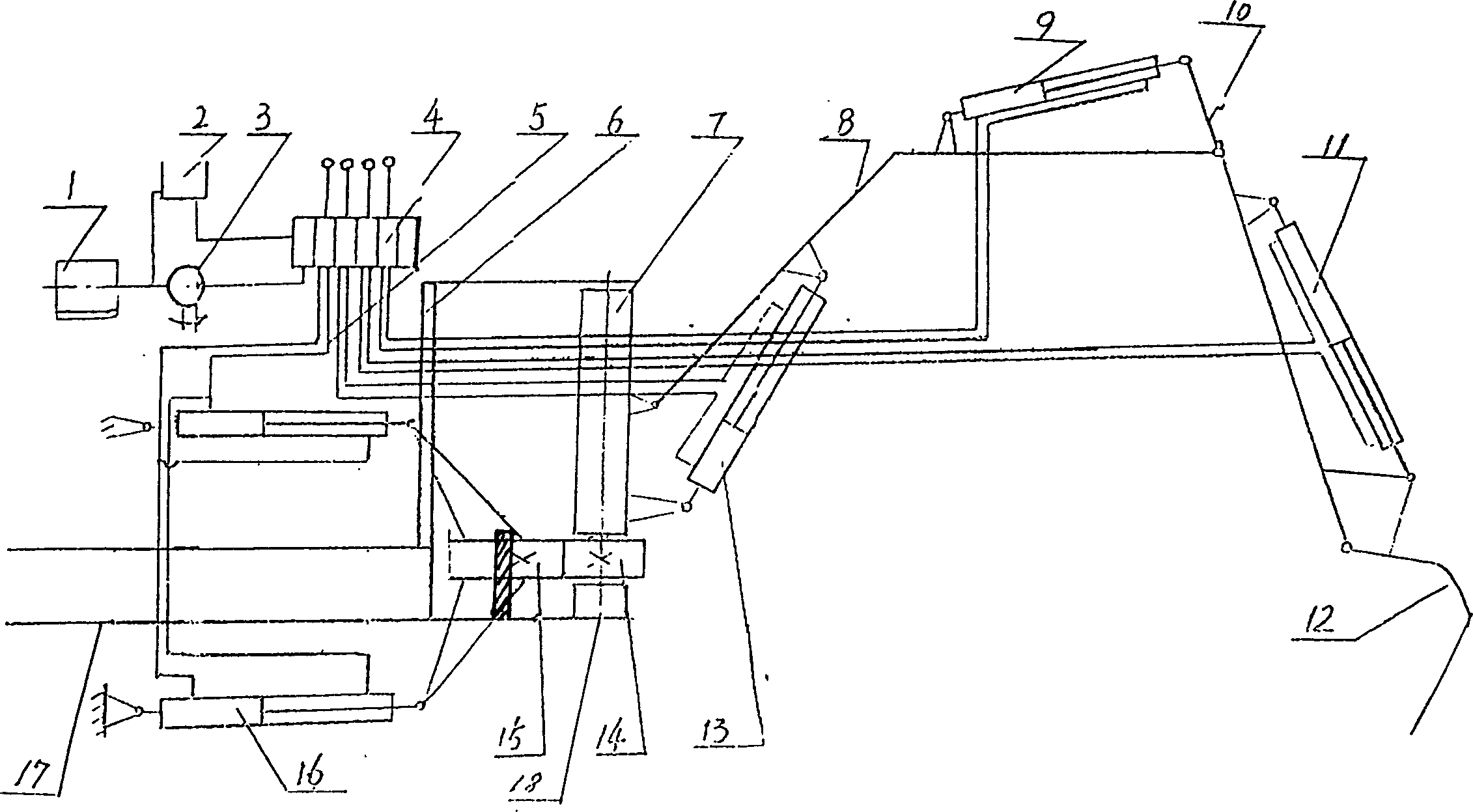

Revolving gear of digging rising arm in digging machine

InactiveCN1284909CSimple structureIncrease the radius of rotationMechanical machines/dredgersRotational axisEngineering

The invention relates to an improvement to the rotating structure of the excavator in order to expand the rotation range of the lifting arm of the excavator. There is an action wheel that drives the digging arm to support the rotating shaft cylinder for rotary motion. Corresponding to the action wheel, a driving device for driving the action wheel for rotary motion is provided on the excavator. The advantages of convenience, safety, reliability and high work efficiency.

Owner:王永昌

Air cushion suspension type rock-soil centrifugal machine

PendingCN113252875AIncrease the radius of rotationImprove securityEarth material testingWireless transmissionAcquisition apparatus

The invention discloses an air cushion suspension type rock-soil centrifugal machine. The centrifugal machine comprises a model test cabin which is located under the ground and movably arranged in a vehicle body of a suspension structure, a linear motor, data acquisition equipment, wireless transmission equipment, power supply equipment and a ground laboratory computer; two parallel first air cushions are arranged on the side portion of the vehicle body of the air cushion suspension structure in a spaced mode, and two parallel second air cushions are arranged at the bottom of the vehicle body of the air cushion suspension structure in a spaced mode; a gap formed between the two first air cushions is connected with a first rail in a matched mode, and a gap formed between the two second air cushions is connected with a second rail in a matched mode; a stator of the linear motor is fixed to the first rail and the second rail, and a rotor of the linear motor is fixed to the vehicle body of the suspension structure; and the data acquisition equipment is arranged in the model test cabin and is in signal connection with the ground laboratory computer through the wireless transmission equipment.

Owner:CHINA INST OF WATER RESOURCES & HYDROPOWER RES

Polarizing device and optical alignment device

ActiveCN109212648AIncrease the radius of rotationHigh-resolutionPolarising elementsNon-linear opticsWire gridImage resolution

The invention provides a polarizing device and an optical alignment device, comprise a polarizing unit and a mounting frame. The polarizing unit comprises a polarizing wire grid, a wire grid frame plate and a wire grid adjustment unit. The wire grid frame plate is used for supporting the polarizing wire grid, and is rotationally installed on the mounting frame in the normal direction of the polarizing wire grid as a rotating shaft. The wire grid adjustment unit provides a driving force for rotation of the wire grid frame plate, and the rotating shaft of the wire grid frame plate and the driving force point of the wire grid adjusting unit are located on a pair of diagonal lines of the wire grid plane of the polarizing wire grid. According to the polarizing device and optical alignment device, the problem that the adjusting resolution of an existing polarizing device cannot meet the actual use requirement is solved.

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

Energy storage system for magnetic floating flywheel

InactiveCN101127465BReduce weightLight weightFlywheelsMechanical energy handlingElectricityLevitation

The utility model discloses a magnetic levitation flywheel energy accumulation system, which has the advantages of small deadweight, large electricity storage, low manufacturing cost, mobile usage, free adjustment of the real-time discharge quantity value to the outside, and quick charge or large real-time discharge; wherein, the axial component of ''the high-vacuum enclosed housing'' is made of materials of low specific gravity. No permanent magnetic material components are positioned on the ''Flywheel'' and the ''Wheel Disk'' is divided into three rings. Four ''Permanent Magnetic Rotating Motor Devices'' are arranged. The ''Magnet bearing'' is ''all magnetic levitation bearing'' or ''semimagnetic levitation bearing''. The utility model is also provided with a device to guarantee the reliability of the mobile usage of the ''Magnet Bearing''.

Owner:严密 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com