Cutting blade of spiral cutter type lawn mower and spiral cutter type lawn mower

A technology for cutting blades and lawn mowers, which is applied to cutters, harvesters, agricultural machinery and implements, etc. It can solve problems such as loud noise, and achieve the effects of avoiding resonance, accelerating cutting speed, and improving cutting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

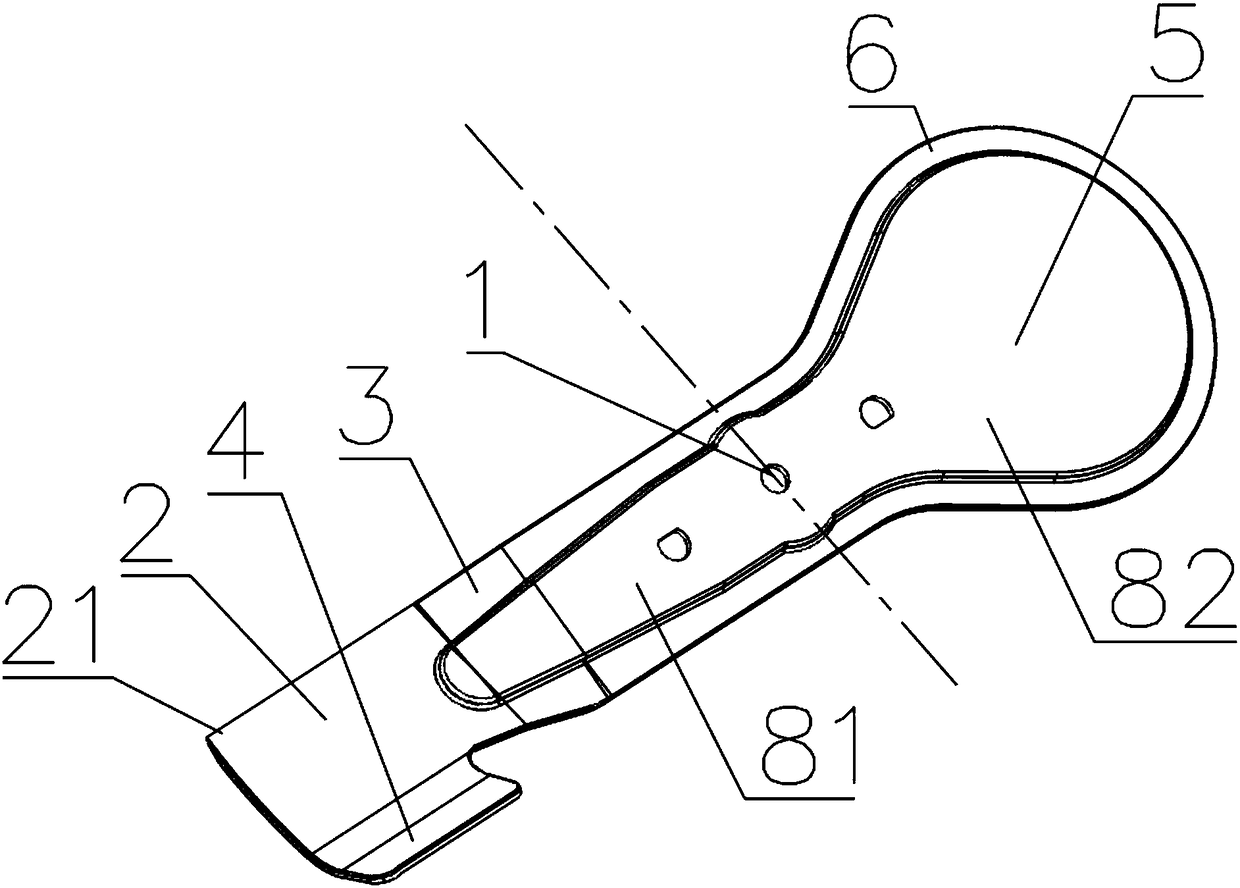

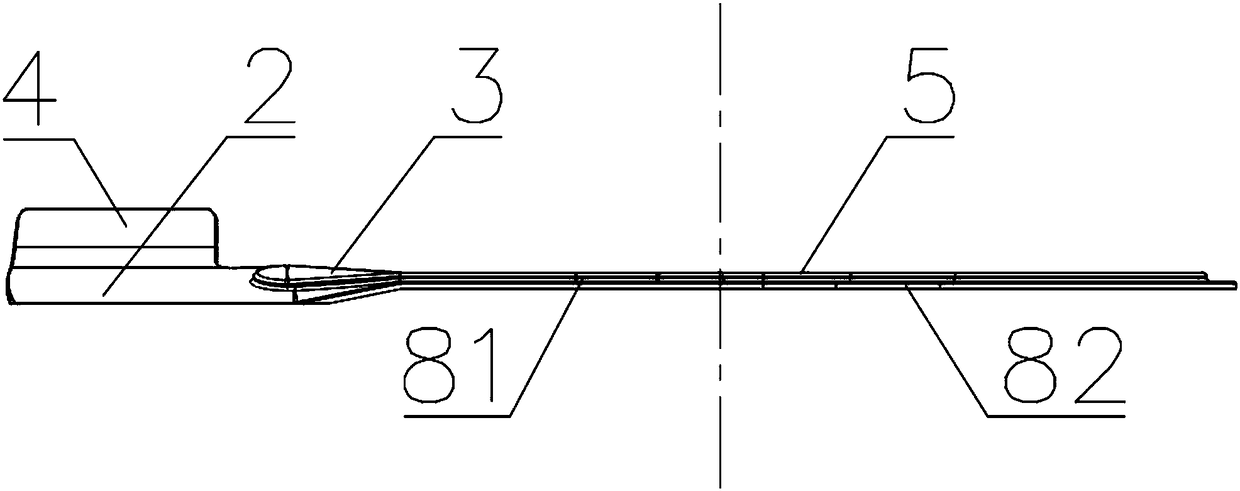

[0037] Such as figure 1 As shown, the present invention provides a cutting blade of a rotary knife mower, the cutting blade is provided with three connecting holes 1 for installing connecting parts, the cutting blade is connected with the output shaft of the motor through the connecting parts and rotates around the cutting blade Center rotation. The cutting blade includes a first section 81 of the cutting blade and a second section 82 of the cutting blade, and the center of rotation of the cutting blade is set on the boundary line between the first section 81 of the cutting blade and the second section 82 of the cutting blade.

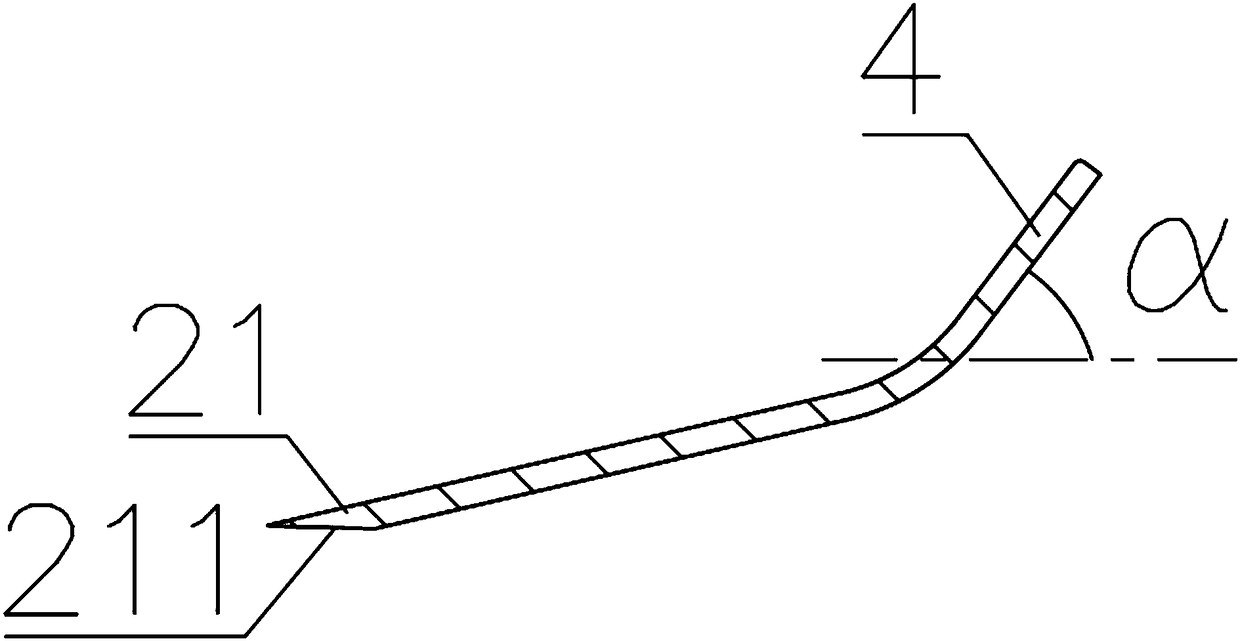

[0038] The cutting blade includes a cutting portion 2 arranged at the end of the first section 81 of the cutting blade, and the cutting portion 2 includes a cutting edge 21 . During the rotation of the cutting blade, the cutting edge 21 of the cutting part 2 cuts the blade of grass. Adopting a single-blade structure with a cutting part at only one end,...

Embodiment 2

[0047] Such as Figure 4 As shown, the present invention provides a cutting blade of a rotary lawn mower, which is different from the cutting blade of a rotary lawn mower provided in Embodiment 1 in that in this embodiment, the cutting blade A noise reduction groove 7 is provided at the end of the air lifting part 4 . Since the air lifting portion 4 is at an inclination angle to the rotation plane of the cutting blade, during the rotation of the cutting blade, the air flow passing through the air lifting portion 4 will generate air resistance against the cutting blade in the direction of rotation of the cutting blade. By arranging the noise reduction groove 7 at the end of the air lifting part 4, the windward area of the air lifting part 4 is reduced to reduce the air resistance caused by the air lifting part, thereby reducing noise.

[0048] Further, the noise reduction groove 7 is wave-shaped. It can be understood that the noise reduction groove 7 can also be zigzag. Th...

Embodiment 3

[0052] Such as Figure 5 As shown, the present invention provides a cutting blade of a rotary lawn mower, which is different from the cutting blade of a rotary lawn mower provided in Embodiment 2 in that in this embodiment, the noise reduction groove 7 is a V-shaped groove extending from the air lifting part 4 to the cutting part 2, and the noise reduction groove 7 is arranged on the side of the air lifting part close to the rotation center of the cutting blade. In this embodiment, the air lifting part 4 has a good air lifting function, and the V-shaped noise reduction groove 7 on one side greatly reduces the windward area of the air lifting part 4, reducing air resistance.

[0053] The remaining structure of the cutting blade of a rotary lawn mower in embodiment 3 is the same as the cutting blade of a rotary lawn mower in embodiment 2 which is not described in embodiment 3.

[0054] This embodiment also provides a rotary lawnmower comprising the above-mentioned cutting bla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com