Vertical-axis high-frequency vibration mixer

A high-frequency vibration and mixer technology, which is applied to cement mixing devices, clay preparation devices, chemical instruments and methods, etc., can solve the problems that the advantages of vibration mixing cannot be fully utilized, the frequency limit of mixer vibration, and the structure of vibration mixer are complicated. Achieve the effects of shortening the stirring time, optimizing the stress state, and simplifying the overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention is further described below in conjunction with accompanying drawing:

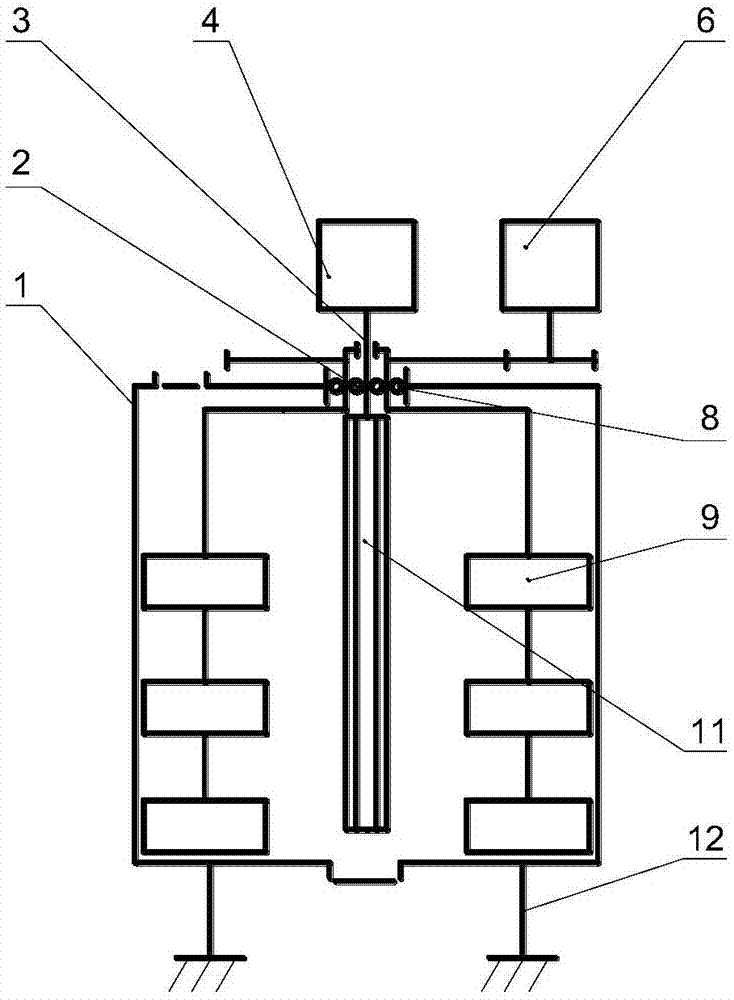

[0022] see figure 1 and figure 2 , a vertical shaft type high-frequency vibration mixer, comprising a vibration drive unit 4, a stirring drive unit 6, a mixing drum 1, a stirring device 9 and an exciter 11; the vibration driving unit 4 and the stirring driving unit 6 are fixedly arranged on the mixing drum 1 above; the inside of the mixing drum 1 is provided with a stirring device 9, the center of the upper cover of the mixing drum 1 is provided with a hole, and the upper end of the stirring device 9 is coaxially arranged in the hole; the inside of the mixing drum 1 below the hole is provided with a vibrator 11, The vibrator 11 is connected to the vibration drive unit 4 through the vibrator connecting shaft 3; the stirring drive unit 6 is connected to the upper end of the stirring device 9;

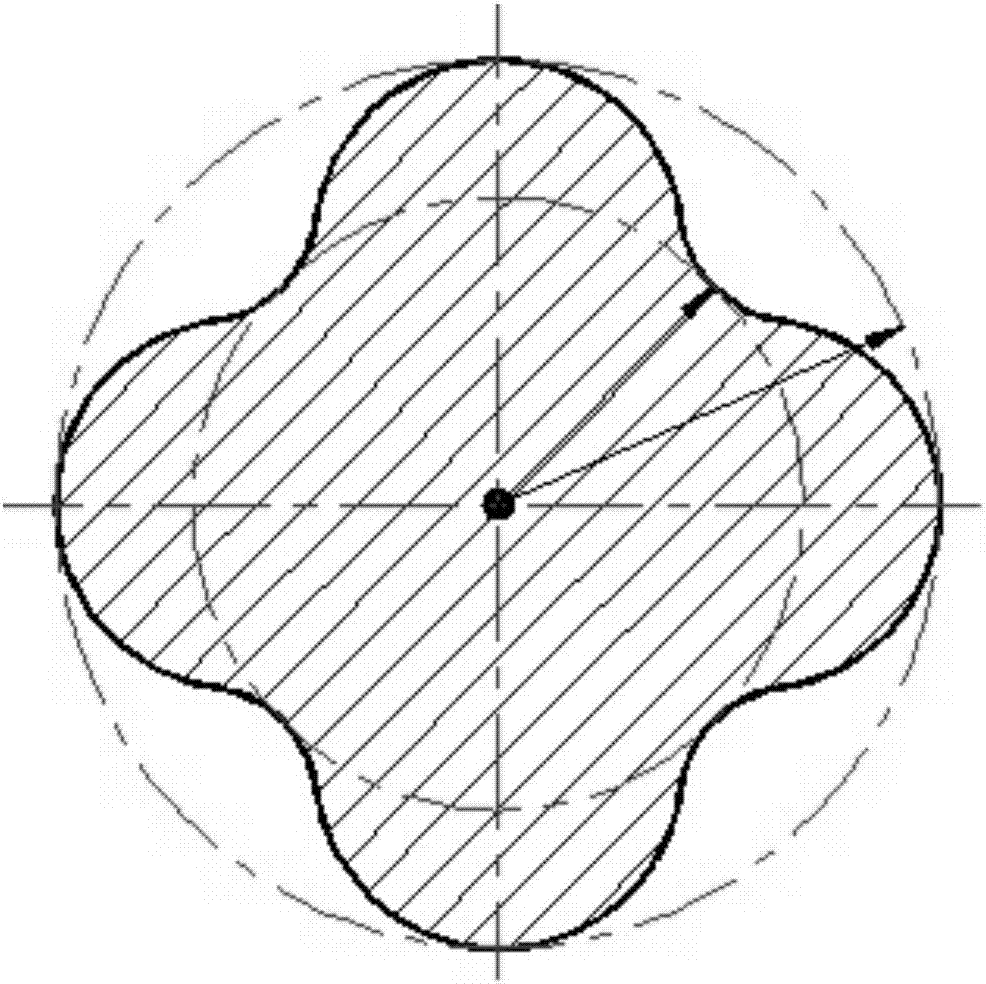

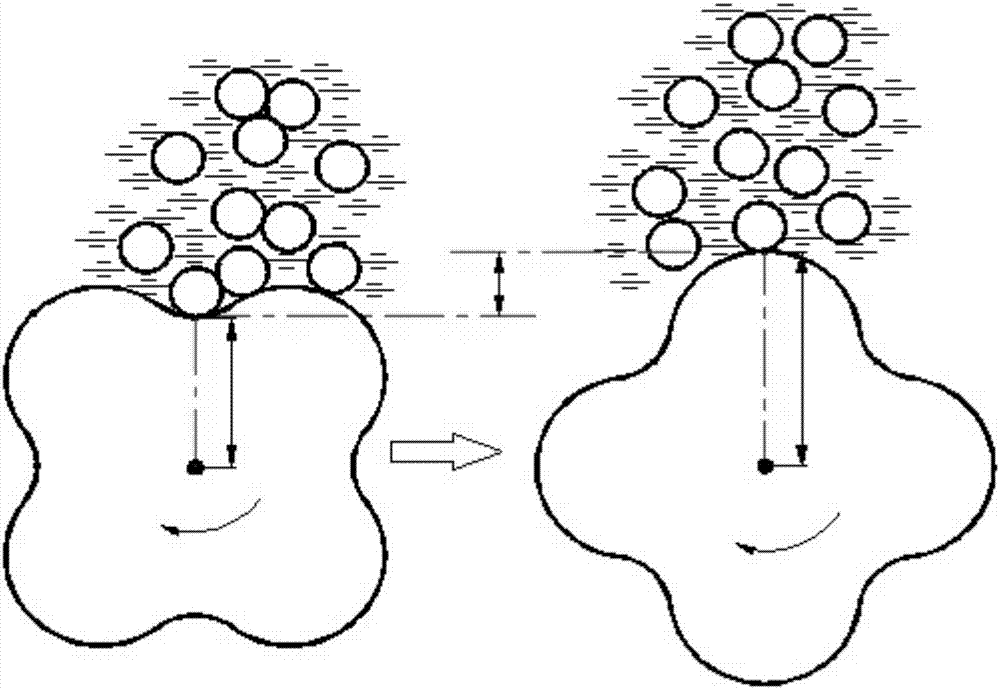

[0023] The vibrator 11 is a polygonal shaft with N smooth protrusions in cross secti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com