Up-conversion piezoelectric-electromagnetic energy harvesting device

An electromagnetic and energy-harvesting technology, applied in piezoelectric effect/electrostrictive or magnetostrictive motors, generators/motors, electrical components, etc. Problems such as low vibration frequency can achieve the effect of improving power generation efficiency, increasing excitation frequency, and increasing output power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to further illustrate the technical means and effects taken by the present invention to achieve the expected purpose, so that the advantages and characteristics of the present invention can be more easily understood by those skilled in the art, the specific implementation methods, structural features and other aspects of the present invention will be described in conjunction with the accompanying drawings and examples. The efficacy is described in detail below.

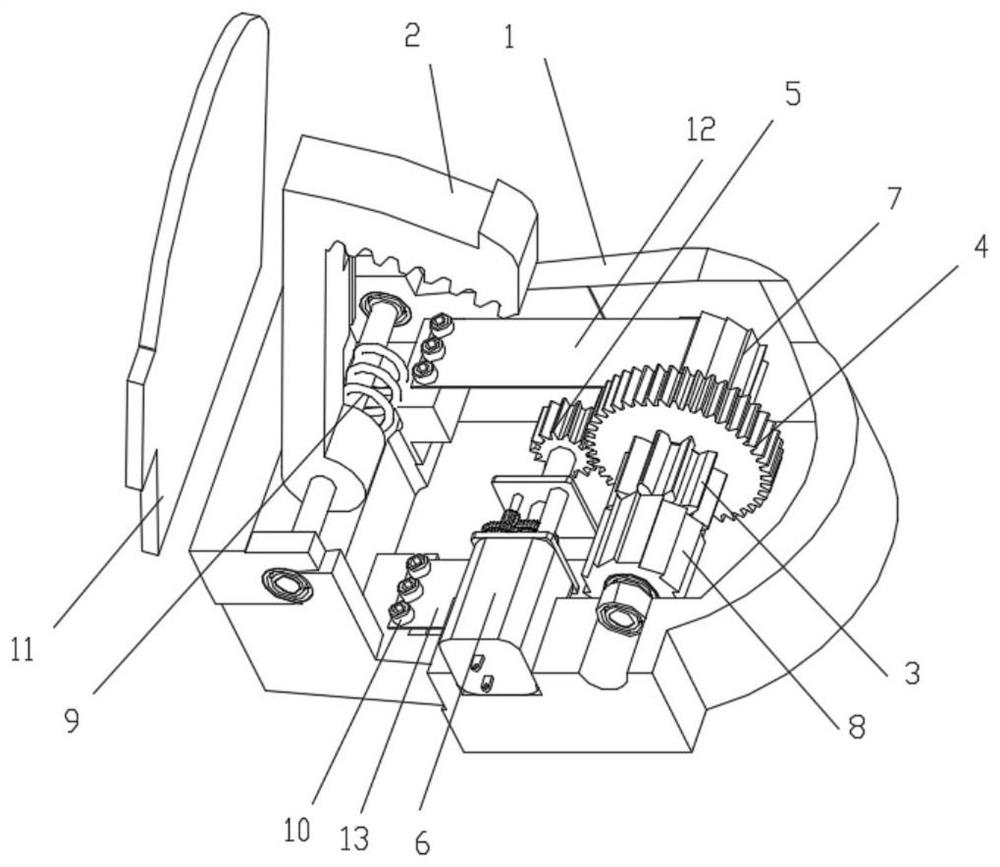

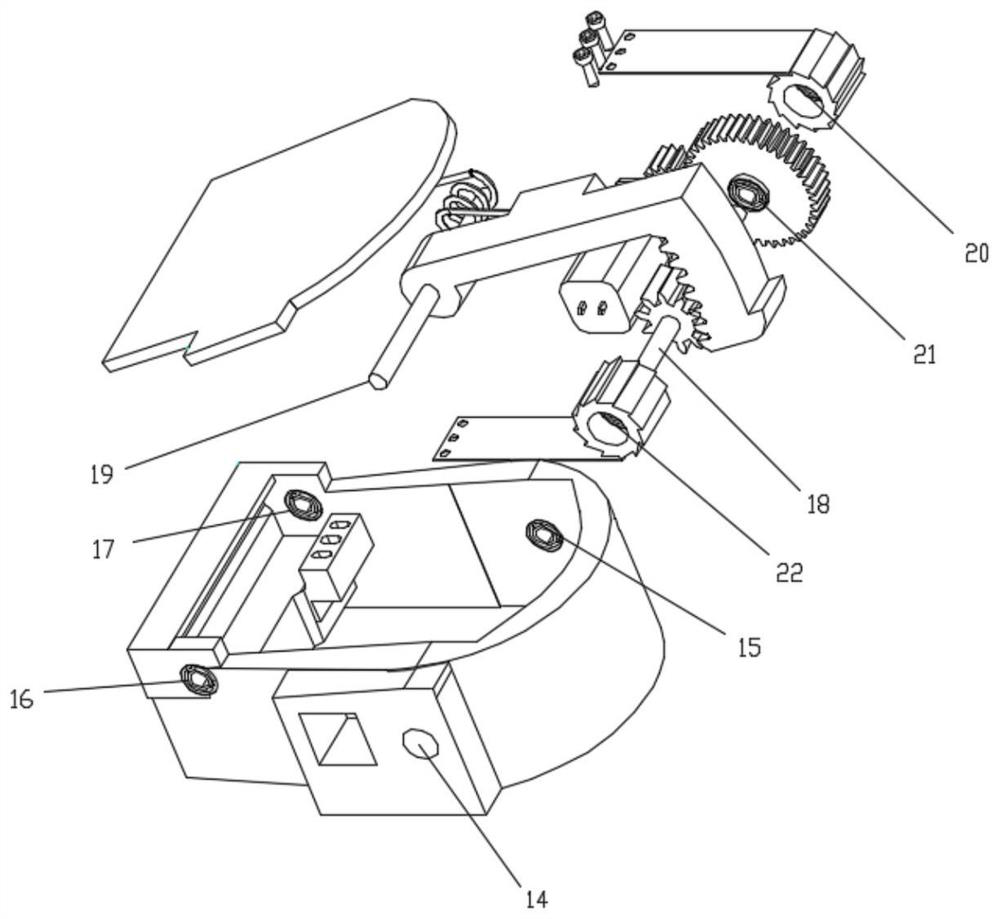

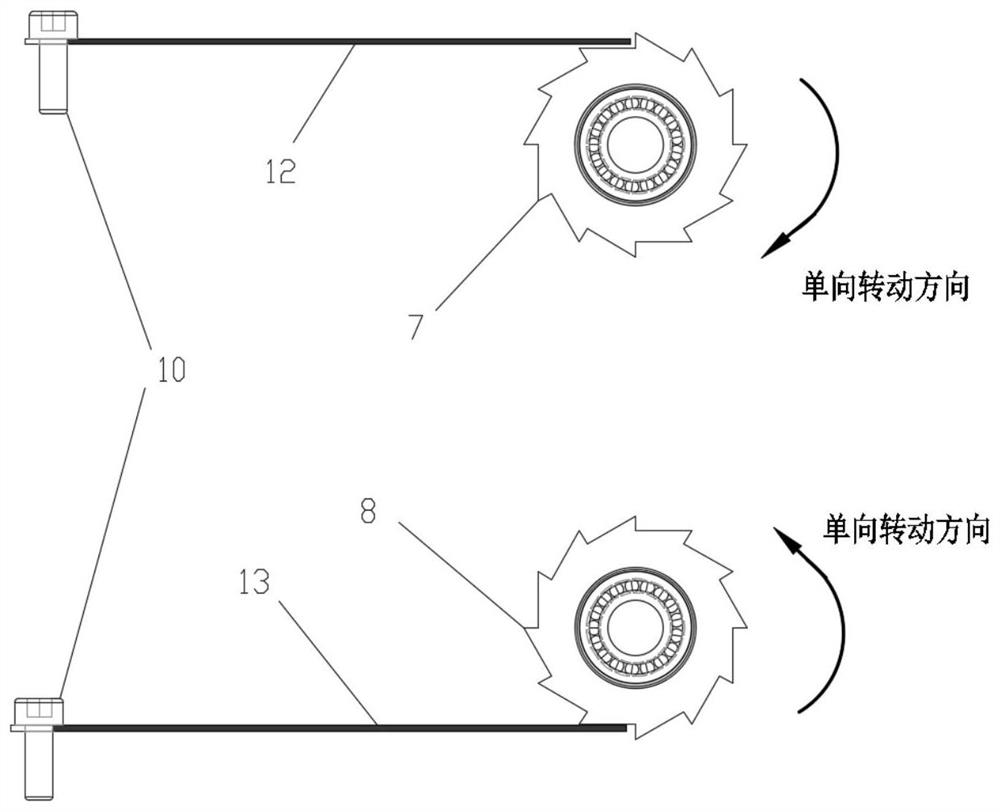

[0031] Such as figure 1 , 2 As shown, a frequency-up piezoelectric-electromagnetic energy harvesting device disclosed in this embodiment consists of a housing 1, an arc rack 2, a primary gear 3, a secondary gear 4, a speed-up gear set 5, a generator 6, Forward rotation ratchet 7, reverse rotation ratchet 8, return spring 9, piezoelectric sheet fastening screw 10, partition 11, piezoelectric sheet one 12, piezoelectric sheet two 13, two-way bearing one 14, two-way bearing two 15, Two-way bearing three...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com