Ring type eccentric dish washing machine

A dishwasher and eccentric technology, which is applied in the washing machine/washing machine for tableware, parts of the washing machine/rinsing machine for tableware, automatic detection under the control of the dishwasher/rinsing machine, etc. Large water consumption and other problems, to achieve the effect of increasing the spray range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings so that those embodiments can be easily realized by those having ordinary skill in the art to which the invention pertains. However, the present invention can also be realized in various forms, so the present invention is not limited to the embodiments described hereinafter. In addition, in order to describe the present invention more clearly, parts not connected with the present invention will be omitted from the drawings.

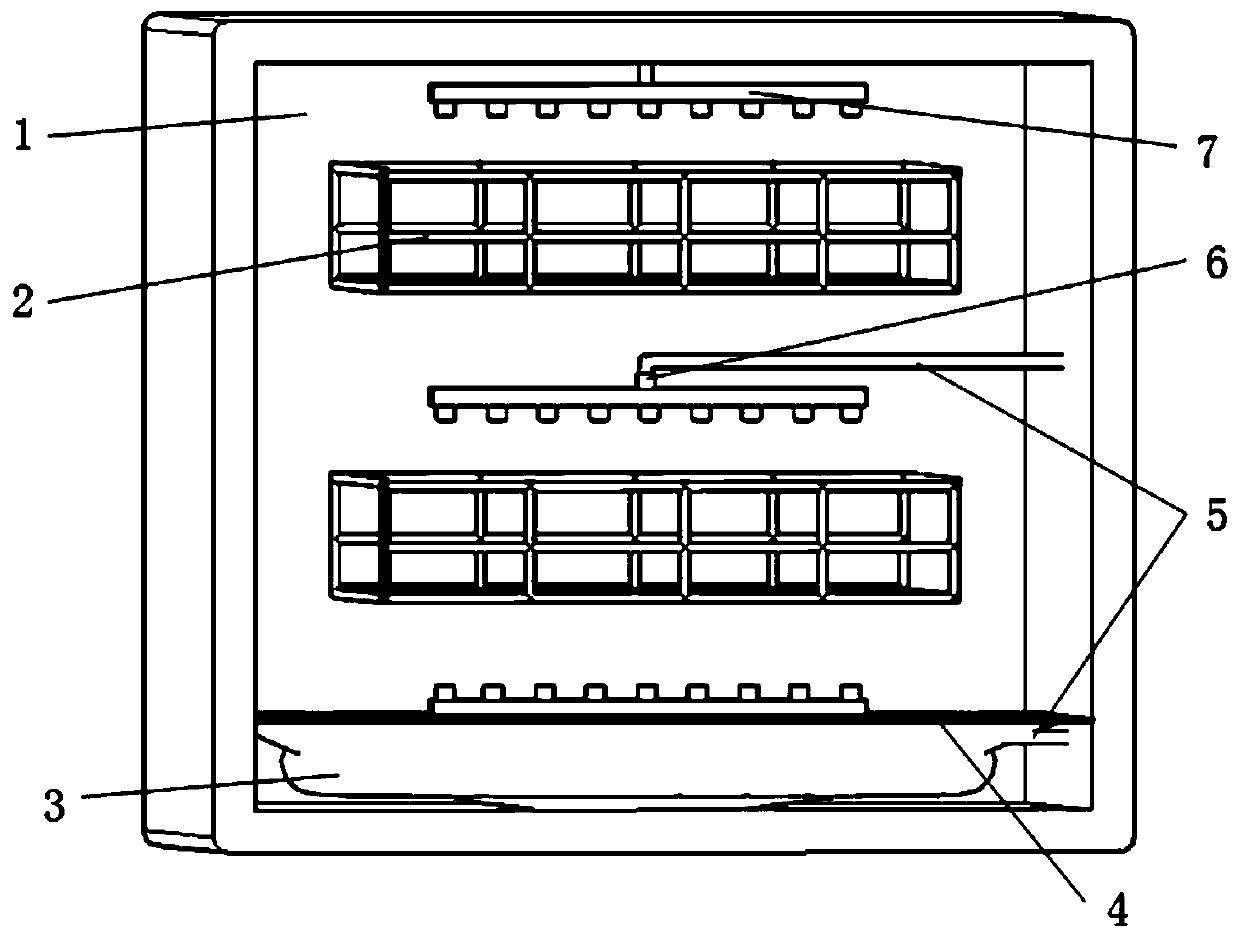

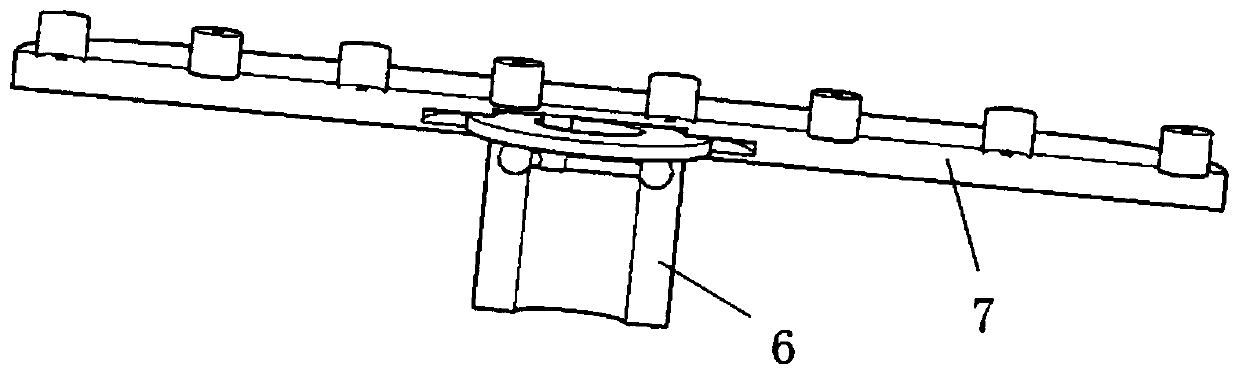

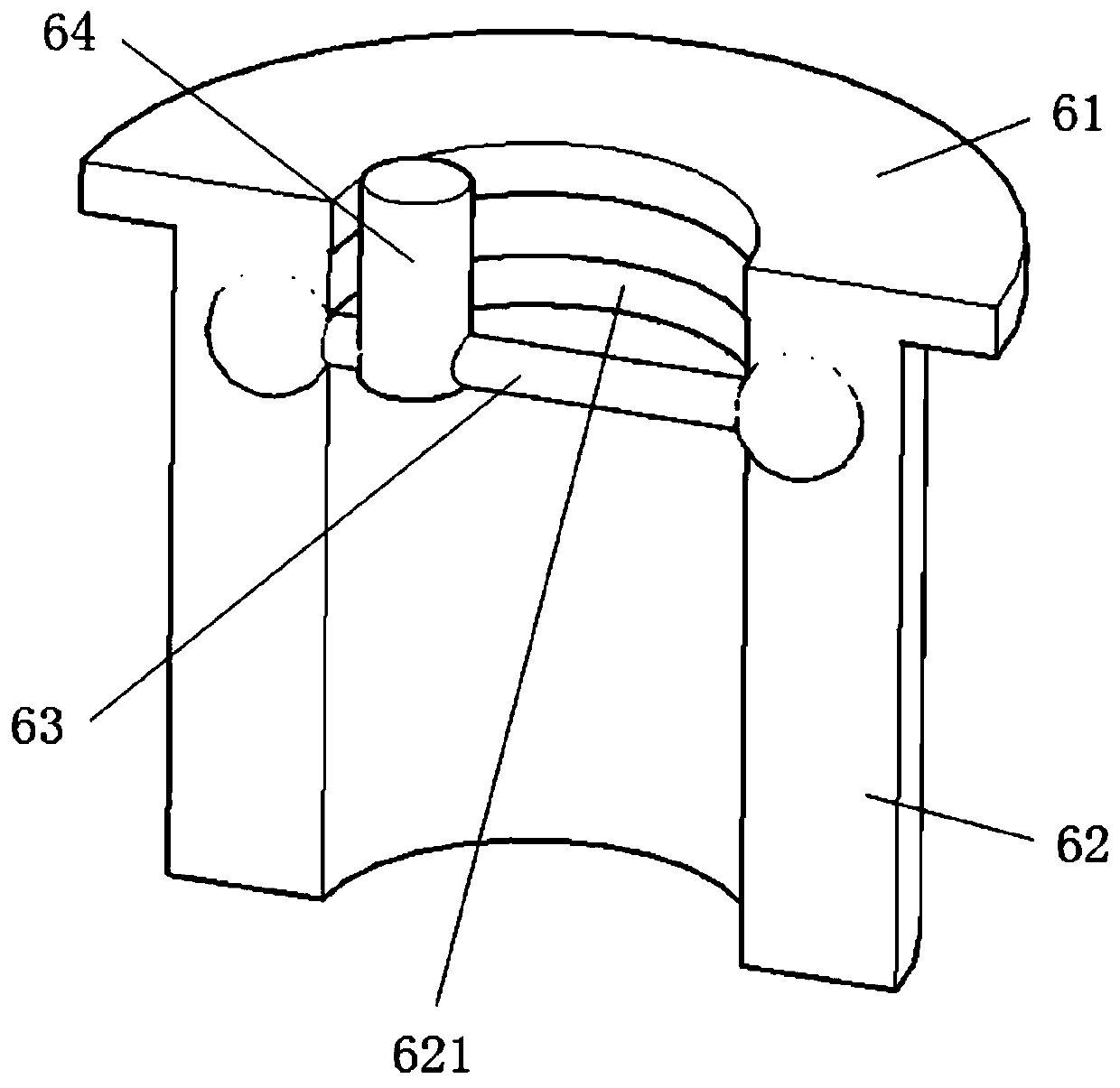

[0024] Such as figure 1 As shown, the present invention provides a ring-type eccentric dishwasher, comprising: a casing 1, a bowl basket 2, a heater 3, a sump 4, a water supply pipe 5, a spin device 6, and a spray device 7;

[0025] The casing 1 is a square, and its front surface is open at the front, forming a washing space for tableware inside the casing 1;

[0026] The bowl basket 2 is a grid structure, and the bowl basket 2 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com