A polarizing device and an optical alignment device

A technology of mounting frame and wire grid, which is applied in optics, polarizing elements, optical elements, etc., can solve the problem that the resolution of the polarizing device cannot meet the actual needs of use, and can increase the rotation radius, improve the resolution, and improve the fine-tuning accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

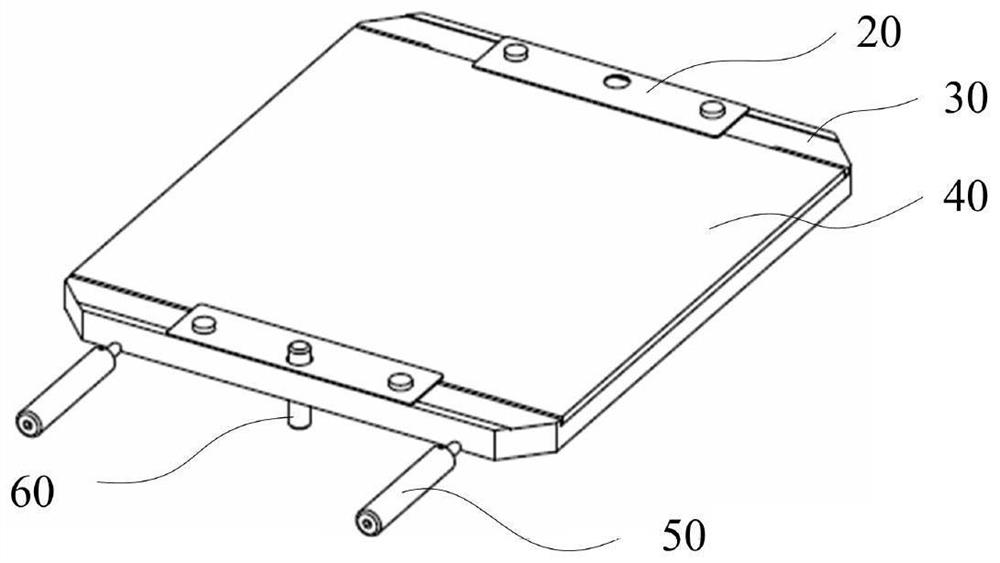

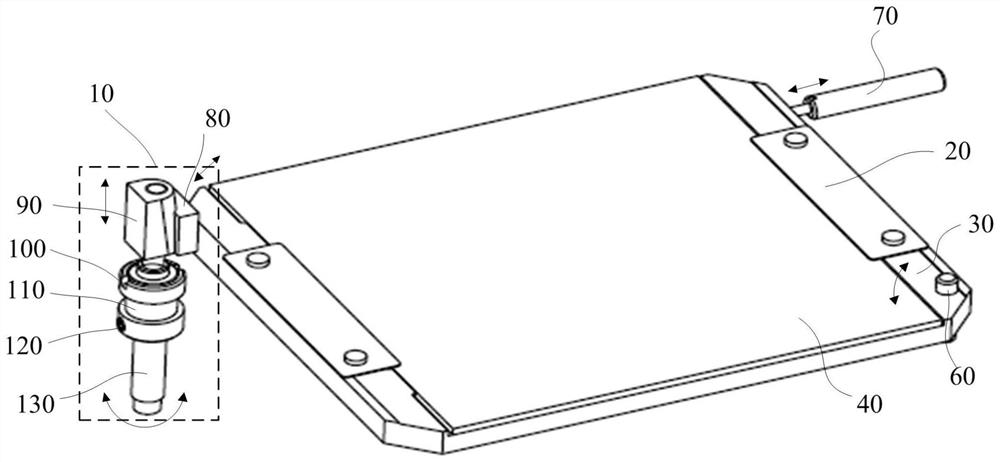

[0033] figure 2 It is a structural diagram of the polarizer provided by Embodiment 1 of the present invention, as shown in figure 2 As shown, it includes a wire grid adjusting unit 10 , a wire grid pressing piece 20 , a wire grid frame plate 30 , a polarizing wire grid 40 , a rotating shaft 60 , and a spring plunger 70 . Both sides of the polarizing wire grid 40 are connected with wire grid frame plates 30 to form a wire grid plane. The wire grid frame plates 30 are used to support the polarizing wire grid 40. The normal direction of the polarizing wire grid 40 is the rotation axis and is rotatably installed on the installation frame. The polarizing wire grid 40 is fixed on the wire grid frame plate 30 by two wire grid pressing pieces 30 through fixing screws, and the rotation axis 60 is fixed on the wire grid frame plate 30, located on the corner of the wire grid plane, and The plane is vertical, and the rotation axis 60 of the wire grid frame plate 30 and the driving for...

Embodiment 2

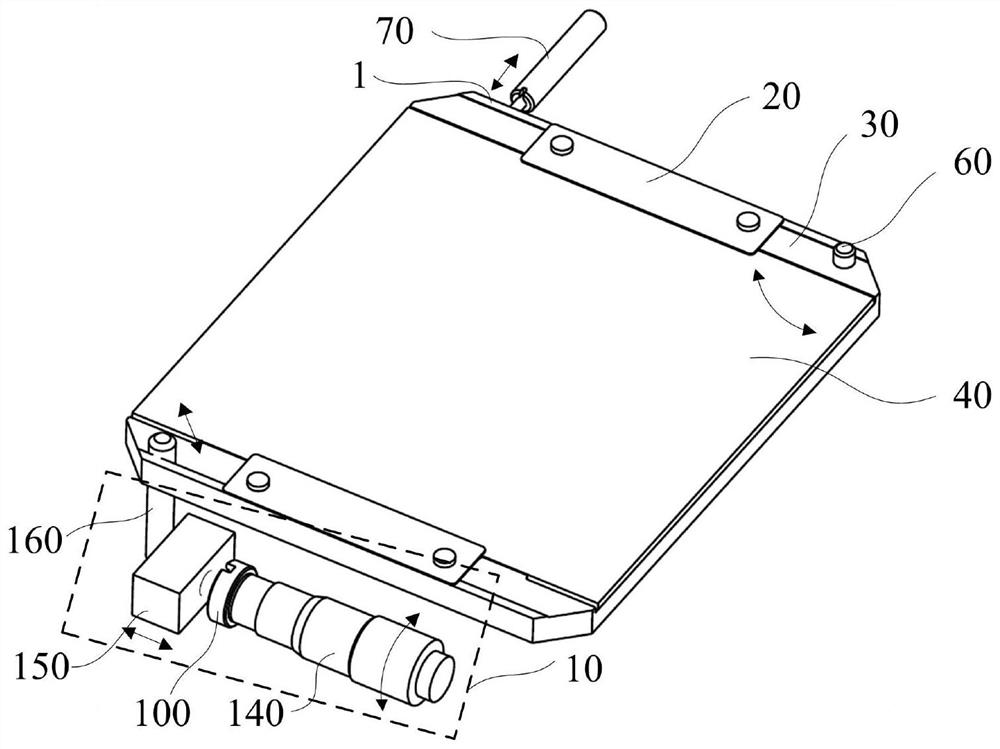

[0045] image 3 It is the structural diagram of the polarizer provided by the second embodiment of the present invention, as shown in image 3 As shown, it includes a wire grid adjusting unit 10 , a wire grid pressing piece 20 , a wire grid frame plate 30 , a polarizing wire grid 40 , a rotating shaft 60 , and a spring plunger 70 . Both sides of the polarizing wire grid 40 are connected with wire grid frame plates 30 to form a wire grid plane. The wire grid frame plates 30 are used to support the polarizing wire grid 40. The normal direction of the polarizing wire grid 40 is the rotation axis and is rotatably installed on the installation frame. The polarizing wire grid 40 is fixed on the wire grid frame plate 30 by two wire grid pressing pieces 30 through fixing screws, and the rotation axis 60 is fixed on the wire grid frame plate 30, located on the corner of the wire grid plane, and The plane is vertical, and the rotation axis 60 of the wire grid frame plate 30 and the dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com