Patents

Literature

30results about How to "High fine-tuning precision" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Convolutional neural network automatic segmentation method and system for mammary molybdenum target data set

InactiveCN110059717AHigh fine-tuning precisionFast testImage enhancementImage analysisReduced modelModel parameters

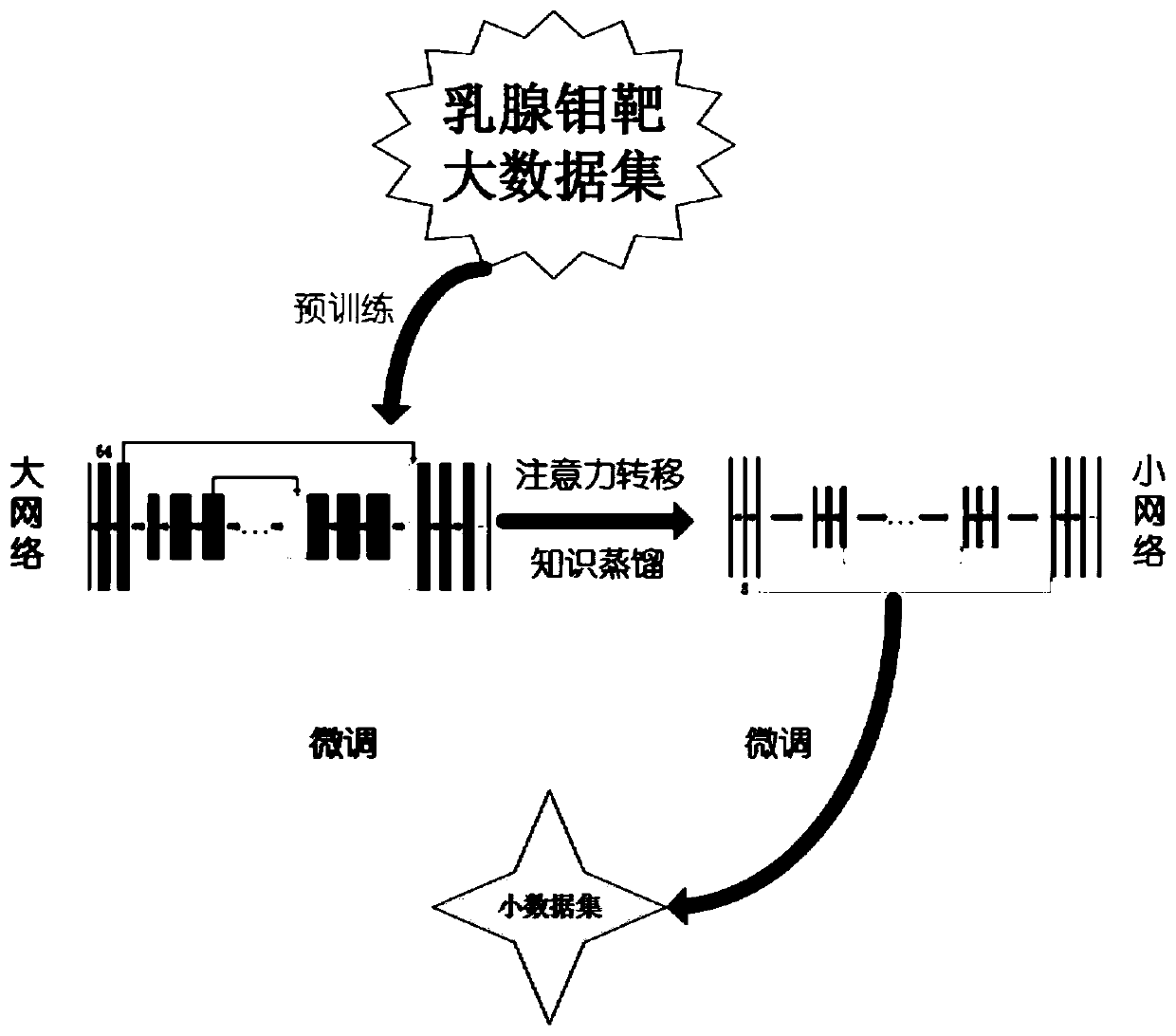

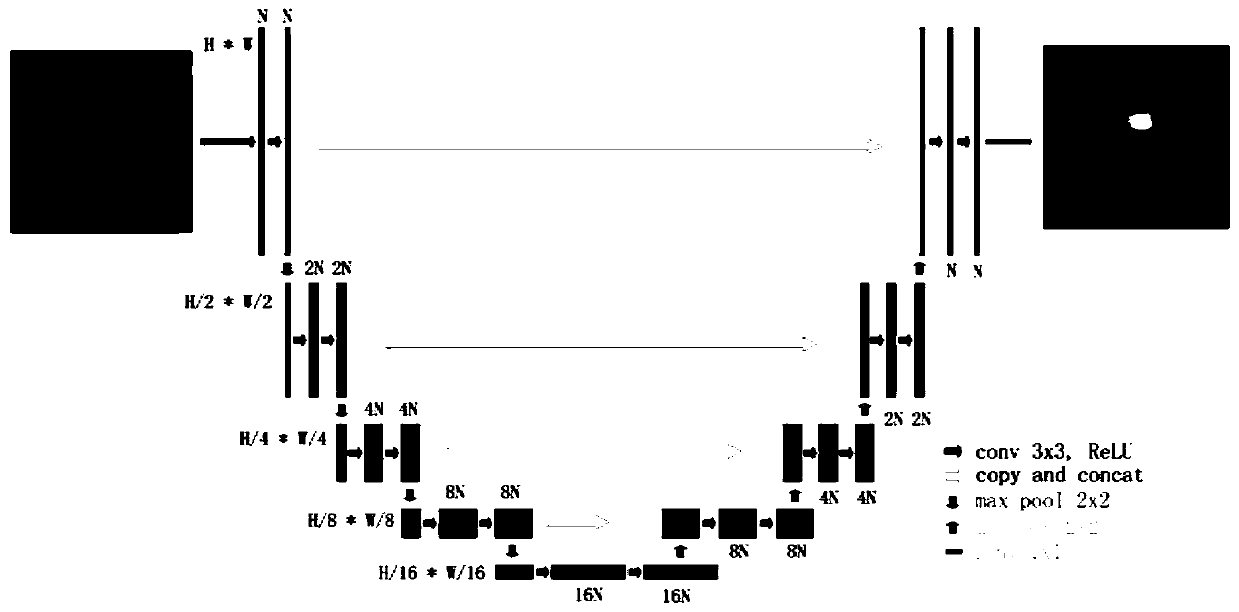

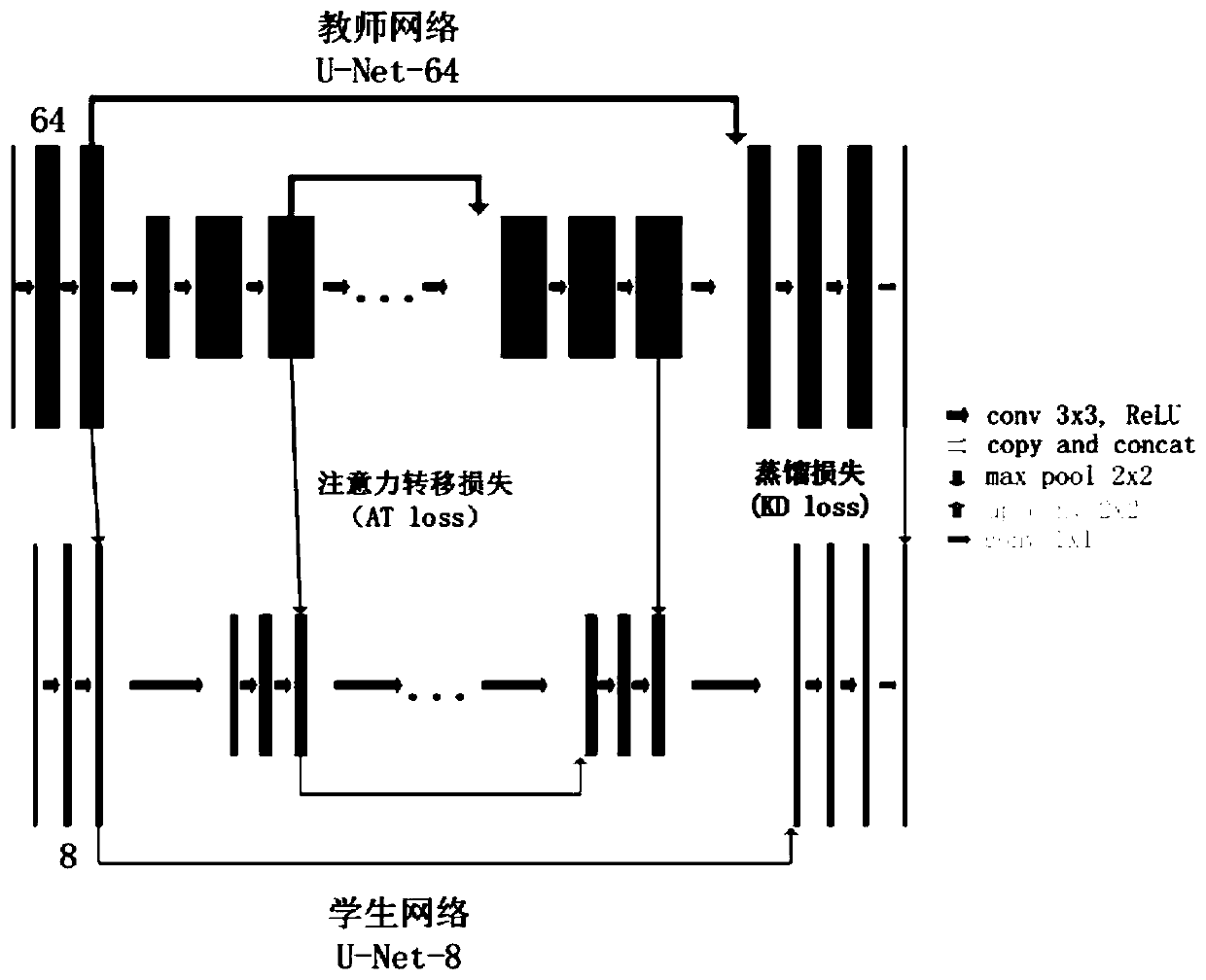

The invention discloses a convolutional neural network automatic segmentation method and system for a mammary molybdenum target data set, which can obviously reduce model parameters and improve the practicability while ensuring the precision of a deep learning model on a mammary molybdenum target small data set. The method comprises the following steps: pre-training a convolutional neural big network on a mammary molybdenum target big data set; performing model compression on the trained convolutional neural large network by adopting attention transfer and knowledge distillation methods to obtain a convolutional neural small network; and carrying out fine tuning on the convolutional neural small network on the mammary molybdenum target small data set.

Owner:SHANDONG UNIV

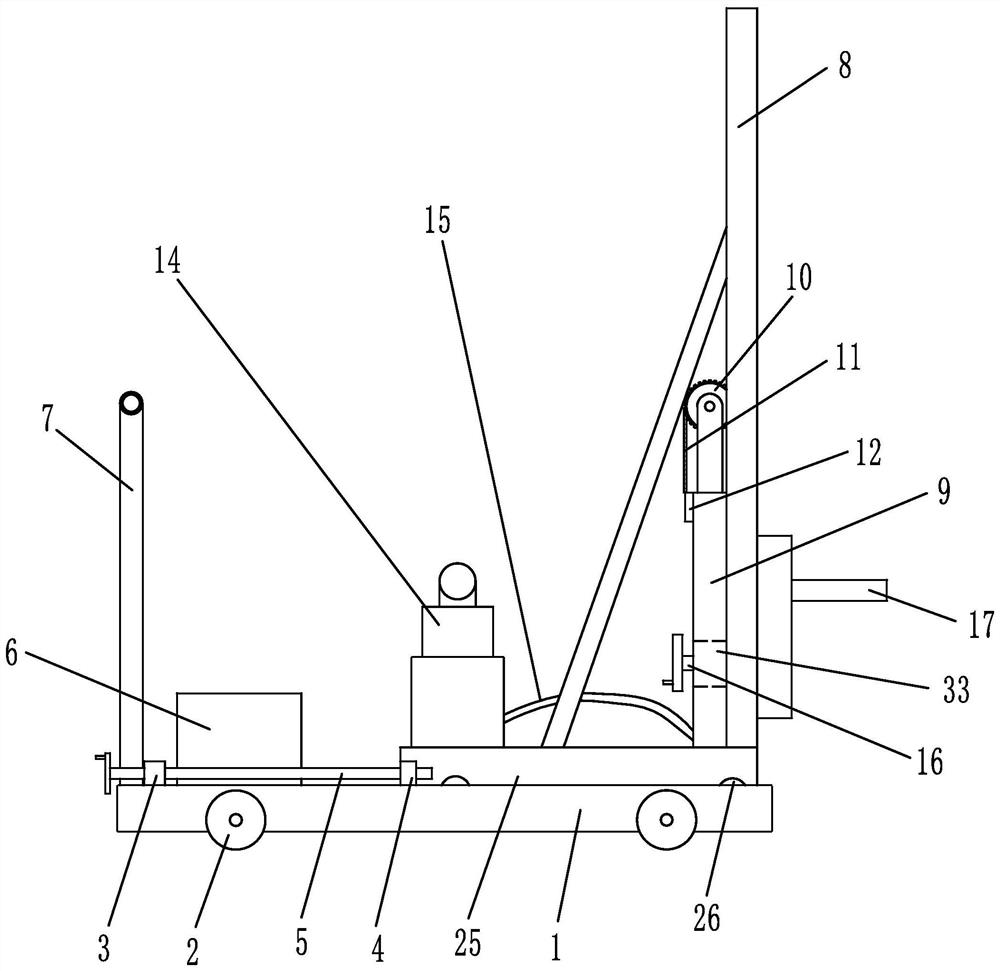

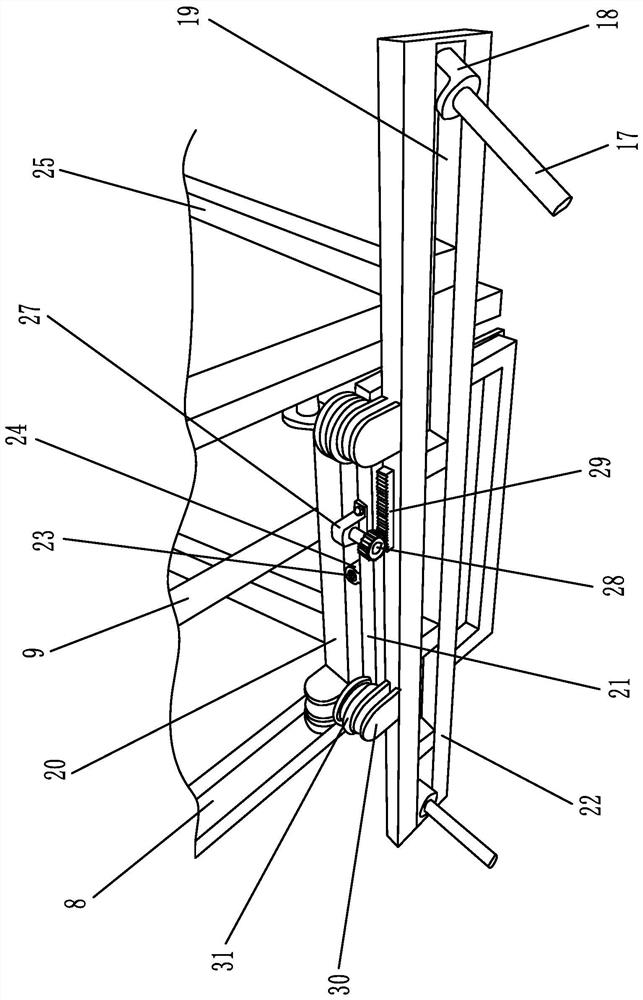

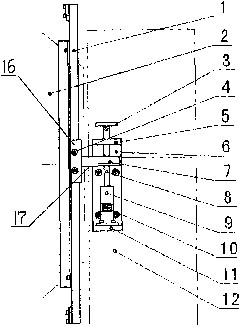

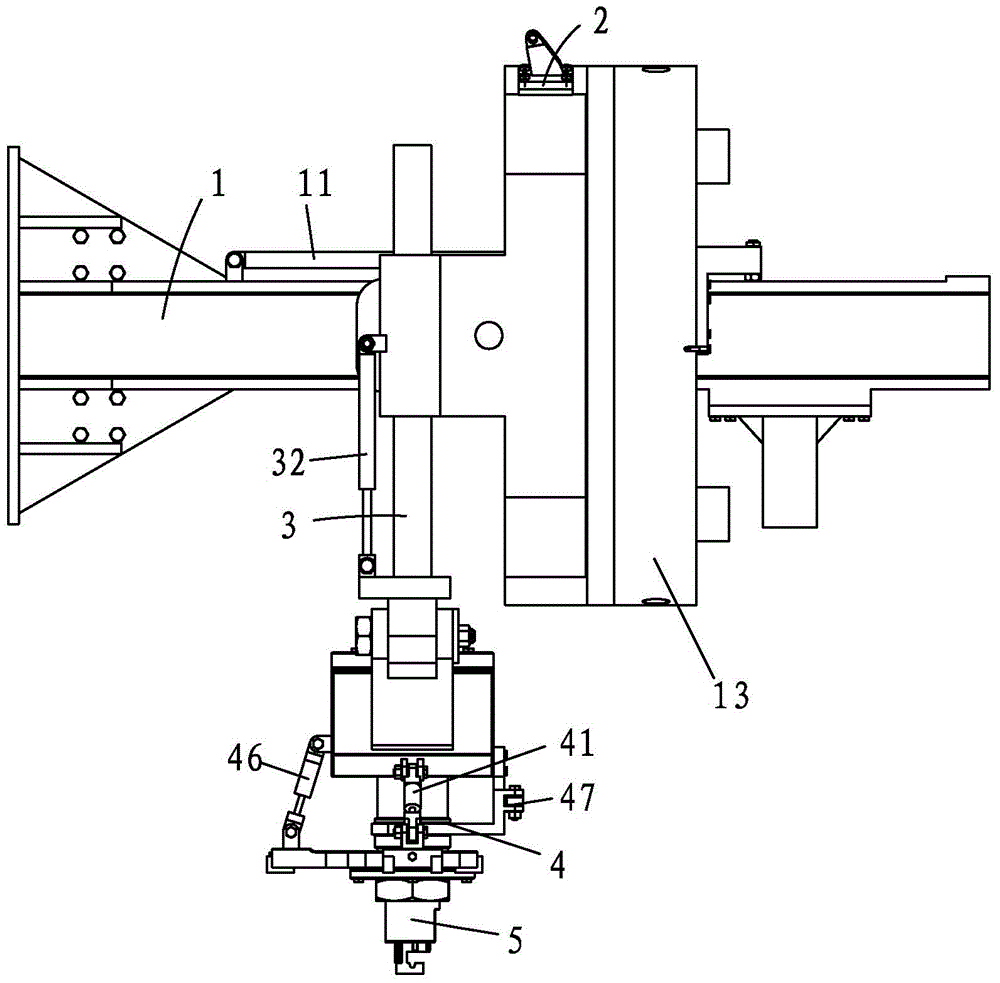

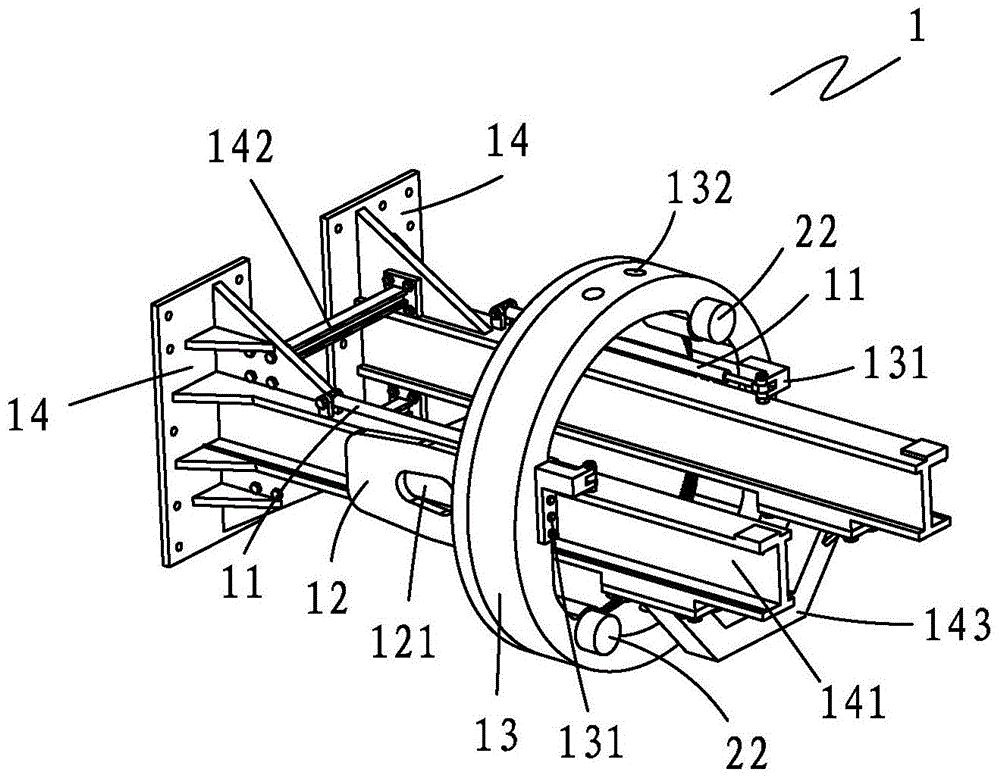

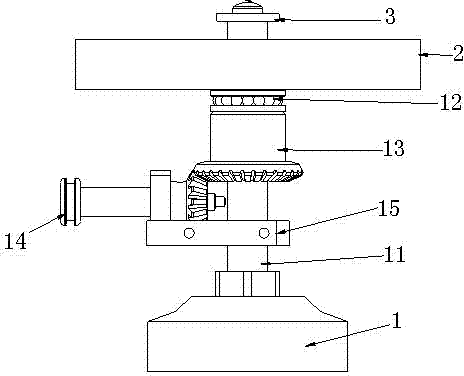

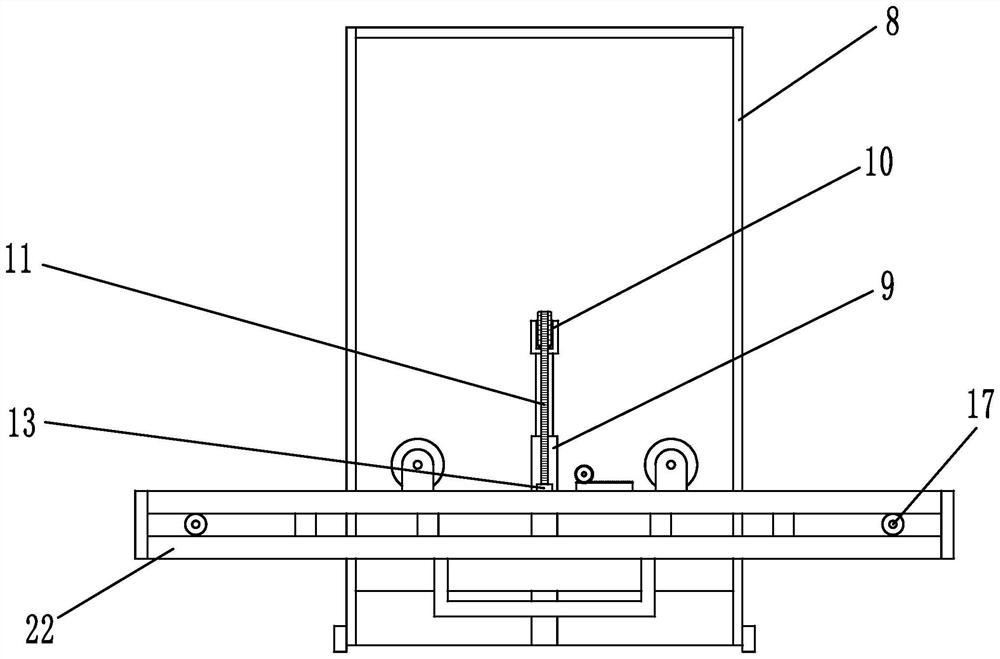

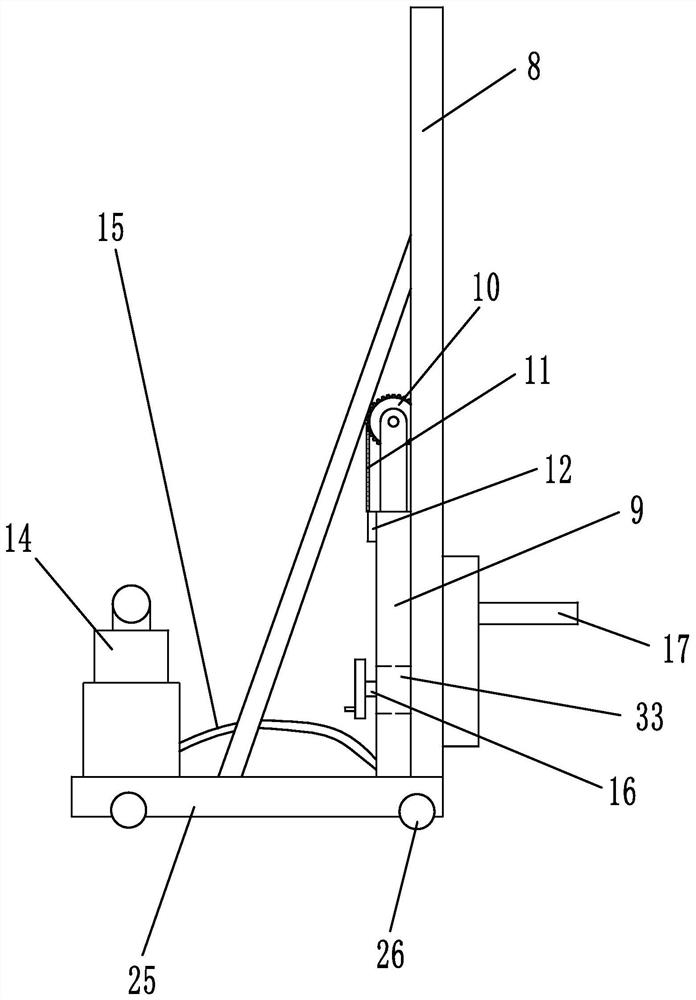

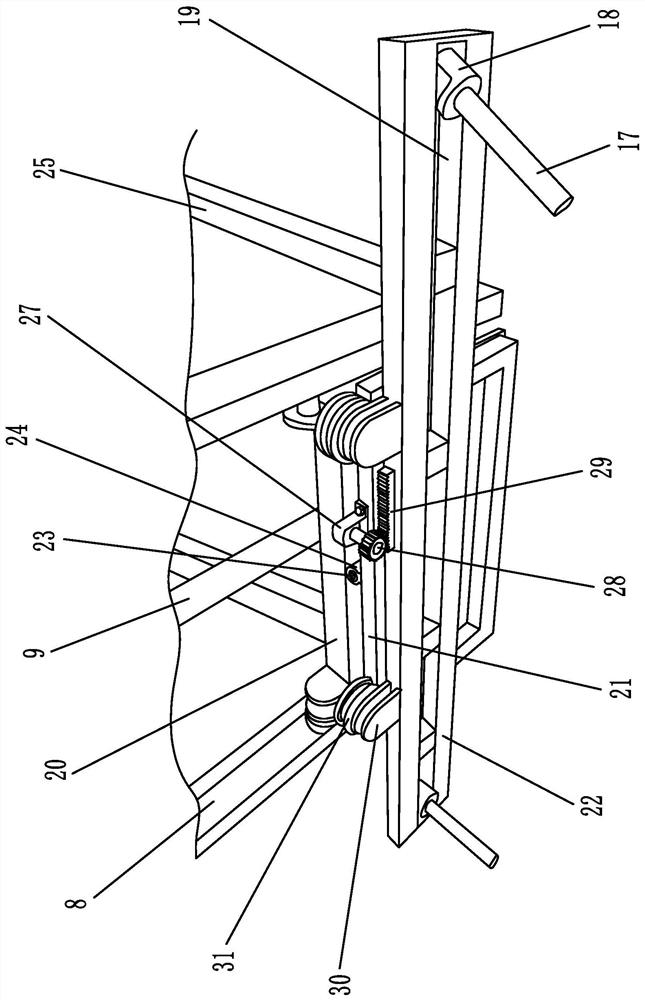

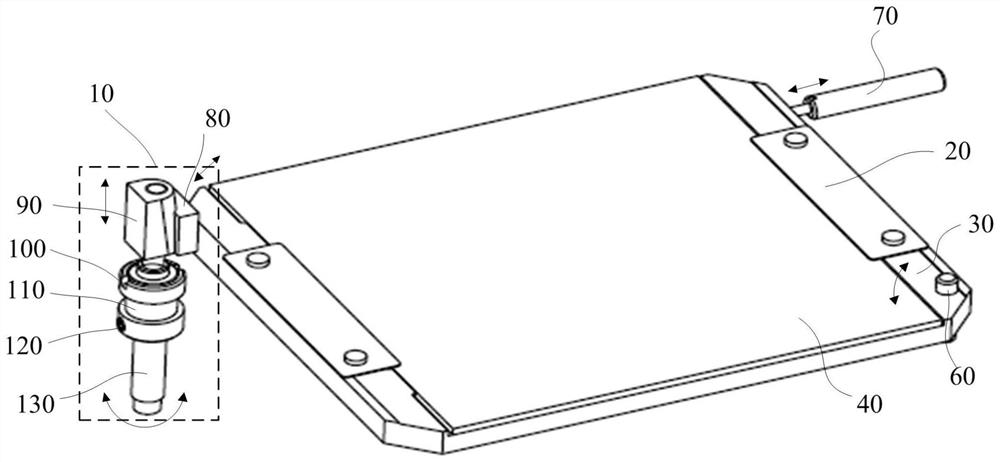

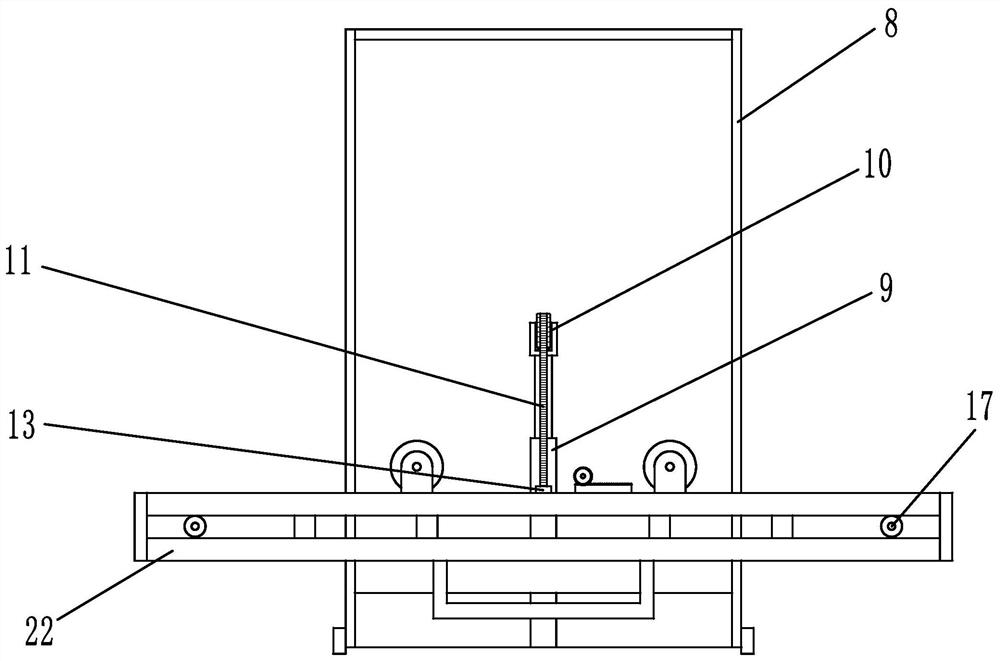

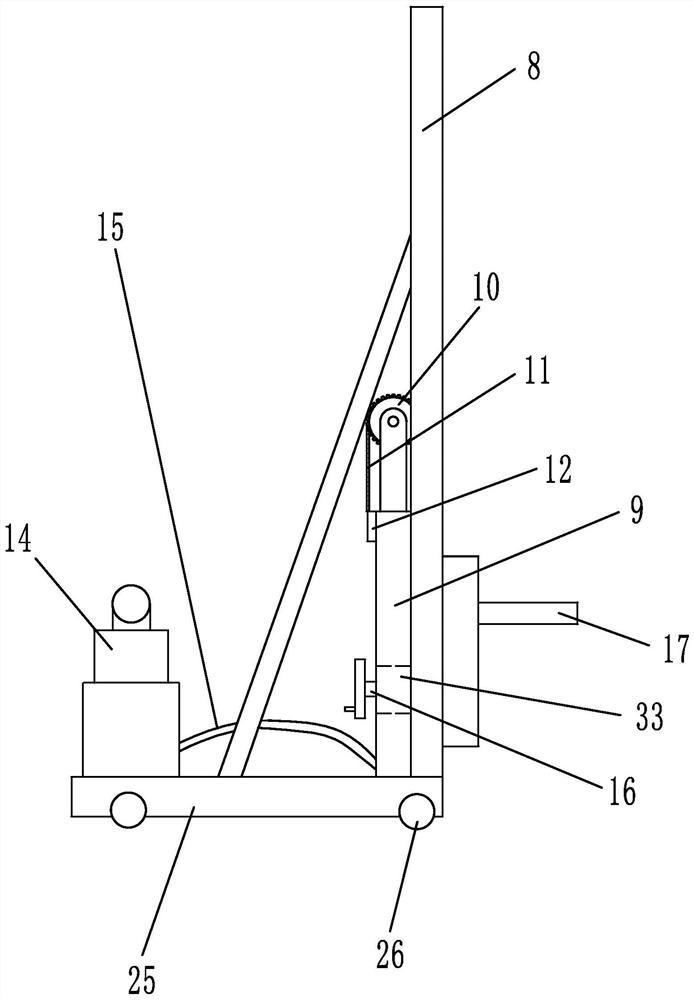

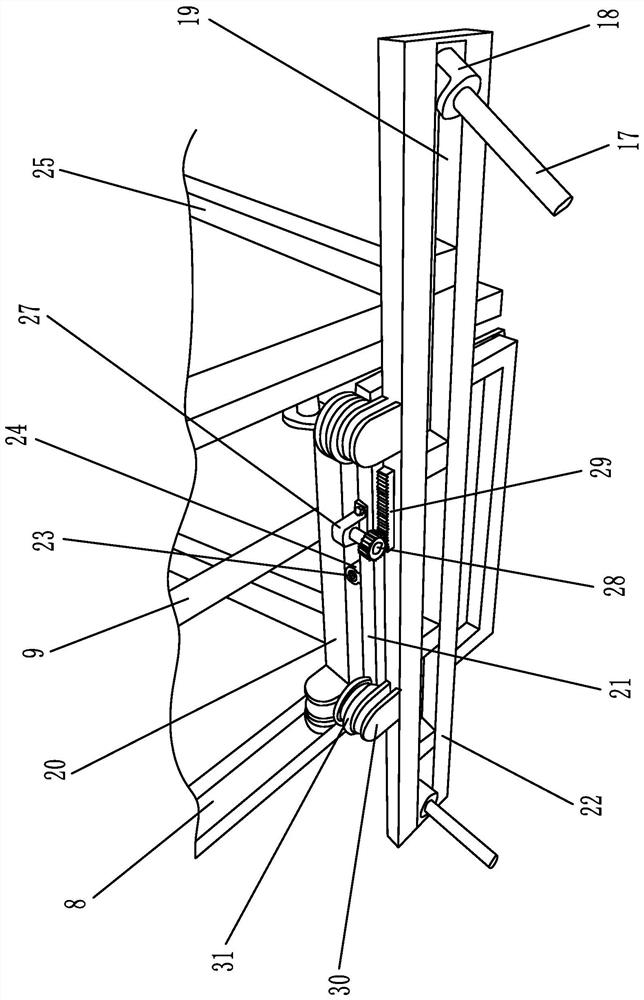

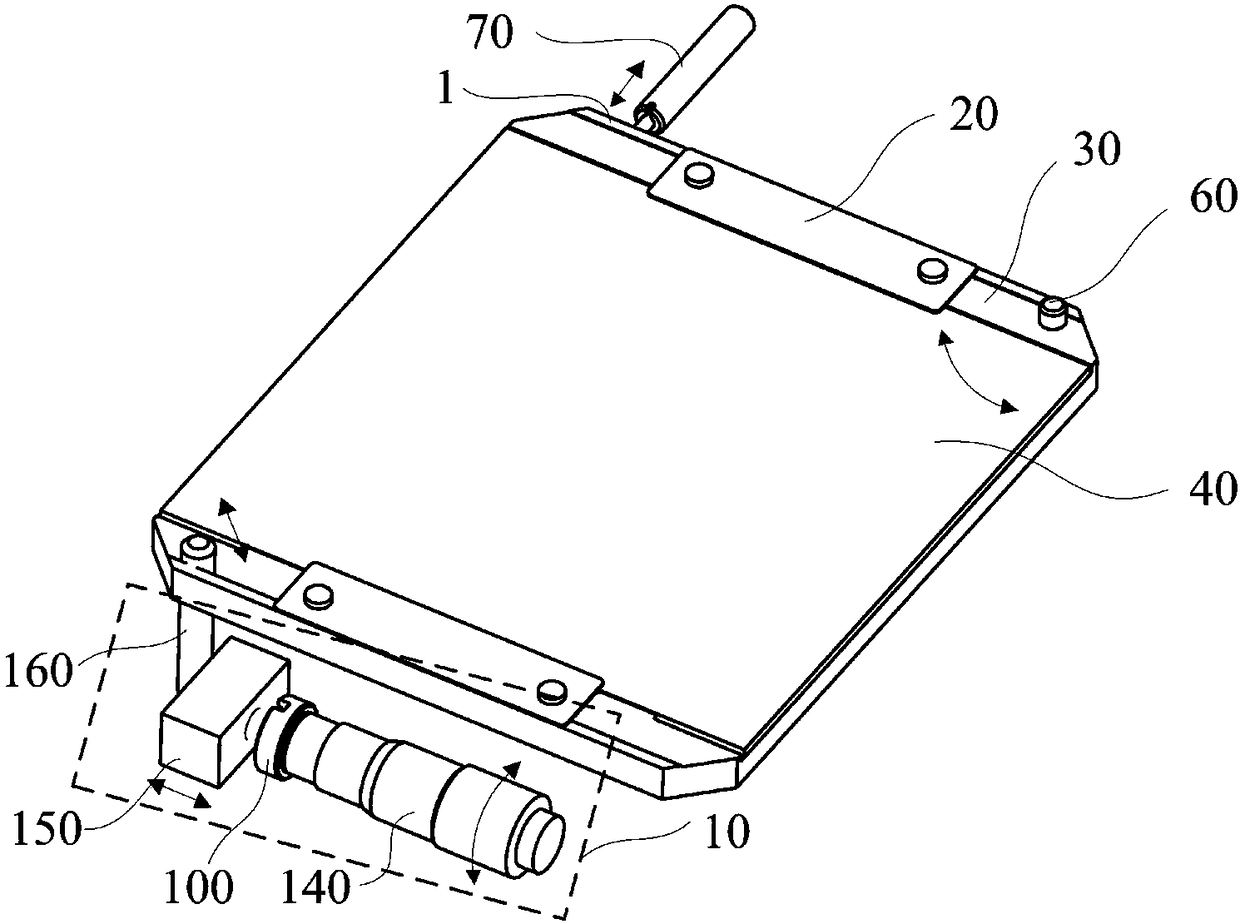

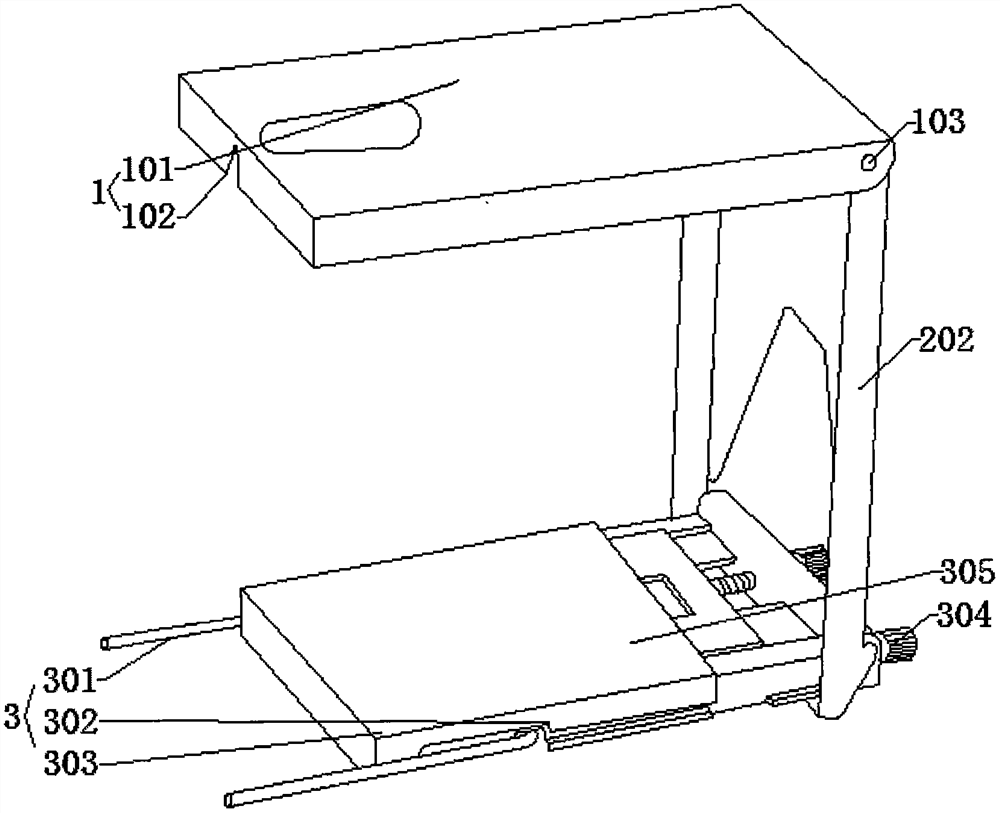

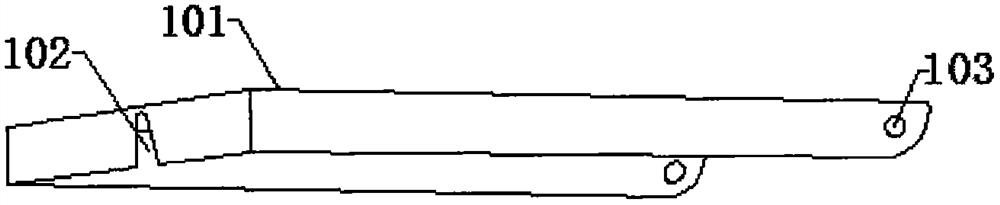

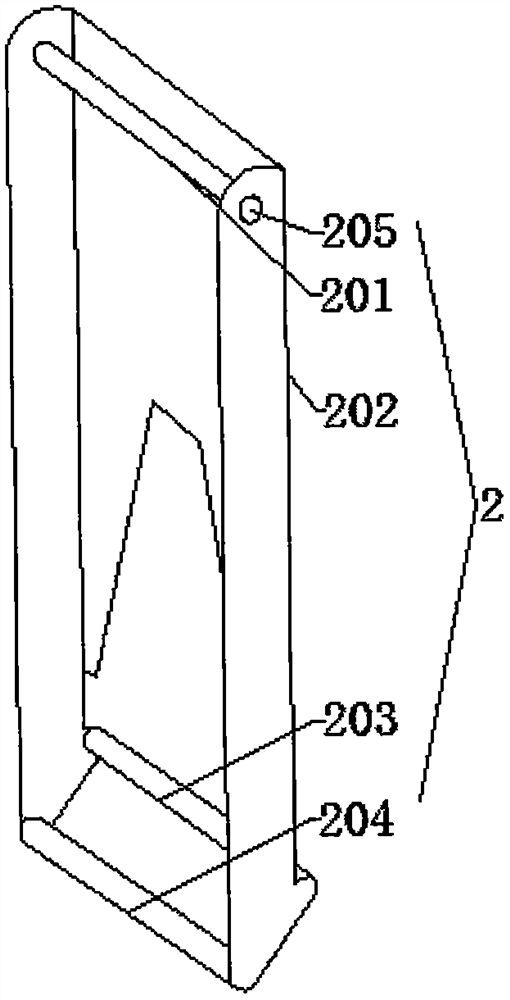

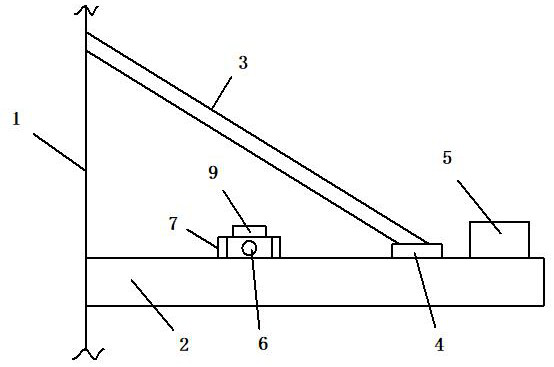

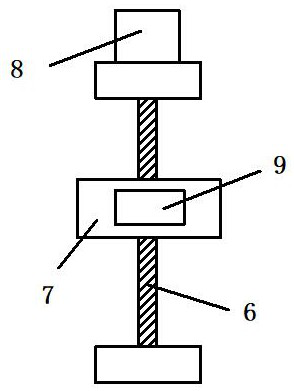

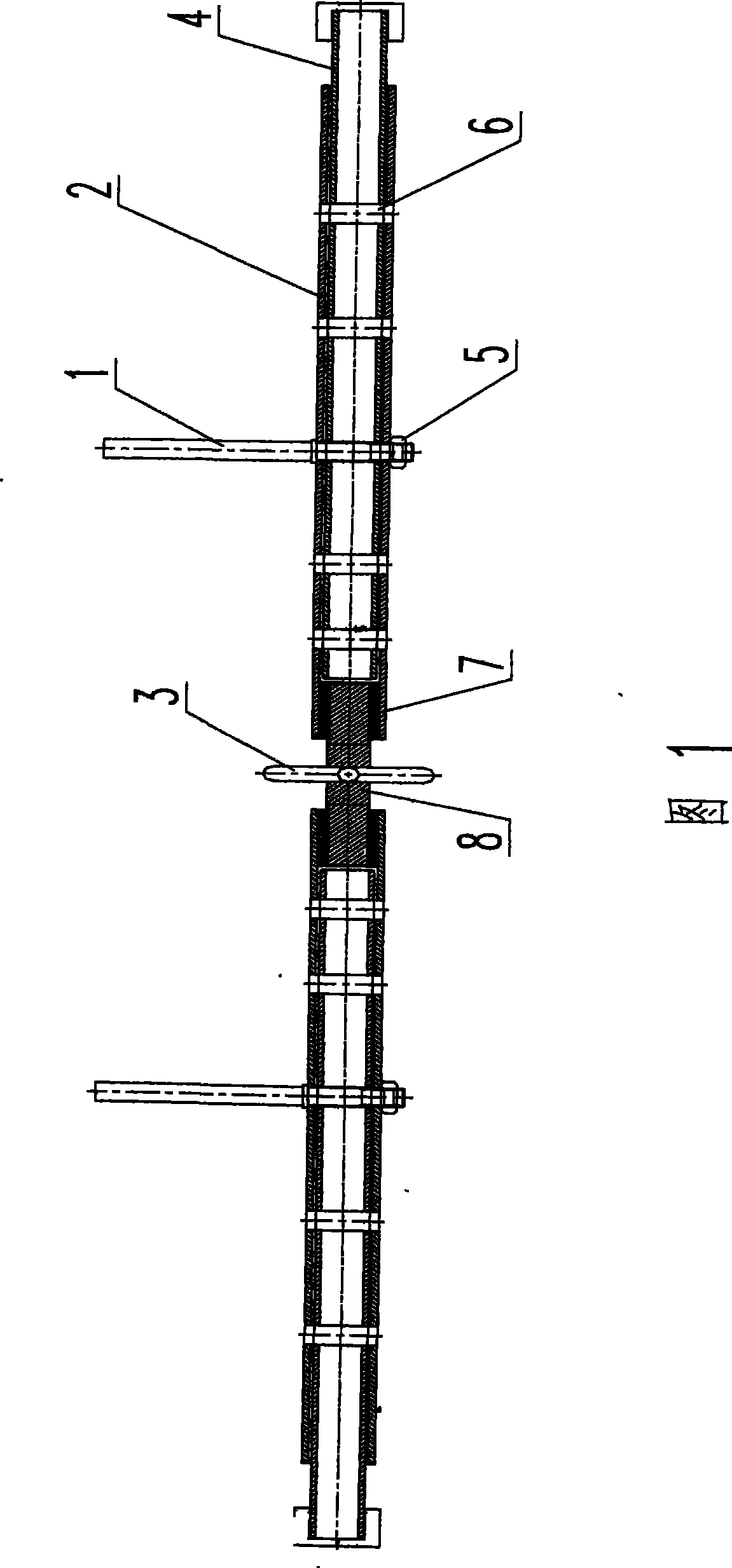

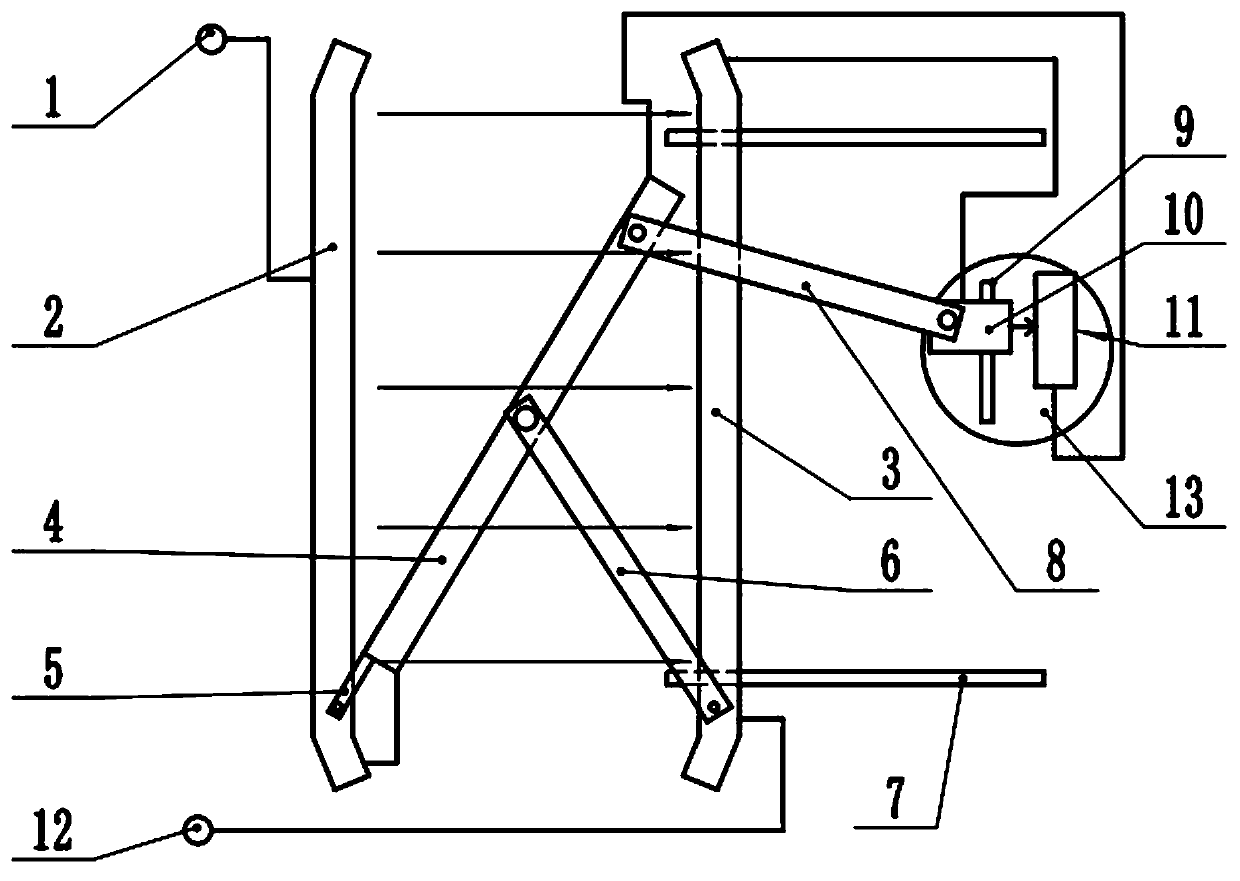

Movable assembling frame for assembled wall

ActiveCN112049434AQuick assemblyHigh fine-tuning precisionBuilding material handlingClassical mechanicsStructural engineering

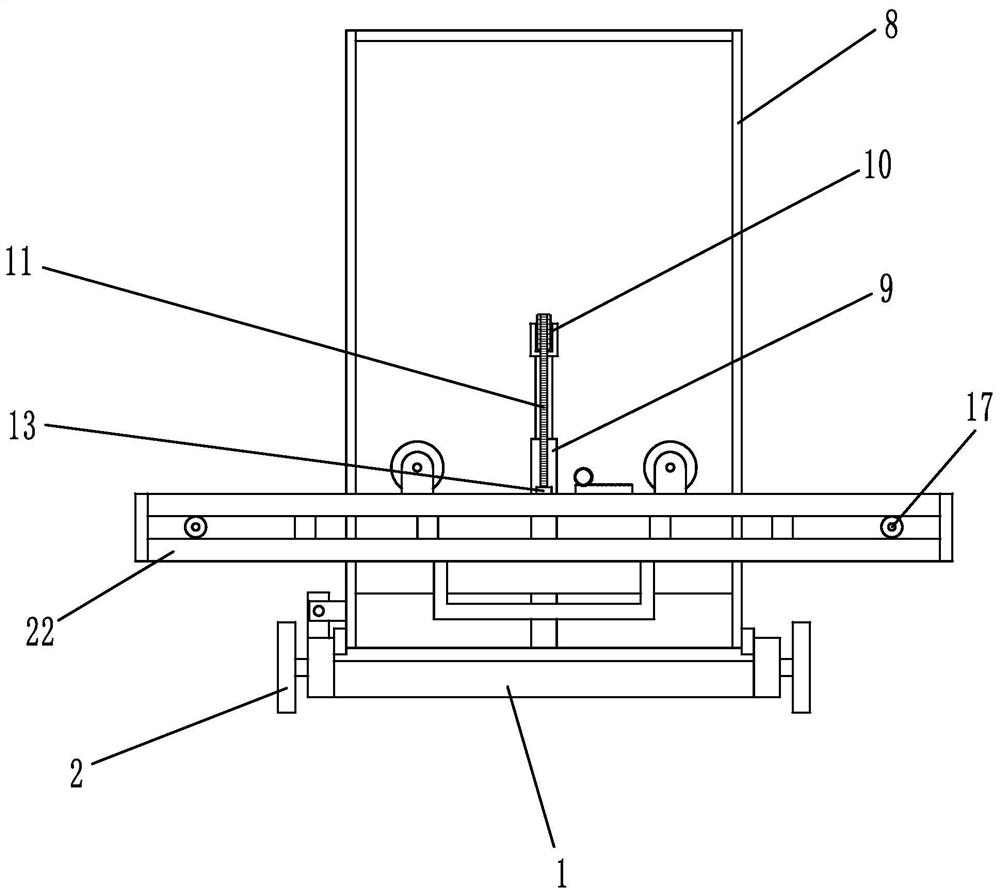

The invention relates to an assembling tool for an assembled wall, in particular to a movable assembling frame for the assembled wall. The movable assembling frame for the assembled wall comprises a tackle, a supporting device, a lifting mechanism, a translation fine adjustment mechanism, a turnover adjusting mechanism and a feeding adjusting mechanism; a rail for the supporting device to slide isarranged on the tackle; the supporting device comprises a sliding base and a support, the support comprises a vertical frame and an adjusting frame connected with the vertical frame in an up-down sliding manner, and a positioning pin is arranged on the adjusting frame; the lifting mechanism is used for driving the adjusting frame to lift up and down; the translation fine adjustment mechanism is used for driving the adjusting frame to horizontally translate; the turnover adjusting mechanism is used for driving the adjusting frame to vertically turn over; and the feeding adjusting mechanism isused for driving the sliding base to feed on the tackle. The movable assembling frame has the beneficial effects of being convenient to transport, capable of effectively conducting assembly fine adjustment according to the situation of an assembled part, convenient to operate and the like.

Owner:徐优富

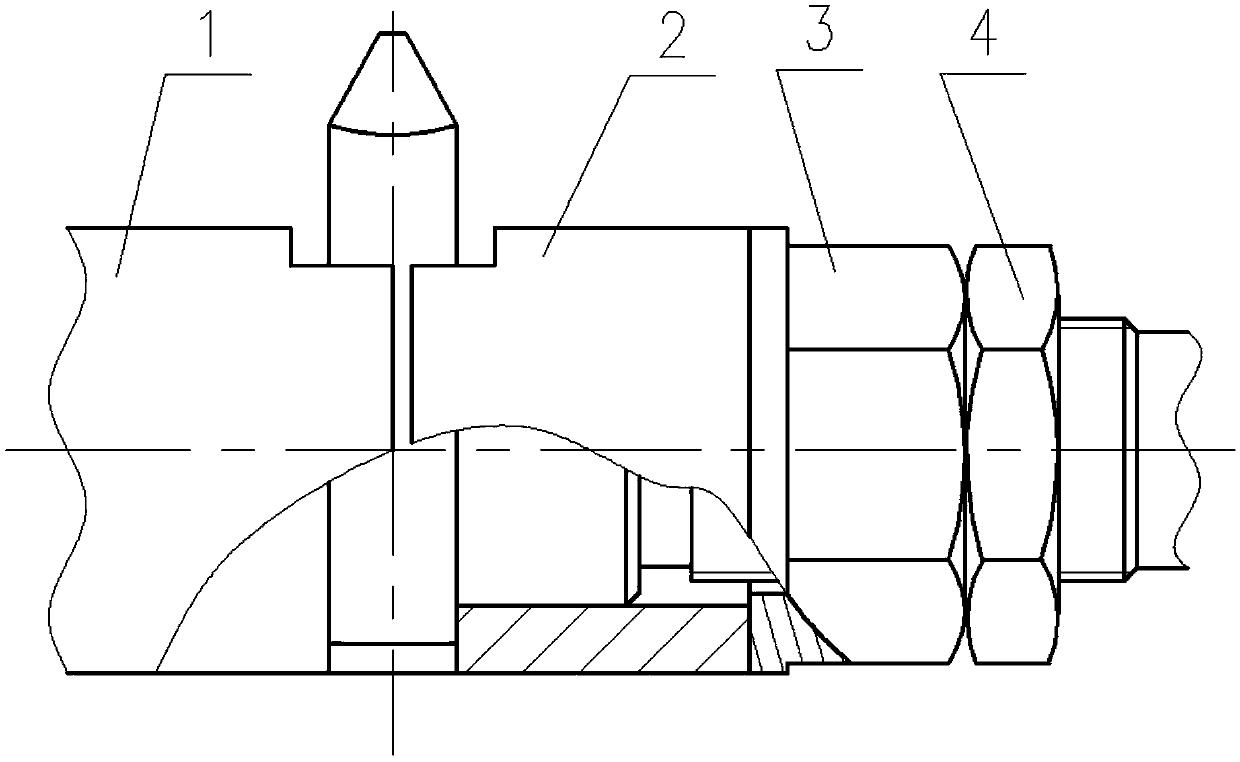

Fine adjustment device for slide block of four-column overhead oil cylinder press

Owner:JDM JINGDA MASCH (NINGBO) CO LTD

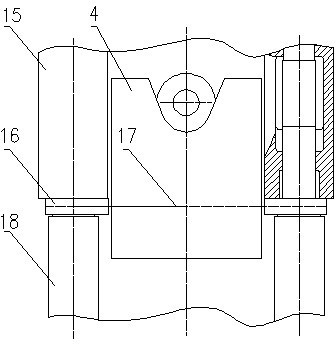

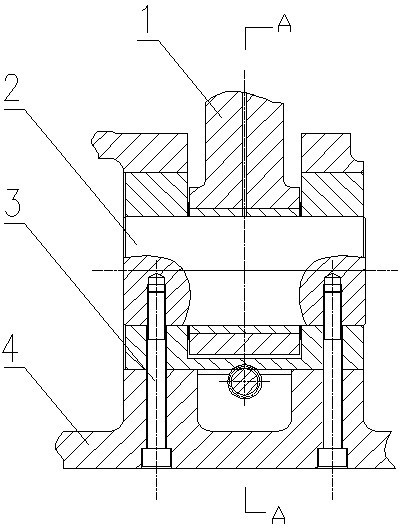

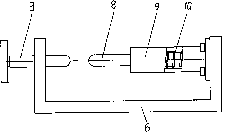

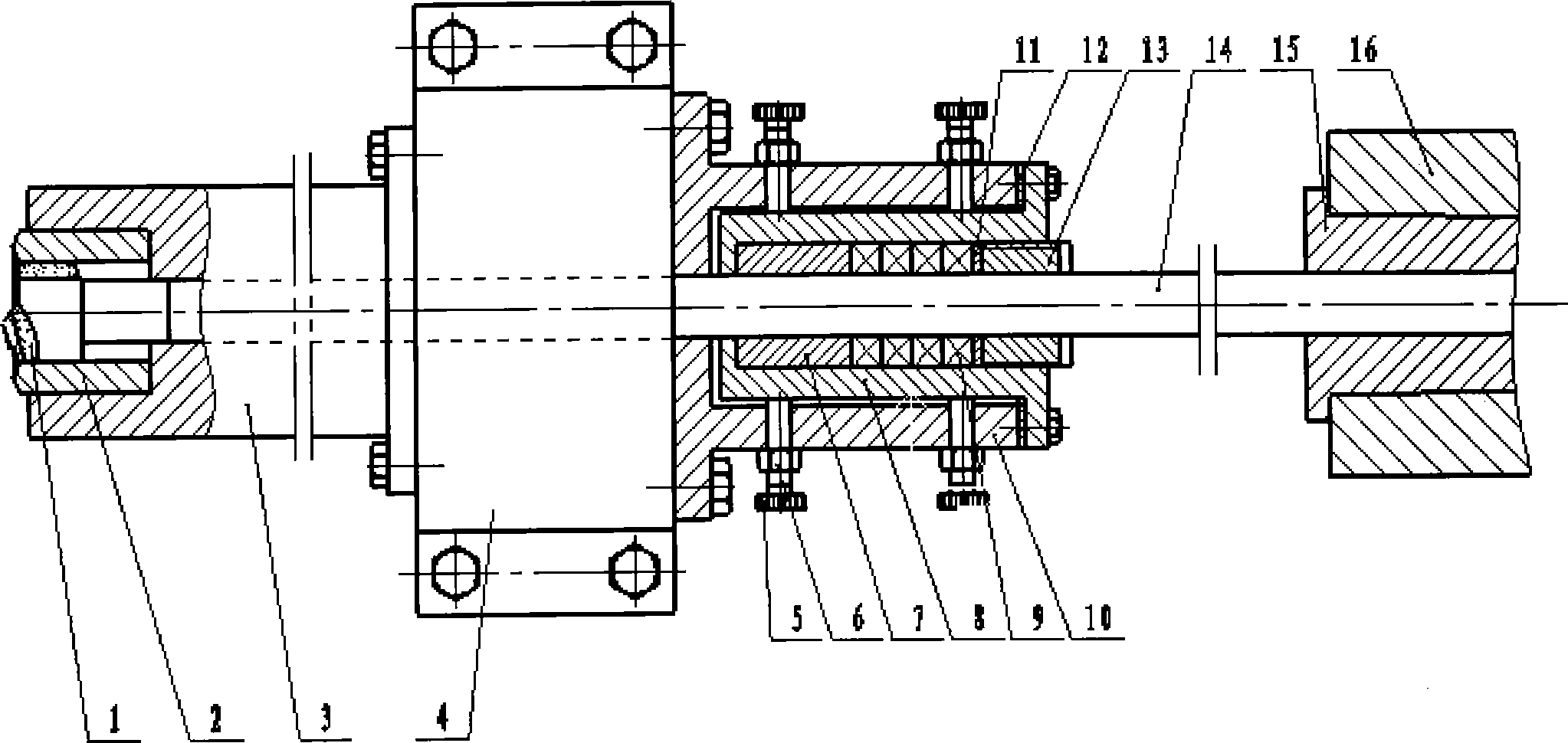

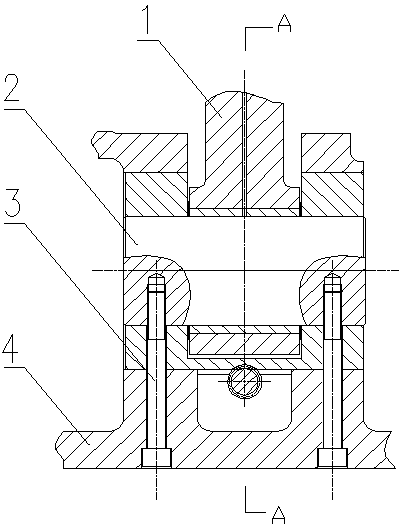

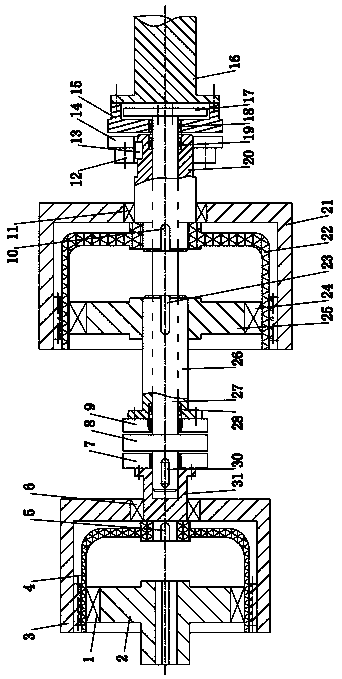

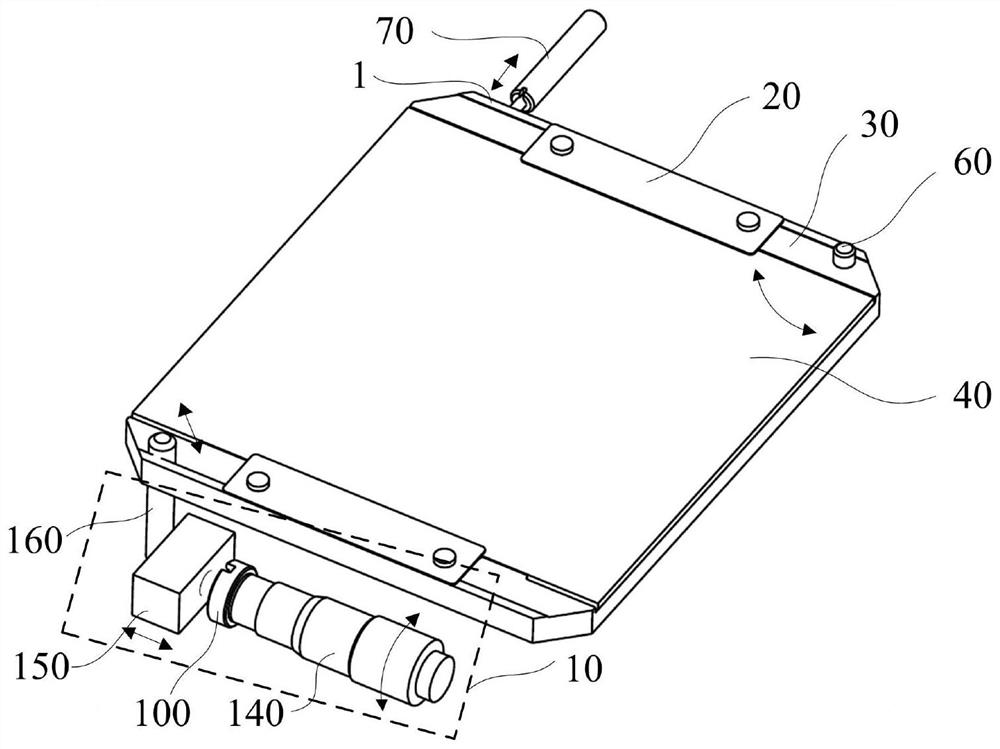

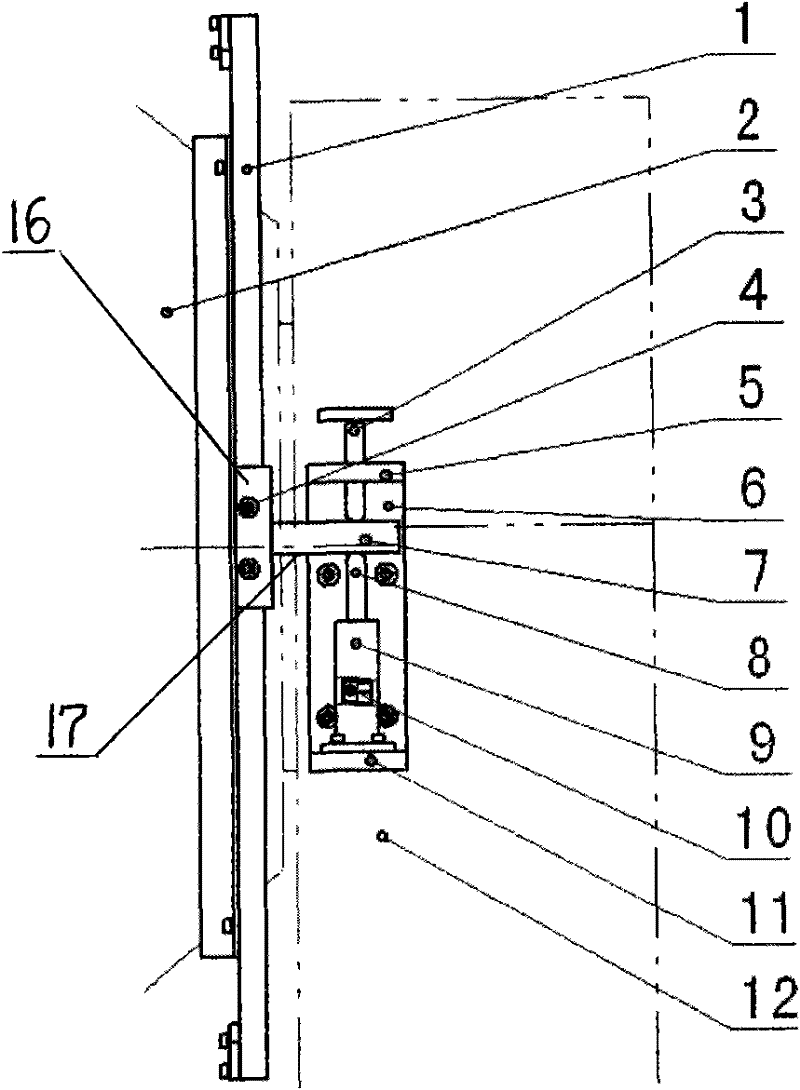

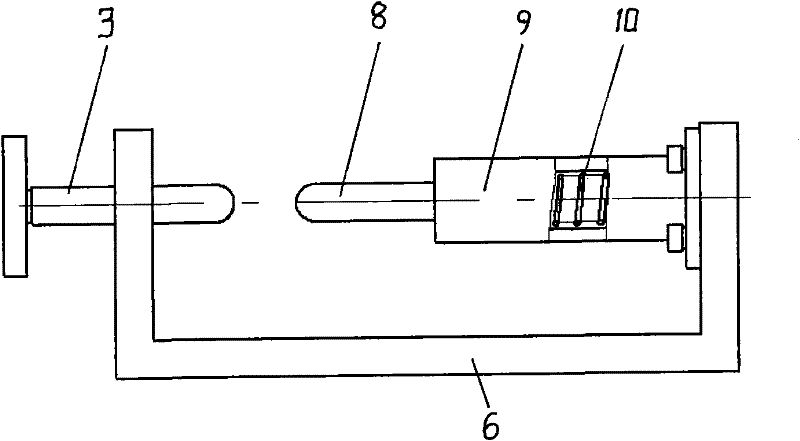

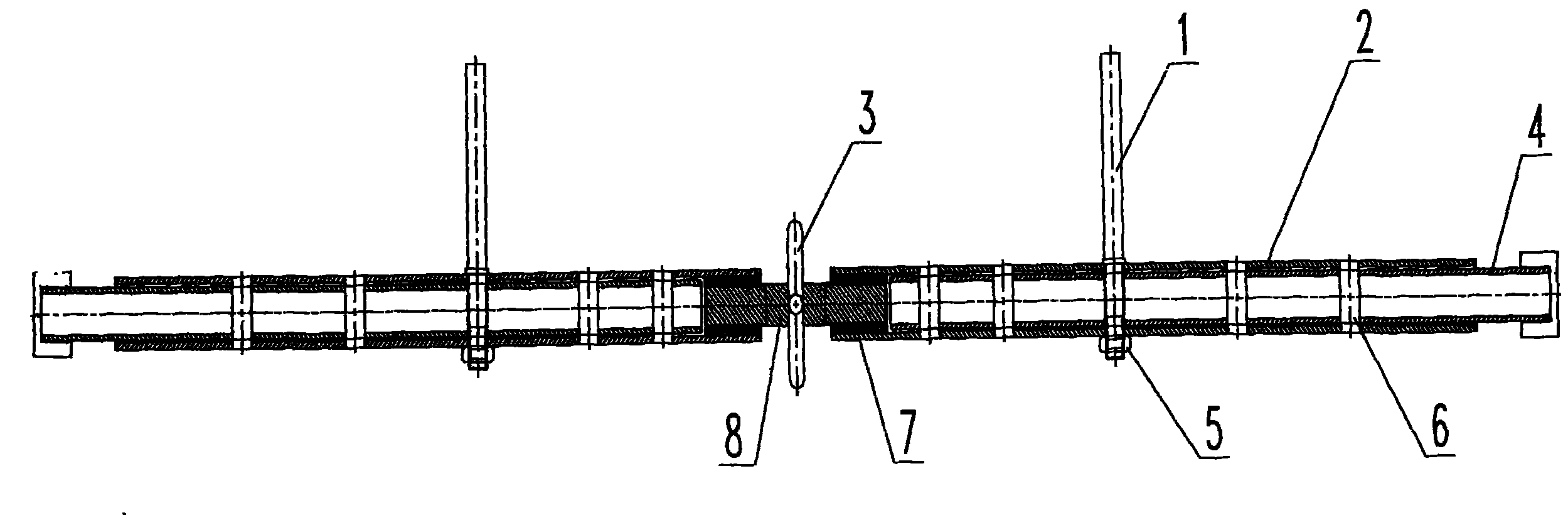

Fine-tuning device for detecting and tuning horizontal axis of telescope and theodolite

InactiveCN101825474ASimple structureEasy to operateMeasurement devicesTelescopesTheodoliteHorizontal axis

The invention discloses a fine-tuning device for detecting and tuning the horizontal axis of a telescope and a theodolite which relates to a fine-tuning device for a detecting instrument. The fine-tuning device comprises a full-circle slide unit, a fine-tuning screw, a fine-tuning sliding block, a fine-tuning base, an ejector pin, a spring and a spring sleeve. The full-circle slide unit is fixed to a cross of the telescope or the theodolite; the fine-tuning sliding block is fixed on the full-circle slide unit; the fine-tuning screw penetrates through a top plate of the fine-tuning base and supporting the fine-tuning sliding block; the spring sleeve is arranged on a lower plate of the fine-tuning base; the ejector pin is arranged inside the spring sleeve; the lower end of the ejector pin penetrates through the upper end of the spring sleeve and is connected with the spring inside the spring sleeve while the upper end of the ejector pin props up the fine-tuning sliding block; and the fine-tuning base is fixed on a column of the telescope or the theodolite. The fine-tuning device has simple structure, convenient operation, low cost, high fine-tuning precision, convenient disassembly and wide application.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

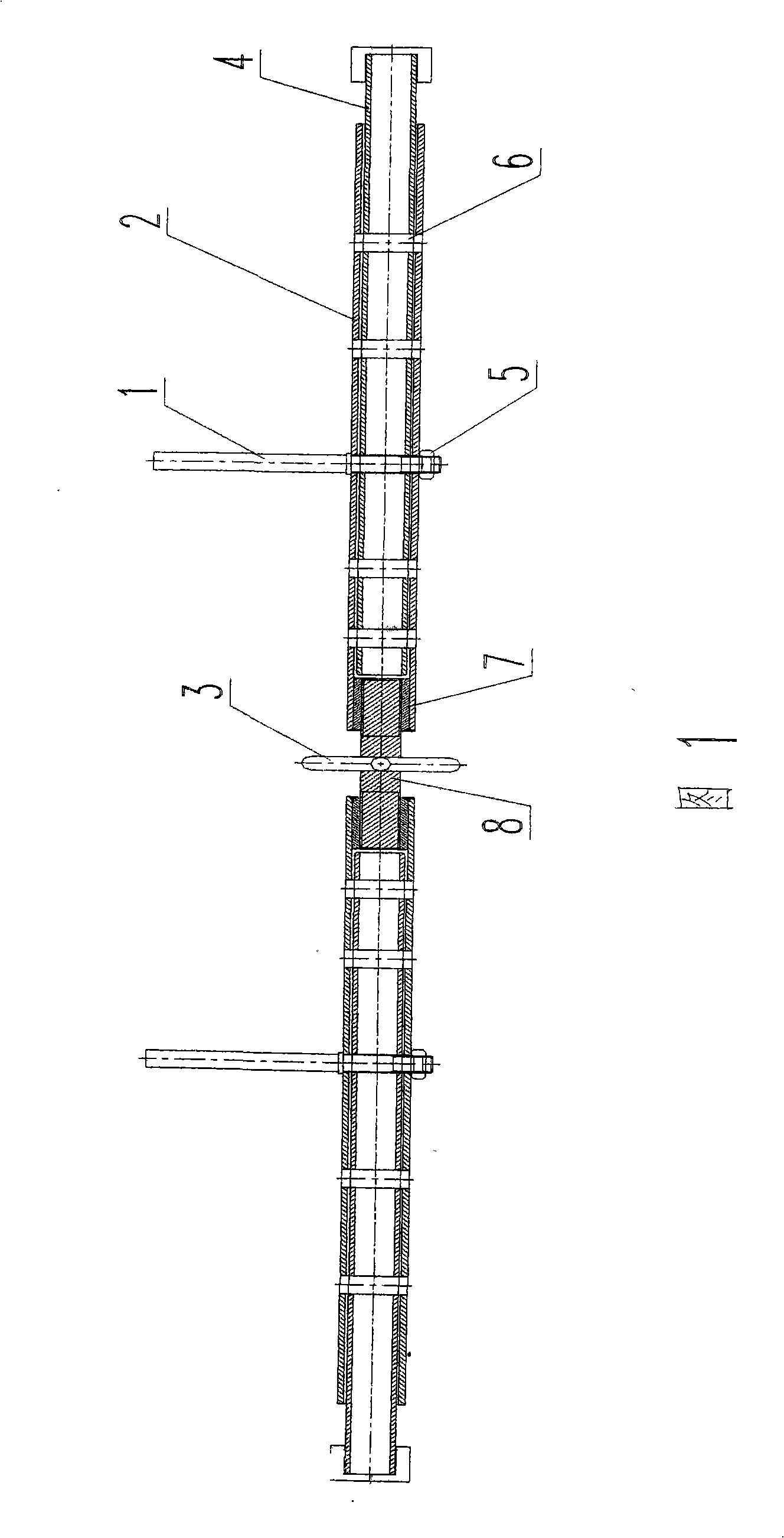

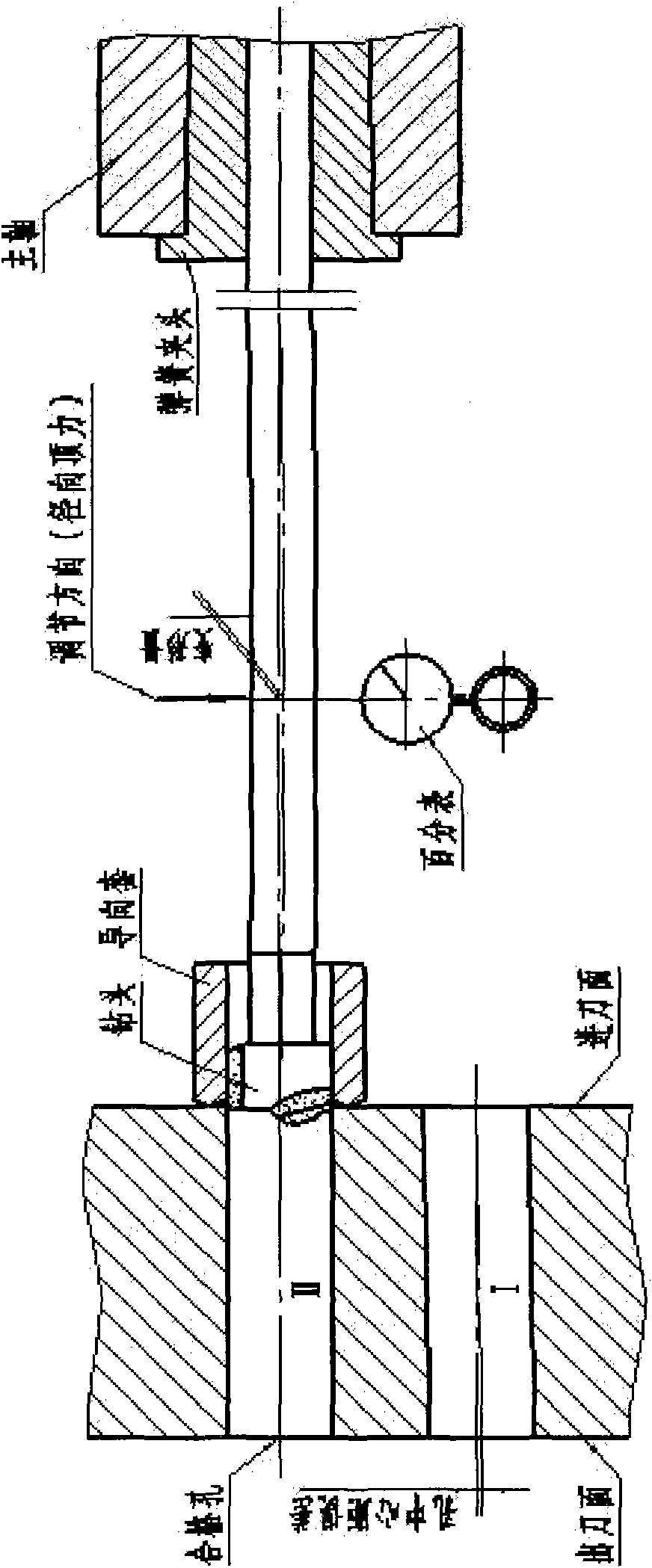

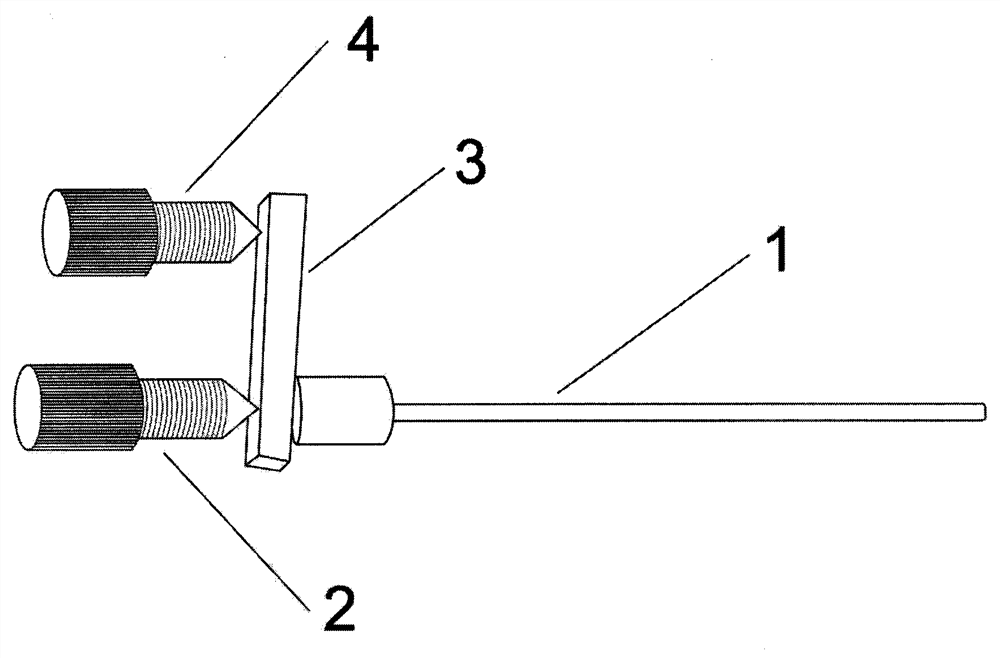

Support tools for equipment assemble

InactiveCN101254581AImprove versatilityHigh fine-tuning precisionMetal working apparatusScrew threadScrew cap

The invention relates to a support tool for assembling equipment. The prior art can achieve equipment assembly through cooperation of a plurality of workers but fails to achieve fine adjustment of the equipment pitch. The support tool is characterized in that a plurality pairs of pin holes with different distances arranged on sleeves and a support pipe on the left and the right sides are combined to carry out pitch coarse adjustment, and a middle hand wheel is used for driving the sleeves connected with each other through a left and a right rotating threads to retract and extend, thus achieving fine adjustment. The support tool consists of a fixing pin, the sleeves, the hand wheel, the support pipe, a fastening screw cap, fixing pin holes, an adjusting screw nut, an adjusting screw and a wood ferrule. The support tool has the positive effects of good generality, high accuracy for fine adjustment, lowered cost and improved work efficiency, and is a labor-saving, time-saving and work-saving assistant tool.

Owner:SHANGHAI FORWARD MASCH CO LTD

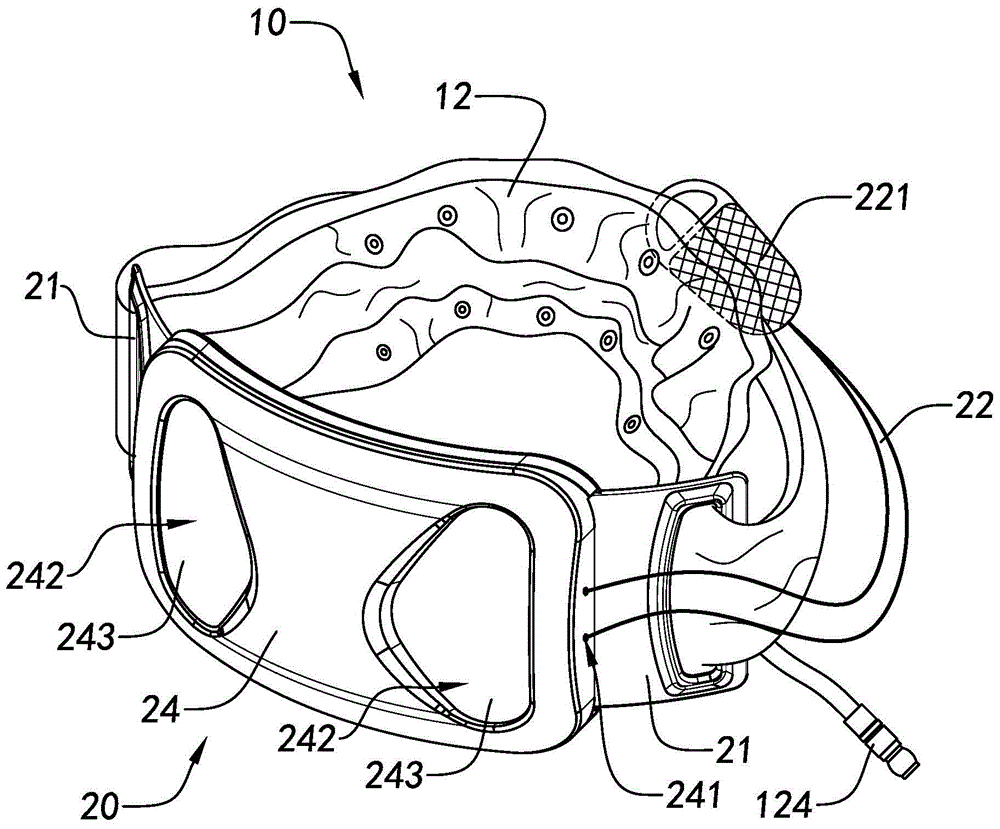

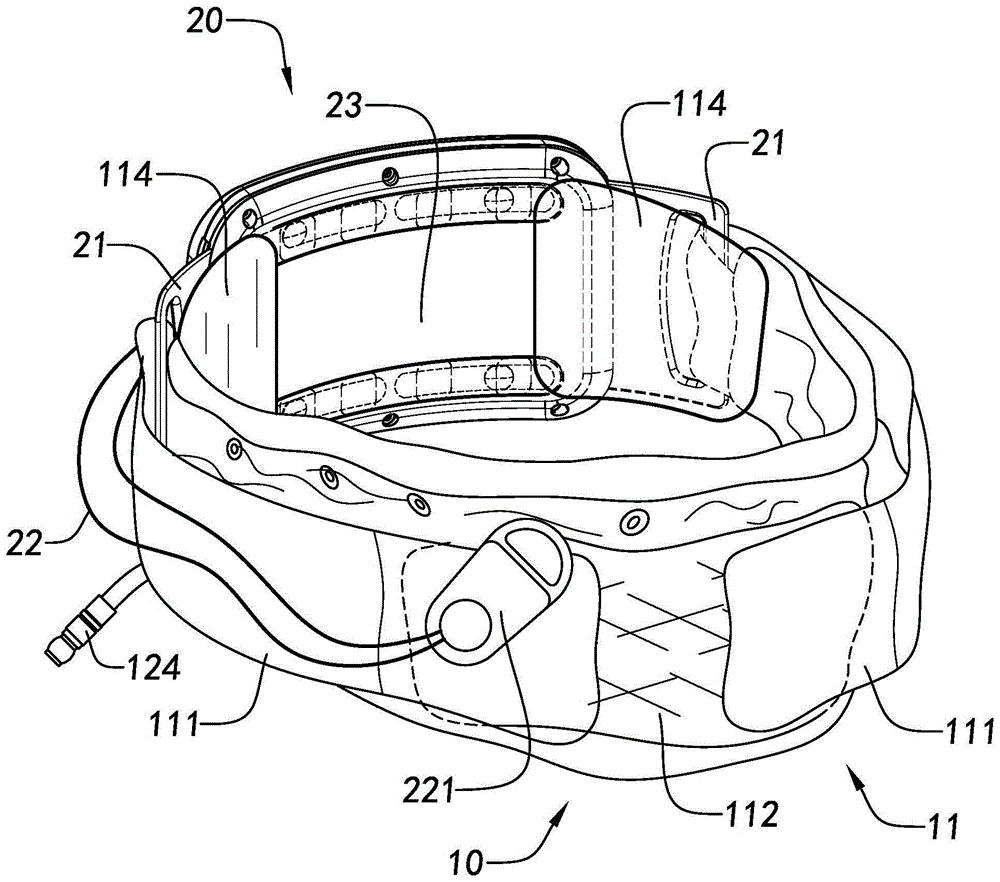

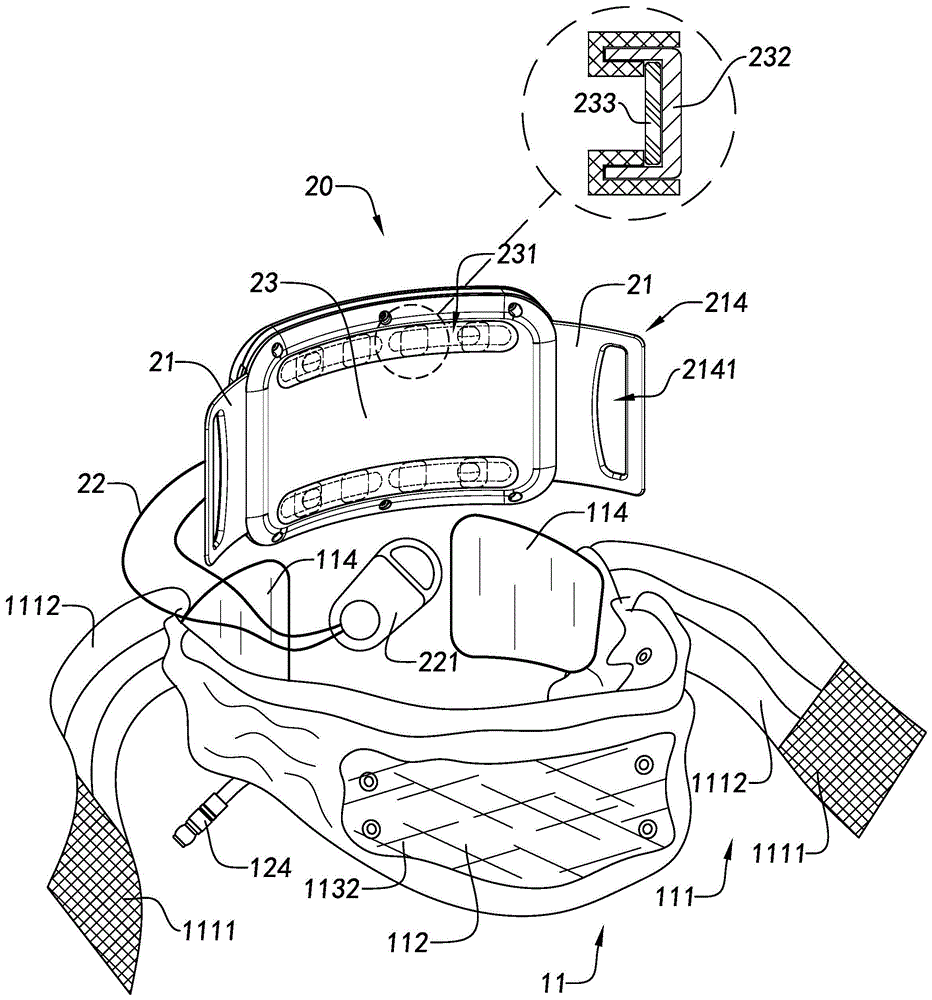

Expansion belt, and adjusting device and adjusting method thereof

PendingCN106551744AAdjustable sizeHigh fine-tuning precisionChiropractic devicesFractureMechanical engineeringEngineering

Owner:JIANGSU ALPHAY MEDICAL DEVICE

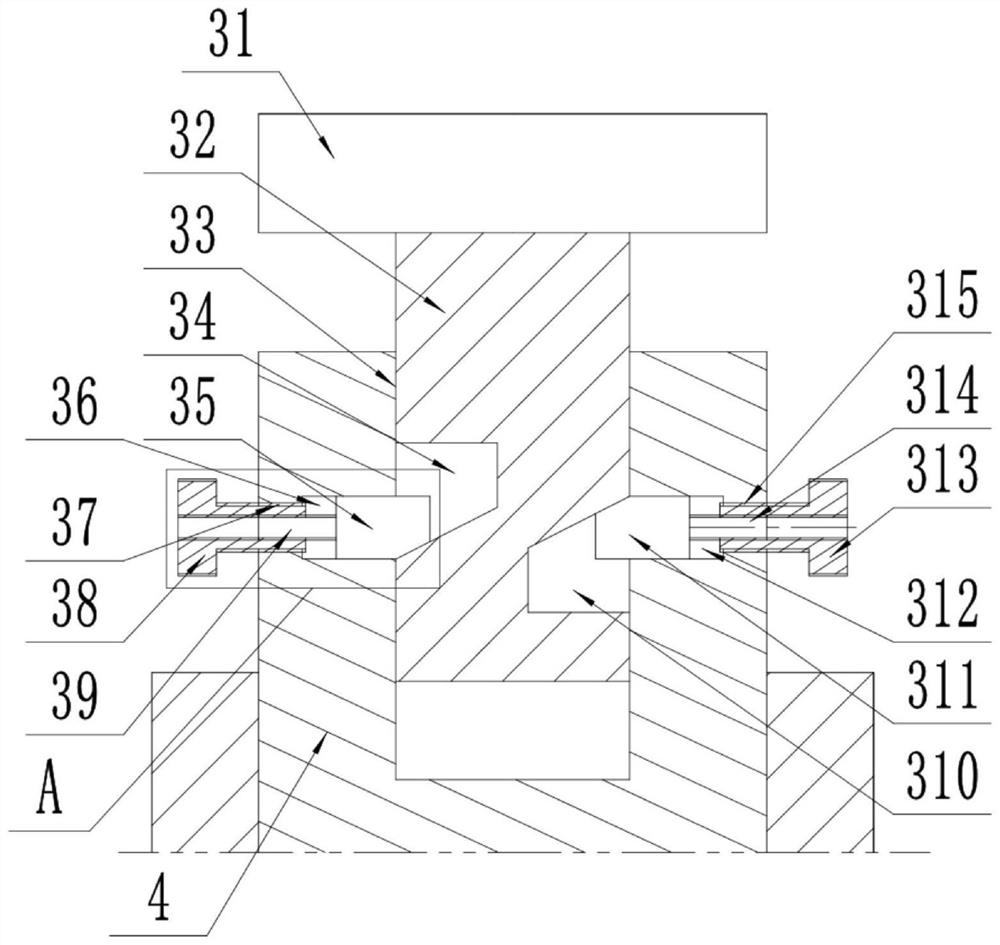

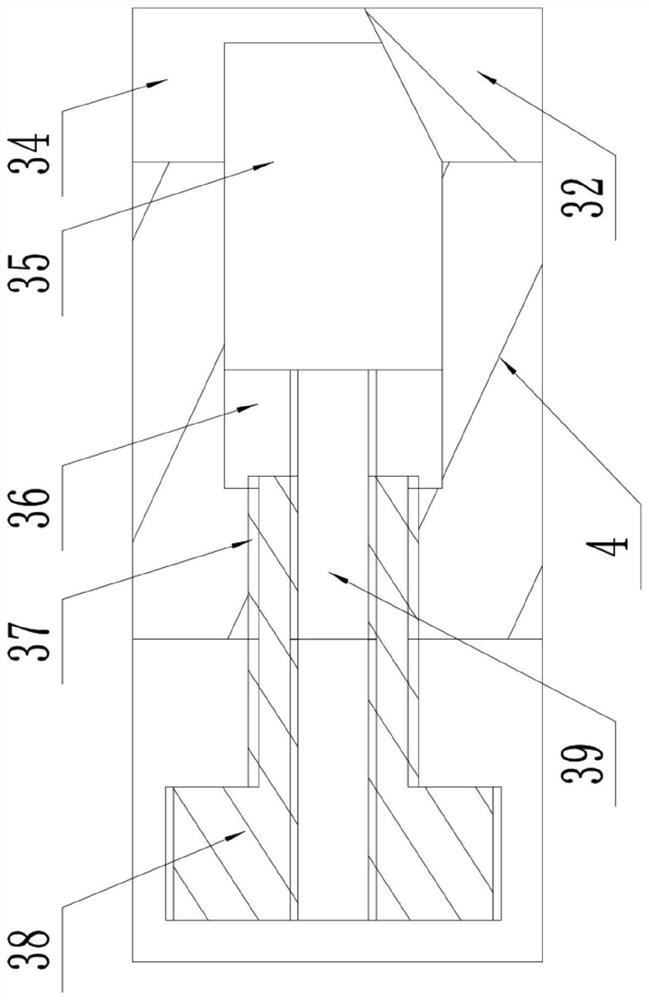

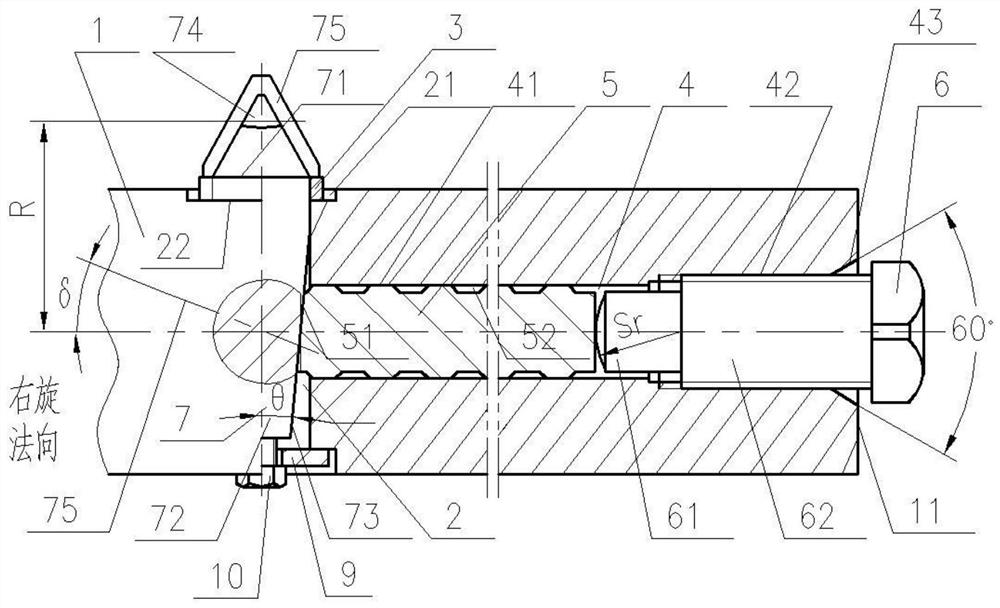

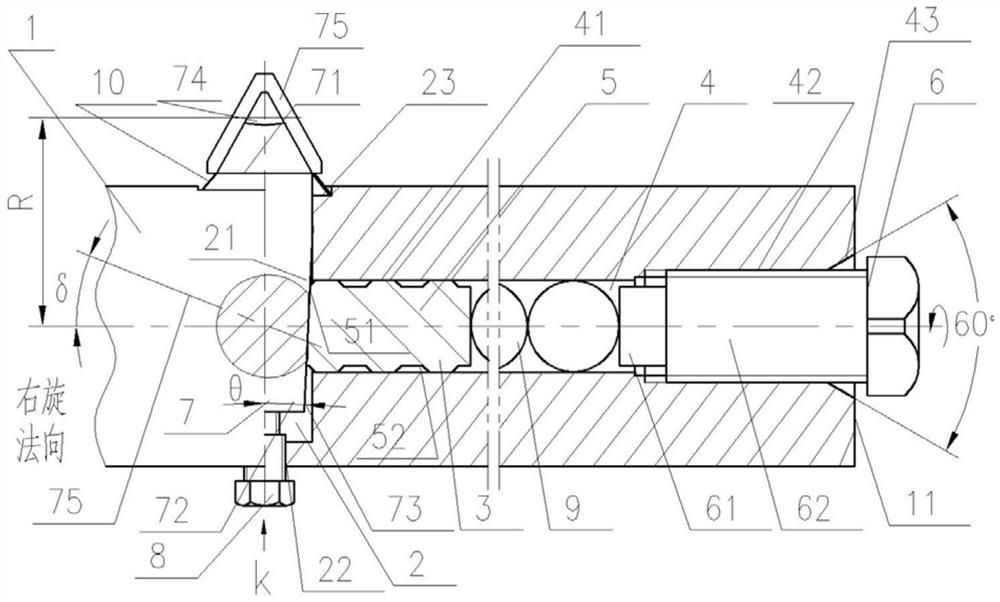

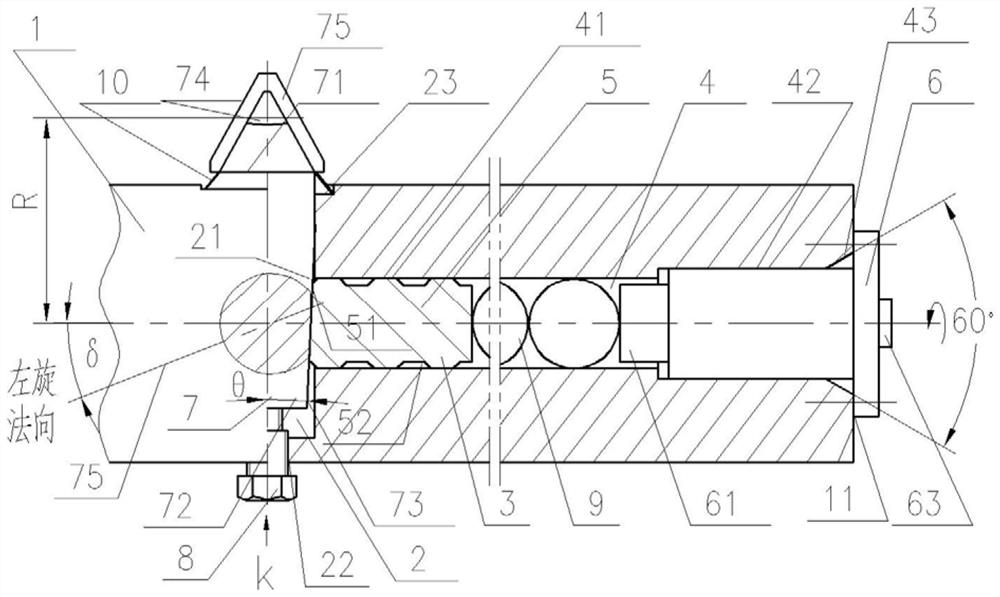

Double vertical clamping structure for finely adjusting double-worm-wheel fly cutter radially

PendingCN111283273AFlexible movementFlexible anti-rustWorm wheelsGear-cutting machinesEngineeringStructural engineering

The invention discloses a double vertical clamping structure for finely adjusting a double-worm-wheel fly cutter radially. A center hole which faces the active end and is concentric with a rotating central line of a cutter bar is formed in the passive end of the cutter bar, two parallel two-section stepped concentric holes for mounting, clamping and finely adjusting the fly cutter are radially formed along the rotating central line of the cutter bar, large holes of the two-section stepped concentric holes are cylindrical holes, small holes of the two-section stepped concentric holes are screwthrough holes, and the center distance between the two-section stepped concentric holes is the axial tooth pitch of a working worm; two sections of threads which are the same in screwing direction anddifferent in screw pitch are arranged on a locking screw and correspondingly connected with the screw through holes and a screw hole formed in a fly cutter round straight handle, so that the fly cutter is never loosened after being finely adjusted and clamped in the radial direction of the cutter bar; and a positioning clamping mechanism is arranged in the center hole, the oblique end faces of the opposite ends of a positioning jacking rod slide onto the obliquely-beveled plane of the fly cutter round straight handle to form close face contact under the combined action of the locking screw and a force applying component, and the fly cutter is fastened in the corresponding cylindrical hole and located at the correct position. The radial fine-adjusting and positioning double vertical clamping technical scheme is suitable for high-precision and large-cutting-force rolling cutting of multi-head worm wheels.

Owner:中钢集团衡阳机械有限公司

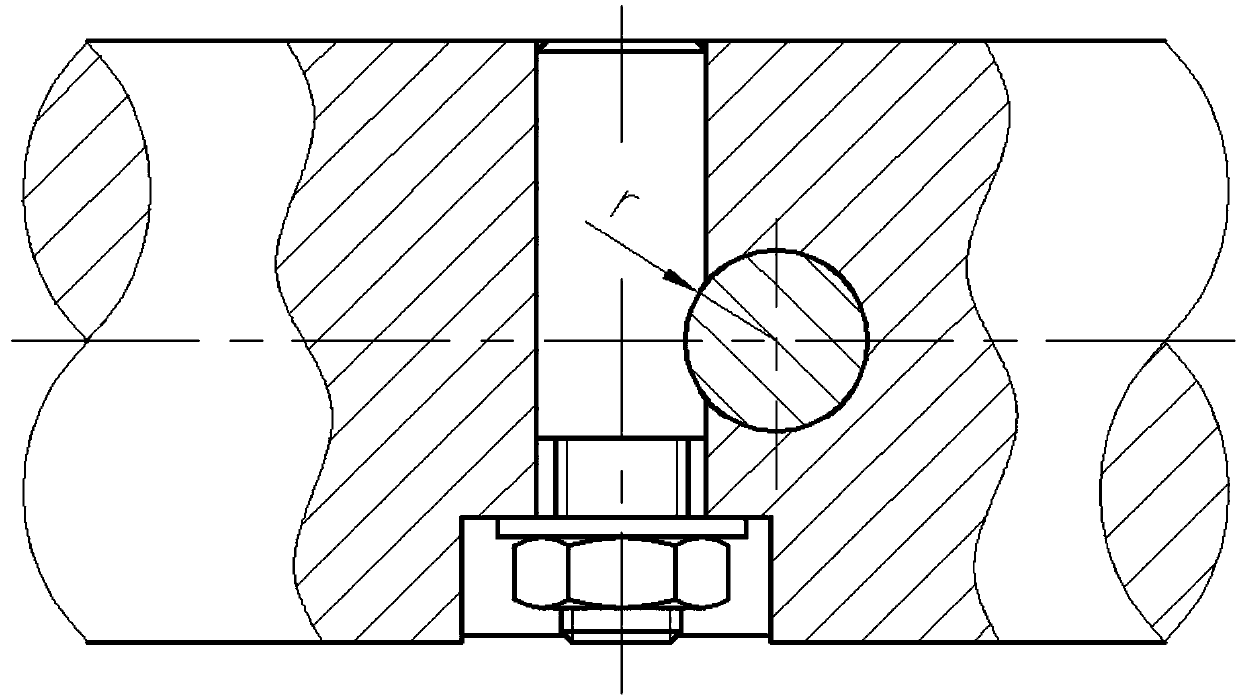

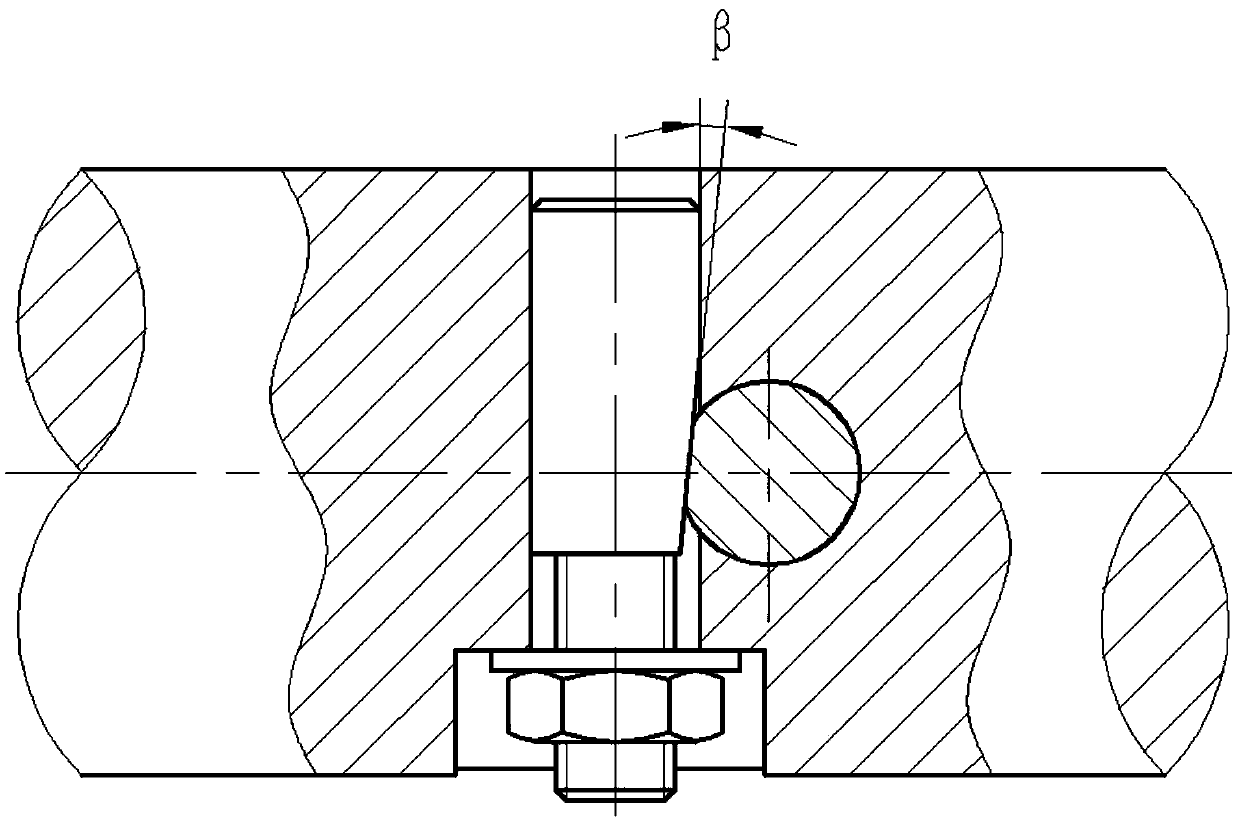

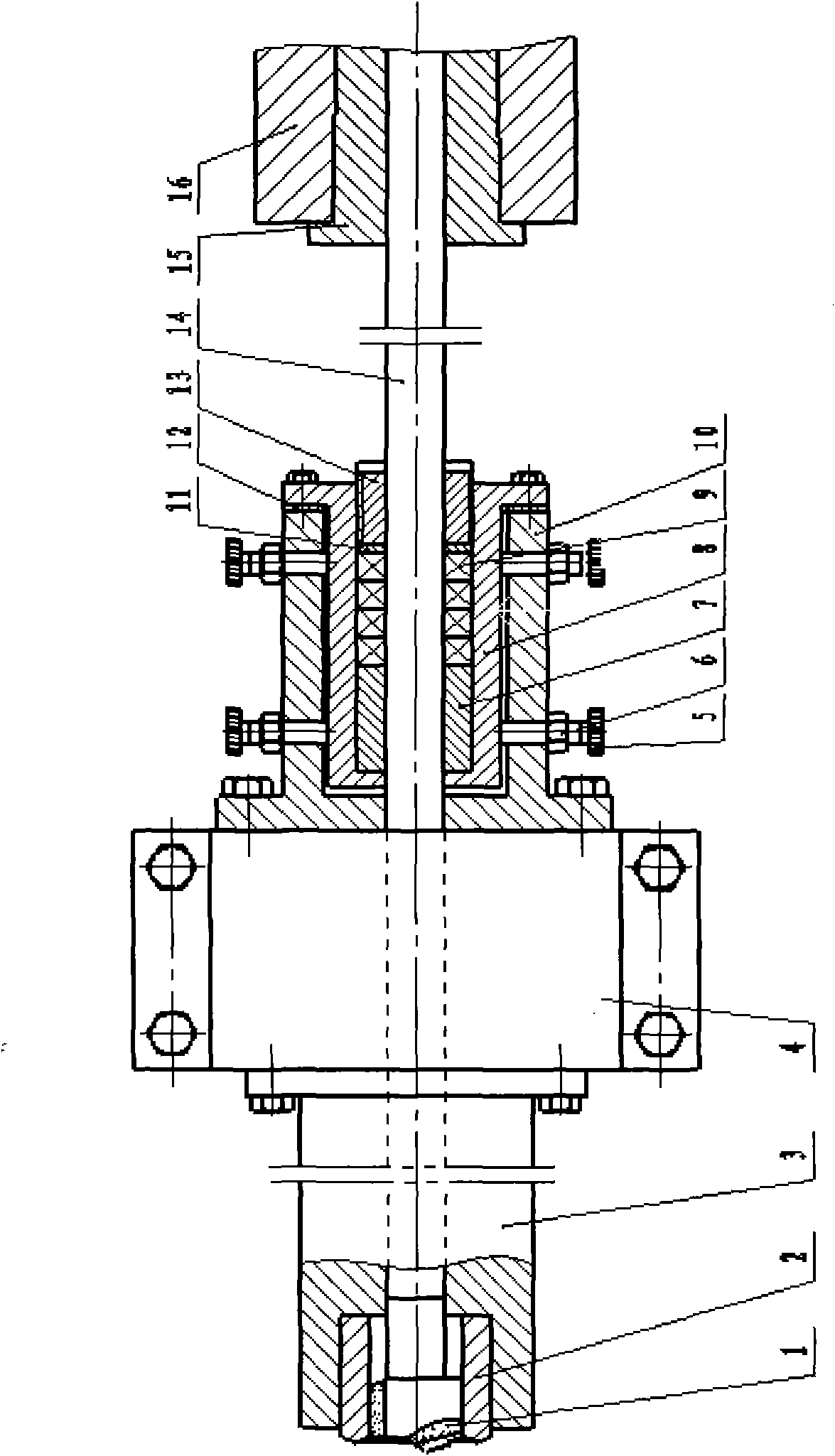

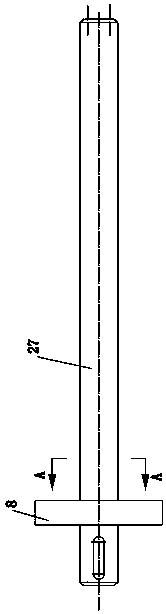

Hole pitch error correction system for numerical control multi-spindle deep hole drilling machine

InactiveCN102581347AImprove machining accuracyHigh fine-tuning precisionDrilling/boring measurement devicesNumerical controlEngineering

The invention relates to a drill spindle system for a multi-spindle deep hole drilling machine. Errors of a plurality of drill spindles for drilling deep holes are corrected by means of mechanical elastic deformation principle. The drill spindle system is characterized in that a drill rod slightly bends and elastically deforms when the acting force of a fine adjustment screw acts at the center of the drill rod, the deformation of the drill rod is determined by means of calculation according to the hole pitch error value of a tool discharge surface of a drilled workpiece (namely the back surface of the workpiece), the position of a drill bit in a drill bushing is slightly shifted relative to an original position at the moment, and the offset value of the drill bit exactly compensates the hole pitch error value of the tool discharge surface when the drill bit axially moves to the tool discharge surface of the workpiece in a drilling manner. The drill rod reliably and axially moves in a drilling manner through a guide sleeve of an embedded structure, holes of different sizes can be machined by changing drill bits, drill rods and buttress sleeves of different sizes, and the hole pitch error correction system enables the drill spindles of the multi-spindle deep hole drilling machine to simultaneously drill 1000mm deep holes with extremely small adjacent hole pitch errors and accumulated hole pitch errors.

Owner:上海悦英机械设备制造限公司

Angle fine adjustment device of wall-mounted fixing device for wall-mounted instrument

PendingCN113107162AHigh fine-tuning precisionEasy to operateBuilding constructionsReference line/planes/sectorsStructural engineeringMechanical engineering

Owner:李昌象

Fine adjustment device for slide block of four-column overhead oil cylinder press

Owner:JDM JINGDA MASCH (NINGBO) CO LTD

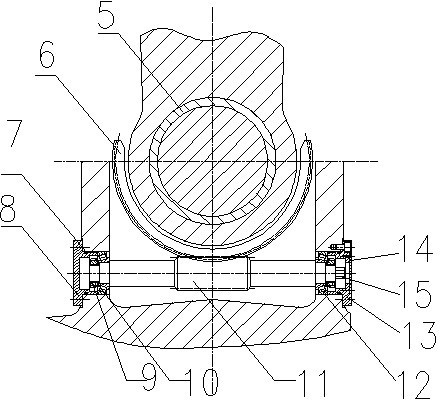

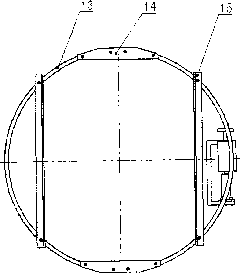

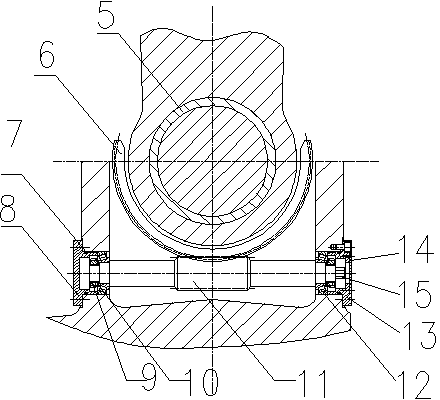

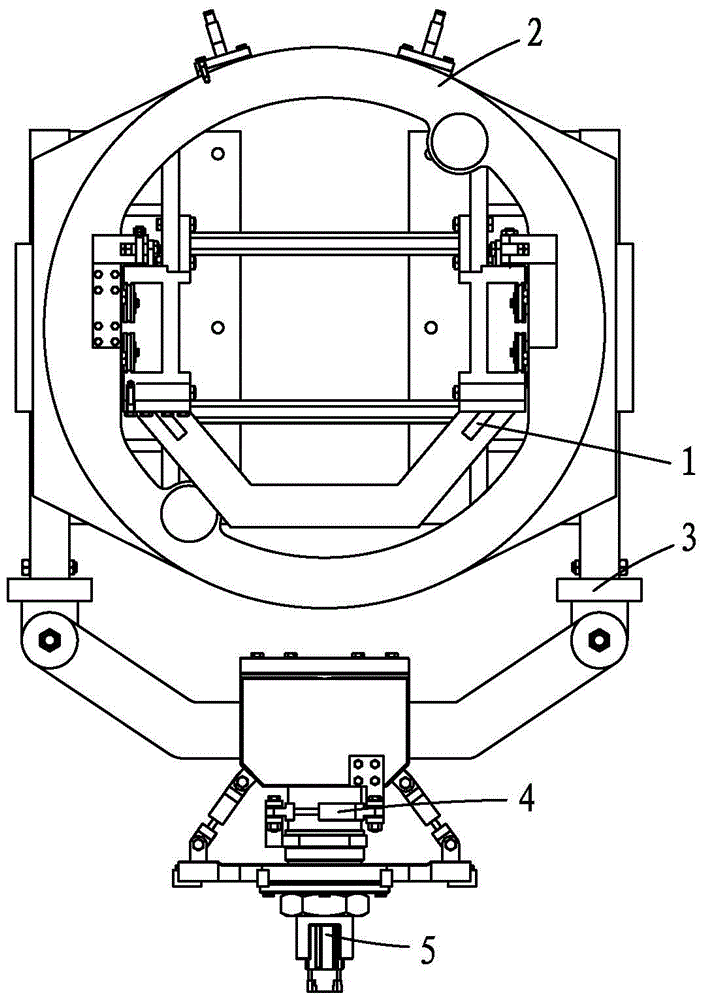

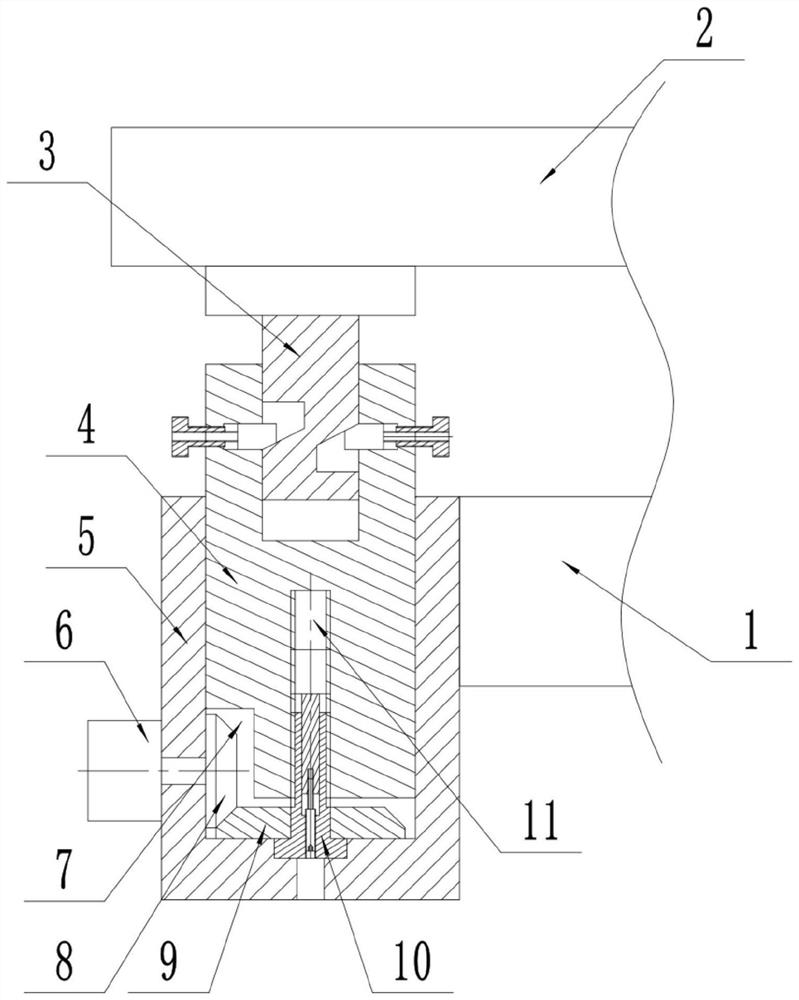

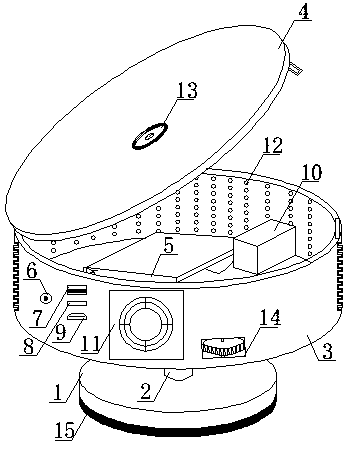

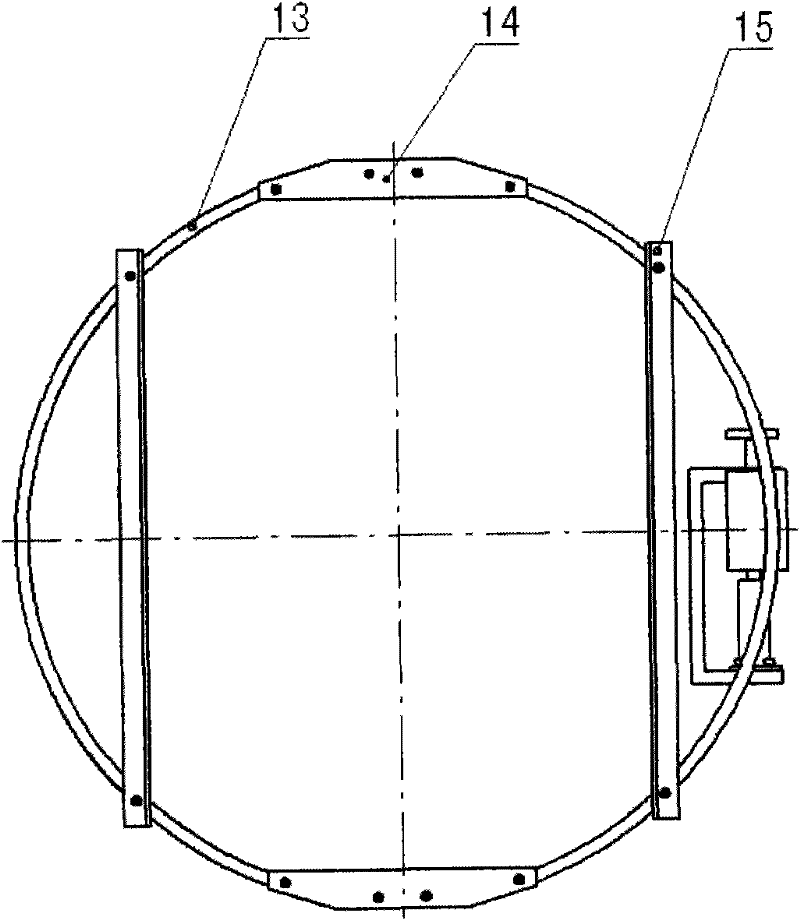

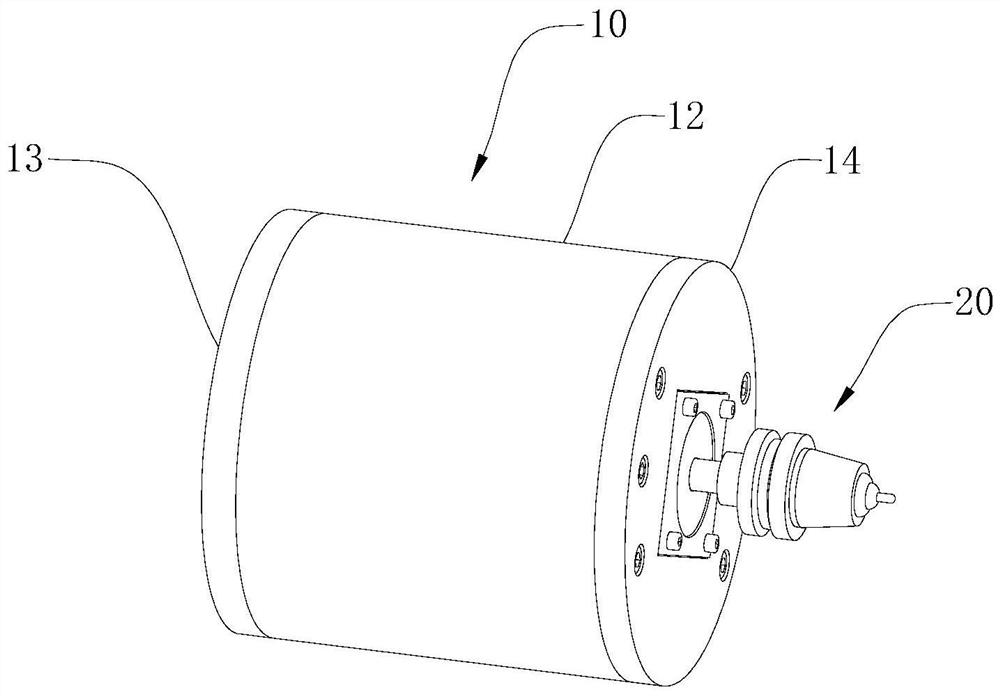

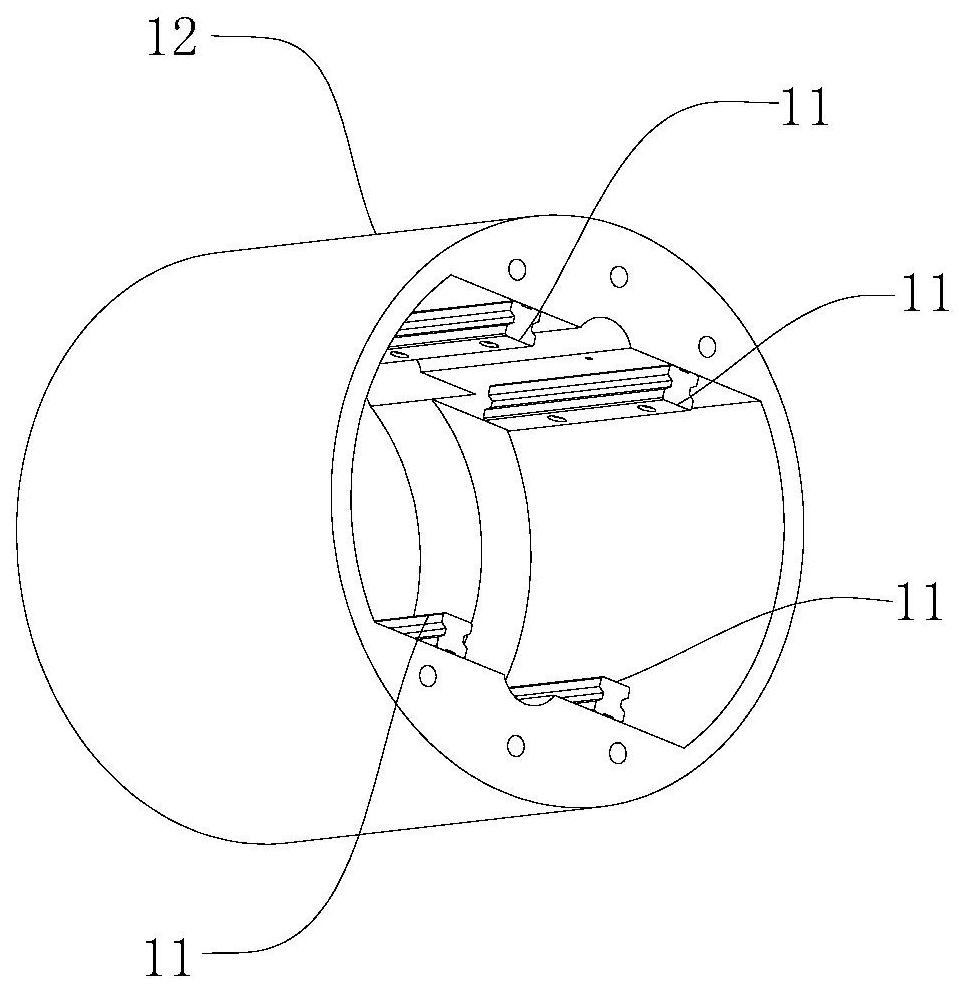

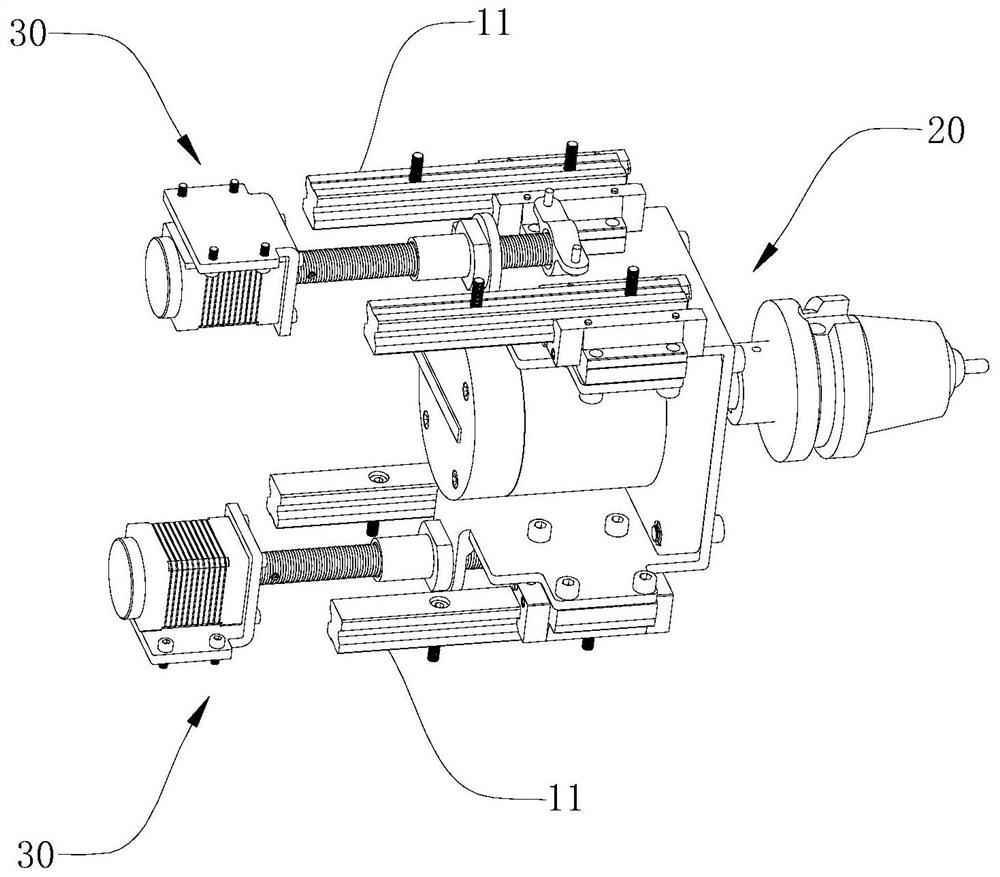

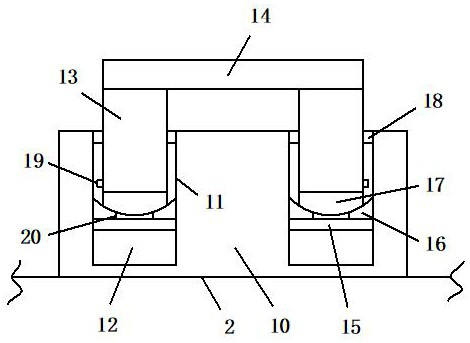

Hydraulic shield machine segment assembly device

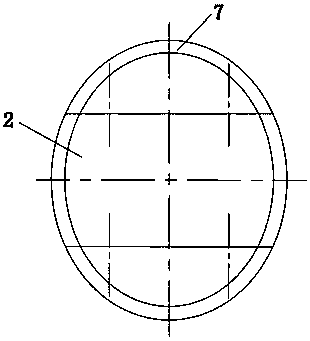

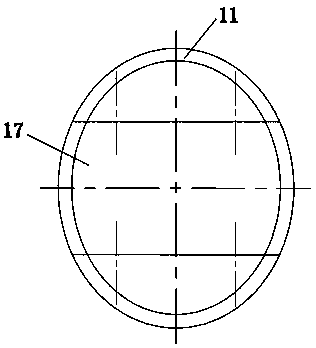

ActiveCN104405414BHigh fine-tuning precisionReduce vibrationUnderground chambersTunnel liningSlewing bearingEngineering

The invention provides a segment assembling device for a hydraulic shield tunneling machine. The segment assembling device comprises a translation system, a rotary system, a lifting system, a fine-tuning system and a grasping system, wherein the translation system is in transition connection with the rotary system through a movable disc body; the rotary system is in transition connection with the lifting system through a rotary disc body; the lifting system is in transition connection with the fine-tuning system through a center joint ball bearing; the fine-tuning system is in transition connection with the grasping system through a fine-tuning shaft. The segment assembling device has the advantages that various actions do not interfere with each other when rolling, pitching and deflection are carried out, so that the stability of the system is improved; the rotary system is connected with the translation system through a single-row four-point-contact ball type slewing bearing, so that vibration of the rotary system is reduced; a simple automatic grasping system is designed, so that grasping is relatively convenient.

Owner:FUJIAN UNIV OF TECH

Machining device capable of accurately adjusting gap

PendingCN114700763ASimple structureReduce manufacturing costLarge fixed membersGear wheelEngineering

The invention discloses a machining device capable of accurately adjusting a gap. The machining device comprises a fine adjustment mechanism, a movable seat, a connecting seat, an adjusting head, a sliding groove, a driving gear, a driven gear, a screw device and a first threaded hole. The device is reasonable and simple in structure, low in production cost and convenient to install, the adjusting head drives the driving gear to rotate, the driving gear rotates to drive the whole screw device to rotate through the driven gear, and the screw device rotates to enable the movable seat and the fine adjustment mechanism to drive the driving arm to move. Therefore, rapid coarse adjustment of the fit clearance between the bottom of the driving arm and the cam is achieved, and the adjustment efficiency is improved. According to the fine adjustment mechanism, the distance of the inclined surface block can be finely adjusted through a differential thread mechanism composed of an adjusting sleeve body, a stud and the like, meanwhile, an inclined surface moving mechanism composed of the inclined surface block and an inner inclined surface groove is further matched, so that the fine adjustment precision is improved, and the driving arm can be driven to be finely adjusted through the connecting block.

Owner:苏迈特智能科技(江苏)有限公司

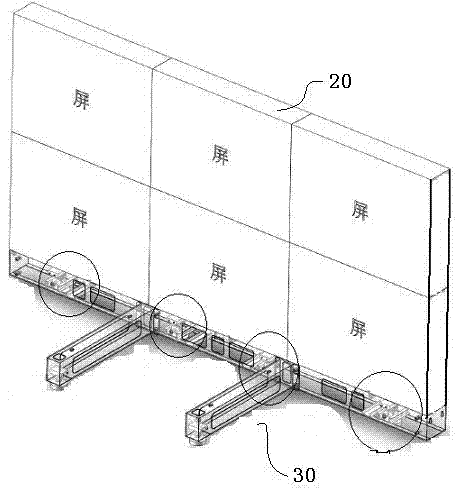

A LED display stack installation adjustment device

InactiveCN102720929BHigh fine-tuning precisionChange support heightStands/trestlesLED displayMaterial resources

The invention relates to an LED display screen stacked installation adjusting device, which includes a base, a gear adjusting mechanism arranged on the base, and a bearing plate arranged on the gear adjusting mechanism; and the gear adjusting mechanism includes a strut vertically mounted on the base, a first gear mounted on the strut through a bearing, and a second gear horizontally arranged and meshed with the lower end of the first gear to realize rotary adjustment. A limiting device is arranged at the upper end of the strut. During the use, the device is mounted below a display screen support, and if the ground is uneven and causes unstable placement of a display screen on the support, the supporting height of the device can be conveniently adjusted through rotating the second gear; and the gear fine adjustment is high in precision and can be in place by one step, so that manpower and material resources are saved, and the installation efficiency is greatly improved.

Owner:HUIZHOU DESAY INTELLIGENT TECH

Complex harmonic transmission device with double clutch mechanisms

ActiveCN108286598AHigh feed resolutionHigh repeat positioning accuracyToothed gearingsGearing detailsHarmonicEngineering

The invention relates to a complex harmonic transmission device with a double-clutch mechanism. the complex harmonic transmission device is characterized by comprising a first wave generator, a secondwave generator, a first flexible outer gear, a second flexible outer gear, a first rigid inner gear, a second rigid inner gear, a first shaft sleeve, a second shaft sleeve, a third shaft sleeve, a first electromagnetic disc, a second electromagnetic disc, a third electromagnetic disc, a fourth electromagnetic disc, a first metal plate, a second metal plate, a center shaft and a total output shaft; the first wave generator and the second wave generator are arranged in the first flexible outer gear and the second flexible outer gear correspondingly; the first flexible outer gear and the secondflexible outer gear are arranged in the first rigid inner gear and the second rigid inner gear correspondingly, and the first shaft sleeve is connected with the first flexible outer gear; the first shaft sleeve and the third shaft sleeve are arranged on the center shaft in a sleeving mode, and the first metal disc is arranged on the center shaft; the first electromagnetic disc and the second electromagnetic disc are located on the left side and the right side of the first metal disc correspondingly; the second wave generator is connected with the second shaft sleeve, and the third shaft sleeveis connected with the second flexible outer gear; and the fourth electric disc is arranged at the right end of the central shaft, the third electromagnetic disc and the fourth electromagnetic disc are located on the left side and the right side of the second metal plate correspondingly, and the total output shaft is connected with the second metal plate. The device has the advantages that conversion can be carried out between the first-stage harmonic transmission and the second-stage harmonic transmission.

Owner:SHUNDE POLYTECHNIC

A mobile support frame for assembling walls

ActiveCN112081350BQuick assemblyHigh fine-tuning precisionBuilding constructionsHand carts with multiple axesClassical mechanicsSupport plane

The invention relates to an assembly tool for assembling a wall, in particular to a mobile support frame for assembling a wall. A mobile supporting frame for assembling a wall, comprising a sliding base and a bracket, the bracket including a vertical frame and an adjusting frame slidingly connected up and down with the vertical frame, positioning pins are arranged on the adjusting frame; a lifting mechanism for driving the adjusting frame up and down; The translation fine-tuning mechanism used to drive the horizontal translation of the adjustment frame; the flip adjustment mechanism used to drive the vertical flip of the adjustment frame. The invention has the beneficial effects of being convenient for transportation, effectively fine-tuning the assembly according to the conditions of the assembled parts, and being easy to operate.

Owner:林佳亮

3D high definition projector

InactiveCN108540785AReasonable structureImprove cooling effectPicture reproducers using projection devicesEngineeringUSB

The invention discloses a 3D high definition projector, wherein a housing is installed on an upper surface of a base through a screw; a cover body is movably installed on an upper edge of the housingthrough a rotating shaft; a signal processor and a storage battery are arranged in the housing; a projection port is formed in a front outer wall of the housing, and a power interface, a USB interface, an SD card socket and a high definition data interface are formed in a side face of the projection port; heat dissipation holes are uniformly formed in an inner wall of the housing; an outer wall board at the rear of the housing is a serrated heat dissipation plate; a switch button is arranged at the center of the upper surface of the cover body; an adjusting roller is further embedded in the outer wall of the housing; and a gear rack is arranged on the outer wall of the adjusting roller and is engaged with an upper segment side face of an adjusting screw. The 3D high definition projector disclosed by the invention is reasonable in structure, good in heat dissipation performance, clear in projection picture and is power failure resistant.

Owner:ANHUI SANDI ELECTRONICS TECH CO LTD

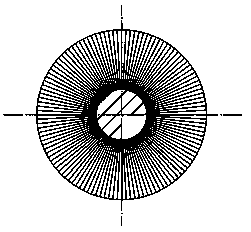

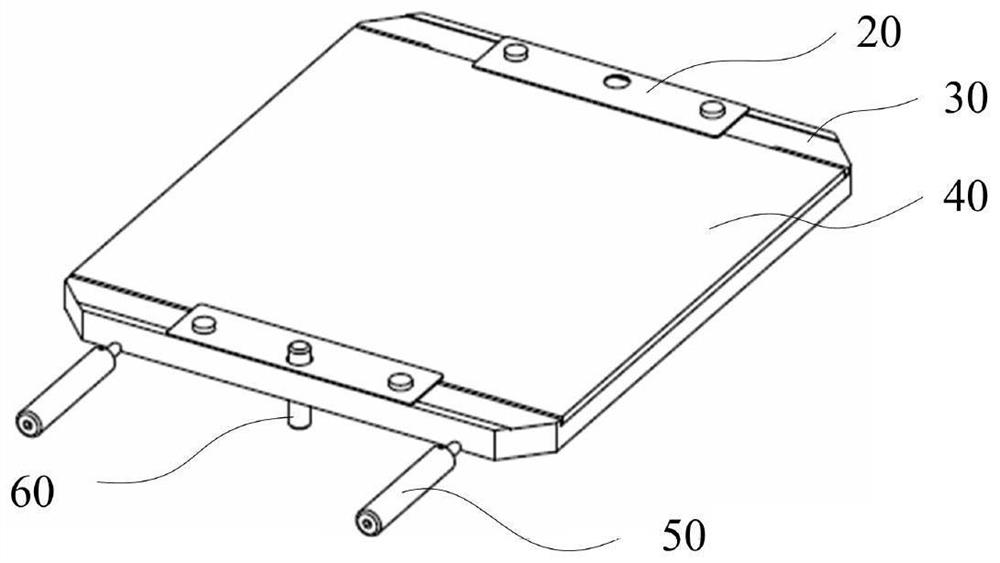

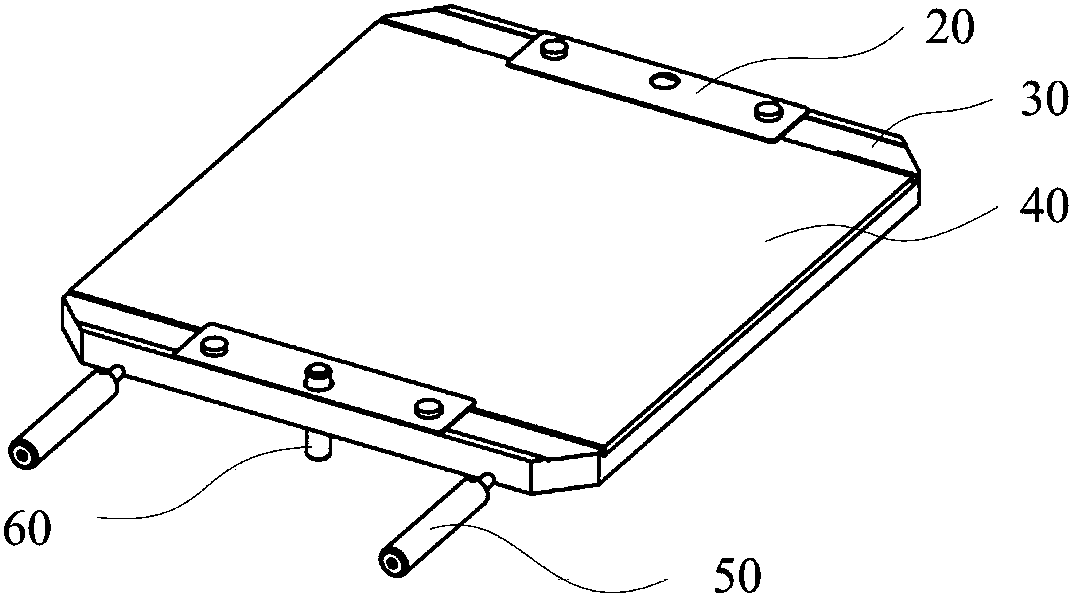

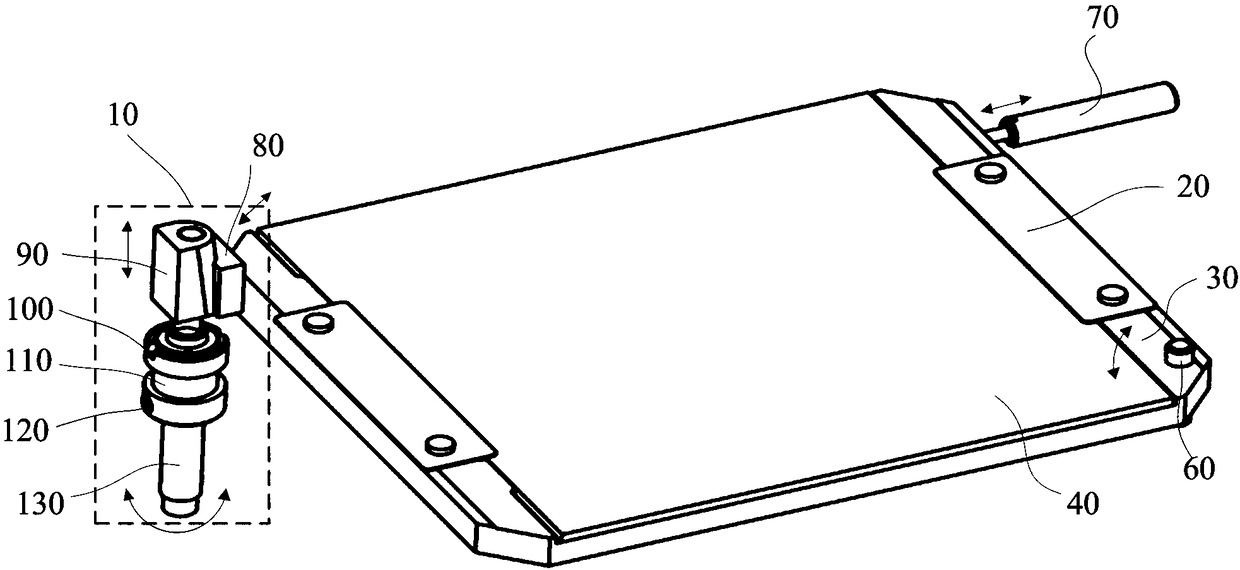

A polarizing device and an optical alignment device

ActiveCN109212648BIncrease the radius of rotationHigh-resolutionPolarising elementsNon-linear opticsRotational axisWire grid

The present invention provides a polarizing device and an optical alignment device, including a polarizing unit and a mounting frame, and the polarizing unit includes a polarizing wire grid, a wire grid frame plate, and a wire grid adjustment unit. The wire grid frame plate is used to support the polarized wire grid, and the wire grid frame plate is rotated and installed on the installation frame with the normal direction of the polarized wire grid as the rotation axis, and the wire grid adjustment unit is The rotation of the wire grid frame plate provides the driving force, the rotation axis of the wire grid frame plate and the driving force point of the wire grid adjustment unit are located on a pair of opposite corners of the wire grid plane of the polarizing wire grid, solving The problem that the adjustment resolution of the existing polarizing device cannot meet the needs of actual use is solved.

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

Wall body supporting device of movable assembling frame

ActiveCN112081350AQuick assemblyHigh fine-tuning precisionBuilding constructionsHand carts with multiple axesClassical mechanicsBody support device

Owner:林佳亮

Fine-tuning device for detecting and tuning horizontal axis of telescope and theodolite

InactiveCN101825474BSimple structureEasy to operateMeasurement devicesTelescopesTheodoliteHorizontal axis

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

Polarizing device and optical alignment device

ActiveCN109212648AIncrease the radius of rotationHigh-resolutionPolarising elementsNon-linear opticsWire gridImage resolution

The invention provides a polarizing device and an optical alignment device, comprise a polarizing unit and a mounting frame. The polarizing unit comprises a polarizing wire grid, a wire grid frame plate and a wire grid adjustment unit. The wire grid frame plate is used for supporting the polarizing wire grid, and is rotationally installed on the mounting frame in the normal direction of the polarizing wire grid as a rotating shaft. The wire grid adjustment unit provides a driving force for rotation of the wire grid frame plate, and the rotating shaft of the wire grid frame plate and the driving force point of the wire grid adjusting unit are located on a pair of diagonal lines of the wire grid plane of the polarizing wire grid. According to the polarizing device and optical alignment device, the problem that the adjusting resolution of an existing polarizing device cannot meet the actual use requirement is solved.

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

Foldable wall-mounted fixing device for wall-mounted instrument

PendingCN112747235AIncrease coefficient of frictionRealize foldable storageStands/trestlesFrictional coefficientClassical mechanics

The invention discloses a foldable wall-mounted fixing device for a wall-mounted instrument which comprises a hanging arm assembly, a vertical connecting assembly and a bearing assembly; the hanging arm assembly is located above the bearing assembly; and the same side ends of the hanging arm assembly and the bearing assembly are rotationally connected with the vertical connecting assembly which is vertically arranged. The foldable wall-mounted fixing device has the beneficial effects that the hanging notch has two design modes, namely a structure with a wide lower part and a narrow upper part or a rubber mat arranged at the hanging notch, so that the nail hanging device can adapt to nails of various specifications through the design with the wide lower part and the narrow upper part; the hanging notch is firmly clamped on the outer side of the rod part of the nail through the overall gravity of the device and the wall sticking instrument, or the friction coefficient between the hanging notch and the nail rod is increased in a mode of arranging a rubber mat; and therefore the effect of stably clamping the outer side of the nail rod part is achieved.

Owner:李昌象

A fine-tuning device for the head of a single-point forming manipulator

The invention discloses a fine-tuning device for the head of a single-point forming mechanical arm, which belongs to the technical field of sheet metal forming. A fine-tuning device for the head of a single-point forming mechanical arm, comprising: a housing, a pressing assembly, and a sliding assembly; the pressing assembly includes a first motor, a needle handle, and a thimble; the first motor is located in the housing and is connected to the housing through the sliding assembly. Sliding fit, the first motor shaft of the first motor passes through the housing and is connected with the needle handle, and the thimble is arranged on the needle handle. The casing of the present invention is directly connected to the mechanical arm, and the first motor drives the needle to rotate. Under the action of the mechanical arm, the metal sheet can be stamped and formed. Since the pressing assembly and the casing can slide through the sliding assembly, The fine-tuning of the top-pressing component can be realized through the sliding component, avoiding the use of a mechanical arm for fine-tuning, thereby improving the precision of fine-tuning and ensuring the forming quality of the metal sheet.

Owner:CHENGDU AERONAUTIC POLYTECHNIC

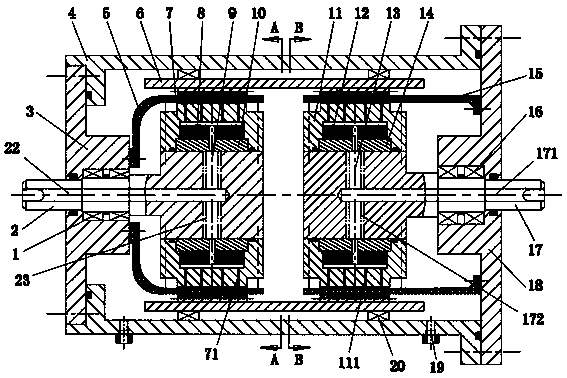

Secondary wave type harmonic drive mechanism

ActiveCN108458085AHigh feed resolutionHigh repeat positioning accuracyToothed gearingsImage resolutionEngineering

The invention relates to a secondary wave type harmonic drive mechanism which is characterized by comprising first to third beraing packs, input and output shafts, a left end cove, a shell, first andsecond flexible outer gears, a rigid inner gear, first and second wave generators, a first vibrating plate, first and second one-way valves, first and second base plates, a second vibrating plate, a right end cover and an oil unloading port, wherein the input shaft is mounted on the left end cover through the first bearing pack and can rotate and the output shaft is mounted on the right end coverthrough the second bearing pack and can rotate; the first base plate and the first vibrating plate are located in an inner cavity of the first wave generator; the rigid inner gear is mounted in an inner hole of the shell through the third bearing pack, and the first flexible outer gear is located on the left side of an inner hole of the flexible inner gear and is engaged to the left inner gear atthe left end of the rigid inner gear; the second flexible outer gear is located on the right side of an inner hole of the rigid inner gear and is engaged to the right inner gear at the right end of the rigid inner gear, and the second vibrating plate and the second base plate are located in the second wave generator. The secondary wave type harmonic drive mechanism is extremely high in feeding resolution, repeated positioning precision and moving stability, and also has the advantages of being ultrahigh in fine adjusting precision, simple in structure, reliable in performance, long in integralservice life and the like.

Owner:SHUNDE POLYTECHNIC

Sensor beam lifting device used for deflectograph

ActiveCN113847525AReal-time monitoring of location statusGuaranteed adjustabilityCounterweightsStands/trestlesHydraulic cylinderGyroscope

The invention discloses a sensor beam lifting device used for a deflectograph. The sensor beam lifting device comprises a bearing mechanism, one end of a sensor beam is in shaft connection to the bearing mechanism, the bearing mechanism is in shaft connection with a first hydraulic cylinder, the piston end of the first hydraulic cylinder is connected to the other end of the sensor beam through a connector, the first hydraulic cylinder is located above the sensor beam, a three-axis gyroscope is installed on the sensor beam, a lead screw is installed on the top face of the sensor beam, a nut seat is installed on the lead screw, a servo motor is connected with a rotating nut in the nut seat, a balancing weight is installed on the surface of the nut seat, the connector comprises a base, two sleeves are symmetrically fixed to the base, second hydraulic cylinders are installed at the bottoms of the two sleeves correspondingly, the piston ends of the second hydraulic cylinders are connected with connecting rods, the tops of the two connecting rods are in shaft connection to the two ends of a top plate correspondingly, and the piston end of the first hydraulic cylinder is fixed to the top plate. By means of the device, the defects in the prior art can be overcome, and the horizontal state of the sensor beam can be automatically monitored and controlled.

Owner:南京侨睿交通技术有限公司

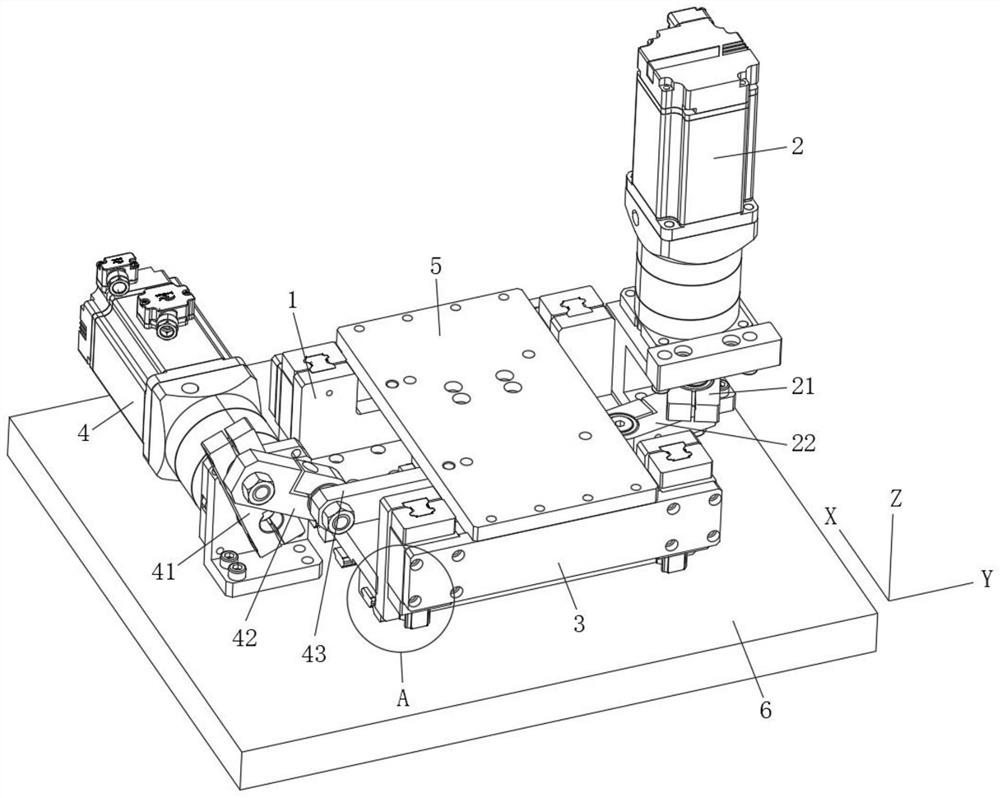

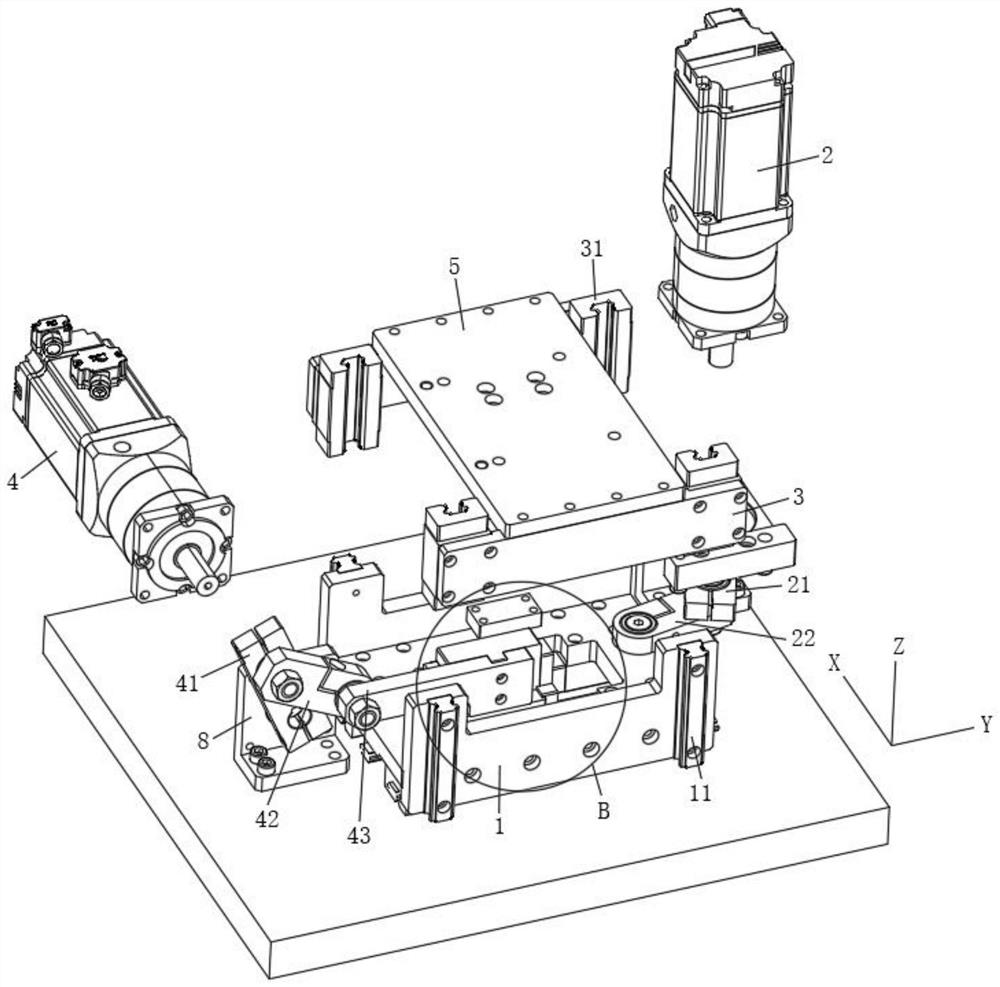

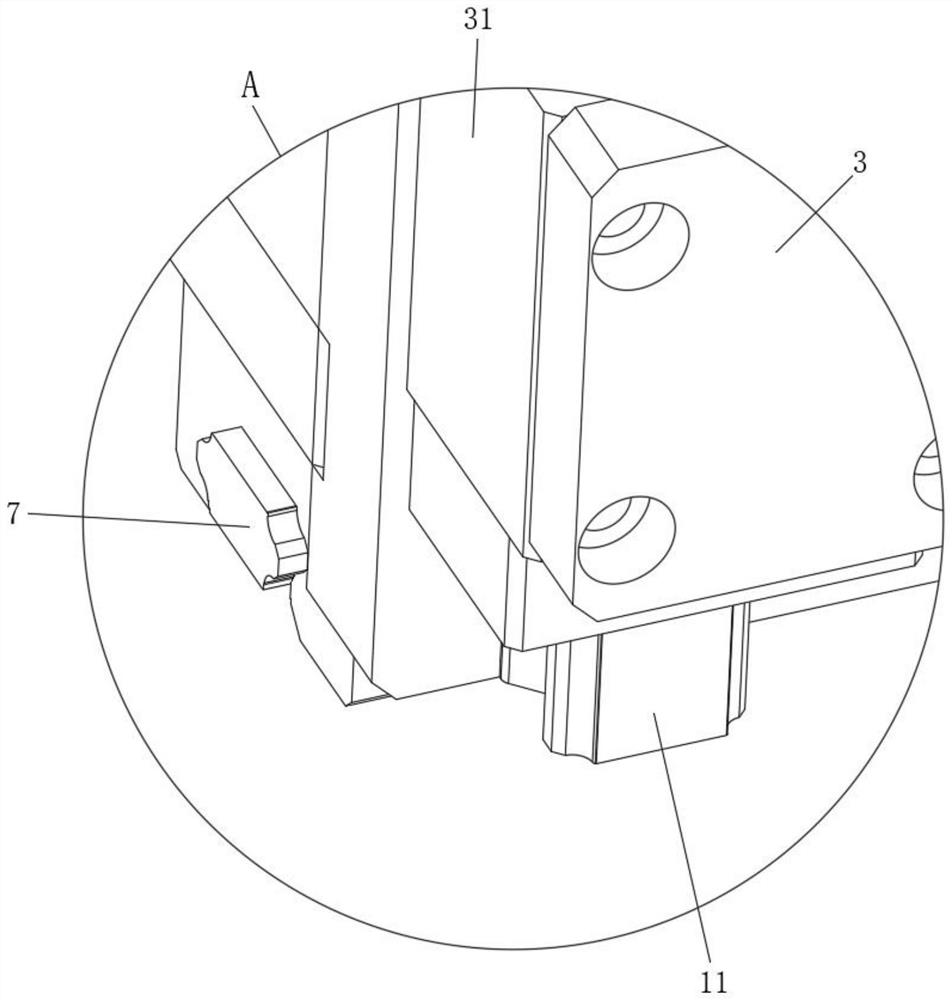

Connecting rod type fine adjustment mechanism

ActiveCN113997196ASimple structureReasonable assemblyGrinding carriagesGrinding drivesElectric machinerySlide plate

The invention belongs to the technical field of polishing fine adjustment and correction, and discloses a connecting rod type fine adjustment mechanism, comprising: a sliding table capable of moving along the Y axis. a Y-axis driving device which is used for driving the sliding table to move along the Y axis and comprises a first motor and a first connecting rod assembly which are sequentially connected from top to bottom along the Z axis, the first motor driving the sliding table to move through the first connecting rod assembly; a sliding plate which can move along the Z axis and is in sliding fit with the outer side of the sliding table; and a Z-axis driving device which is used for driving the sliding plate to move on the sliding table along the Z axis and comprises a second motor and a second connecting rod assembly which are sequentially connected along the Y axis, the second motor driving the sliding plate to move through the second connecting rod assembly. In conclusion, the connecting rod assembly swings to drive the sliding structure connected with the connecting rod assembly to move, so that fine adjustment is achieved on the corresponding Y-axis and Z-axis. The fine adjustment mechanism has the advantages of being simple in structure, reasonable in assembly, low in cost and high in fine adjustment precision.

Owner:朝华力拓精密(深圳)有限公司

Support tools for equipment assemble

InactiveCN101254581BImprove versatilityHigh fine-tuning precisionMetal working apparatusScrew threadScrew cap

The invention relates to a support tool for assembling equipment. The prior art can achieve equipment assembly through cooperation of a plurality of workers but fails to achieve fine adjustment of the equipment pitch. The support tool is characterized in that a plurality pairs of pin holes with different distances arranged on sleeves and a support pipe on the left and the right sides are combinedto carry out pitch coarse adjustment, and a middle hand wheel is used for driving the sleeves connected with each other through a left and a right rotating threads to retract and extend, thus achieving fine adjustment. The support tool consists of a fixing pin, the sleeves, the hand wheel, the support pipe, a fastening screw cap, fixing pin holes, an adjusting screw nut, an adjusting screw and a wood ferrule. The support tool has the positive effects of good generality, high accuracy for fine adjustment, lowered cost and improved work efficiency, and is a labor-saving, time-saving and work-saving assistant tool.

Owner:SHANGHAI FORWARD MASCH CO LTD

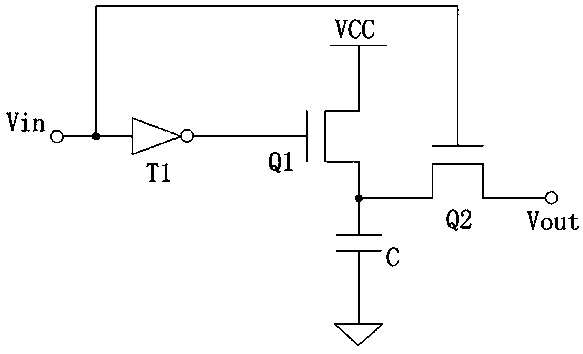

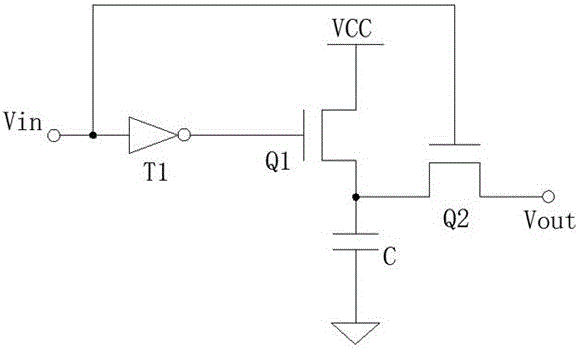

Voltage output trimming circuit

ActiveCN105703619BSimple structureLow implementation costApparatus without intermediate ac conversionCapacitanceEngineering

Owner:中山芯达电子科技有限公司

Voltage output fine tuning circuit

ActiveCN105703619ASimple structureLow implementation costApparatus without intermediate ac conversionCapacitanceEngineering

The invention provides a voltage output fine tuning circuit. The circuit is characterized in that the circuit includes a MOS pipe Q1, a MOS pipe Q2, a capacitor C and an inverter T1; the MOS pipe Q1 and the capacitor C are connected in series between a power supply VCC terminal and a ground terminal, a grid is connected to an input terminal Vin of the circuit through the inverter T1, and the MOS pipe Q1 is used for realizing on and off according to an inversion signal of the input terminal Vin so as to charge the capacitor C; the MOS pipe Q2 is connected to the capacitor C and an output terminal Vout of the circuit, a grid is connected to the input terminal Vin of the circuit and is used for realizing on and off according to a signal of the input terminal Vin so as to output an electric quantity of the capacitor C. The circuit has advantages that the circuit structure is simple and enforcement cost is low; through different duty ratios of a periodic square wave, a charging amount of the capacitor C is adjusted and fine tuning precision is high; the integral circuit has no resistive component, a resistance of the integral circuit is not influenced; and an engineer does not need to consider a circuit calorific value and energy consumption.

Owner:中山芯达电子科技有限公司

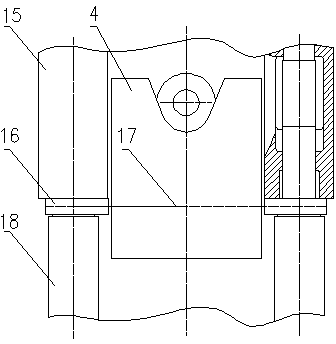

Voltage Dividers for High Voltage Energy Metering Devices

ActiveCN106771461BLinear UniformReduce distanceVoltage dividersElectrical resistance and conductanceEnergy metering

The invention discloses a voltage divider applied to a high voltage energy metering device. The voltage divider comprises a left polar plate (2), a right polar plate (3), a high voltage arm resistor (4), a low voltage arm resistor (11), a horizontal slide rail (7), a rotating bracket (5) and a strut (6). According to the invention, the distance between the left polar plate (2) and the right polar plate (3) can be adjusted; the rotating bracket (5) and the strut (6) form an isosceles triangular mechanism to ensure that lower and upper ends of the high voltage arm resistor (4) are always close to the left polar plate (2) and the right polar plate (3) in the moving process of the right polar plate (3); the gradient of electric field distribution between electrodes is always consistent with the gradient of voltage distribution on the high voltage arm resistor (4); the voltage divider can be adjusted according to the position of other components with large calorific value relative to the voltage divider; the influence of temperature on the linearly uniform distribution of potential is reduced; and the measurement accuracy is improved. The voltage divider provided by the invention can be used as the voltage divider of various high voltage metering devices.

Owner:ZHANGJIAKOU POWER SUPPLY COMPANY OF STATE GRID JINBEI ELECTRIC POWER COMPANY +1

Double perpendicular clamping structure for finely adjusting worm wheel flying cutter in radial direction

PendingCN111745232AImprove cutting conditionsHigh precisionWorm wheelsGear-cutting machinesTool bitCentre of rotation

The invention relates to a double perpendicular clamping structure for finely adjusting a worm wheel flying cutter in the radial direction. A center blind hole which faces a driving end and is concentric with the rotary center of a cutter bar is arranged at the driven end of the cutter bar, and a two sections of stepped concentric holes are formed in the radial direction of the rotary center lineof the cutter bar, the large hole is a cylindrical hole, and the small hole is a threaded through hole. Two sections of threads same in turning direction and different in screw pitch are arranged on alocking screw and are connected with the threaded through hole and a screw hole in a round and straight handle of the flying cutter correspondingly. An elastic part is arranged between the plane of the input end of the cylindrical hole and the plane of a cutter bit of the flying cutter, and a positioning and clamping mechanism is arranged in the center blind hole. Under the combined action of thelocking screw and a force applying component, the inclined end face of the opposite end of a positioning ejector rod slides to the cutting plane of the round and straight handle of the flying cutterto form close face contact, the flying cutter is fastened in the cylindrical hole and never loosens after being precisely and finely adjusted and clamped in the radial direction, and the cutting portion of the flying cutter is located at the position the same as a working worm. The technical scheme is suitable for roll cutting a worm wheel small in cutter bar diameter, high in precision and largein cutting force.

Owner:中钢集团衡阳机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com