Machining device capable of accurately adjusting gap

A technology for gap adjustment and mechanical processing, which is applied in the direction of metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve the problems of large error, time-consuming and labor-intensive adjustment, and difficult control of the gap size during adjustment, so as to achieve low production cost and eliminate Effect of connecting gaps, ensuring stability and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

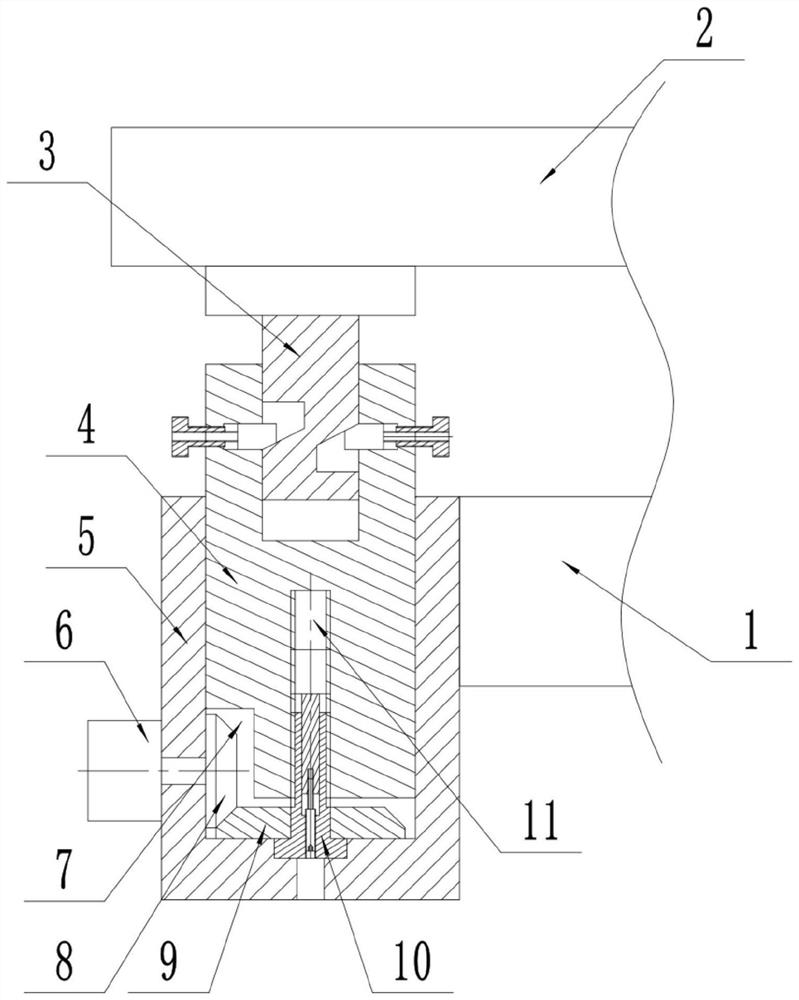

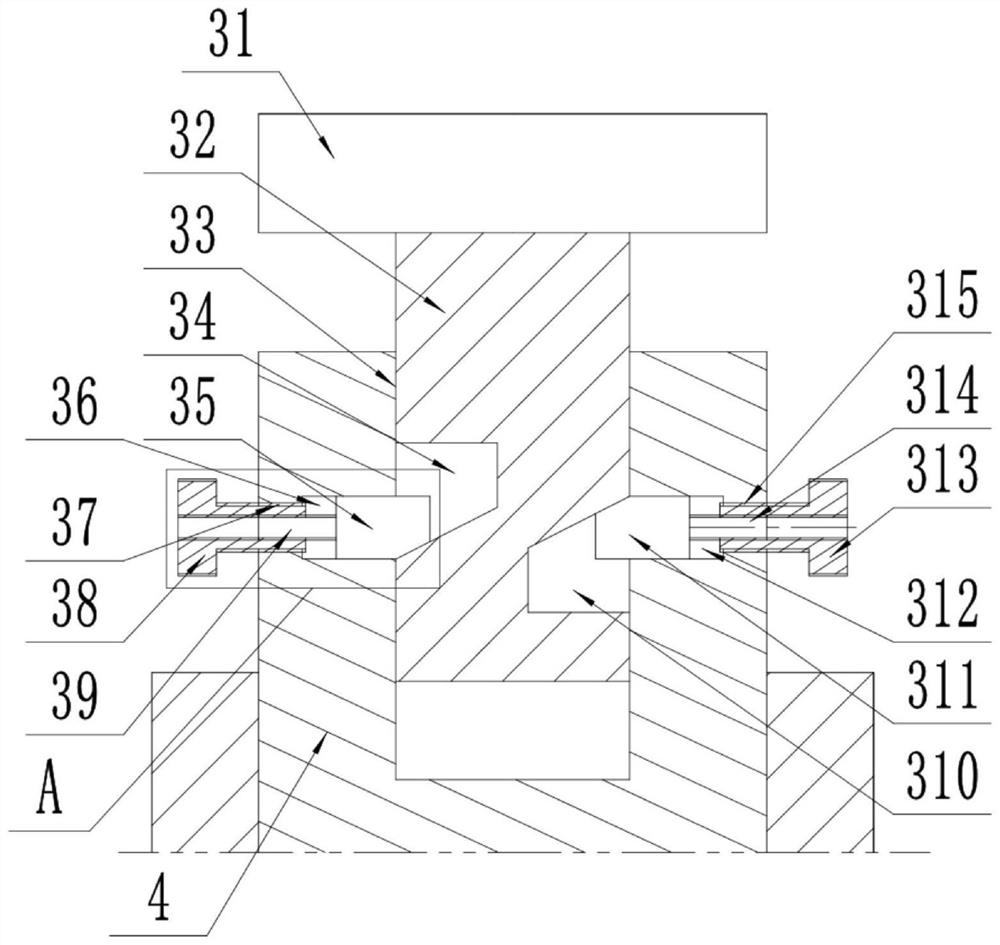

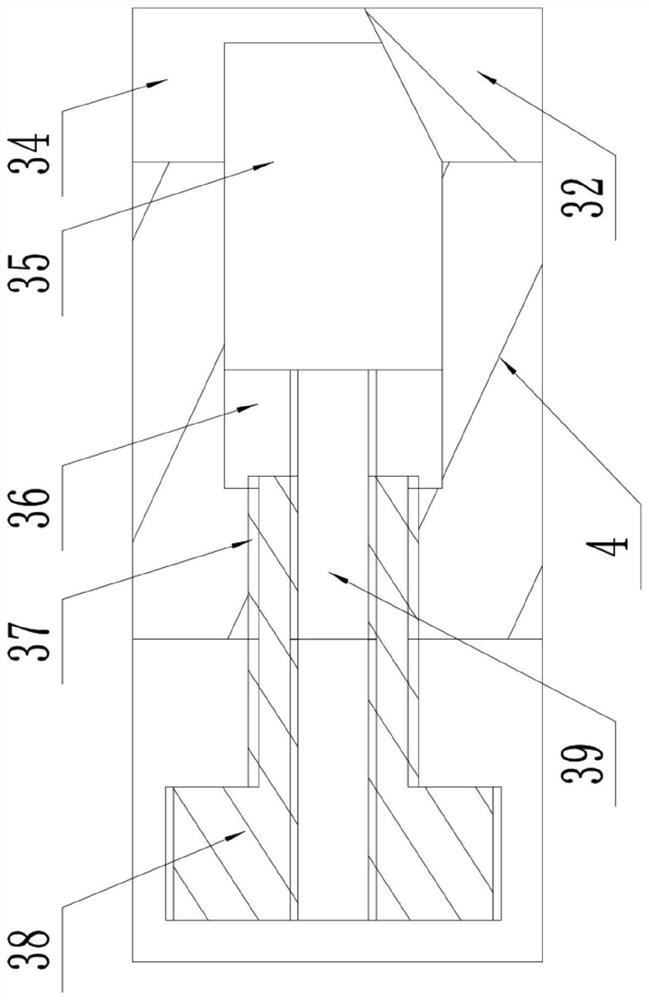

[0021] like figure 1 As shown, this specific embodiment adopts the following technical solutions: a machining device capable of accurately adjusting the gap, comprising a fixed seat 1 and a driving arm 2, and also includes a fine adjustment mechanism 3, a movable seat 4, a connection seat 5, an adjustment head 6, A chute 7, a driving gear 8, a driven gear 9, a screw device 10 and a threaded hole 11; the end of the fixing base 1 is fixedly connected with a connecting base 5; the upper side of the connecting base 5 is provided with a chute 7; The outside of the movable seat 4 is vertically movably connected inside the chute 7, the upper side of the movable seat 4 is provided with a fine-tuning mechanism 3, and the upper side of the fine-tuning mechanism 3 is connected with the drive arm 2, and the lower side of the movable seat 4 There is a threaded hole 11 inside; the driving gear 8 is movably connected to the lower left side of the chute 7, and the adjustment head 6 is fixedly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com