Patents

Literature

47results about How to "Eliminate connection gaps" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

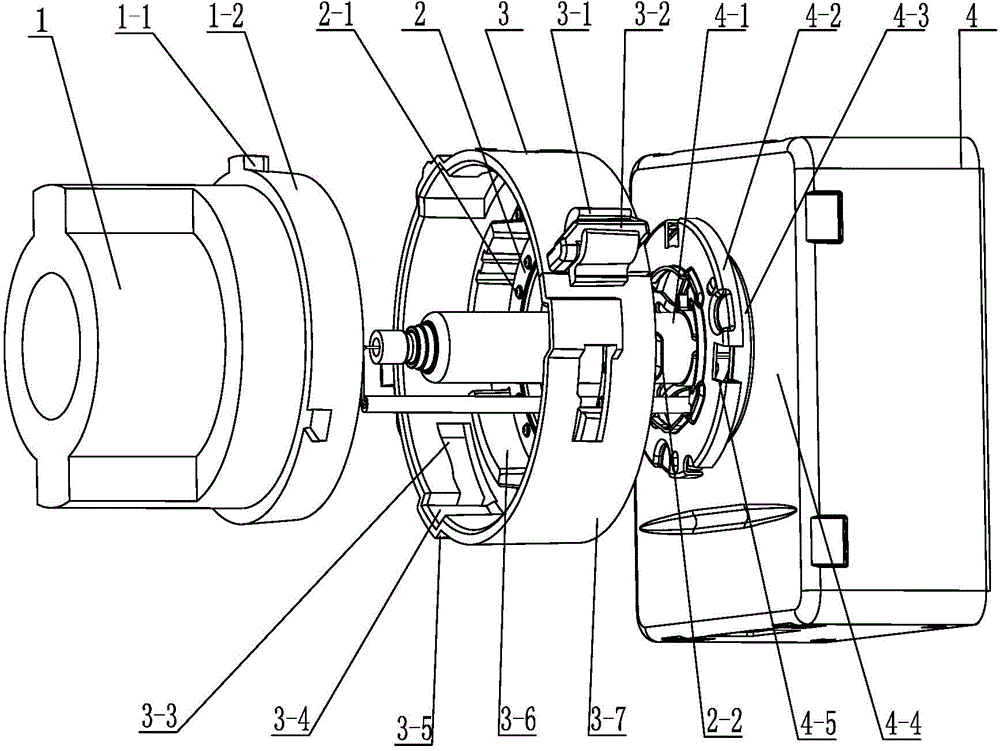

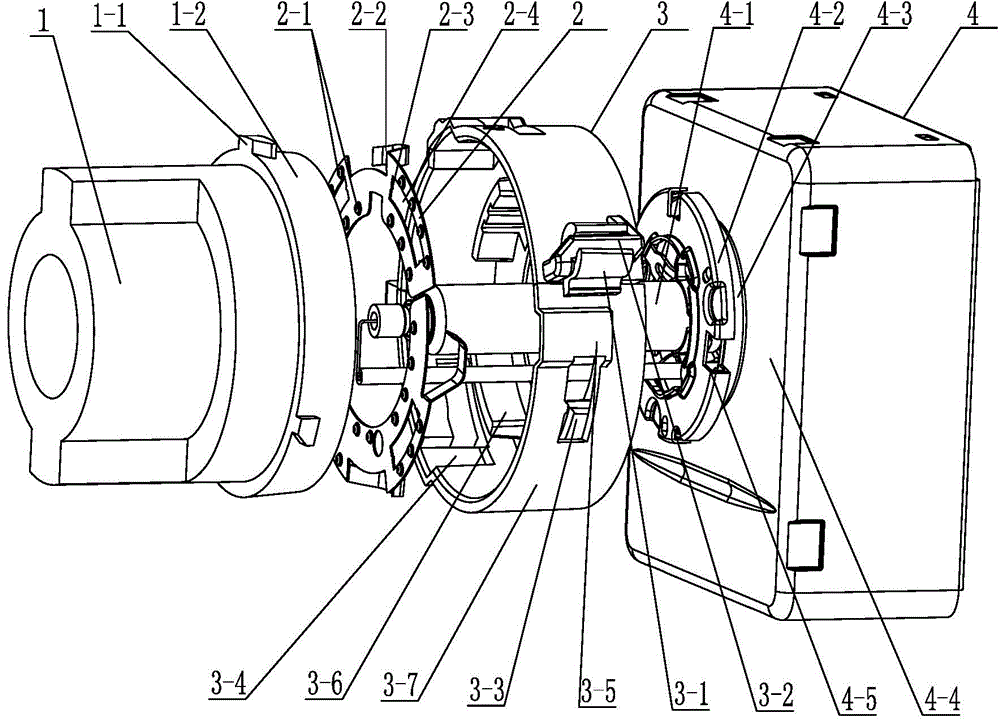

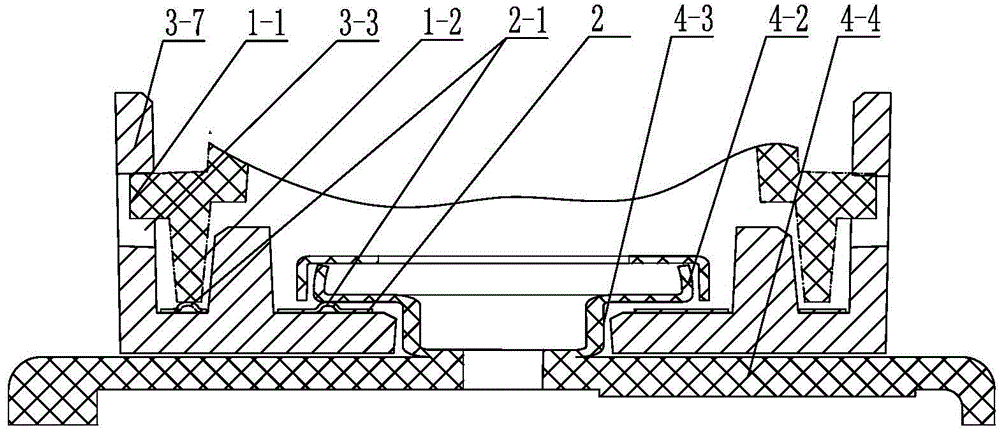

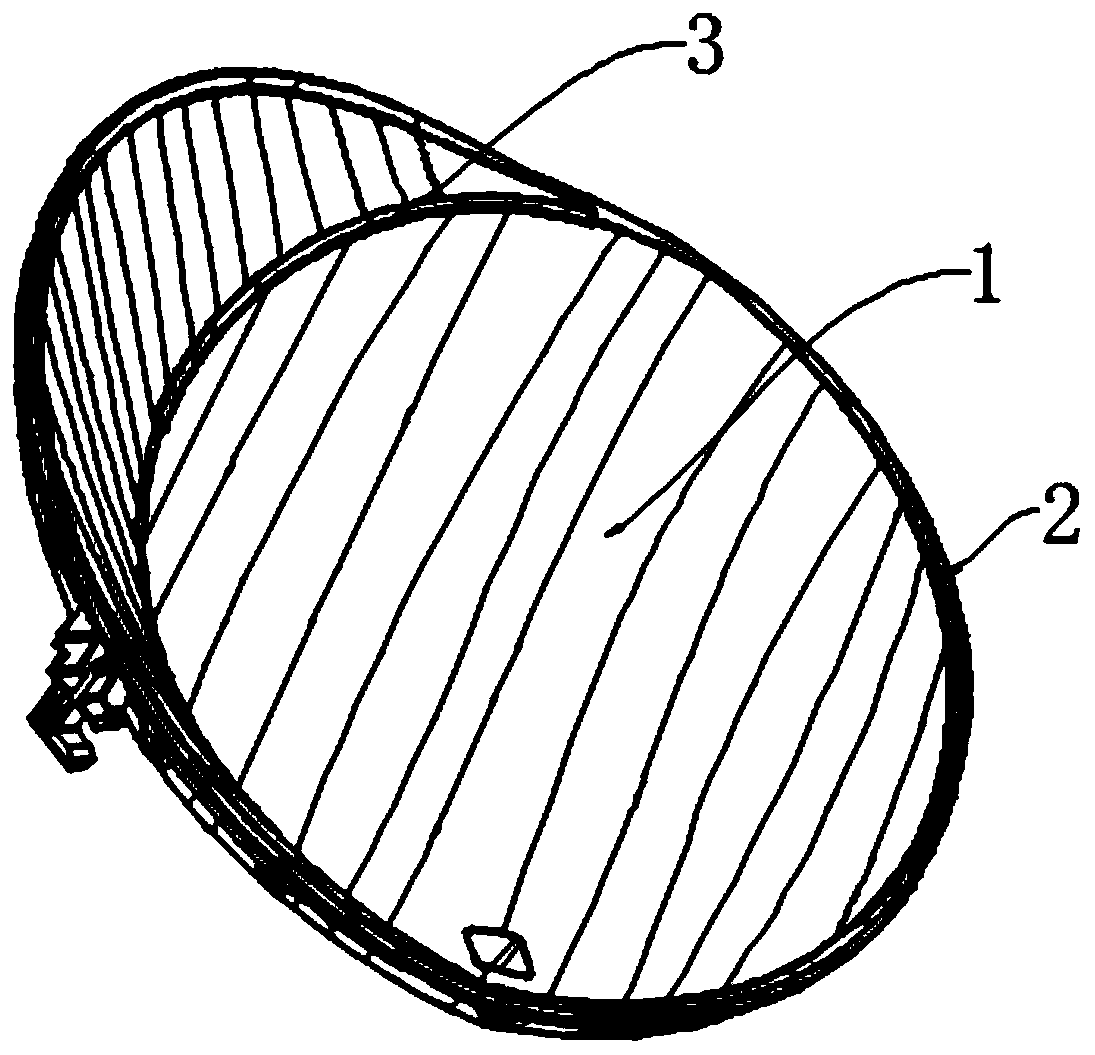

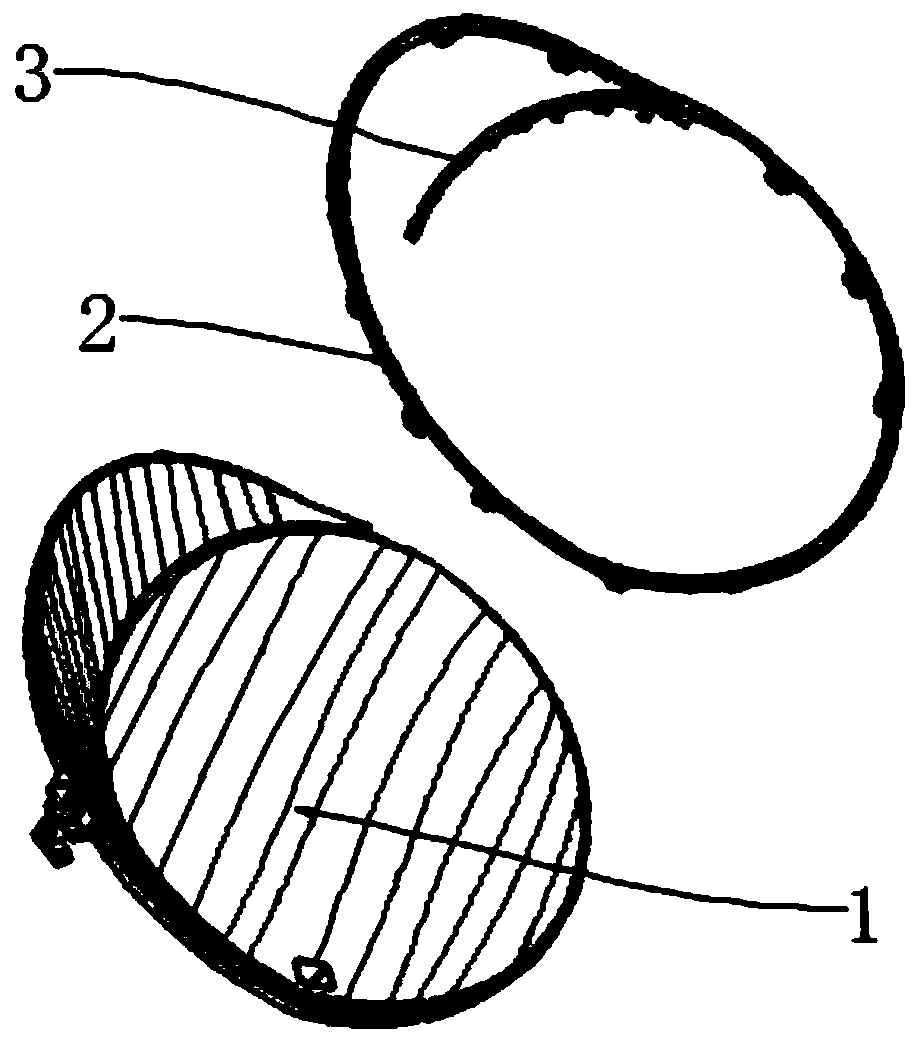

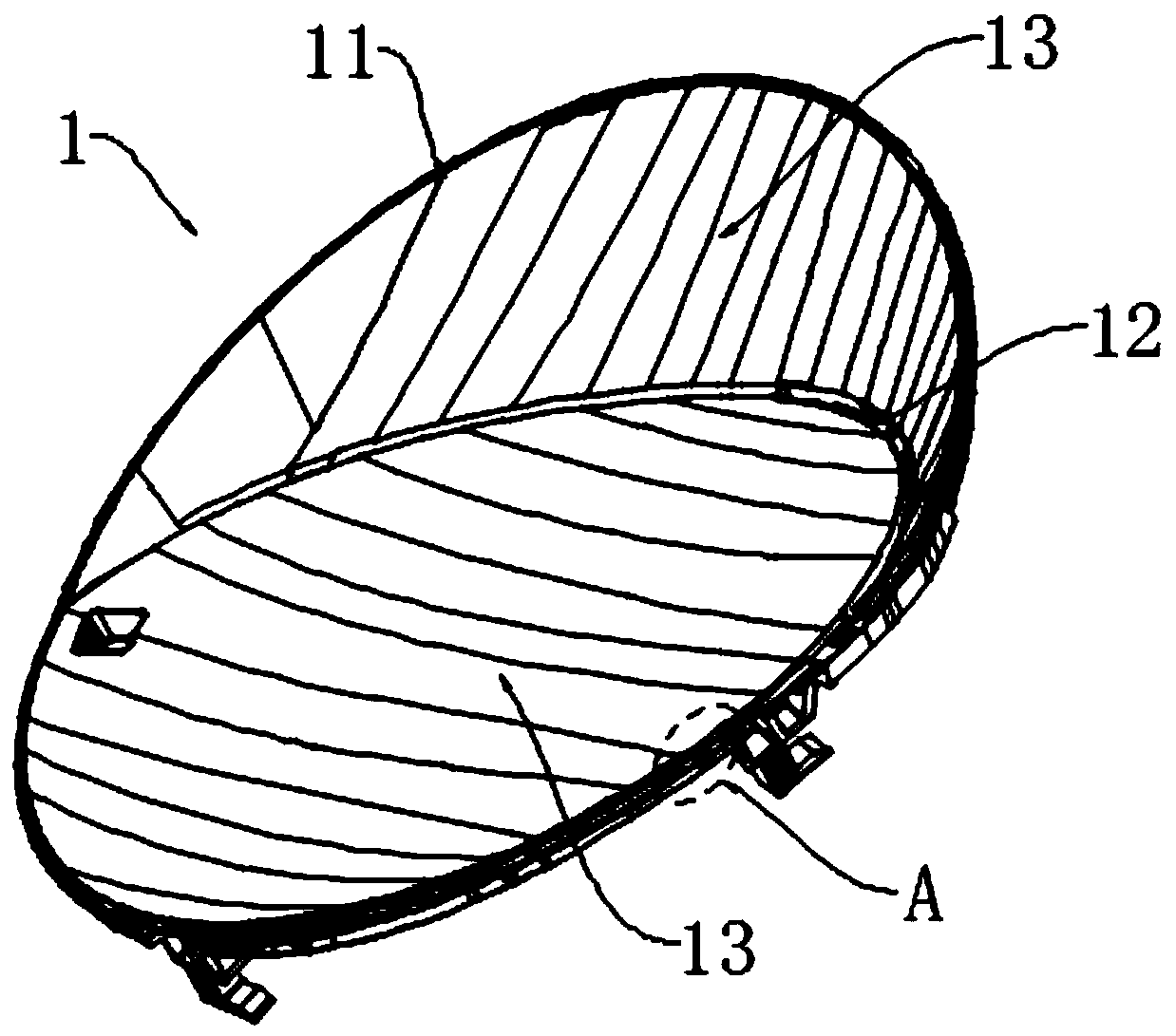

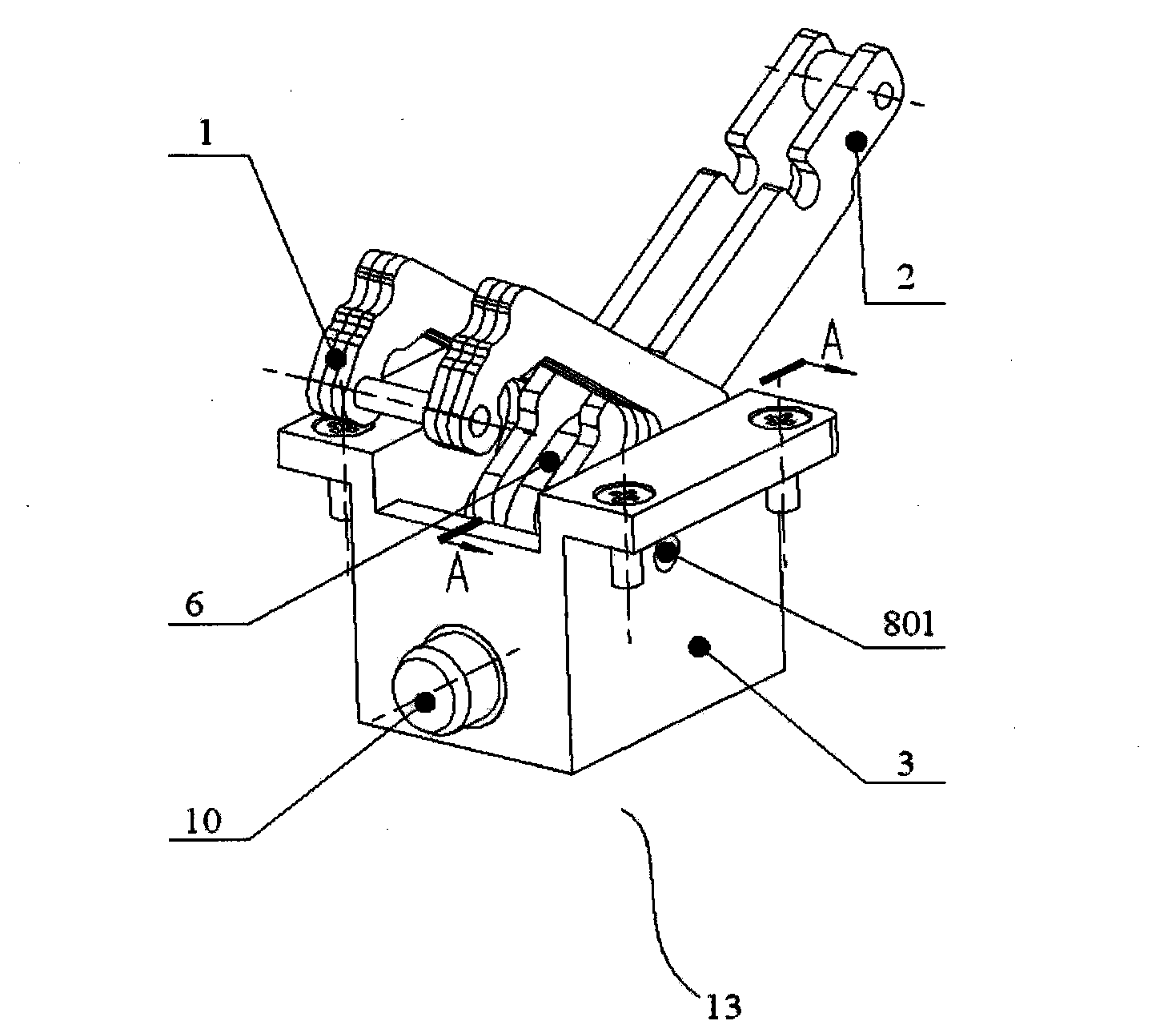

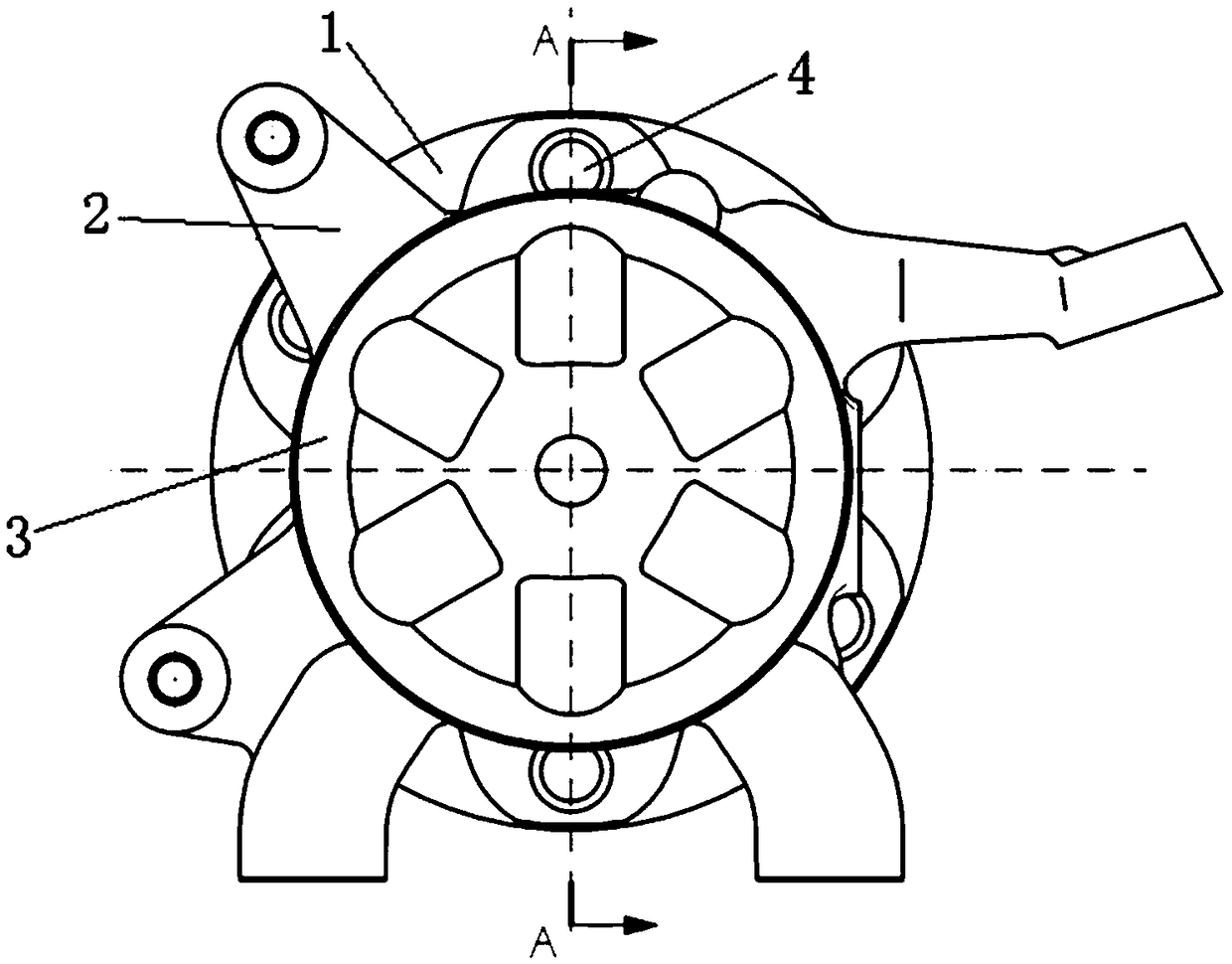

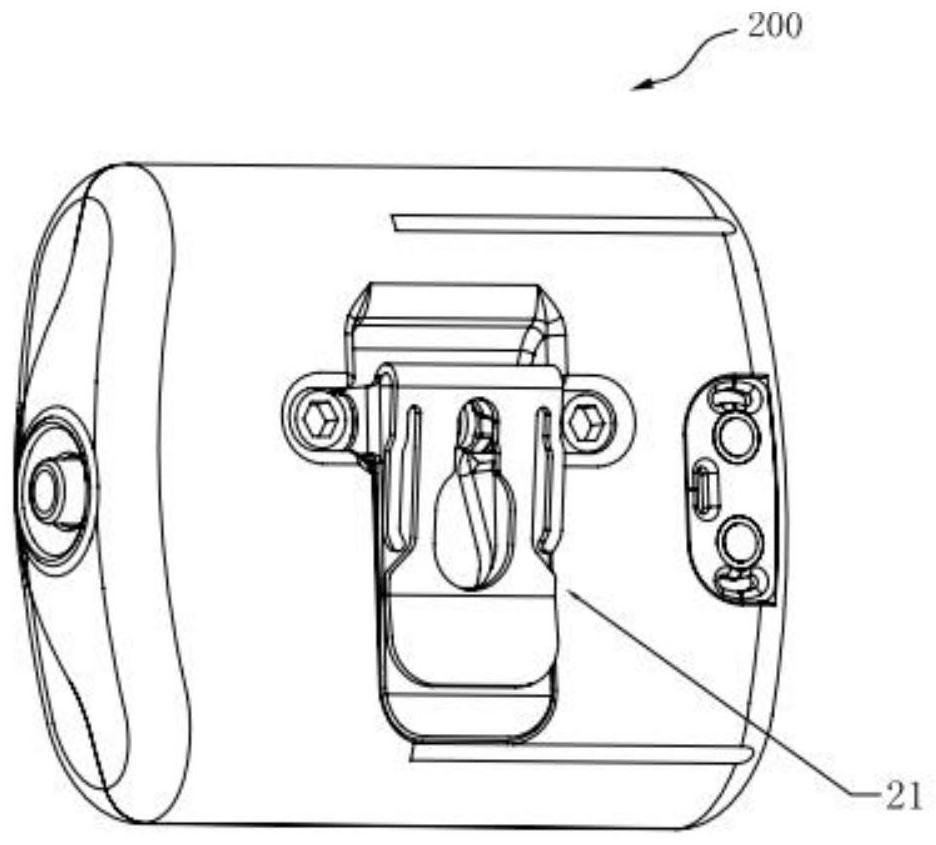

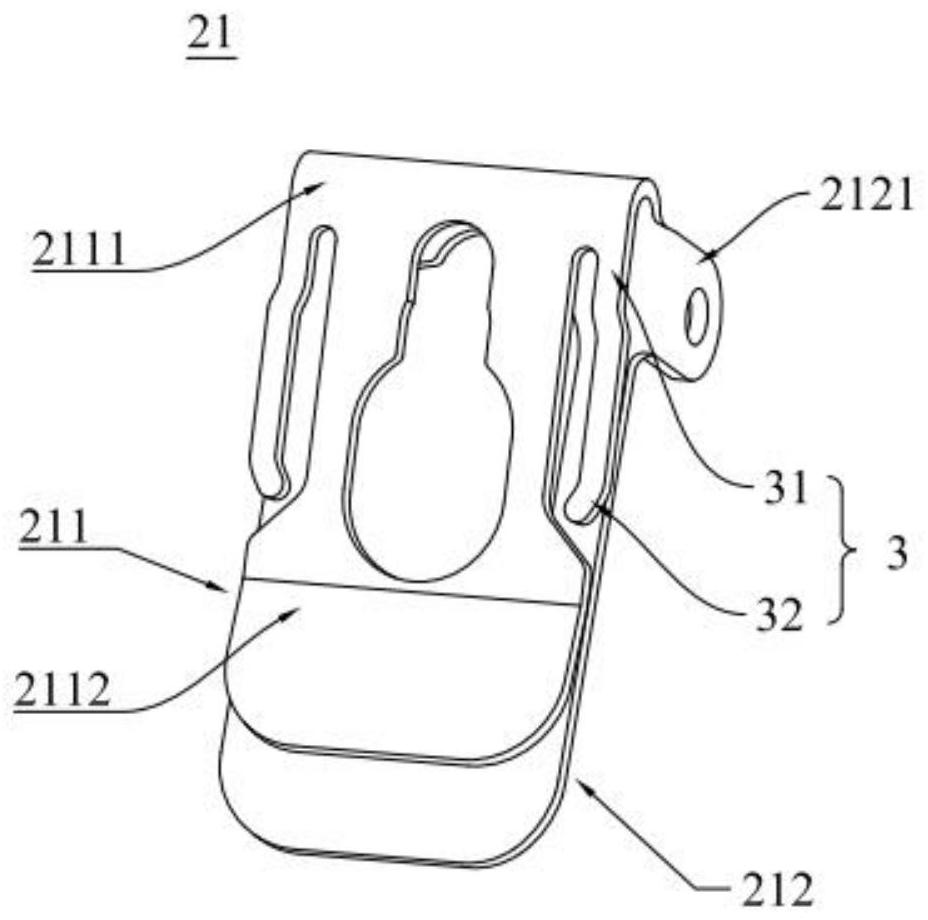

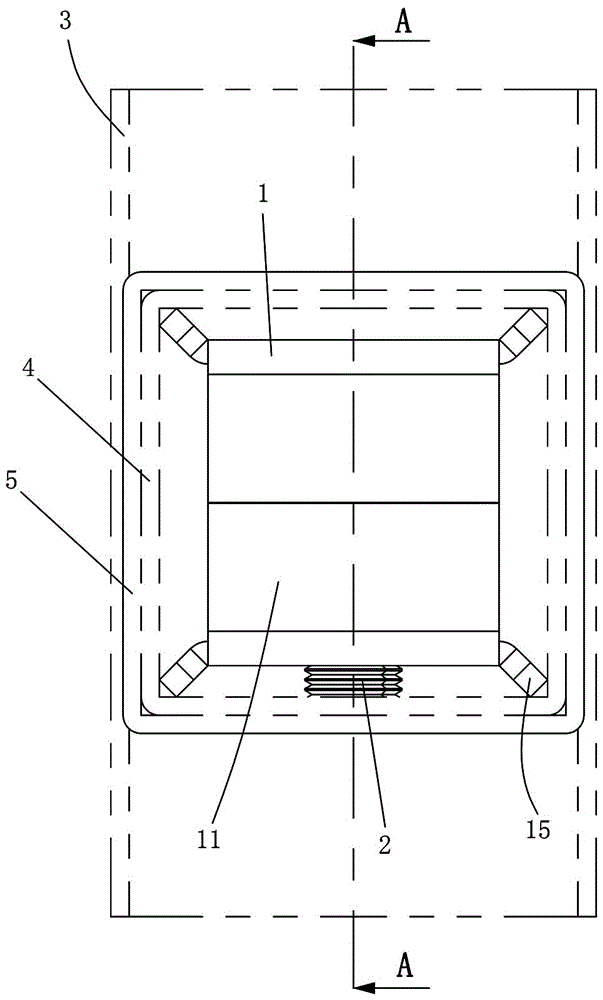

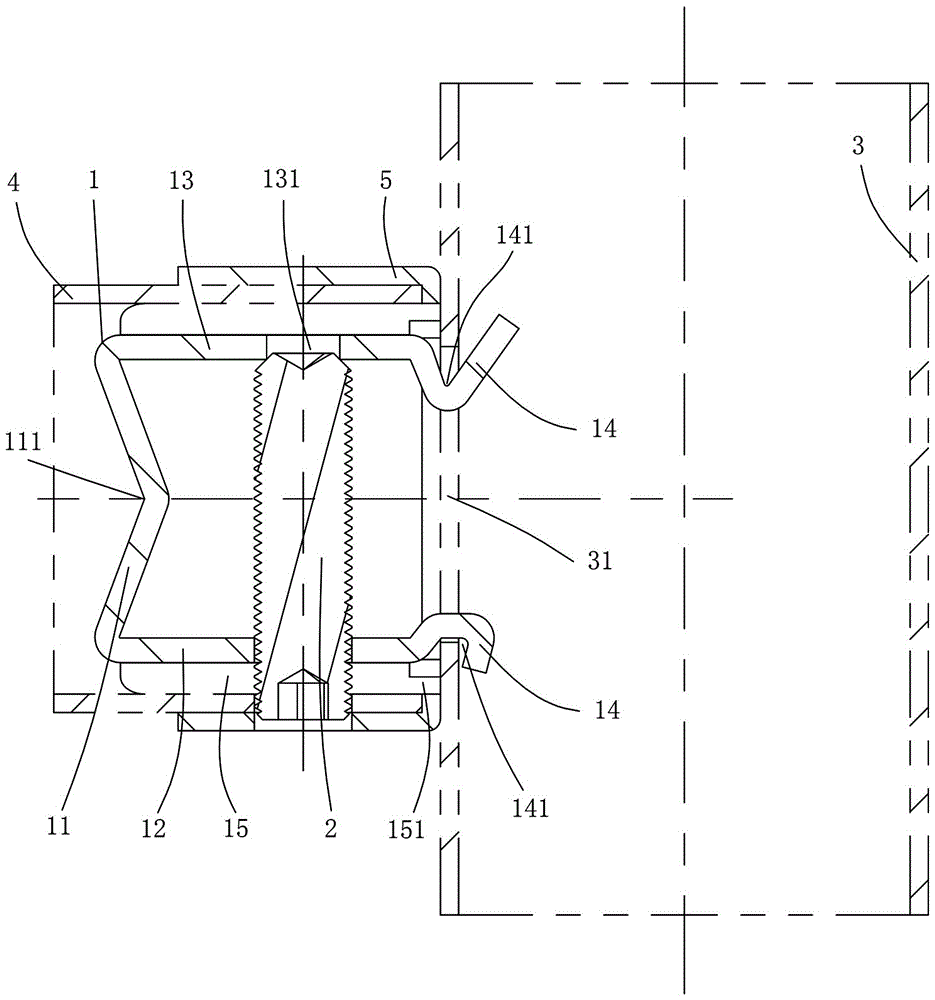

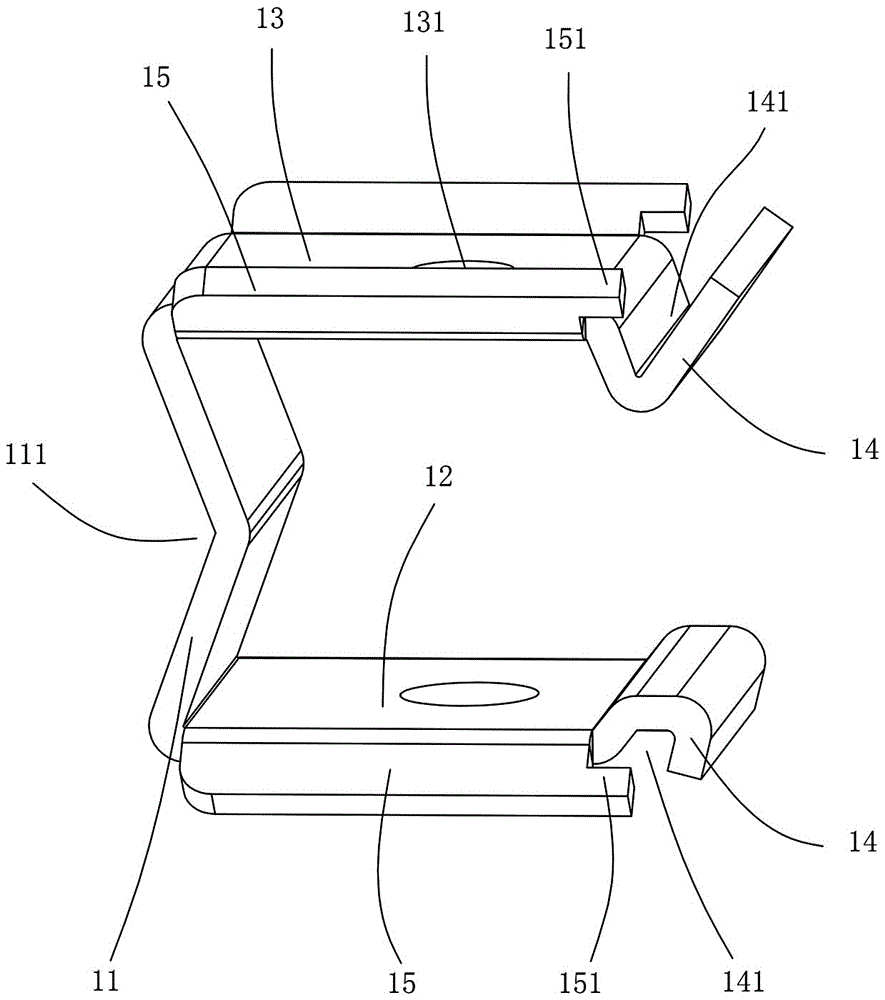

Fixing structure for automotive headlamp xenon bulb

ActiveCN106195843AEasy to install and replace the lamp holderReliable connectionRoad vehiclesLight fasteningsLamp shellHeadlamp

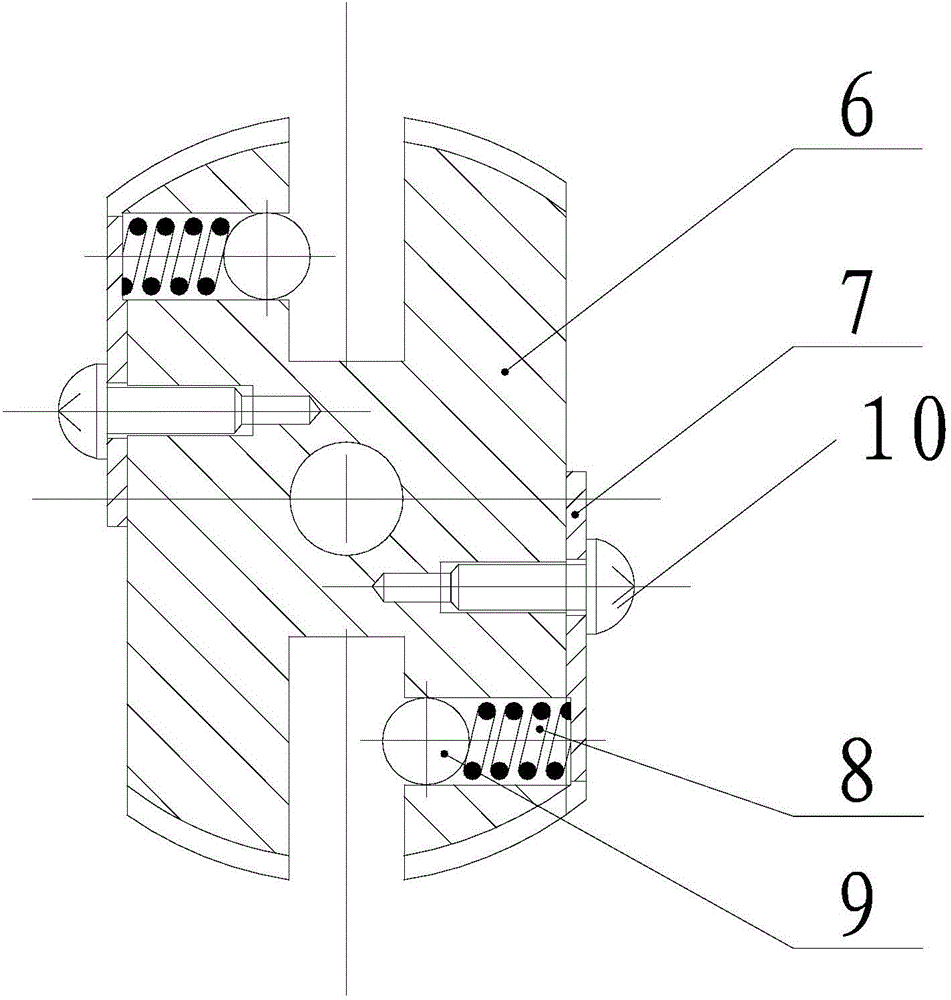

The invention relates to a fixing structure for an automotive headlamp xenon bulb. The bulb is mounted on a lamp shell of a lamp holder. A bulb fixing seat comprises two semicircular seat bodies. Each seat body is provided with a boss and a limiting post. A vertical groove in the inner side of the protruding arc wall and a peripheral clamping groove in the peripheral wall of each seat body communicate with each other. Two spring pieces are connected to the bosses on the corresponding seat bodies through at least one corresponding assembling hole in a pressing manner. Bottom plates of the two seat bodies are inserted into the neck of the lamp shell and connected in a bucked manner. An upper convex point on the inner side of each spring piece abuts against the bottom face of a lamp holder limiting disc. Elastic pins penetrate gaps in the bottom plates of the seat bodies and abut against the lamp shell of the lamp holder. At least two protruding blocks on the periphery of each base for a reflector penetrate the corresponding vertical grooves and are rotated to the peripheral clamping groove. Reflectors are clamped to the corresponding seat bodies. The bases of the reflectors are pressed on the upper convex points of the outer sides of the corresponding spring pieces. The fixing structure has the beneficial effects of being simple in structure, capable of fixing the reflectors and the lamp holder without loosening and capable of effectively solving the problems of light scattering and poor concentrating caused by waggling of the lamp bulb of an automotive lamp.

Owner:CHANGZHOU XINGYU AUTOMOTIVE LIGHTING SYST

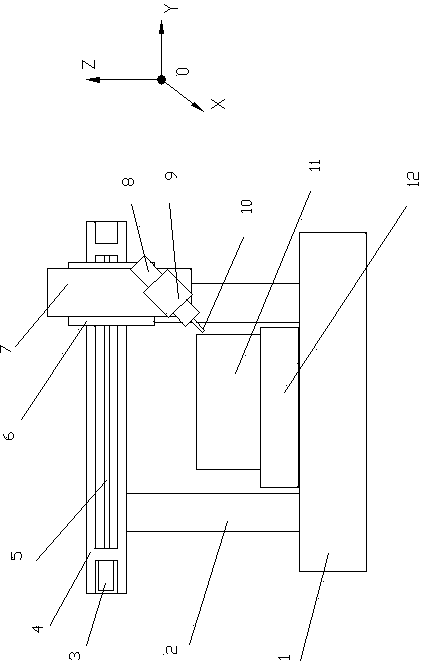

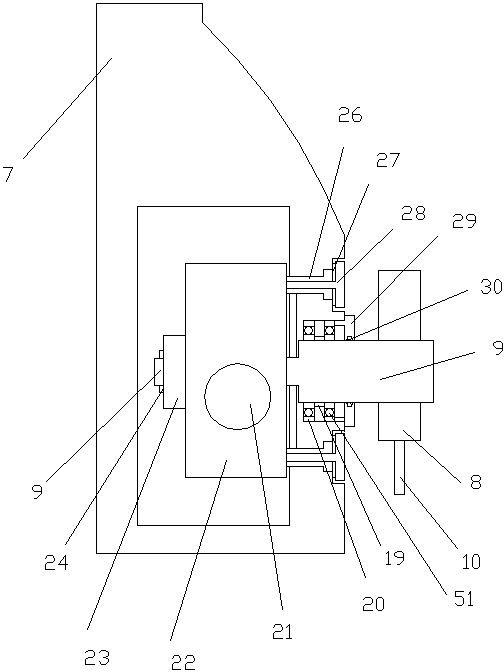

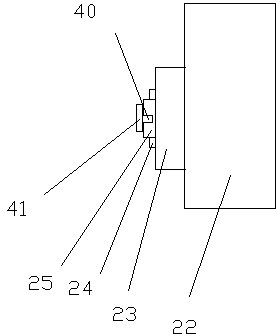

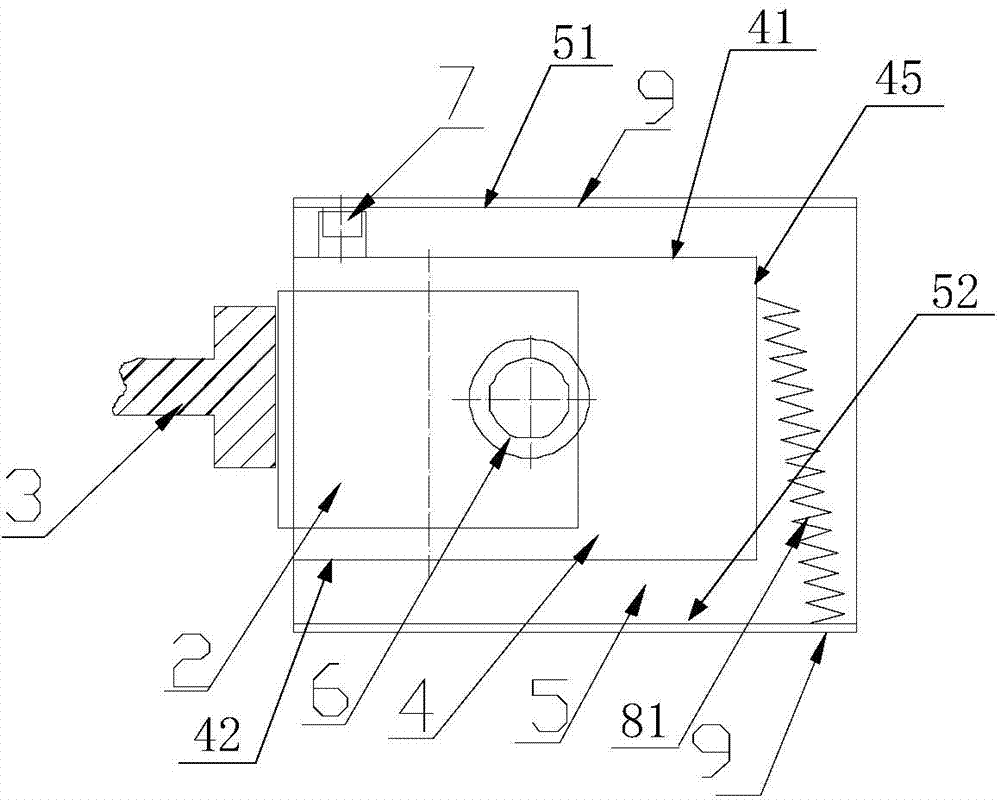

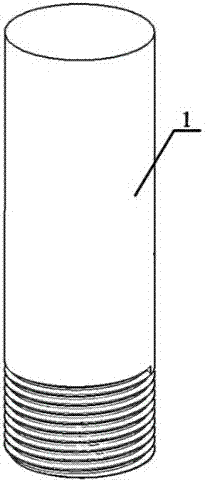

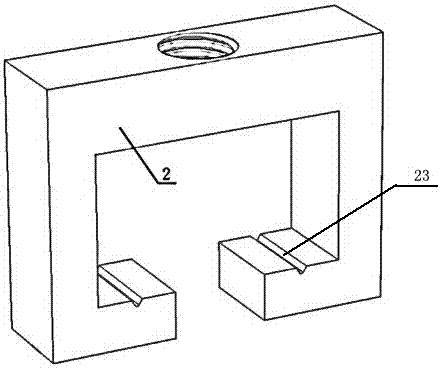

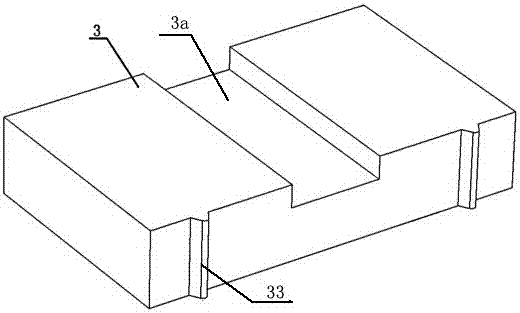

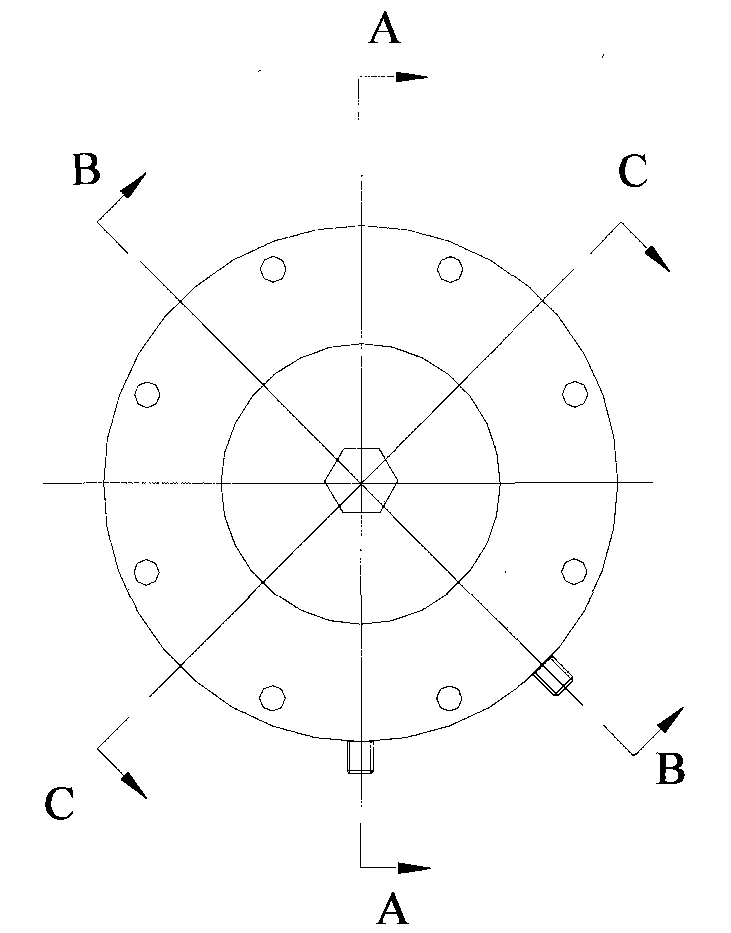

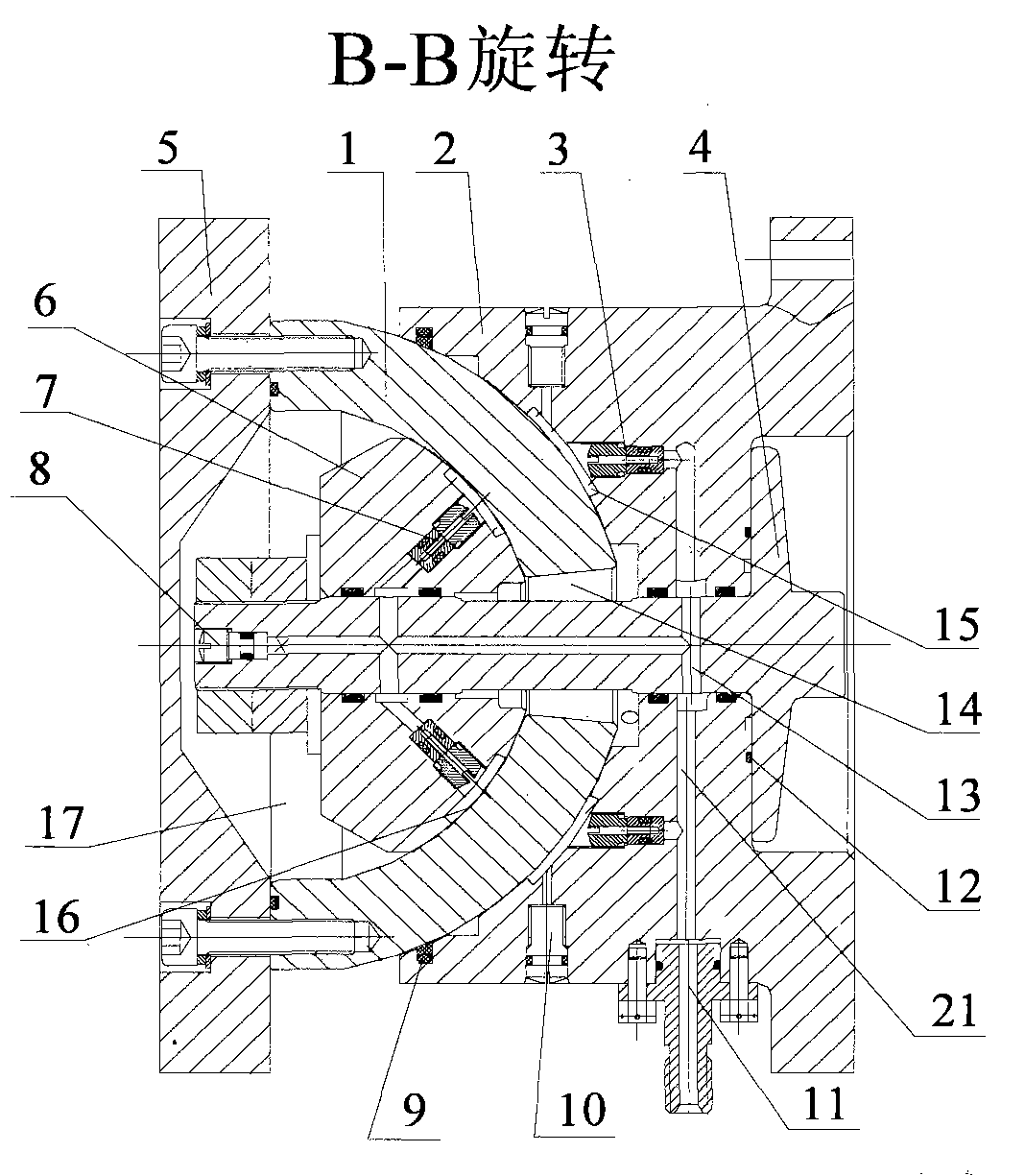

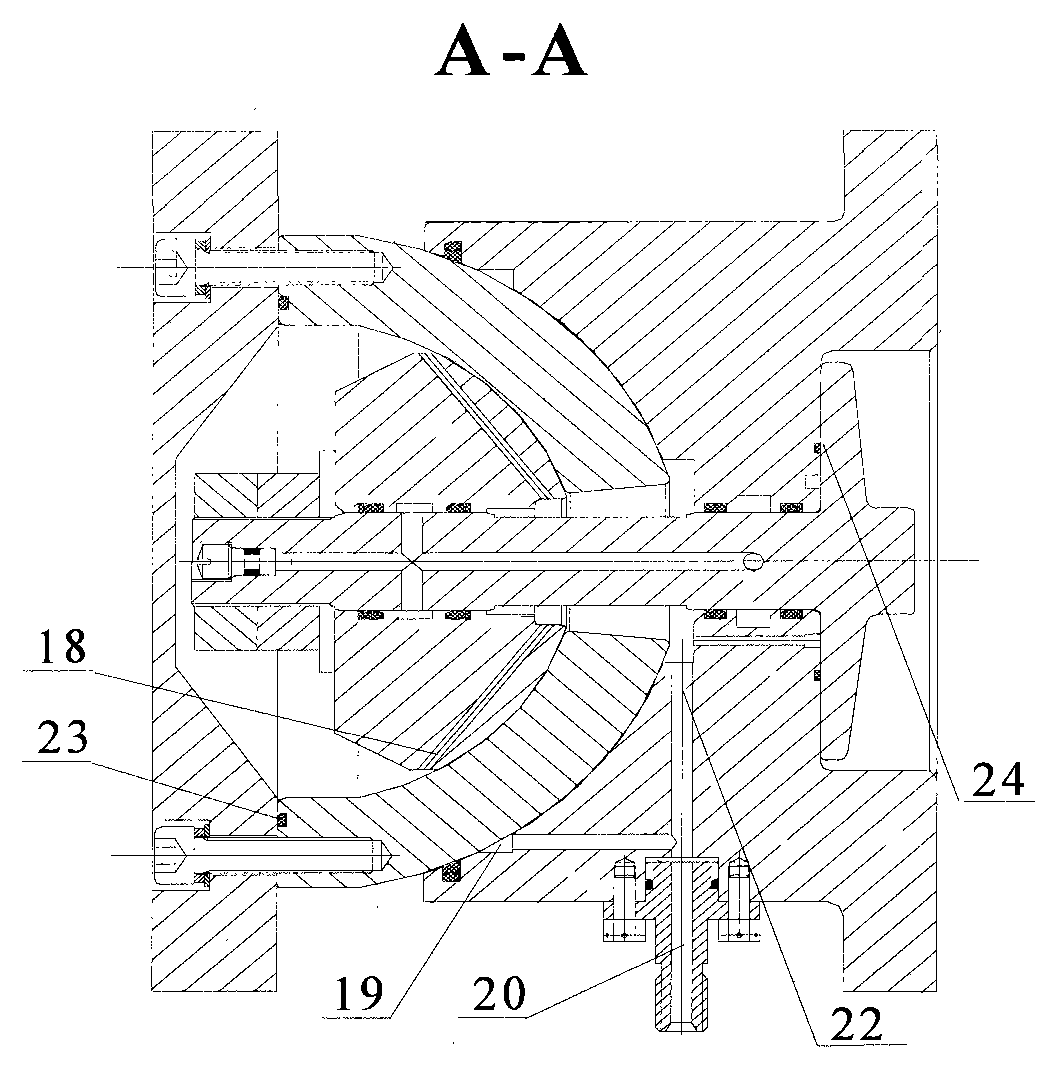

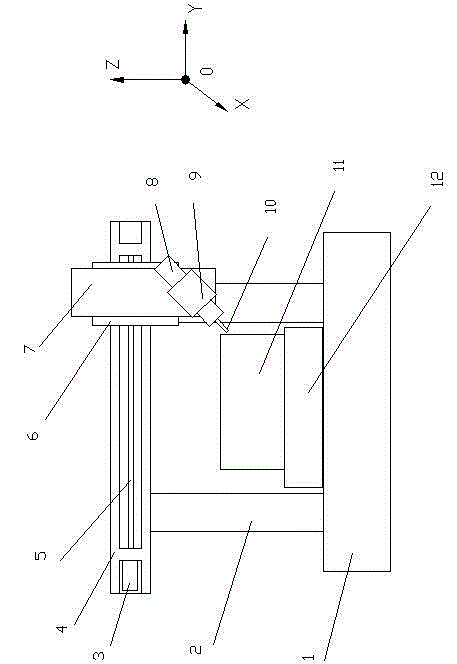

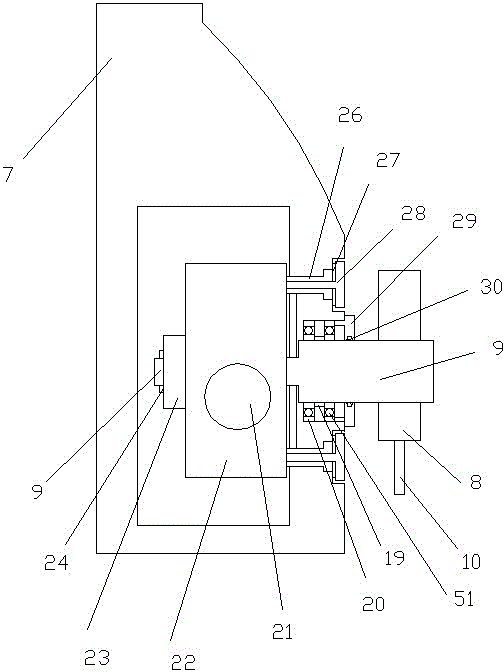

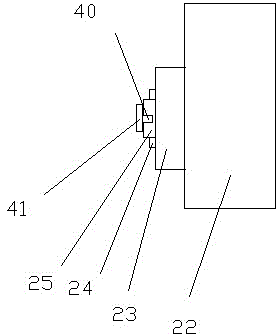

Vertical five-shaft linkage machine tool

The invention discloses a vertical five-shaft linkage machine tool. The vertical five-shaft linkage machine tool comprises an overhanging-eave-type portal frame, a swing input motor (21), a swing speed reducer (22), a motorized spindle clamping head (9) and a motorized spindle (8), wherein the swing speed reducer (22) is arranged in a ram (7) and is in bolted connection with the ram (7), the swing input motor (21) is connected with the swing speed reducer (22) through a coupling, the swing speed reducer (22) is of a worm and gear structure, a worm-wheel shaft is a hollow output shaft (24), a worm is connected with the swing input motor (21) through a coupling, the rear end of the motorized spindle clamping head (9) is connected with the worm-wheel hollow output shaft (24) through an expansion sleeve (23), and the front end of the motorized spindle clamping head (9) is installed on the ram (7) through a bearing. The rigidity of the machine tool is improved by more than four times when compared with that of a traditional series machine tool, a connection gap between the swing input motor and the motorized spindle is avoided, swing precision is improved, rolled steel can be efficiently machined at the speed of 10000 turn / min, and the overall performance, including the rigidity, precision and machining speed, of the machine tool is substantially improved when compared with that of existing domestic and overseas machine tools.

Owner:NANJING GEWAI TRACK TRAFFIC EQUIP CO LTD

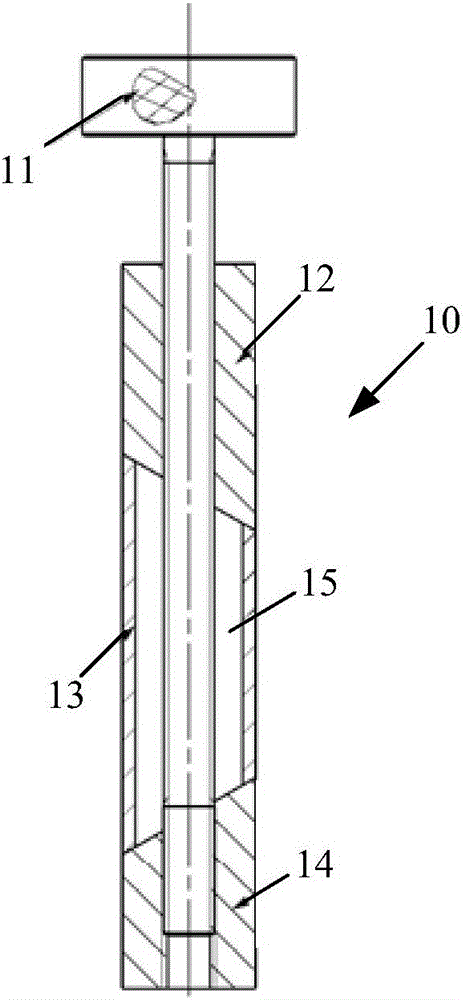

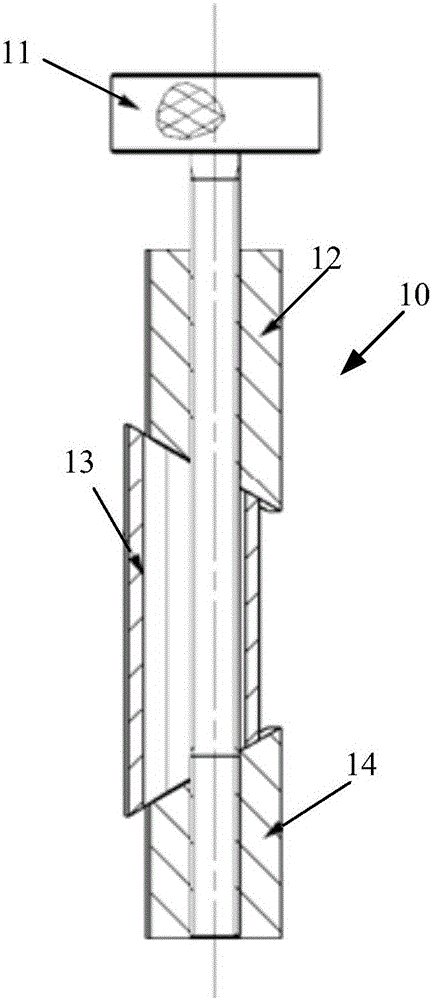

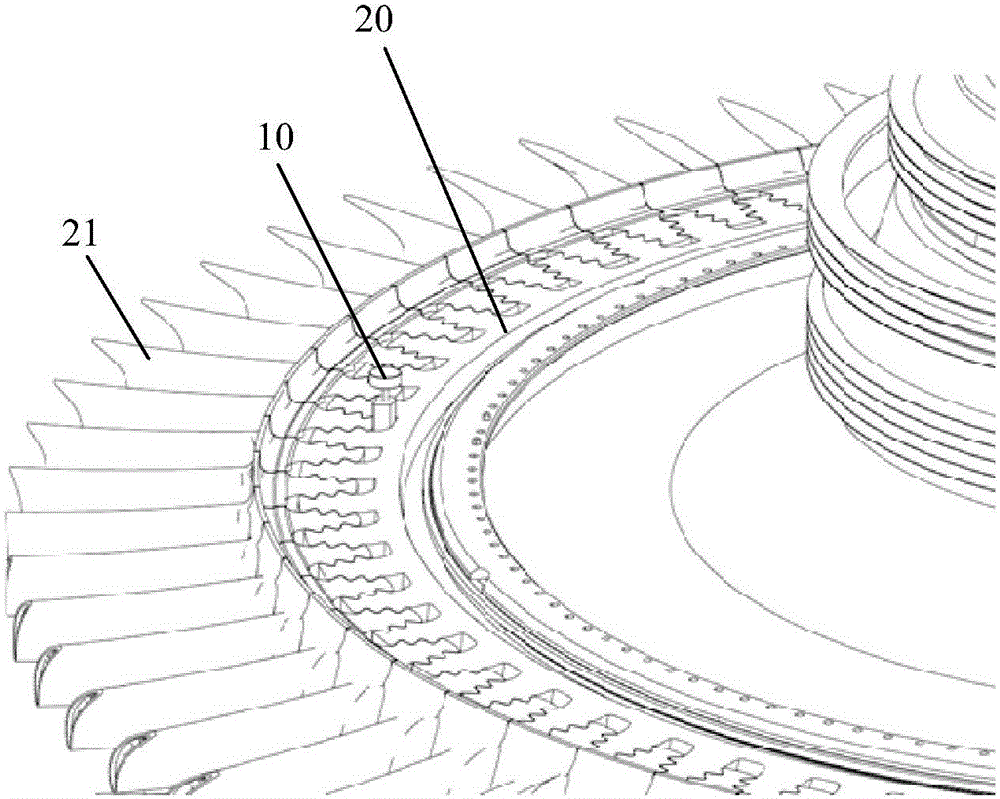

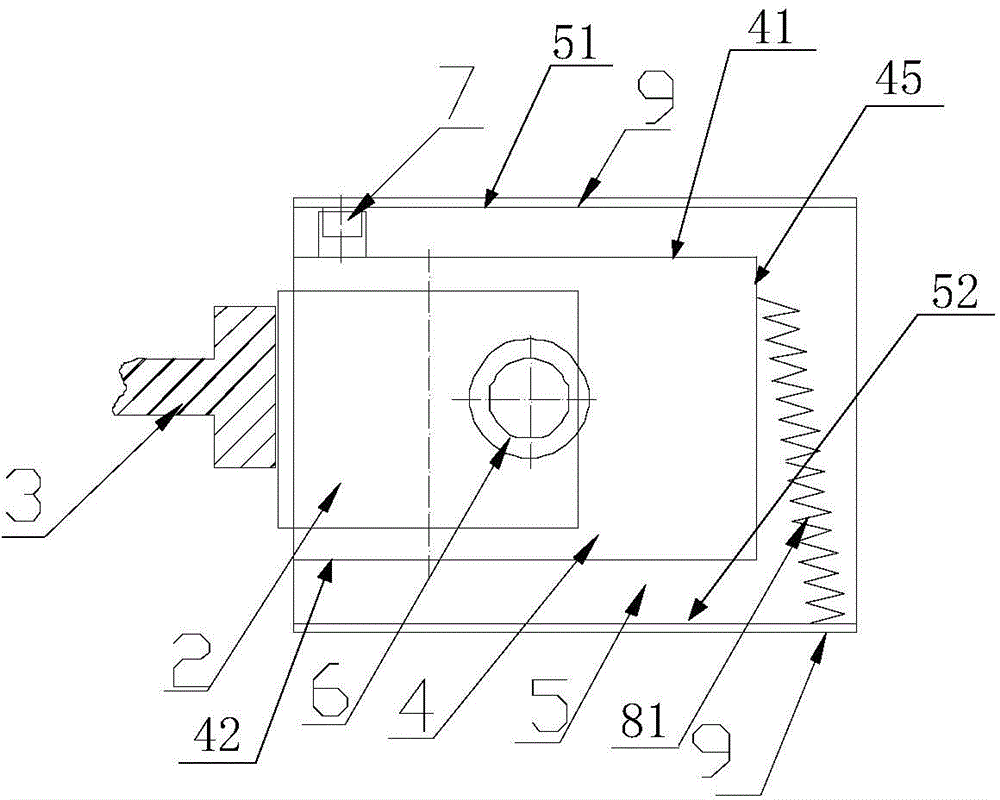

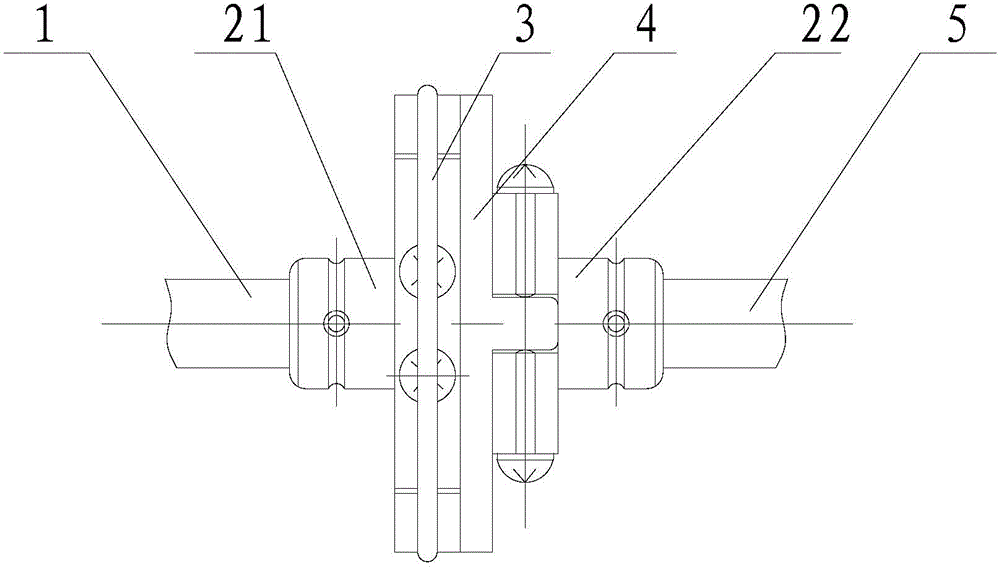

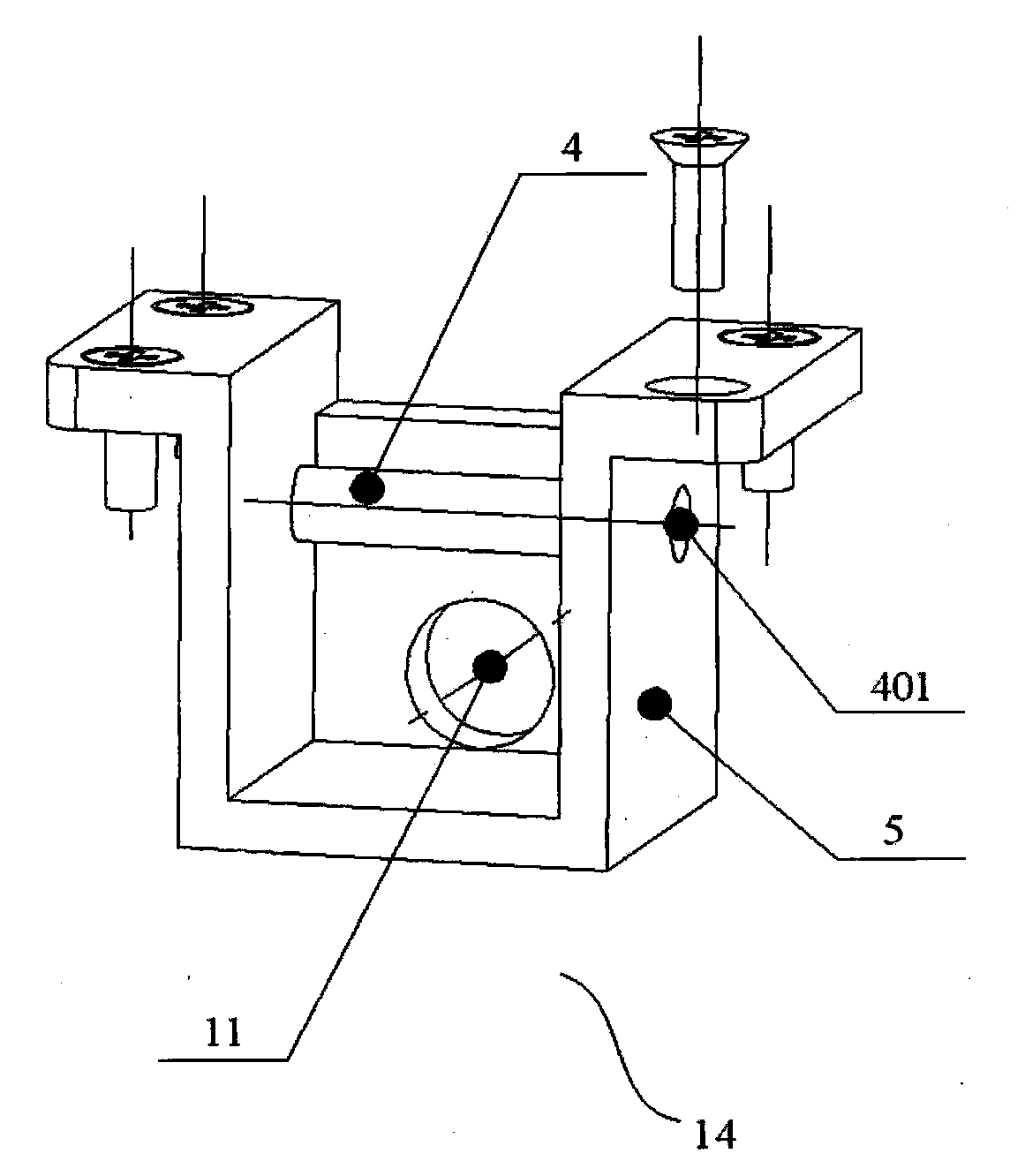

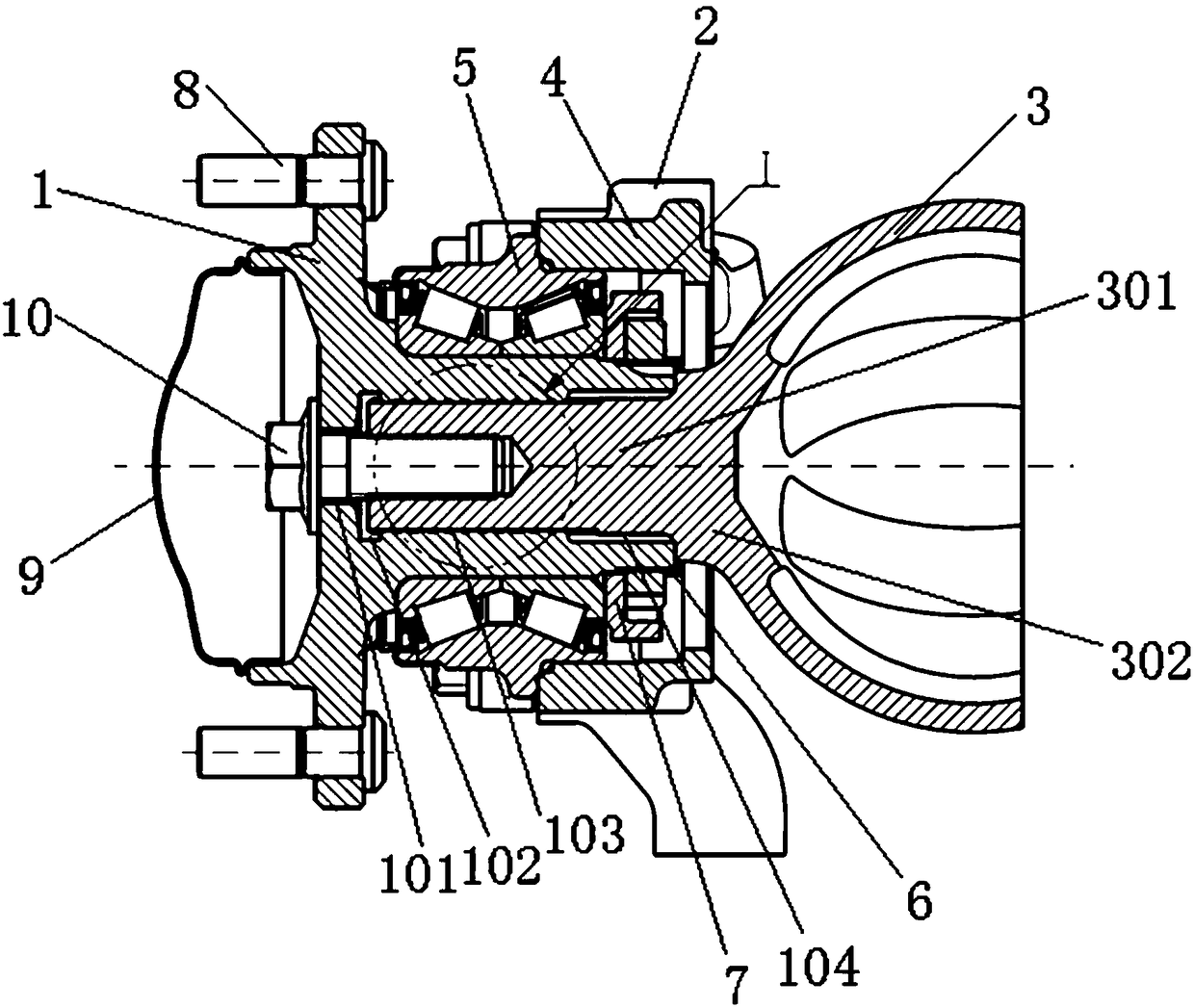

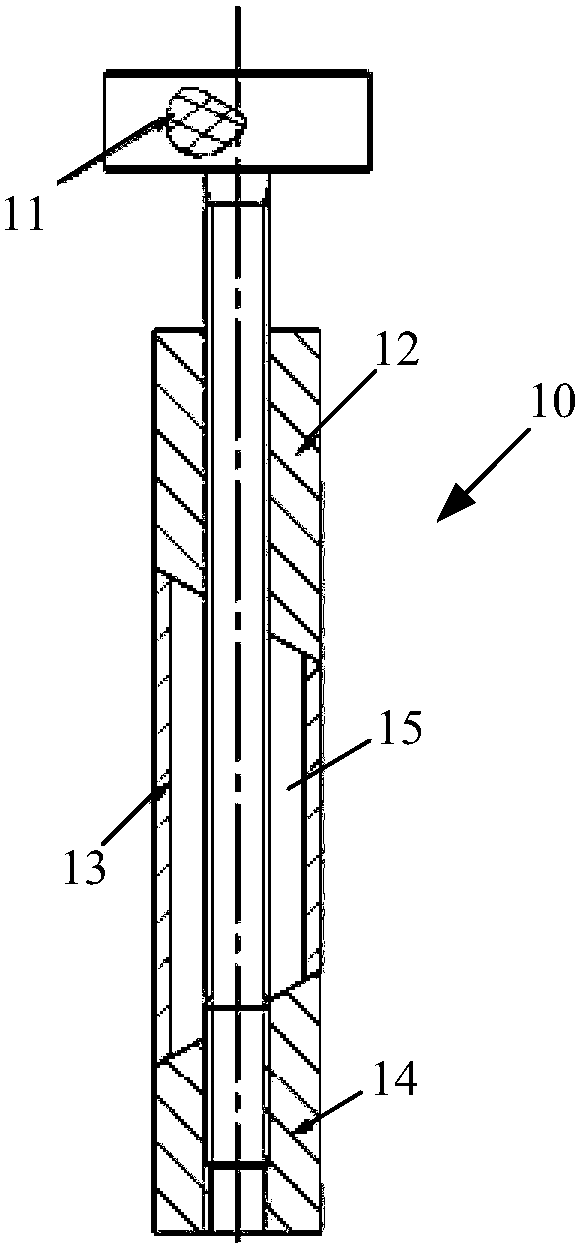

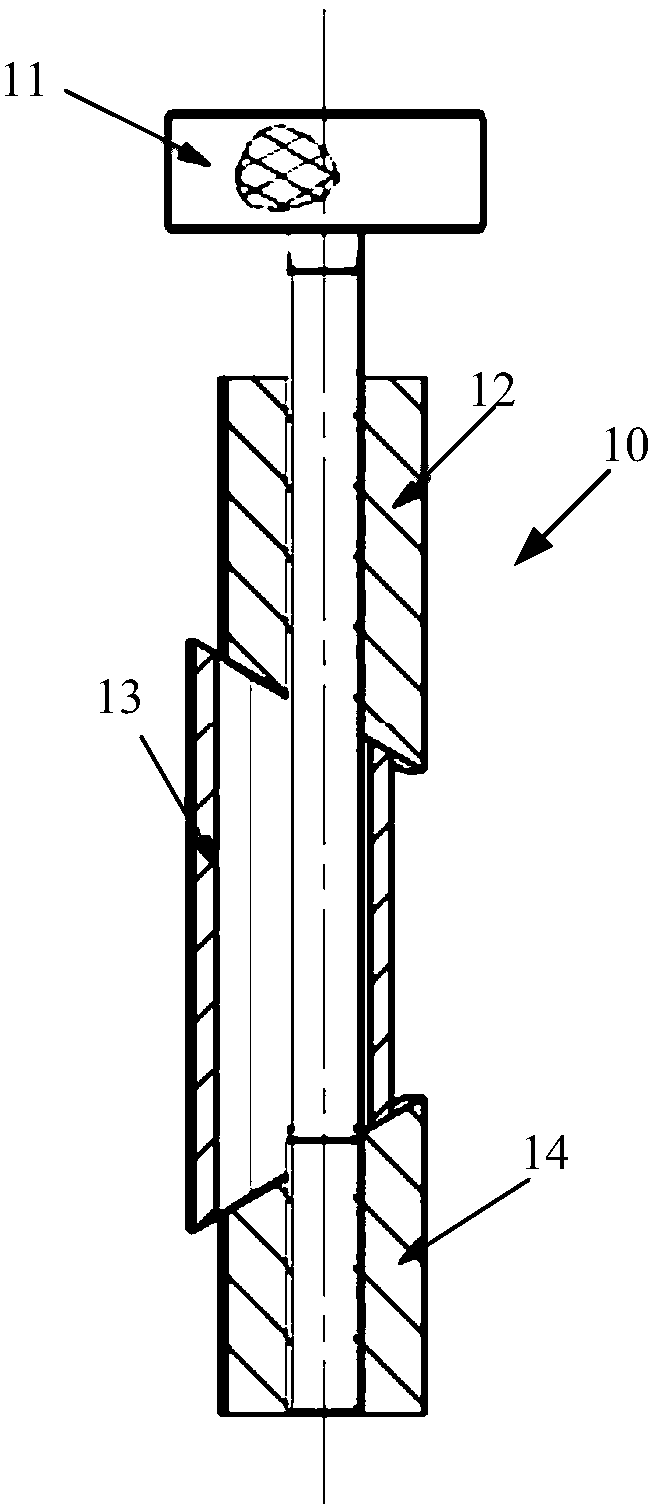

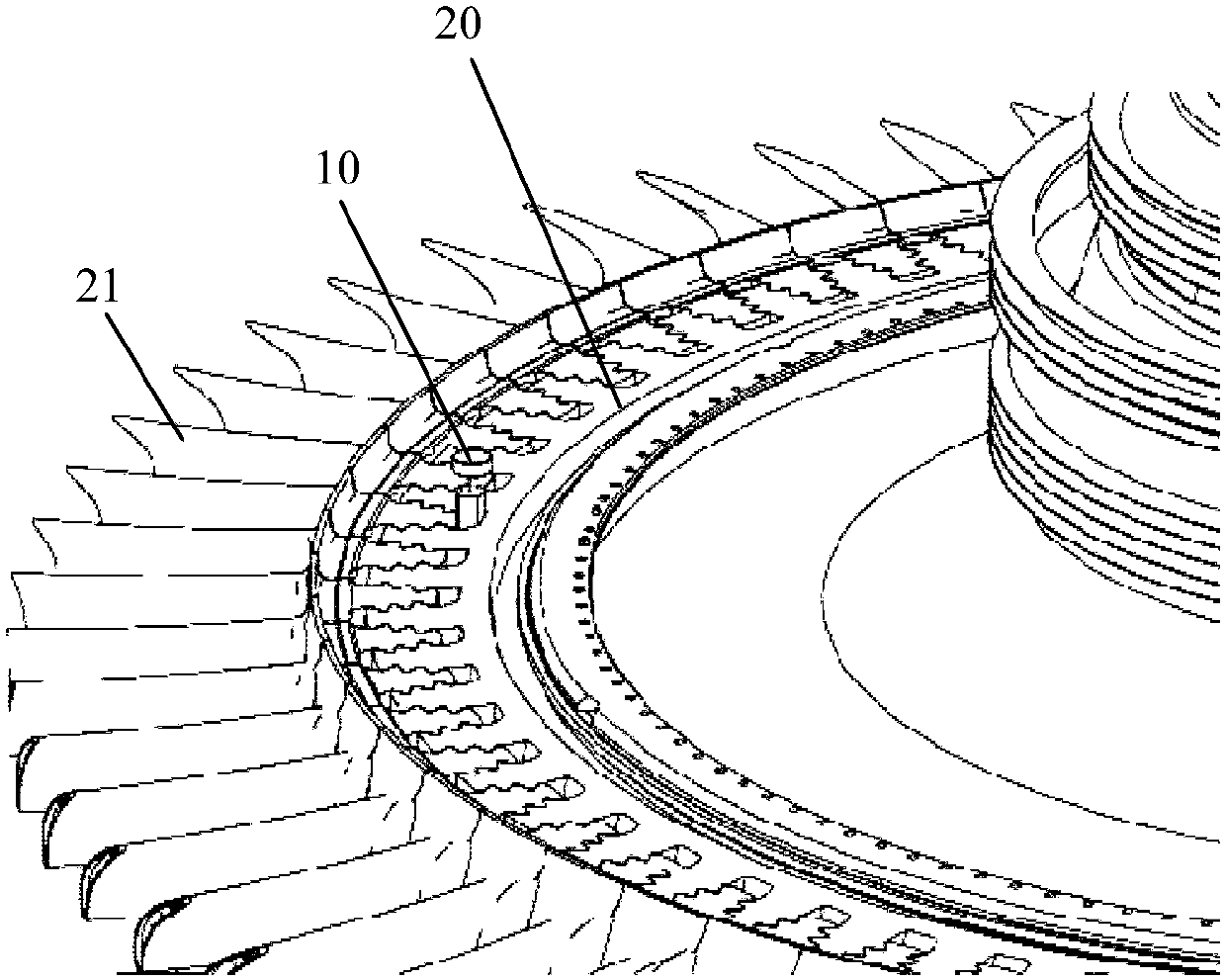

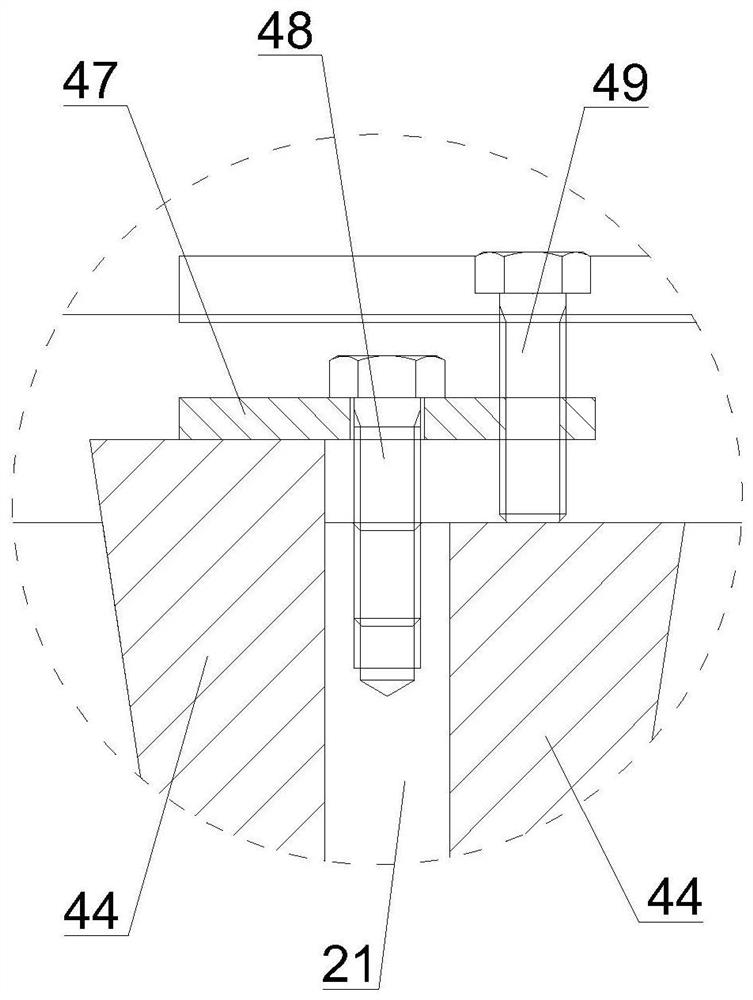

Tool and method for eliminating connection gaps of high-pressure turbine rotor blades

ActiveCN107524477AEliminate connection gapsSimple structureLeakage preventionMachines/enginesTurbine bladeHigh pressure

The invention provides a tool and method for eliminating connection gaps of high-pressure turbine rotor blades. The tool comprises an adjusting screw rod, an upper driving block, a squeezing block and a lower driving block. The squeezing block and the lower driving block are sequentially arranged on the adjusting screw rod in a penetration mode. When the adjusting screw rod is screwed, the upper driving block drives the adjusting screw rod to rotate to squeeze the squeezing block downward. The lower driving block drives the adjusting screw rod to rotate to squeeze the squeezing block upwards, so that the squeezing block protrudes outwards. In the method, the tool for eliminating the connection gaps of the high-pressure turbine rotor blades is adopted. By means of the tool and method for eliminating the connection gaps of the high-pressure turbine rotor blades, the connection gaps between the high-pressure turbine rotor blades and a turbine disk can be effectively eliminated, so that the diameter of high-pressure turbine blade tips is accurately obtained. The tool is simple in principle, simple in structure and low in manufacturing cost and maintenance cost.

Owner:AECC SHANGHAI COMML AIRCRAFT ENGINE MFG CO LTD +1

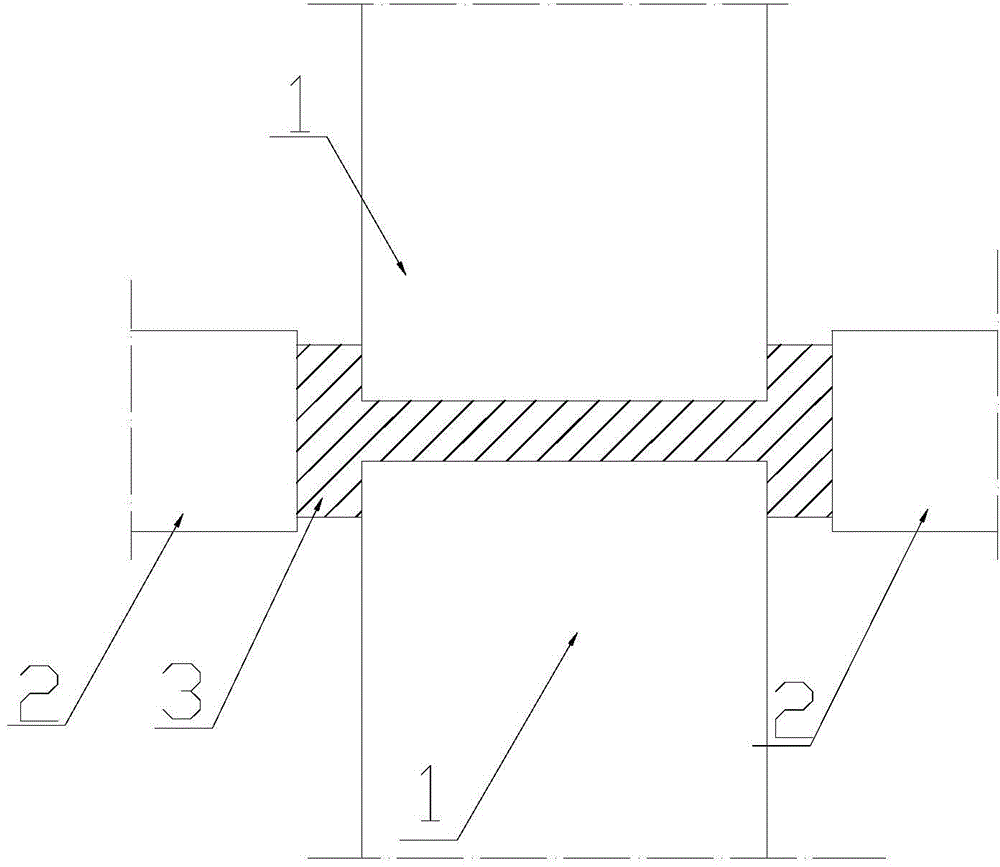

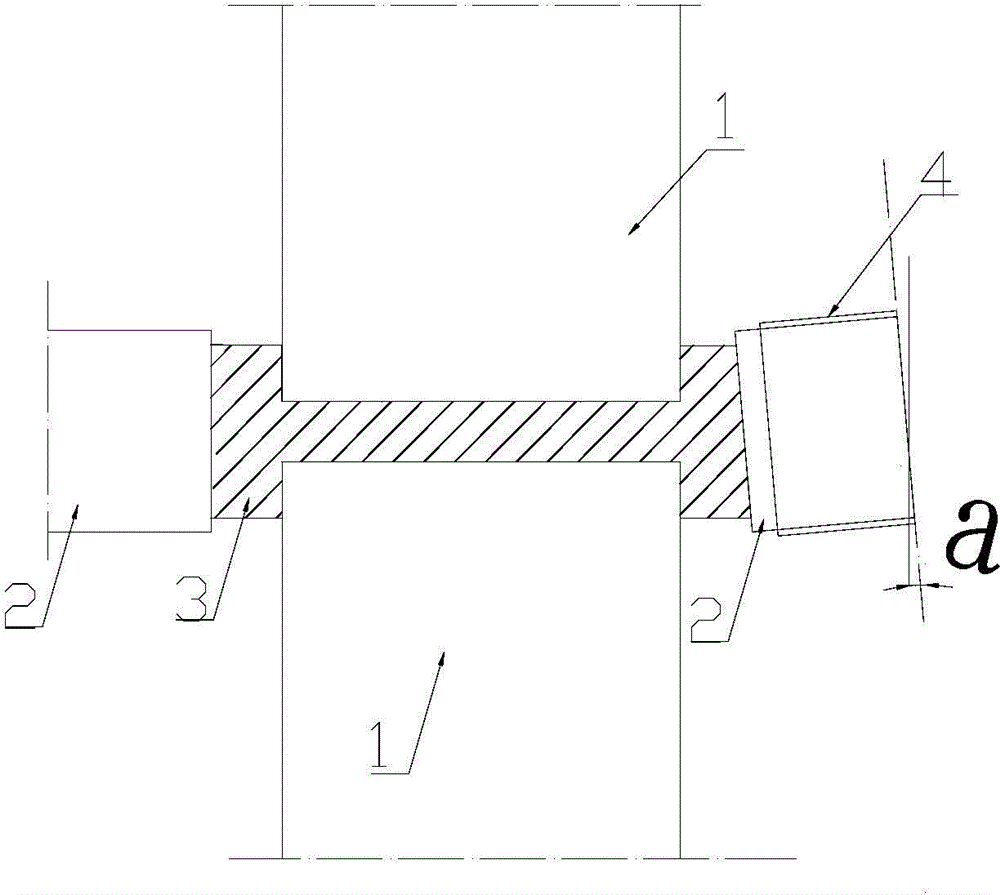

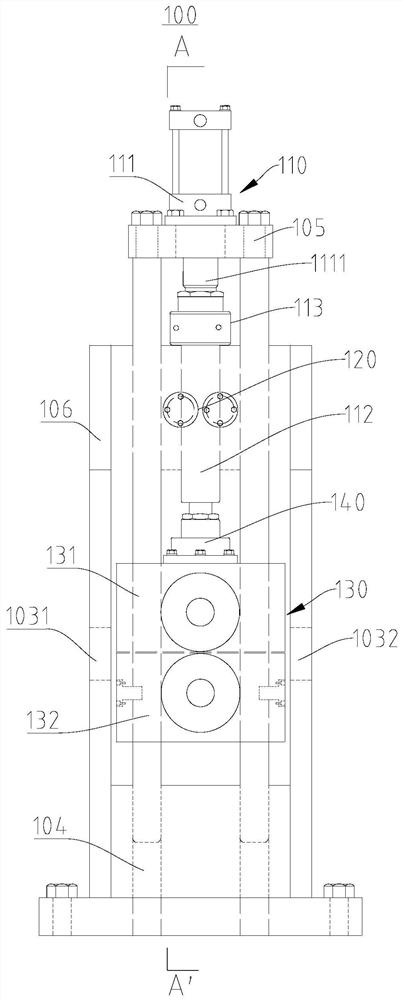

Universal rolling mill and rolling mill vertical roll device with adjustable vertical roll rotation axis angles

ActiveCN103551386AEliminate connection gapsAddressing non-adjustable deficienciesMetal rolling stand detailsMetal rolling arrangementsHydraulic cylinderEngineering

The invention discloses a universal rolling mill and a rolling mill vertical roll device with adjustable vertical roll rotation axis angles. The rolling mill vertical roll device with the adjustable vertical roll rotation axis angles comprises a vertical roll, an internal case with a first internal surface and a first external surface, an external case with a second internal surface and a second external surface, a hydraulic cylinder with a cylinder bottom and a piston rod and a pair of half shafts; the universal rolling mill comprises two horizontal rollers and two rolling mill vertical roll devices; the rolling mill vertical roll devices are the above rolling mill vertical roll devices with the adjustable vertical roll rotation axis angles. According to the technical scheme of the universal rolling mill and the rolling mill vertical roll device with the adjustable vertical roll rotation axis angles, inclined rotation axis angles of the vertical roll is rapidly and effectively corrected, the efficiency is high, and the cost is low.

Owner:LAIWU IRON & STEEL GRP

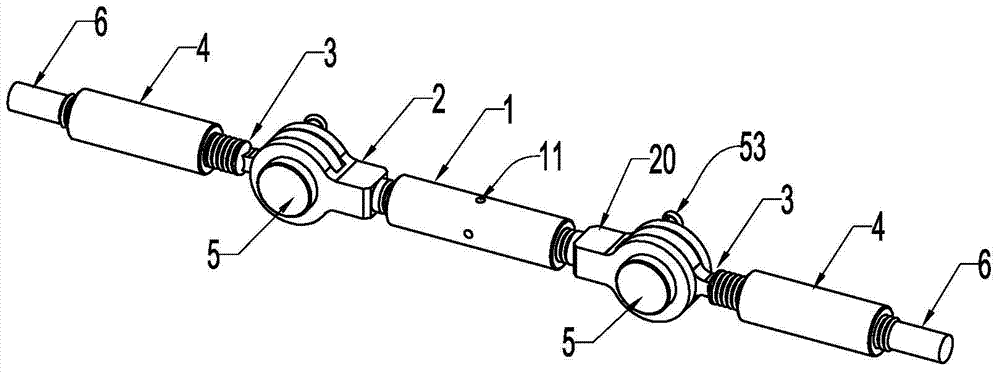

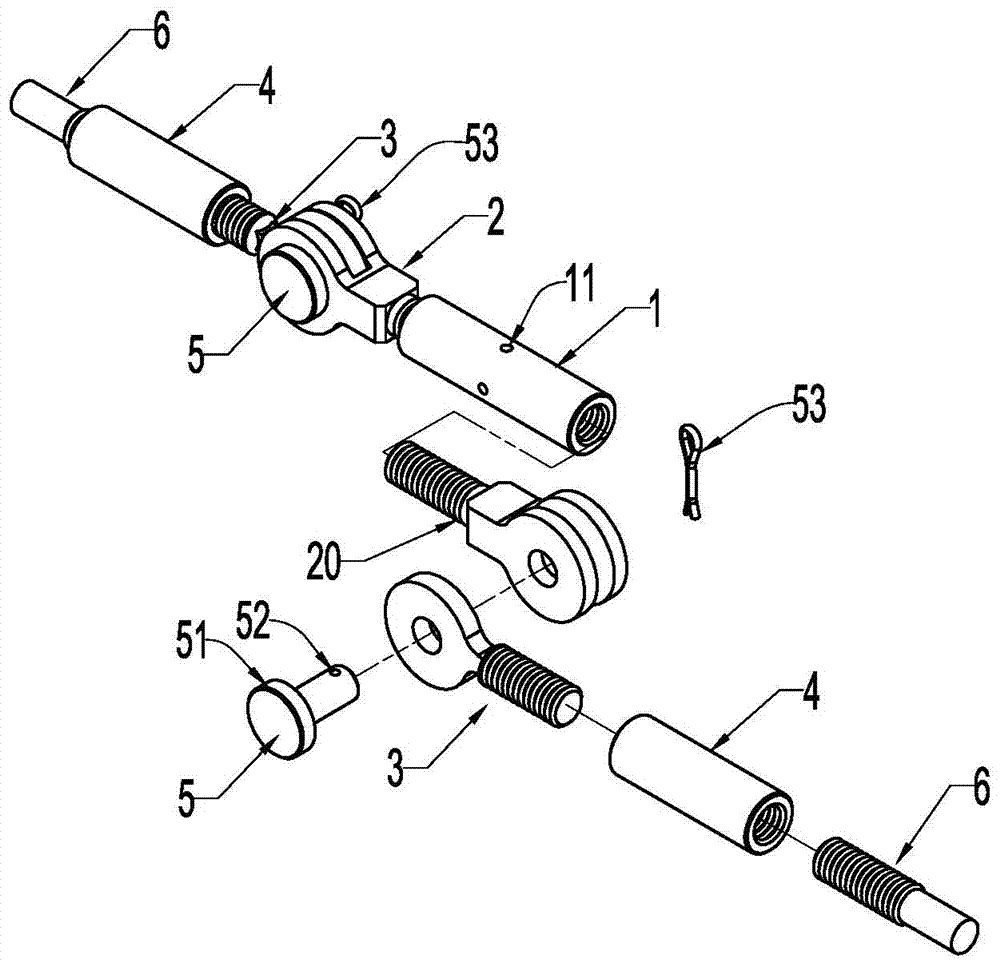

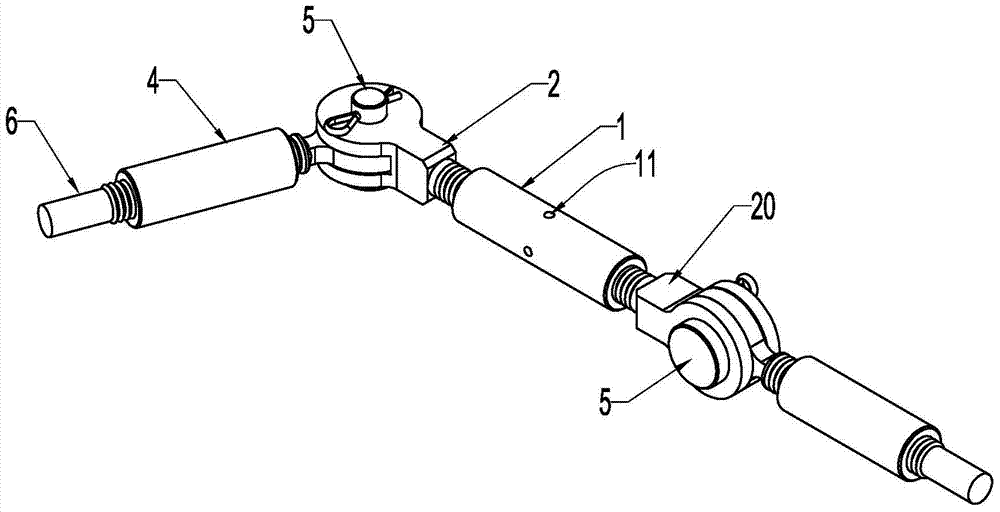

Telescopic steel bar connecting external member

ActiveCN105064622AEasy connection and constructionReduce short-distance connectionsBuilding reinforcementsButt jointShortest distance

The invention relates to a telescopic steel bar connecting external member. An external member body comprises a bidirectional thread sleeve, a forward spinning screw rod seat, a reverse spinning screw rod seat, screw connectors, one-way thread sleeves and pin shafts. An internal thread at one end of the bidirectional thread sleeve is consistent with internal threads of the one-way thread sleeves, and the forward spinning screw rod seat, the screw connectors and external threads headed and turned by steel bar heads are consistent. All the components in the external member can be organically combined, for example, the components are increased or reduced, two steel bar heads with different intervals are in butt joint, and the external member for connection of the steel bar heads on a construction site is provided. The telescopic steel bar connecting external member has the advantages that the combining mode is flexible, according to the needs for steel bar intervals, short-distance connection can be achieved by reducing the components, the needs for long-distance connection can be met by adding the components connected in series, and connecting clearances are tightened and eliminated through the bidirectional thread sleeve; connection is reliable, no deformation exists, the requirement for stress design can be met, the telescopic steel bar connecting external member meets the connection needs of two staggered steel bar heads with different included angles, and connection construction of the steel bars is greatly facilitated.

Owner:裴敏雅

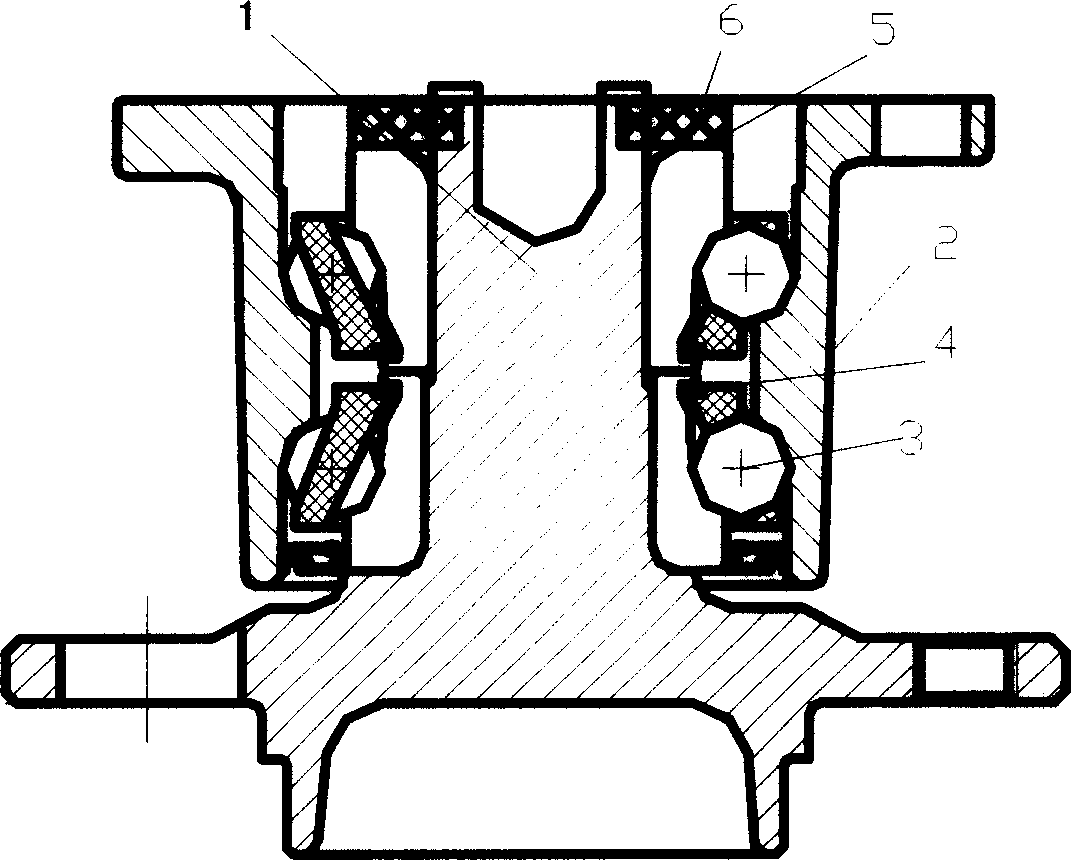

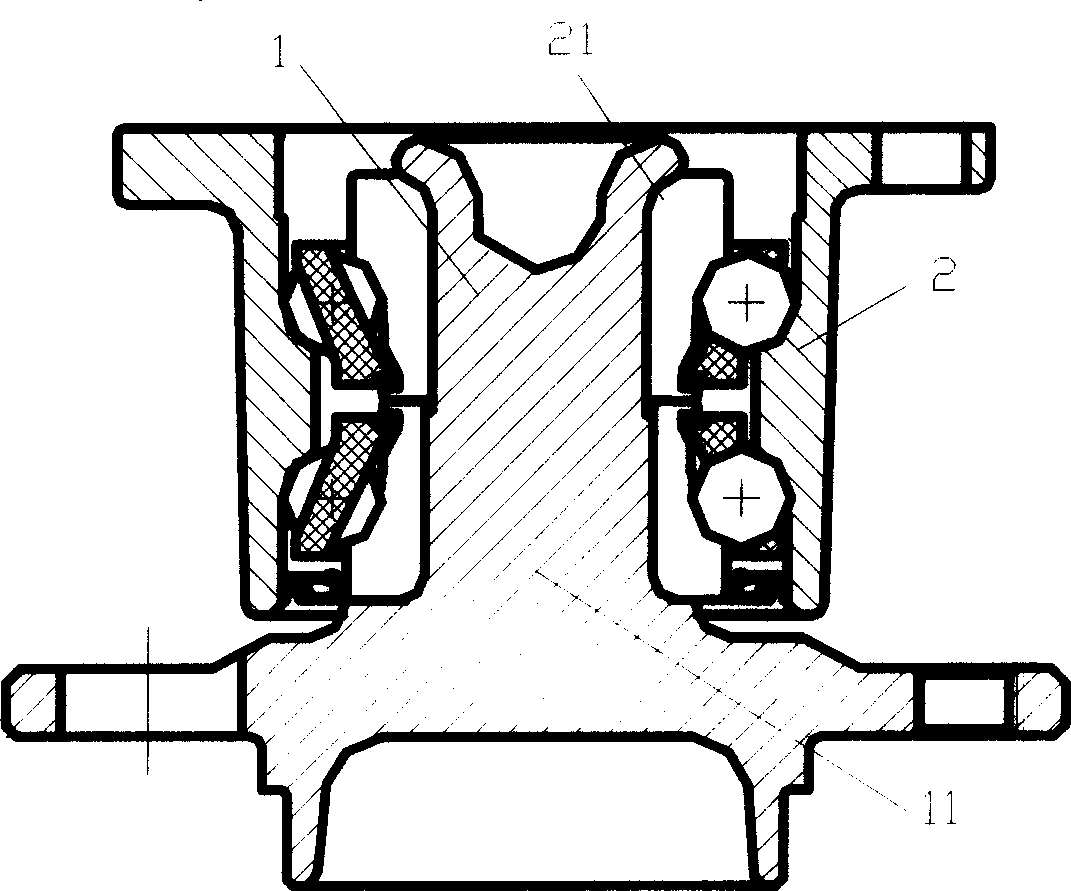

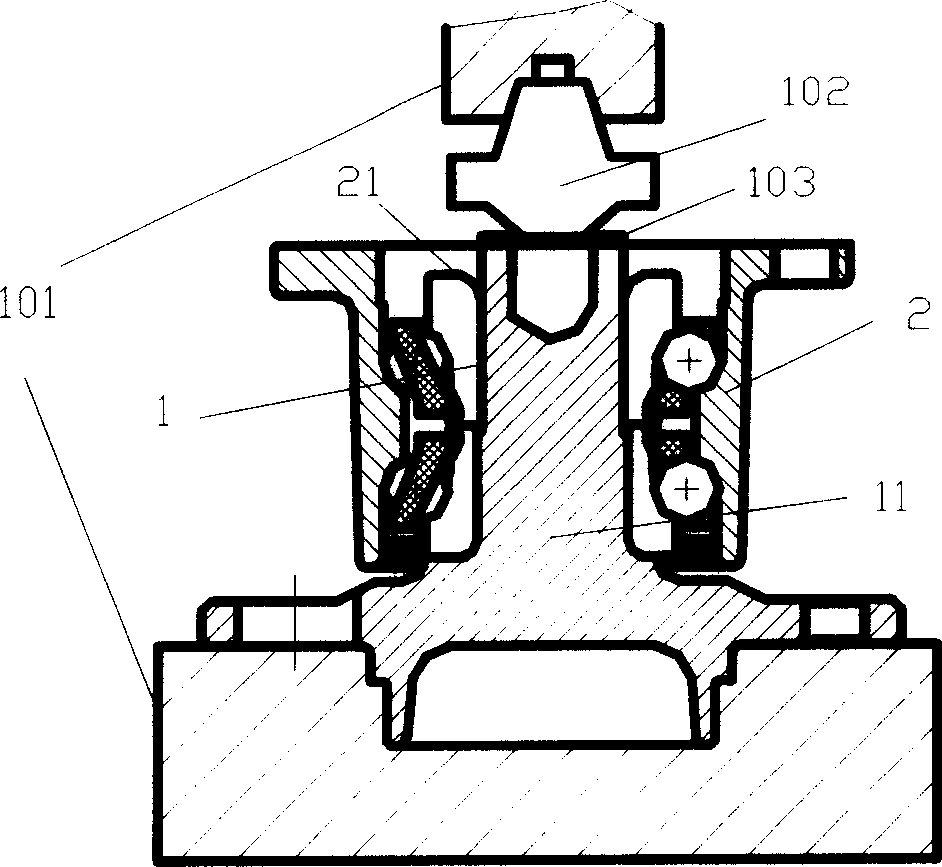

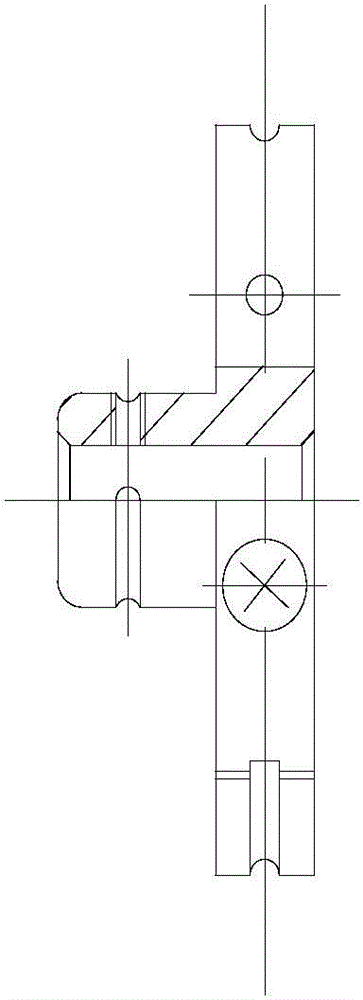

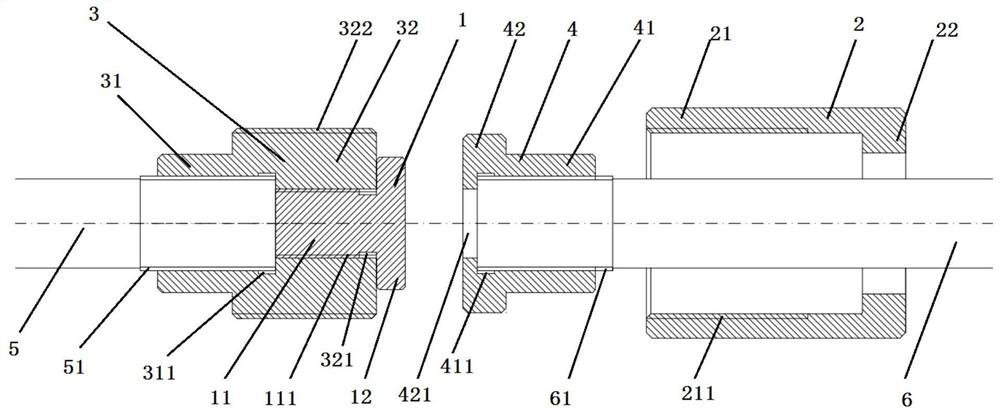

Inside and outside flange connecting apparatus for wheel hub bearing and manufacturing method thereof

InactiveCN1763390AFirmly connectedEliminate connection gapsHubsBearing unit rigid supportEngineeringCirclip

The invention relates to an in-and-out flange connecting device and making method in the hub bearing, which comprises the following parts: inner flange (1), outer flange with double channels (2), wherein the touching position of in-and-out flange contains an inner circlet (21); the shaft (11) of inner flange (1) connects the inner circlet (21) through epigene action. The device affirms the fixing connection of in-and-out flange without gap, which is convenient to manufacture without circlip.

Owner:上海人本轴承有限公司

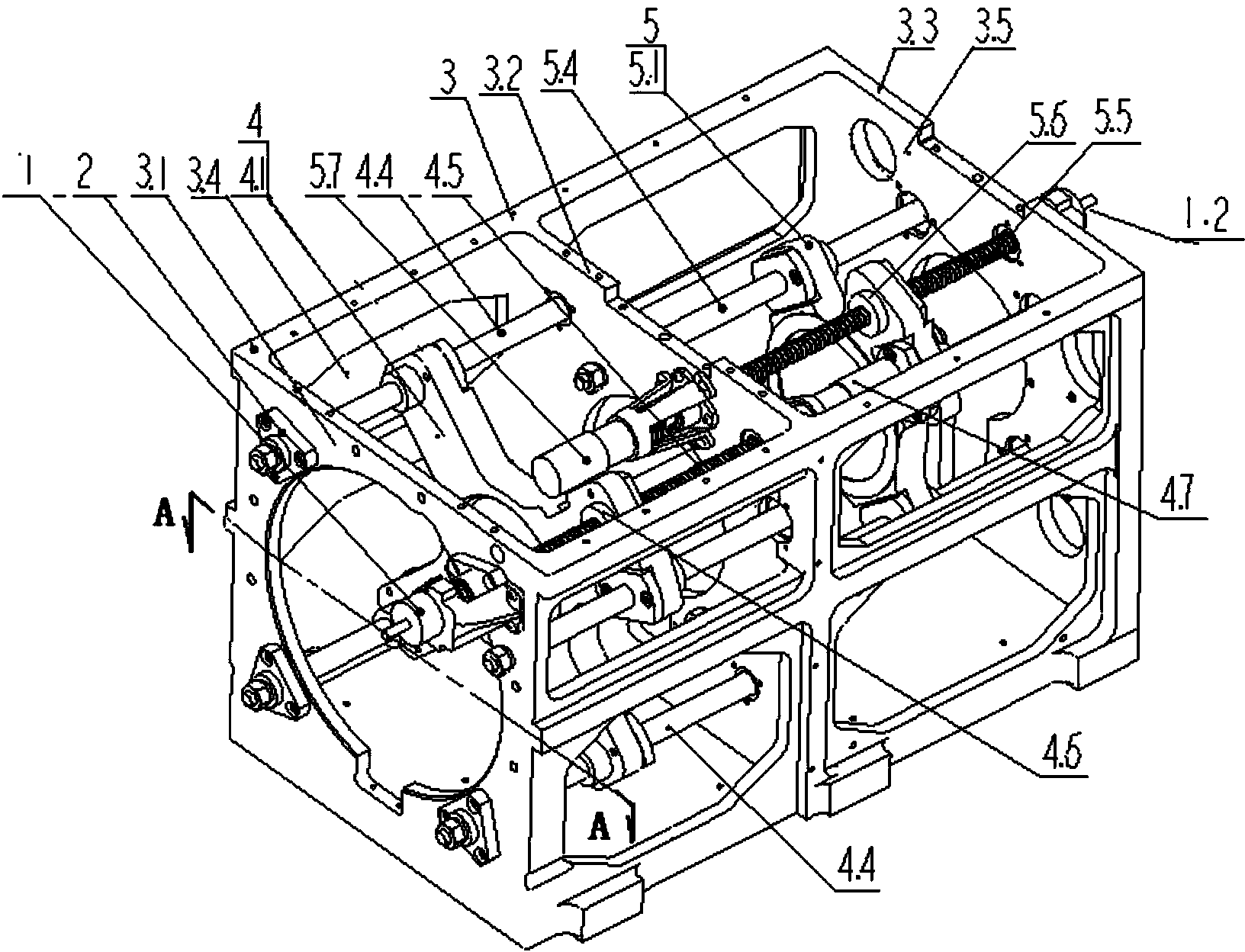

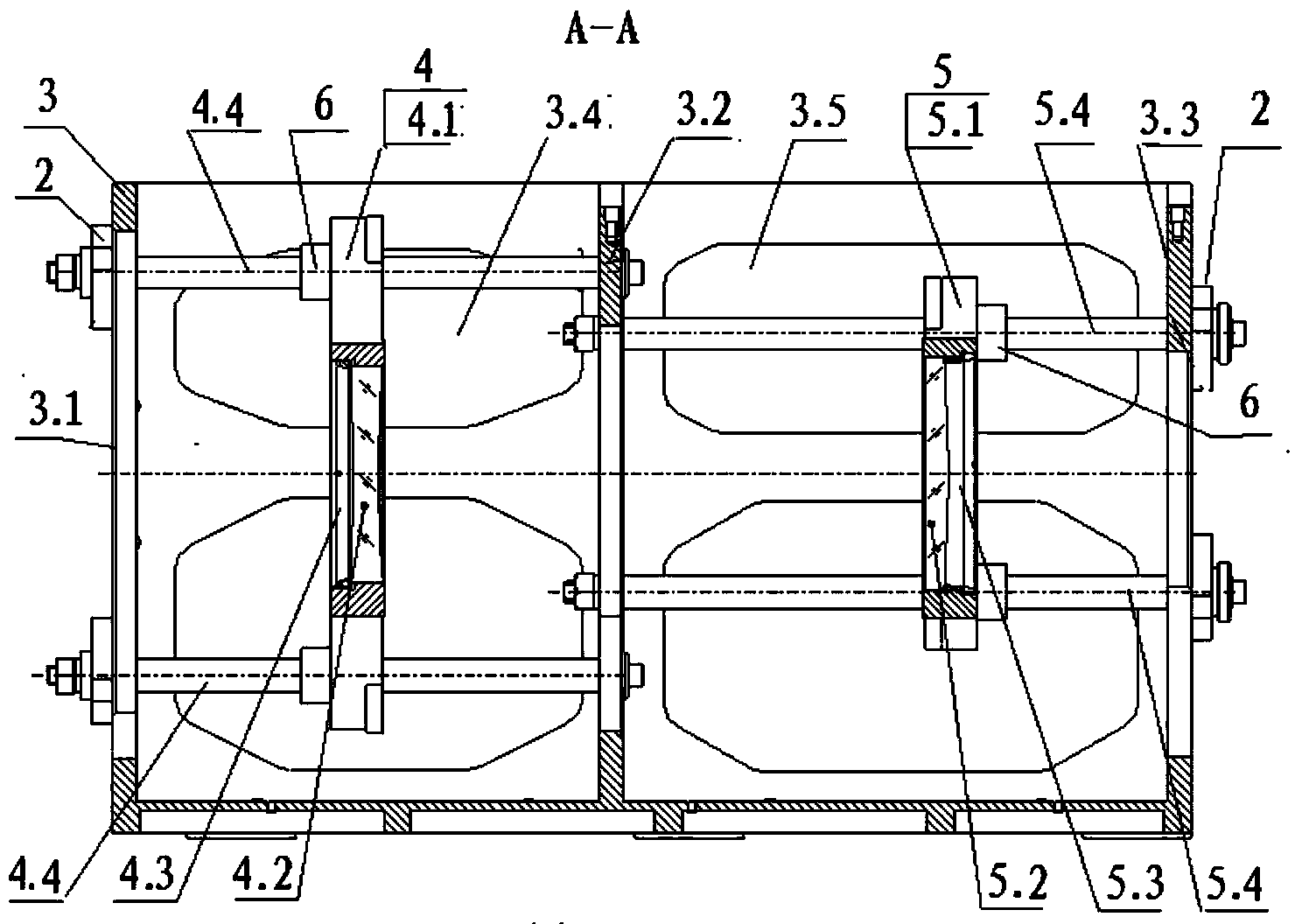

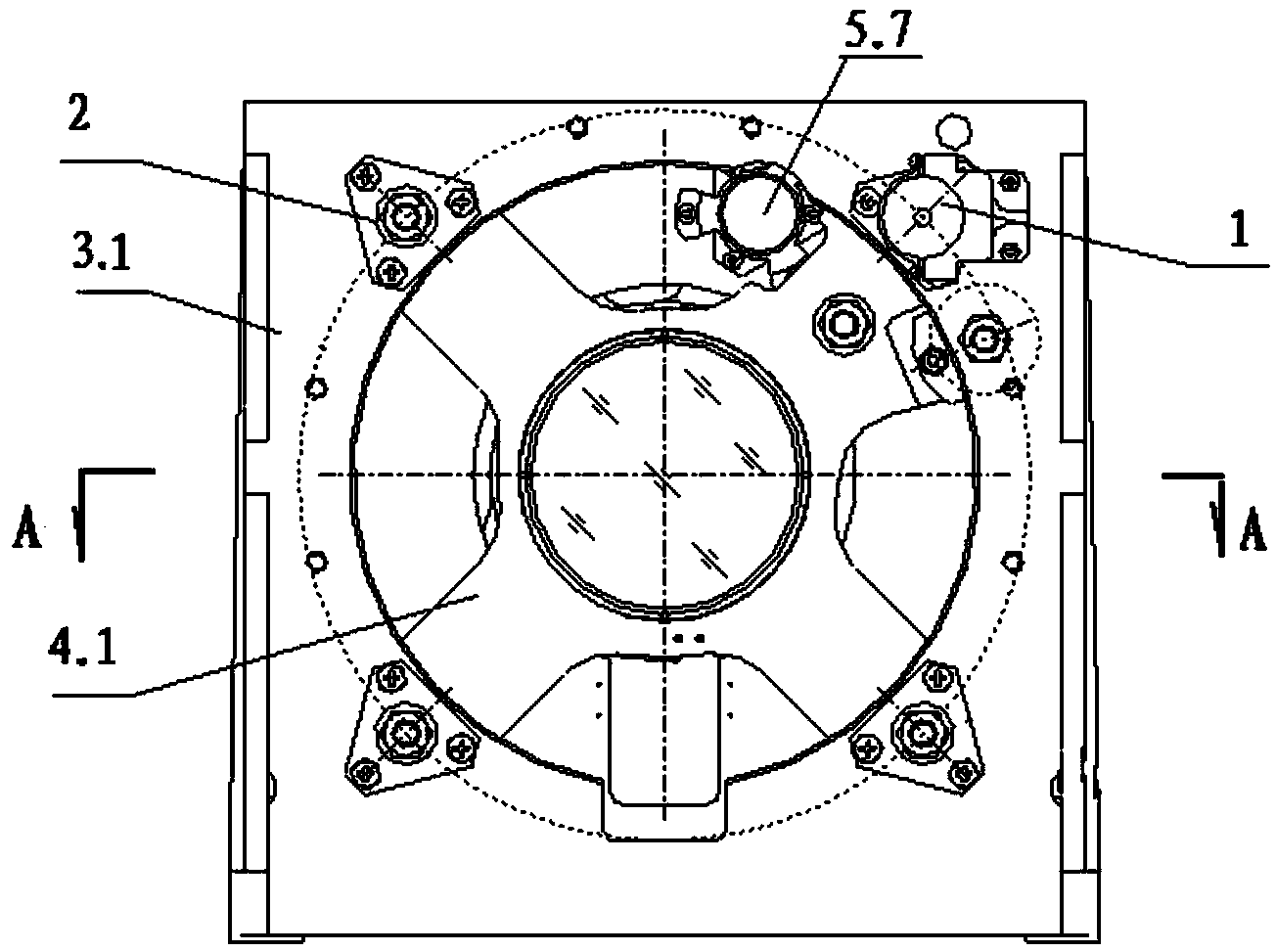

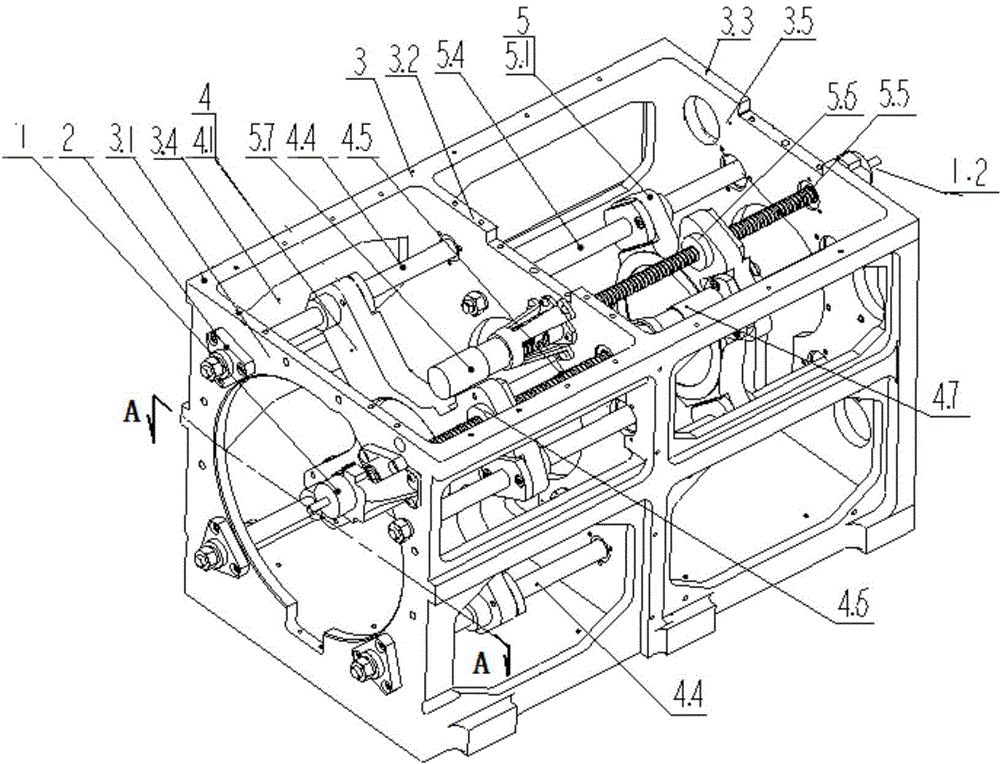

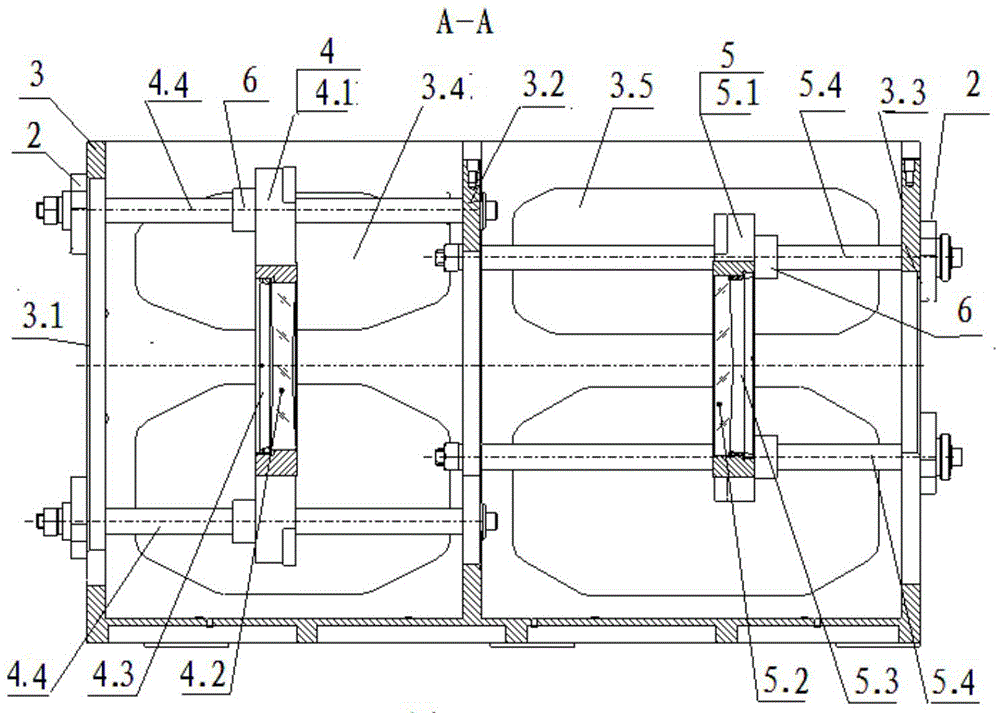

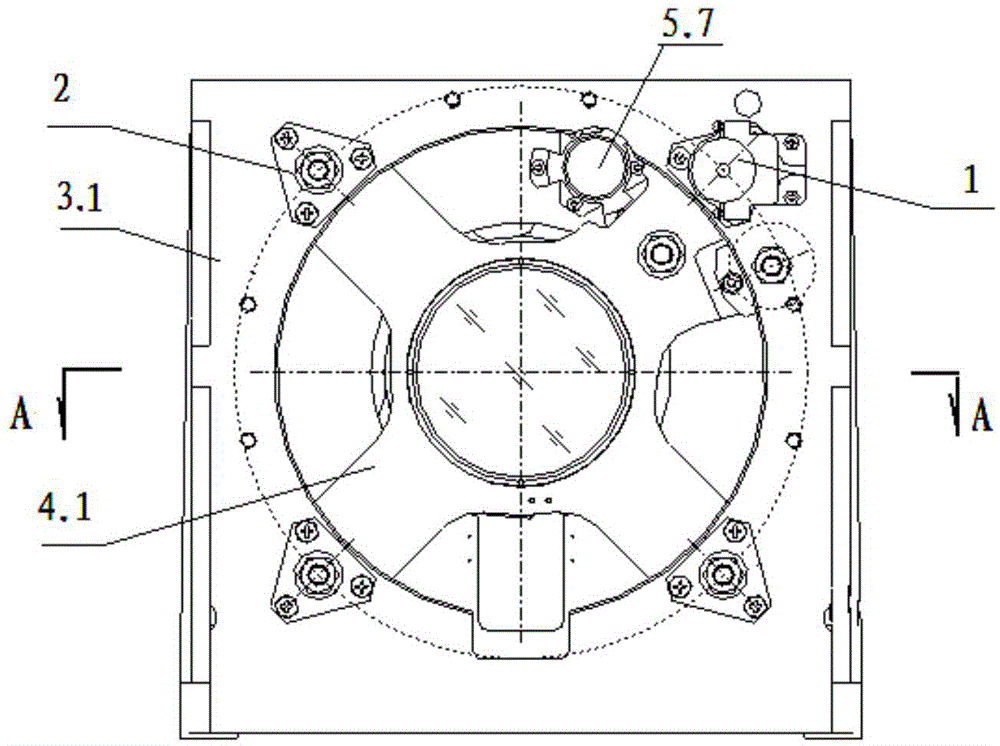

Frame integration type multi-rod guiding continuous zooming device

The invention relates to a frame integration type multi-rod guiding continuous zooming device which comprises a frame with two cavities. The frame is a whole. A zooming lens group and a compensation lens group are arranged in the cavities. At least three straight line bearings and a zooming lens base lead screw nut are arranged on a zooming lens base. One end of a zooming lens base lead screw is connected with a zooming driving motor, and the other end of the zooming lens base lead screw is inserted into a zooming encoder. At least three straight line bearings and a compensation lens base lead screw nut are arranged on a compensation lens base. One end of a compensation lens base lead screw is connected with a compensation driving motor, and the other end of the compensation lens base lead screw is inserted into a compensation encoder. The zooming driving motor and the compensation driving motor are fixed on stand walls respectively. The frame integration type multi-rod guiding continuous zooming device has the advantages that whole rigidness is good, accuracy is high, images are stable under vibration conditions, the whole device is high in environment adaptability, multi-rod guiding is used for achieving the coaxality of moving, the structure technology is good, machining is easy, adjustment accuracy is improved, and the optical axis consistence during guiding lens moving is guaranteed.

Owner:HUBEI JIUZHIYANG INFRARED SYST CO LTD

Frame-integrated multi-rod guide continuous zoom device

The invention relates to a frame integration type multi-rod guiding continuous zooming device which comprises a frame with two cavities. The frame is a whole. A zooming lens group and a compensation lens group are arranged in the cavities. At least three straight line bearings and a zooming lens base lead screw nut are arranged on a zooming lens base. One end of a zooming lens base lead screw is connected with a zooming driving motor, and the other end of the zooming lens base lead screw is inserted into a zooming encoder. At least three straight line bearings and a compensation lens base lead screw nut are arranged on a compensation lens base. One end of a compensation lens base lead screw is connected with a compensation driving motor, and the other end of the compensation lens base lead screw is inserted into a compensation encoder. The zooming driving motor and the compensation driving motor are fixed on stand walls respectively. The frame integration type multi-rod guiding continuous zooming device has the advantages that whole rigidness is good, accuracy is high, images are stable under vibration conditions, the whole device is high in environment adaptability, multi-rod guiding is used for achieving the coaxality of moving, the structure technology is good, machining is easy, adjustment accuracy is improved, and the optical axis consistence during guiding lens moving is guaranteed.

Owner:HUBEI JIUZHIYANG INFRARED SYST CO LTD

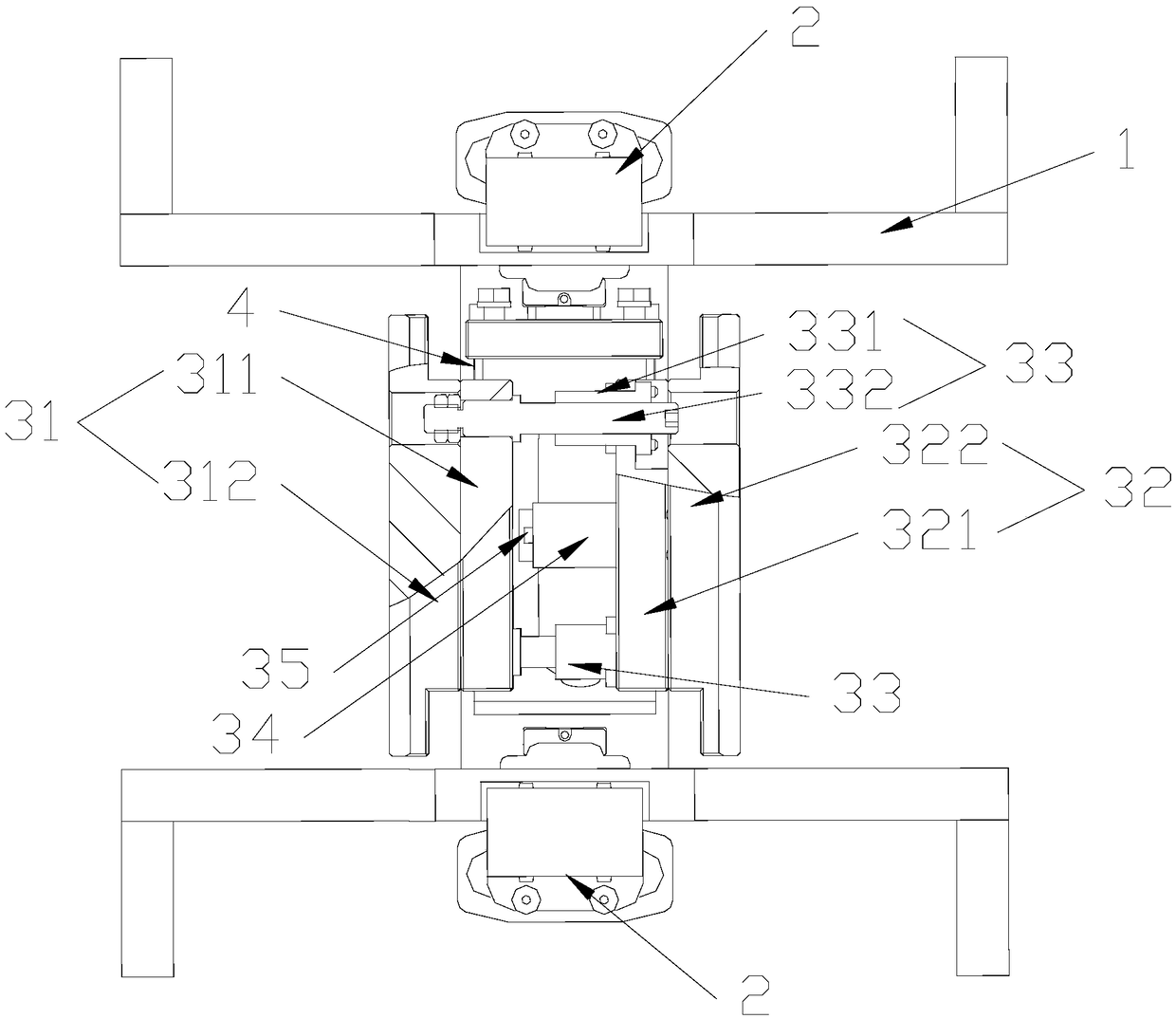

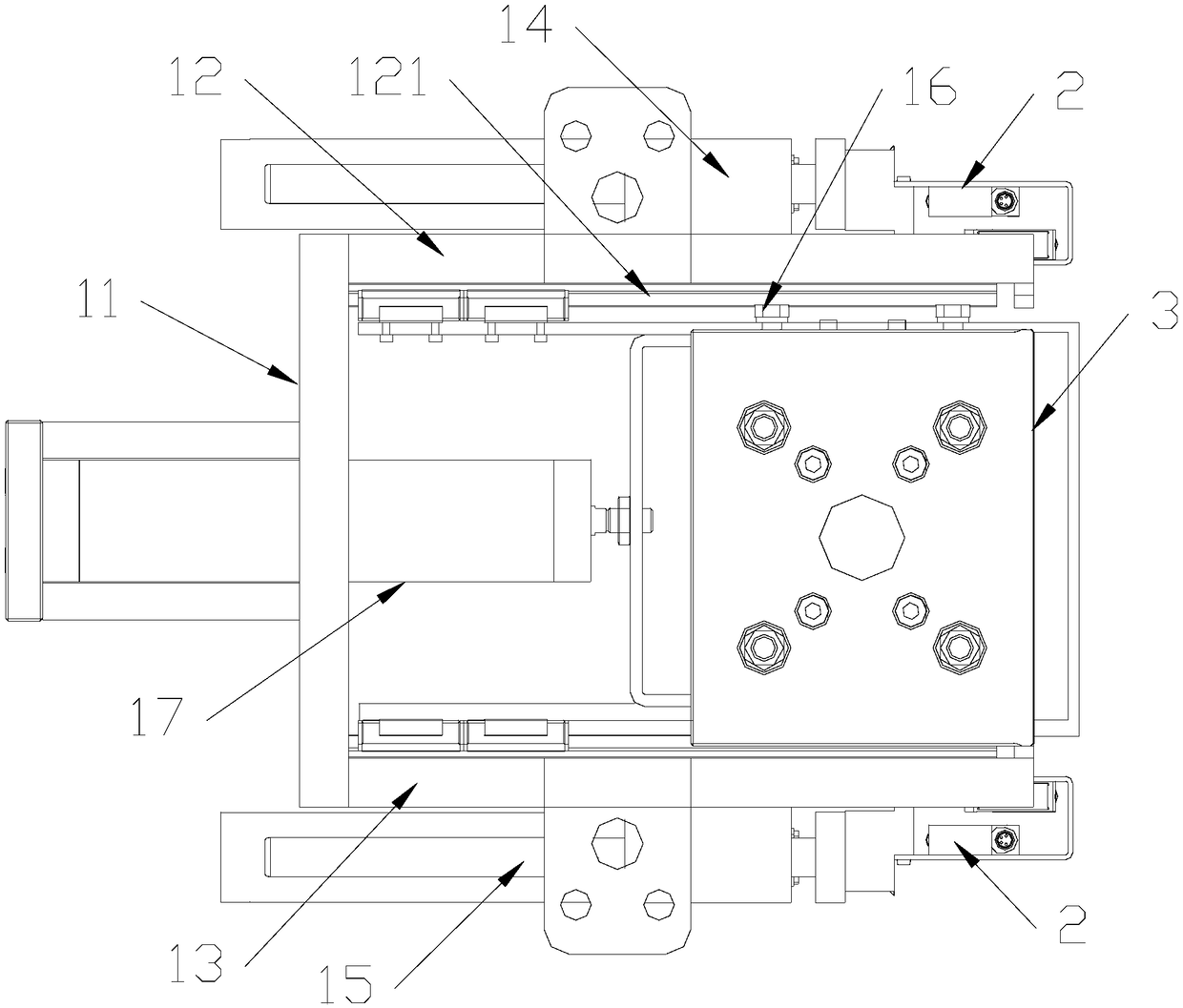

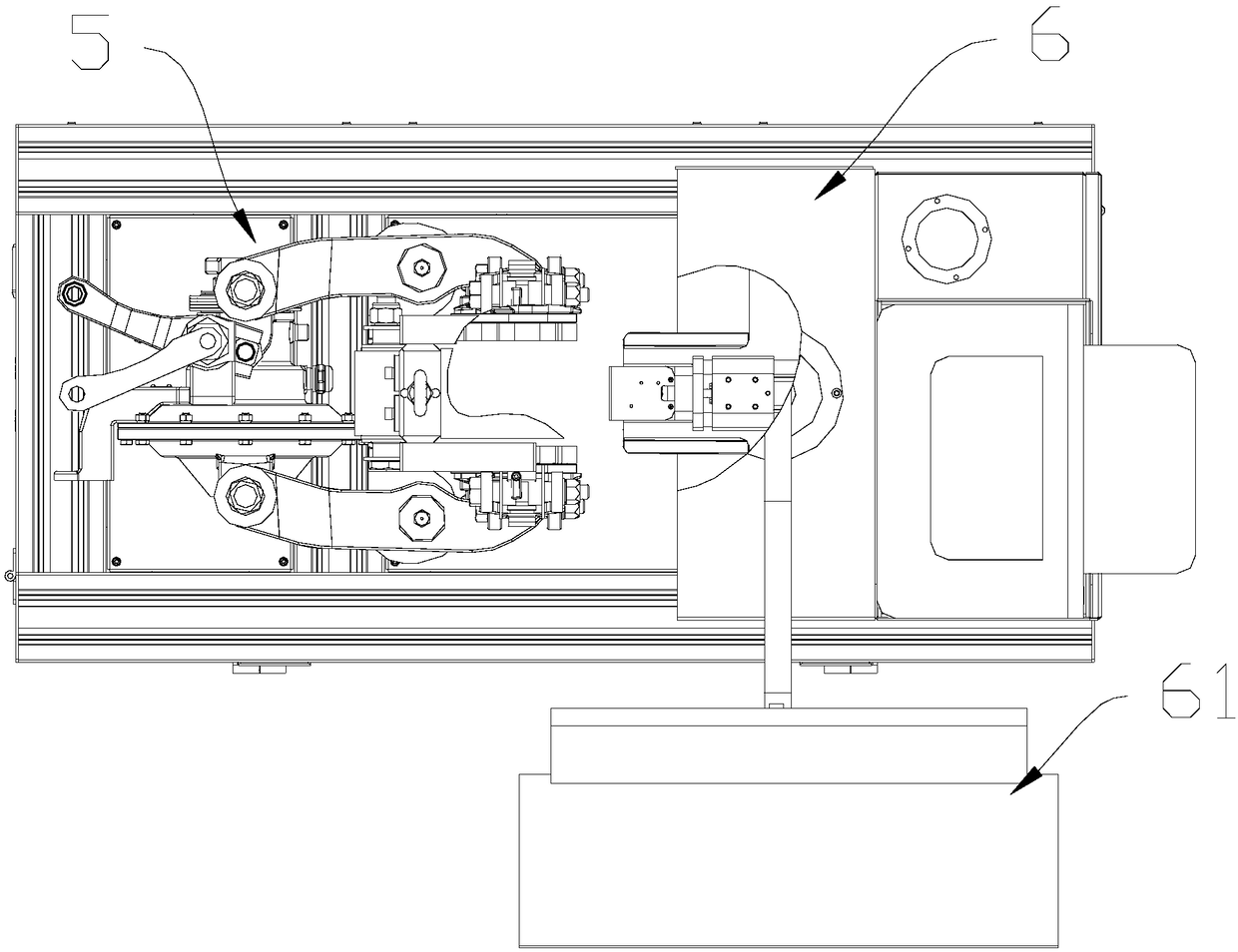

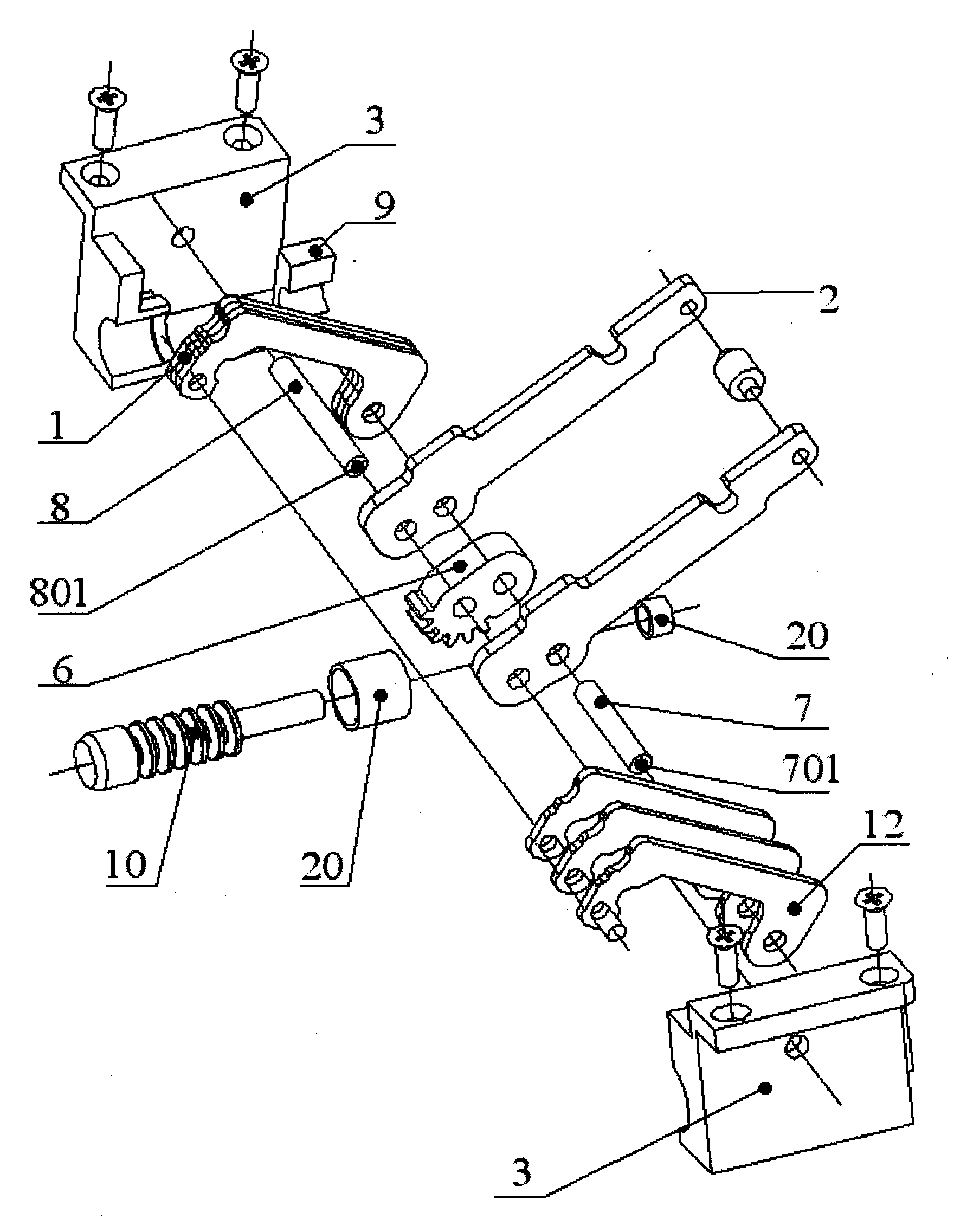

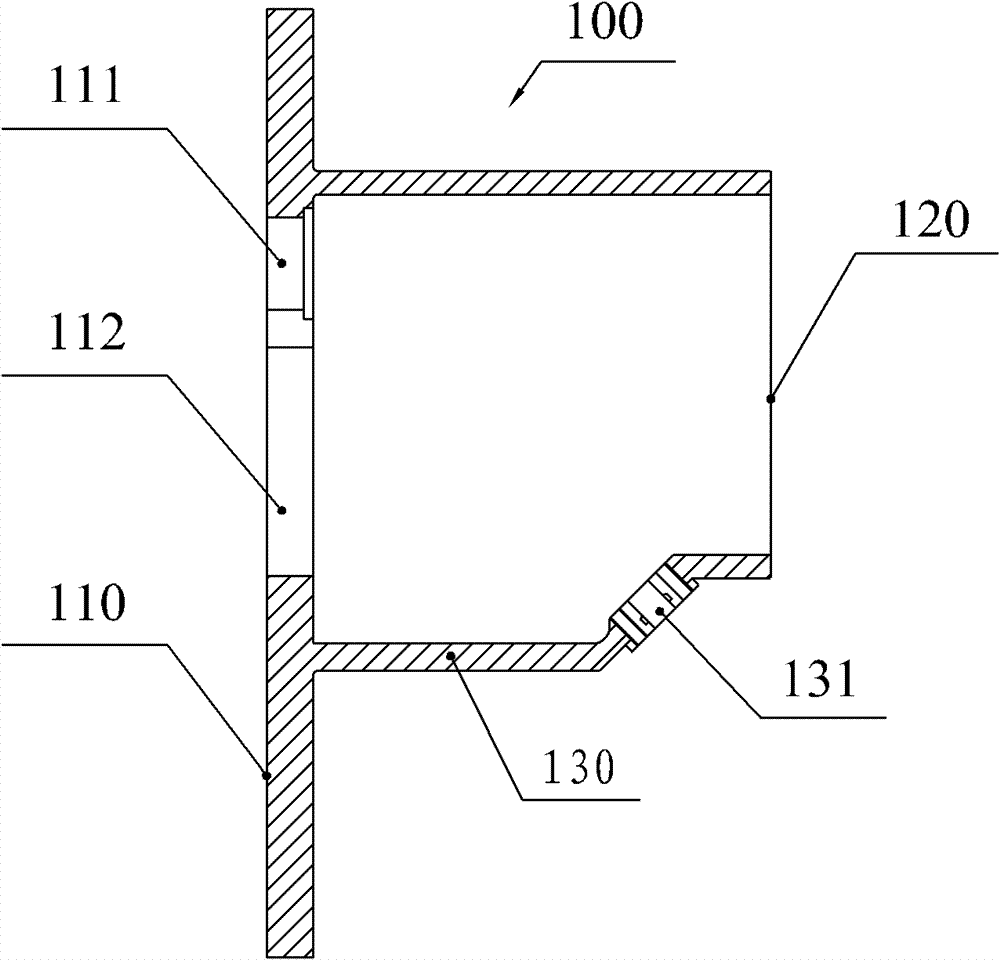

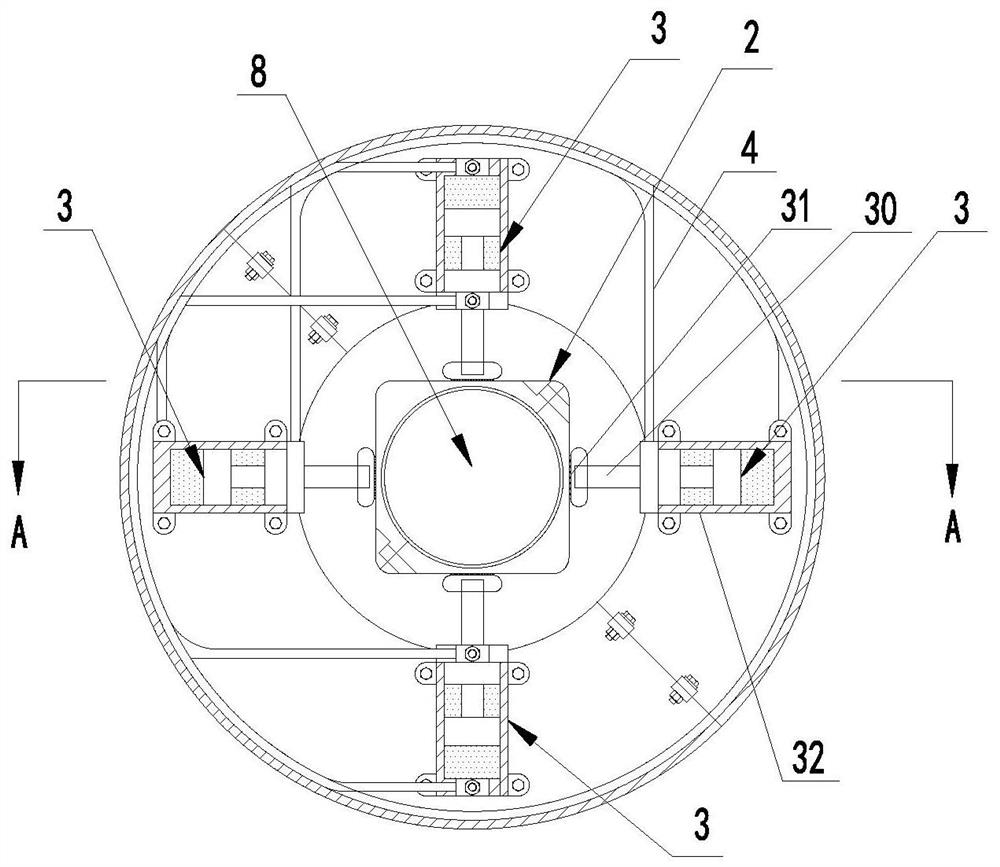

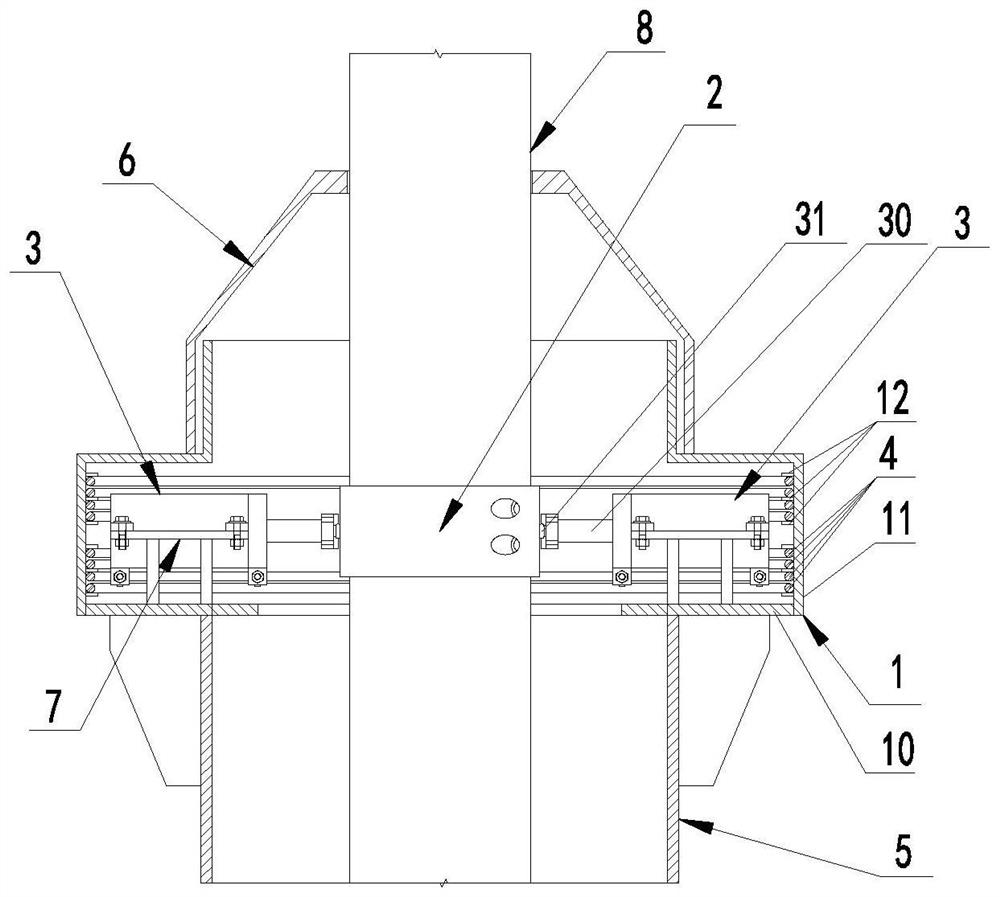

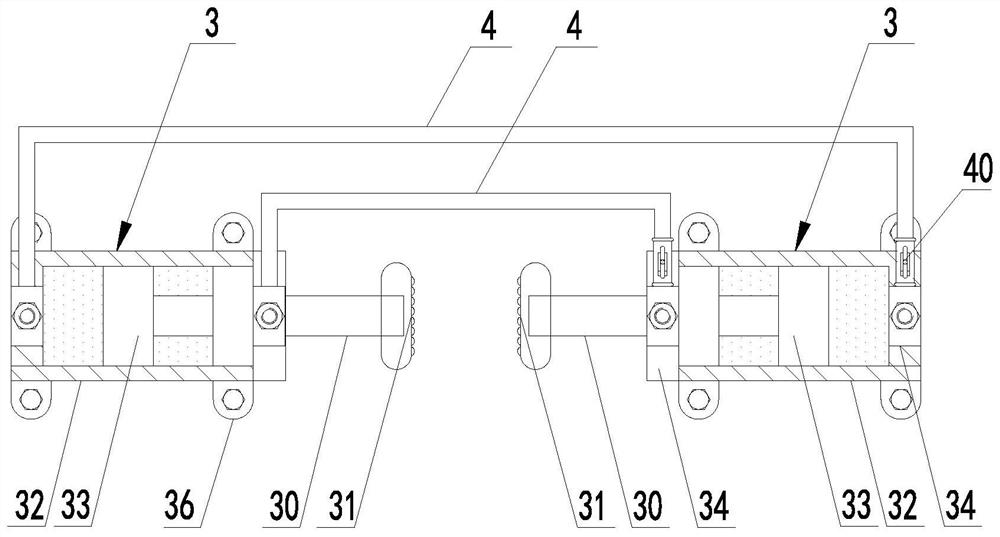

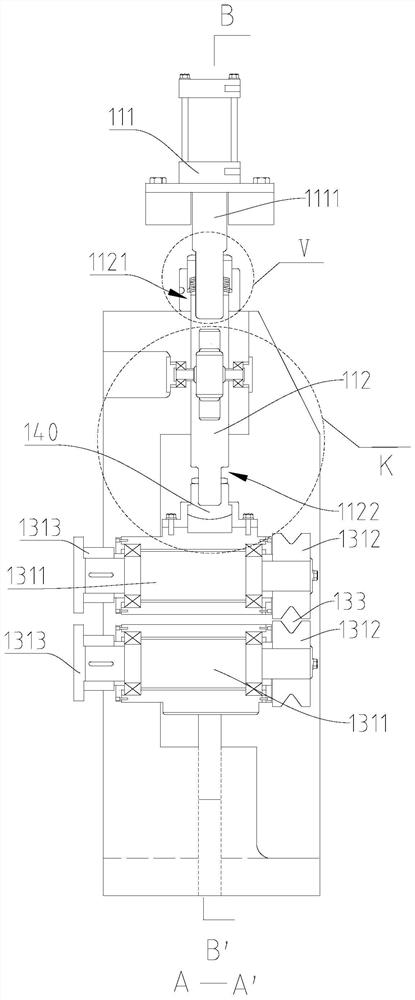

Device and method for detecting railway vehicle brake clamp unit

PendingCN109374321AGood test statusImprove accuracyRailway vehicle testingEngineeringMechanical engineering

The invention discloses a device and method for detecting a railway vehicle brake clamp unit and relates to the technical field of rail transit. The device comprises a bracket mechanism, a plurality of displacement sensors installed on the bracket mechanism, and a clamping force measuring mechanism which is connected to the bracket mechanism by a rope body such that the clamping force measuring mechanism can swing freely. The clamping force measuring mechanism comprises a first dummy disc and a second dummy disc which are oppositely arranged, multiple shaft units which are installed on the first dummy disc and the second dummy disc and can allow the first dummy disc and the second dummy disc to generate translation in mutually facing directions, a first cylinder arranged between the firstdummy disc and the second dummy disc, and a force sensor for measuring the clamping force between the first dummy dis and the second dummy disc. According to the device, the first dummy disc and the second dummy disc can run oppositely along the shaft units under the effect of the first cylinder such that the first dummy disc and the second dummy disc generate a relative distance change while theparallelism of the first dummy disc and the second dummy disc are maintained, and therefore, the accuracy of a test is effectively improved.

Owner:CHINA ACADEMY OF RAILWAY SCI CORP LTD +3

Top cover structure and air conditioner

PendingCN110595045AIntegrity guaranteedImprove aestheticsHeating and ventilation casings/coversMechanical engineeringEngineering

The invention provides a top cover structure and an air conditioner. The top cover structure comprises a top cover and decoration strips, wherein the decoration strips comprise a first decoration strip and a second decoration strip which are integrally arranged mutually; the top cover comprises a plurality of curved surfaces, the outer edges of the multiple curved surfaces are connected to form aperipheral edge part, every two adjacent curved surfaces are crossed to form a first connecting part, the first decoration strip is mounted on the peripheral edge part, and the second decoration stripis mounted on the first connecting part; a plurality of connecting assemblies are arranged between the decoration strips and the top cover; and each connecting assembly comprises a clamping claw anda convex column which is matched with the clamping claw. According to the top cover provided by the invention, the first decoration strip and the second decoration strip are set to an integrally formed structure, so that a connecting gap between the first decoration strip and the second decoration strip is effectively eliminated, integrity of the decoration strips is guaranteed, integral aestheticsense of the top cover is improved, and assembly efficiency is also improved. A structure of connecting the clamping claw to the convex column in a matched mode is adopted, so that fixed mounting ofmulti-dimensional multi-part decoration strips can be adapted.

Owner:NINGBO AUX ELECTRIC +1

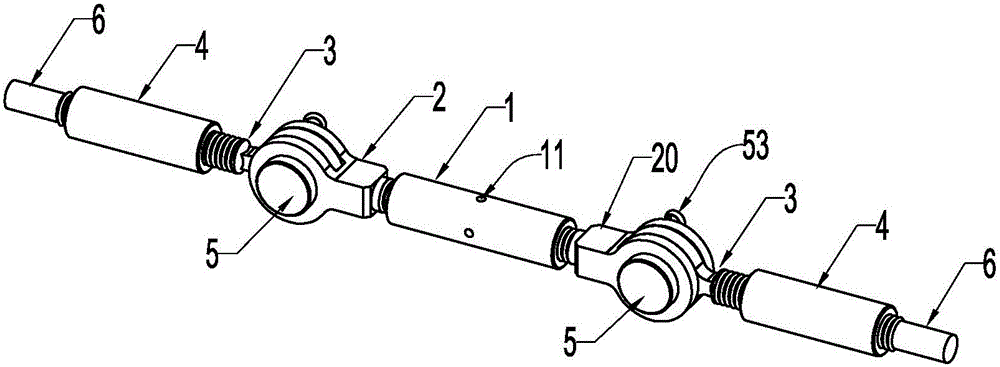

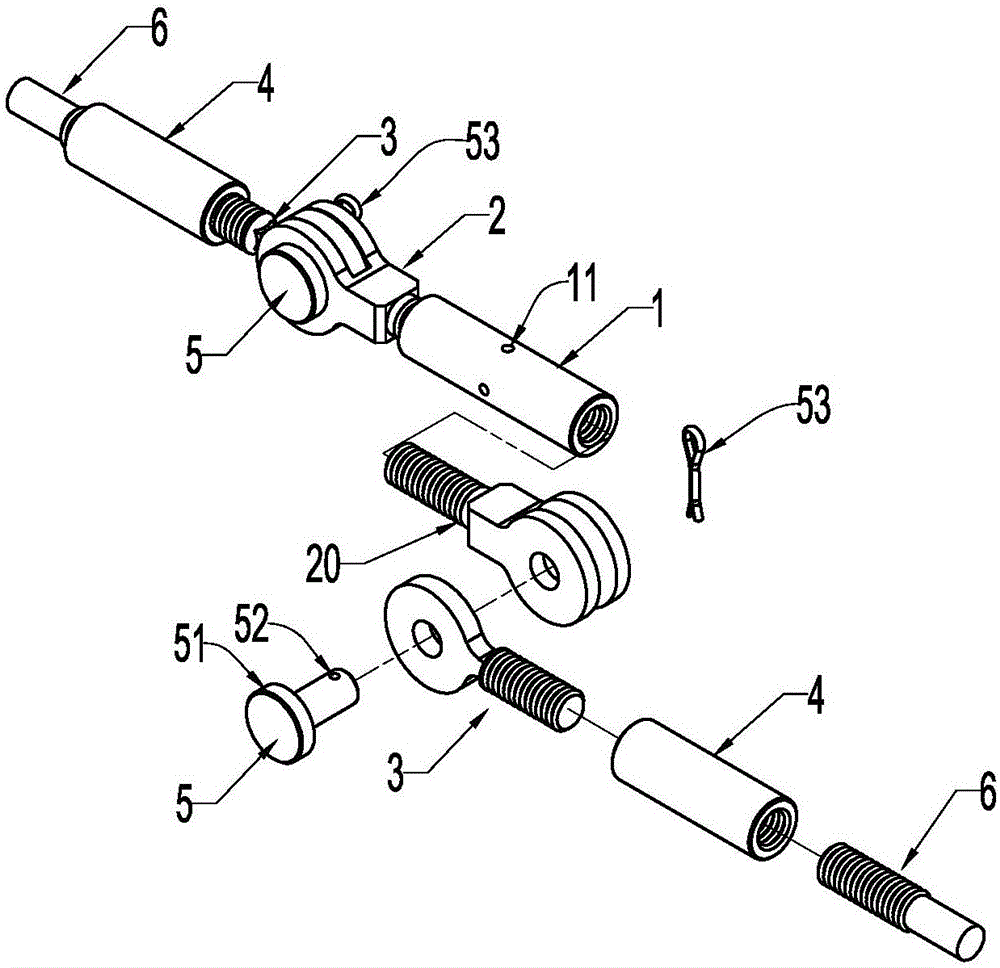

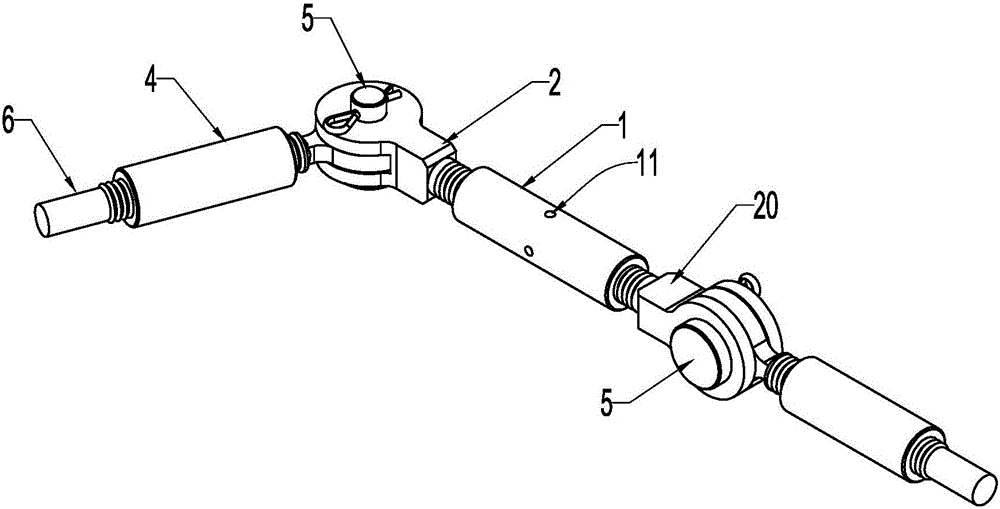

Drive plate coupling

The invention relates to a drive plate coupling. The coupling is connected with a first shaft and a second shaft and comprises a left half coupling body, a right half coupling body, a spring ring and a cross joint, wherein after the first shaft is installed in the left half coupling body and fixed, one end of the cross joint is inserted in a groove of the left half coupling body and provided with the spring ring, then, the second shaft is installed in the right half coupling body and fixed, and finally, the other end of the cross joint is inserted in a groove of the right half coupling body. Compared with the prior art, the drive plate coupling has the advantages of being simple in structure, low in cost, convenient to disassemble and assemble, high in reliability and the like.

Owner:SHANGHAI HUANGPU MARINE INSTR

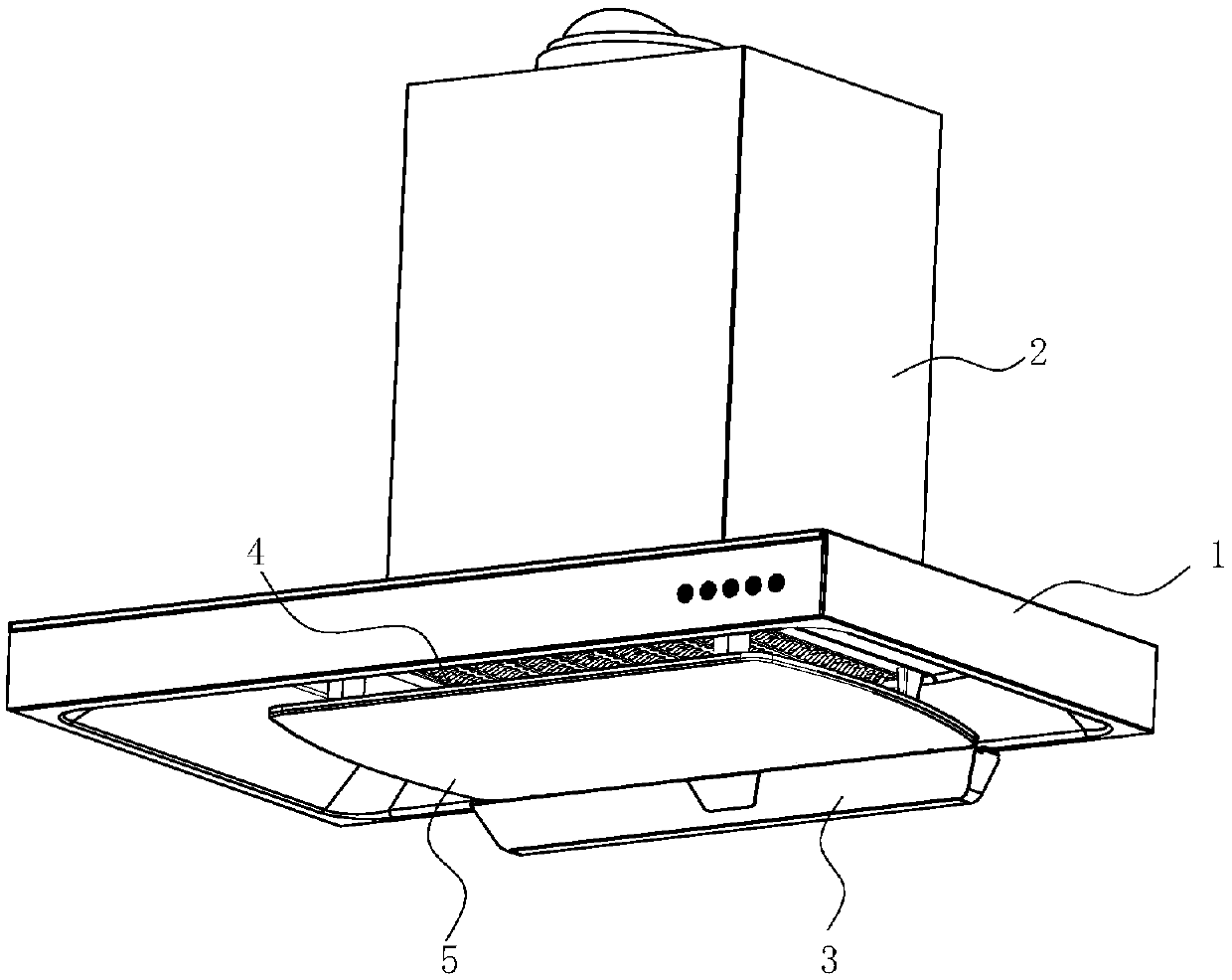

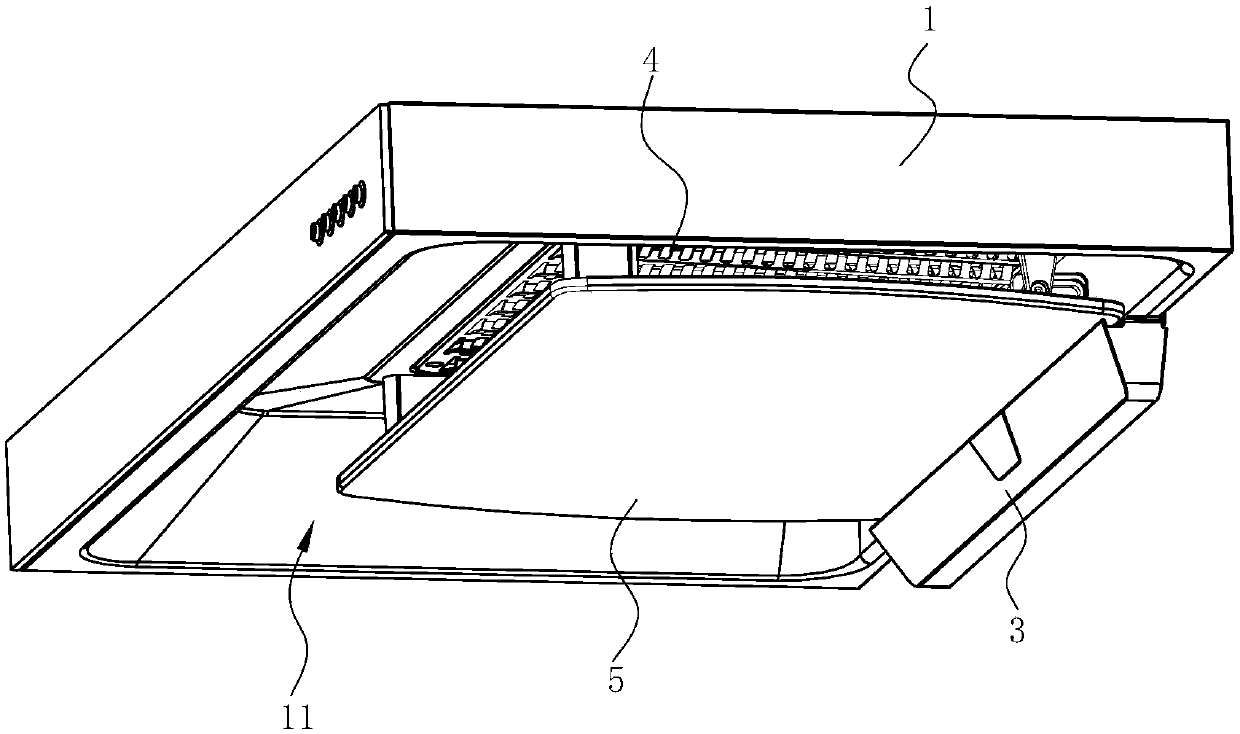

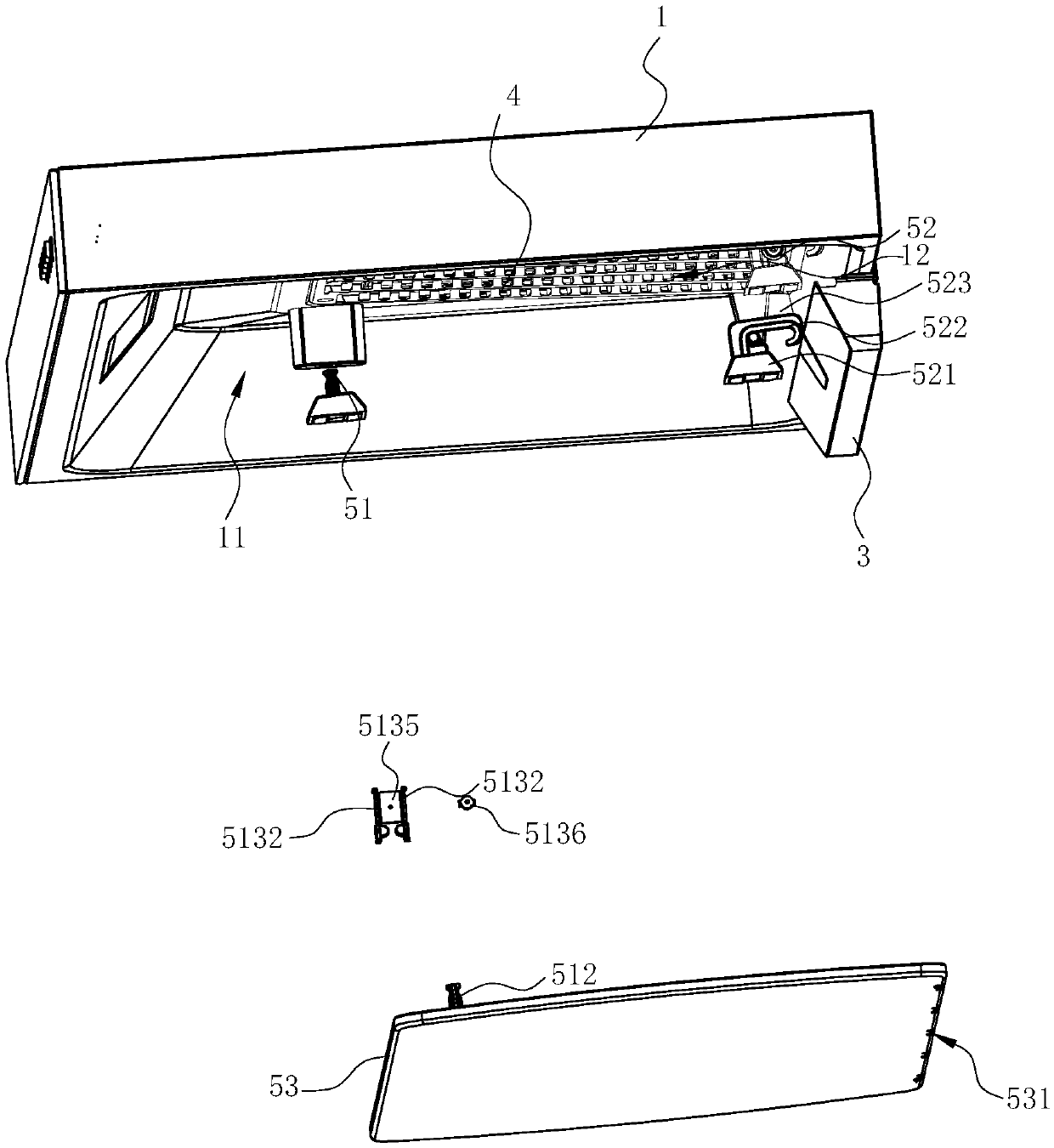

Extractor hood with commutated plate and control method

ActiveCN111121117ARun automatic controlEliminate connection gapsDomestic stoves or rangesLighting and heating apparatusSuction forceStructural engineering

The invention discloses an extractor hood which comprises a fume collecting hood. An air inlet is formed in the fume collecting hood. A fume collecting cavity concaved upwards is formed in the fume collecting hood. The commutated plate is arranged at the position, located below the air inlet, in the fume collecting cavity. The front portion of the commutated plate is clamped with the fume collecting hood through a clamped connection structure. The rear portion of the commutated plate is hinged to the fume collecting hood. The clamped connection structure comprises clamping claws arranged on the two sides of the front portion of the upper surface of the commutated plate. The extractor hood is characterized in that the clamped connection structure further comprises buckles, and the buckles can be in clamped connection with the clamping claws, apply suction force and can apply repellent force to the clamping claws to be separated from each other. The invention further discloses a controlmethod of the extractor hood.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

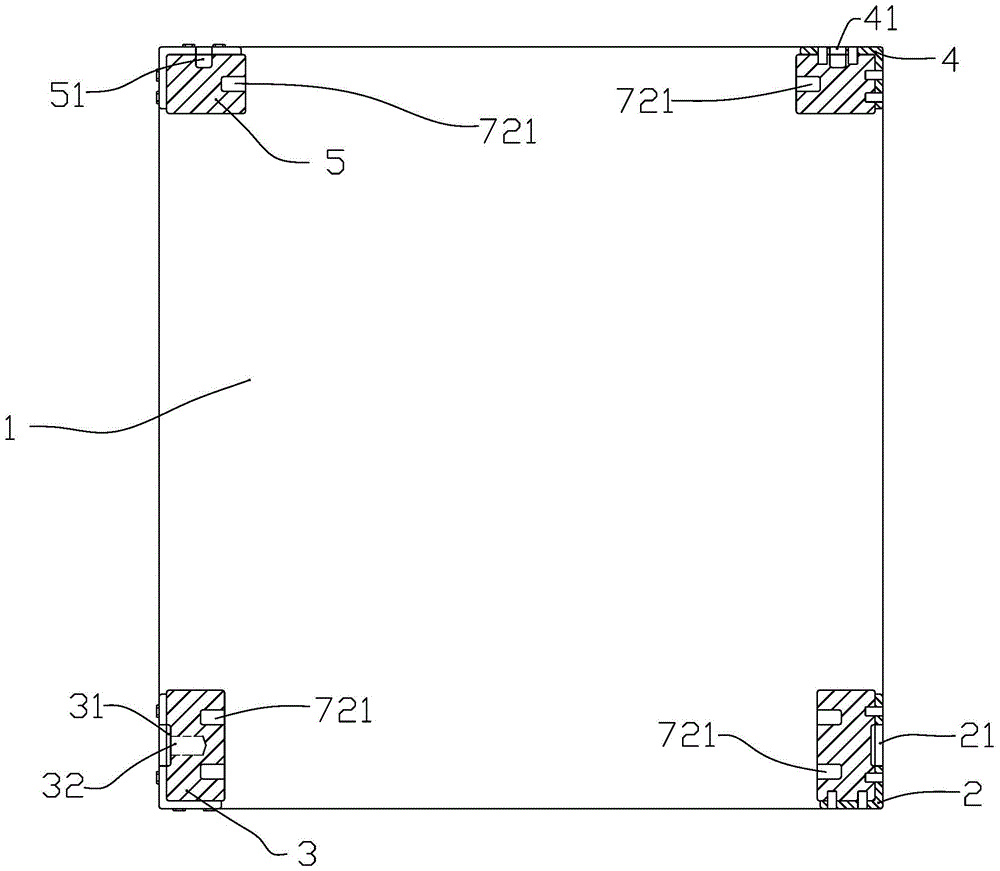

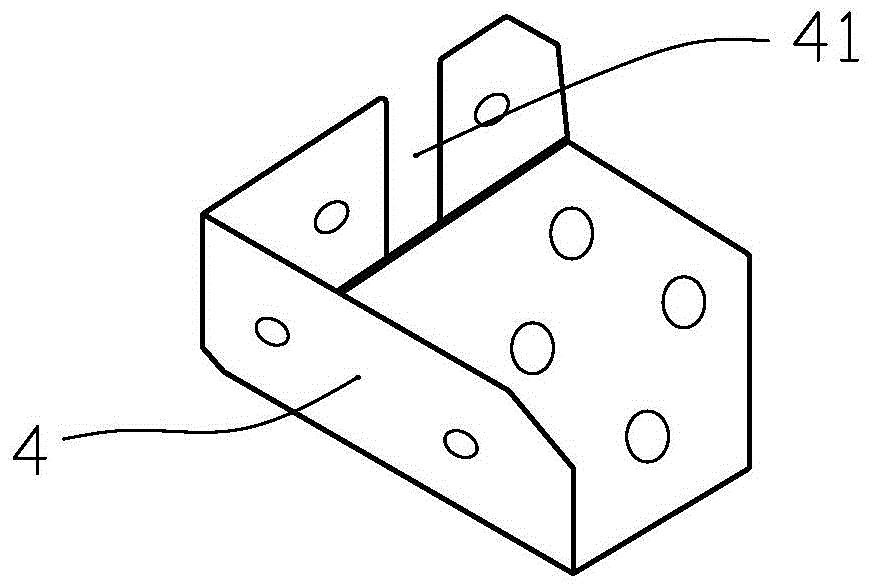

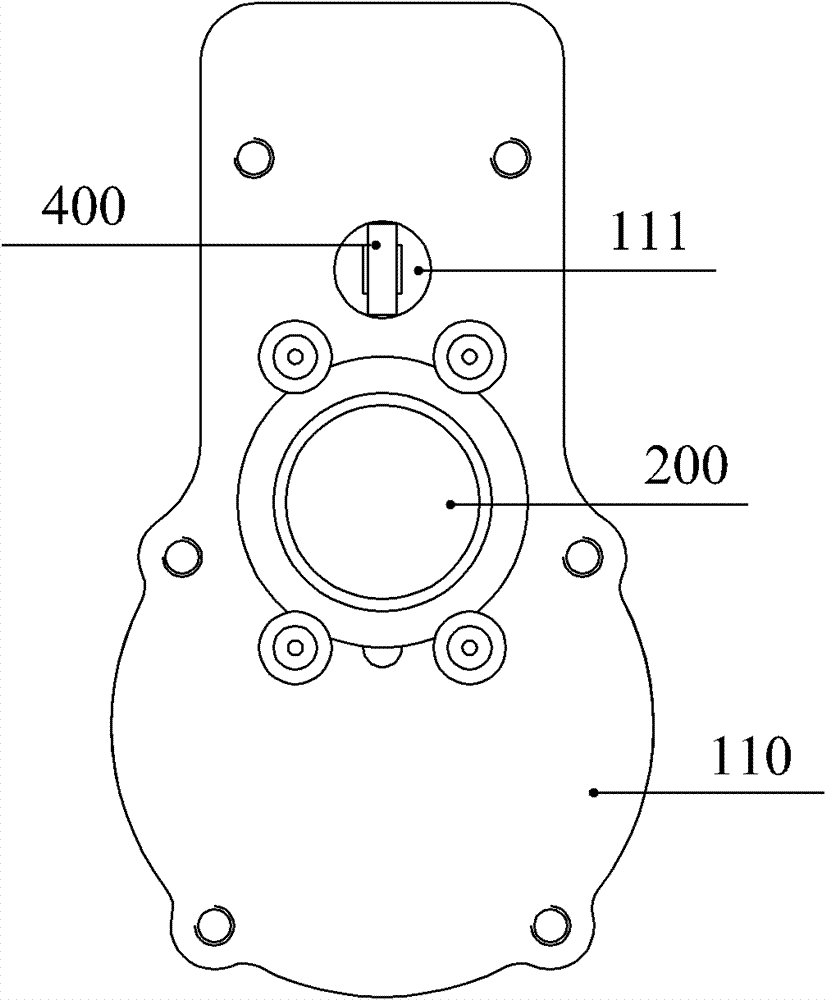

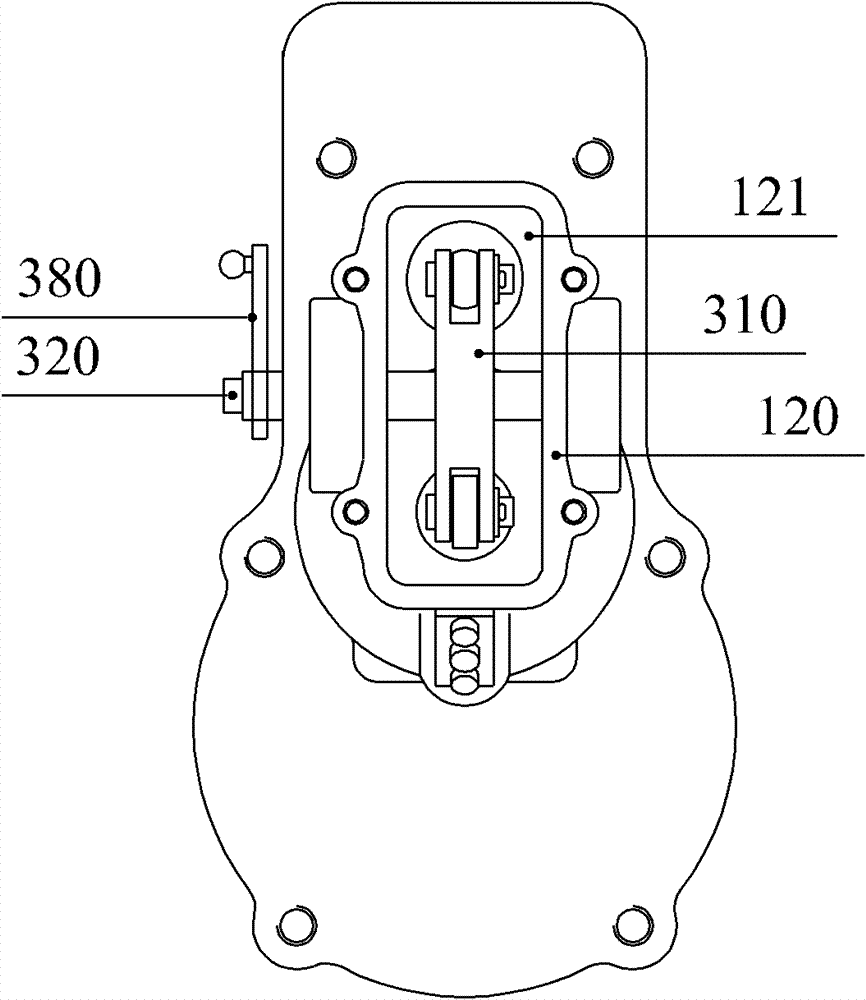

Locking connecting device, LED (Light Emitting Diode) screen box and LED display screen

InactiveCN102829039BSimple structureNot easy to get stuckCasings/cabinets/drawers detailsSecuring devicesLED displayGear wheel

The invention provides a locking connecting device, an LED (Light Emitting Diode) screen box and an LED display screen. The locking connecting device comprises a lock hook component and a rod pin component, wherein the lock hook component comprises a lock hook base; a lock hook and a handle are arranged on the lock hook base; a gear is arranged in the handle; a plug is arranged on the lock hook base and is connected with the gear; the rod pin component comprises a rod pin base; a rod pin is arranged on the rod pin base; a fixing pin hole is arranged on the rod pin base; the lock hook component and the rod pin component are connected with the fixing pin hole through the lock hook, the rod pin and the plug which are matched with each other; the LED screen box comprises an LED box shell with an LED display component; the lock hook component and the rod pin component are respectively arranged on two opposite lateral edges of the LED box shell; and the LED display screen is formed by connecting adjacent LED screen boxes through the locking connecting device. The locking connecting device provided by the invention has the advantages of higher bearing capacity, compact and accurate connection, convenience in operation and reliable property.

Owner:上海大晨显示技术有限公司

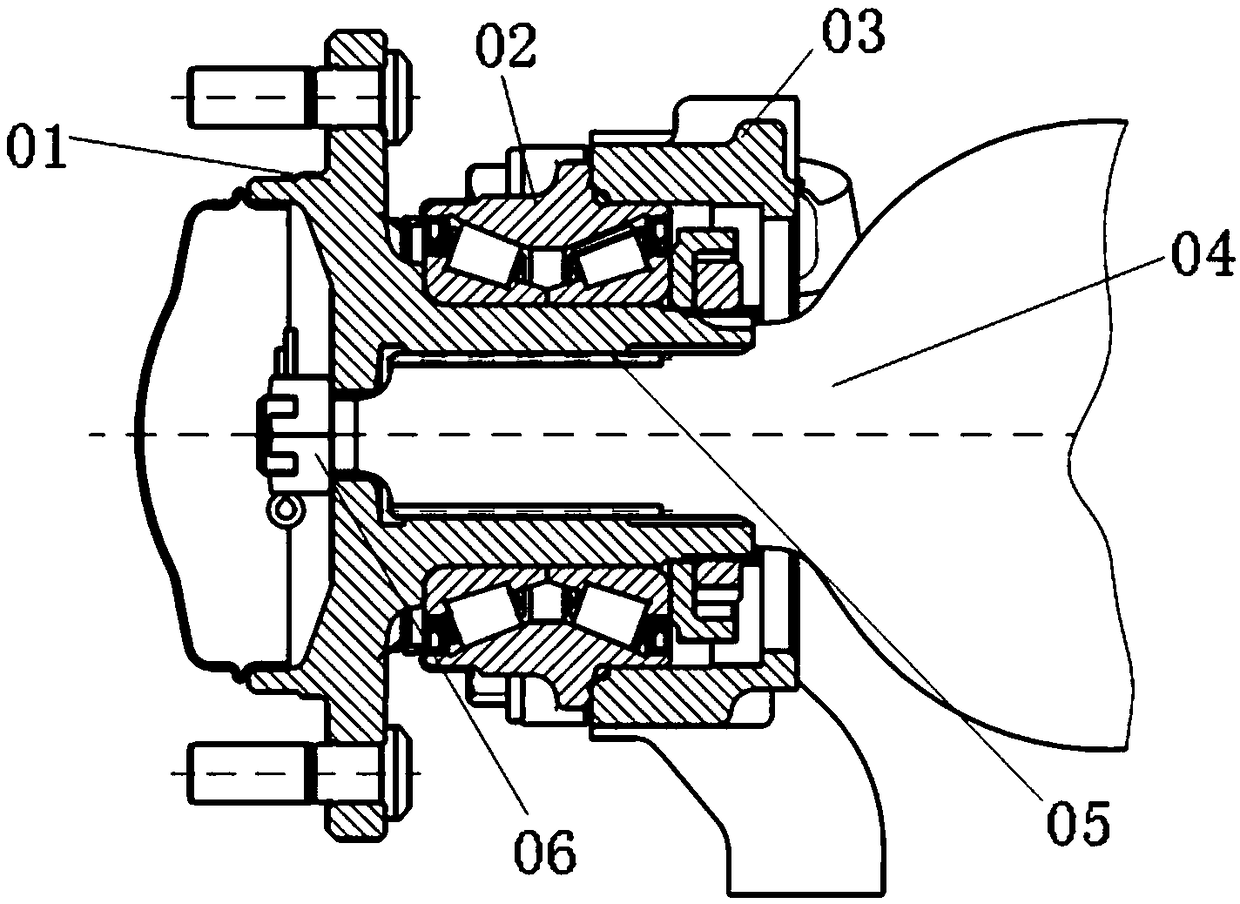

A connection structure between constant velocity universal joint and wheel hub and automobile

InactiveCN106379111BEliminate connection gapsEliminate fluctuationsAxle unitsUniversal jointConstant velocity

The invention relates to a connecting structure of a constant velocity universal joint and a wheel hub and an automobile. The connecting structure comprises the wheel hub, a steering knuckle, the constant velocity universal joint, bearings, bearing bolts, locking nuts and a self-locking nut, wherein a central inner cavity of the wheel hub extends from a wheel to the direction of the locking nuts, the central inner cavity sequentially comprises a first cylindrical inner cavity, a second cylindrical inner cavity, a third cylindrical inner cavity and a fourth cylindrical inner cavity; radii of the second cylindrical inner cavity and the fourth cylindrical inner cavity are identical and are respectively greater than the radius of the third cylindrical inner cavity; a plurality of sharp toothed protrusions are axially arranged on the side surface of the outer end of the constant velocity universal joint; the distance between tips of the sharp toothed protrusions and a central line of the outer end of the constant velocity universal joint is greater than the radius of the third cylindrical inner cavity; the hardness of the outer end of the constant velocity universal joint is greater than that of the wheel hub. According to the technical scheme, by means of a crimping structure of the outer end of the constant velocity universal joint and the inner cavity of the wheel hub, a connecting clearance between the wheel hub and the constant velocity universal joint is completely eliminated, the fluctuation of a transmission torque is eliminated, and transmission vibration and wheel vibration are reduced.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

An electrical cabinet with a combined structure

ActiveCN104244647BGuaranteed connection tightnessEnsure connection clearanceCasings/cabinets/drawers detailsHermetically-sealed casingsSquare cross sectionAgricultural engineering

Disclosed is a combined structure electrical cabinet. The combined structure electrical cabinet comprises a bottom plate, a top plate, a front column and a rear column with square cross sections, a front hinged plate and a rear hinged plate corresponding to the front column and the rear column and a U-shaped cover plate. Both the front hinged plate and the rear hinged plate comprise a bottom plate and an L-shaped side plate respectively, and connecting screw holes and straight slot type notches are formed on the front hinged plate and the rear hinged plate. The front hinged plate and the rear hinged plate are fixed at four corners of the bottom plate and the top plate respectively. The front column and the rear column are vertically arranged and connected with the bottom plate and the top plate through the front hinged plate and the rear hinged plate respectively. The front column is provided with a first straight slot, and threaded holes are formed on the bottom surface of the first straight slot. The rear column is provided with a second straight slot. Both ends of the inner side of the middle connecting plate of the U-shaped cover plate are provided with a first boss respectively, and end portions of a left side plate and a right side plate are provided with a second boss respectively. Due to the U-shaped cover plate and the integral assembly and disassembly characteristics, maintenance convenience is achieved, transportation and anti-corrosion spraying are facilitated, and packing and transportation cost are reduced.

Owner:山东恒瑞德电力设备有限公司

Machining device capable of accurately adjusting gap

PendingCN114700763ASimple structureReduce manufacturing costLarge fixed membersGear wheelEngineering

The invention discloses a machining device capable of accurately adjusting a gap. The machining device comprises a fine adjustment mechanism, a movable seat, a connecting seat, an adjusting head, a sliding groove, a driving gear, a driven gear, a screw device and a first threaded hole. The device is reasonable and simple in structure, low in production cost and convenient to install, the adjusting head drives the driving gear to rotate, the driving gear rotates to drive the whole screw device to rotate through the driven gear, and the screw device rotates to enable the movable seat and the fine adjustment mechanism to drive the driving arm to move. Therefore, rapid coarse adjustment of the fit clearance between the bottom of the driving arm and the cam is achieved, and the adjustment efficiency is improved. According to the fine adjustment mechanism, the distance of the inclined surface block can be finely adjusted through a differential thread mechanism composed of an adjusting sleeve body, a stud and the like, meanwhile, an inclined surface moving mechanism composed of the inclined surface block and an inner inclined surface groove is further matched, so that the fine adjustment precision is improved, and the driving arm can be driven to be finely adjusted through the connecting block.

Owner:苏迈特智能科技(江苏)有限公司

Tool and method for eliminating joint clearance of high pressure turbine rotor blades

ActiveCN107524477BEliminate connection gapsSimple structureLeakage preventionMachines/enginesTurbine bladeHigh pressure

The invention provides a tool and method for eliminating connection gaps of high-pressure turbine rotor blades. The tool comprises an adjusting screw rod, an upper driving block, a squeezing block and a lower driving block. The squeezing block and the lower driving block are sequentially arranged on the adjusting screw rod in a penetration mode. When the adjusting screw rod is screwed, the upper driving block drives the adjusting screw rod to rotate to squeeze the squeezing block downward. The lower driving block drives the adjusting screw rod to rotate to squeeze the squeezing block upwards, so that the squeezing block protrudes outwards. In the method, the tool for eliminating the connection gaps of the high-pressure turbine rotor blades is adopted. By means of the tool and method for eliminating the connection gaps of the high-pressure turbine rotor blades, the connection gaps between the high-pressure turbine rotor blades and a turbine disk can be effectively eliminated, so that the diameter of high-pressure turbine blade tips is accurately obtained. The tool is simple in principle, simple in structure and low in manufacturing cost and maintenance cost.

Owner:AECC SHANGHAI COMML AIRCRAFT ENGINE MFG CO LTD +1

Steel bar mechanical connecting device and method

PendingCN113323281AEliminate connection gapsEasy to reduce deformationBuilding reinforcementsResidual deformationEngineering

The invention discloses a steel bar mechanical connecting device and method. According to the steel bar mechanical connecting device and method, a connecting gap between a first steel bar and a second steel bar is eliminated through a pressure-bearing inner ejector rod, so that deformation of a connector under large pressure is easier to reduce, meanwhile direct or indirect connection of the first steel bar and the second steel bar is achieved through an outer threaded sleeve, therefore, the connection is easy without being limited by trouble of difficulty in connection when trajectory lines are not coincident. Through cooperation of the pressure-bearing inner ejector rod and the outer threaded sleeve, mechanical connection between two connecting steel bars with a certain gap in the axial position can be achieved, residual deformation of the connector can be controlled within a small range, and after specified high-stress and large-deformation repeated pulling and pressing circulation, the ultimate tensile strength and deformation performance of the steel bar can still meet regulations in high-stress repeated tension and compression and large-deformation repeated tension and compression in the industrial standard JGJ 107 General Technical Regulations for Mechanical Connection of Reinforcing Steel bars. Steel bar mechanical connection construction under a vertical narrow gap connection working condition of a prefabricated structure is facilitated, and qualified rate of the steel bar mechanical connection device is increased.

Owner:徐瑞榕 +1

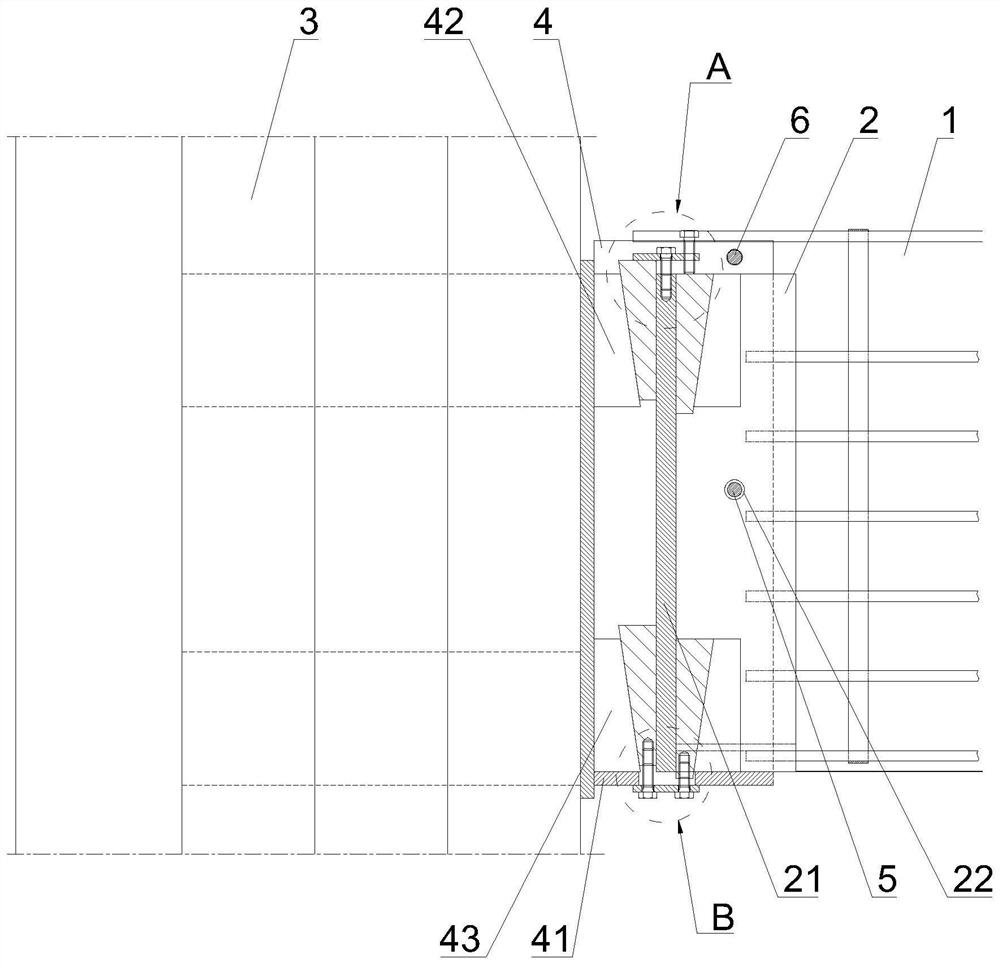

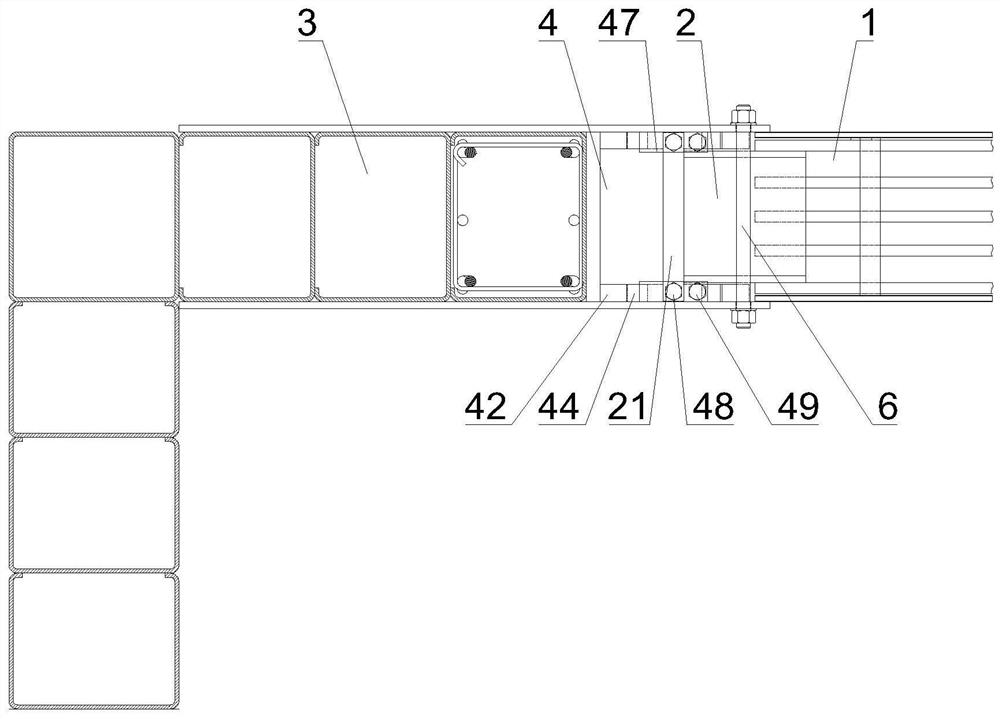

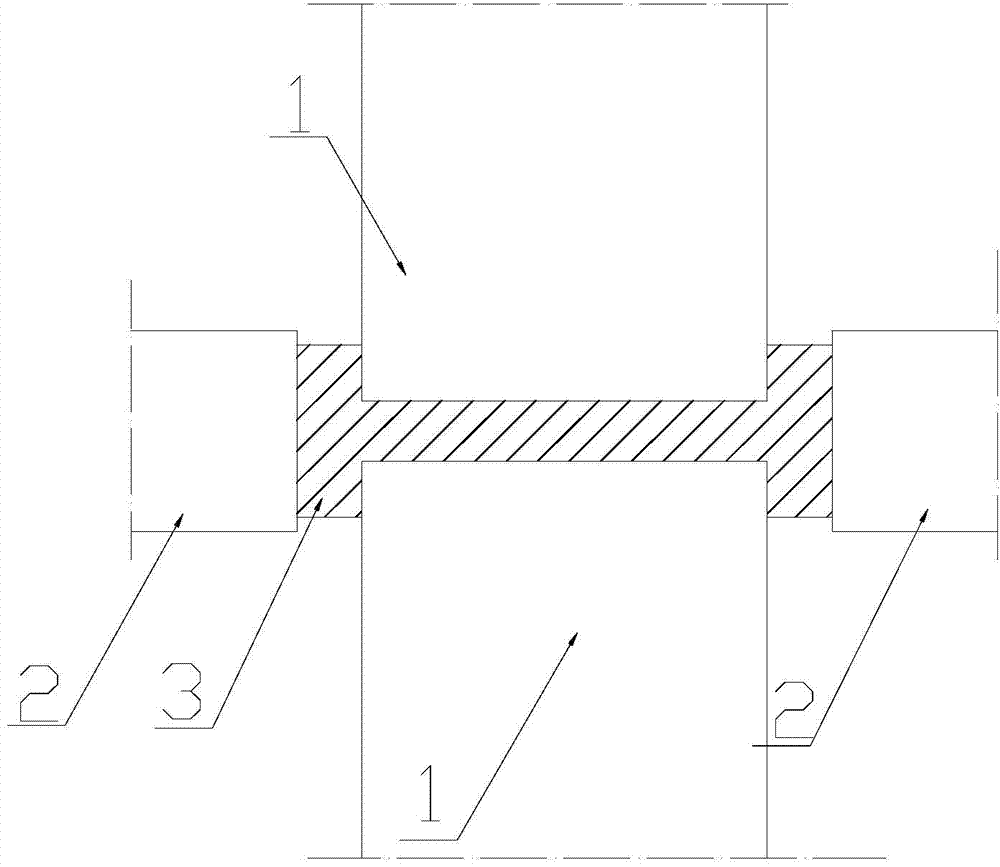

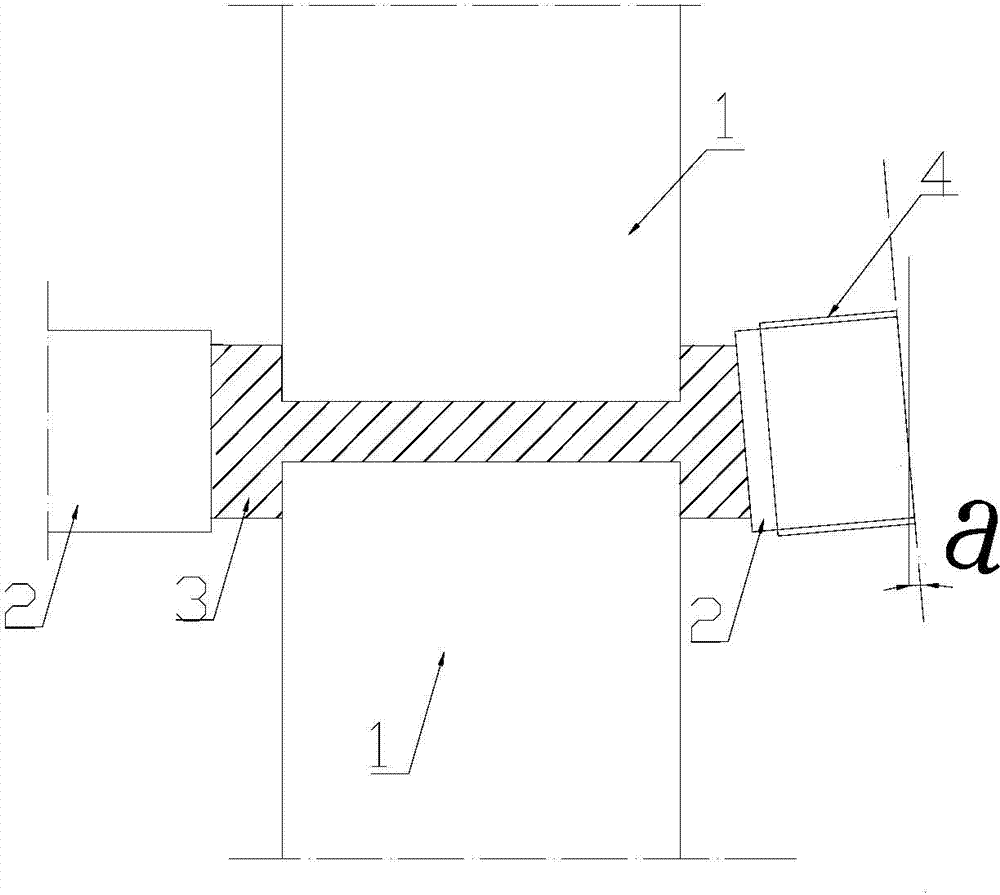

Mounting structure of large-size cross beam on integrated steel and construction method

The invention discloses a mounting structure of a large-size cross beam on integrated steel. According to the mounting structure, a reinforcement cage tenon is arranged at the end of the large-size cross beam, a limiting edge protrudes out of the reinforcement cage tenon, a supporting connector is arranged on the integrated steel, mounting seams are formed in the supporting connector, when the reinforcement cage tenon and the supporting connector are assembled, the limiting edge is embedded into the upper mounting seam and the lower mounting seam at the same time, a first brake iron and a second brake iron are inserted into gaps of the corresponding mounting seams, the reinforcement cage tenon is supported by a bottom plate, a tension bolt penetrates through the bottom plate and is in threaded connection with the second brake iron, a cover plate for limiting the upper portion of the first brake iron is arranged on the first brake iron, a fastening bolt penetrates through the cover plate and is in threaded connection with the second brake iron, and the fastening bolt is in threaded connection with the upper end of the reinforcement cage tenon. According to the mounting structure, reliable fixation of the tenon is fully guaranteed, the connection gap is eliminated, the pre-tightening force is improved, the connection strength is guaranteed, and the field assembly difficulty is reduced. The invention further discloses a construction method of the large-size cross beam on the integrated steel.

Owner:WUXI GUANGCAI MACHINERY MFG

Electromagnetic performer

InactiveCN102360704BSimple structureImprove sealingFuel-injection pumpsMachines/enginesEngineeringMechanical engineering

Owner:SHANGHAI DELCO ELECTRONICS & INSTR

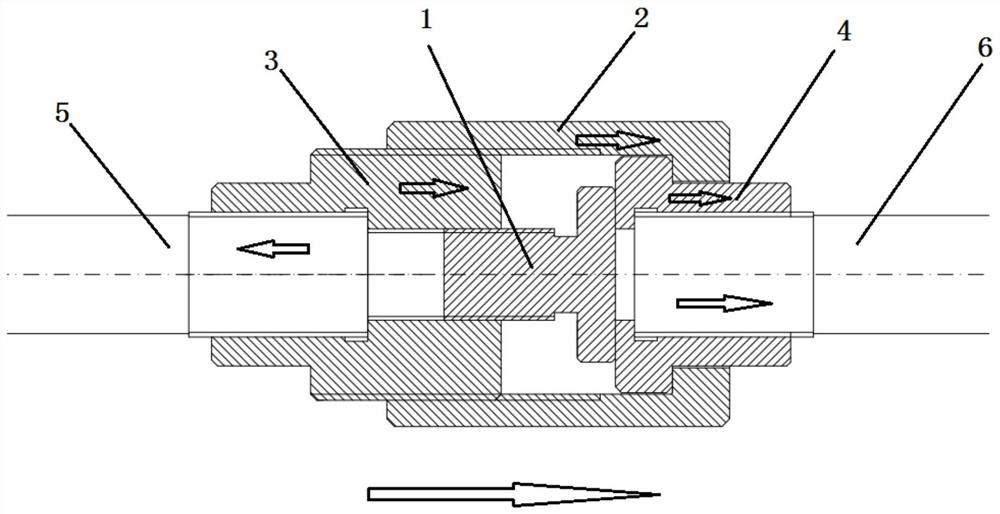

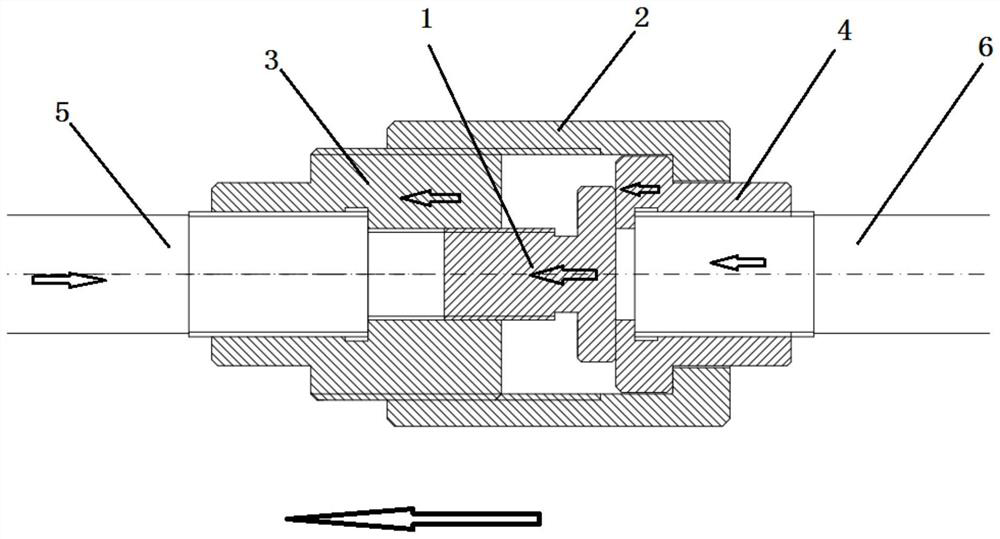

Built-in damping vibration attenuation device

PendingCN113357302AImprove structural vibration control effectEliminate connection gapsSpringsLiquid based dampersNegative stiffnessClassical mechanics

The invention relates to a built-in damping vibration attenuation device. The built-in damping vibration attenuation device comprises a connecting cylinder and a damping set; the connecting cylinder is internally provided with a containing area used for containing a clamp for clamping a vibration attenuation target; the damping set is arranged in the connecting cylinder and comprises two hydraulic dampers, the two hydraulic dampers of the damping set are symmetrically arranged on the two sides of the containing area, cylinder barrels of the two hydraulic dampers contained in the damping set communicate with each other through a guide pipe, and piston rods of the hydraulic dampers are used for abutting against the clamp. Interconnection of the two opposite hydraulic dampers is achieved through the guide pipe, so that hydraulic inerter between the two hydraulic dampers of the damping set is achieved, negative rigidity is provided for the structure through the hydraulic inerter, and the vibration control effect of the structure can be greatly improved.

Owner:中铁桥研科技有限公司 +3

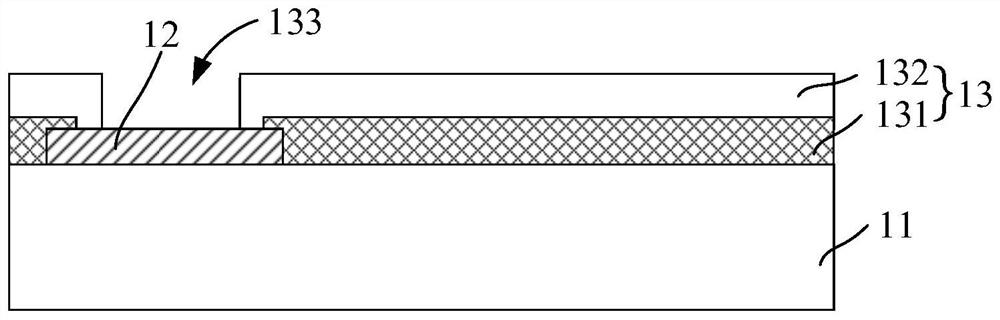

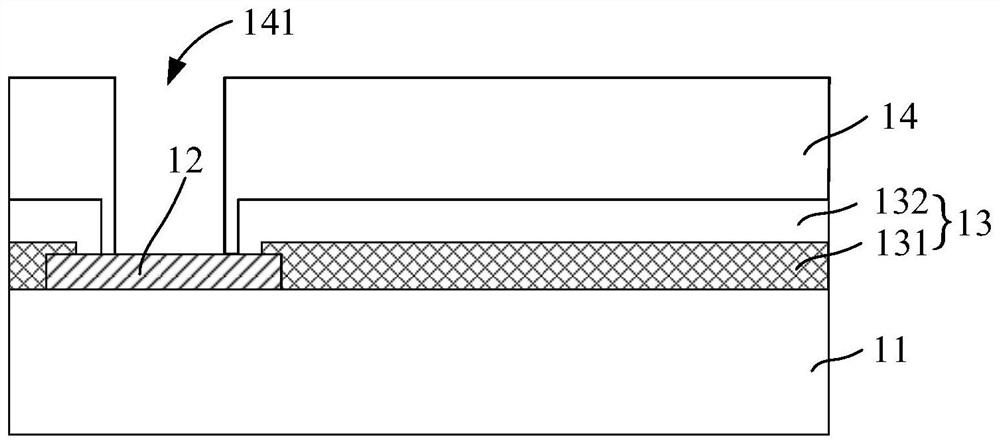

Semiconductor structure and manufacturing method thereof

InactiveCN112885799AReduce process stepsShorten the manufacturing cycleSemiconductor/solid-state device detailsSolid-state devicesSemiconductor structureDielectric layer

The embodiment of the invention relates to a semiconductor structure and a manufacturing method thereof. The manufacturing method of the semiconductor structure comprises the steps of providing a substrate and a welding pad located on the substrate, forming an insulating medium layer on the substrate, wherein the insulating medium layer covers the welding pad, patterning the insulating dielectric layer, forming a first window in the insulating dielectric layer, and enabling the first window to expose the welding pad, forming a mask layer is formed on the insulating dielectric layer, the mask layer is patterned, a second window is formed in the first window, and the welding pad is exposed out of the second window; forming a first conductive layer in the second window, forming a second conductive layer on the first conductive layer, removing the mask layer to expose the side wall of the first conductive layer, and performing reflow treatment on the second conductive layer, so that the second conductive layer covers the top and the side wall of the first conductive layer at the same time. The reflow treatment process is adopted, the second conductive layers located on the top and the side wall of the first conductive layer are integrally formed, and connecting gaps are eliminated.

Owner:CHANGXIN MEMORY TECH INC

Universal rolling mill and vertical roll device with adjustable vertical roll rotation axis angle

ActiveCN103551386BEliminate connection gapsAddressing non-adjustable deficienciesMetal rolling stand detailsMetal rolling arrangementsHydraulic cylinderEngineering

The invention discloses a universal rolling mill and a rolling mill vertical roll device with adjustable vertical roll rotation axis angles. The rolling mill vertical roll device with the adjustable vertical roll rotation axis angles comprises a vertical roll, an internal case with a first internal surface and a first external surface, an external case with a second internal surface and a second external surface, a hydraulic cylinder with a cylinder bottom and a piston rod and a pair of half shafts; the universal rolling mill comprises two horizontal rollers and two rolling mill vertical roll devices; the rolling mill vertical roll devices are the above rolling mill vertical roll devices with the adjustable vertical roll rotation axis angles. According to the technical scheme of the universal rolling mill and the rolling mill vertical roll device with the adjustable vertical roll rotation axis angles, inclined rotation axis angles of the vertical roll is rapidly and effectively corrected, the efficiency is high, and the cost is low.

Owner:LAIWU IRON & STEEL GRP

Tensile test loading device and test method for unidirectional fiber reinforced composite materials perpendicular to the fiber direction

ActiveCN105334110BAvoid damageSmooth goingMaterial strength using tensile/compressive forcesEngineeringFiber-reinforced composite

The invention discloses a loading device and method for testing the tension strength of a unidirectional fiber reinforced composite perpendicular to the fiber direction. The loading device comprises an upper clamping rod, a loading frame, a force transferring piece, a threaded connecting rod, a gap eliminating nut and a lower clamping rod. The force transferring piece comprises upper force transferring piece bodies and lower force transferring piece bodies, the upper force transferring piece bodies are pasted on the upper end of a unidirectional fiber reinforced composite test specimen, the lower force transferring piece bodies are pasted to the lower end of the unidirectional fiber reinforced composite test specimen, and fibers in the unidirectional fiber reinforced composite test specimen are perpendicular to the tension strength testing direction. The loading frame comprises an upper loading frame body and a lower loading frame body, the upper force transferring piece bodies are fixedly installed in the upper loading frame body, and the lower force transferring piece bodies are fixedly installed in the lower loading frame body. The upper clamping rod is fixedly connected with the upper loading frame body. The lower clamping rod is fixed to the lower loading frame body in a matched mode through the threaded connecting rod and the gap eliminating nut. The loading device has the advantages that damage, caused by clamping force of a tester, on the test specimen can be avoided, connecting gaps between clamp components can be eliminated, testing precision can be improved, and accurate alignment of the test specimen can be achieved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

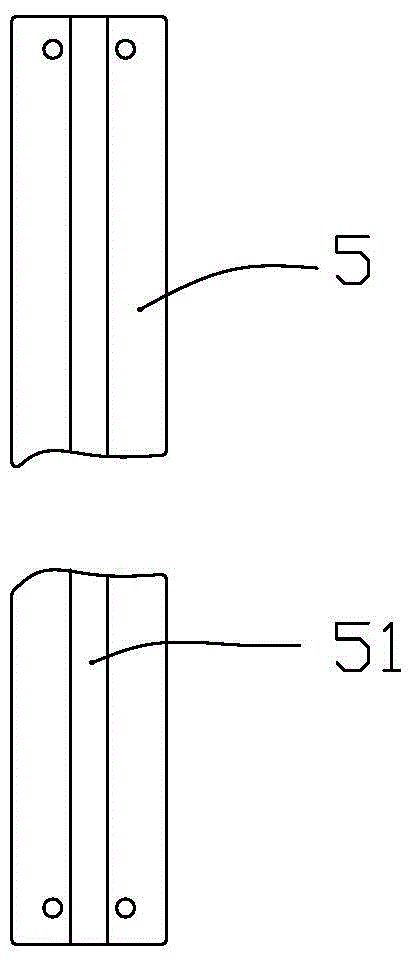

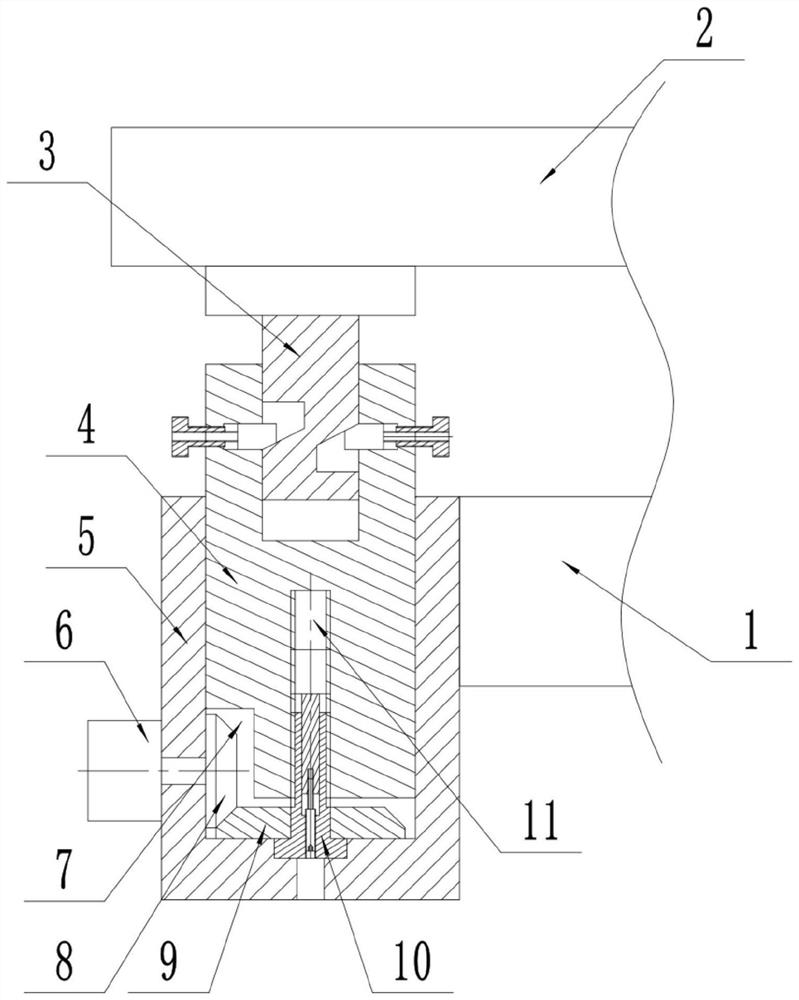

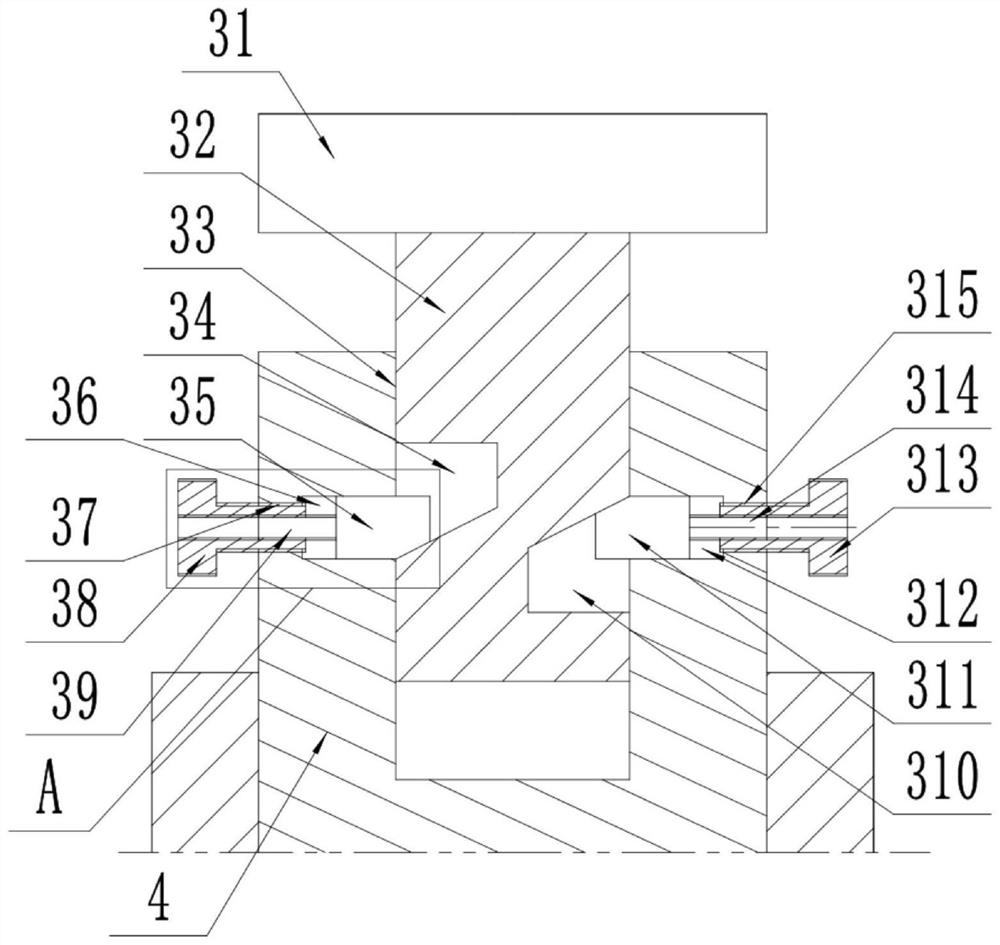

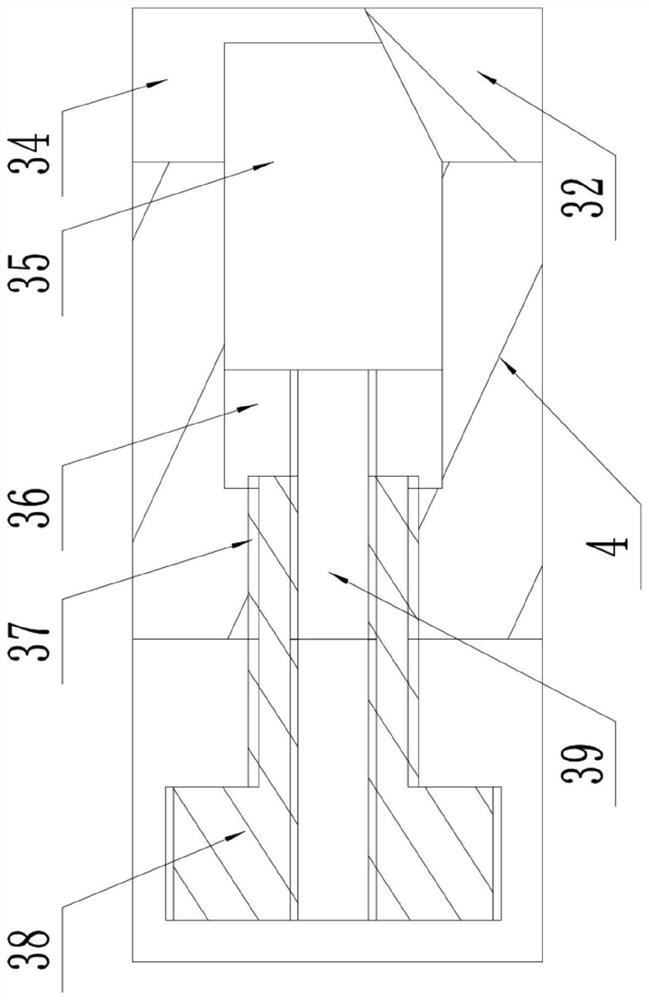

Clamping device and system, control method and bar clamping and conveying method

ActiveCN112894408APrevent deviationEliminate connection gapsMetal working apparatusPositioning apparatusPhysicsEngineering

The invention relates to the field of machining, in particular to a clamping device and system, a control method and a bar clamping and conveying method. According to the clamping device, when a boosting rod is driven by a driving piece to move in the first direction, a first pressing roller support is driven to move in the first direction, and a transmission assembly drives a second pressing roller support to move in the opposite direction, so that the first pressing roller support and the second pressing roller support get close to each other to reduce a clamping space or get away from each other to expand the clamping space; an adjusting mechanism elastically acts on the driving piece and the boosting rod in the axial direction so that a connecting gap can be eliminated, precision is guaranteed, and accumulative errors are avoided; and the first pressing roller support is connected to the boosting rod in a floating mode such that a large displacement floating compensation function can be achieved, the problem of deviation such as vertical shaking in the workpiece conveying process is solved, and it is guaranteed that the axes of clamped bars and the center of a rotating cutter wheel are always kept consistent in the machining process such that the product quality problems that in the cutting process of the surfaces of the bars, the cutting thicknesses are different or some bars are not cut off and the like can be solved.

Owner:BAOSTEEL SPECIAL STEEL SHAOGUAN CO LTD

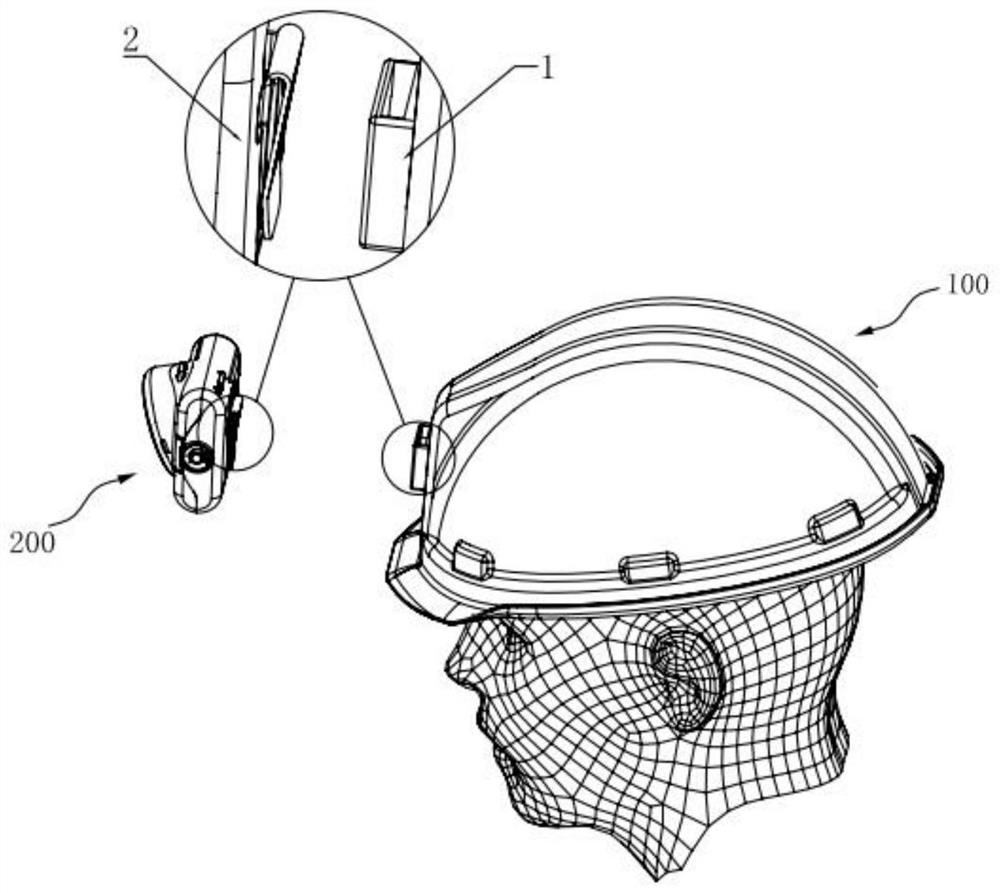

Helmet hook suspension device

ActiveCN112944282AAvoid leaningGuaranteed validityLighting applicationsMechanical apparatusStructural engineeringLight head

Owner:SHENZHEN ZHONGFUNENG ELECTRIC EQUIPMENG CO LTD

Three-freedom double-layer oil film type spherical hinge

ActiveCN101429967BImprove connection stiffnessExtended service lifePivotal connectionsMatched pairDegrees of freedom

The invention relates to a three-dimensional double-layer oil film type spherical hinge, wherein a ball and socket is provided with a oil feeding pressure inlet and an oil-return pressure inlet; a major semi-sphere is arranged in the concave spherical surface of the ball and socket, and a minor semi-sphere is arranged in the major semi-sphere; the end surface of the major semi-sphere is connectedwith a cover board; a mandrel respectively passes through a central circular hole of the ball and socket, the major semi-sphere, and the minor semi-sphere; the ball and socket, the major semi-sphere,and the minor semi-sphere are mounted and connected together; a ball-and-socket oil groove is arranged on the concave spherical surface, and is communicated with the oil feeding pressure inlet through an oil passage, and an oil inlet of the ball-and-socket oil groove is provided with a ball-and-socket throttleer; and the convex spherical surface of the minor semi-sphere is provided with a minor semispherical oil groove which is communicated with a mandrel oil passage arranged in the mandrel, and an oil passage inlet of the minor semispherical oil groove is provided with a minor semispherical throttleer. The spherical hinge has large transmission rigidity in structure, little friction, and long service life, and can obtain a mechanism of five degree of freedom when the spherical hinge is used in matched pair, is applied to multidimensional vibration as a driving source and a connecting piece of a table board, and can improve dynamic response performance of the table board.

Owner:BEIJING XINCHANGZHENG TIANGAO INTELLIGENT MACHINE TECH CO LTD

Telescopic Rebar Splice Kit

ActiveCN105064622BEasy connection and constructionReduce short-distance connectionsBuilding reinforcementsLong spacingArchitectural engineering

The invention relates to a telescopic steel bar connection kit, the main body of which includes a two-way screw sleeve, a forward screw seat, a reverse screw seat, a screw joint, a one-way screw sleeve and a pin shaft; one end of the two-way screw sleeve The inner thread of the thread is consistent with the inner thread of the one-way thread sleeve, and the outer thread of the forward screw seat, screw joint and steel head pier is consistent; each part in the kit can be organically combined, such as adding or subtracting Parts, for the butt connection of two steel bar heads with different spacing, and provide a kit for the connection of steel bar heads at the construction site. The combination method is flexible. According to the requirements of the steel bar spacing, it can reduce the number of parts to form a short-distance connection, and can also increase the number of parts in series to meet the needs of long-distance connections. With the help of two-way threaded sleeves, it can achieve tension and eliminate connection gaps; the connection is reliable, no The amount of deformation can meet the stress design requirements, and it is suitable for the connection of two steel bar heads with dislocation and different angles, which greatly facilitates the construction of steel bar connection.

Owner:裴敏雅

Vertical five-axis linkage machine tool

The invention discloses a vertical five-shaft linkage machine tool. The vertical five-shaft linkage machine tool comprises an overhanging-eave-type portal frame, a swing input motor (21), a swing speed reducer (22), a motorized spindle clamping head (9) and a motorized spindle (8), wherein the swing speed reducer (22) is arranged in a ram (7) and is in bolted connection with the ram (7), the swing input motor (21) is connected with the swing speed reducer (22) through a coupling, the swing speed reducer (22) is of a worm and gear structure, a worm-wheel shaft is a hollow output shaft (24), a worm is connected with the swing input motor (21) through a coupling, the rear end of the motorized spindle clamping head (9) is connected with the worm-wheel hollow output shaft (24) through an expansion sleeve (23), and the front end of the motorized spindle clamping head (9) is installed on the ram (7) through a bearing. The rigidity of the machine tool is improved by more than four times when compared with that of a traditional series machine tool, a connection gap between the swing input motor and the motorized spindle is avoided, swing precision is improved, rolled steel can be efficiently machined at the speed of 10000 turn / min, and the overall performance, including the rigidity, precision and machining speed, of the machine tool is substantially improved when compared with that of existing domestic and overseas machine tools.

Owner:NANJING GEWAI TRACK TRAFFIC EQUIP CO LTD

Fastening fittings for pipes with pre-punched holes

ActiveCN103410823BEliminate connection gapsSimple structureRod connectionsDowelsStructural engineeringPipe

The invention discloses a fastening connection fitting for a pipe with a pre-punched hole, which includes a joint and a top wire. The part outside the pre-punched hole is tightly connected with the ordinary pipe by tightening the top screw, and drives the clip to expand and fasten the pre-punched hole. The utility model has the advantages of simple structure, convenient installation, elimination of installation gap and improvement of connection strength.

Owner:HUNAN GOLDWELL NEW MATERIALS TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com