Steel bar mechanical connecting device and method

A technology of mechanical connection and reinforcement, applied in the direction of structural elements, building components, building reinforcements, etc., can solve the problems of unqualified connection performance, size error, connection thread damage, etc., to save assembly process and assembly time, reduce the number of , reduce the effect of deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

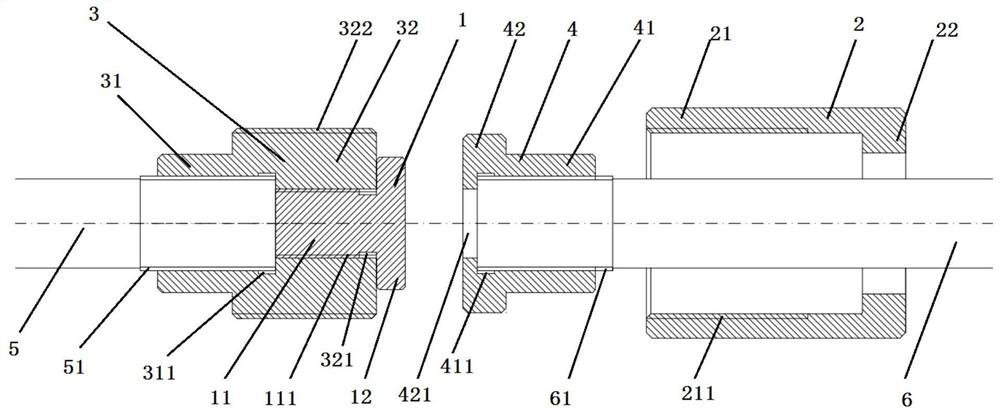

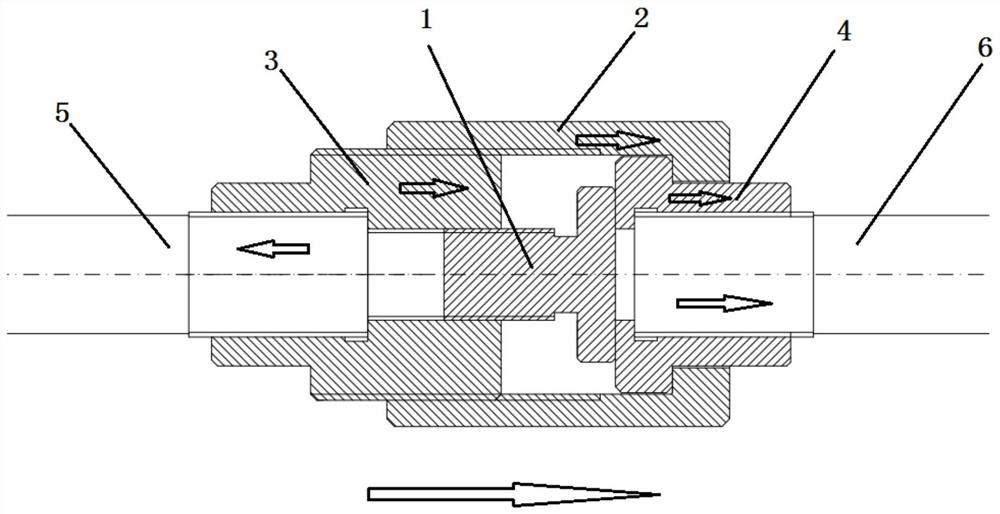

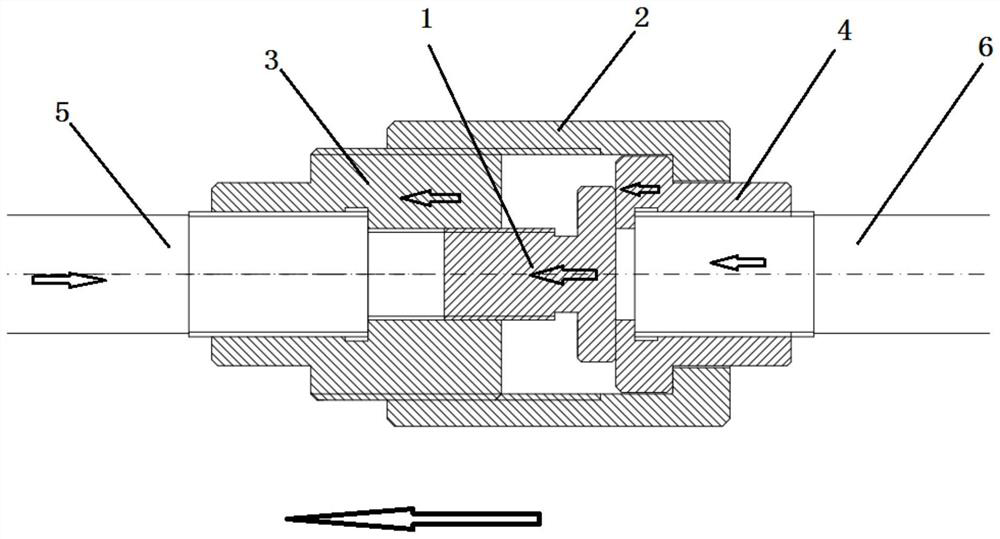

[0049] Such as Figure 1-3 As shown, a mechanical connection device for steel bars is used to connect the first steel bar 5 and the second steel bar 6, including a pressure-bearing inner push rod 1 and an outer screw sleeve 2; the end of the first steel bar 5 is provided with an outer diameter larger than The first connecting part 3 of the first steel bar 5, the end of the second steel bar 6 is provided with a second connecting part 4 whose outer diameter is larger than that of the second steel bar 6, and the pressure-bearing inner push rod 1 includes a screw thread The screw joint section 11 and the top joint section 12, the end of the first connecting part 3 is provided with an axial pressure-bearing internal thread hole 321 matched with the pressure-bearing external thread 111 of the screw joint section 11, the The jacking section 12 is jacked to the end of the second connecting member 4 by adjusting the length of the threaded joint section 11 screwed to the axial pressure-...

Embodiment 2

[0063] The difference from the above-mentioned embodiment is that, if Figure 4 As shown, the connection between the first connecting member 3 and the second connecting member 4 and the first steel bar 5 and the second steel bar 6 can be replaced by welding connection or adhesive connection. Specifically, the first steel bar connection end 31 is a solid end, and is fixed to the end of the first steel bar 5 by welding or bonding. The second connection part 4 can adopt the solution of Embodiment 1, and can also preferably be the following solution, the second steel bar connection end 41 is a solid end and is fixed to the second steel bar 6 by welding or bonding. Ends.

[0064] As preferred, such as Figure 5 As shown, the first steel bar connecting end 31 is a solid end, and is fixed to the end of the section steel 7 by welding or bonding.

Embodiment 3

[0066] The difference from the above-mentioned embodiment is that, if Image 6As shown, the connection method between the first connecting part 3 and the second connecting part 4 and the first steel bar 5 and the second steel bar 6 can be replaced by a steel bar upsetting type. Specifically, the first connecting part 3 includes a first end portion 52 formed after the first steel bar 5 is upset, and the axial pressure-bearing internal thread hole 321 and the first external thread 322 are provided on the The first end portion 52 . The second connection part 4 can adopt the solution of embodiment 1 or 2, and can also preferably be the following solution, the second connection part 4 includes the second end 62 formed after the second steel bar 6 is upset, so The second end portion 62 is provided with a boss 621 whose diameter is smaller than the inner diameter of the straight thread sleeve 21 and larger than the diameter of the second steel bar and the diameter of the inner hole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com