Fastening fittings for pipes with pre-punched holes

A fastening connection and pre-punching technology, which is applied to the connection of rods, connecting members, pins, etc., can solve the problems of affecting the appearance of the connection position, affecting the strength of the pipe, and uncoordinated installation, so as to achieve a beautiful external connection position and eliminate holes Connection gap, not easy to loose effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

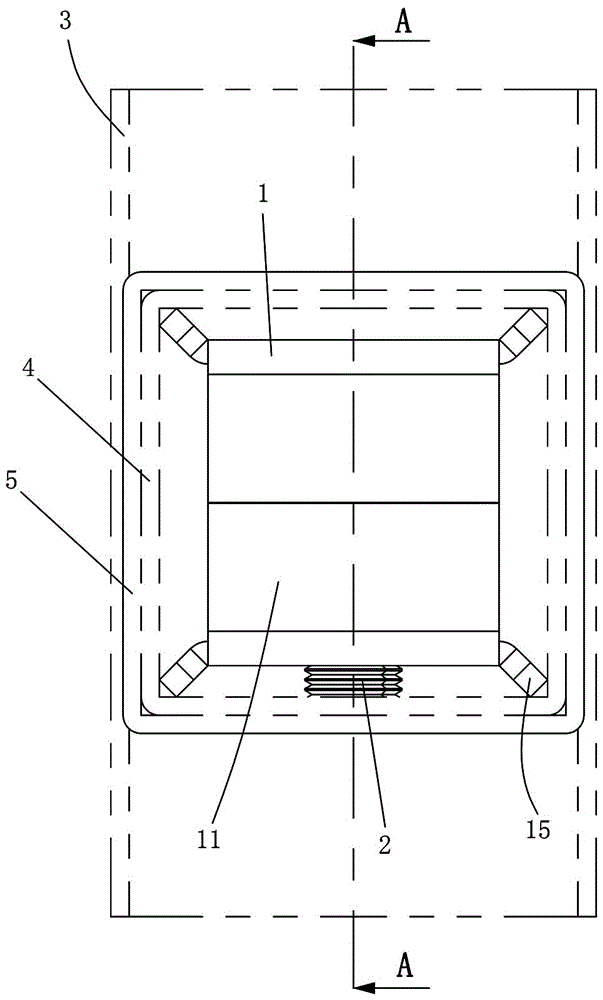

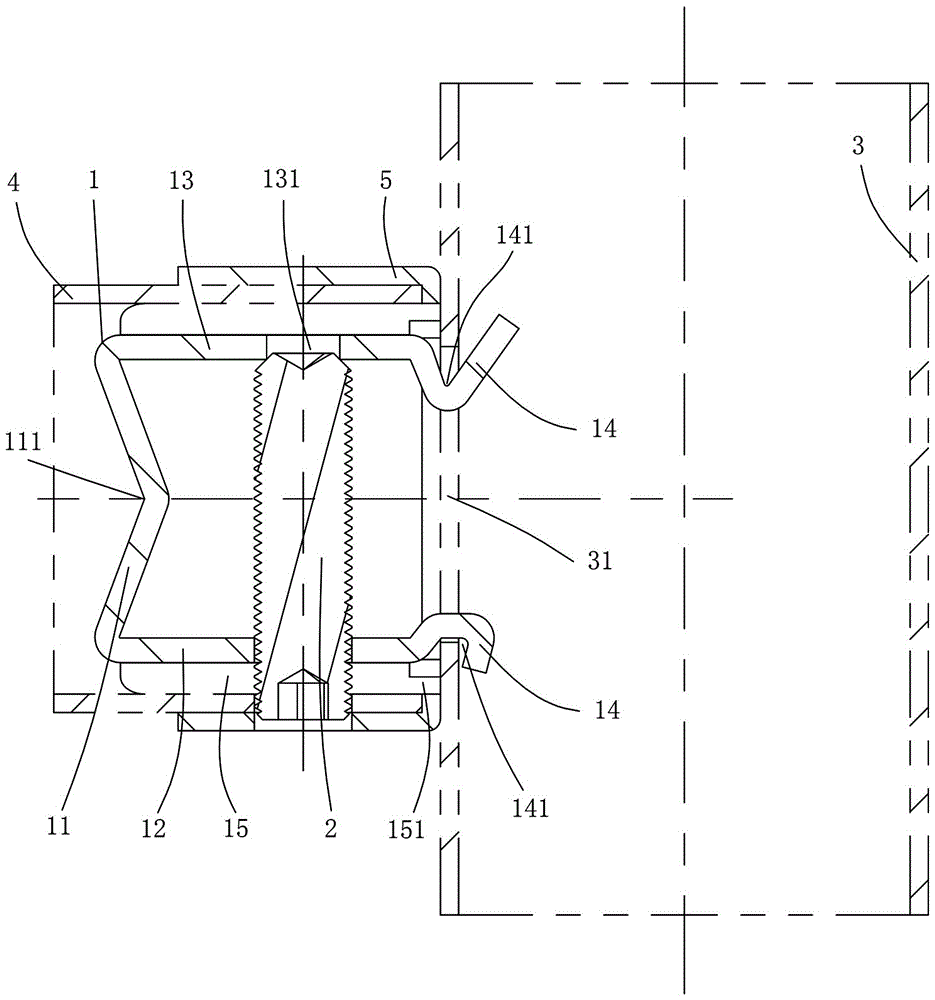

[0027] Figure 1 to Figure 4 It shows the first embodiment of the fastening connection fitting for pipes with pre-punched holes according to the present invention. The pair of clamping feet 14 that are clamped by the punching hole 31, the part protruding out of the pre-punching hole 31 is tightly connected with the ordinary pipe 4 by tightening the top screw 2, and drives the pair of clamping feet 14 to expand and fasten the pre-punching hole 31. Its structure is simple and easy to install. When assembling, first insert the clip 14 on the joint 1 obliquely into the pre-punched hole 31 on the pre-punched pipe 3, so that the clip 14 and the pre-punched hole 31 form a buckle connection , and then another ordinary pipe 4 is inserted into the part of the joint 1 protruding out of the pre-punched hole 31, and the top screw 2 is tightened through the opening of the ordinary pipe 4 with a tool, so that it is contained in the ordinary pipe 4. The joint 1 expands to connect with the in...

Embodiment 2

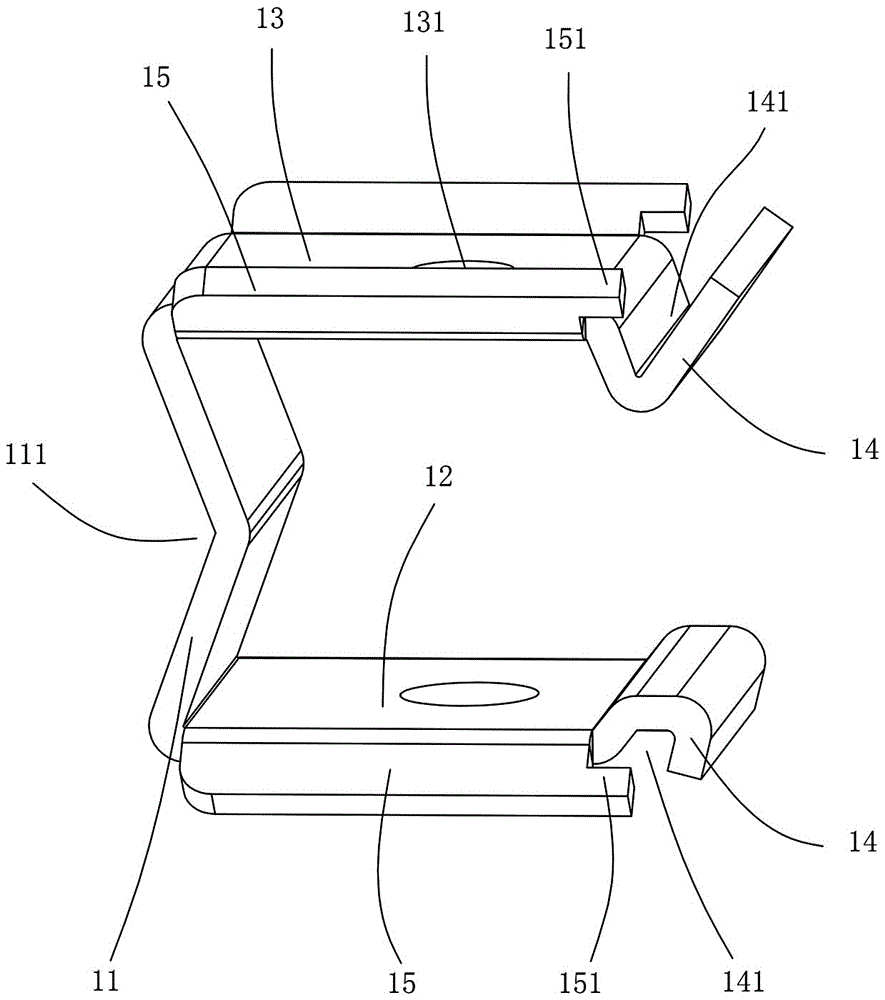

[0035] Figure 5 to Figure 7 It shows the second embodiment of the fastening connection fittings for pipes with pre-punched holes of the present invention, the connection fittings are basically the same as the first embodiment, the only difference is that the clamp feet 14 are arranged on the pull plate 12 and the top plate 13 On the same side, both ends of the pull plate 12 and the top plate 13 are bent with a folded edge 15 for tightening the inner wall of the ordinary pipe 4, and are connected to the side plate 11 through the folded edge 15 at one end, and connected to the side plate 11 through the clamp on one side of the joint 1. The foot 14 connects the two pipes. When the top wire 2 is tightened, the folded edge 15 and the bent portion formed by the folded edge 15 and the side plate 11 will simultaneously tighten the ordinary pipe 4 that is sleeved outside the joint 1. Inner wall, in this structure, there is also no need to use large-span connectors to avoid the pre-pun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com