Patents

Literature

111results about How to "Guaranteed connection tightness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

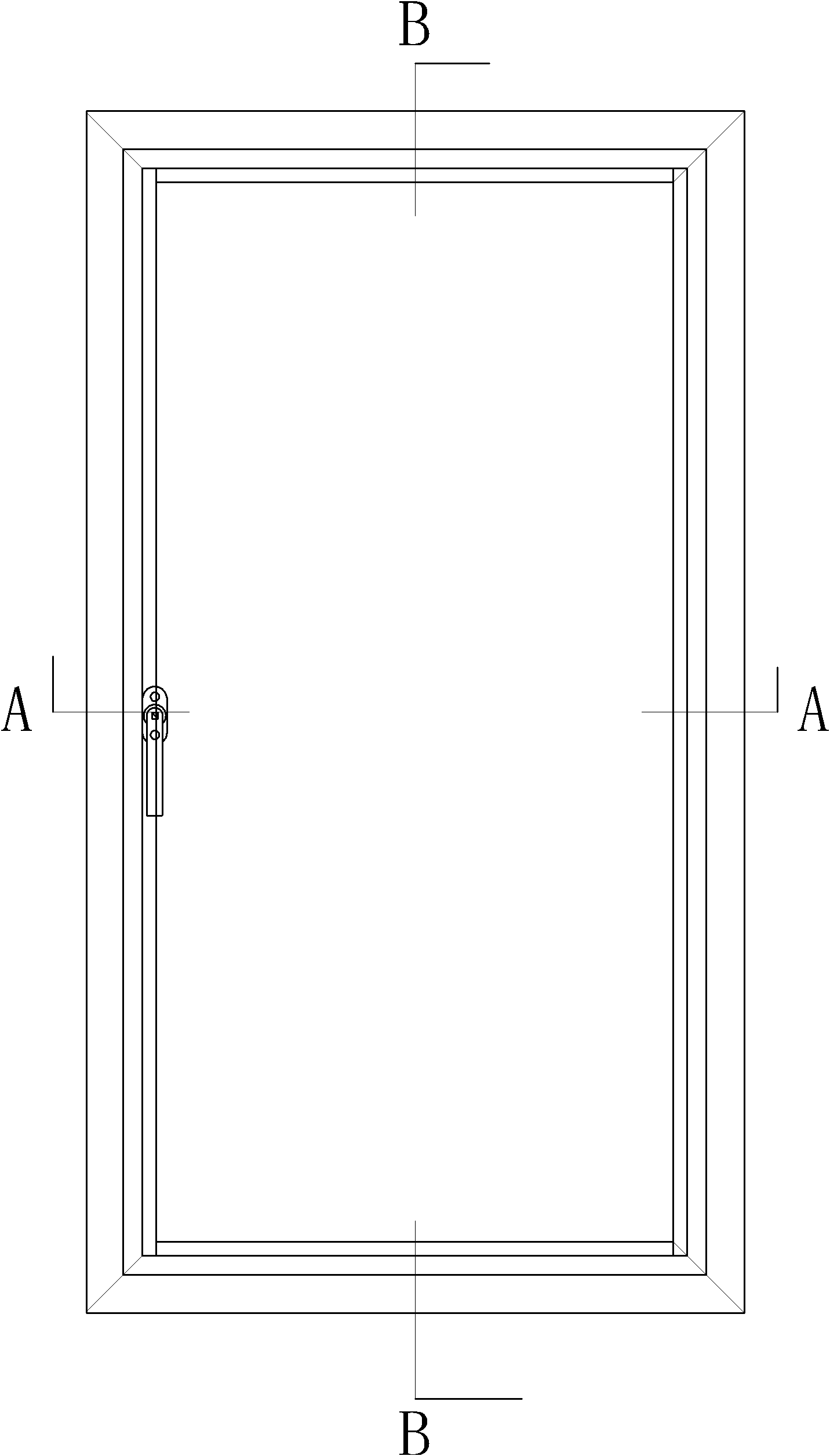

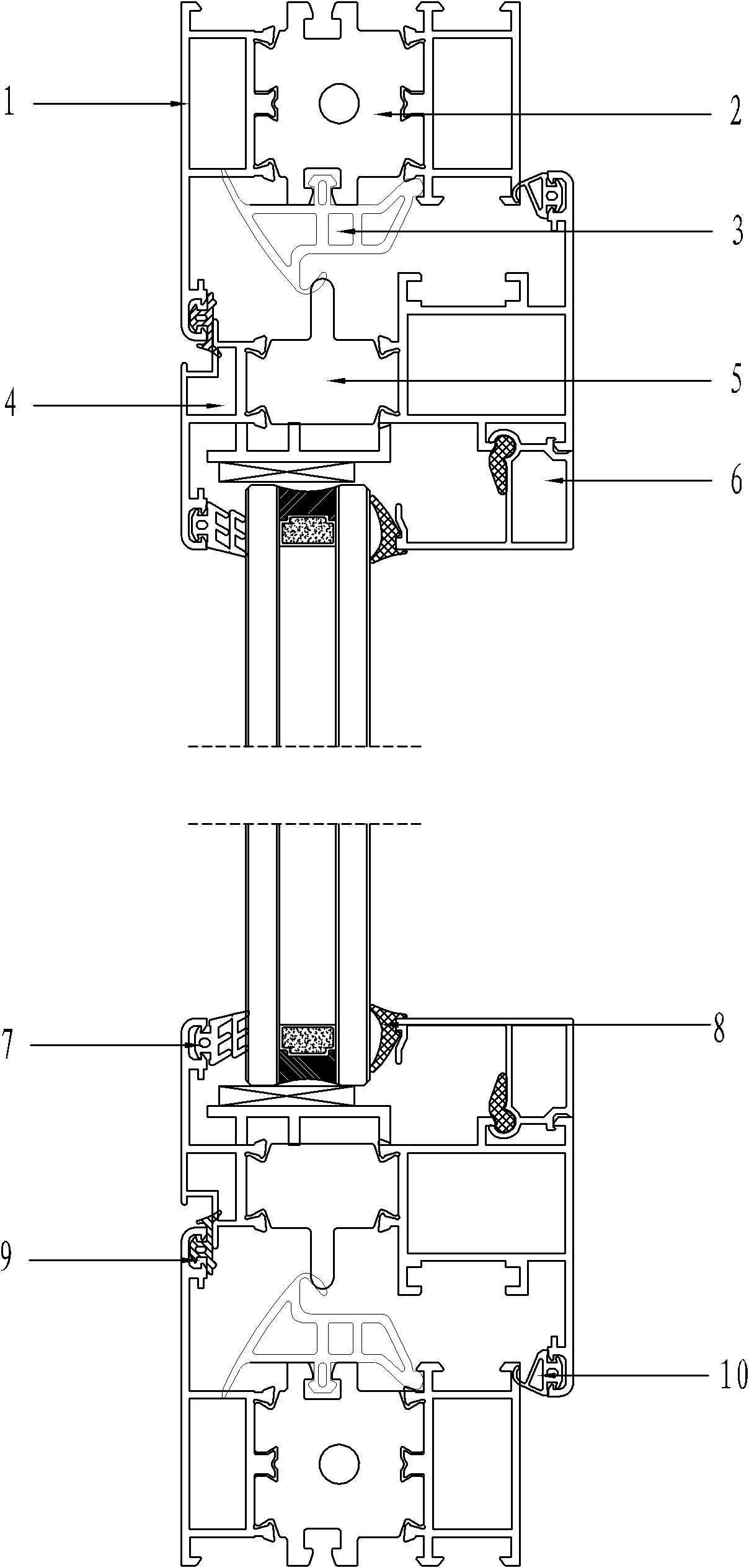

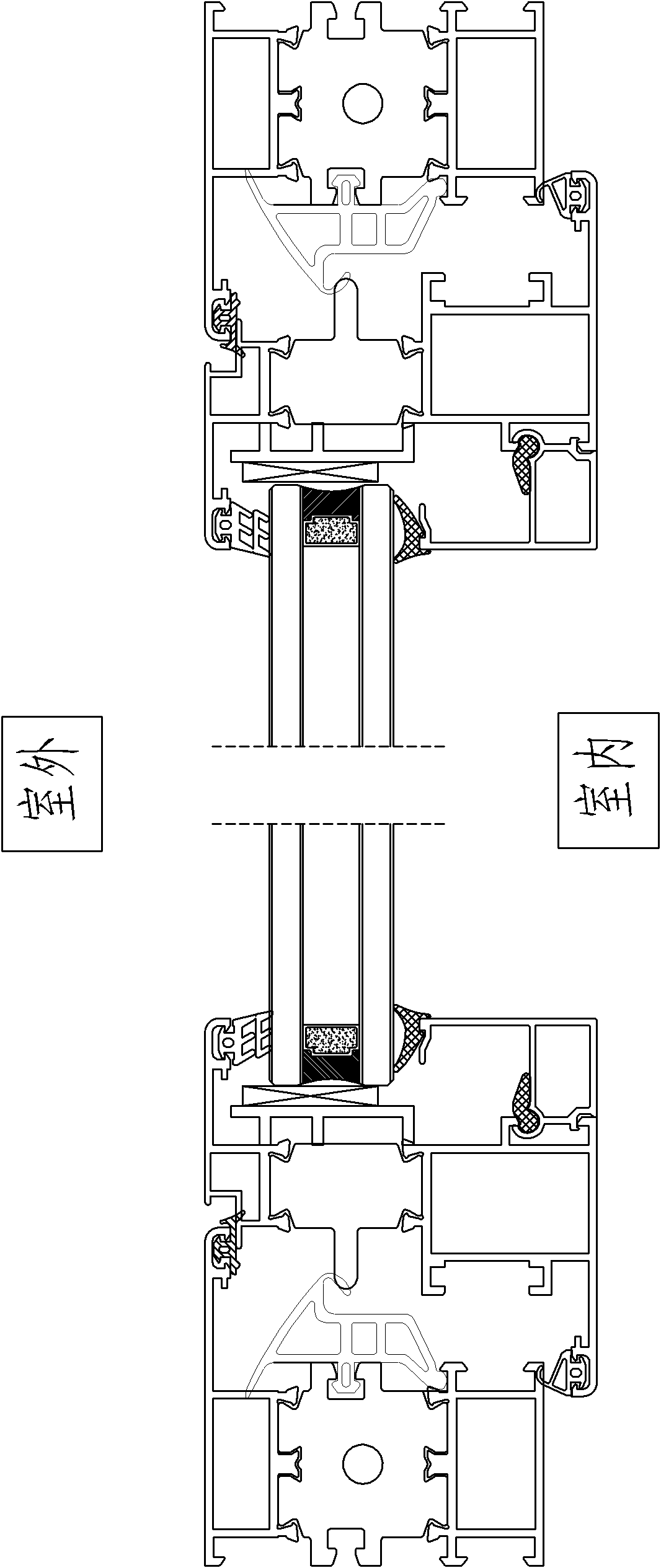

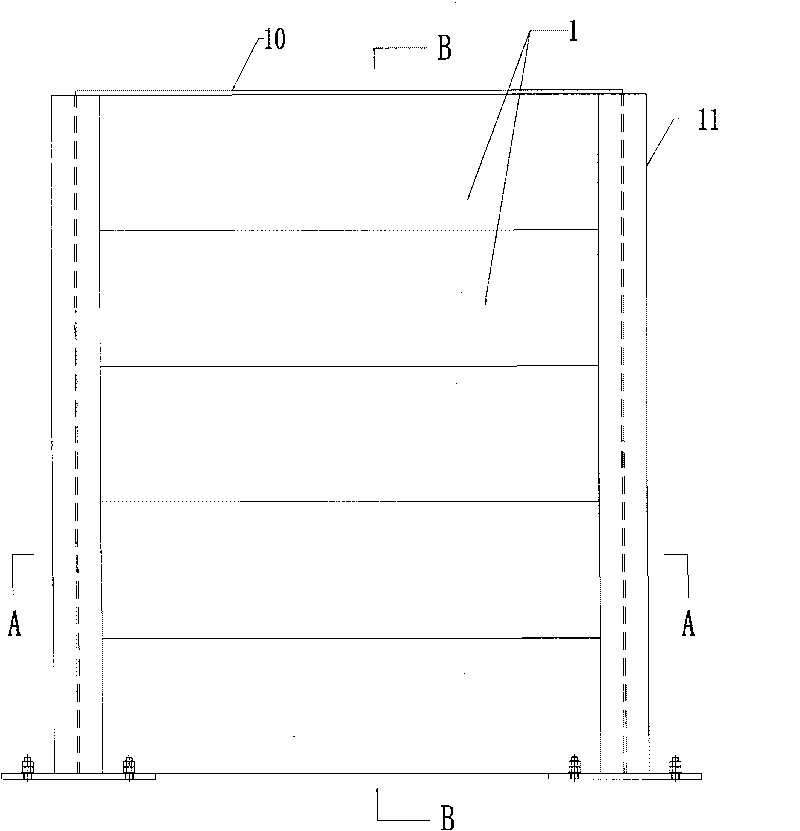

Novel heat-insulated energy-saving aluminum-alloy window

InactiveCN102635301AHigh strengthGuaranteed tightnessSealing arrangementsStructural engineeringMechanical engineering

The invention discloses a novel heat-insulated energy-saving aluminum-alloy window, which comprises a window frame, a window sash, window glass and a pressing bar. The window frame and the window sash both have insulating broken-bridge structures, a frame insulating penetrating bar is arranged in the window frame, a sash insulating penetrating bar is arranged in the window sash, a frame and sash intermediate rubber strip and a frame-sash sealing rubber strip are arranged between the window frame and the window sash, an outer glass rubber strip is arranged between the outer side of the window glass and the window sash, an inner glass rubber strip is arranged between the inner side of the window glass and a pressing line, one side of the inner glass rubber strip clings to the pressing line, and a gap is formed between the other side of the inner glass rubber strip and the window glass. In terms of design of section bars, both the window frame and the window sash have the insulating broken-bridge structures, the insulating penetrating bars made of micro-foaming materials are adopted in the middle of the window frame and the window sash, so that the heat transmitting path through the window frame and the window sash is blocked, and high efficiency and energy saving are achieved. The way of rolling the bars prior to penetrating the bars are both employed in the window frame and the window sash, so that sealing and shearing force of the section bars of the window frame and the window sash are guaranteed, and strength of the section bars is higher.

Owner:ZHEJIANG ROOMEYE ENERGY SAVING TECH CO LTD

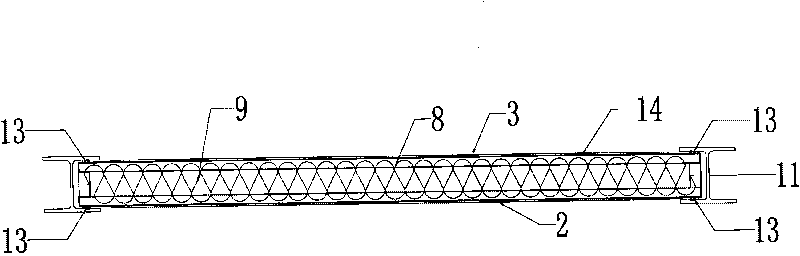

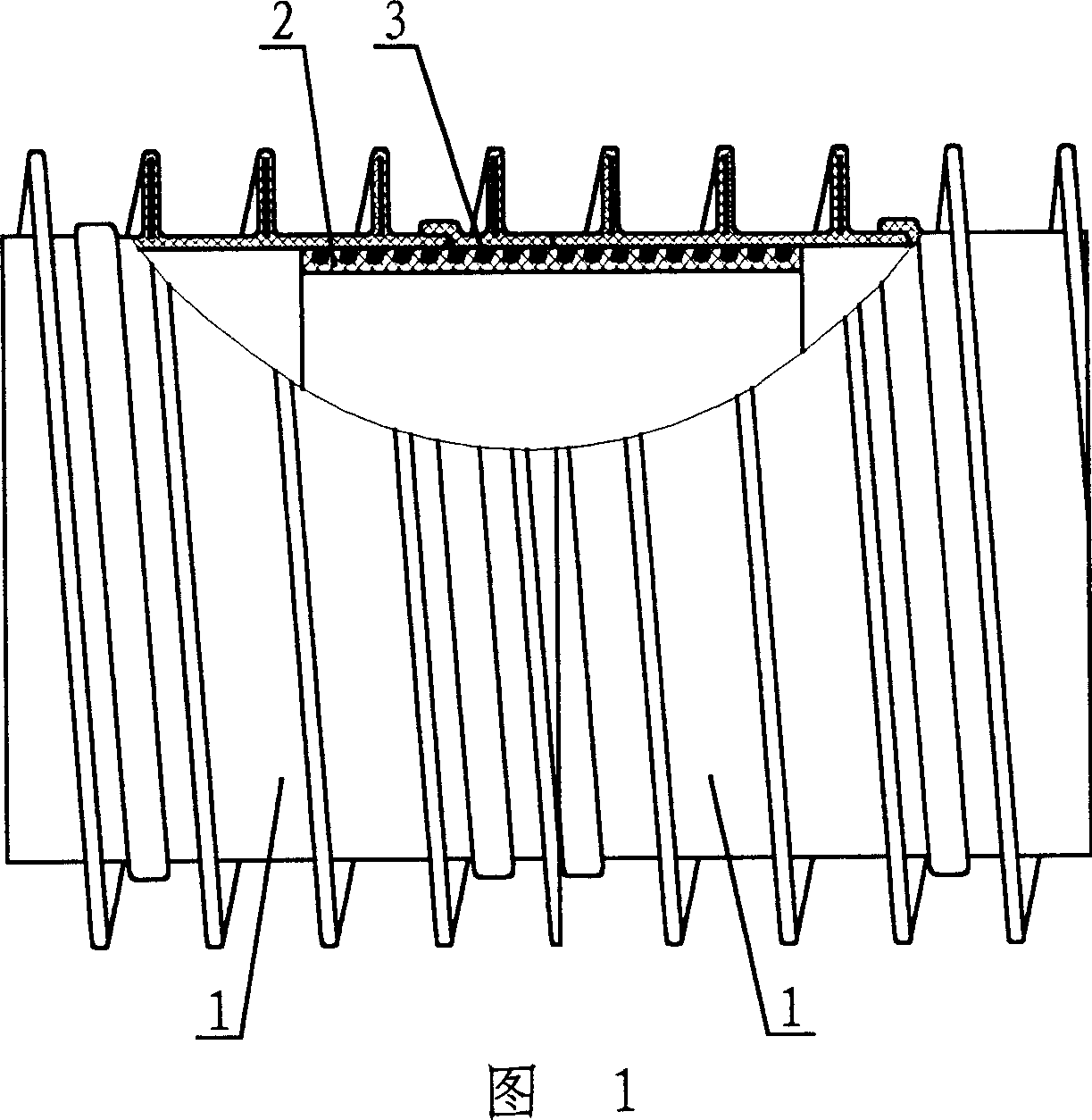

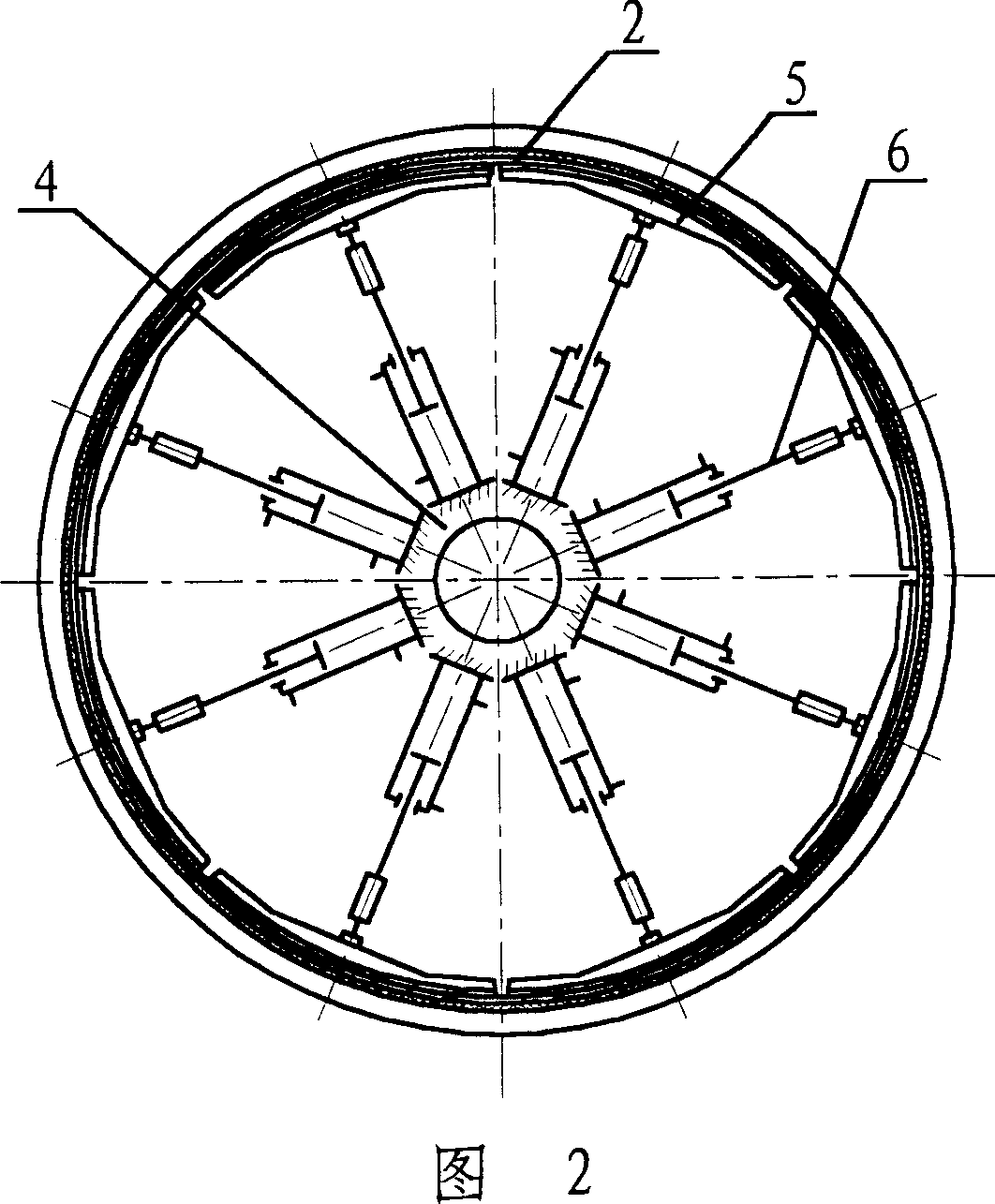

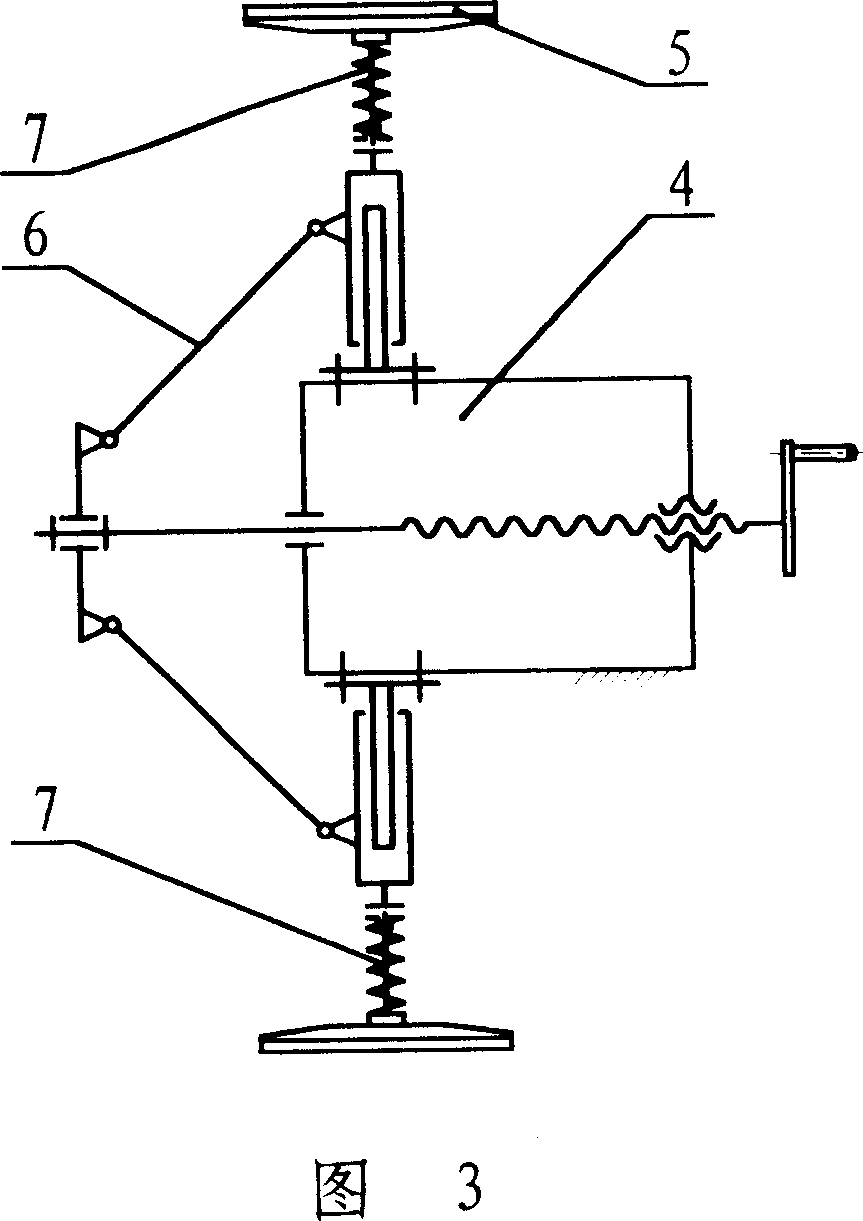

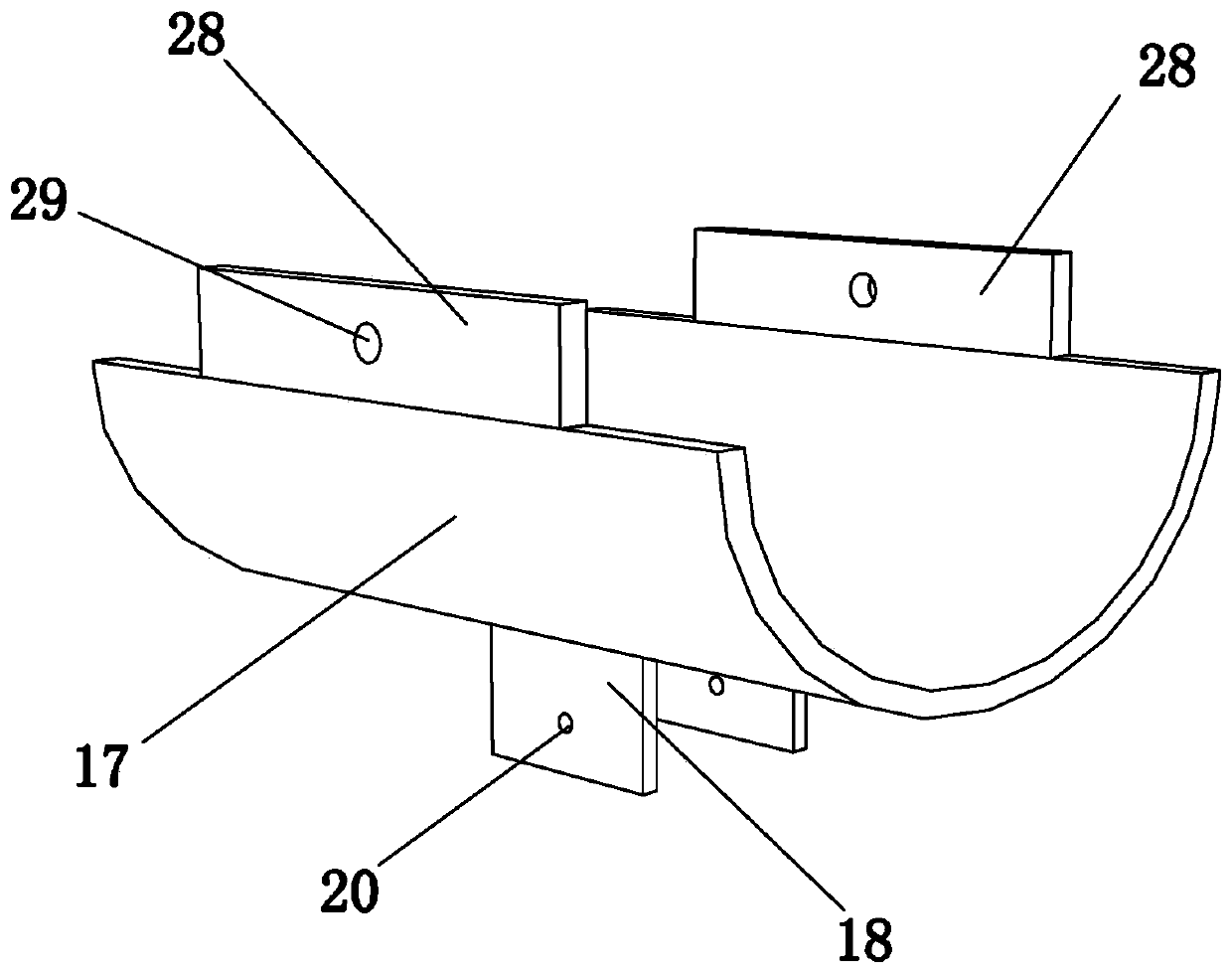

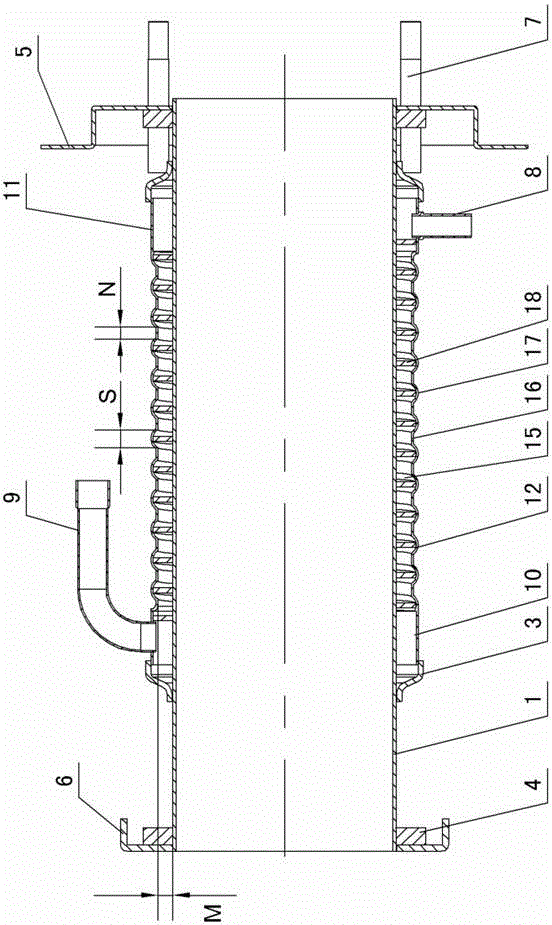

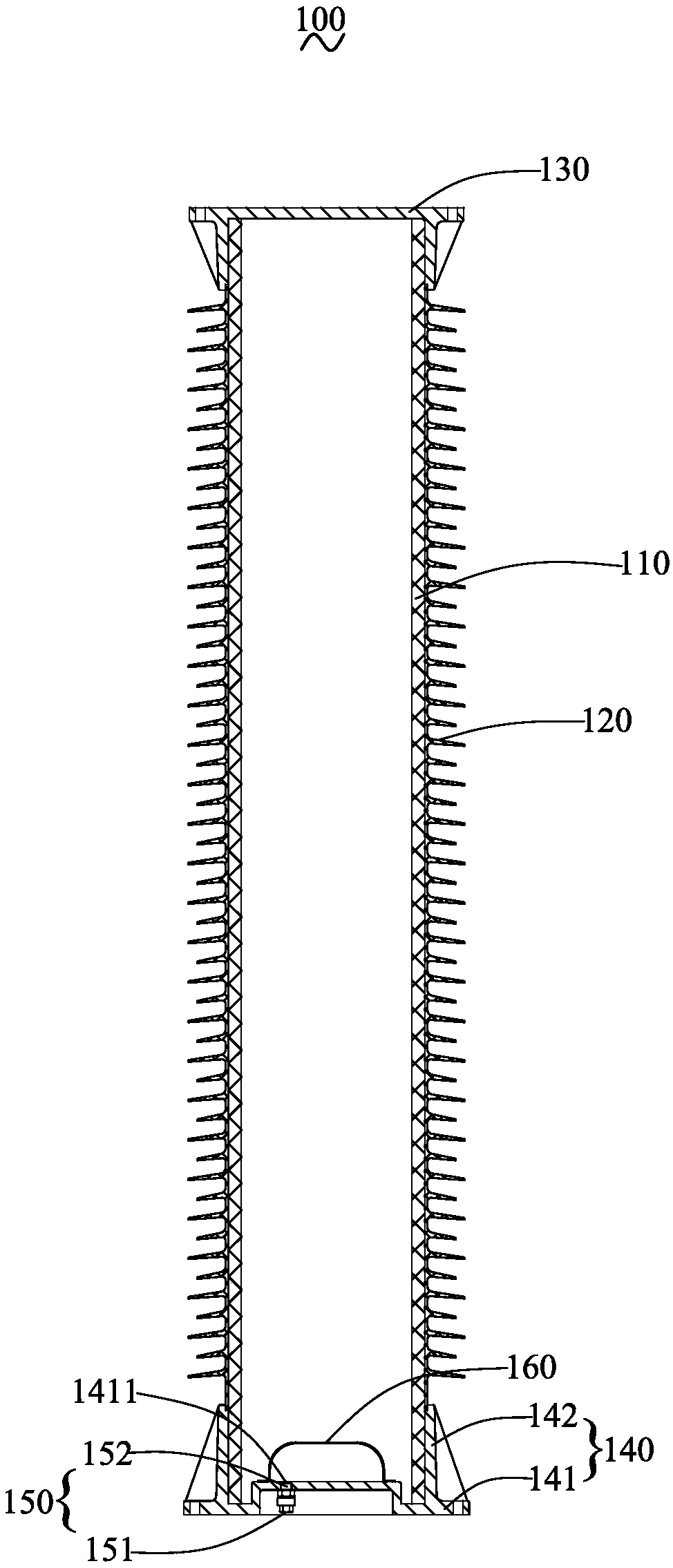

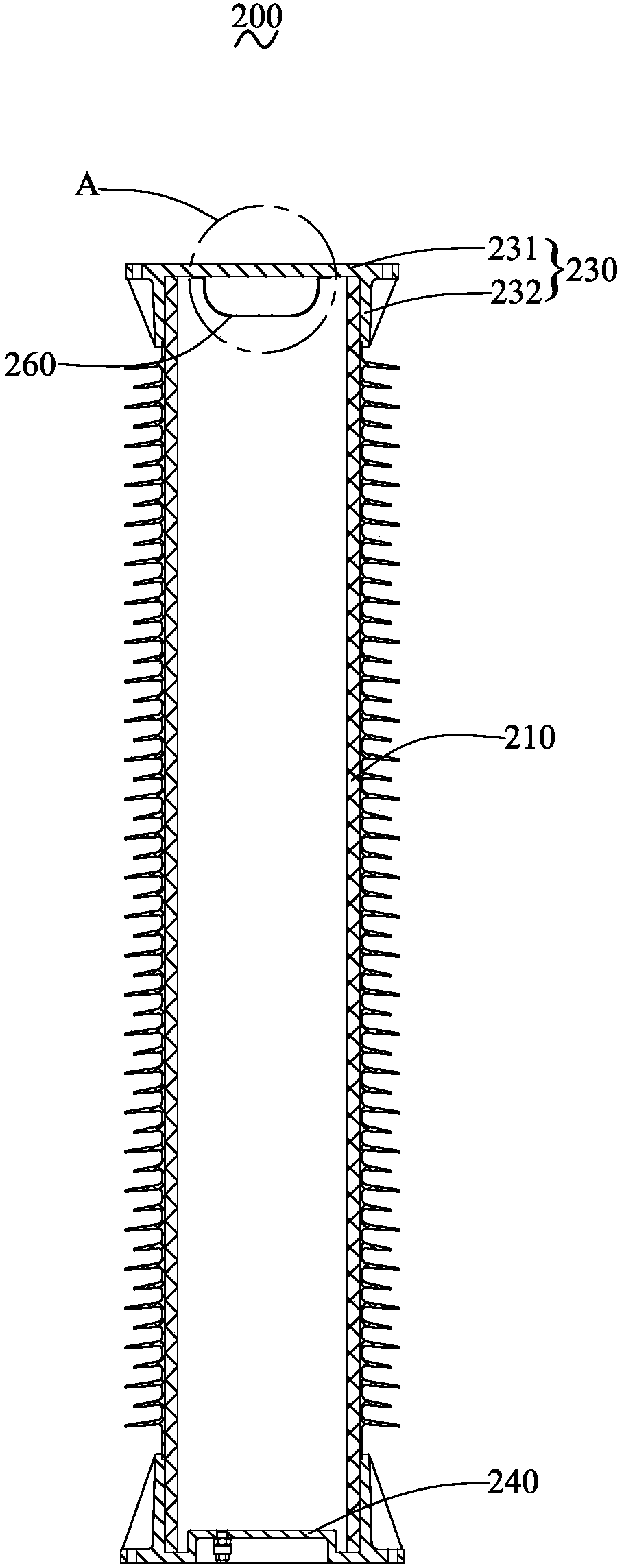

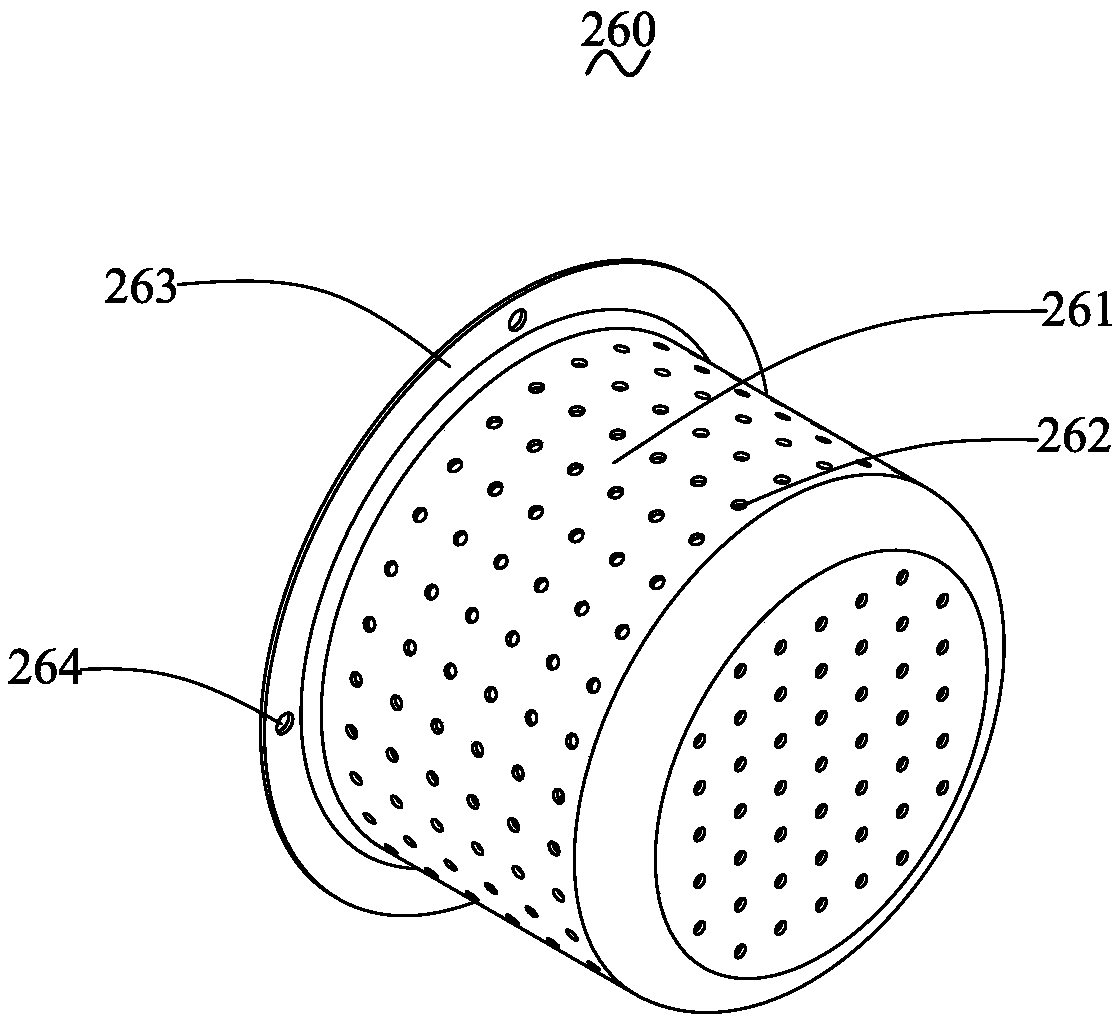

Sound barrier structure for high speed railways

InactiveCN101713171ALighten the loadIncrease stiffnessNoise reduction constructionSound barrierShock resistance

The invention relates to a sound barrier structure for high speed railways. The sound barrier structure comprises a steel upright post and a plurality of sound barrier absorption / sound insulation unit plates which are transversely inserted in the steel upright post; elastic rubber is filled in a gap between a flange plate of the steel upright post and the sound barrier absorption / sound insulation unit plate; the sound barrier absorption / sound insulation unit plate comprises a front side plate, a rear side plate, locking buckles, a central framework and a sound absorption material, wherein the front side plate and the rear side plate are locked to a first locking plate and a second locking plate and the upper side and lower side of the central framework through the locking buckles; and the sound absorption material is filled in the gaps inside the locked front and rear side plates. Based on the conventional sound barriers, the sound barrier structure has good economic performance and durability by improving and expanding the types of the conventional sound barriers, and particularly the mechanical strength is greatly improved; and because the technology of bolt-free connection is adopted, the rigidity, shock resistance, fatigue resistance and safety performance of the sound barrier structure are greatly improved.

Owner:ATEC ENERGY&ENVIRONMENT CO LTD

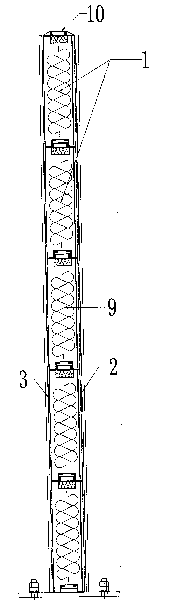

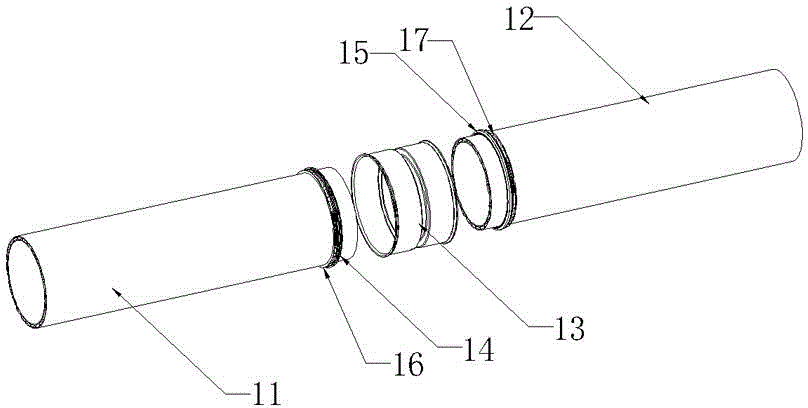

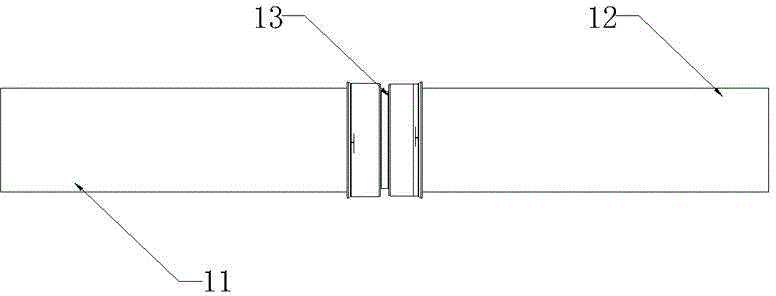

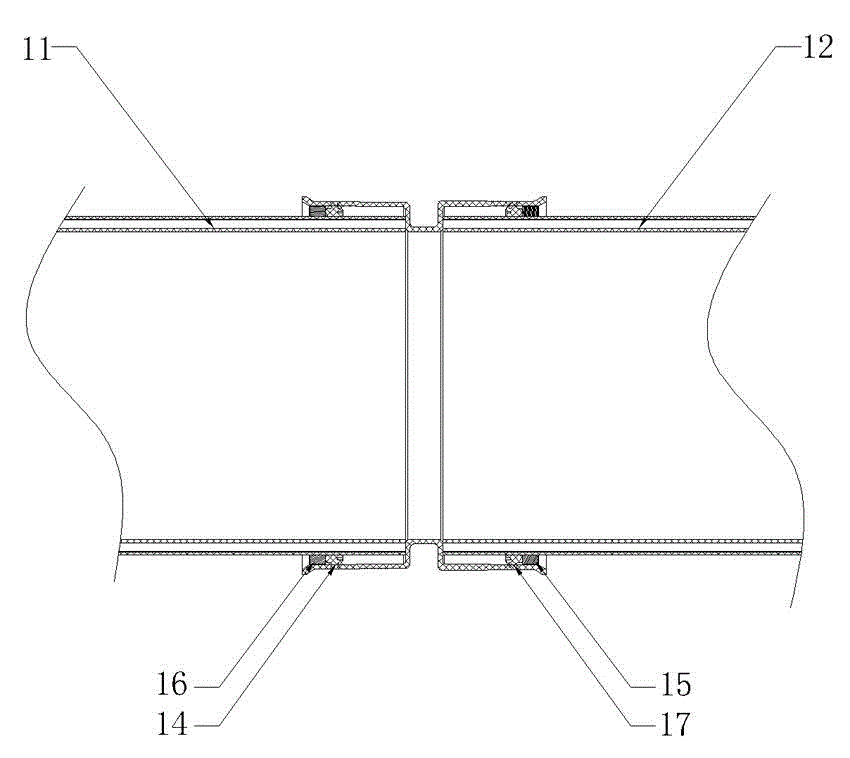

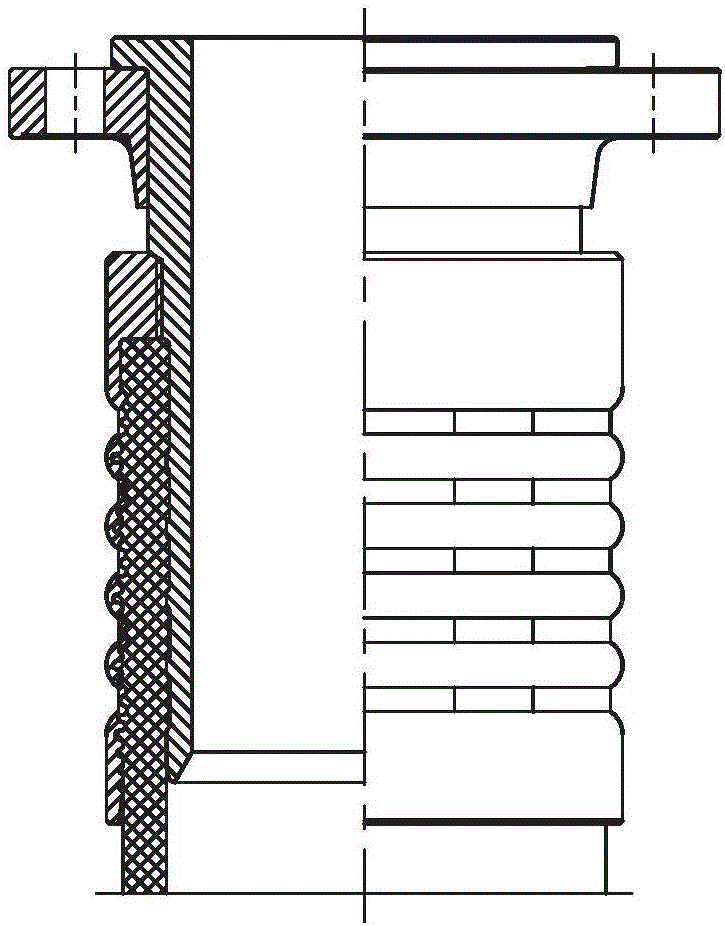

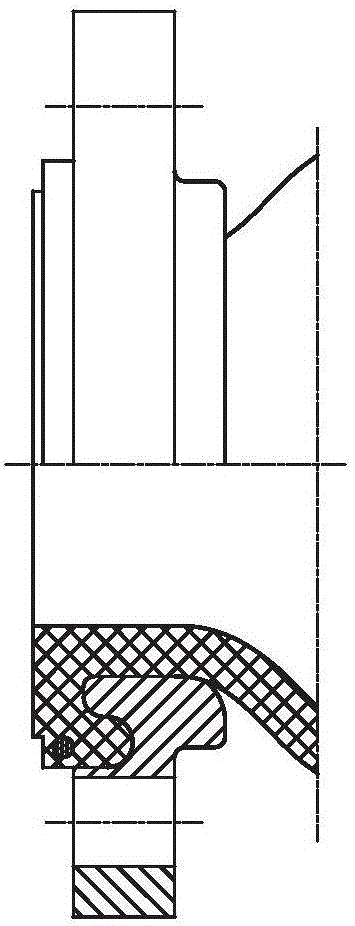

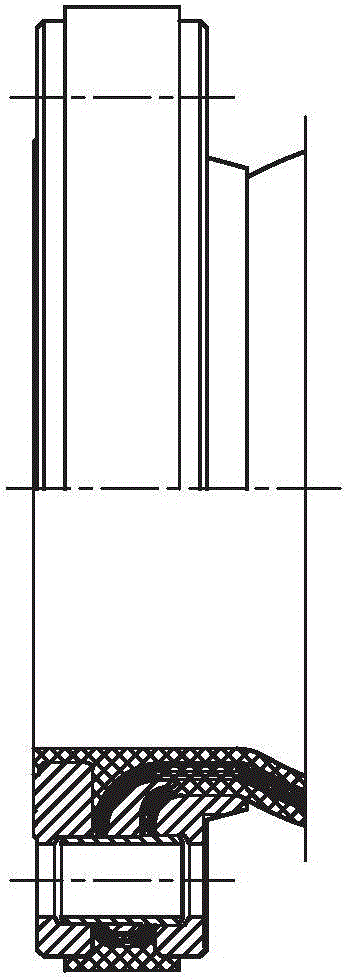

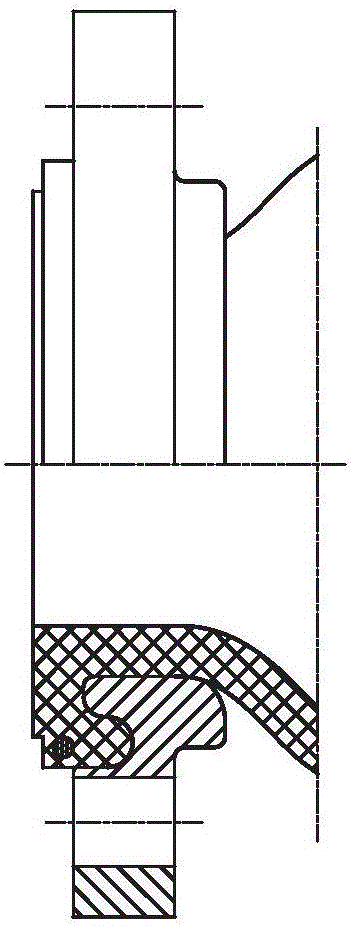

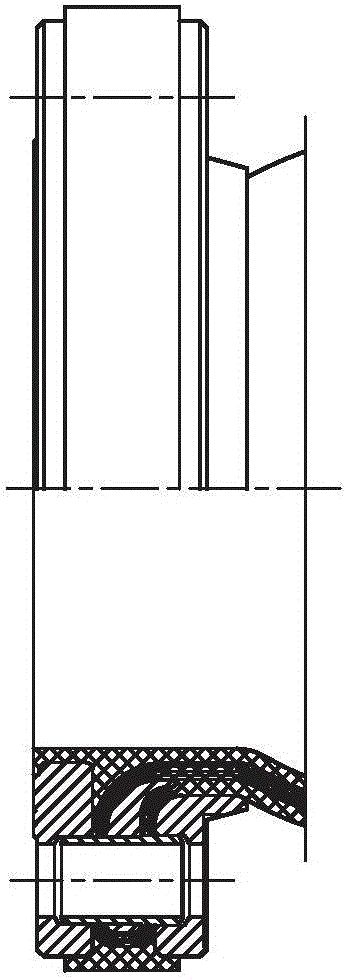

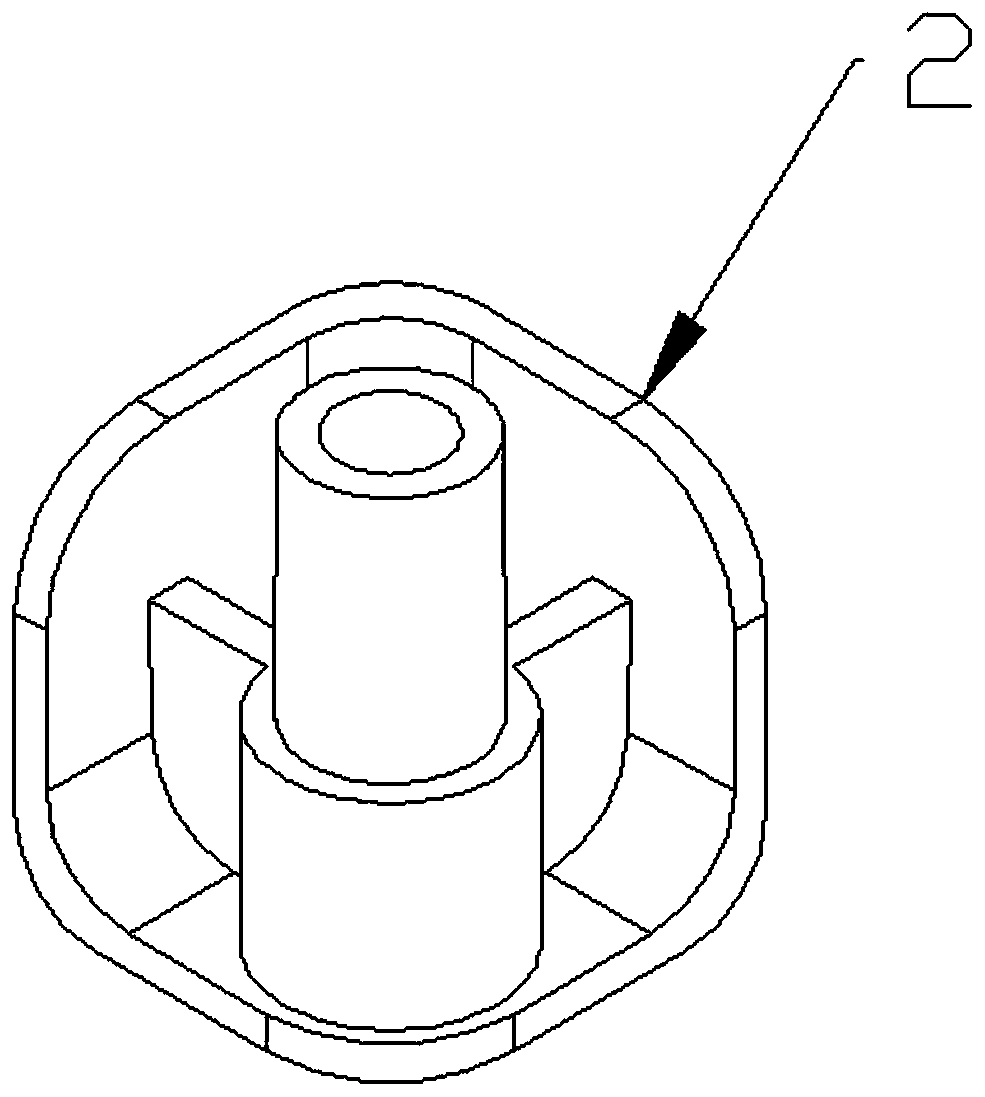

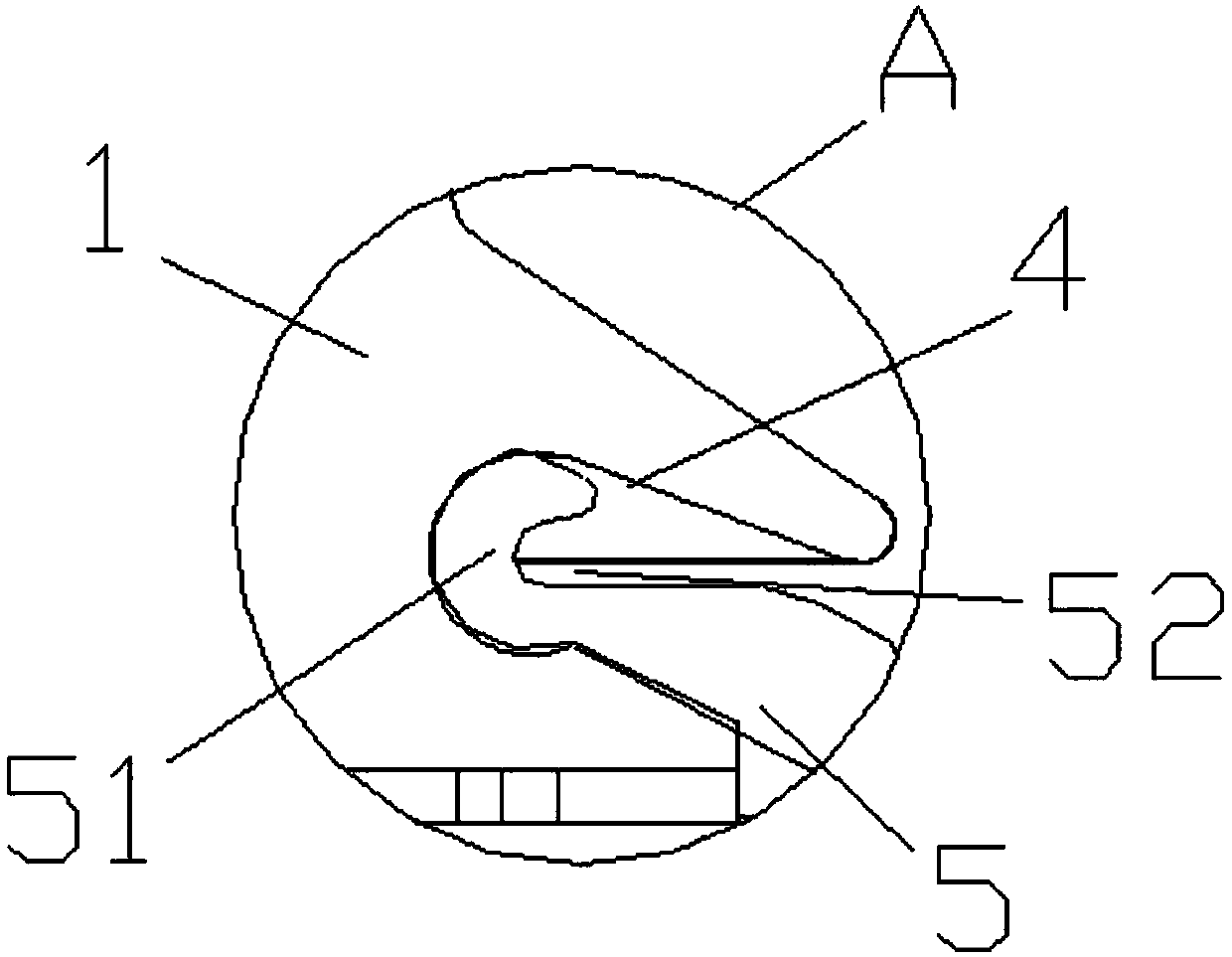

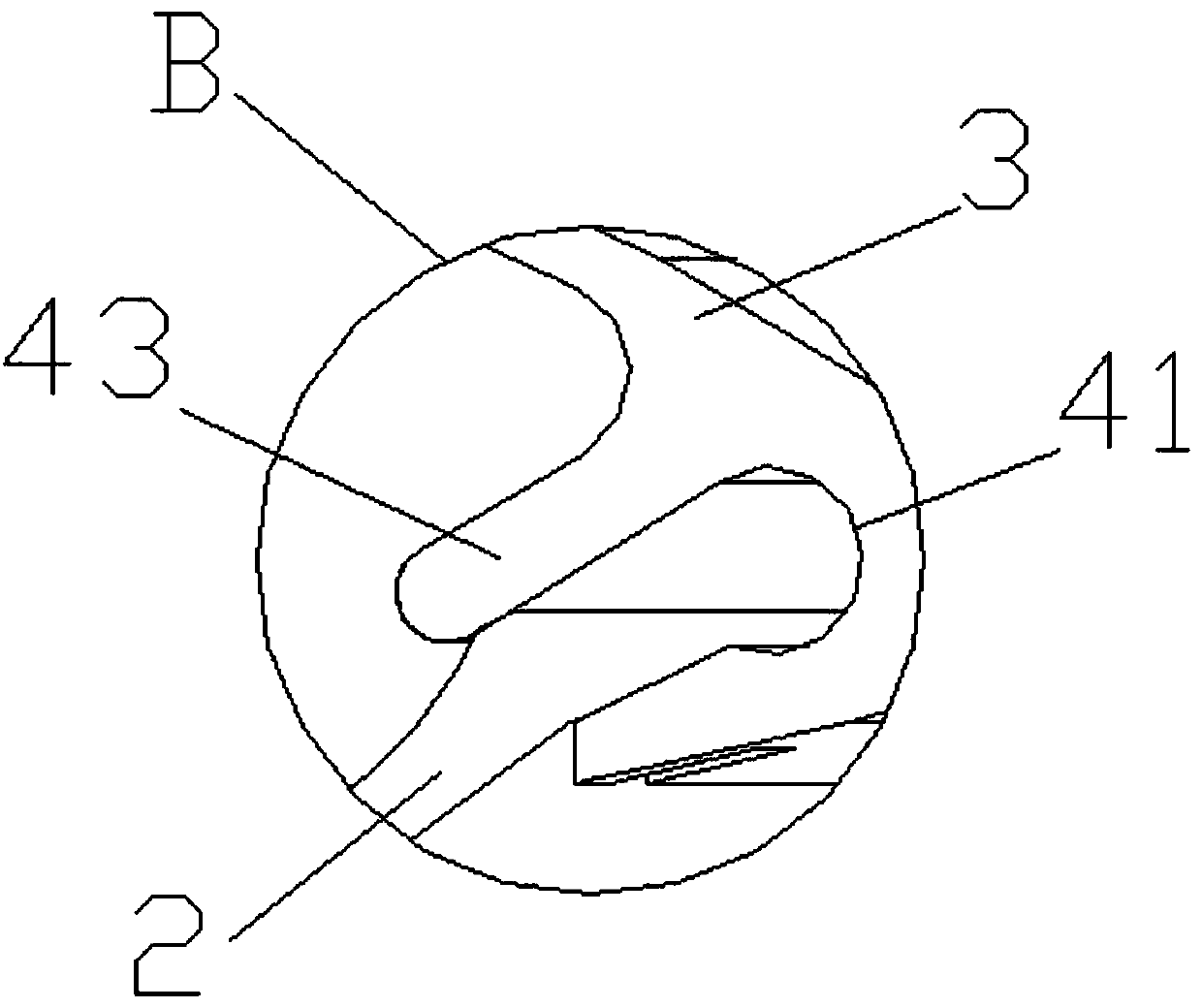

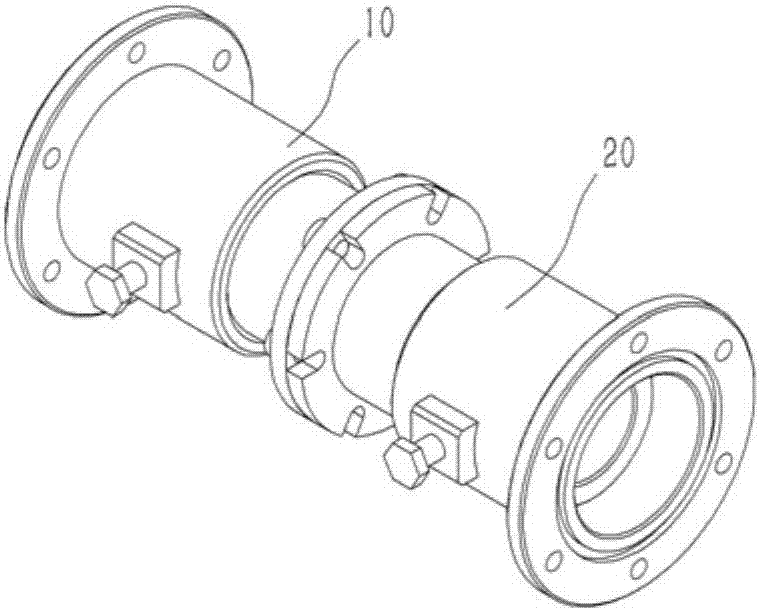

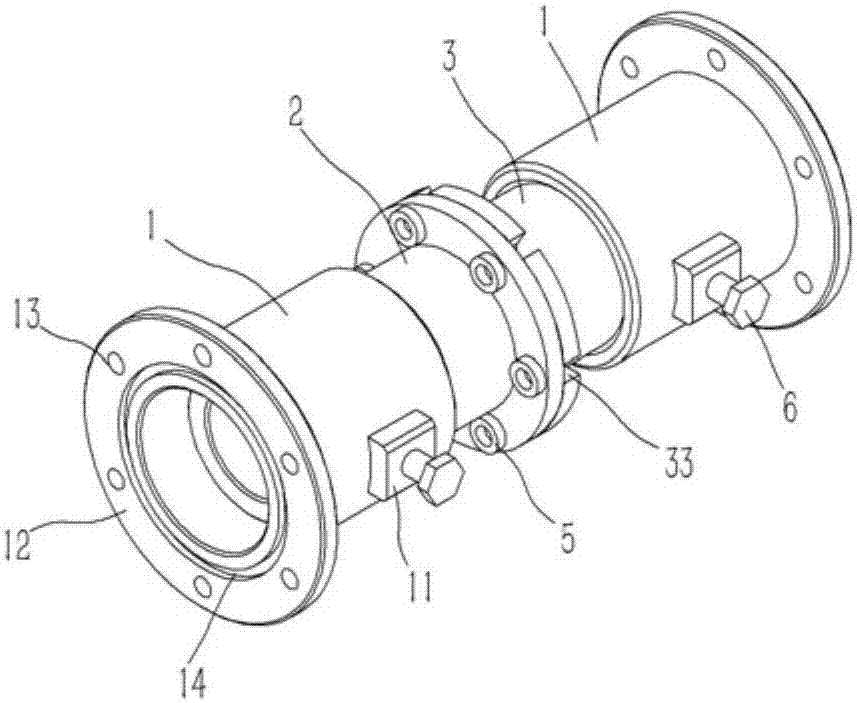

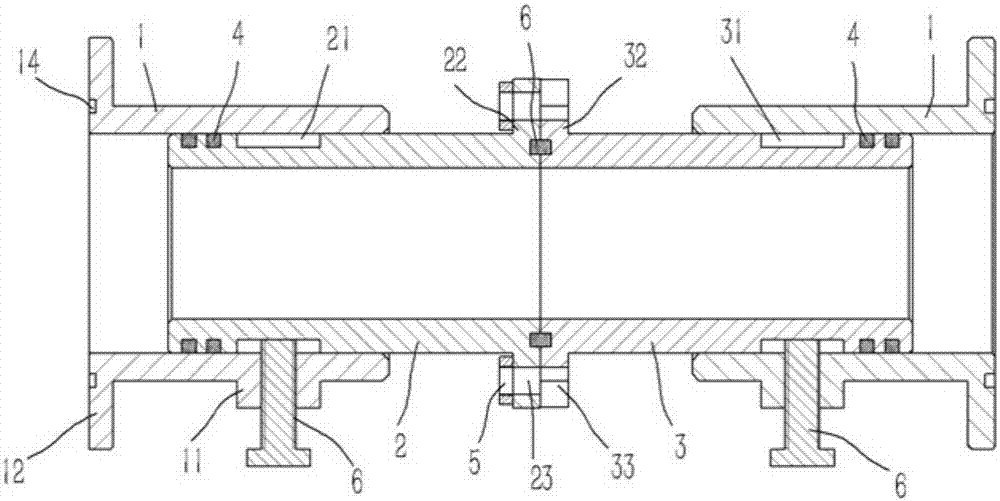

Hollow wall winding pipe connecting structure

The invention discloses a hollow wall winding pipe connecting structure which comprises a first pipe fitting, a second pipe fitting, a connecting pipe sleeve, two sealing rings and two positioning hoops; the first pipe fitting is mounted and inserted into one end of the connecting pipe sleeve, the first pipe fitting is sleeved and equipped with the first sealing ring and the first positioning hoop, the first sealing ring and the first positioning hoop are both arranged between the outer wall of the first pipe fitting and the inner wall of the connecting pipe sleeve, and the first positioning hoop is clung to the outer side of the first sealing ring; the second pipe fitting is mounted and inserted into the other end of the connecting pipe sleeve, the second pipe fitting is sleeved and equipped with the second sealing ring and the second positioning hoop, the second sealing ring and the second positioning hoop are both arranged between the outer wall of the second pipe fitting and the inner wall of the connecting pipe sleeve, and the second positioning hoop is clung to the outer side of the second sealing ring. According to the structure, the sealing rings are arranged between the pipe fittings and the connecting pipe sleeve, and the positioning hoops are further mounted to be propped against the two sealing rings, so that the sealing rings can be effectively prevented from sliding on the pipe fittings, and the sealing reliability is ensured.

Owner:HUBEI BADATONG NEW MATERIAL APPL TECH

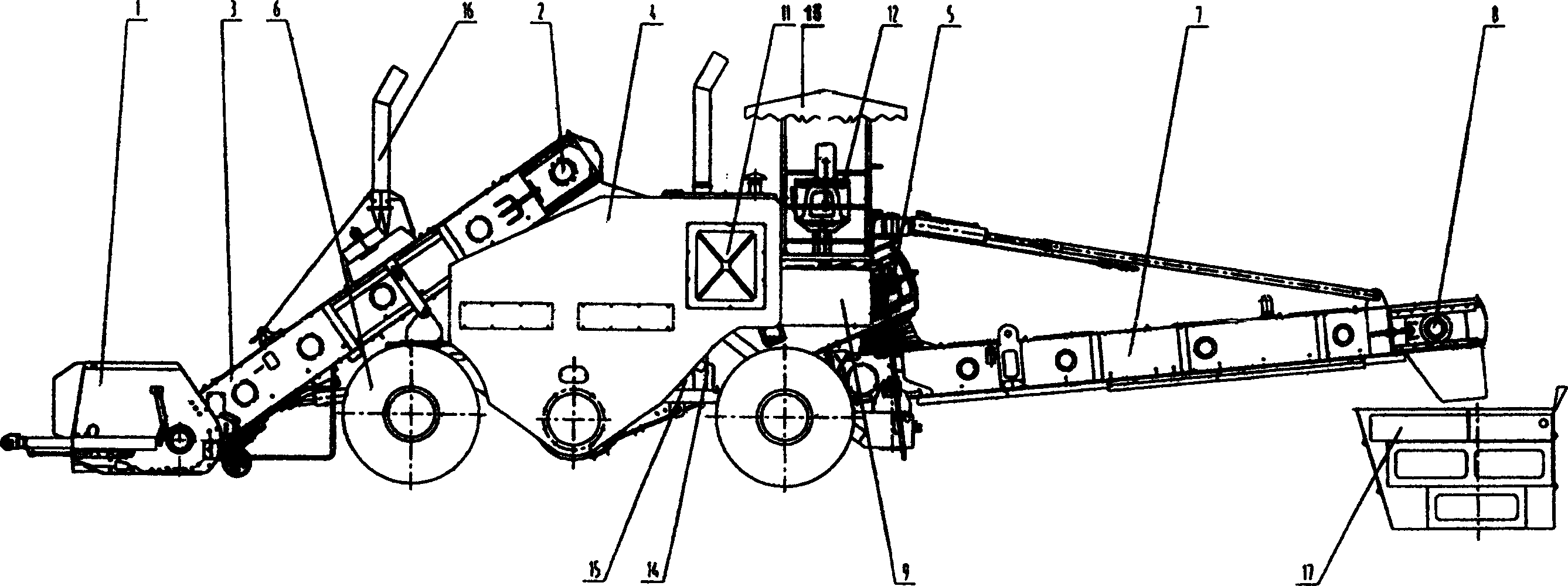

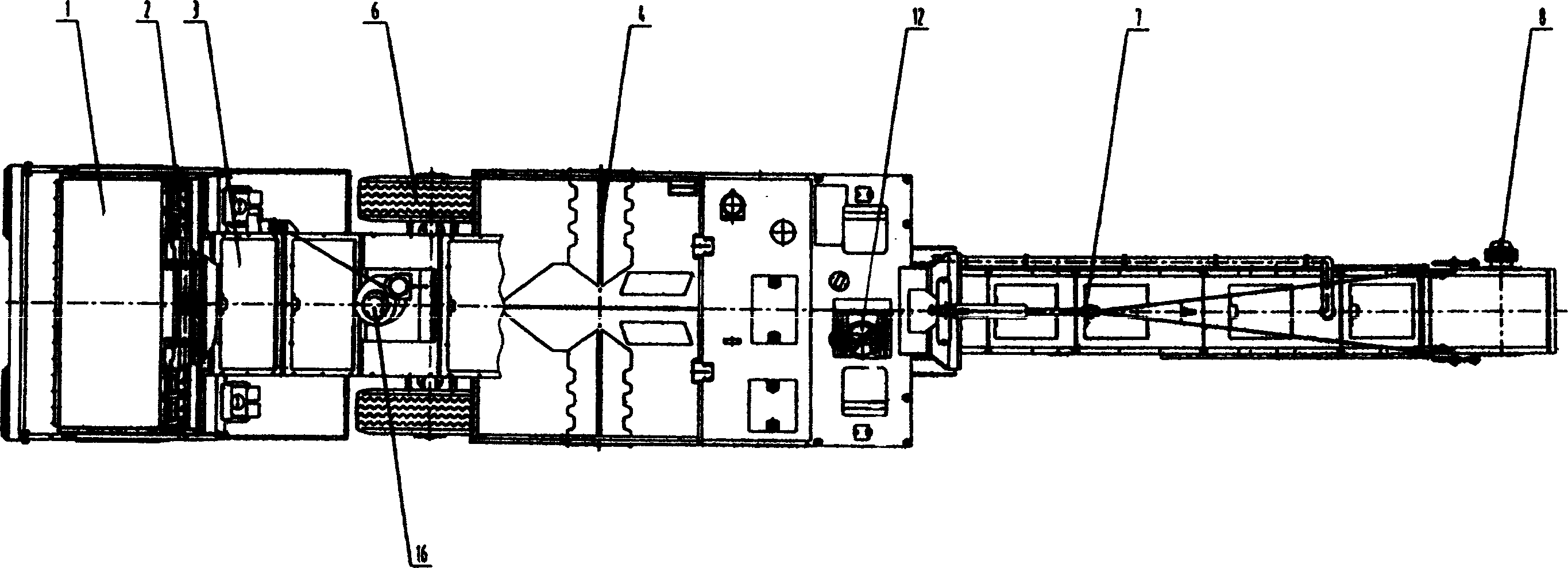

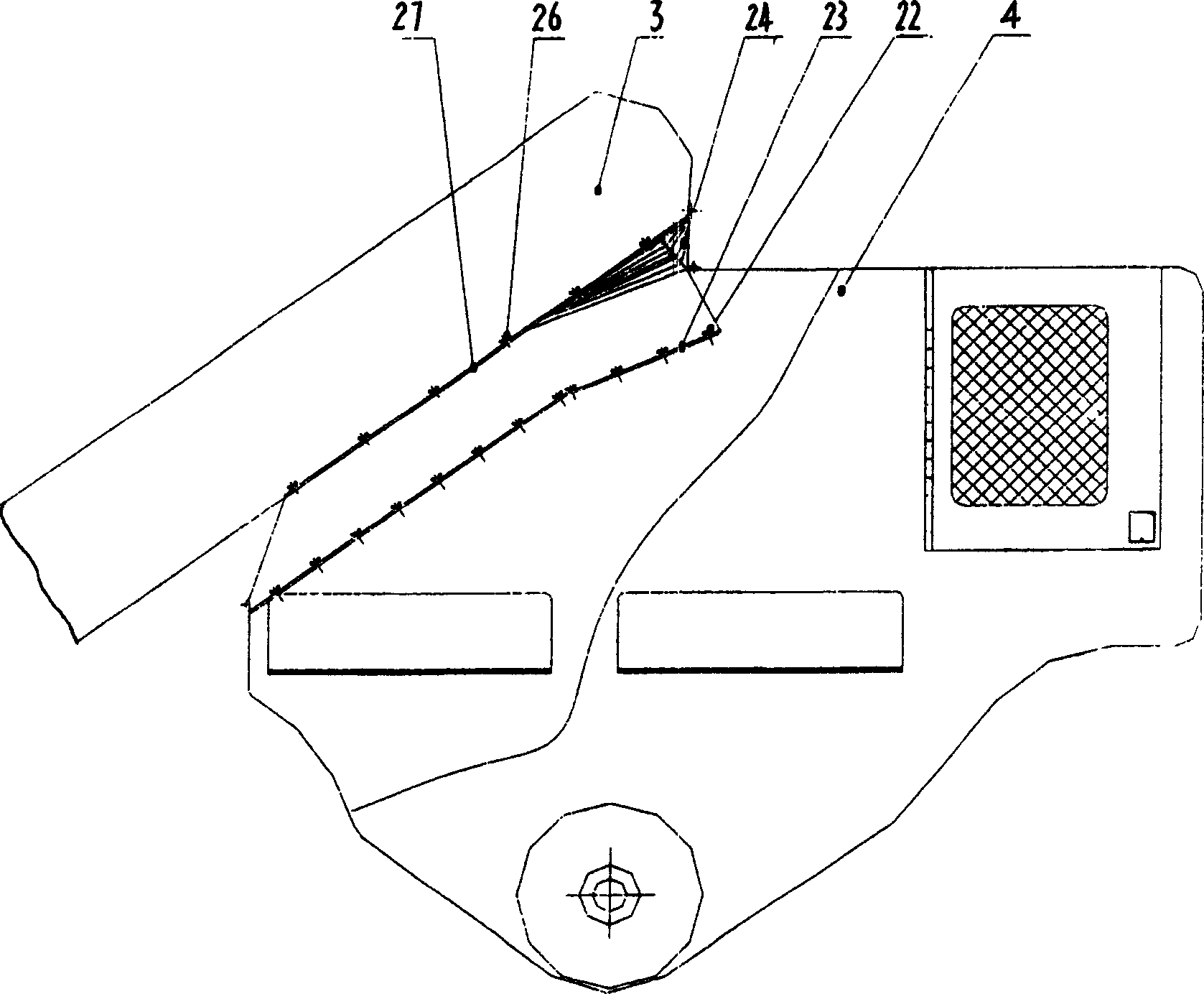

Bituminous mixture transfer car

InactiveCN1594739AFully lubricatedSimple structureRoads maintainenceLoading/unloadingRoad surfaceCopper

Bituminous mixture transfer car comprises hopper, material inlet helix, material tank body, material tank, first discharge device, moving system, second discharge device, second discharge drive system, hydraulic pressure system, electrical system, power system, driving cap, top, cleaning device, centralized lubricating system, exhaust emission system and discharge holding hopper. The invention improves the copper, material tank body, material tank, first discharge device, second discharge device, hydraulic pressure system, top, centralized lubricating system, and discharge holding hopper so as to increase the combination property index of the set. Meanwhile, the using effect and operating style gets a good improvement relative to the current bituminous mixture transfer car so as to improve the pavement spreading quality.

Owner:益阳市科技成果转化服务中心 +1

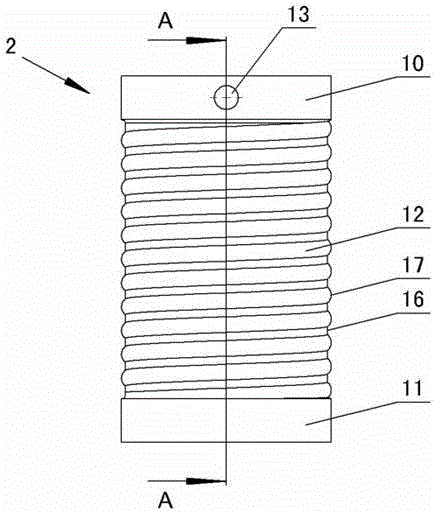

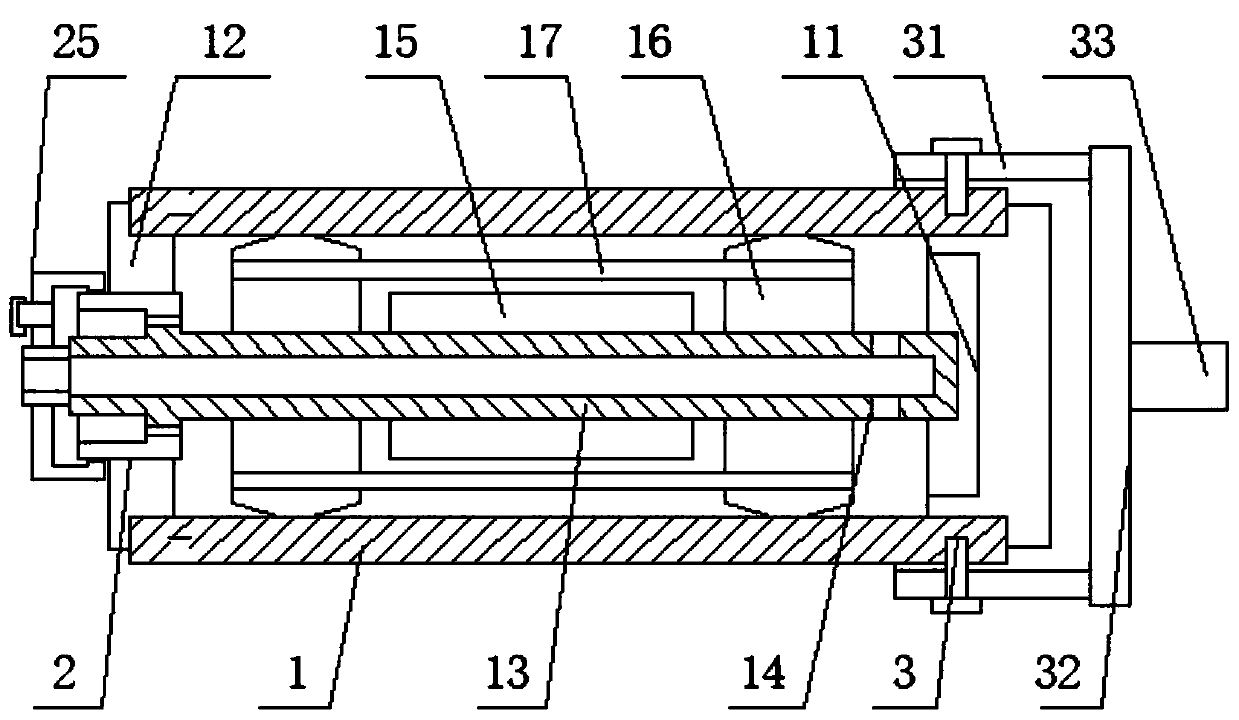

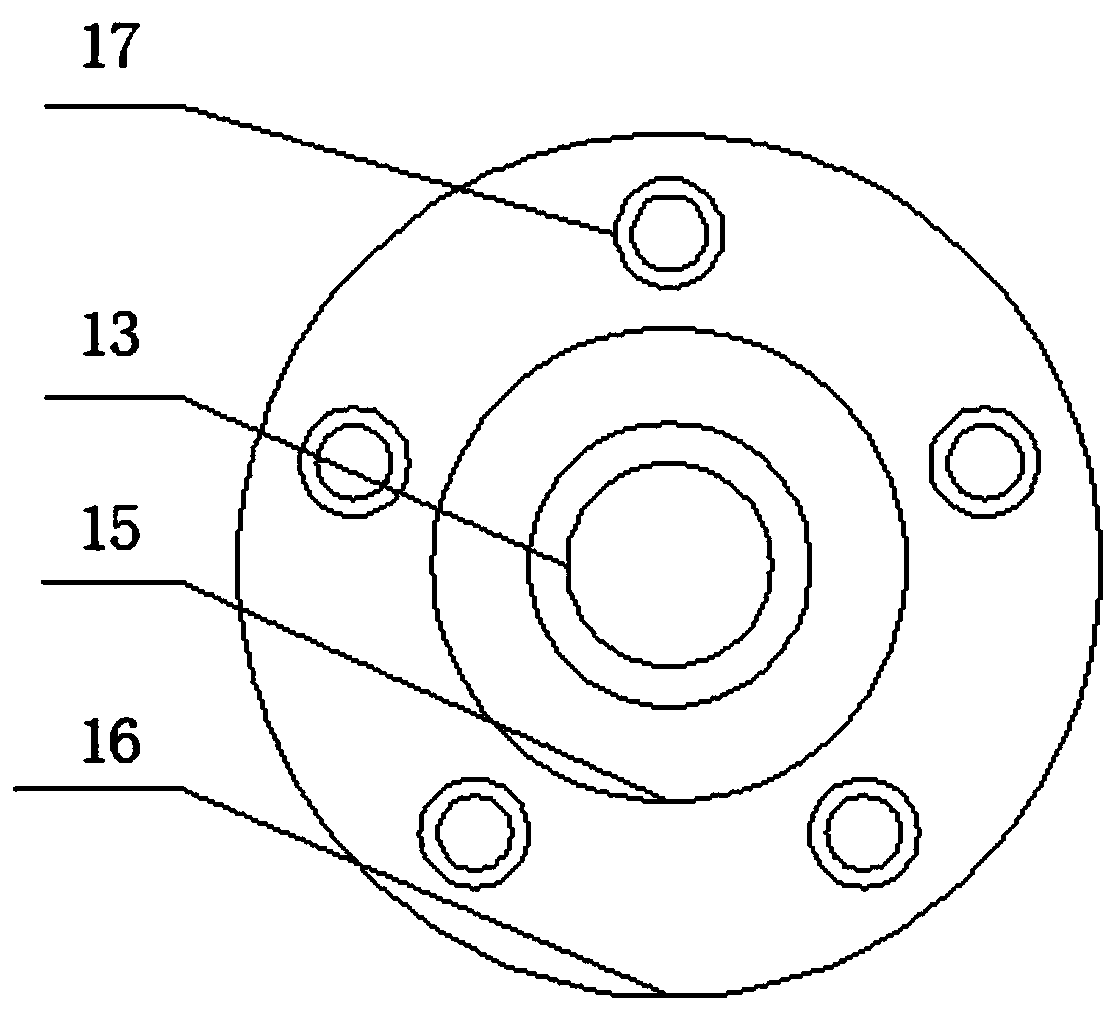

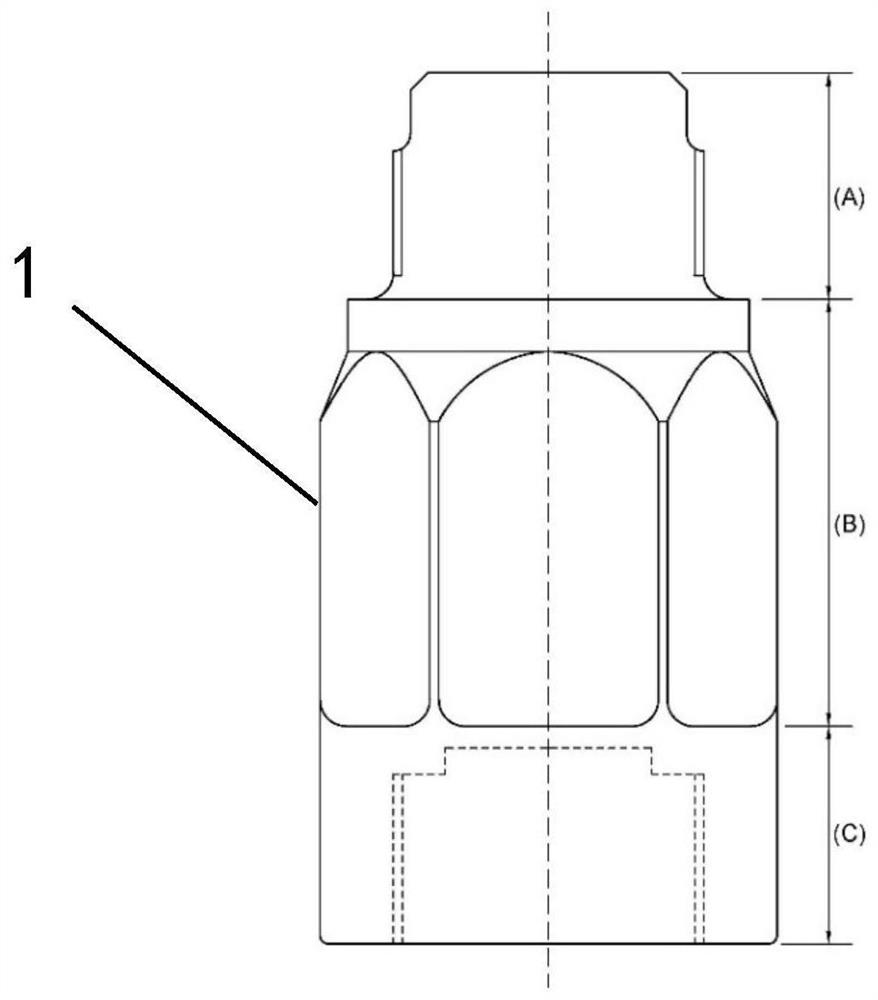

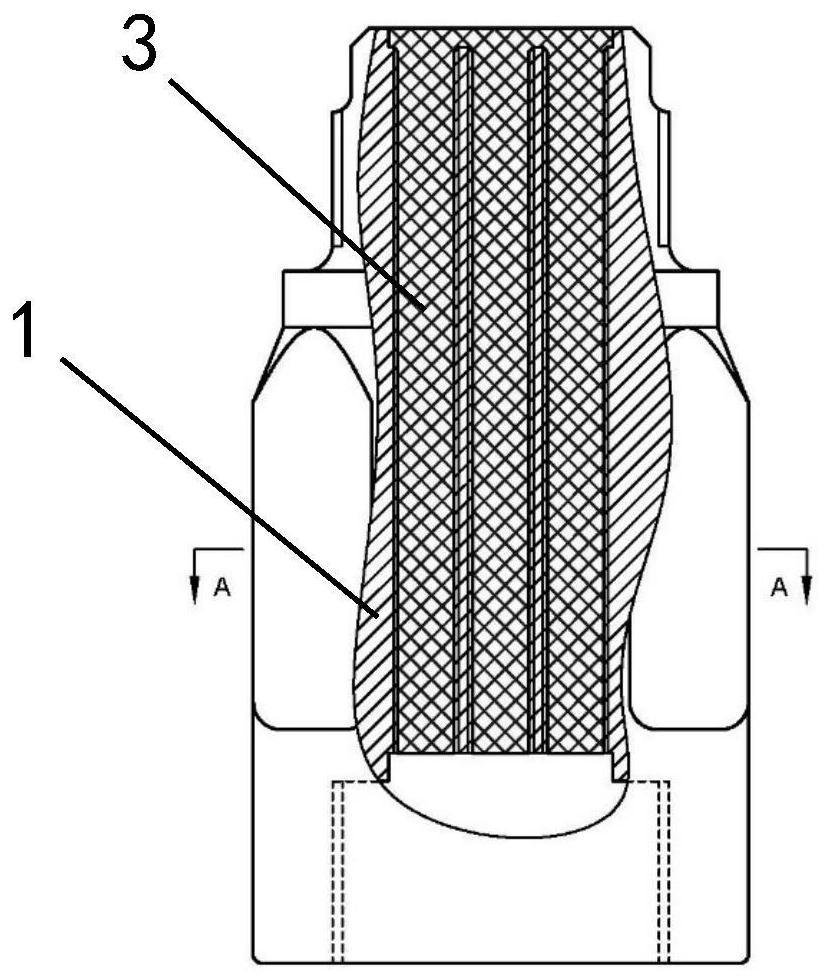

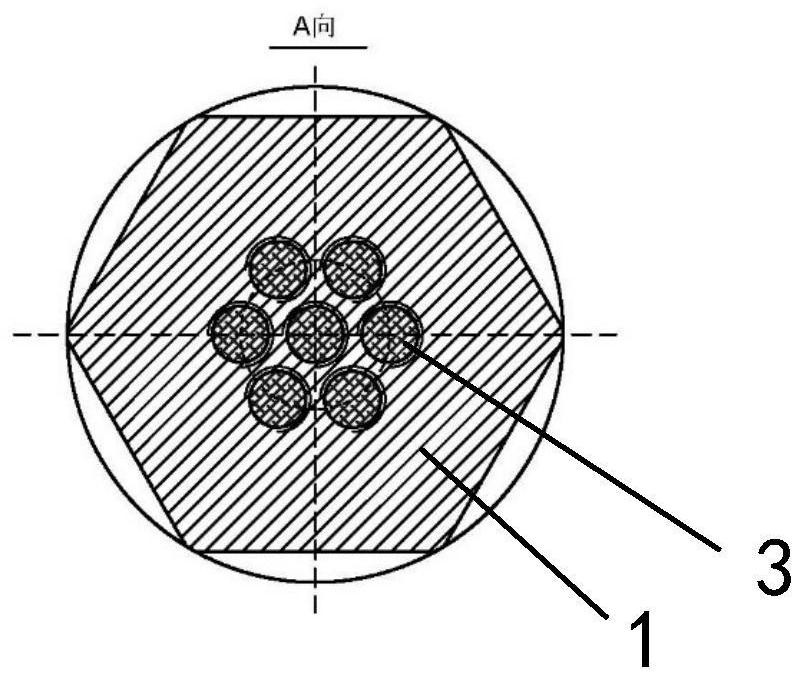

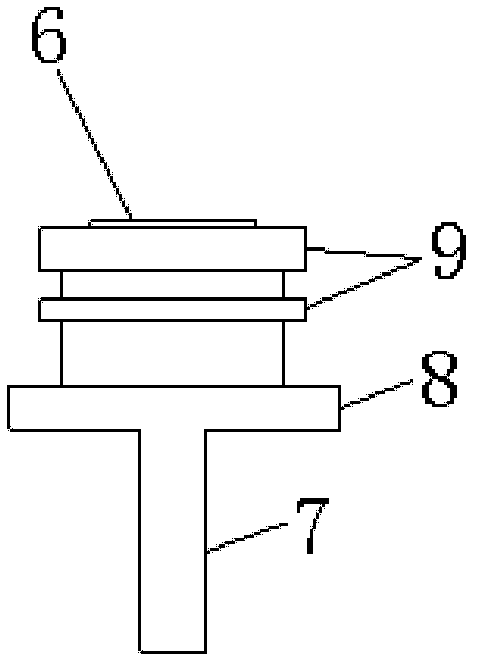

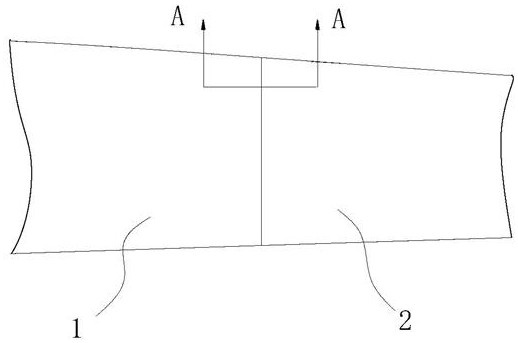

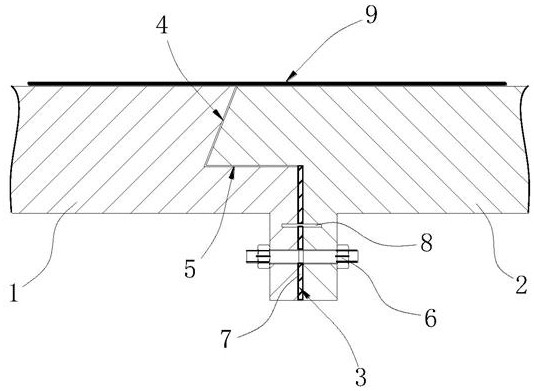

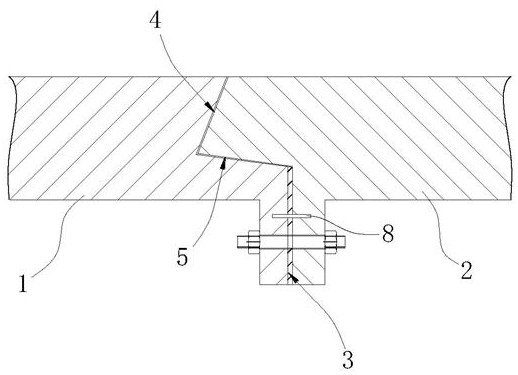

External pressure resistance composite material cylinder body and metal end socket co-curing connecting structure and manufacturing method thereof

InactiveCN105643961AOvercoming the technical problem of poor assembly connection effectGuaranteed connection strengthUltimate tensile strengthMetal

The invention relates to an external pressure resistance composite material cylinder body and metal end socket co-curing connecting structure and a manufacturing method of the external pressure resistance composite material cylinder body and metal end socket co-curing connecting structure. The connecting structure comprises two metal flanges. Each metal flange is provided with a base and a first connecting segment. The two bases are fixedly connected with two metal end sockets correspondingly. The free end of the first connecting segment of each metal flange is provided with a 27-degree taper angle. The two ends of a composite material cylinder body are correspondingly provided with second connecting segments matched with the taper angles of the two metal flanges. The inner diameter of each metal flange is equivalent to the inner diameter of the composite material cylinder body. The external pressure resistance composite material cylinder body and metal end socket co-curing connecting structure overcomes the existing technical defect that the assembly and connecting effects of external pressure resistance composite materials and metal end sockets is poor, and the metal flanges with the 27-degree taper angles and the composite material cylinder body are wound, co-cured and formed to be mechanically connected with the metal end sockets after demoulding. Accordingly, the connecting structure can guarantee the connecting strength and airtightness of the composite material cylinder body and metal end socket cylinder bodies.

Owner:WUHAN UNIV OF TECH

Built-in type hot melt belt connection method of steel plastic composite tube with outer wall possessing vertical reinforcing rib

InactiveCN1923495AGuaranteed connection strengthGuaranteed connection tightnessWork holdersStructural engineeringHot melt

Owner:ハルビンスターウェイマシーナリーマニュファクチャリングカンパニーリミテッド

Ecological pipe network construction method based on digital management system

ActiveCN111520538AGuaranteed stabilityGuaranteed to be placed horizontallyPipe laying and repairEnvironmental resource managementEngineering

The invention discloses an ecological pipe network construction method based on a digital management system. The ecological pipe network construction method based on the digital management system comprises the following construction steps of (a) early-stage preparation; (b) splicing of a supporting frame; (c) installation of ecological pipelines; and (d) detection and backfill. According to the ecological pipe network construction method based on the digital management system, the ecological pipelines are supported and stabilized through cooperation of the supporting frame, and the supportingframe is also fixed to a trench base, so that indirect fixation between the ecological pipelines and a trench is achieved, and the ecological pipelines are effectively prevented from shifting in the trench; and meanwhile, the positions of the connector ends of two ecological pipelines needing butt-joint can also be adjusted through the supporting frame, the connector parts of the two ecological pipelines are aligned and flushed mutually, the connection sealing performance at the connectors of the two ecological pipelines after sweat soldering is ensured, the connecting pressure at the connector ends of the two ecological pipelines is relieved, leakage, deformation and the like at the connectors of the pipelines are effectively prevented, and the service life of the ecological pipe networkis prolonged.

Owner:ZHEJIANG UNIV OF WATER RESOURCES & ELECTRIC POWER

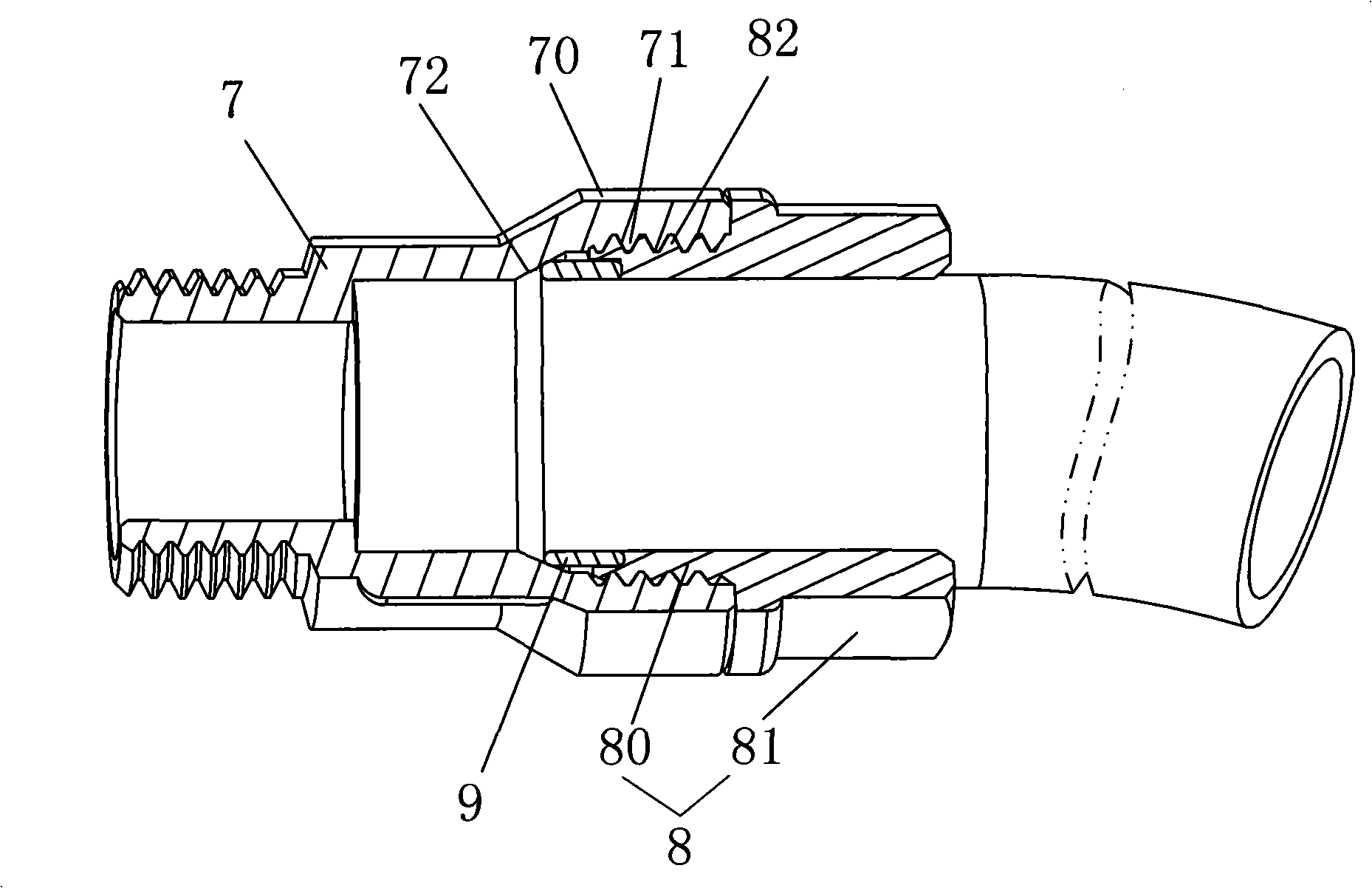

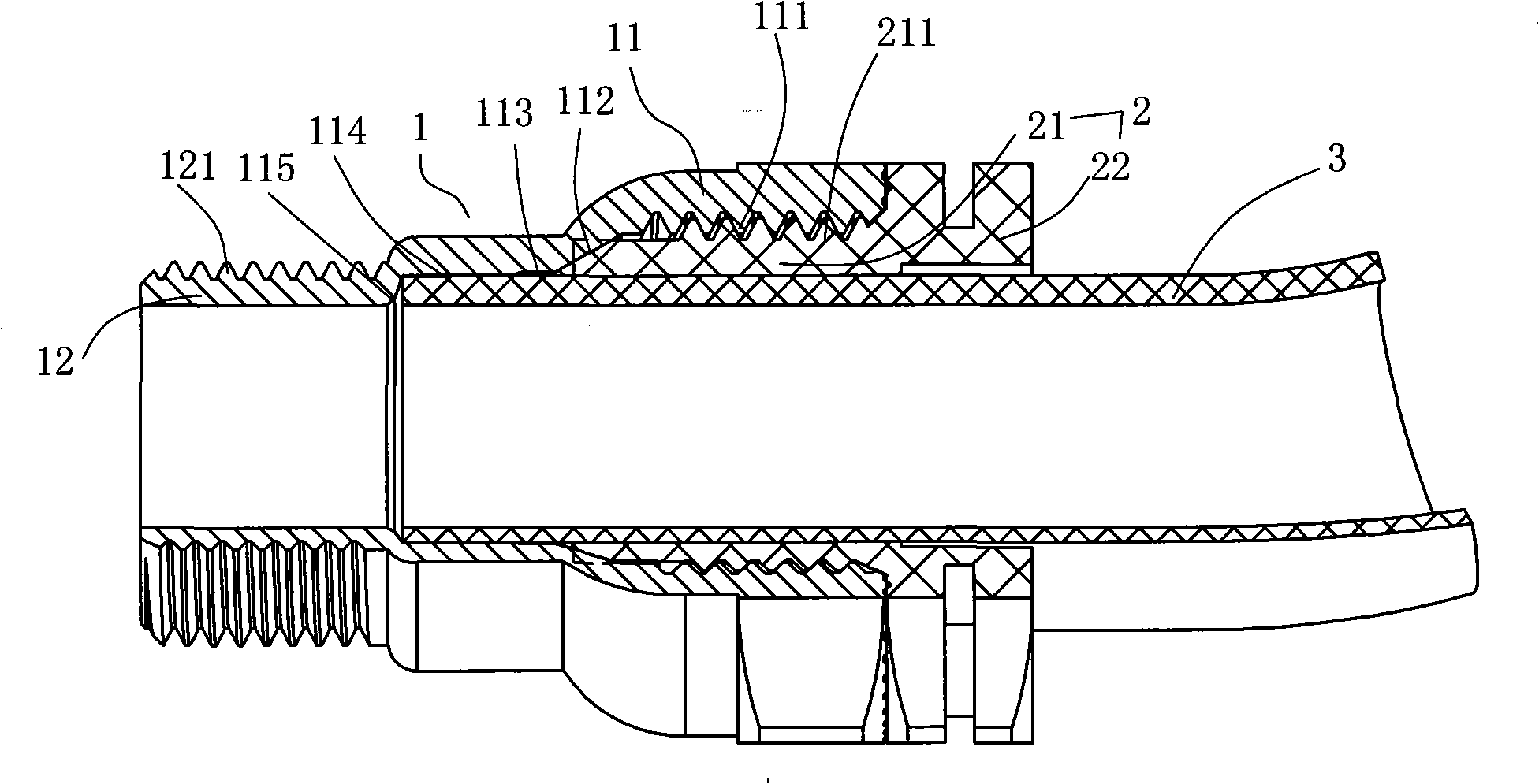

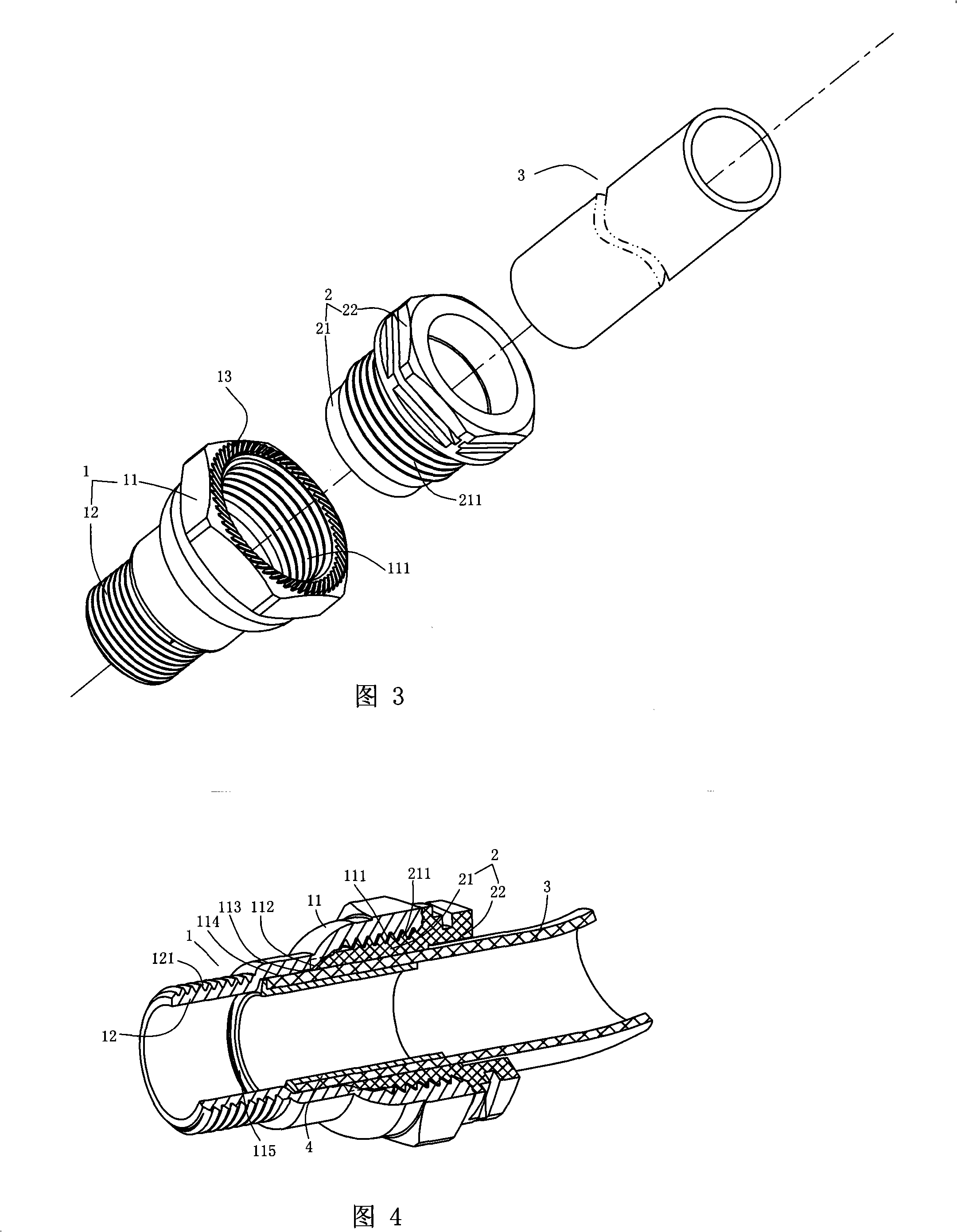

Jointing pipe pieces

InactiveCN101329002ACause sealing hazardOmit structurePipe connection arrangementsPlastic materialsPipe fitting

The invention discloses a connecting pipe fitting, which comprises a pipe fitting connector and an attachment cap matched with the joint of the pipe fitting connector, wherein, the joint of the pipe fitting connector is provided with an internal thread, and the lower end of the internal thread is provided with a fastening port with certain slope, a pipe fitting hole and a stopping ring sequentially. The attachment cap is made of plastic materials, which has a through hole in the middle and comprises a cylinder part and a fastening head part, wherein, part or all of the outer surface of the cylinder is lathed with an external thread matched with the internal thread of the joint of the pipe fitting connector, the length of the cylinder part is greater than that of the inlet of the fastening port of the pipe fitting connector to the end face, the head of the cylinder part pushes against the slope of the fastening port of the pipe fitting connector directly. Compared with the connecting pipe fitting in the prior art, the invention has the advantages of safety, reliability and fast connection, and is particularly applied to the connection between the plastic pipes or between the plastic pipe and the metal pipe fitting.

Owner:浙江世进水控股份有限公司

Tumbler residue-free emulsion bottle capable of replenishing emulsion

The invention discloses a tumbler residue-free emulsion bottle capable of replenishing emulsion. The tumbler residue-free emulsion bottle comprises a tumbler base, a mounting seat, a driven gear, a worm gear and a bottle cap; according to the tumbler base, a protective shell is fixed to the top of the tumbler base, an emulsion bottle body is assembled on the inner side of the protective shell, a fastener is fixed to the top of the emulsion bottle body, a first bearing is fixed to the middle of the bottom end of the emulsion bottle body, a lead screw is assembled on the inner side of the firstbearing, a piston and a scraper are connected to the lead screw in a threaded mode, the piston is fixed to the top of the scraper, and the scraper is connected with the emulsion bottle body in an up-down sliding mode; and according to the mounting seat, the mounting seat is of an L-shaped structure integrally, the inner part of the mounting seat is hollow, a worm is arranged on the inner side of the mounting seat in the vertical direction, and the worm is rotatably connected with the mounting seat through a second bearing. The tumbler residue-free emulsion bottle capable of replenishing emulsion has the anti-toppling and emulsion replenishing capabilities, the emulsion at the bottom of a bottle can be taken and used, the residue of the emulsion is avoided, resources are saved, elastic wearis not existed, and the service life is long.

Owner:温州联豪化妆品有限公司

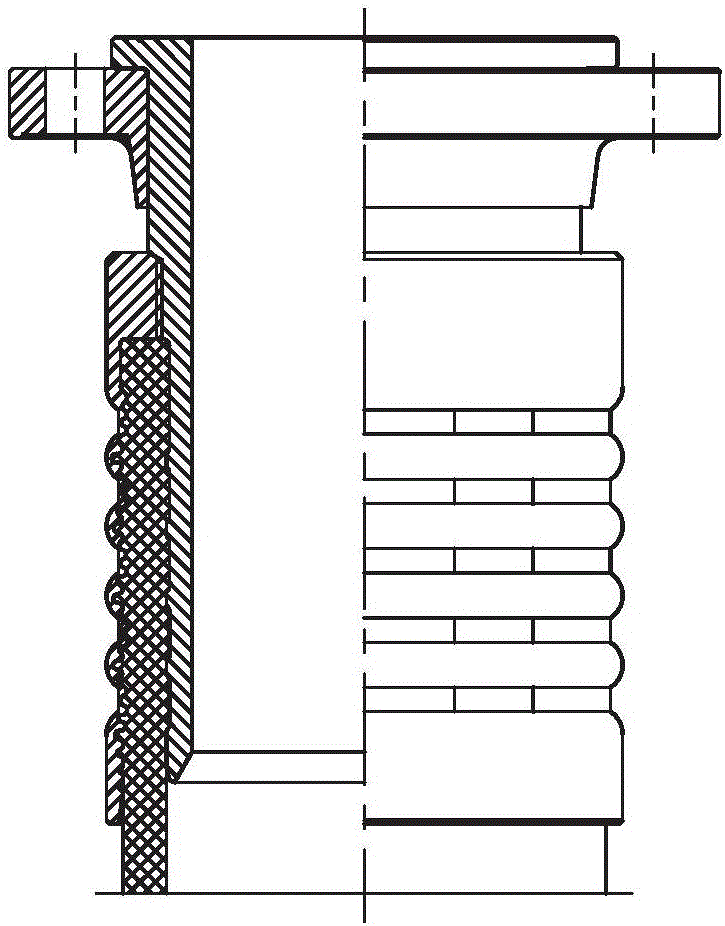

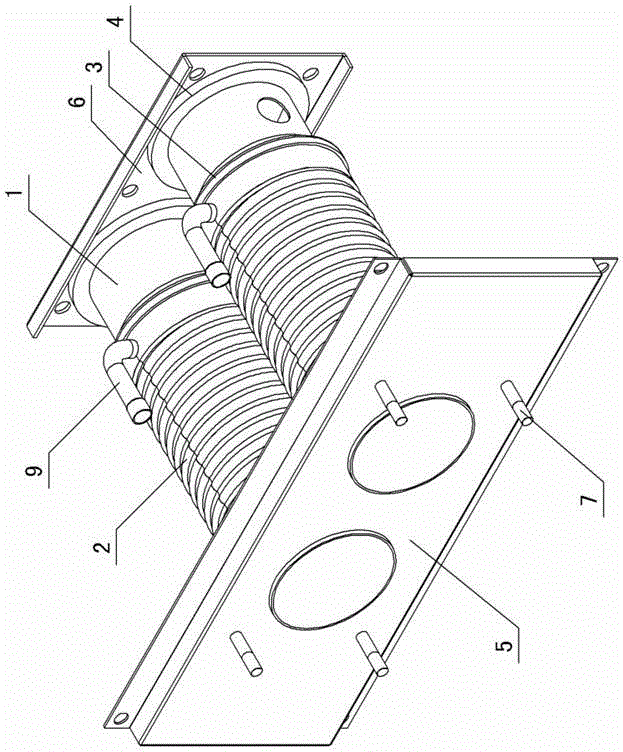

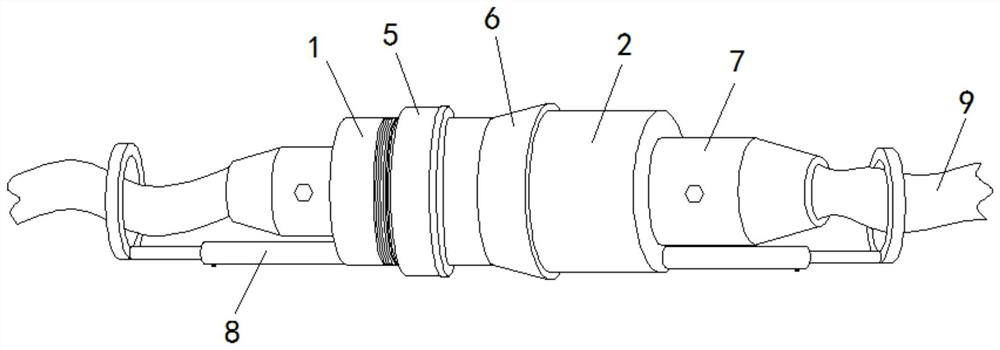

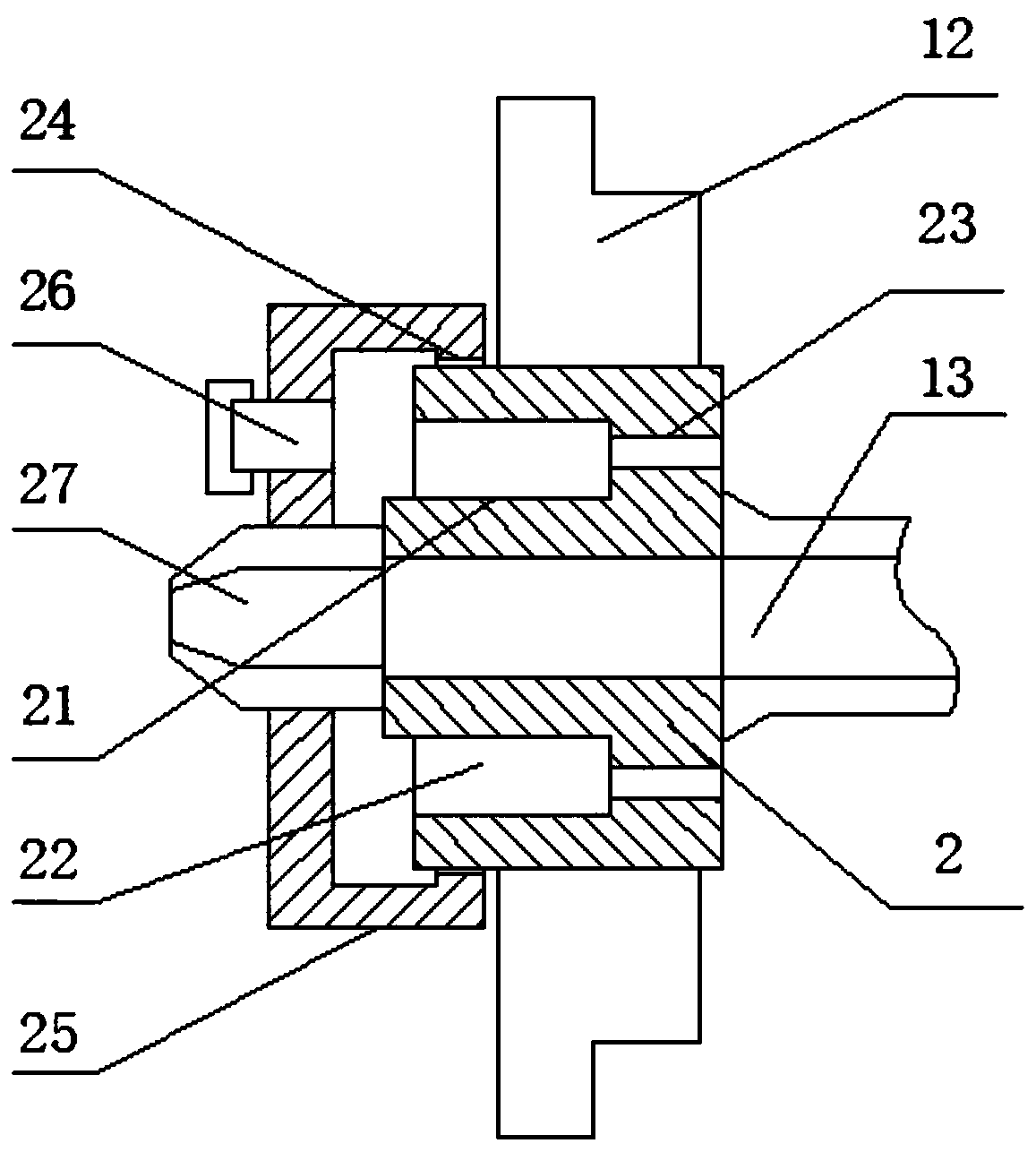

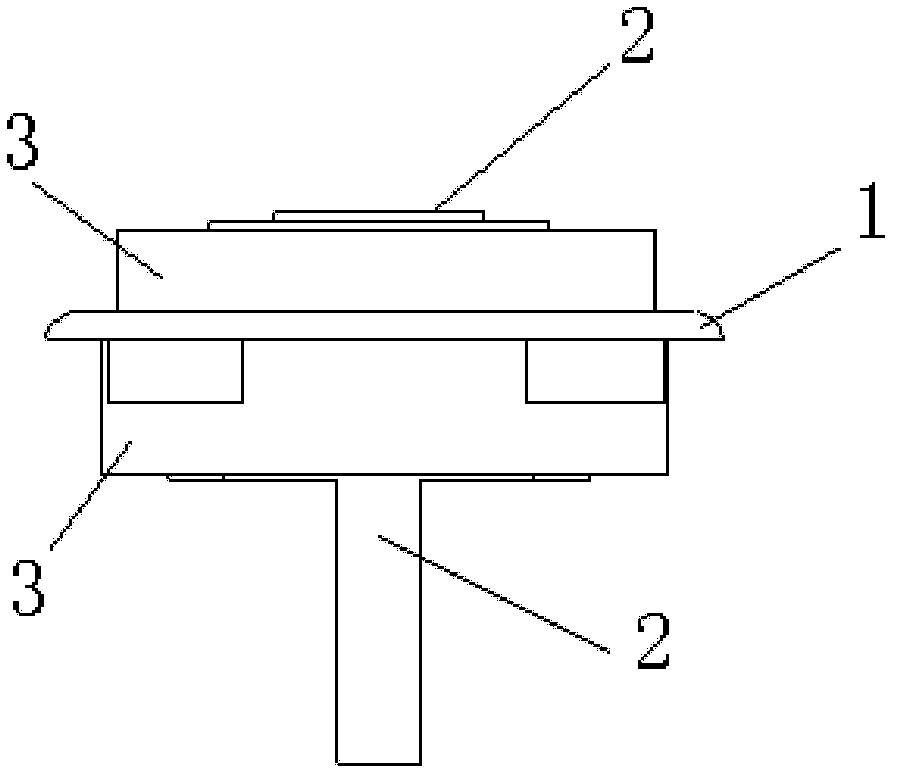

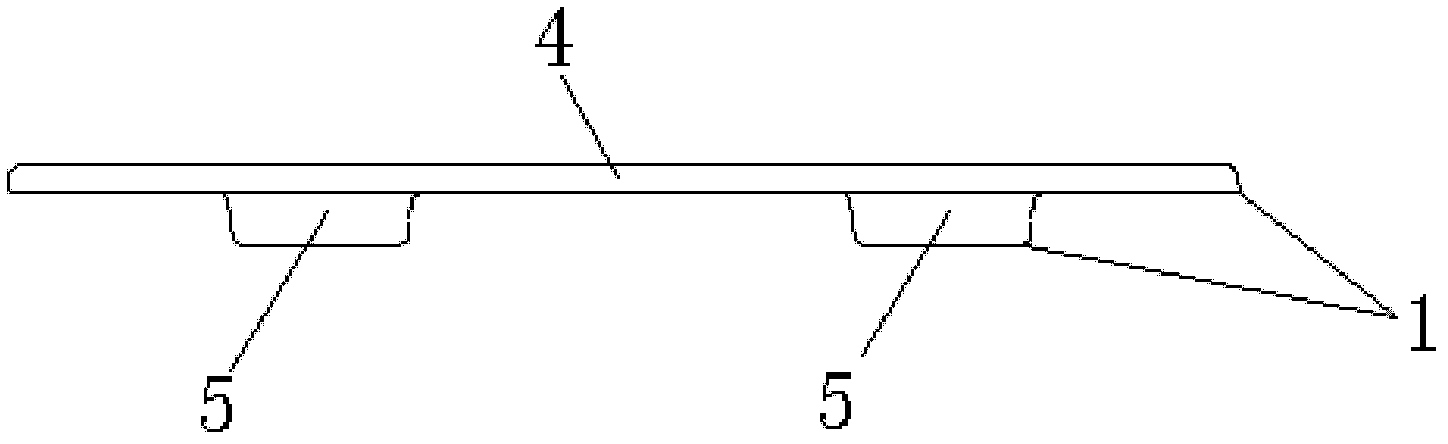

Large-diameter low-rigidity balancing flexible connecting tube for moveable flange and self-locking joint

The invention relates to a large-diameter low-rigidity balancing flexible connecting tube for a moveable flange and a self-locking joint. The connecting tube comprises a flexible tube body and buckling joints, wherein an inner glue layer, a skeleton layer and an outer glue layer are successively arranged in the flexible tube body from inner to outer; the buckling joints are symmetrically arranged at the two ends of the flexible tube body; each of the buckling joints comprises an outer pressing ring and an inner pressing ring; the outer pressing ring is arranged on the exterior of the inner glue layer at the end part of the flexible tube body in a sleeving manner; the front end of the skeleton layer is outward back turned and reversely wrapped on the front end face and the side wall of an annular plate; the inner glue layer, the skeleton layer, the outer glue layer, the outer pressing ring and the inner pressing ring are vulcanized and integrally formed. Through the symmetrical structures at the two ends of the tube body and the structure of the buckling joints, the technical problems of the traditional connecting tube of easiness in creeping, aging and losing efficacy, falling risk, complex joint structure, high dead weight, low flexibility, inferior vibration-reducing noise-attenuating effect, insufficient displacement compensation performance and easiness in cracking of welding joint are solved.

Owner:NAVAL UNIV OF ENG PLA +1

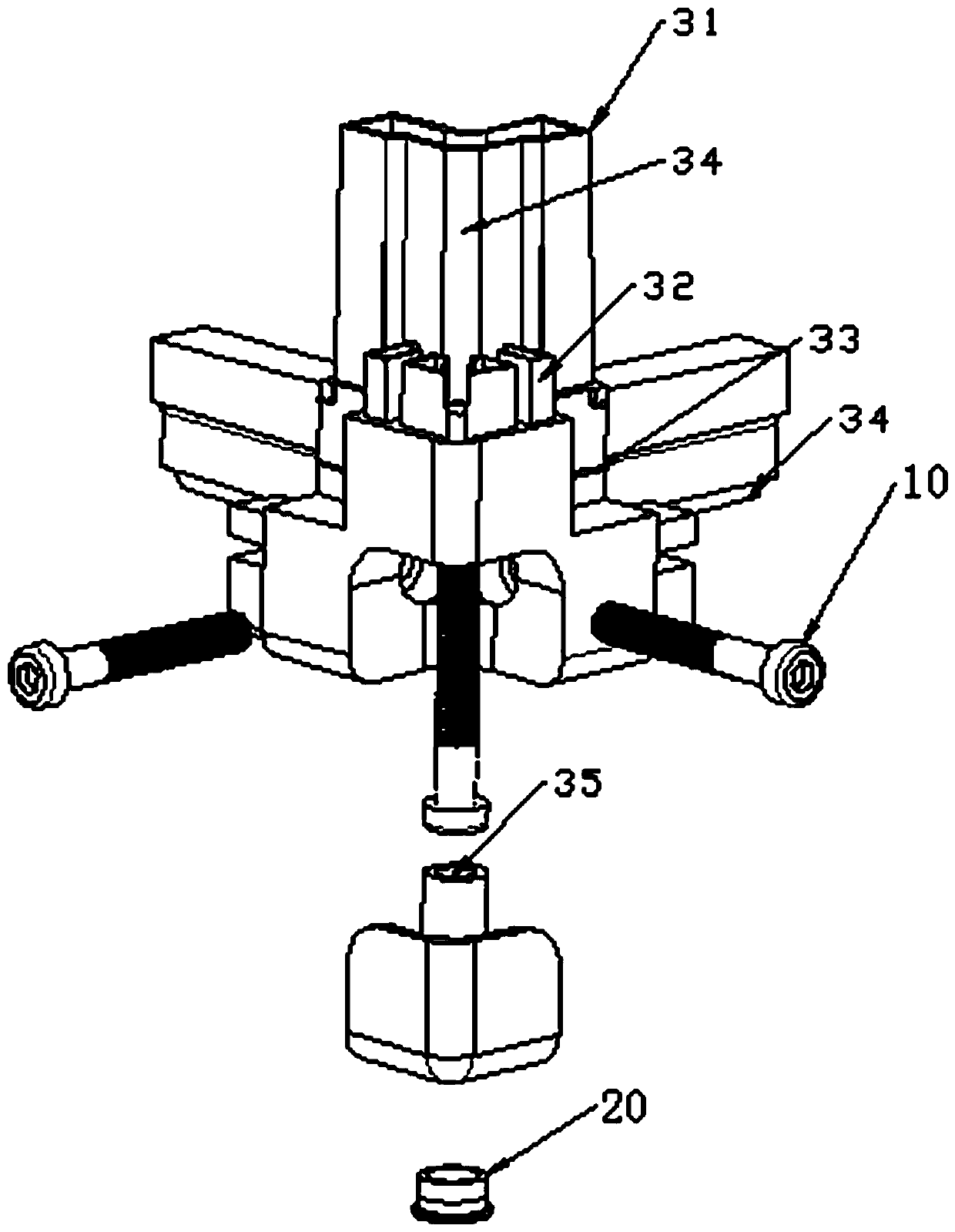

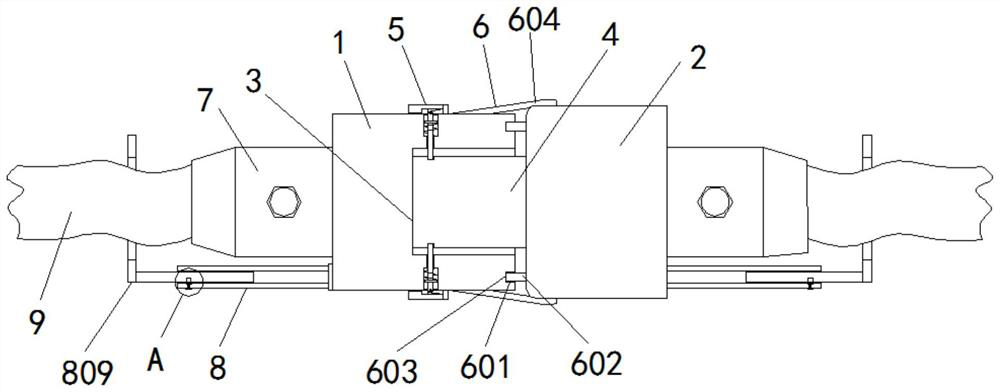

Axial buckling and pressing connector

The invention relates to an axial buckling and pressing connector. The axial buckling and pressing connector comprises an intra-pipe glue layer, a framework layer and an extra-pipe glue layer which are all of cylindrical structures and are sequentially connected in a sleeved manner from inside to outside to form a pipe body; the intra-pipe glue layer and the framework layer extend out of the pipe body from the same end, and the framework layer is made of flexible materials; the buckling and pressing connector further comprises an outer pressing ring and an inner pressing ring, the front end of the extending-out end of the intra-pipe glue layer is sleeved with the outer pressing ring, and the back section of the framework layer is sleeved with the inner pressing ring; and the outer pressing ring, the front section of the framework layer, the inner pressing ring and a piston flange are sequentially pressed in a butting manner from the extending-out end to the other end in the axial direction of the pipe body and are integrally molded through vulcanization. Compared with a flexible connecting pipe with the same length, a connecting structure adopting the connector and the pipe body is characterized in that the connector size is small, the flexibility section of the pipe body is long, the structure is simple, installation is flexible, and the connector and the pipe body are more firmly combined through vulcanization integrated molding. The technical problems that a traditional axial buckling and pressing connector is low in connecting strength, poor in pulling and dropping resistance and free of the self-locking function are solved.

Owner:NAVAL UNIV OF ENG PLA +1

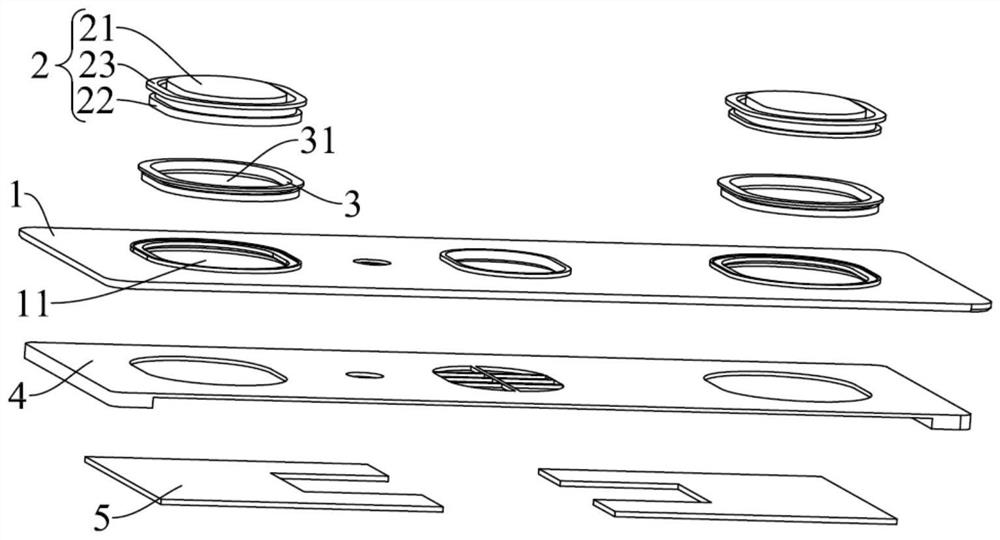

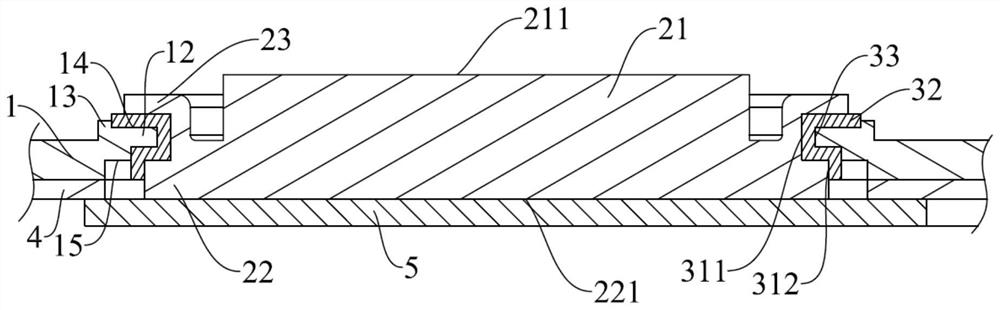

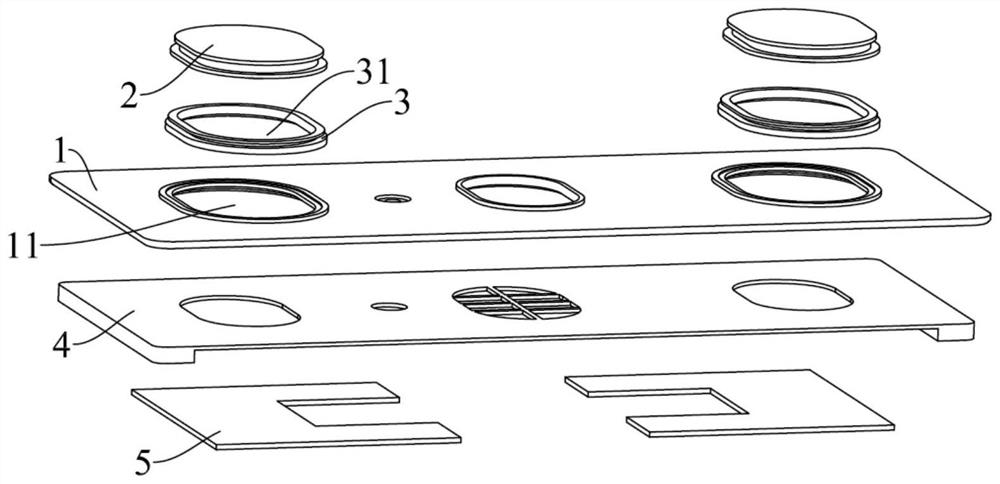

Top cover assembly, assembling method of top cover assembly and battery

PendingCN114361667ALower the altitudeSimple structureFinal product manufactureSecondary cells manufactureElectrical batteryElectrical connection

The invention discloses a top cover assembly, an assembling method of the top cover assembly and a battery, the top cover assembly comprises a top cover piece, a terminal post, a sealing piece, a lower plastic piece and an electric connecting piece, the top cover piece is provided with a post matching hole, the terminal post is arranged in the post matching hole in a penetrating manner and is provided with a first connecting surface and a second connecting surface which are oppositely arranged, and the sealing piece is arranged on the first connecting surface; the sealing piece is arranged on the terminal pole in a sleeving mode and clamped among the terminal pole, the inner circumferential wall of the pole matching hole and the upper surface of the top cover piece, the lower plastic piece is attached to the lower surface of the top cover piece, and the electric connecting piece is attached to the lower plastic piece and connected with the terminal pole. According to the top cover assembly, the overlapping height of the terminal post and the top cover plate is increased on the premise of ensuring insulation of the terminal post and the top cover plate, so that the energy density of a battery cell is improved.

Owner:HUBEI JINQUAN NEW MATERIALS CO LTD

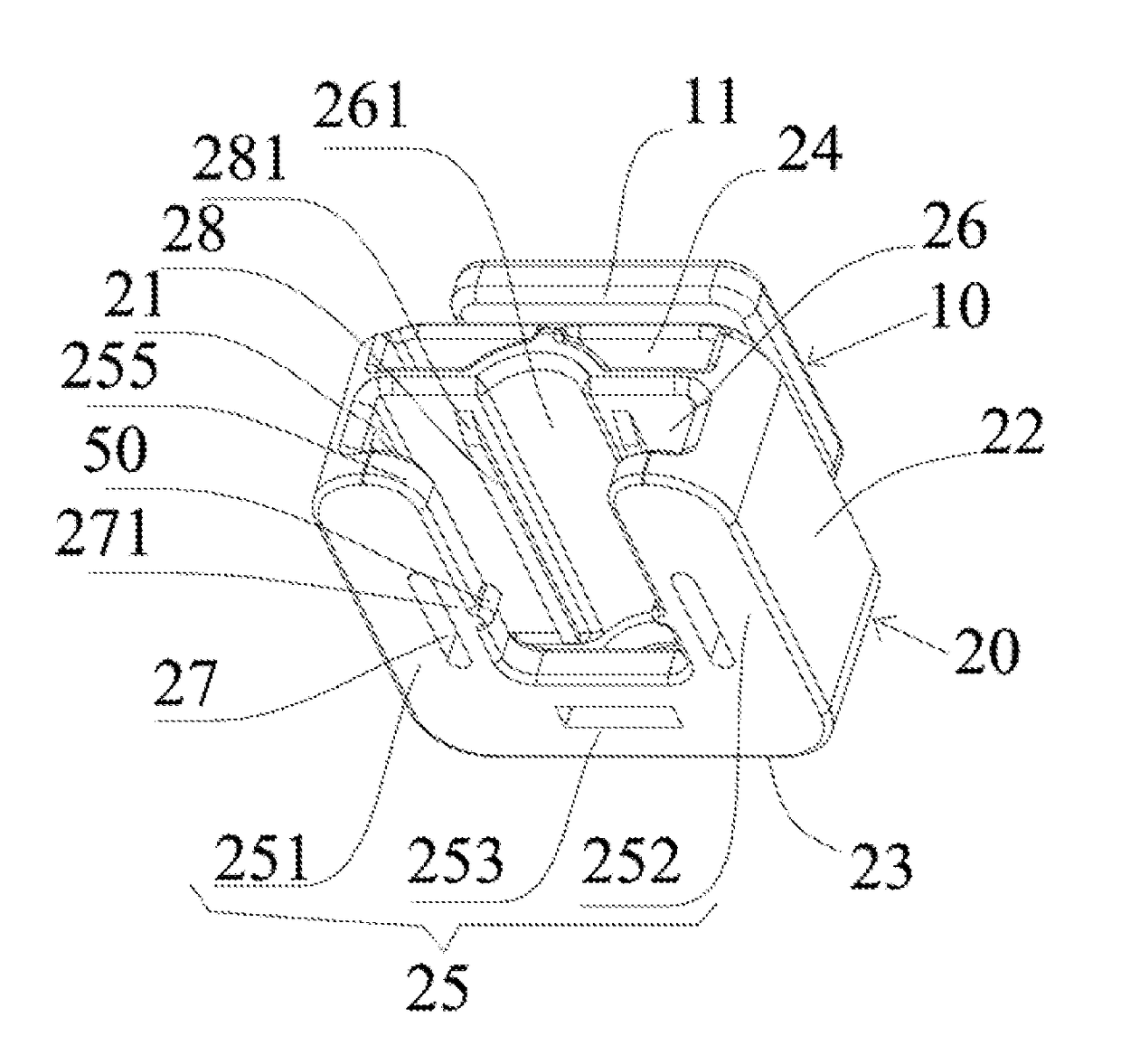

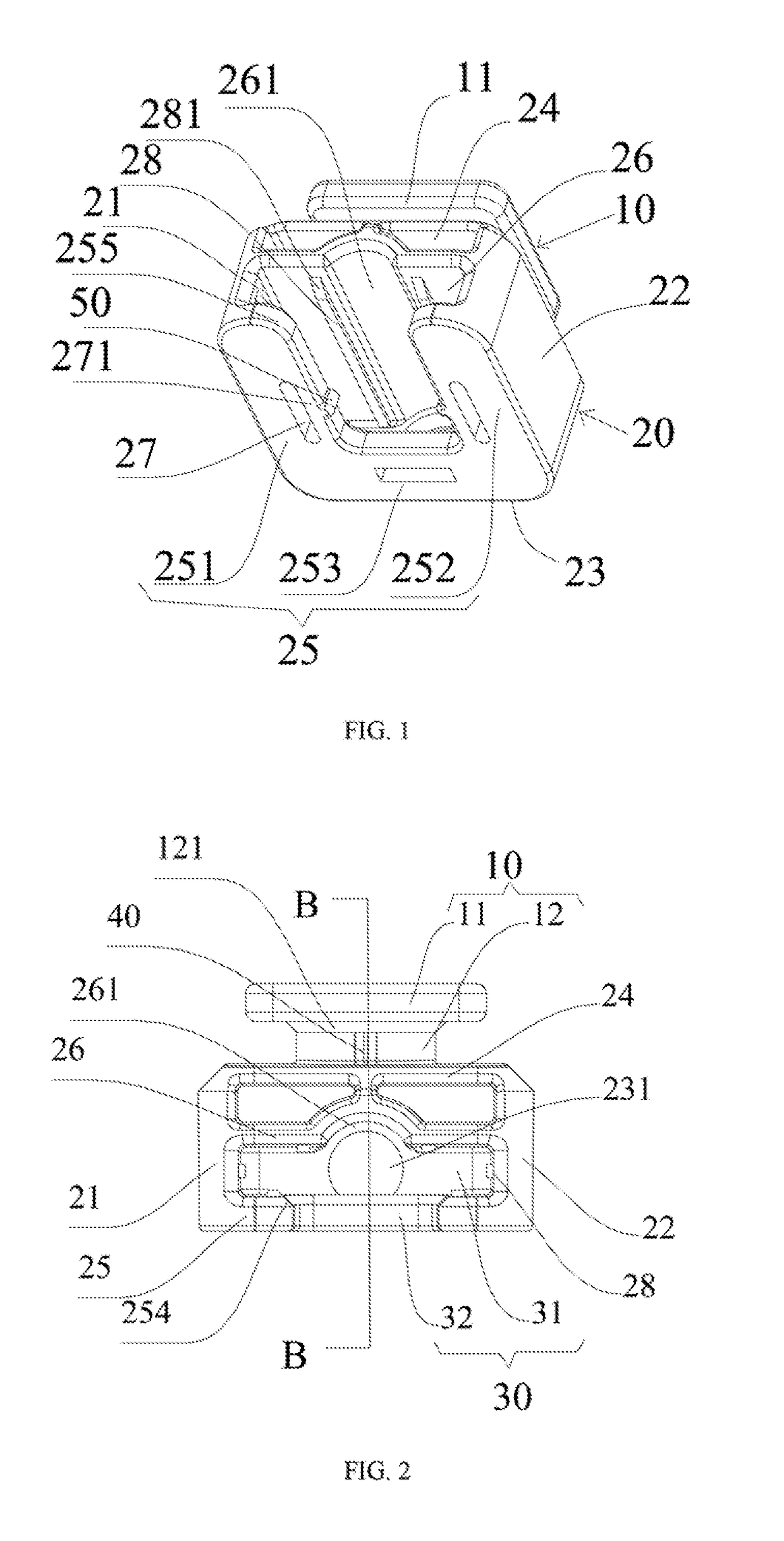

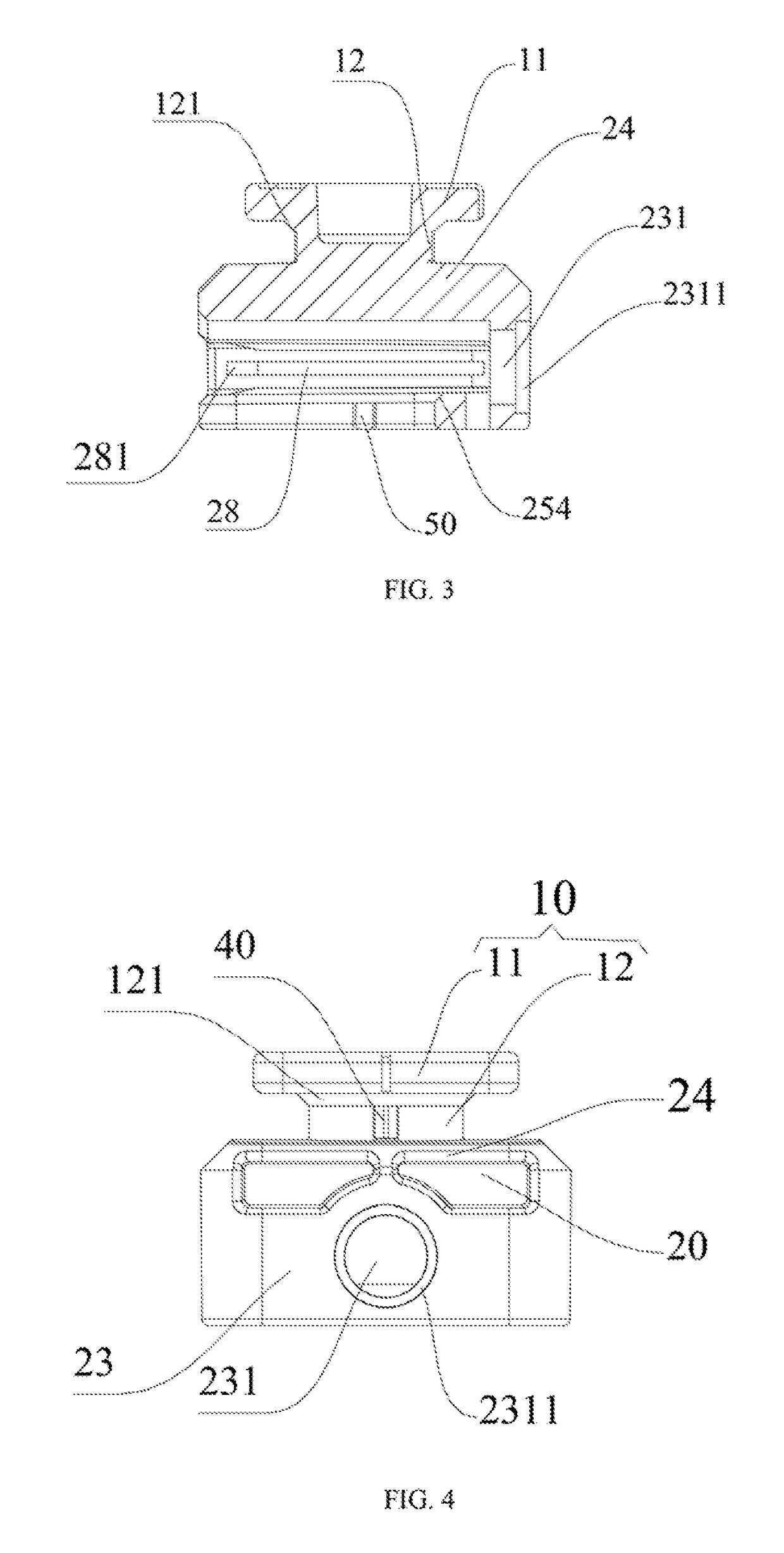

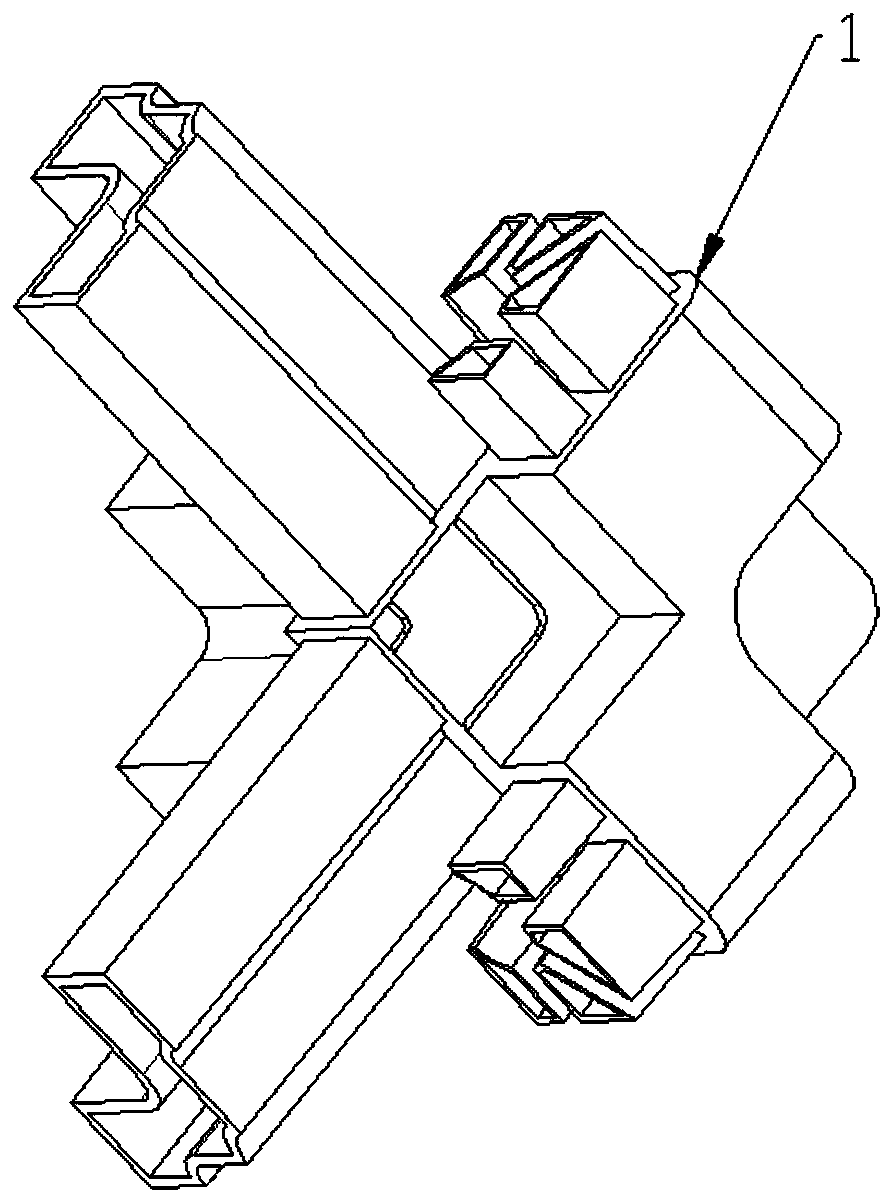

Toy assembling apparatus

ActiveUS20170274295A1Guaranteed connection tightnessImprove convenienceToysEngineeringElectrical and Electronics engineering

Owner:UBTECH ROBOTICS CORP LTD

Angle connecting device used for air-conditioning box and angle wrapping structure

PendingCN109827316AEasy accessGuaranteed connection tightnessHeating and ventilation casings/coversAluminiumSurface plate

Owner:孚莱美科(江苏)环境科技有限公司

Outer spiral steel cylinder of evaporator for ice cream machine and machining method thereof

ActiveCN104315759ASimple structureEasy to processEvaporators/condensersHeat exchanger casingsArchitectural engineeringIce cream

Disclosed are an outer spiral steel cylinder of an evaporator for an ice cream machine and a machining method thereof. The outer spiral steel cylinder comprises an inner steel cylinder, a spiral vane and an outer steel cylinder. Outer steel cylinder flanges are connected between the two ends of the outer steel cylinder and the inner steel cylinder. Two ends of the inner steel cylinder are connected with inner steel cylinder flanges, a front panel and a rear connecting plate. The front panel is provided with a screw. The outer steel cylinder is provided with a coolant incoming connector and a coolant outgoing connector. The outer spiral steel cylinder is characterized in that the outer steel cylinder comprises a left connecting segment, a right connecting segment and a middle spiral surrounding segment; the left connecting segment is tubular; the outer wall of the left connecting segment is connected with the left outer steel cylinder flange by welding; the left connecting segment is provided with a left connecting hole connected with the coolant outgoing connector; the right connecting segment is tubular; the outer wall of the right connecting segment is connected with the right outer steel cylinder flange by welding; the right connecting segment is provided with a right connecting hole connected with the coolant incoming connector; the middle spiral surrounding segment is provided with spiral grooves; the spiral grooves are connected through straight faces; the outer wall of the spiral surrounding segment is provided with spiral protrusions corresponding to the spiral grooves; the spiral vane is arranged in the spiral grooves.

Owner:ZHEJIANG SIBEILE REFRIGERATION ELECTRIC

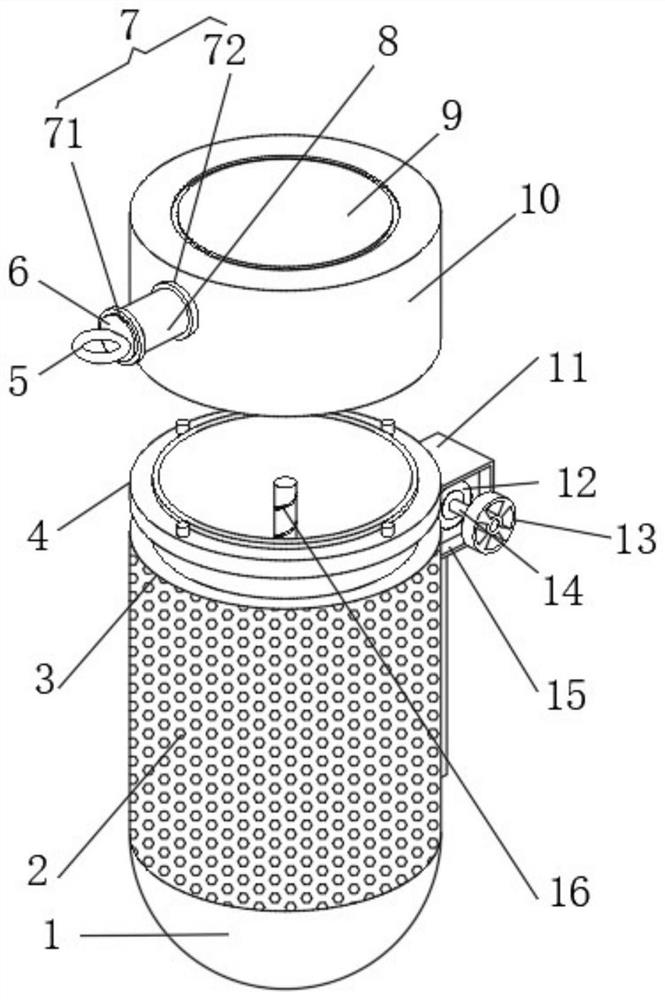

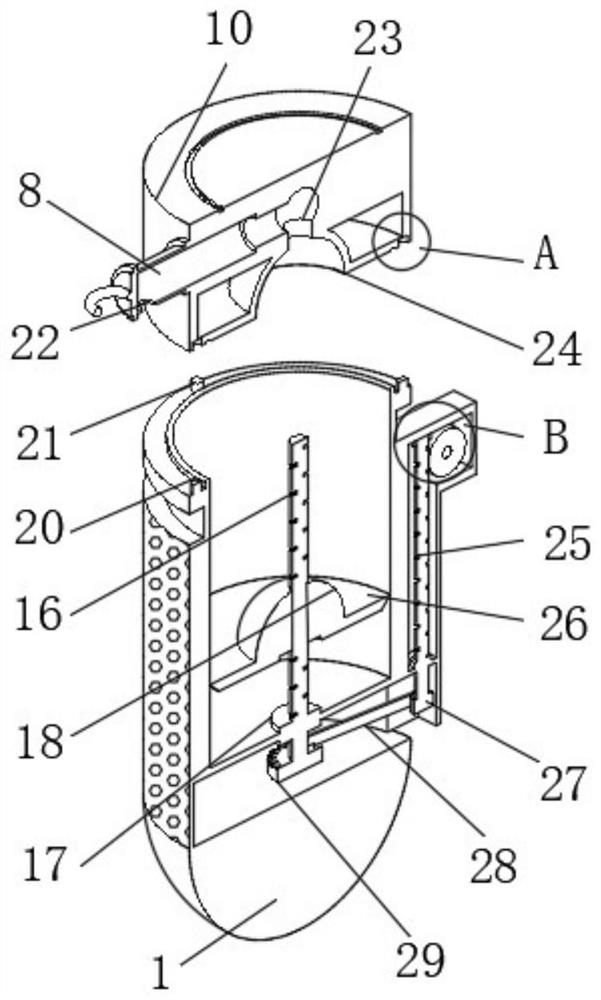

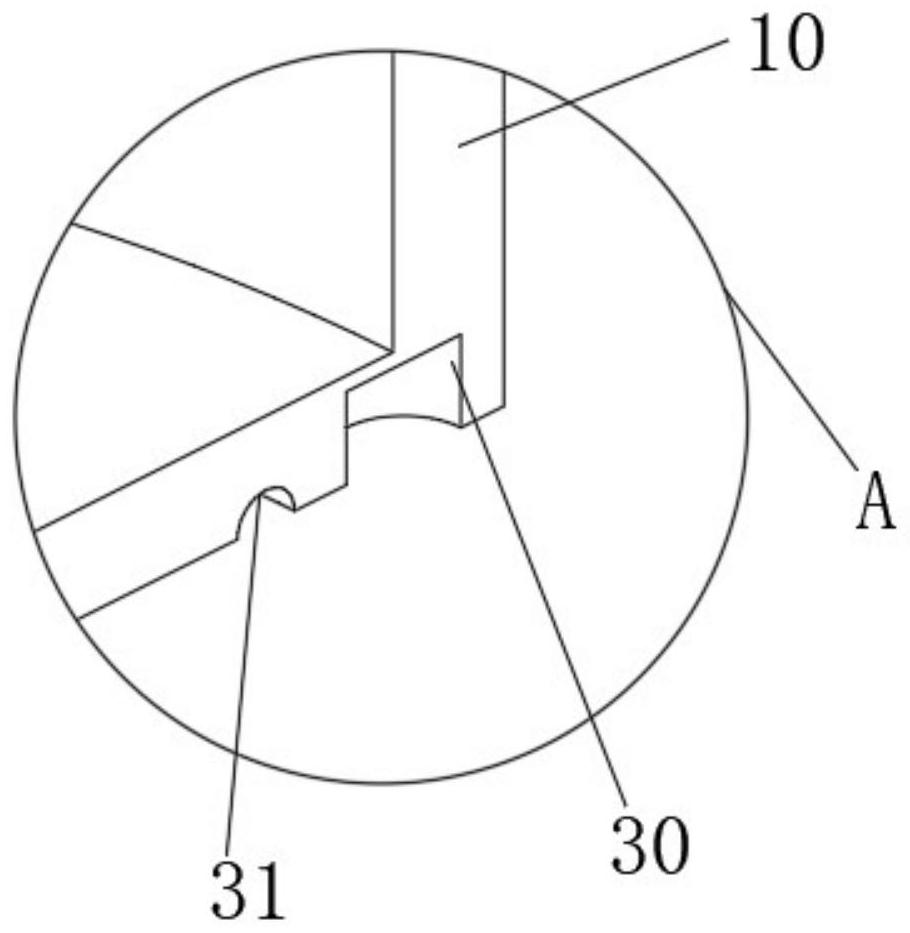

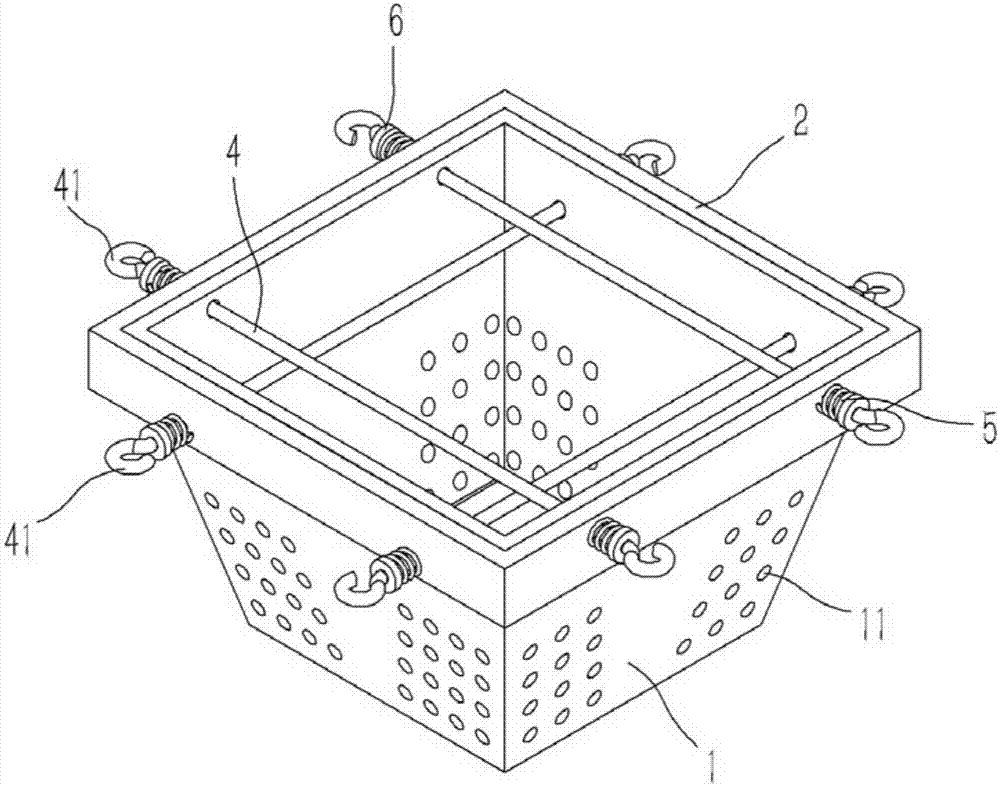

Aquatic plant growing basket used for landscape water purification

InactiveCN107466829AEasy to install and connectRealize the installation connectionAgriculture gas emission reductionCultivating equipmentsArchitectural engineeringOuter Cannula

The invention discloses an aquatic plant growing basket used for landscape water purification. The aquatic plant growing basket comprises two opposite pipe assemblies, each pipe assembly comprises an outer sleeve and an inner adapter pipe, a first flange is formed at the outer end of each outer sleeve, and a plurality of installation holes are formed in each flange; a rectangular boss is formed on the outer wall of each outer sleeve, each inner adapter pipe is inserted into the corresponding outer sleeve, a plurality of seal rings are fixedly arranged on the outer wall at one end of each inner adapter pipe in inserted and sleeving modes, and the seal rings are pressed against the inner walls of the outer sleeves respectively. An annular adjusting groove is formed in the outer wall, closes to the seal rings, of each inner adapter pipe, a fastening bolt is inserted into each adjusting groove, each fastening bolt is in threaded connection with the boss of the corresponding outer sleeve, and a second flange is formed at the other end of each inner adapter pipe. A moving sleeve is arranged on the inner adapter pipe of one pipe assembly in inserted and sleeving modes, an inner threaded sleeve is formed on the outer ring of the moving sleeve, an outer threaded sleeve is arranged on the inner adapter pipe of the other pipe assembly in inserted and sleeving modes, and the outer threaded sleeve is in threaded connection with the inside of the inner threaded sleeve of the moving sleeve. The installation and connection between a purification processor and an exhaust pipe can be conveniently achieved.

Owner:东莞市足之履鞋业有限公司

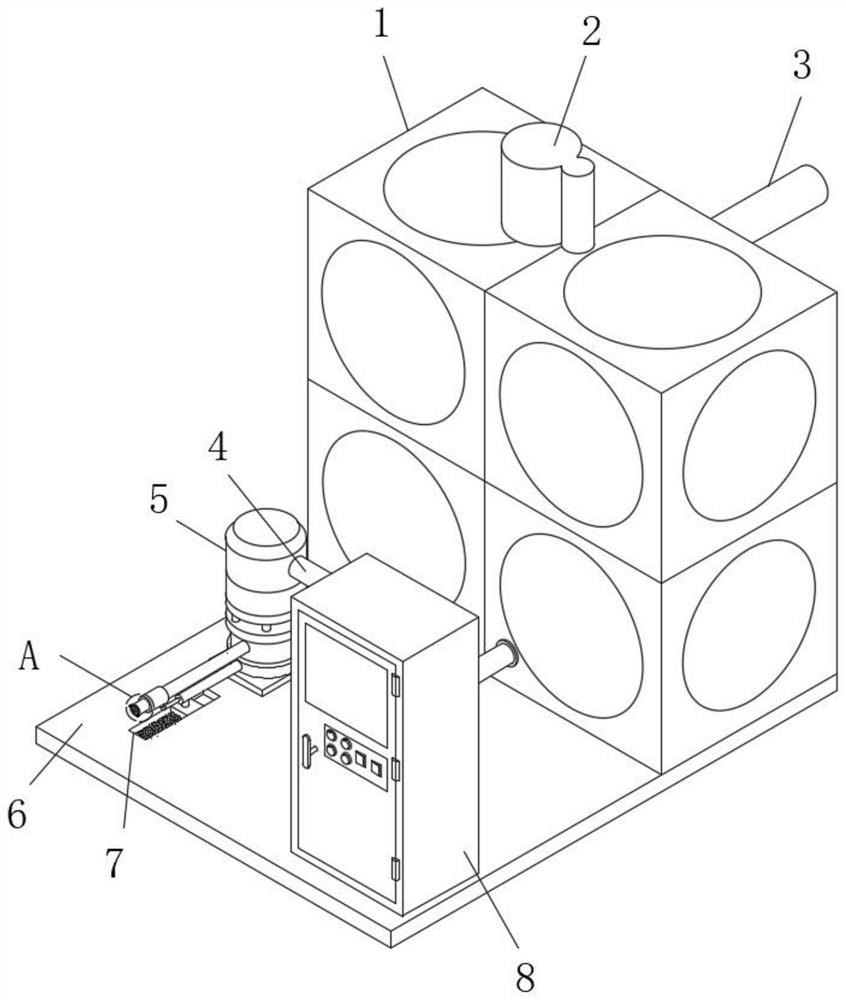

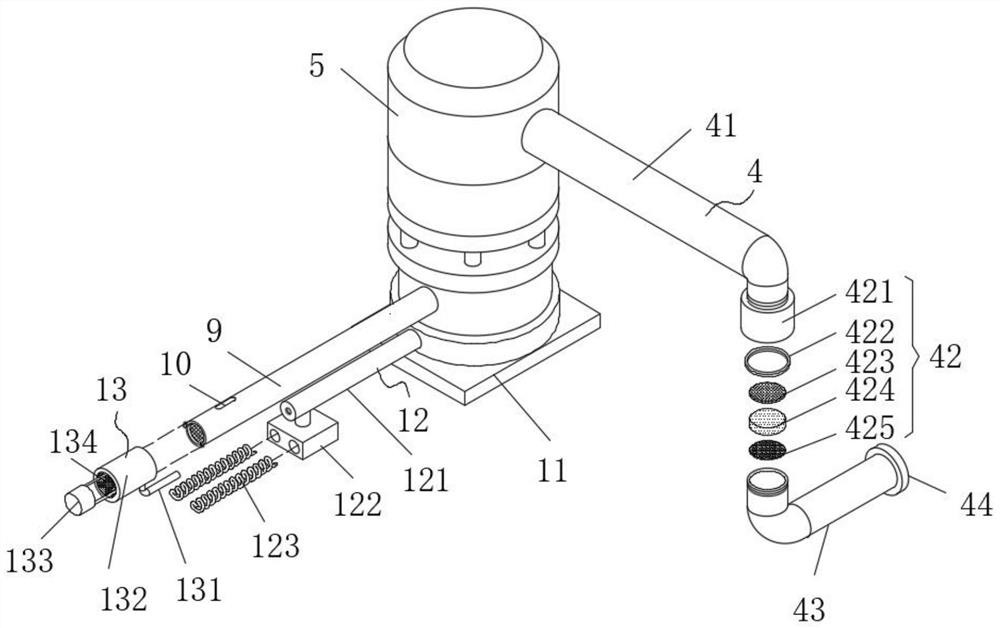

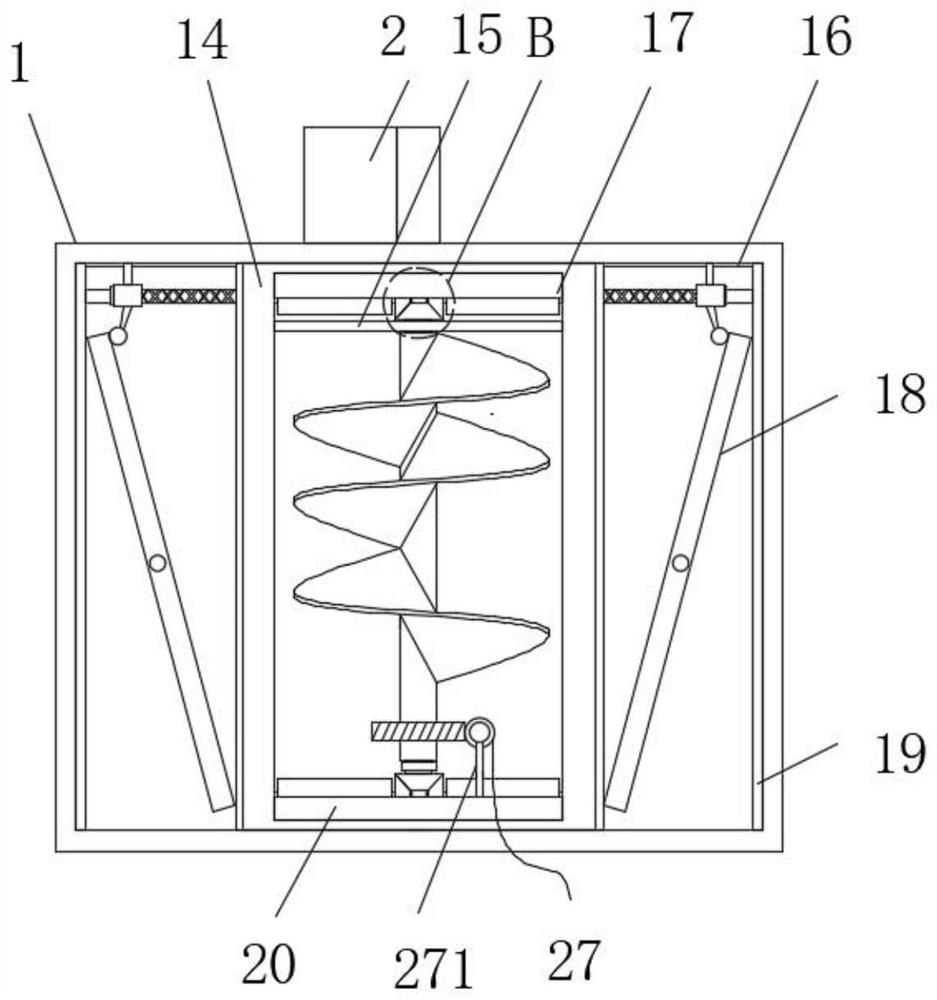

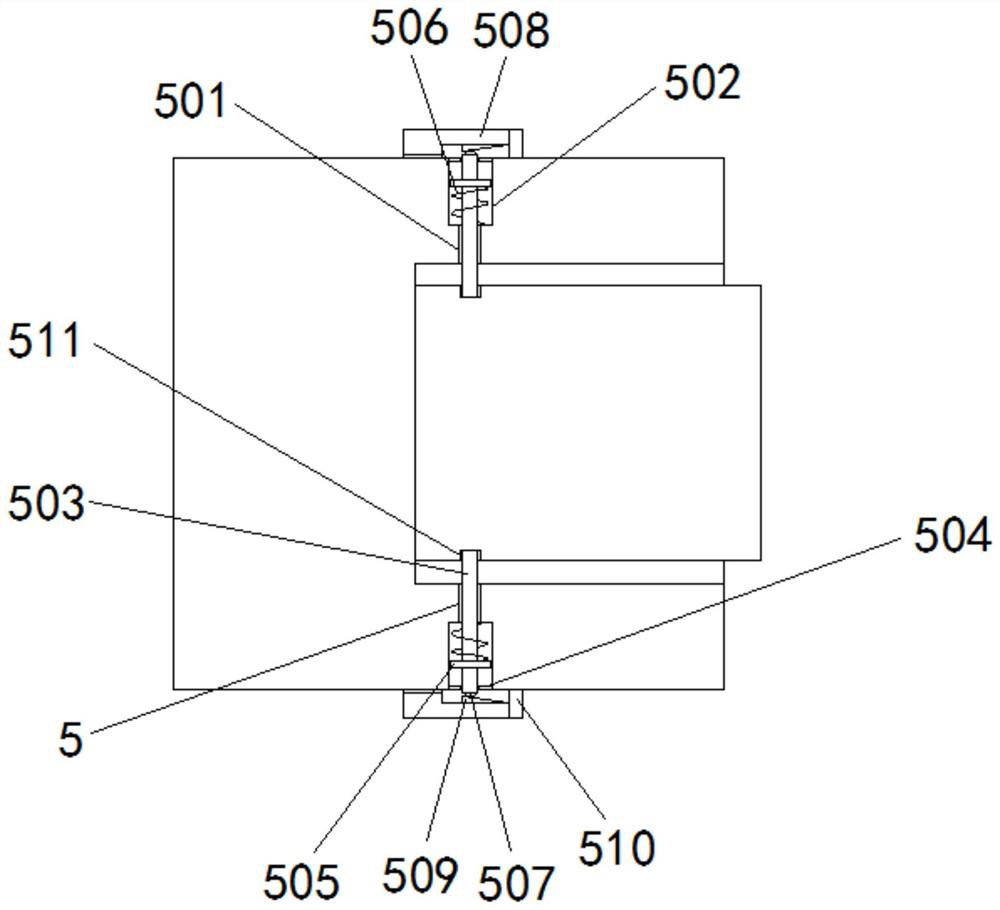

Box type non-negative pressure water supply equipment

ActiveCN113684894ARealize the hedging effectEffective electrolytic removalRotary stirring mixersTreatment involving filtrationMechanical engineeringWater resource management

The invention discloses box type non-negative pressure water supply equipment, and belongs to the technical field of water supply equipment. The box type non-negative pressure water supply equipment comprises a water supply box, a water supply pump and a bottom plate, the water supply box, a water pump seat and a control box are fixedly mounted at the top of the bottom plate, the water supply pump is fixedly mounted at the top of the water pump seat, a top groove is formed in the top surface of the bottom plate, a water pumping assembly is arranged on the outer wall of one side of the water supply pump, a buffer vibration guide mechanism is arranged outside the water supply pump through a buffer ring, and a water diversion pipe is fixedly mounted on the other side wall of the water supply pump. According to the box type non-negative pressure water supply equipment, the buffering vibration guide mechanism is arranged outside the water supply pump, and on the one hand, the buffering vibration guide mechanism can effectively relieve vibration generated during work of the water supply pump; and on the other hand, unavoidable vibration is utilized and compensated reversely, the effect of dredging in a pipe without an additional driving source is achieved, the situation that the interior of the pipe is blocked due to impurity gathering and caking caused by alternate cooling and heating is effectively avoided, and the working effect of equipment is greatly improved.

Owner:ZHEJIANG LEO ENVIRONMENT TECH CO LTD

Photovoltaic module wiring device for photovoltaic power generation

PendingCN114498172AQuick connectionAchieve connectionPhotovoltaicsCouplings bases/casesMechanical engineeringPhysics

The invention relates to a photovoltaic module wiring device for photovoltaic power generation, which comprises a connector and a mounting head, the right end of the connector is provided with a jack, the left end of the mounting head is fixedly connected with a plug inserted into the jack, the connector is provided with a mounting assembly, and a sealing assembly is arranged between the connector and the mounting head. Cable heads are fixedly connected to the ends, opposite to each other, of the connector and the mounting head, adjustable protection assemblies are arranged at the bottoms of the ends, opposite to each other, of the connector and the mounting head, and cables are fixedly connected to the ends, opposite to each other, of the connector and the mounting head. According to the photovoltaic assembly wiring device for photovoltaic power generation, the installation assembly is arranged on the connector, the installation head and the connector can be rapidly connected through the installation assembly, so that connection of two cables is achieved, later-stage disassembly is facilitated, operation is easy and convenient, the sealing assembly is arranged between the installation head and the connector, the connection sealing performance of the installation head and the connector is guaranteed, and the installation head and the connector are convenient to use. The use is convenient.

Owner:LIAONING TECHNICAL UNIVERSITY

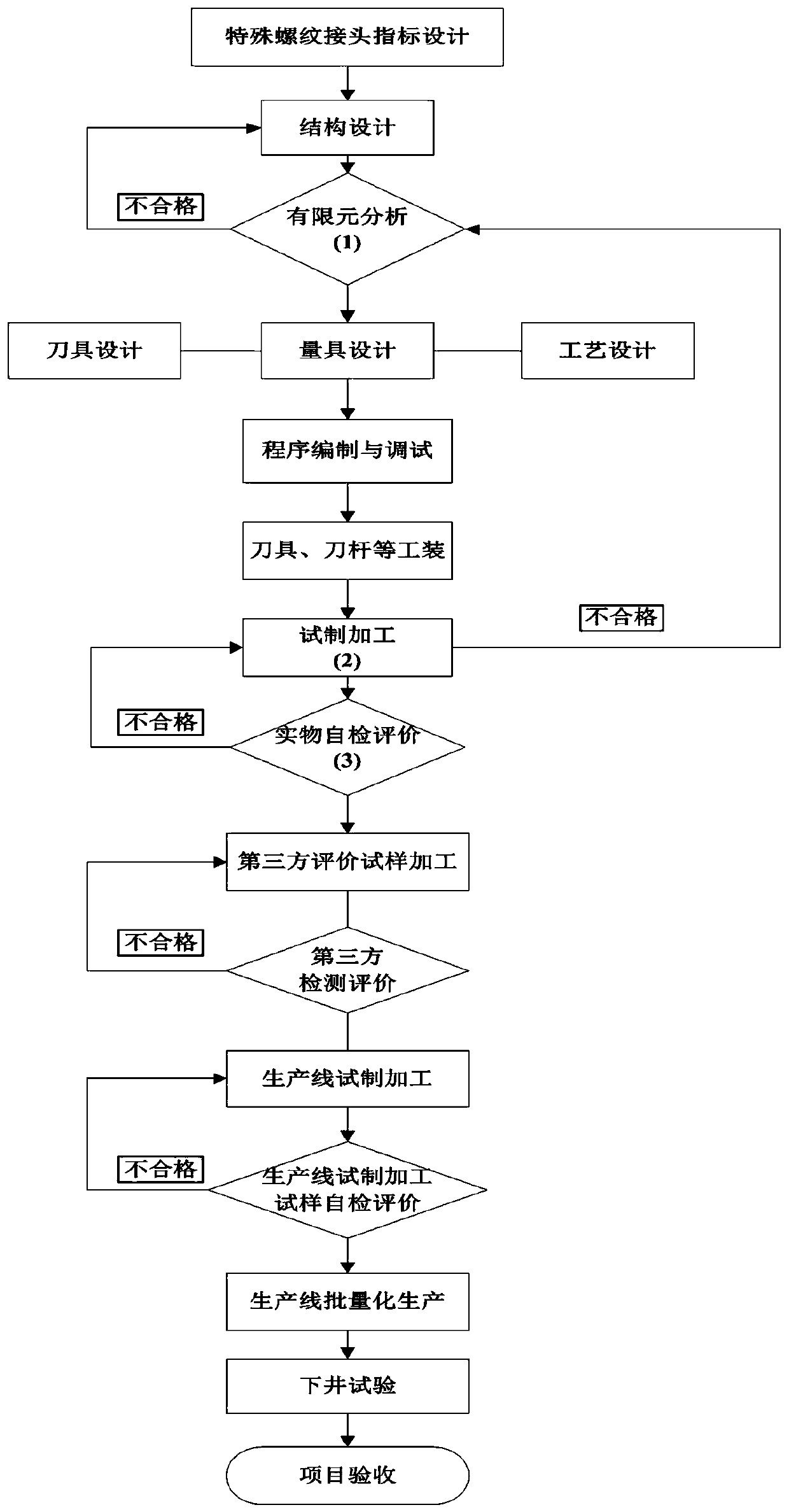

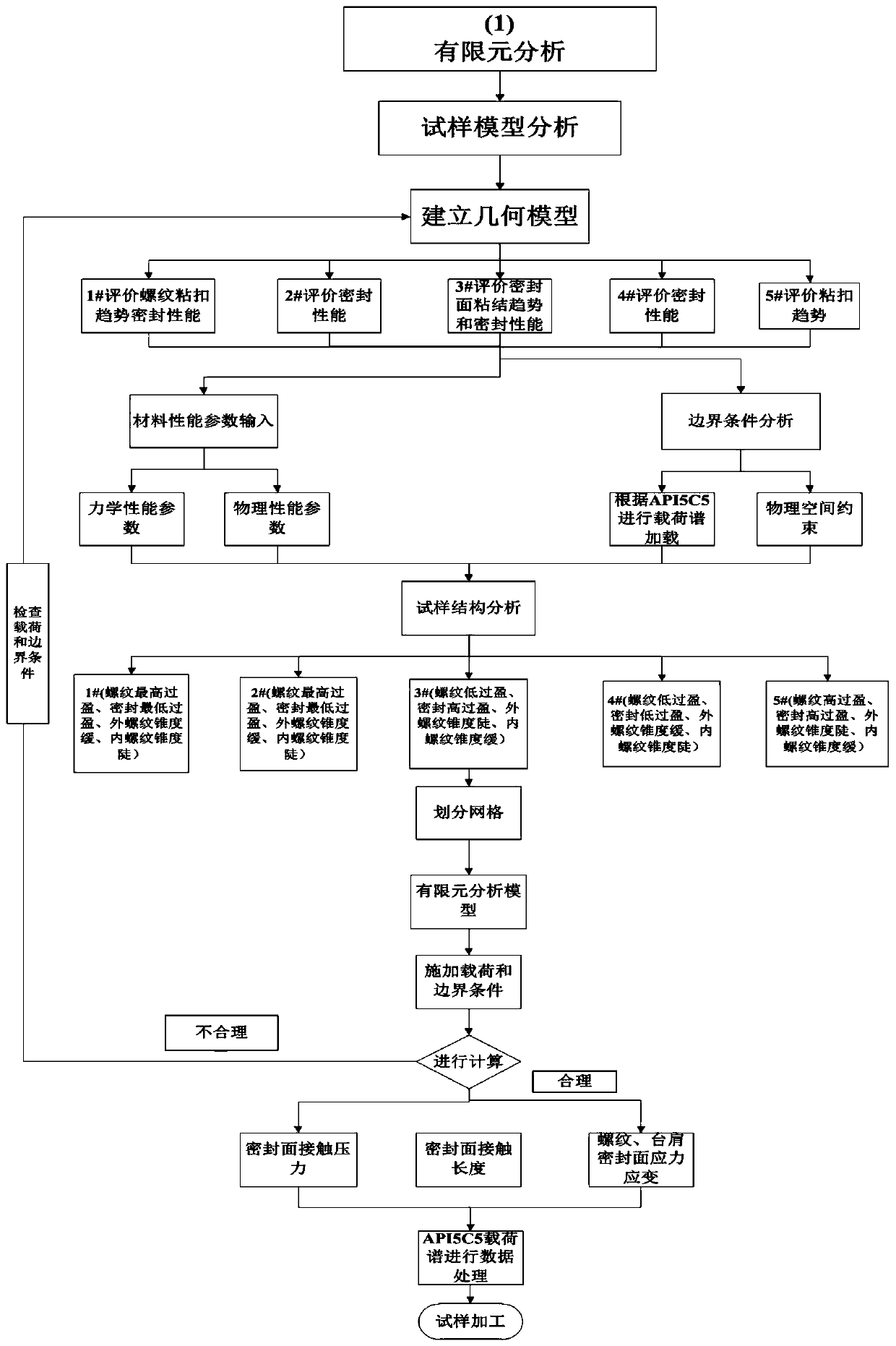

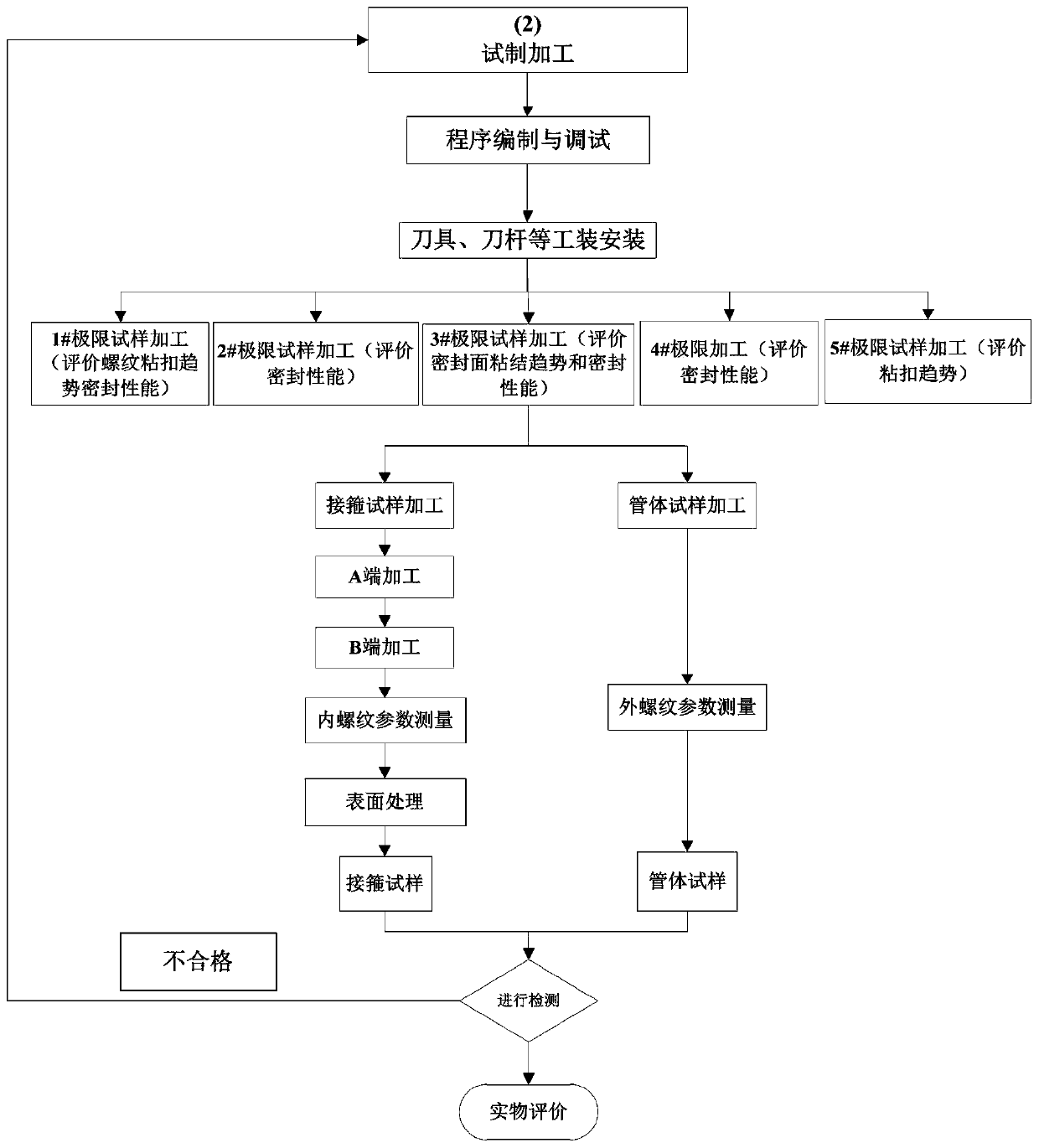

Full-process design optimization method for special screwed joint oil casing for shale gas

InactiveCN111581749APrecise positioningEffective positioningGeometric CADDesign optimisation/simulationContact pressureEngineering

The invention discloses a full-process design optimization method of a special screwed joint oil casing for shale gas, which mainly comprises the following steps: determining various performance indexes of the special screwed joint oil casing; creating a geometric model and a specific constitutive equation, fully considering material performance attributes and boundary conditions, applying a proper load working condition and making a finite element simulation calculation analysis by adopting an air-tight seal criterion criterion of a'contact pressure weighting index + minimum contact length ';selecting a special cutter measuring tool, and designing a trial machining process; trial-manufacturing processing of the coupling and the pipe body is carried out; and performing a physical performance detection and evaluation test. Organic unification of all links and elements in the whole process design is fully considered, specific process elements can be accurately and efficiently positioned, integrated design optimization of the integrity of the special screwed joint for the shale gas is achieved, the overall strength and the sealing performance of the structure are improved, and the use safety is guaranteed.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Rotary target of magnetron sputtering coating machine

ActiveCN110344014AImprove cooling effectEasy access to waterVacuum evaporation coatingSputtering coatingEngineeringCooling pipe

The invention discloses a rotary target of a magnetron sputtering coating machine, and belongs to the field of coating machines. The rotary target of the magnetron sputtering coating machine comprisesa target material, a first cover plate is fixedly arranged on the surface of the back side of the target material, a second cover plate is fixedly arranged on the front side surface of the target material, a cooling pipe is fixedly arranged in the middle of the rear side surface of the second cover plate, a communication hole is formed in the rear end of the outer surface of the cooling pipe, a magnet ring is fixedly connected to the middle of the outer surface of the cooling pipe, sealing supporting plates are fixedly adhered to the two ends of the outer surface of the cooling pipe, the outer surface of the sealing supporting plate is slidably connected to the two ends of the inner side surface of the target material, a connecting pipe is fixedly inlaid in the inner surface of the sealing supporting plate, a connecting seat is fixedly connected to the center of the inner part of the second cover plate, an inner pipe is arranged in the connecting seat, so that the convenience and thestability of use can be greatly improved, and the safety and efficiency are ensured.

Owner:贵州商学院

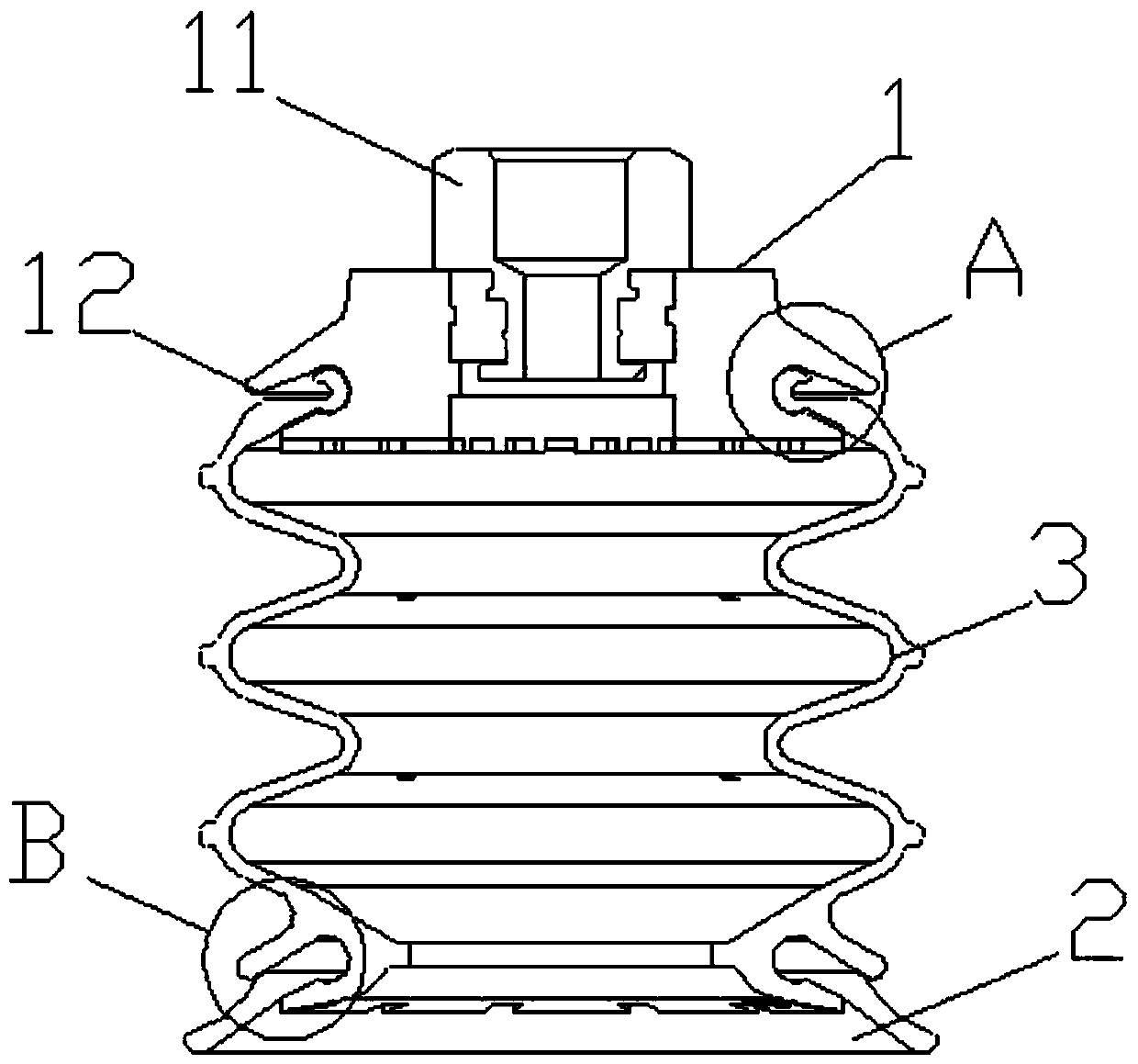

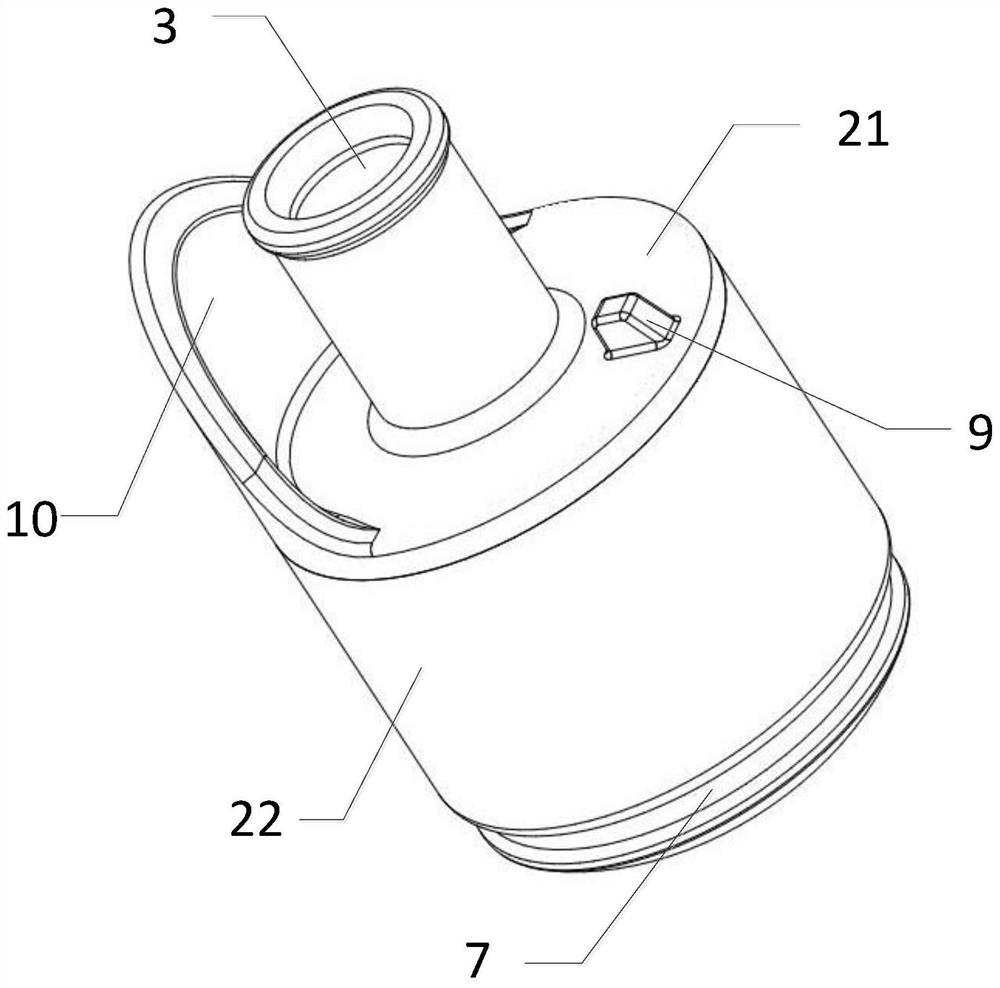

Combined type suction cup

PendingCN107605925AIncreased flexibility of useAvoid frequent replacement operationsSuction cupsBellowsEngineering

The invention discloses a combined type suction cup used in the field of vacuum suction cups. The combined type suction cup is structurally comprises a connecting piece, an suction cup lip side and aplurality of connecting corrugated pipes, wherein the connecting piece comprises a working end and a connecting end which are connected with vacuum equipment; clamping grooves used for being connectedwith the suction cup lip are circumferentially formed in the connecting end, a clamping protruding edge which is matched with the corresponding clamping groove is arranged on one end of each connecting corrugated pipe, a clamping groove is formed in the other end of each connecting corrugated pipe, the connecting piece, the connecting corrugated pipes and the suction cup lip are sequentially andclosely clamped and connected, and a gas channel is formed in the connecting piece, the connecting corrugated pipes and the suction cup lip. According to the combined type suction cup, by structural arranging of the connecting corrugated pipes in the combined suction cup, overall frequent changing of the suction cup during operating and using is avoided, working efficiency is improved, using flexibility of the suction cup is expanded effectively, so that the application range of the suction cup can be expanded extremely, the reasonable utilizing rate of the suction cup is guaranteed, meanwhile, the storage space required by the suction cup is reduced, and reasonable allocation of resources is realized effectively.

Owner:YAMILA AUTOMATION TECH (SUZHOU) CO LTD

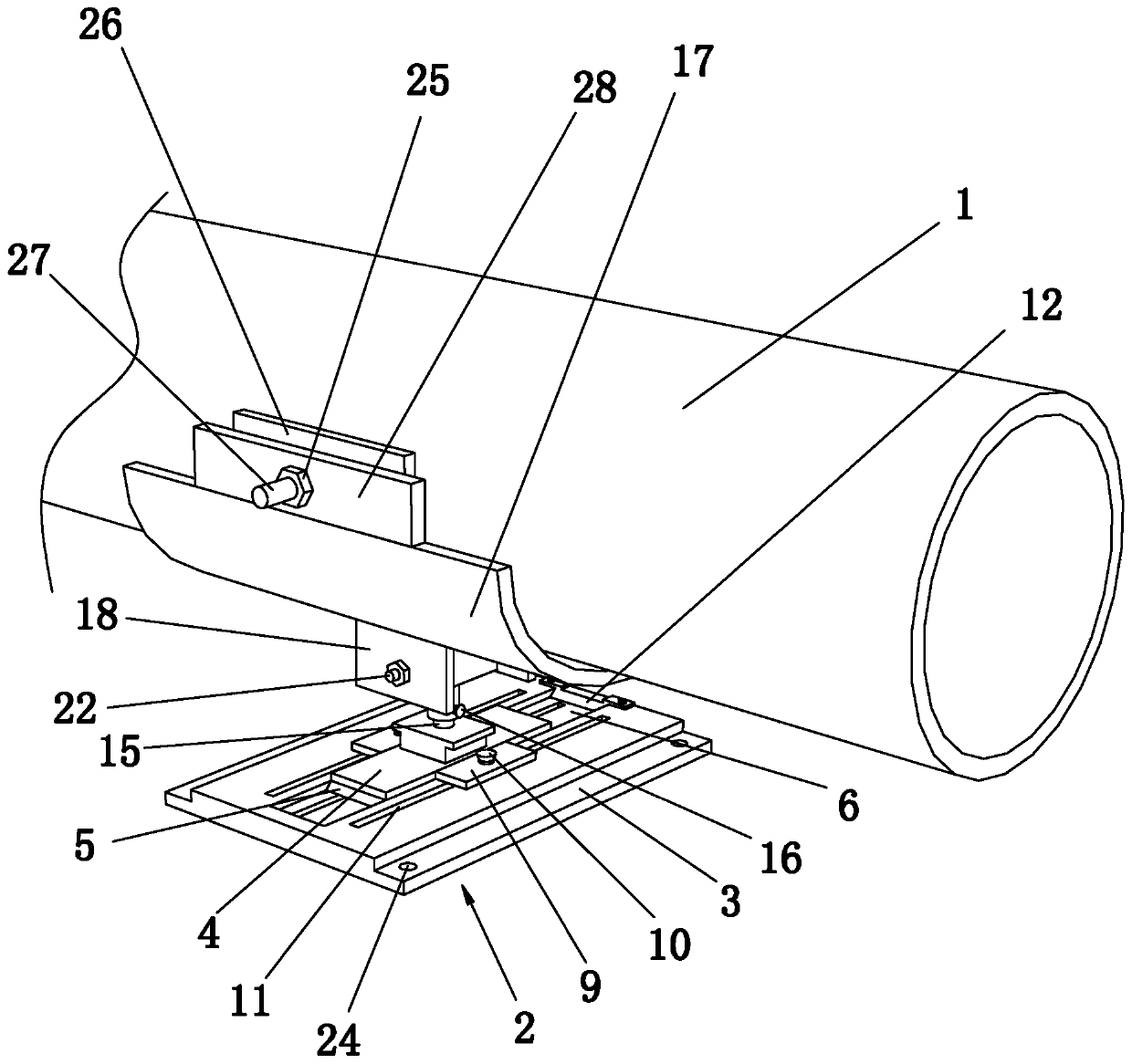

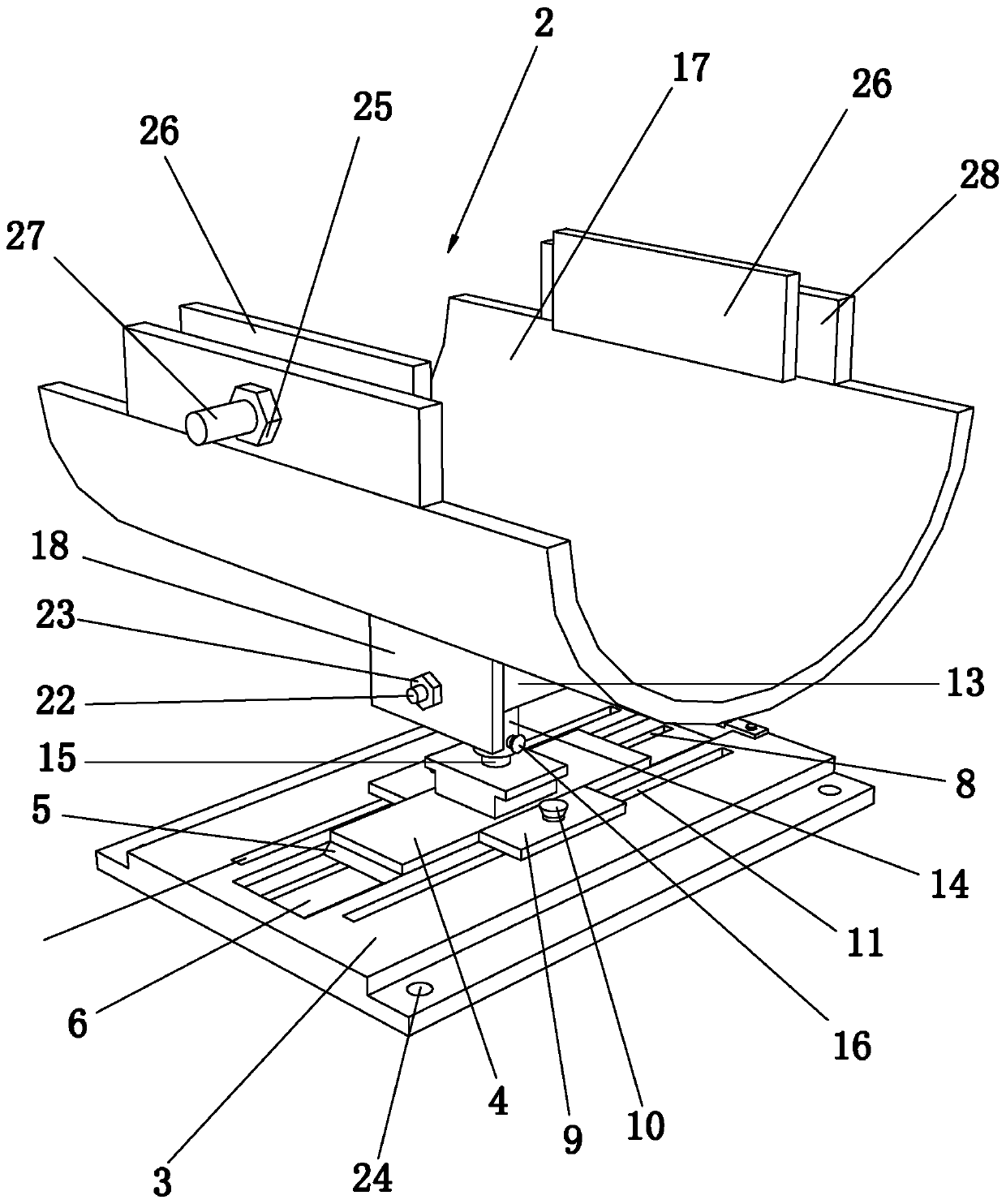

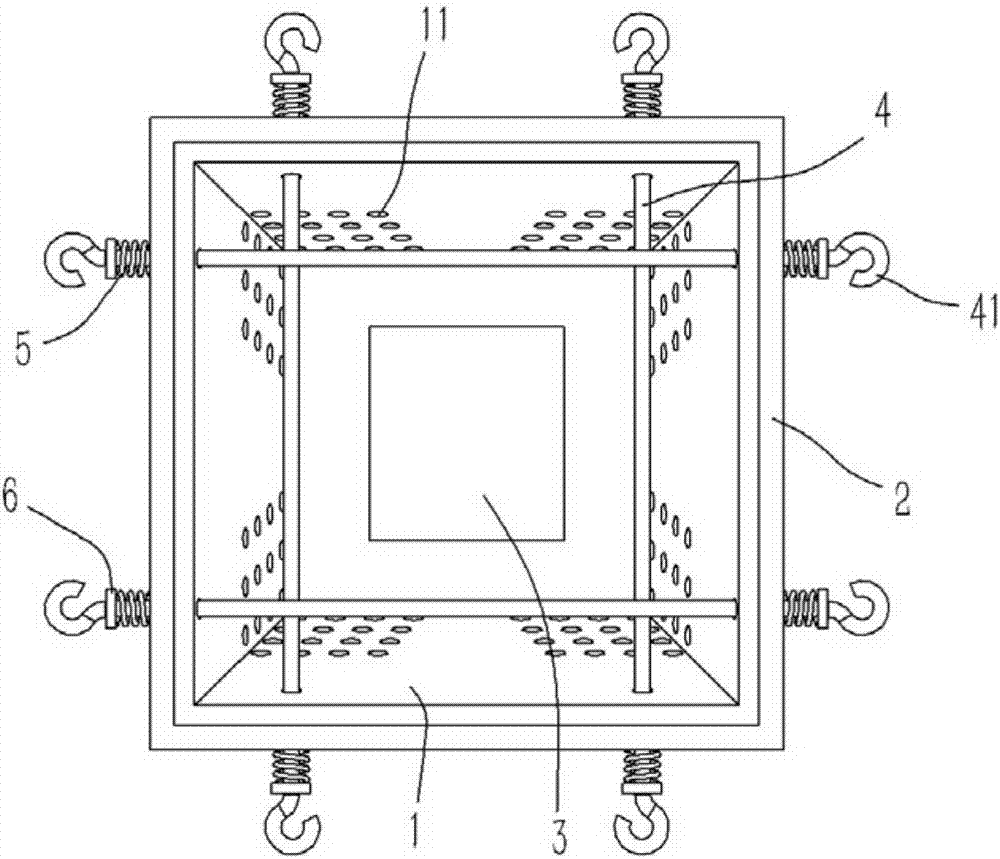

Connecting pipe of automobile exhaust gas purification equipment

InactiveCN107448708AEasy to install and connectSimple structureFlanged jointsExhaust apparatusArchitectural engineeringExhaust pipe

The invention discloses a connecting pipe on an automobile tail gas purification device, which comprises a first connecting pipe group and a second connecting pipe group, the first connecting pipe group is composed of an outer pipe and a first inner pipe, and the second connecting pipe group is composed of an outer pipe and a second pipe. The second inner tube is formed, the outer end of the outer tube is formed with a first flange, the first flange is formed with a number of mounting holes, the outer wall of the outer tube is formed with a rectangular boss, the first inner tube and the second The two inner tubes are respectively plugged into the outer casing of the first connecting group and the outer casing of the second connecting group. One end of the first inner tube and the second inner tube are inserted and fixed with a number of sealing rings, and the sealing rings are pressed against the outer casing. On the inner wall of the first inner tube or the second inner tube adjacent to the outer wall of the sealing ring, there are ring-shaped first adjustment grooves and second adjustment grooves respectively, and the first adjustment groove or the second adjustment groove are inserted into the A fastening bolt is connected, and the fastening bolt is screwed on the boss of the outer casing. The invention facilitates the installation and connection between the purification processor and the exhaust pipe.

Owner:DONGGUAN BEIYANG IND DESIGN CO LTD

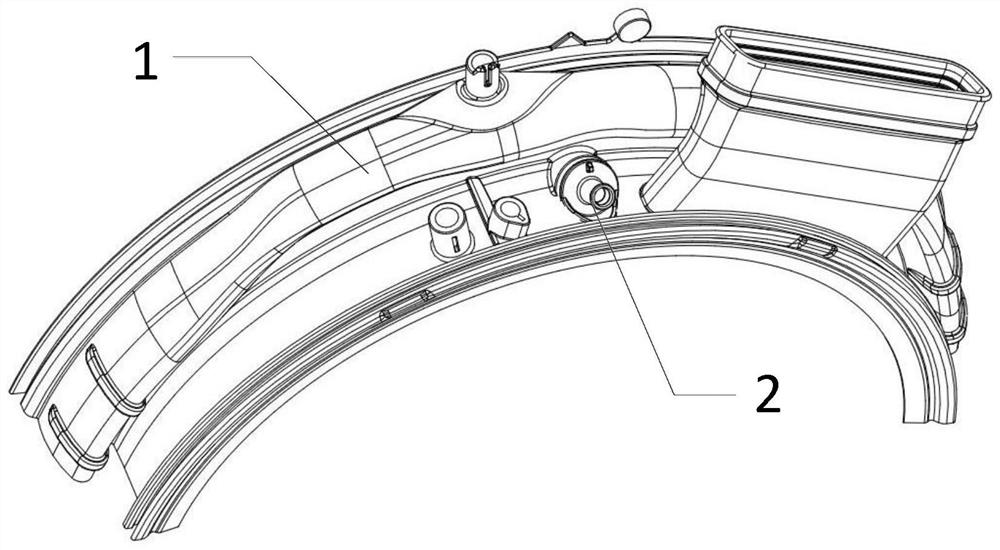

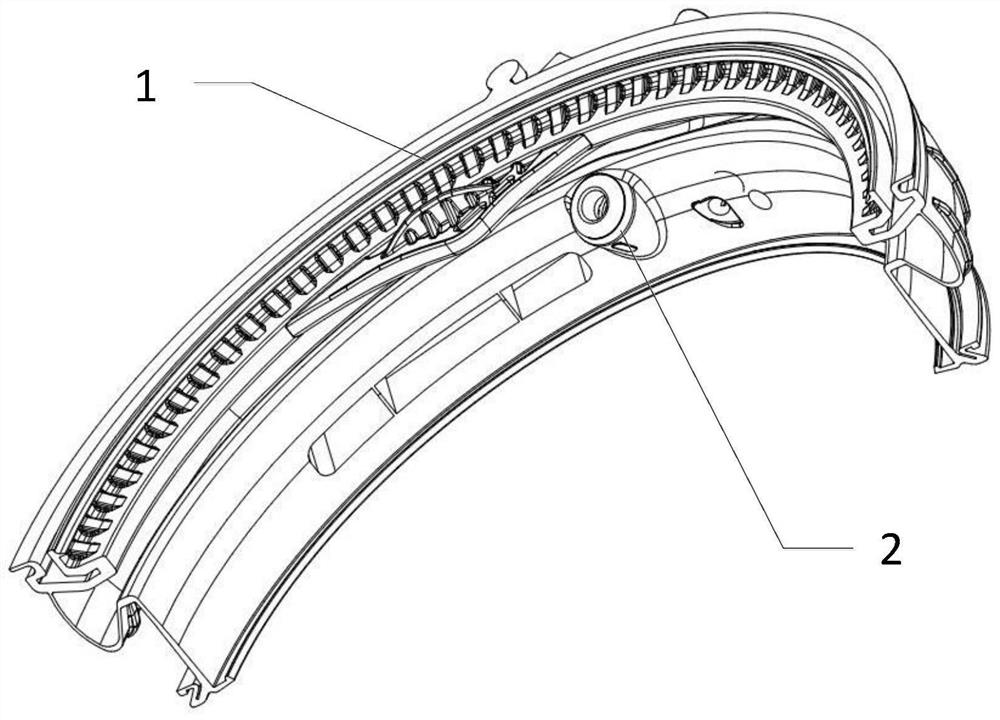

Atomizing device for clothes treatment equipment

PendingCN111691109AFirmly connectedReduce usageOther washing machinesWashing machine with receptaclesManufacturing engineeringMechanical engineering

The invention belongs to the technical field of clothes treatment, and provides an atomizing device for clothes treatment equipment to solve the problem that existing clothes treatment equipment adopts a split atomization device which may lead to poor sealing performance after long-time use and thus cause safety accidents. The clothes treatment equipment comprises a fixed member and an accommodating cavity capable of accommodating clothes. The atomizing device comprises a first module, a second module and an atomizing generator; at least one of the first module and the second module is arranged on the fixed member; the atomizing generator is arranged between the first module and the second module; a connecting structure is arranged between the first module and the second module; and the first module is connected with the second module through the connecting structure. The connection strength and sealability of the atomizing device can be ensured after the clothes treatment equipment isused for a long time, the short circuit phenomenon of the atomizing device due to poor sealing is avoided, and the safety of the clothes treatment equipment is ensured.

Owner:QINGDAO HAIER WASHING MASCH CO LTD +1

Post insulator and insulation post

ActiveCN108257741ALess likely to leakReduce control difficultySupporting insulatorsHigh pressureFlange

The invention discloses a post insulator which comprises a hollow insulation tube, a shed on the periphery of the hollow insulation tube, and an upper flange and a lower flange respectively arranged at the two ends of the hollow insulation tube. The hollow insulation tube is filled with gas hermetically, and the absolute pressure of the gas is equal to 0.1-0.15Mpa. The invention further disclosesan insulation post which is formed by connecting the post insulators end to end. According to the post insulator and the insulation post, the problem about interfaces in padding of internal insulationsolid materials and the problem of gas leakage in use of high-pressure gas filling are both solved, and detection and maintenance of the post insulator are avoided; besides, micro-water control rangemargin is increased while difficulty in micro-water control and production and manufacturing is lowered.

Owner:JIANGSU SHENMA ELECTRIC CO LTD

Separate fusible alloy structure security release device

PendingCN111795194AVenting is effectiveRapid responseVessel mounting detailsContainer filling methodsGas cylinderAlloy

The invention provides a separate fusible alloy structure security release device. The separate fusible alloy structure security release device comprises a pressure bearing structure, one end of the pressure bearing structure is used for being connected with a high pressure pipeline, the other end of the pressure bearing structure is used for being connected with a blowdown pipeline, a plurality of pressure release holes are formed between two ends of the pressure bearing structure, and fusible alloys are injected into the pressure release holes. A porous structure is adopted, compared with aconventional single-hole structure, the porous structure has the advantages that the jointing area of the shaped fusible alloys with the inner surface of a hole channel can be enlarged, the shearing strength of part of the fusible alloys can be reinforced, a conventional rupture disk structure is not used, and the condition that after a gas cylinder is burnt by a fire, internal pressure of the gascylinder is insufficient to achieve operating pressure of a rupture disk and the pressure cannot be released, so that invalidation is caused, can be effectively avoided.

Owner:CHINA SPECIAL EQUIP INSPECTION & RES INST +1

High-capacity lithium-ion power battery post sealing structure

ActiveCN102290544BGuarantee the safety of useEnsure connection stabilityCell component detailsPower batteryLithium

The invention discloses a high-capacity lithium-ion power battery post sealing structure, which comprises a cover plate and a post which is connected with the cover plate in a sealing way, wherein one end of the post is a connecting post, and the other end of the post is an electrode end; the cover plate comprises a cover plate body, cover plate bosses extended out along the center of the cover plate body, and the centers of the cover plate body and the cover plate bosses are provided with post holes; a sealing table is arranged on the post; after a sealing gasket is arranged on the sealing table, the electrode end passes through the post holes of the cover plate; the space between the post and the post holes and the space between the cover plate bosses and the sealing table are subjected to sealed insulation through the sealing gasket; an insulating protective sleeve is molded at a position, which is close to the electrode end and passes through the cover plate body, on the post; and another insulating protective sleeve is molded on the cover plate bosses, the sealing table and an outer surface of the sealing gasket between the cover plate bosses and the sealing table. By the sealing structure, the connecting stability and the sealing performance of the battery can be effectively guaranteed, and the using safety performance of the battery is further guaranteed.

Owner:奇瑞新能源汽车股份有限公司

High-strength connecting structure and sectional type wind power blade

ActiveCN113339190AAvoid punchingStructural strength does not affectMachines/enginesWind energy generationMarine engineeringWind power

The invention relates to the technical field of wind power blades, in particular to a high-strength connecting structure and a sectional type wind power blade. The high-strength connecting structure comprises a first section and a second section which are arranged in the length direction of the wind power blade, and the first section and the second section comprise first matching faces, second matching faces, connecting faces and connecting bolts; the first matching faces extend towards the interior of the wind power blade, and the first matching faces are perpendicular to the length direction of the wind power blade; the second matching faces and the first matching faces are staggered, and the second matching faces are staggered in the direction close to the first section relative to the first matching faces; the connecting faces are connected with the first matching faces and the second matching faces; the connecting bolts are located in the wind power blade and penetrate through the two first matching faces to fix the first section and the second section, and the connecting bolts are parallel to the length direction of the wind power blade; and an anti-flanging structure is arranged between the first section and the second section, and the anti-flanging structure limits the second section from being flanged towards the outer side of the wind power blade. According to the high-strength connecting structure and the sectional type wind power blade, the connecting strength and the sealing performance are guaranteed, and the service life of the wind power blade is prolonged.

Owner:CHANGZHOU HONGFA ZONGHENG ADVANCED MATERIAL TECH

Roof construction technology of light-steel villa

InactiveCN111042420AShort construction periodEasy to installBuilding roofsRoof covering using slabs/sheetsArchitectural engineeringRoof tile

The invention relates to a roof construction technology of a light-steel villa. The roof construction technology comprises the following steps of step 1, truss splicing; step 2, truss transportation;step 3, plane inspection and surveying and setting out; step 4, installation of a roof truss and a wall connecting part; step 5, installation of a cornice and a small roof ridge plate; step 6, installation of a roof panel; step 7, laying of a waterproof coiled material; step 8, construction of a roof ventilation pipe; step 9, gutter water falling construction; step 10, laying of roof tiles; step 11, construction of roof heat preservation sound insulation cotton; and step 12, construction of roof inner top plate. By means of the roof construction technology, the effects of short construction period, convenient installation, light self weight of roof structure and high waterproof performance are achieved.

Owner:青岛泰合洋房建设有限公司

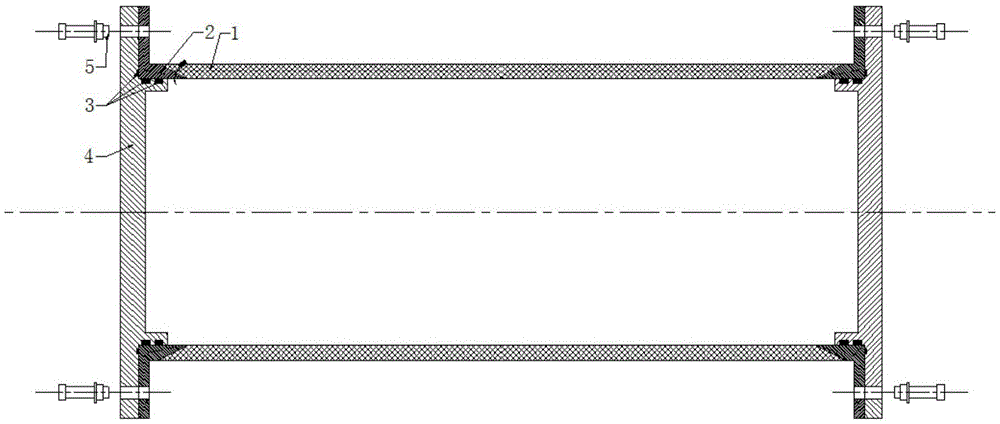

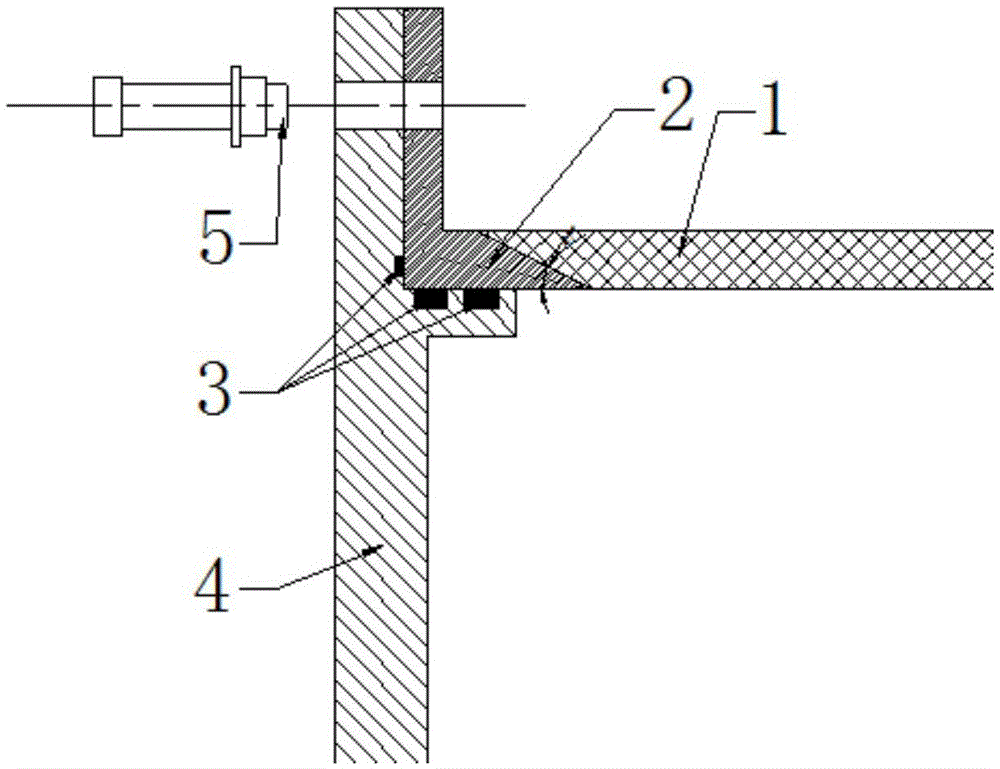

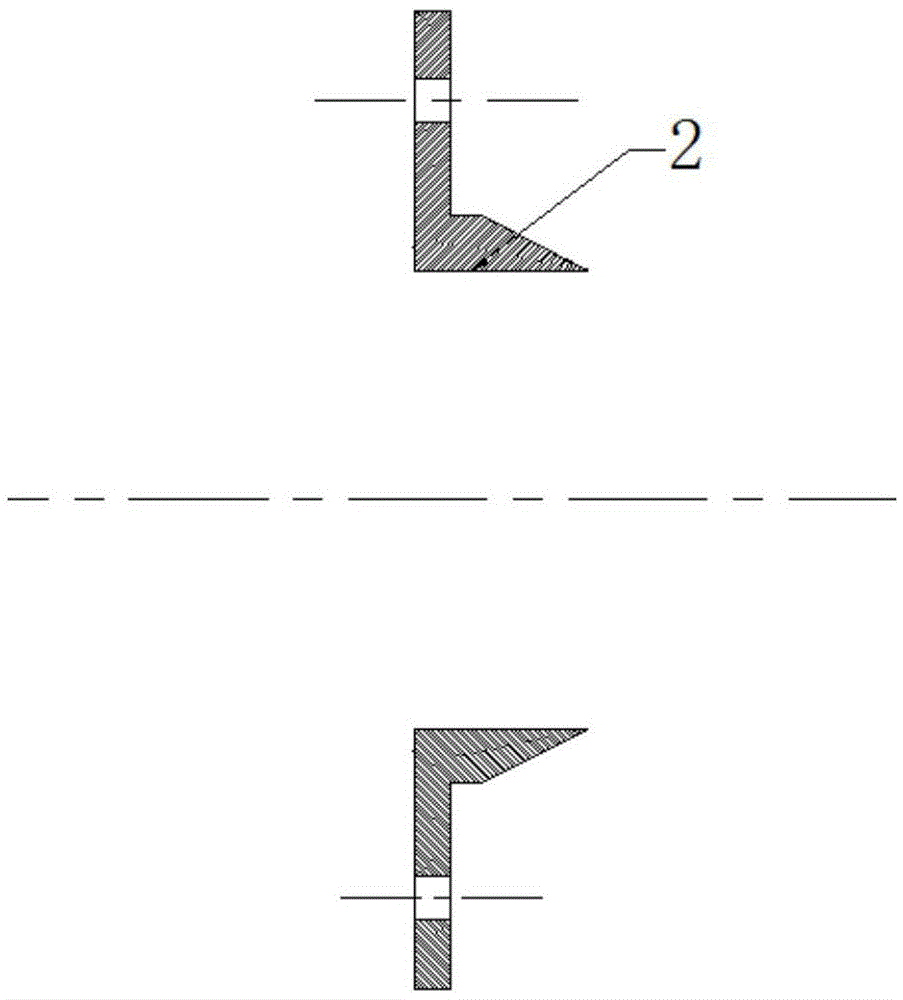

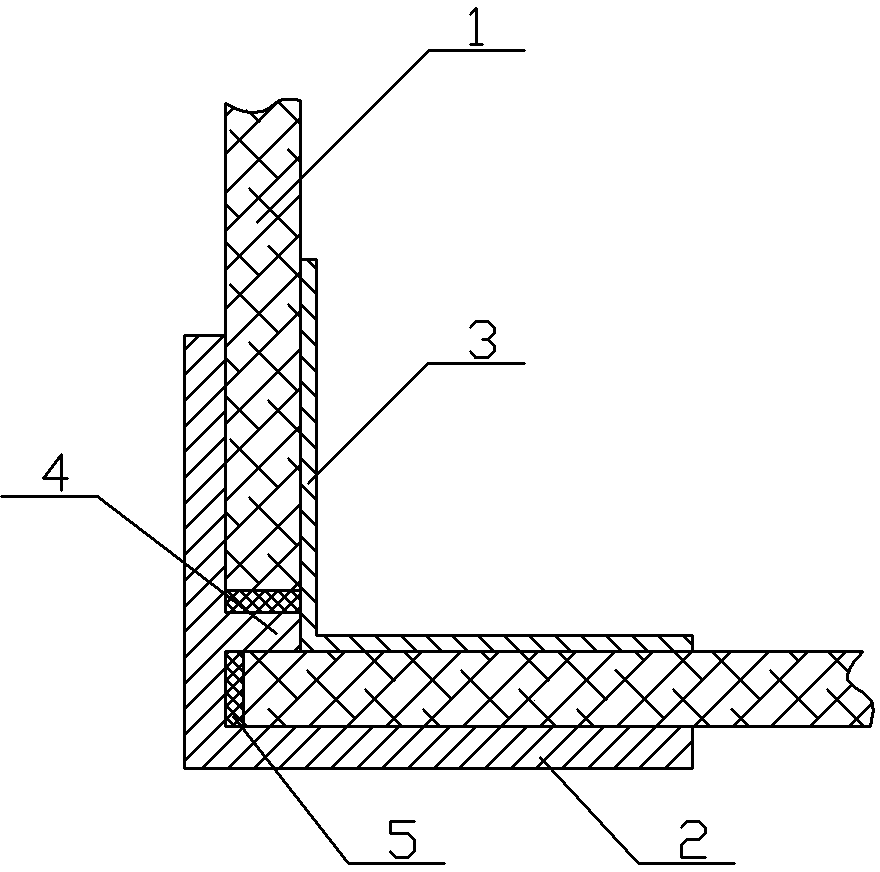

Shaping form for external corners of walls

InactiveCN103669830AGuaranteed connection strengthGuaranteed connection tightnessForms/shuttering/falseworksAuxillary members of forms/shuttering/falseworksEngineeringBuilding construction

The invention relates to a component for buildings, in particular to a shaping form for external corners of walls in building construction sites. The shaping form comprises an L-shaped angle steel main body and formworks. The formworks are arranged on the inner side of the angle steel main body, a rectangular protrusion is arranged at an edge of the inner side of the angle steel main body, the height of the rectangular protrusion is equal to the distance from the edge of the inner side of the angle steel main body to the other edge of the inner side of the angle steel main body and is equal to the thickness of each formwork, the rectangular protrusion is magnetic, an L-shaped steel sheet is arranged on the inner sides of the formworks, and the outer side of the steel sheet clings to the inner sides of the formworks and is attracted onto the rectangular protrusion. According to the technical scheme, the shaping form for the external corners of the walls has the advantages that the shaping form is low in service cost and convenient to construct, and leakage of the formworks can be prevented.

Owner:CHONGQING ZHIRUIDE TECH

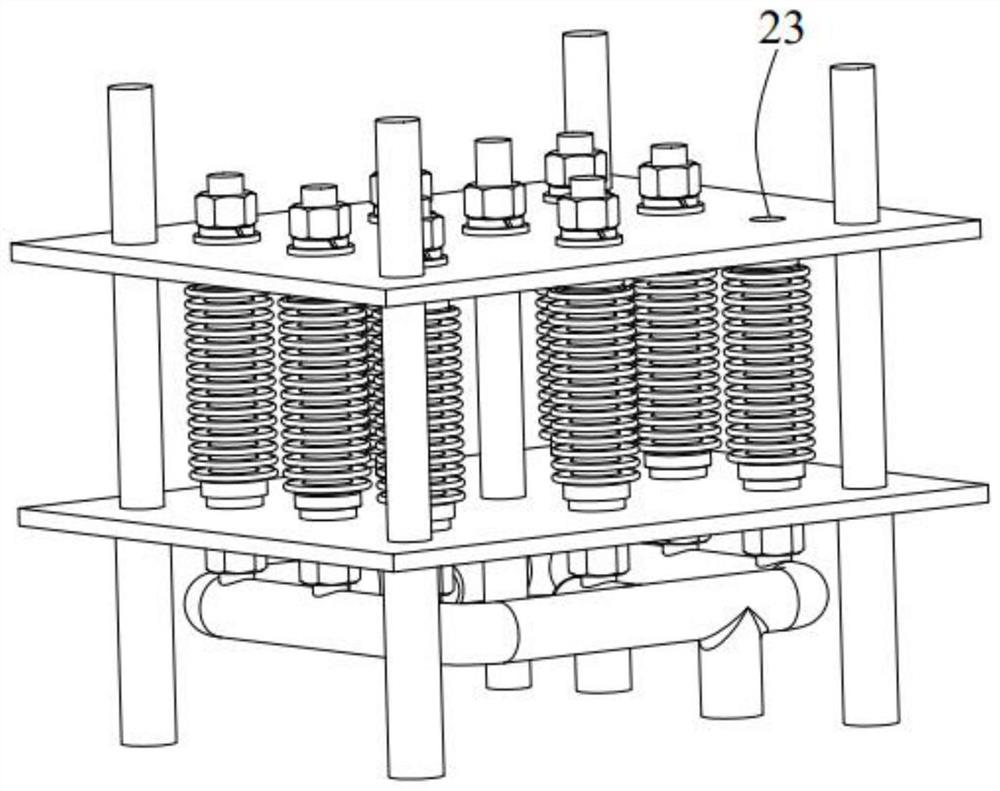

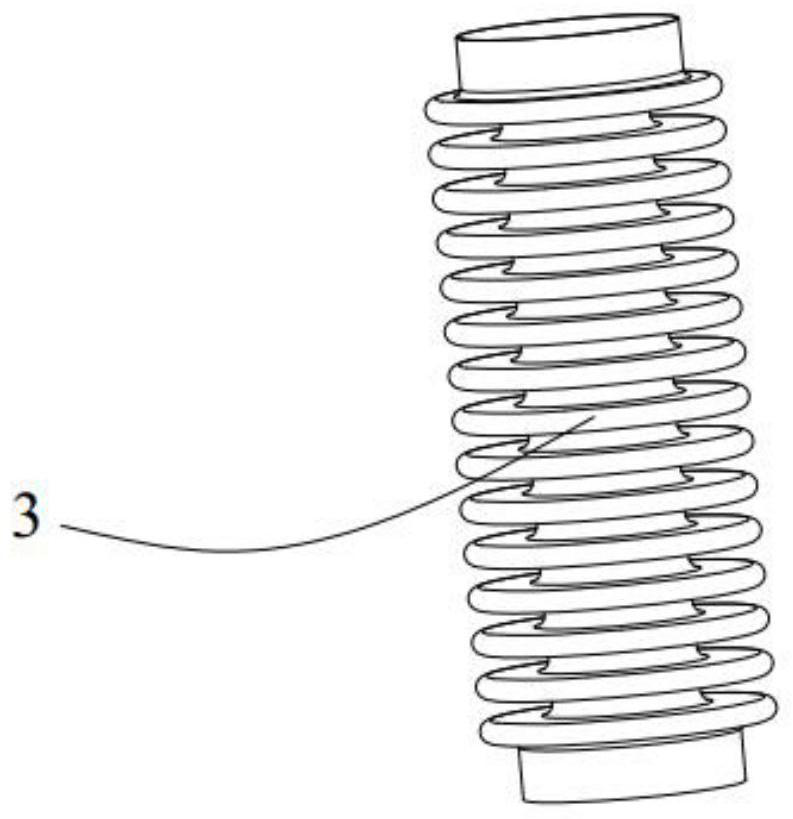

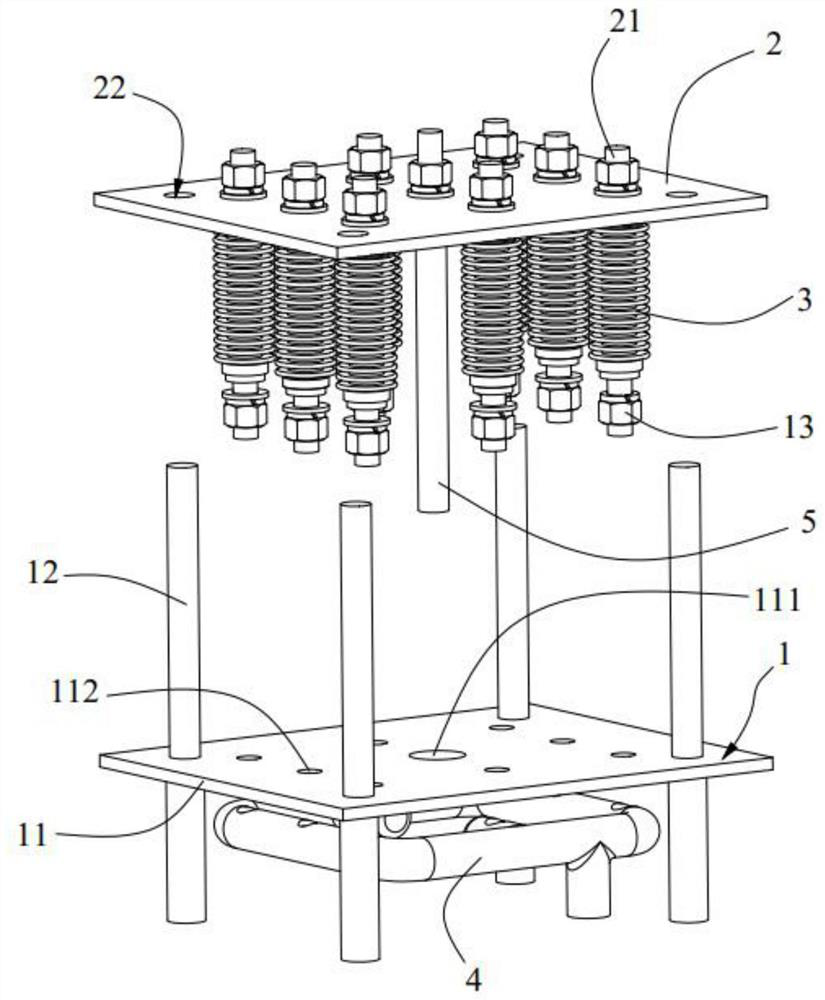

Corrugated pipe service life test device

PendingCN113008545ATightly sealed connectionGuaranteed connection tightnessMachine part testingStructural engineeringMechanical engineering

The invention discloses a corrugated pipe service life test device, and belongs to the technical field of vacuum arc extinguish chamber tests. The corrugated pipe service life test device comprises a supporting assembly and a movable part, the movable part can reciprocate in the vertical direction relative to the supporting assembly, sealing inflation assemblies on the supporting assembly and sealing fixing assemblies on the movable part are arranged in a one-to-one correspondence mode, and the sealing inflation assemblies and the sealing fixing assemblies are configured to be connected with the two ends of a corrugated pipe in a sealed mode and fill gas with the set pressure into the corrugated pipes, the real working condition is simulated, at least two corrugated pipes can be tested, and the detection efficiency is improved.

Owner:陕西宝光集团有限公司 +1

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com