Patents

Literature

386results about How to "Less likely to leak" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

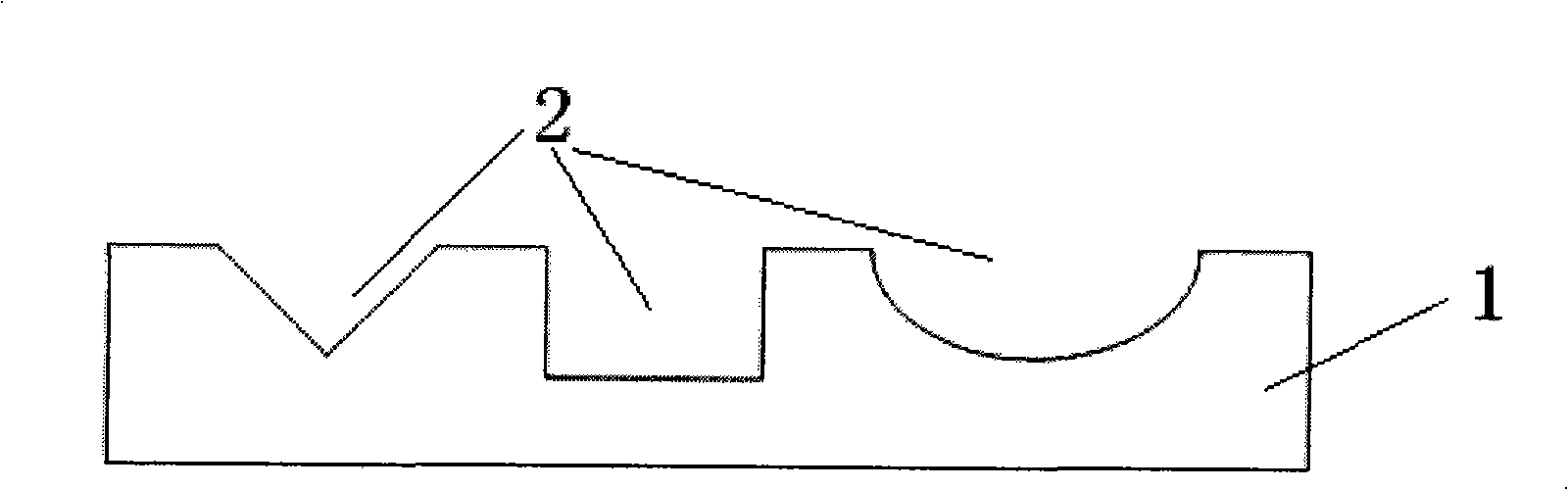

Dried hanging thermal insulation decorative curtain wall and mounting process thereof

InactiveCN101302782AReduce construction costsShorten construction timeCovering/liningsWallsThermal insulationKeel

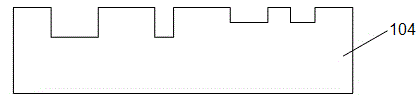

The invention discloses a dry-hanging curtain wall for thermal insulation and decoration and an installation technique thereof, which essentially comprises a 'duplex F' shape installation hanging part; the radial frameworks and the zonal frameworks of the 'duplex F' shape installation hanging part are vertically arranged; a first layer of the radial frameworks with two or more than two layers is level to the zonal frameworks and the radial framework at the last layer is at a certain distance from the tail end of the zonal framework; the width and thickness of the radial frameworks at every layer can be equal or not. Insulation boards can be fixed in a point-typed installation and location method by the installation hanging part, thus overcoming the defects of the prior art, providing an installation technique of the thermal insulation and decoration curtain wall without installing the horizontal and the vertical joist, simplifying the installation procedure, saving the installation raw materials and cost and overcoming the defect that the rain leakage is easy to happen in the splicing seam of the insulation board adopting the traditional method.

Owner:SHENZHEN MINGYUAN BUILD MATERIALS TECH

Nano metal fluid with high heat-transfer performance

ActiveCN1955252AImprove thermal conductivityFast absorption and deliveryDigital data processing detailsSemiconductor/solid-state device detailsLiquid metalSolvent

This invention provides a high heat transfer performance liquid nano-metal. It relates to cooling fluid working medium, and especially it can be used under high rush density condition which need high intensity cooling fluid working medium for heat exchanging and cooling, such as computer array and reactor. The solvent of this invention is liquid metal, and the soluble of this invention is nanometer particle. This invention solve the problem of high price of present metal liquid cooling working medium and the limited performance of common metal liquid, leaking out easily taken place using common liquid and easy forming sediment of present nanometer cooling agent.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

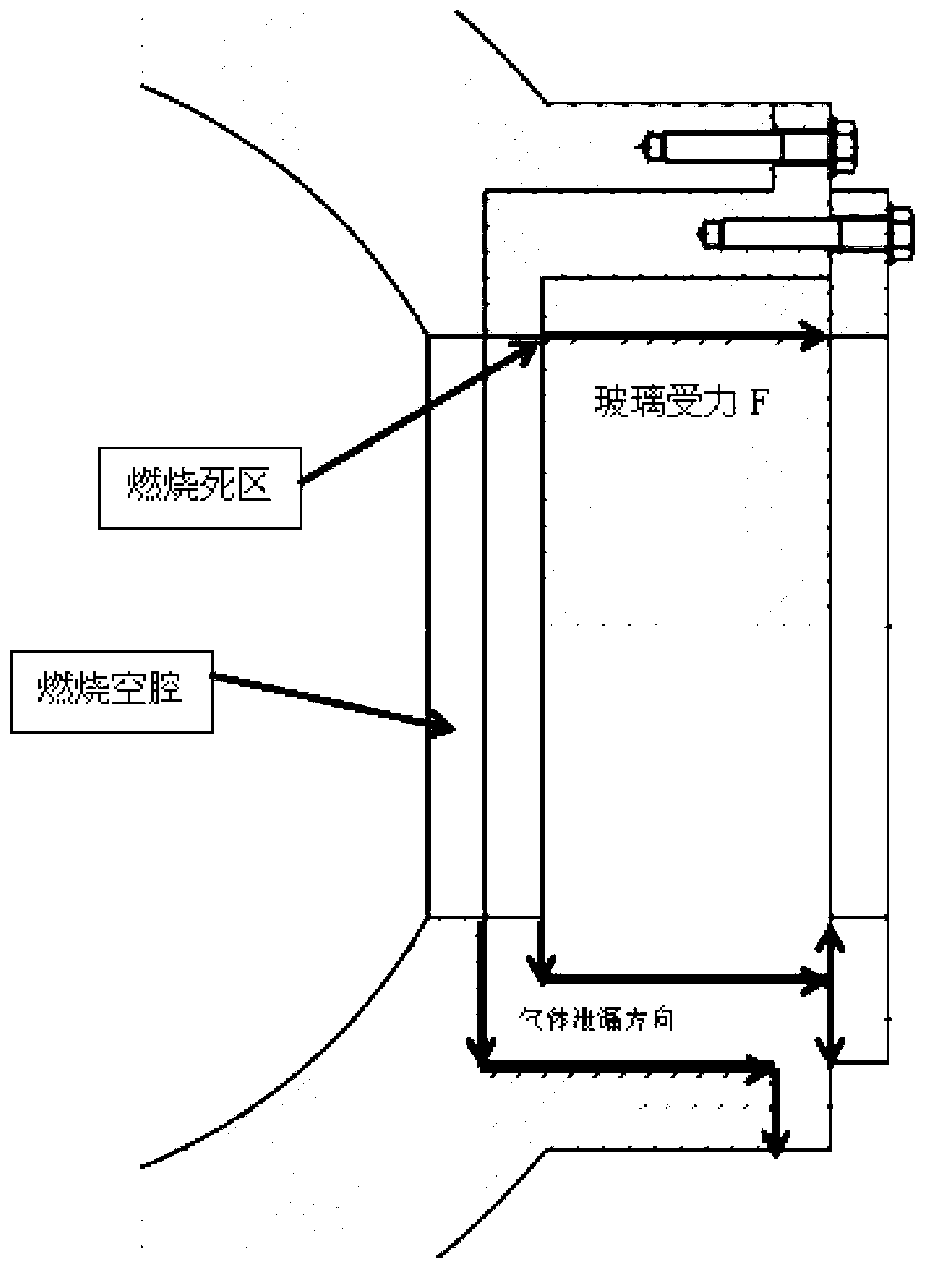

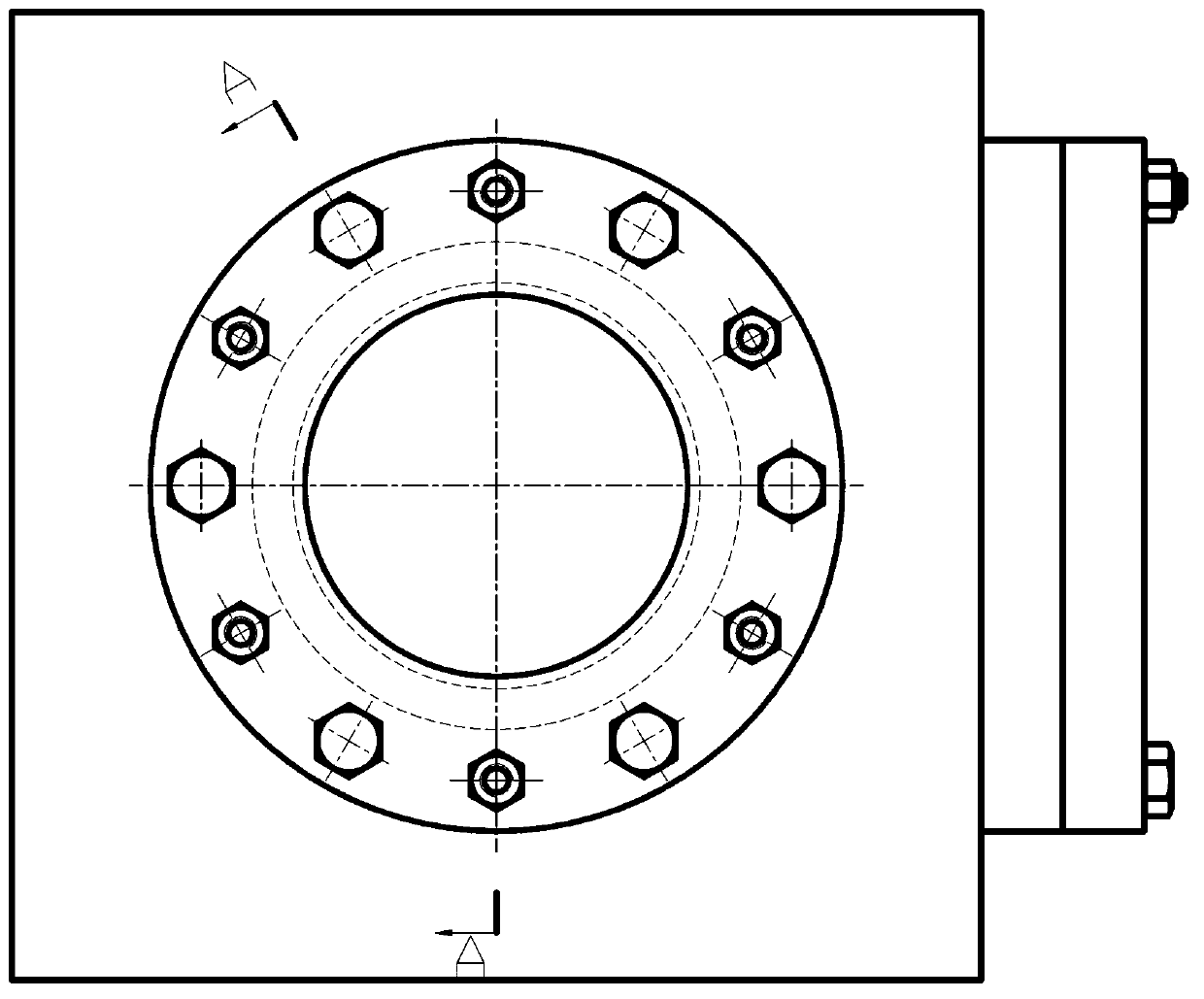

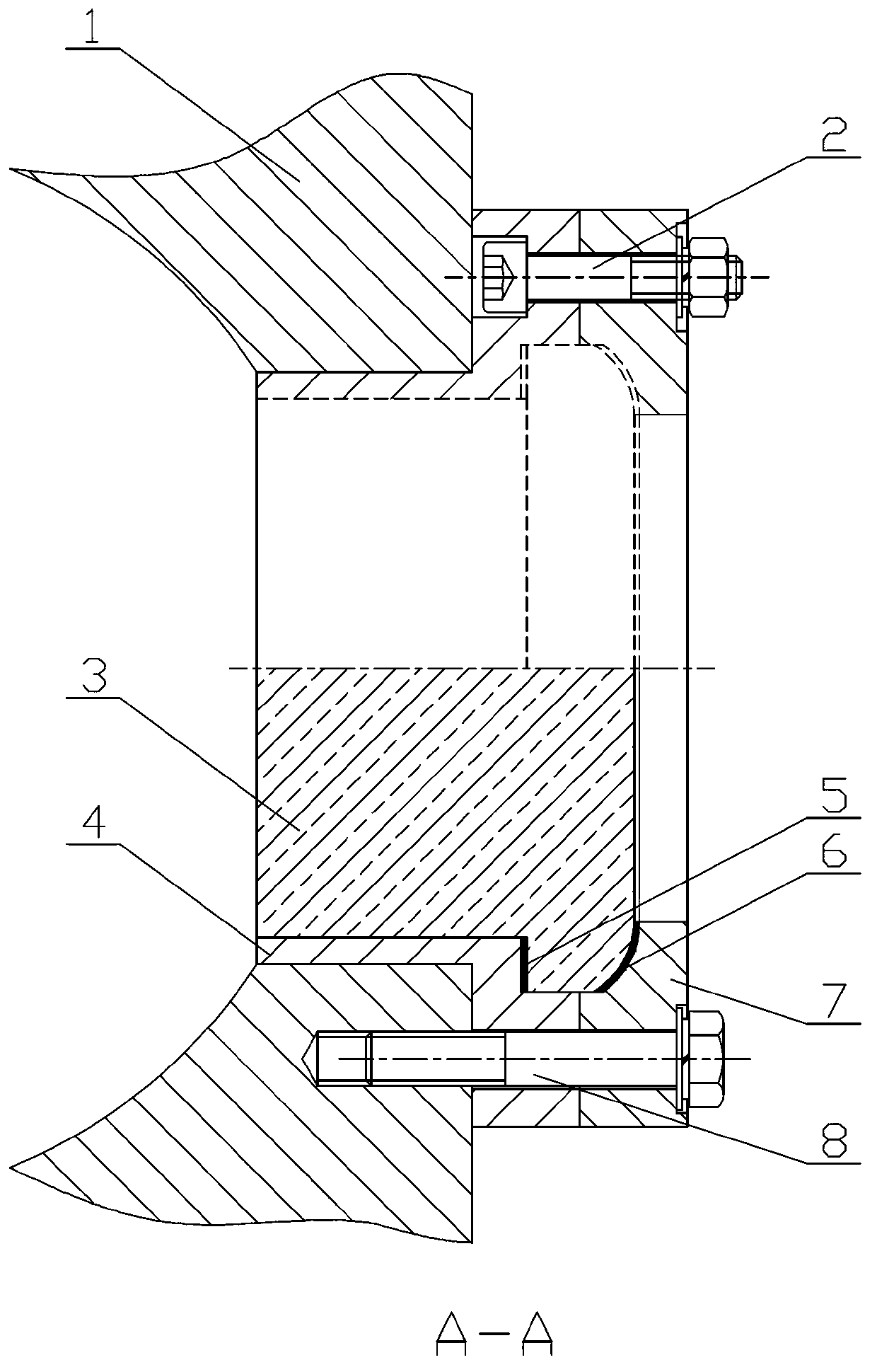

Constant volume combustion device for observing mutual effect of flame and pressure wave

InactiveCN103278331ASmooth structureReduce interlacingInternal-combustion engine testingCombustionEngineering

The invention discloses a constant volume combustion device for observing the mutual effect of a flame and a pressure wave. A combustion bomb body is provided with an observation hole provided with an optical observation window; the optical observation window comprises optical glass provided with an annular boss on the outer side; the inner side and the outer side of the optical glass are respectively provided with an embedding end cover and a compressing end cover which are mutually connected through a bolt; the embedding end cover and the compressing end cover are arranged on the combustion bomb body through bolts; and high-temperature resistant gaskets are respectively arranged among the embedding end cover, the compressing end cover and the optical glass. According to the constant volume combustion device, the influence of the installation of the optical observation window of the combustion bomb body to the regularity of the inner cavity shape of the optical observation window is reduced, and the inner cavity smoothness is improved, so that the reflection effects of an inner flow field and a wall pressure wave are improved; and meanwhile, the stress manner of glass in the traditional optical observation window is changed, the thickness of the glass is reduced, and the device is beneficial to observation and shooting effects of experiments.

Owner:TIANJIN UNIV

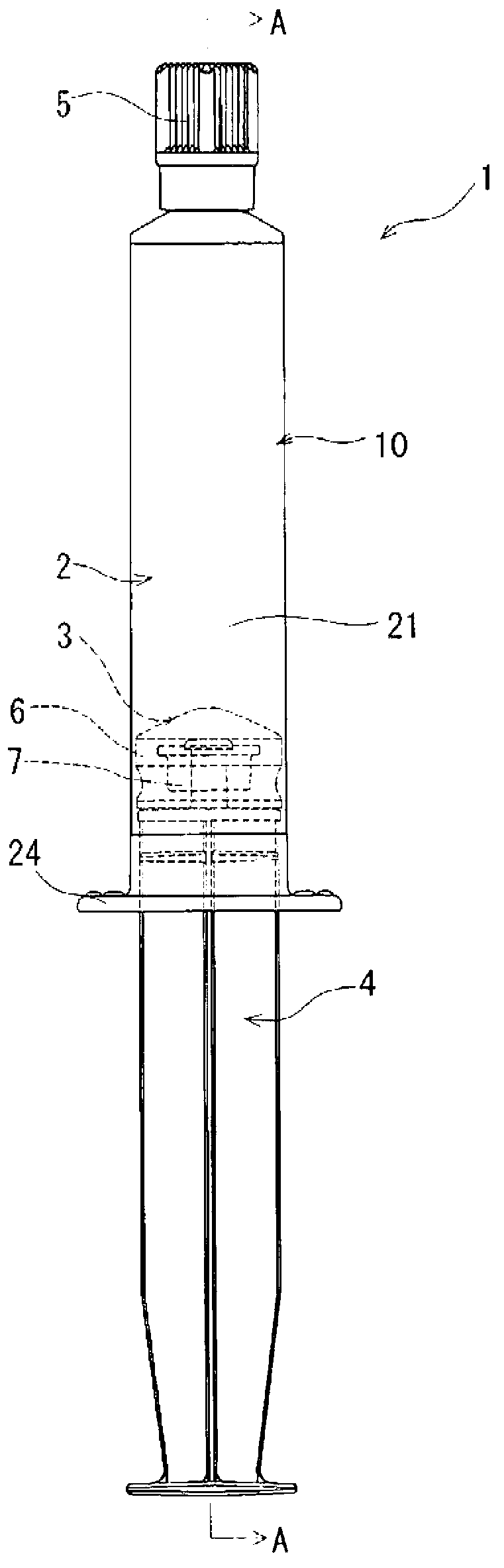

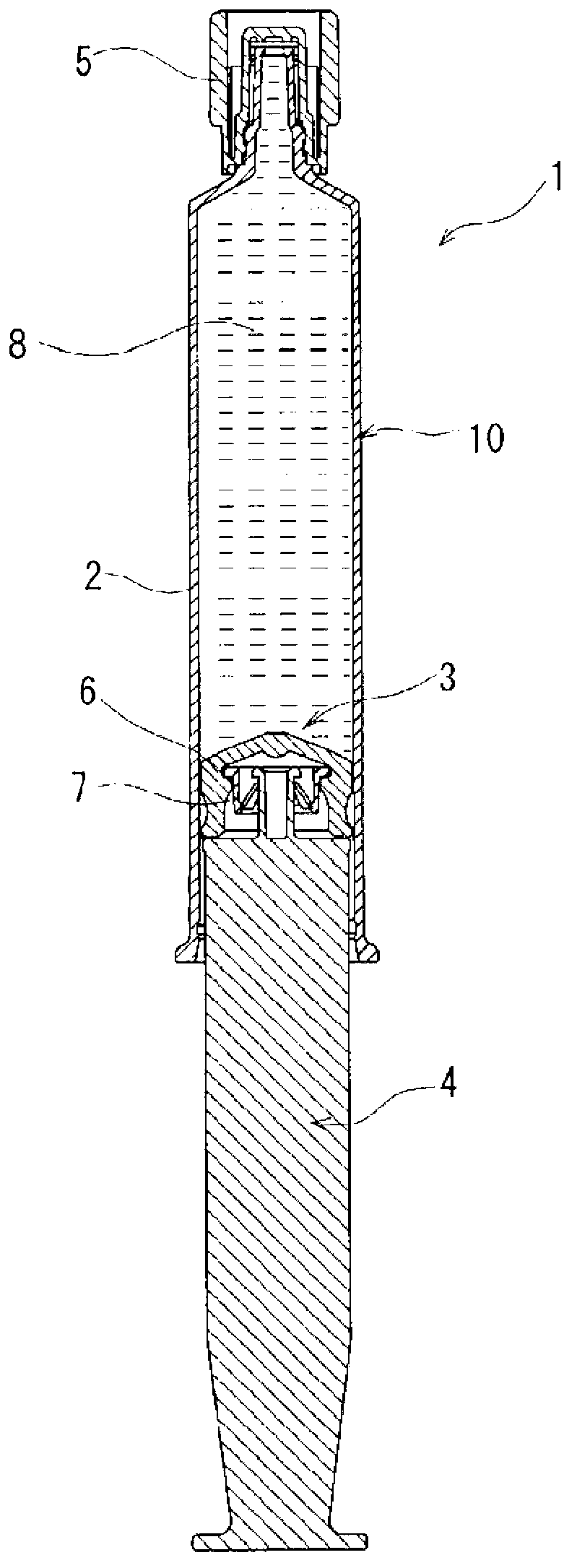

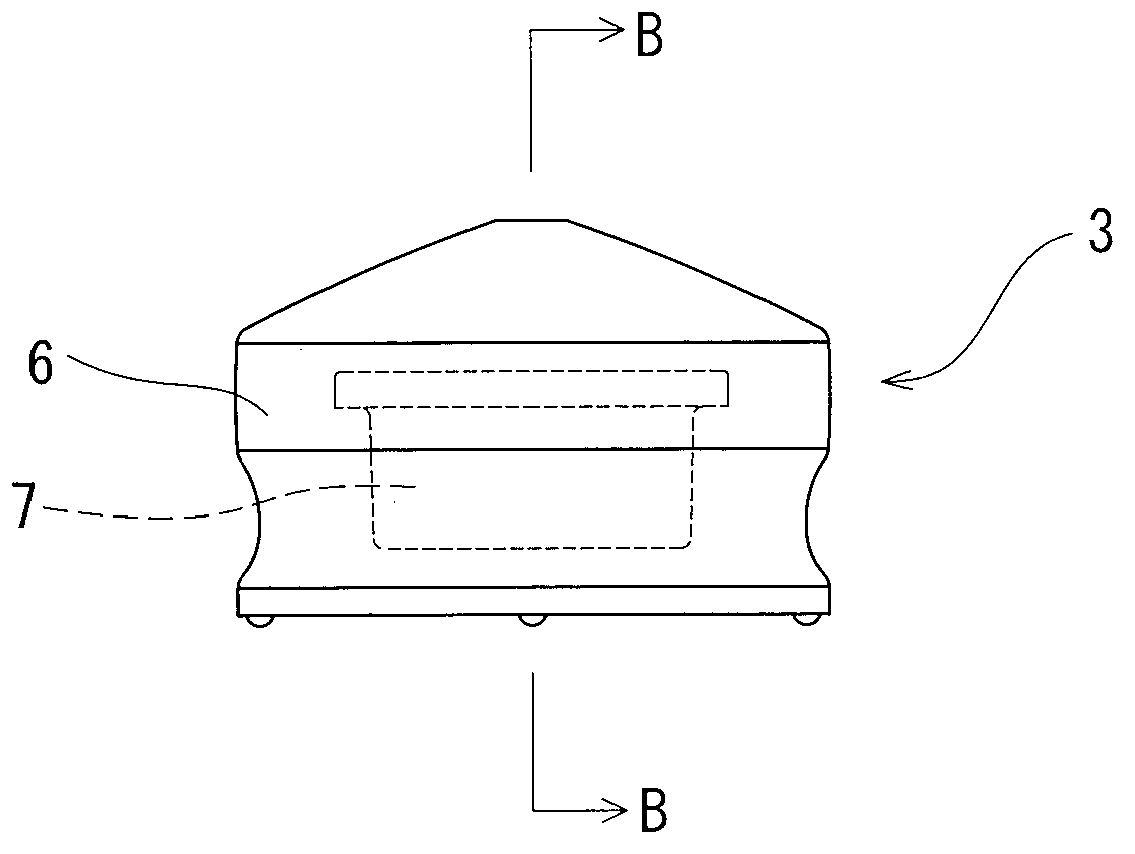

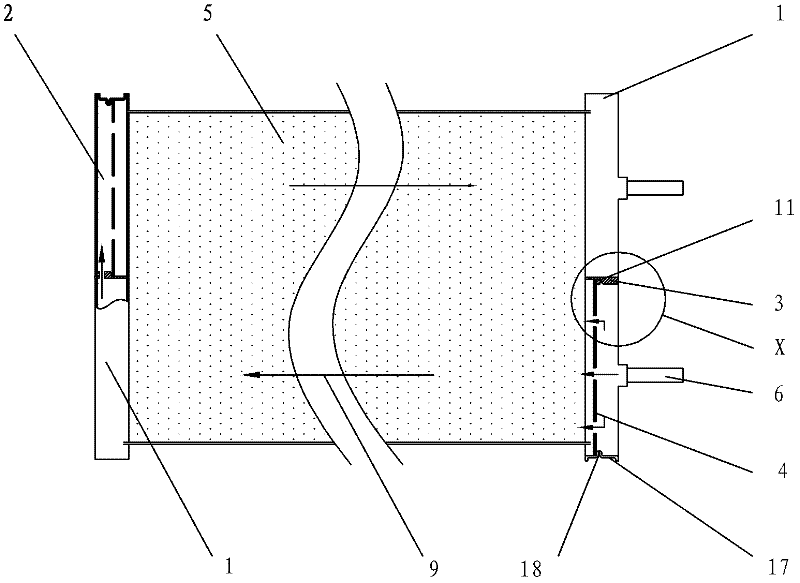

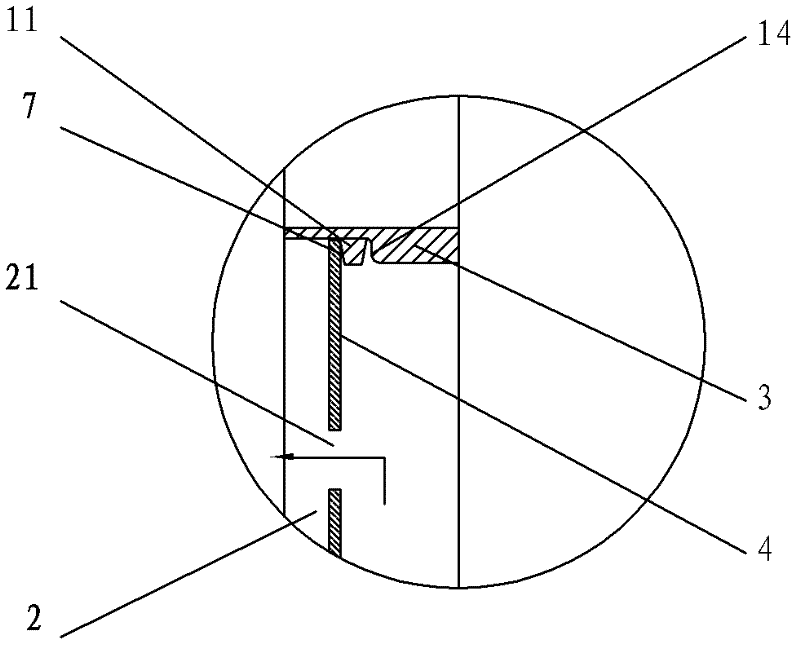

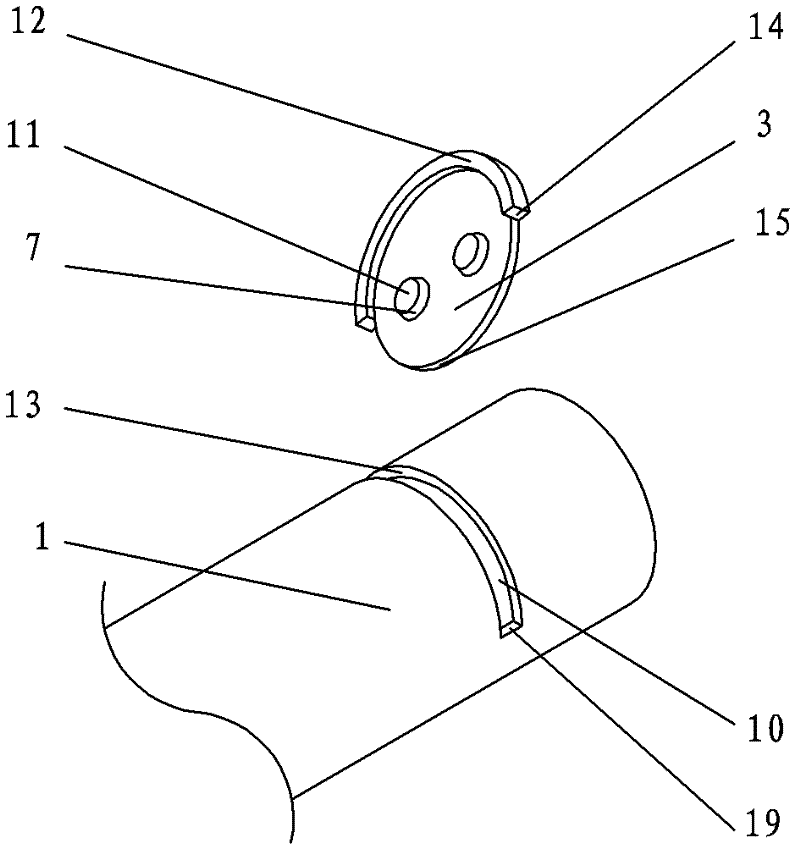

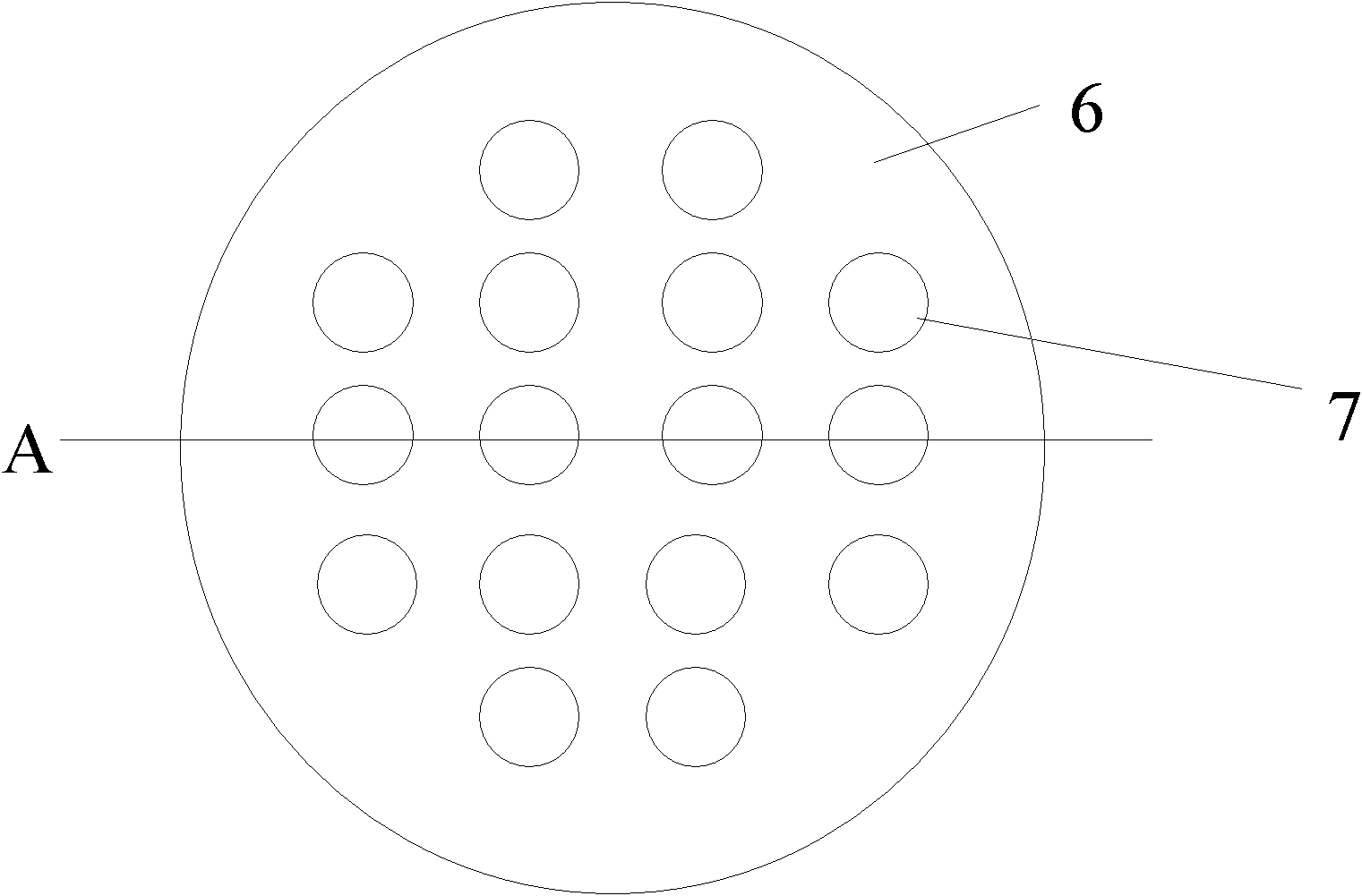

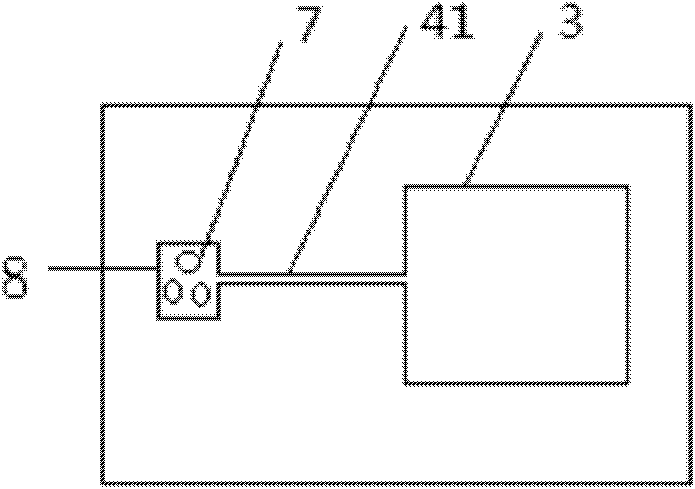

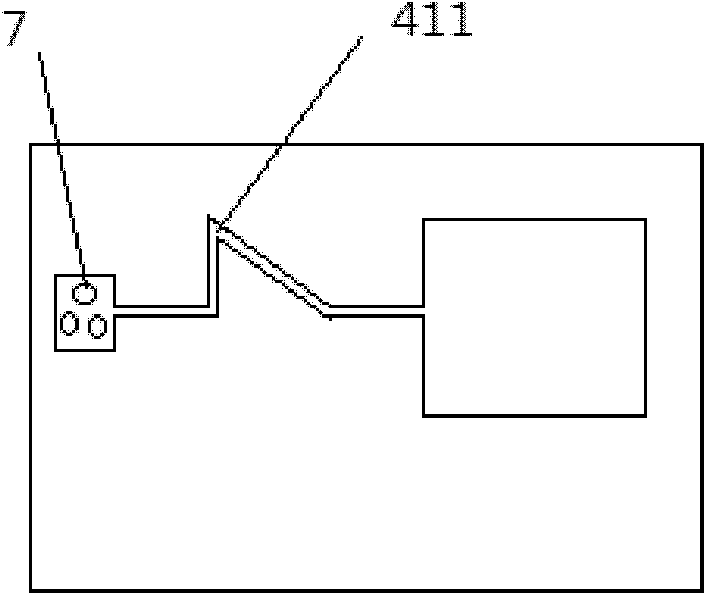

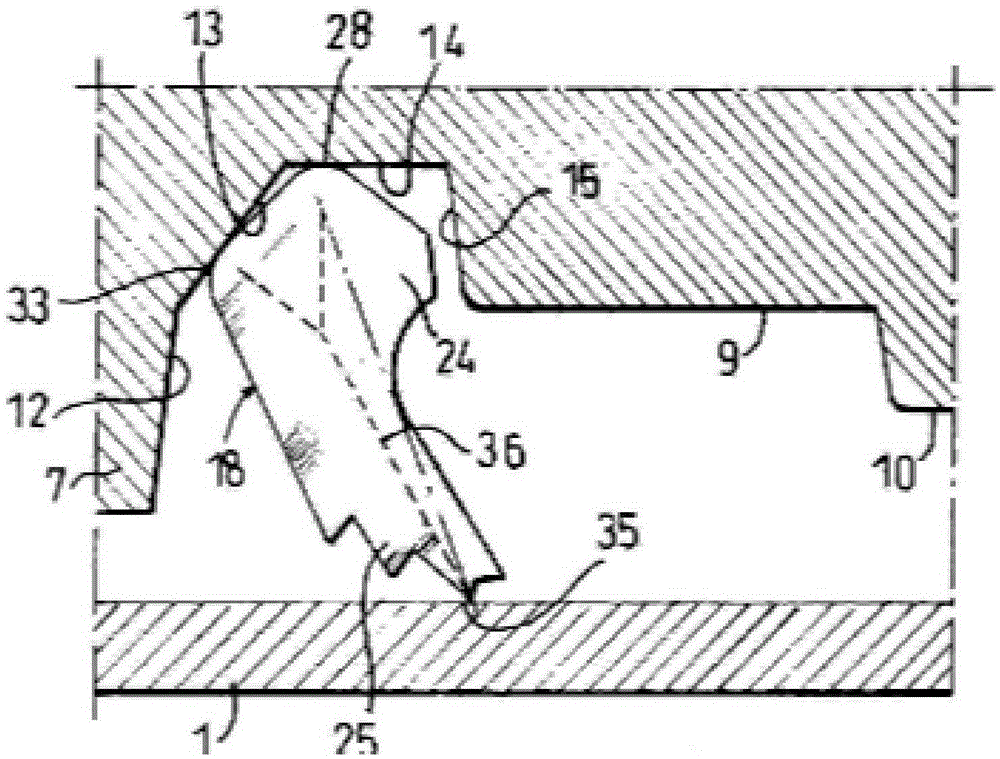

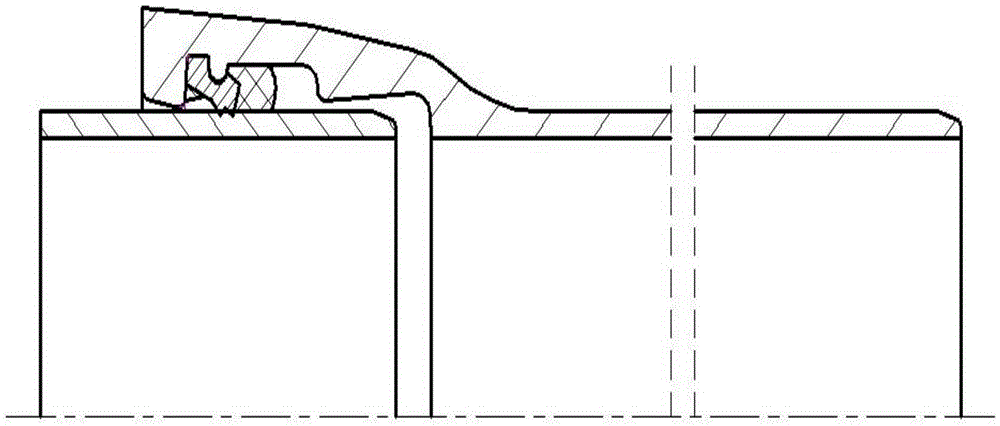

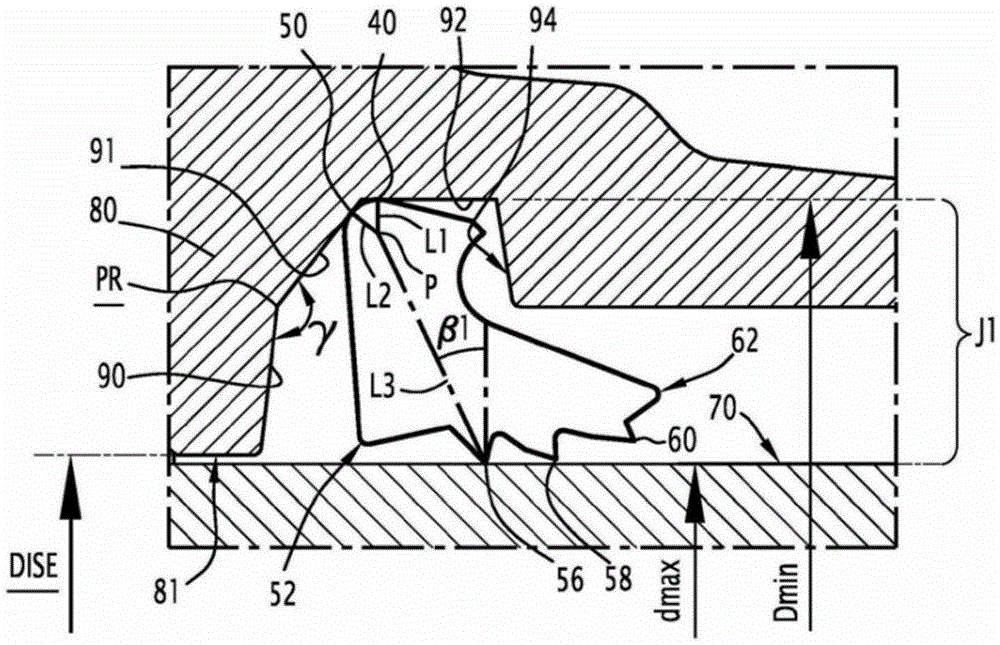

Prefilled syringe

ActiveCN102821803APrevent disengagementWill not deformInfusion syringesIntravenous devicesPrefilled SyringeBiomedical engineering

A gasket (3) for a prefilled syringe (1) comprises a gasket body (6) and a member (7) which is adapted for mounting on the plunger. The gasket body (6) has formed on the inner surface thereof a rib (62) for retaining the member for mounting on the plunger. The member for mounting on the plunger is provided with: an outer surface protrusion section (73) engaging with the rib (62) of the gasket body (6), the rib (62) retaining the member for mounting on the plunger; elastically deformable inside protrusion sections (75) extending obliquely, from an inner section on the rear end side of the member (7) for mounting on the plunger, in the direction toward the center of the member (7); and plunger retaining engagement sections (76) respectively formed at the free ends of the inside protrusion sections. The plunger (4) is provided with: a tubular front end section (42) capable of entering the inside of the member (7) for mounting on the plunger; and an outer surface protrusion section (43) engaging with the plunger retaining engagement sections of the member (7) for mounting on the plunger.

Owner:TERUMO KK

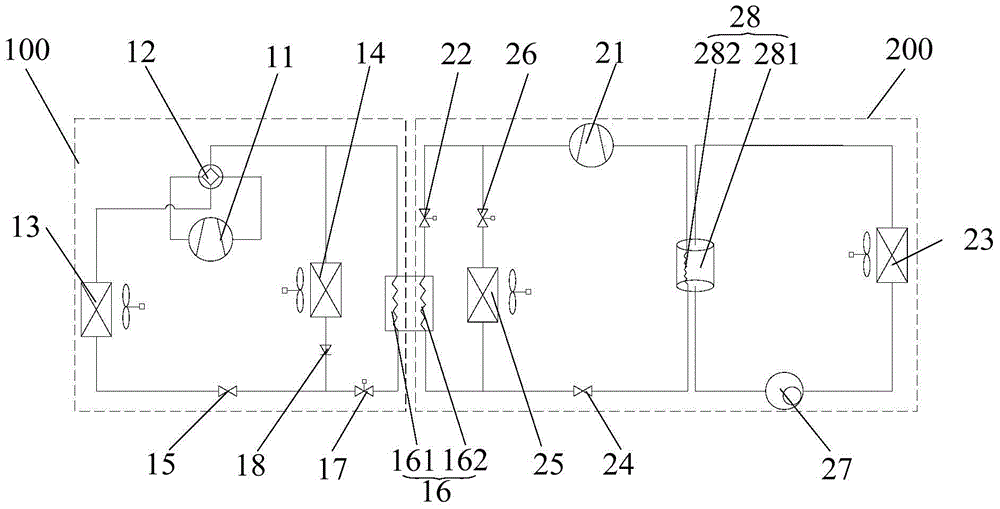

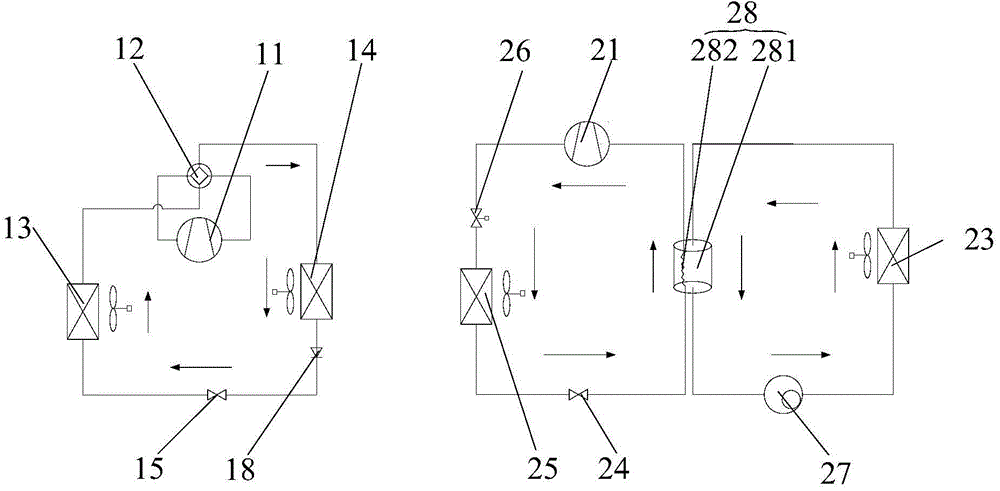

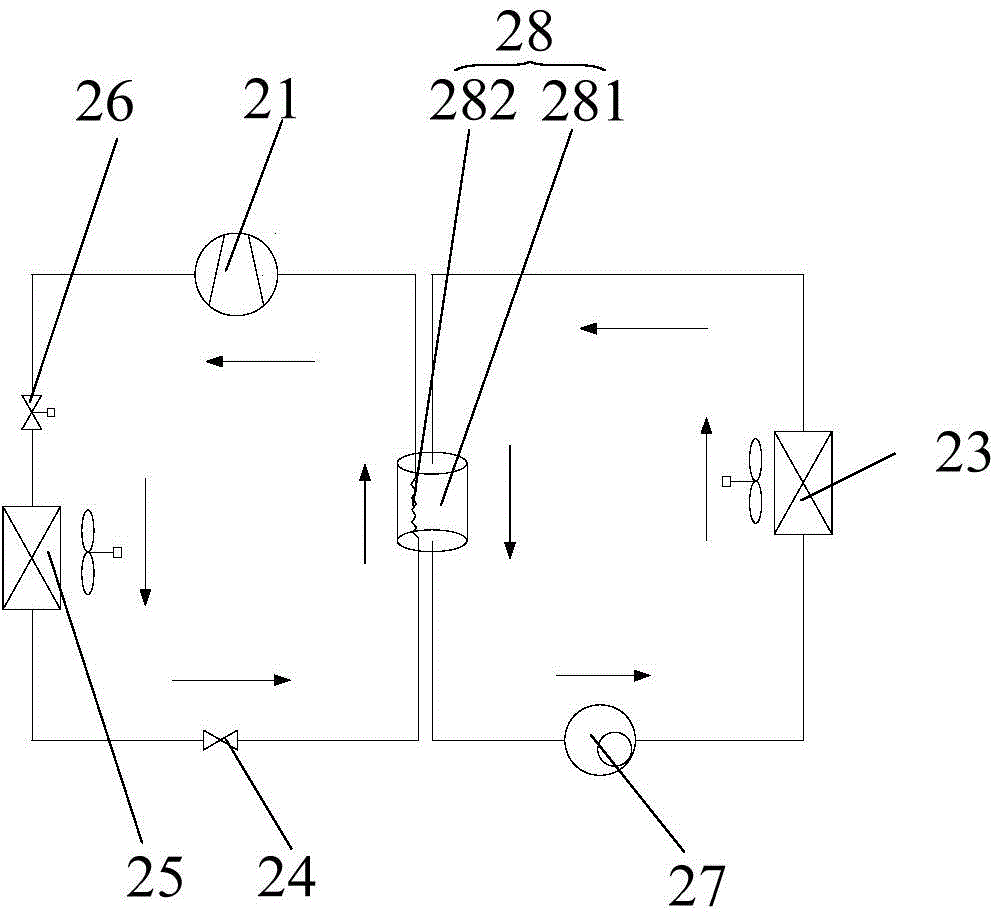

Combined air-conditioning system

ActiveCN104964371AImprove reliabilityImprove heat transfer uniformityEnergy recovery in ventilation and heatingMechanical apparatusFrostTransfer procedure

The invention provides a combined air-conditioning system, comprising a room air-conditioning system and a machine room air-conditioning system connected with the room air-conditioning system. A heat transferring medium in the room air-conditioning system can perform heat exchange with a heat transferring medium in the machine room air-conditioning system. A control device controls on-off of a bypass-valve, a main valve body, and an auxiliary valve body according to operating mode of the room air-conditioning system, so as to change flowing paths of the heat transferring medium in the air-conditioning system. Thus, on the basis of ensuring stable operation of the machine room air-conditioning system, the room air-conditioning system can fully recycle and use heat exhausted by the machine room air-conditioning system in an operation process, preventing conditions in the prior art that an outdoor heat exchanger frosts and heating efficiency is low caused by using outdoor environment temperature. A liquid pump, an evaporator, and a heat exchange reservoir form a cold-carrying circulation loop, and reliability of long distance heat transport of the machine room air-conditioning system is improved.

Owner:GD MIDEA HEATING & VENTILATING EQUIP CO LTD +1

Water purifier

ActiveCN105521652AReduce installationReduce disassembly stepsTreatment involving filtrationFiltration separationWater leakageLocking mechanism

The invention provides a water purifier. The water purifier comprises a filter bottle mechanism, a rotating seat mechanism and a mounting seat mechanism, and the rotating seat mechanism is arranged on the mounting seat mechanism in a rotating manner; the rotating seat mechanism is provided with a connecting position used for connecting or dismounting the filter bottle mechanism and a positioning position corresponding the position of the filter bottle mechanism in a working state; the water purifier also comprises a locking mechanism used for locking the filter bottle mechanism in the position in the working state; and the connecting end of the filter bottle mechanism is plugged in the filter bottle cap of the rotating seat mechanism in a fit manner, and a sealing ring is arranged between the connecting end and the filter bottle cap to make the connecting end compact the sealing ring through the end surface when the filter bottle mechanism rotates to the position in the working state. The water purifier has the advantages of saving of labor consumed in the mounting and dismounting process, and difficult water leakage.

Owner:魏斯瓦瑟环境技术(嘉兴)有限公司

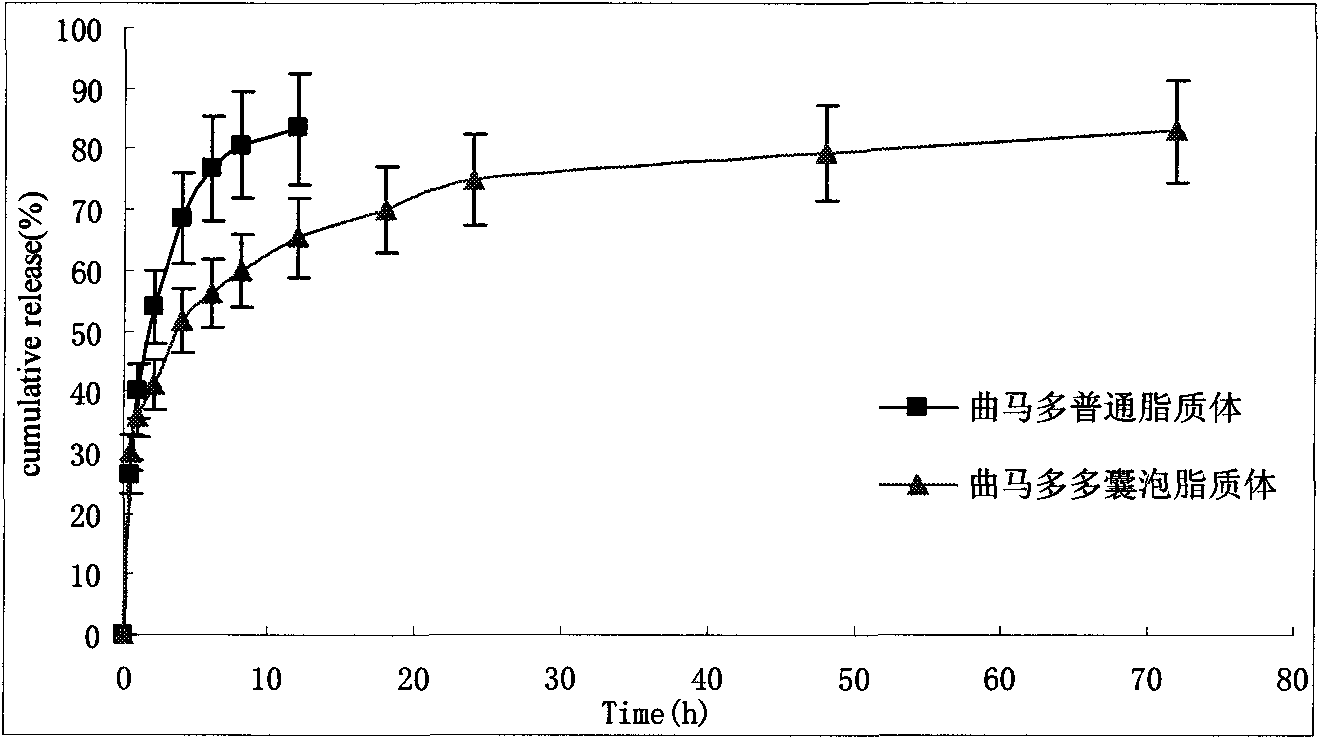

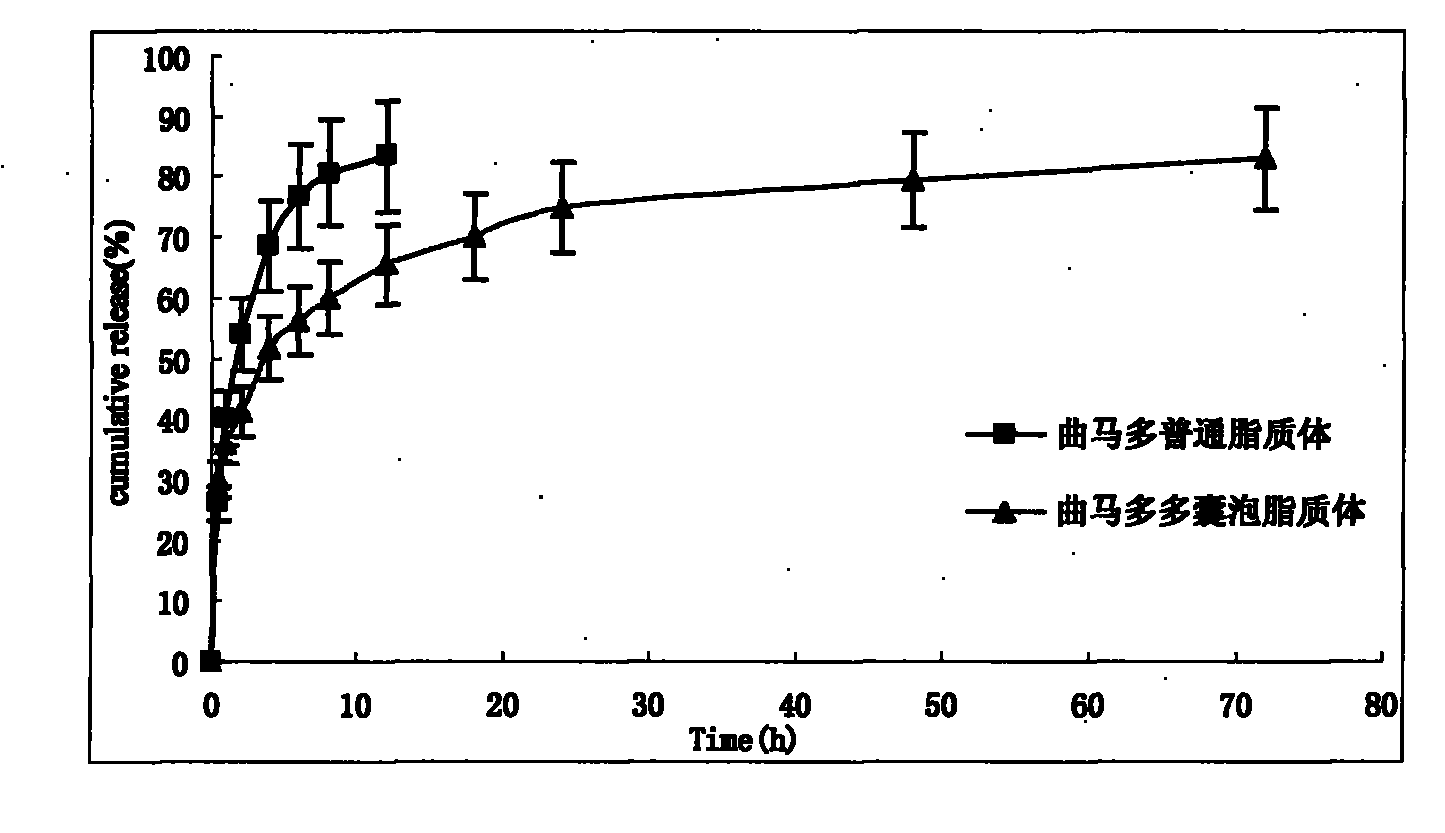

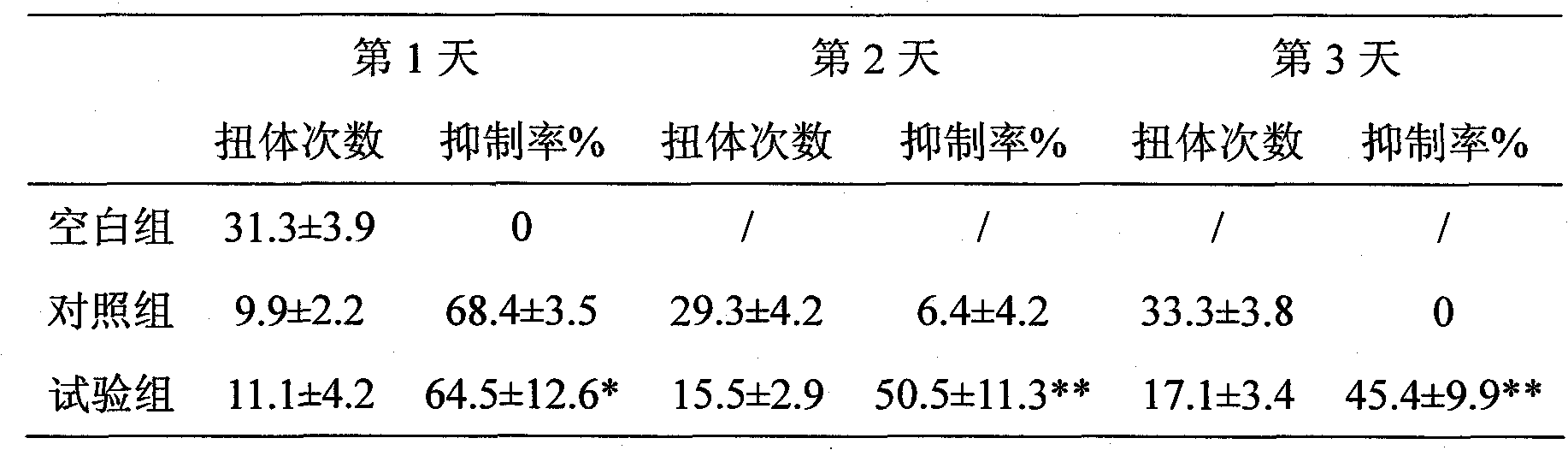

Tramadol multivesicular liposome and preparation method thereof

InactiveCN101780039AFirmly connectedHigh encapsulation efficiencyOrganic active ingredientsNervous disorderCholesterolNitrogen gas

The invention discloses a tramadol multivesicular liposome and a preparation method thereof. The preparation method comprises the following steps of: 1, dissolving phospholipids, cholesterol and neutral lipids into organic solvents to obtain a mixture which serves as an organic phase; 2, preparing 10 to 500mmol / L tramadol solution which serves as an internal water phase; 3, adding the internal water phase with the same volume as that of an organic phase into the organic phase, and mixing and emulsifying the mixture to obtain water-in-oil primary emulsion; 4, preparing an external water phase containing amino acid and osmotic modulators and / or surfactants, and adding the external water phase of which the volume is 2 to 10 times that of the water-in-oil primary emulsion into the water-in-oil primary emulsion, stirring the mixture to form oil-in-water type double emulsion; 5, adding the emulsion into the solution of the amino acid, introducing nitrogen or carbon dioxide into the mixed solution to remove the organic solvent from the emulsion to obtain suspension; 6, dissolving the suspension into the solution of amino acid, centrifuging and taking lower liposome suspension to obtain the tramadol multivesicular liposome. The prepared tramadol multivesicular liposome has the advantages of higher encapsulation efficiency, good slow release effect, and longer analgesic effect.

Owner:NANJING HAILING TRADITIONAL CHINESE MEDICINE RES CO LTD +2

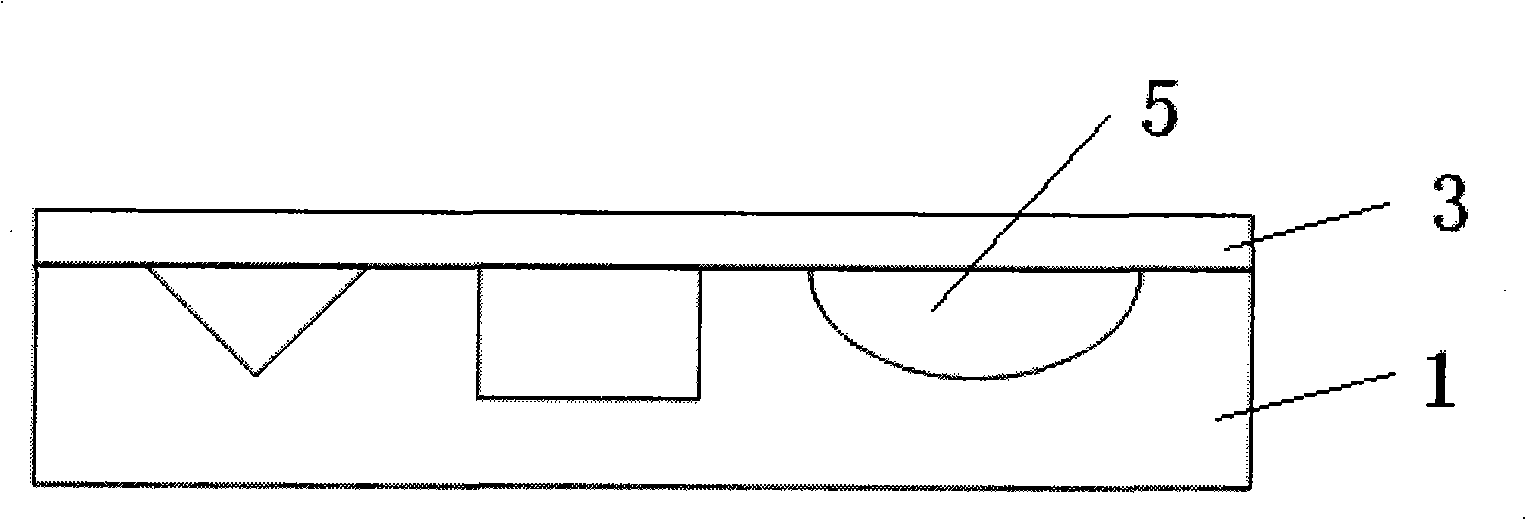

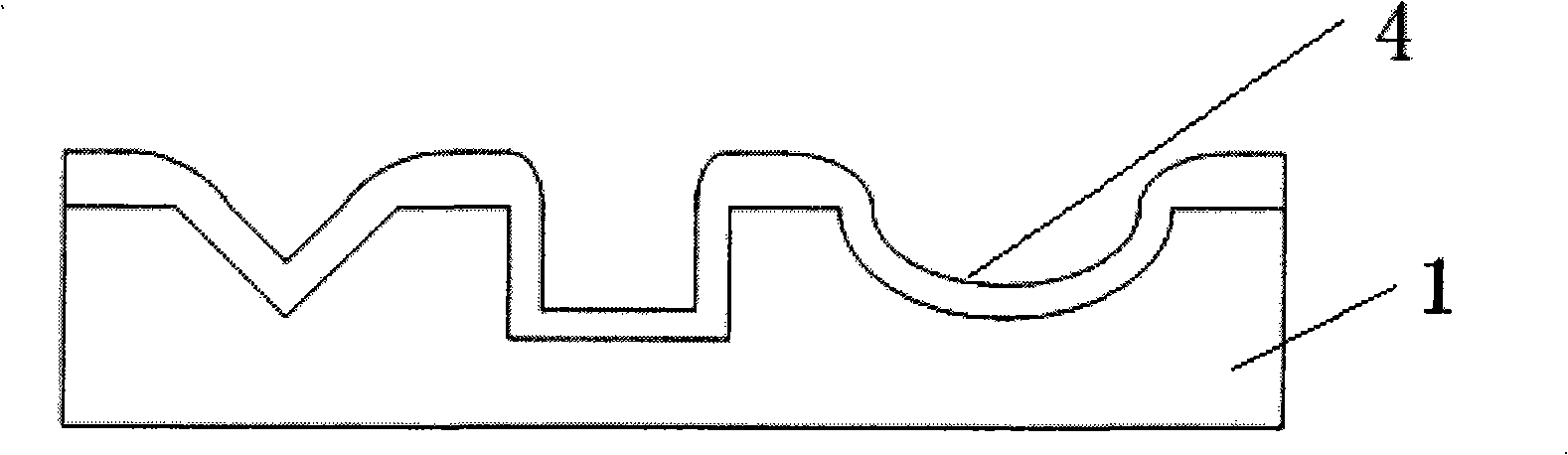

Method for manufacturing wafer-stage glass micro-cavity

InactiveCN101259951AReduce roughnessHigh bonding strengthPrecision positioning equipmentSoldering apparatusMetallurgyMachining process

The invention provides a fabrication method for a wafer-class glass micro-chamber, comprising the steps as follows: a first step: a special pattern is etched on a Si wafer to form a special pattern by a Si micro-machining process; a second step: the Si wafer and a Pyrex7740 glass wafer are bonded to each other under the atmosphere of less than 1Pa, thus leading the special pattern on the Pyrex7740 glass to form a sealing chamber body; a third step: the bonded wafers are heated to 810 to 890 DEG C under one atmosphere and the temperature is kept, the pressure different inside and outside the chamber leads the softened glass to form a structure corresponding to the micro-chamber pattern structure which is then cooled, and the wafer is annealed to eliminate the stress under normal pressure. The fabrication method of the wafer-class glass micro-chamber has the characteristics of simple process, precise forming, high depth-width-ratio of micro-chamber transmission, good surface characteristic of the micro-chamber, etc., can be widely applied to the fabrication of glass micro-chamber in an MEMS (micro-electron mechanical system), and belongs to wafer-class MEME fabrication process.

Owner:SOUTHEAST UNIV

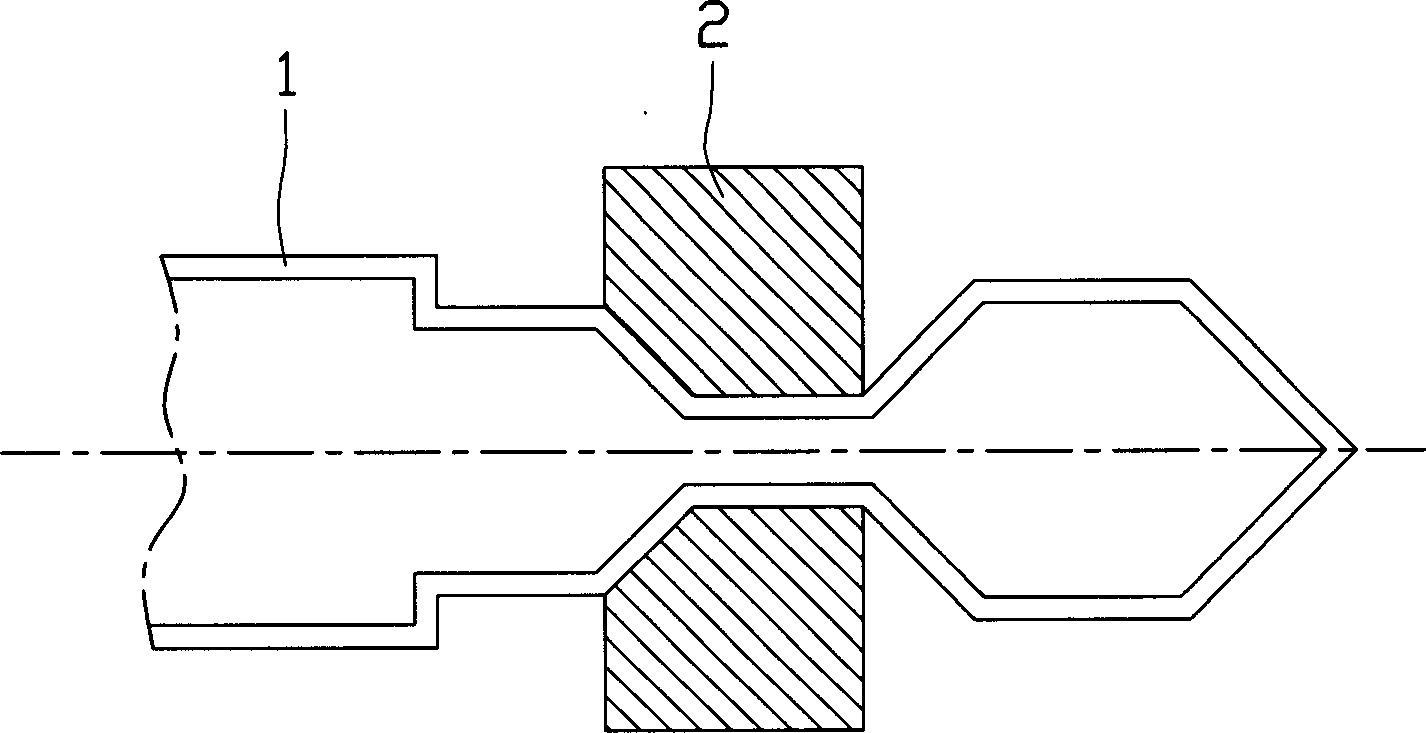

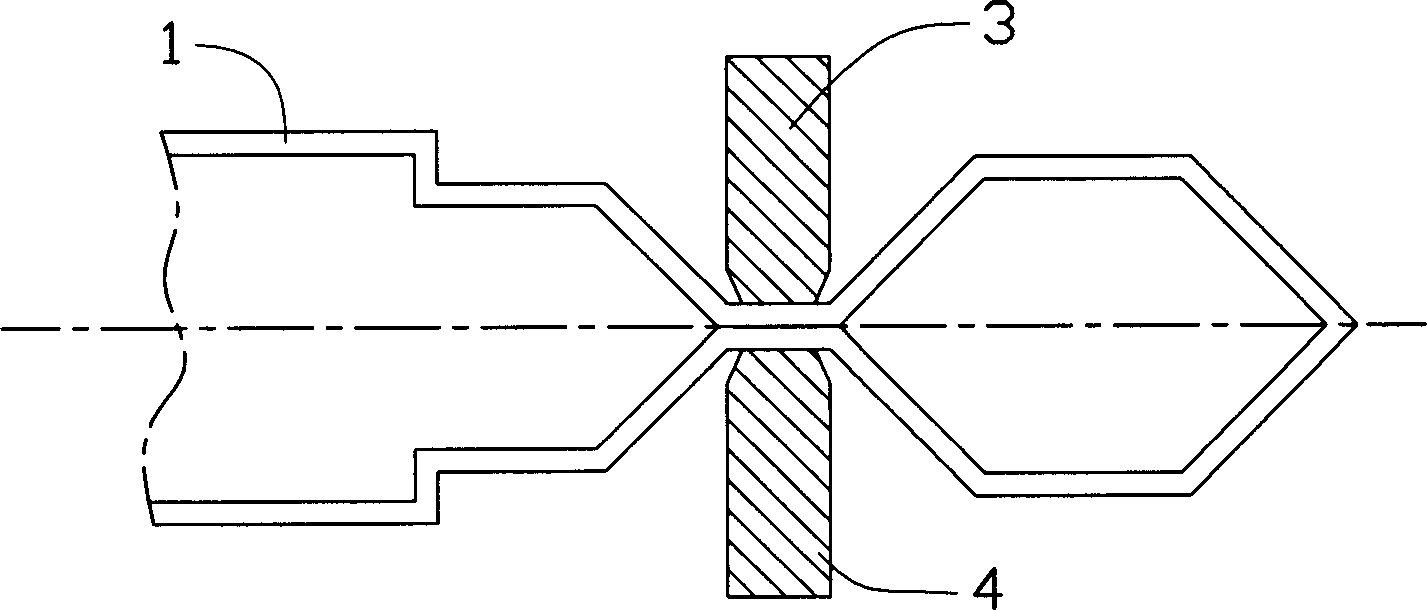

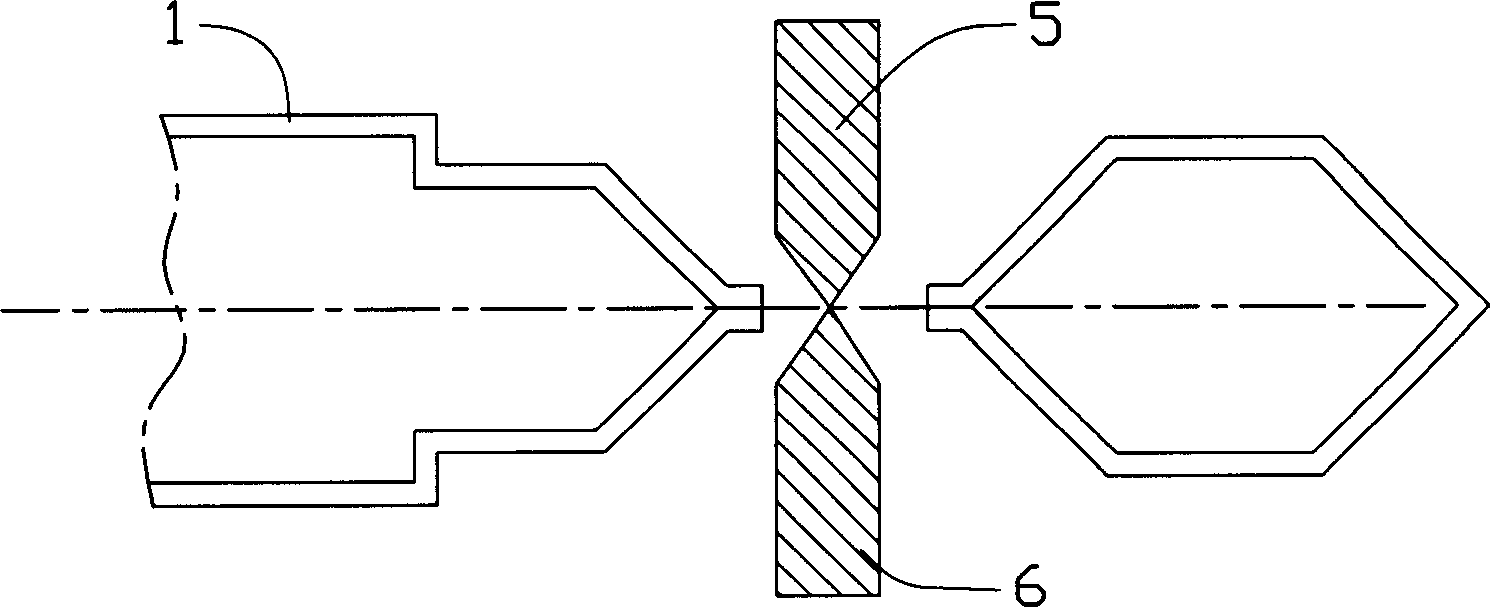

Parallel-flow heat exchanger and fabrication method thereof

ActiveCN102519180AStable heat transfer performanceImprove quality stabilityEvaporators/condensersEngineeringEqualization

The invention relates to a parallel-flow heat exchanger and a fabrication method thereof. The parallel-flow heat exchanger comprises collecting pipes, a plurality of flat pipes arranged between the collecting pipes, and fins arranged between adjacent flat pipes. One end of a refrigerant pipe is connected with the collecting pipes in which flow equalization boards provided with flow equalization holes are arranged; a clapboard fixing groove is arranged on the collecting pipes; a fixed clapboard passes through the clapboard fixing groove; and a first crimping face of the fixed clapboard is crimped on the flow equalization boards. The clapboard fixing groove comprises a side wall and a stopping face; the fixed clapboard comprises a clapboard main body; a sealing lug boss matching with the surfaces of the collecting pipes is arranged on the clapboard main body; the sealing lug boss is in tight contact with the side wall and the stopping face; and the thickness L of the sealing lug boss is equal to the width of the clapboard fixing groove. The fixed clapboard further comprises a clapboard inner side which matches with the inner walls of the collecting pipes. The parallel-flow heat exchanger is simple and reasonable in structure, flexible in operation, low in fabrication cost, firm in connection, small in gap, little in leakage, good in stability and board in application range.

Owner:MIDEA GRP CO LTD

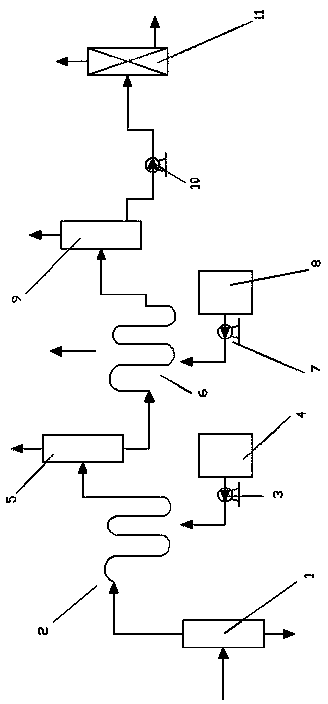

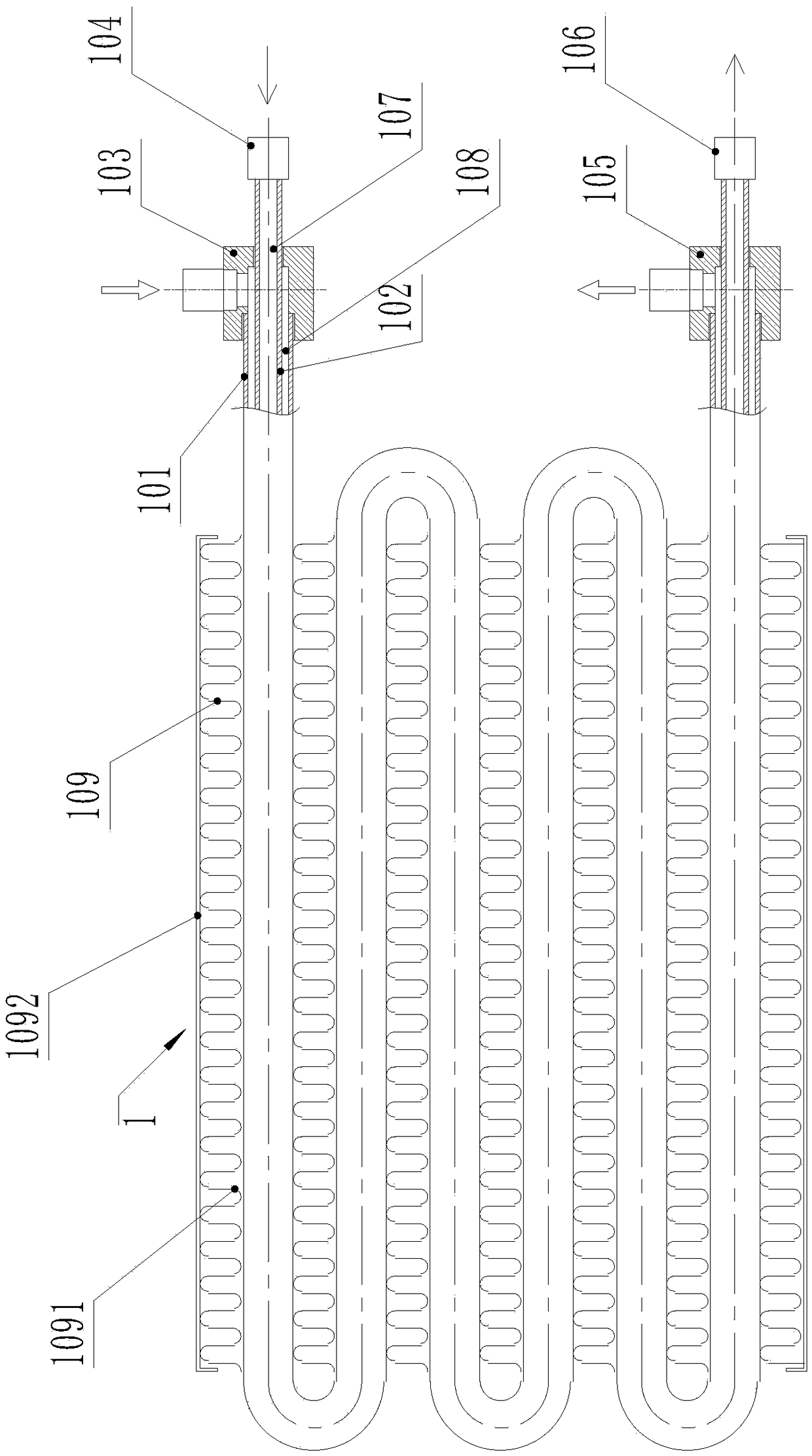

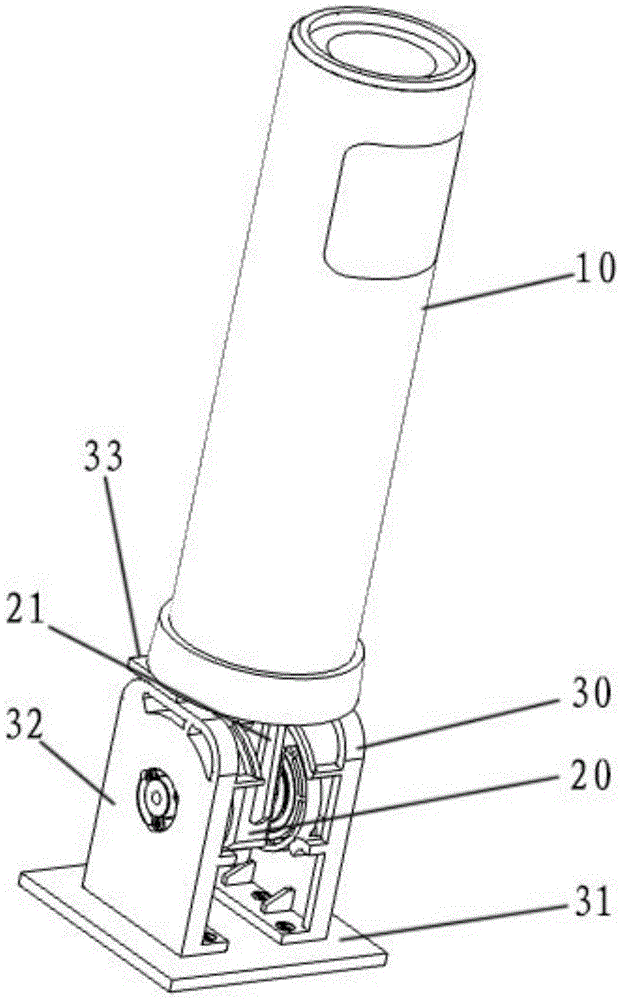

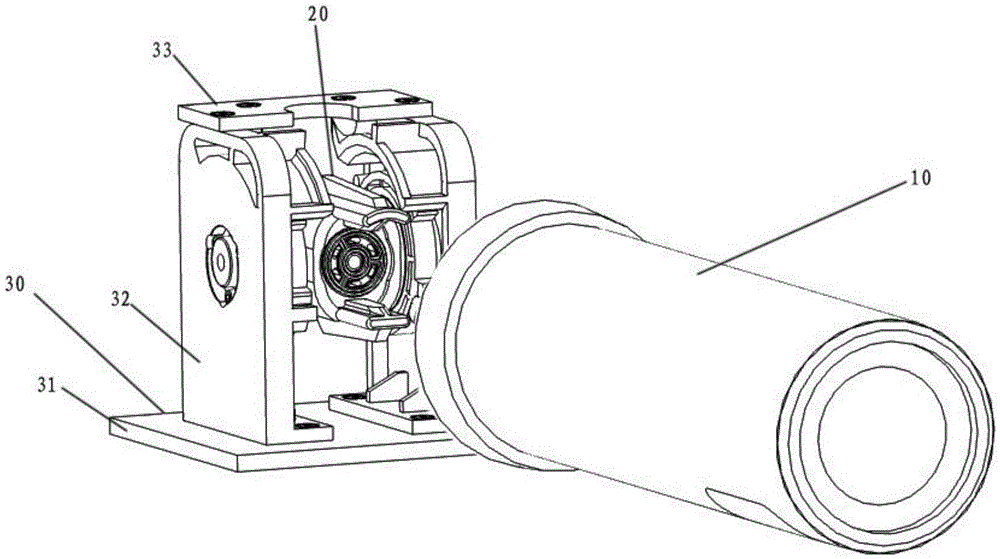

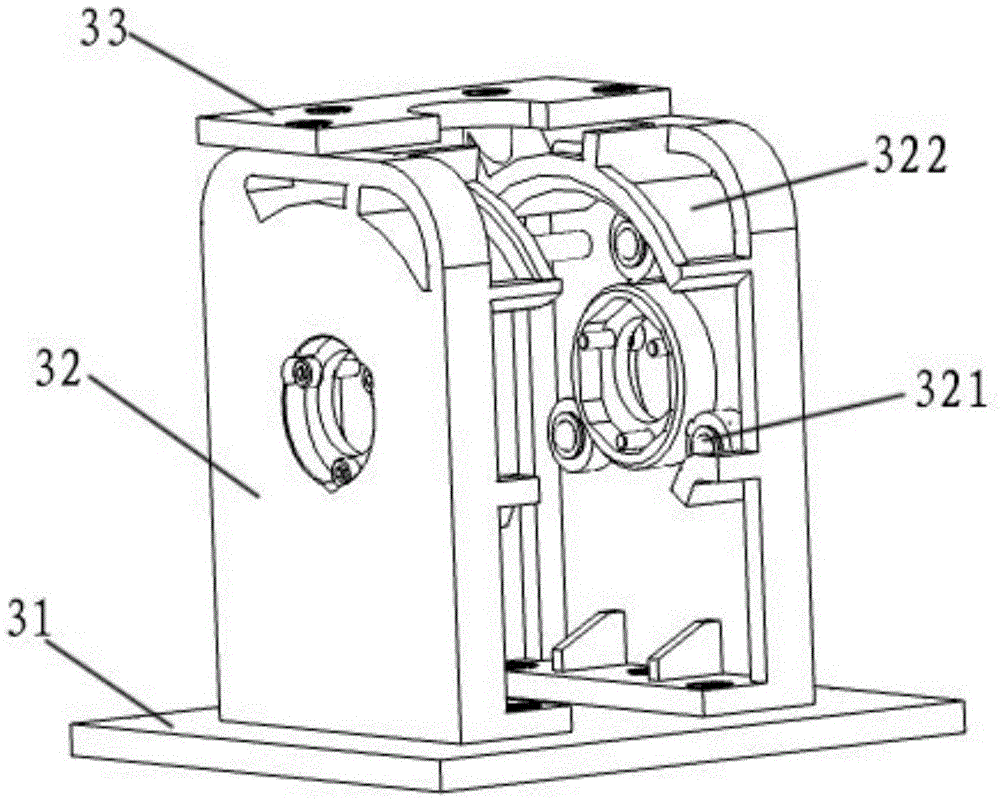

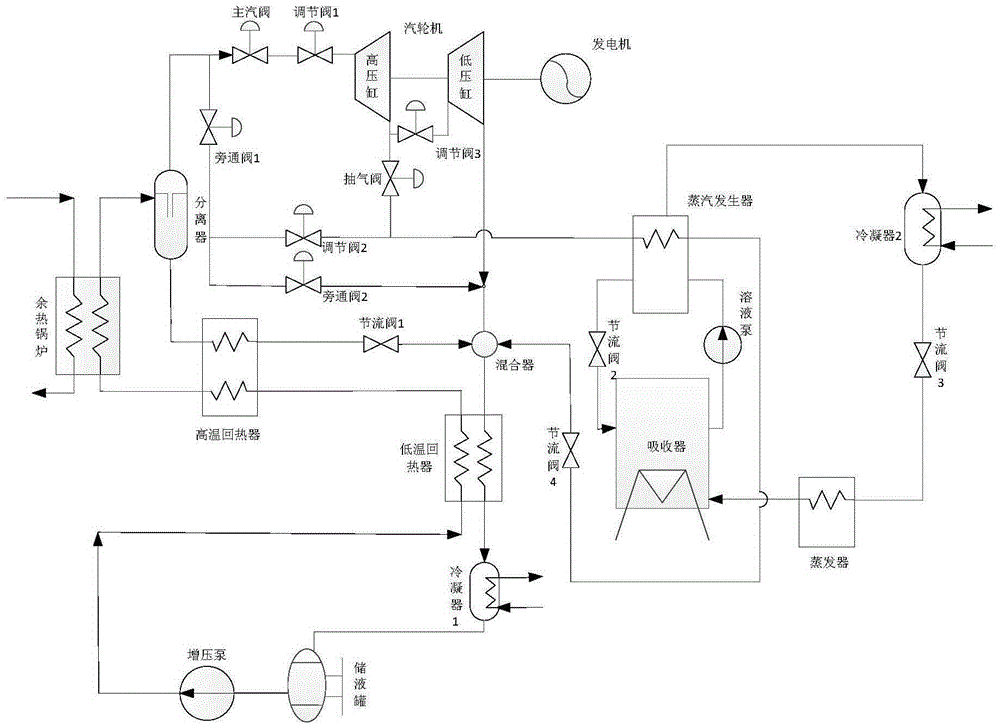

Combined cooling and power system and refrigeration, power generation and combined cooling and power method based on combined cooling and power system

InactiveCN105402926ALess likely to leakLow costClimate change adaptationEnergy efficient heating/coolingSolubilityEngineering

The invention relates to a combined cooling and power system and a refrigeration, power generation and combined cooling and power method based on the combined cooling and power system. According to the combined cooling and power system and the refrigeration, power generation and combined cooling and power method based on the combined cooling and power system, a low-grade heat source which cannot be effectively recycled in the industrial production process is used as a heat source, and power generation is achieved by heating non-azeotropic point mixing working media; in a refrigerating system, water is used as an absorbing agent, ammonia is used as a refrigerant, the refrigerant is absorbed by the absorbing agent under the low-temperature and low-pressure condition by means of the characteristic that the refrigerant has different solubilities in a solution at different temperatures, the refrigerant is evaporated from the solution under the high-temperature and high-pressure condition, and thus the purpose of circulating refrigeration is achieved. By adjusting the electric energy production and the refrigeration output, the adaptability of the combined cooling and power system to variable working conditions is improved, various actual production requirements are met, and the combined cooling and power system can be in a power generation mode, a refrigeration mode, a combined cooling and power mode and a combined cooling and power variable-working-condition mode. Adjustment of the electric energy production and the refrigeration output under different working condition requirements is achieved.

Owner:XI AN JIAOTONG UNIV

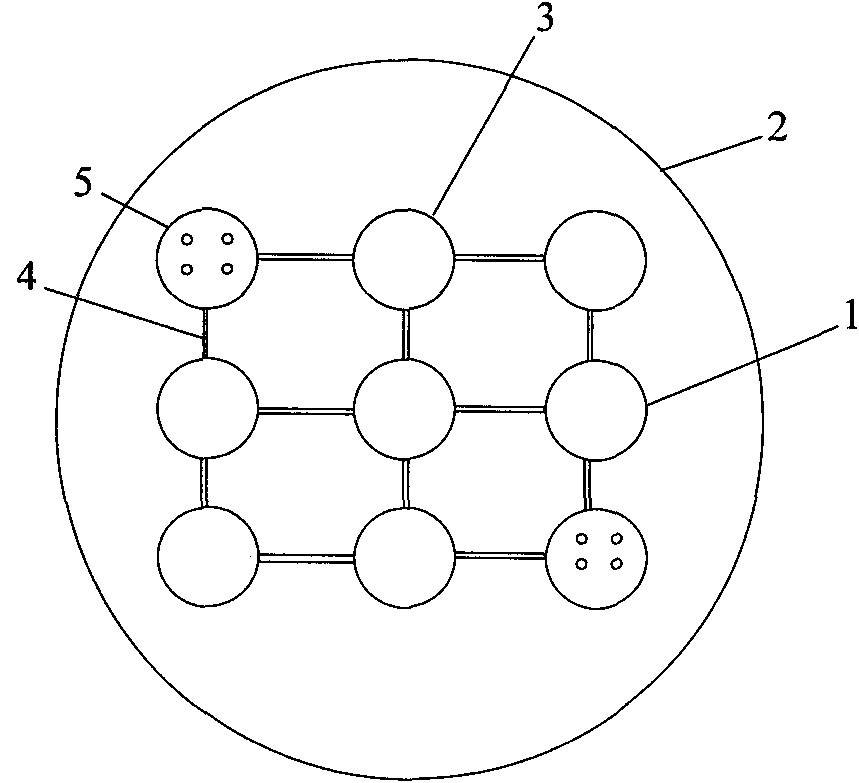

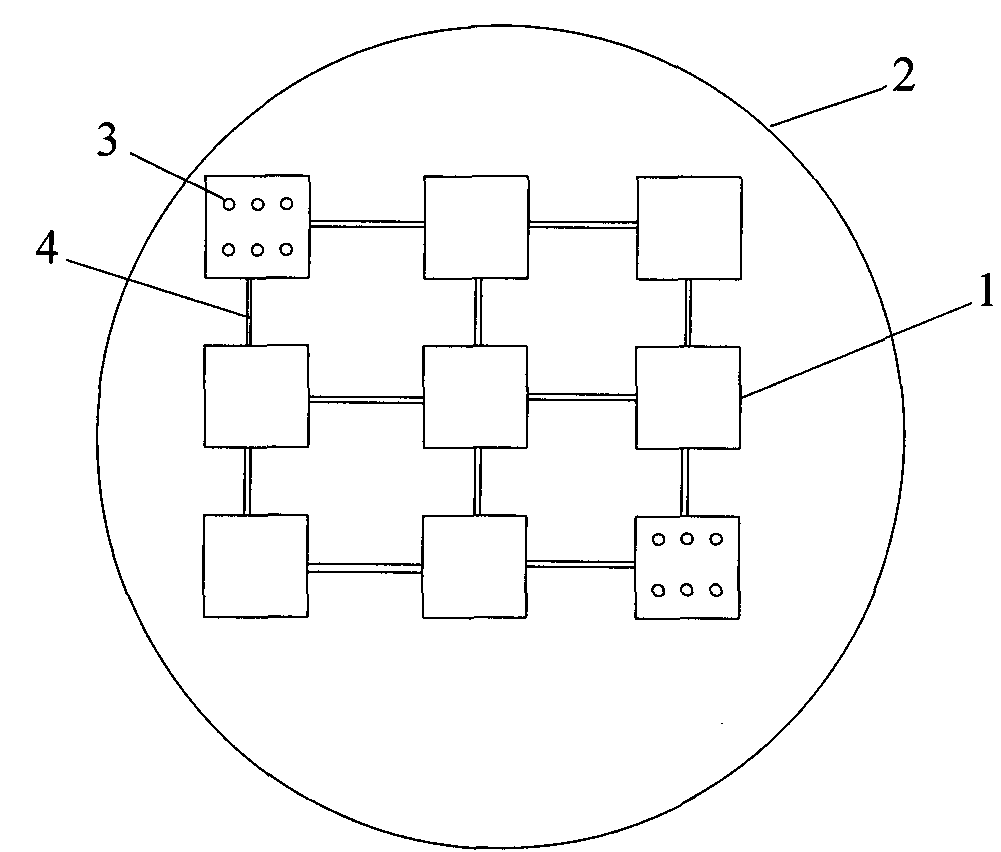

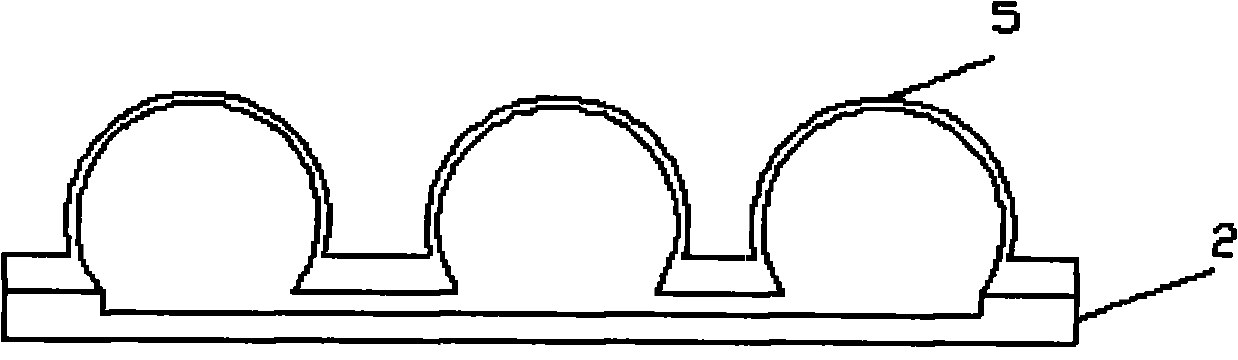

Method for packaging glass-silicon wafer-grade chiponboard (COB) of light emitting diode (LED)

ActiveCN102097545AReduce luminous attenuationImprove performanceSolid-state devicesSemiconductor devicesHeat resistanceSilica gel

The invention discloses a method for packaging a glass-silicon wafer-grade chiponboard (COB) of a light emitting diode (LED). The method comprises the following steps: 1, etching a silicon micro slot array with the micro slots communicated with each other through micro channels, and placing a proper amount of heat outgas agent in the micro slots; 2, performing anodic bonding on the Si wafer with patterns and the heat outgas agent and borosilicate glass wafer in air or in vacuum to form a sealed cavity; 3, heating and preserving heat to form a spherical glass micro cavity, cooling the cavity to normal temperature, annealing and removing silicon to obtain a wafer-grade glass micro cavity; 4, preparing a lead substrate; 5, mounting a chip and leading a wire; 6, carrying out wafer-grade bonding; and 7, filling silica gel to realize the wafer-grade packaging of the LED. By achieving the integration with the wafer-grade LED reflecting cup, the method reduces heat resistance and cost.

Owner:SOUTHEAST UNIV

High-efficiency water-absorbing composite core as well as sanitary towel and paper diaper with same

InactiveCN102715986AImprove absorption rateIncrease the speed of diffusionSanitary towelsBandagesPorositySurface layer

The invention relates to a structure used as the absorber of an absorbing product, particularly relates an absorbing structure used as the absorbing core or layer of a sanitary towel or paper diaper, and more particularly relates to a high-efficiency water-absorbing composite core. The composite core comprises a surface layer and a bottom layer which are made of fluff pulp or non-woven fabric; a layer of mixed materials is arranged between the surface layer and the bottom layer; the mixed materials comprise diatomite powder and borneol powder; the surface layer and the bottom layer are connected together by sewing thread; and the composite core is divided into a plurality of mesh structures by the sewing thread. Because the mixed materials comprise the diatomite powder and the borneol powder, and the diatomite powder is porous and has the high porosity of about 90% and strong water absorbing capacity, the speed of absorbing and diffusing the liquid of the composite core is increased. In addition, in the mesh structure, the composite core is not easy to cake, break or roll when being twisted.

Owner:重庆百亚卫生用品股份有限公司

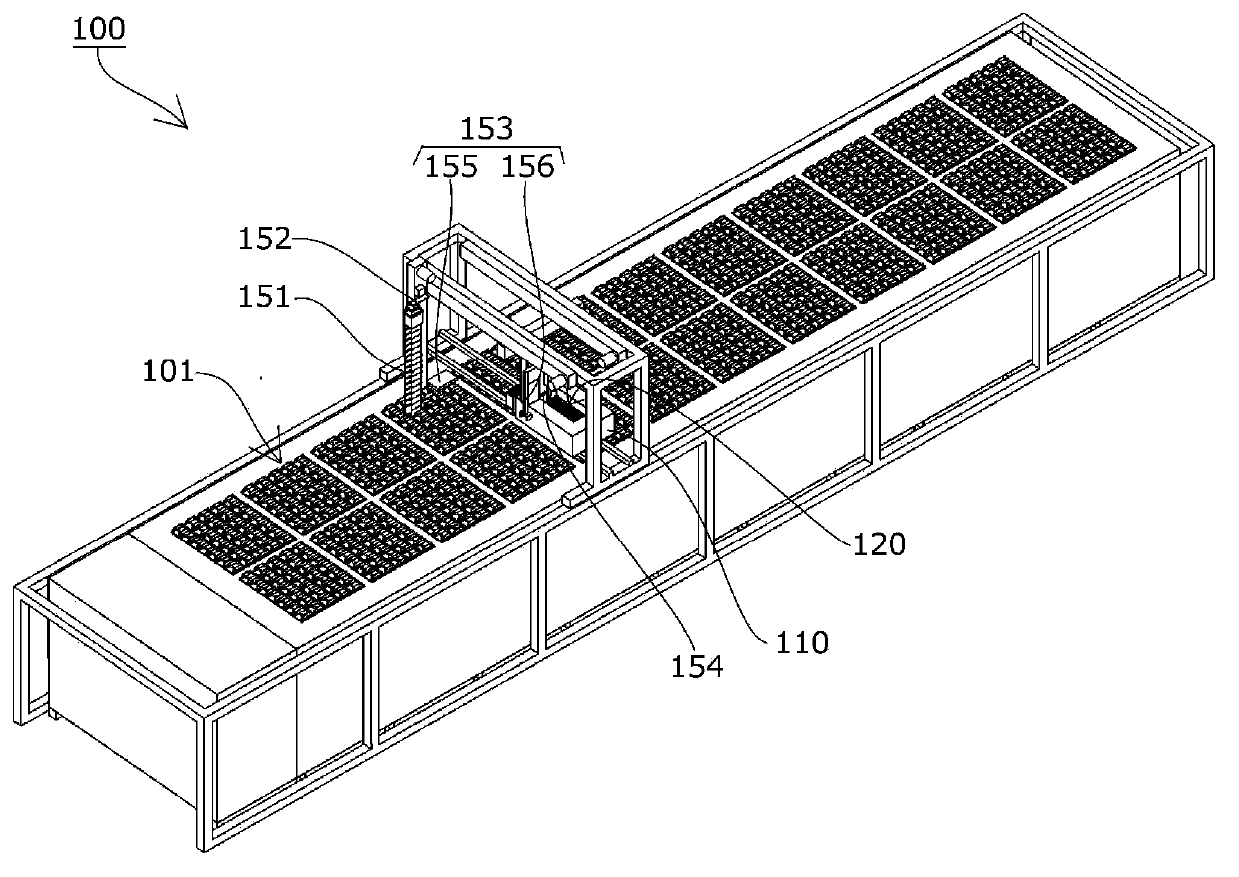

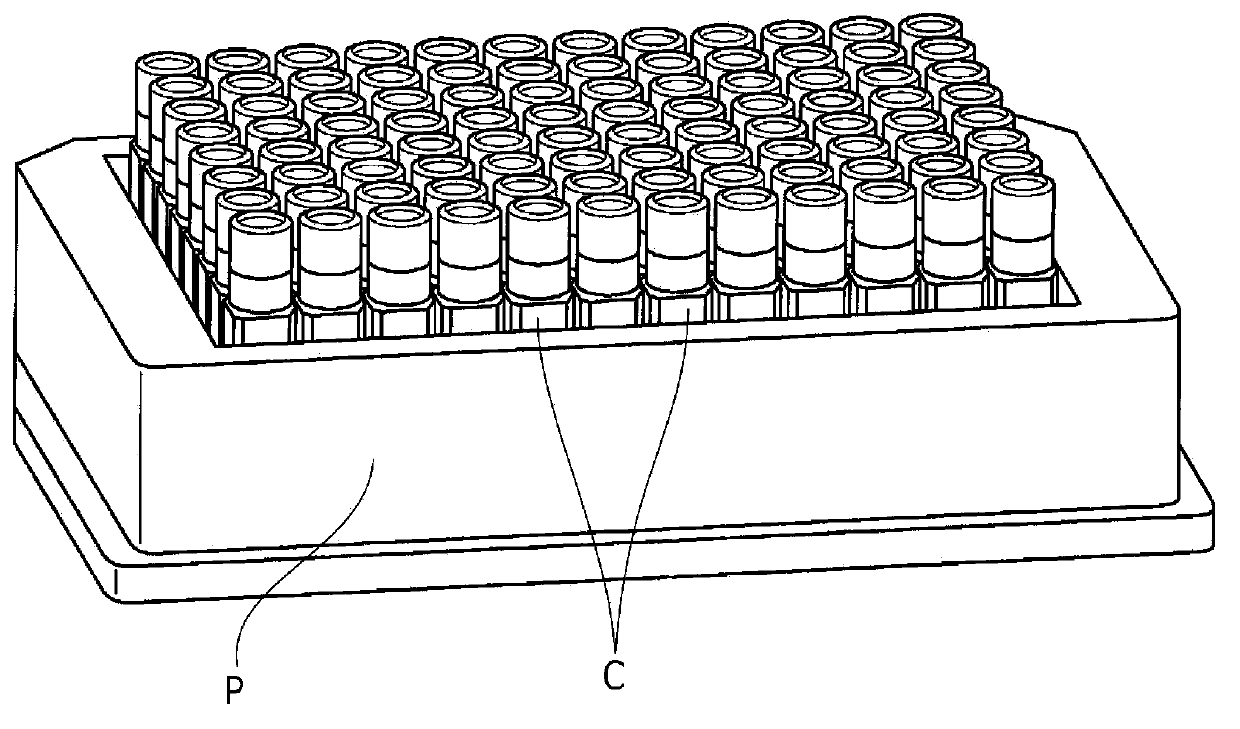

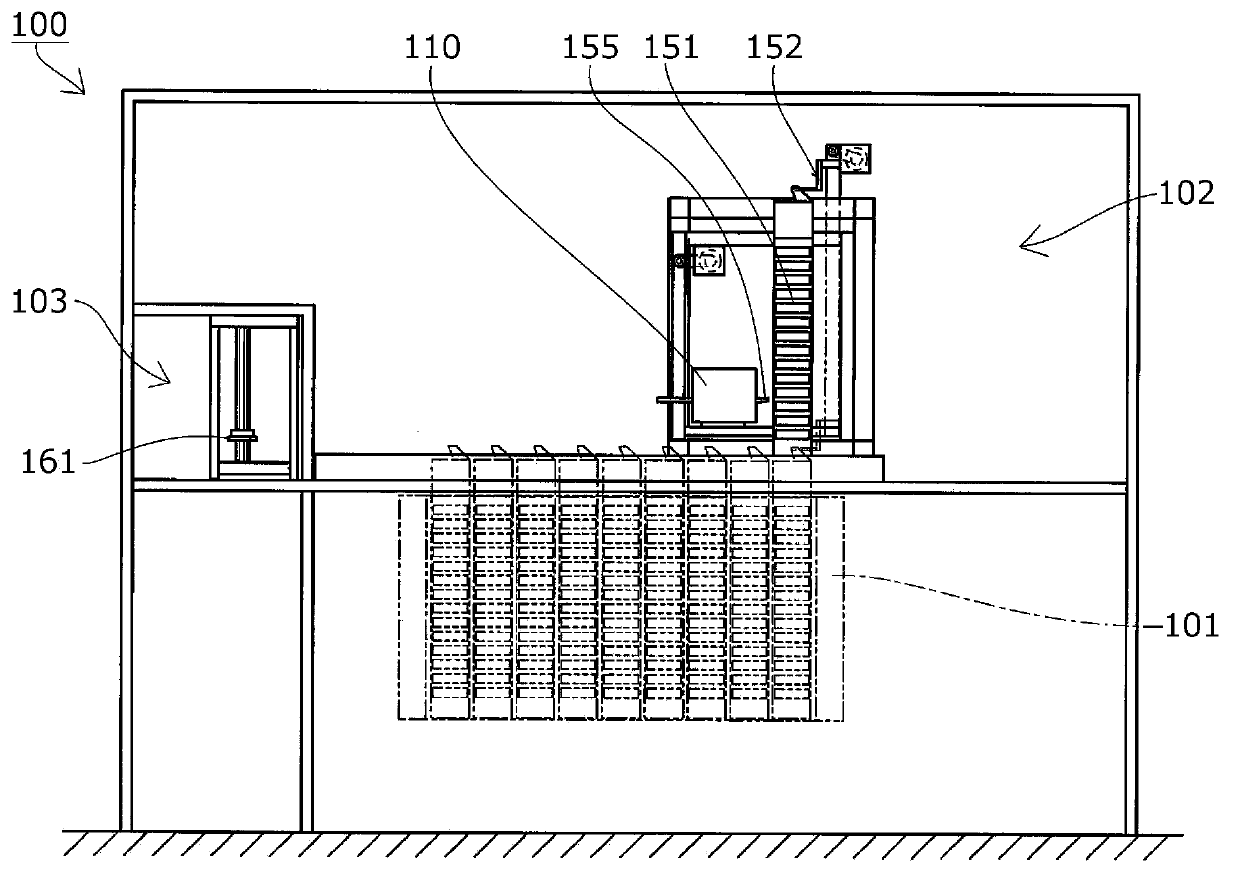

Low-temperature storage system

InactiveCN103964110AWork at high speedLow costPreparing sample for investigationStorage devicesMoisture condensationCoolant

The invention provides a low-temperature storage system, which does not cause a temperature rise of a container in extraction action, prevents deterioration of a sample in the container and moisture condensation on the container, does not require a special machine, and can work at high speed, and costs required by manufacture and use are reduced and the system is easy to use. Specifically, a low-temperature storage system (100) has a container housing unit (110) which formed in a manner of being movable in a space at an upper side of a lower-temperature storage chamber (101) where a plurality of containers (C) housing samples are stored, and the container housing unit (110) has a low-temperature housing groove (120), an upper opening, and housing containers (C), and a coolant tube (121) which cools the inside of the low-temperature housing groove (120).

Owner:TSUBAKIMOTO CHAIN CO +1

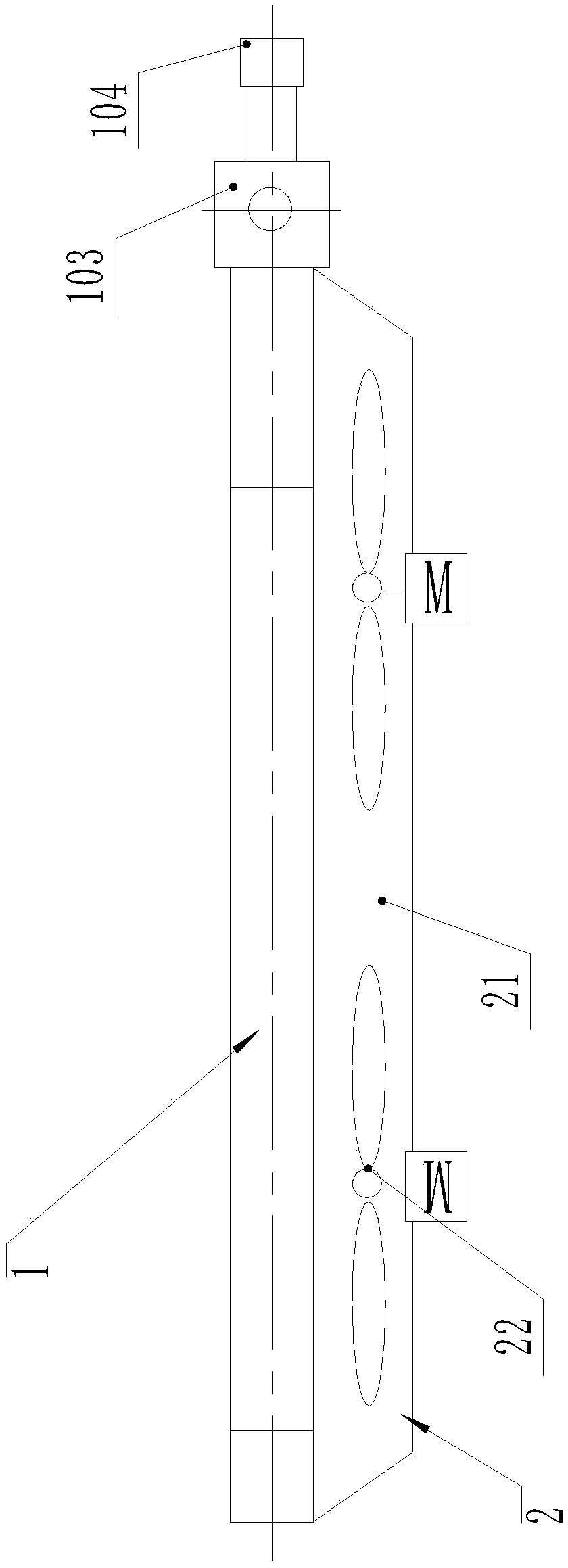

Microfluidic atom cavity, on-chip atomic clock chip and preparation method

InactiveCN102515084AAvoid enteringReduce performanceApparatus using atomic clocksDecorative surface effectsChemical physicsMicrofluidics

The invention discloses a microfluidic atom cavity, an on-chip atomic clock chip and a preparation method. The method includes steps: a silicon substrate with a microfluidic channel and a borosilicate glass assembly wafer with a glass microcavity structure corresponding to the microfluidic channel are bonded to form a closed system, the closed system comprises a glass atom cavity, a reactant partition microfluidic channel and a reactant microcavity, reactant particles of materials necessarily required by atomic clock generation are arranged in the reactant microcavity, the glass atom cavity is communicated with the reactant microcavity through the reactant partition microfluidic channel, the aperture of the reactant microcavity on a bonding surface is smaller than that of the glass atom cavity, the minimum width of the reactant partition microfluidic channel is no larger than the minimum particle diameter of the reactant particles, and the glass micro cavity is provided with a light incidence plane. The smaller microcavity containing the reactant powder is connected with the larger microcavity required by forming of the spherical glass microcavity, forming of a spherical rubidium steam cavity and sealing of gas can be completed at one step, fine sealing performance is achieved, no impurities can be led in, performance of an atomic clock can be improved, the spherical rubidium steam cavity can be integrated into a microchip-level atomic clock system, planar packaging of the atomic clock can be realized, and size of the atomic clock is reduced effectively.

Owner:SOUTHEAST UNIV

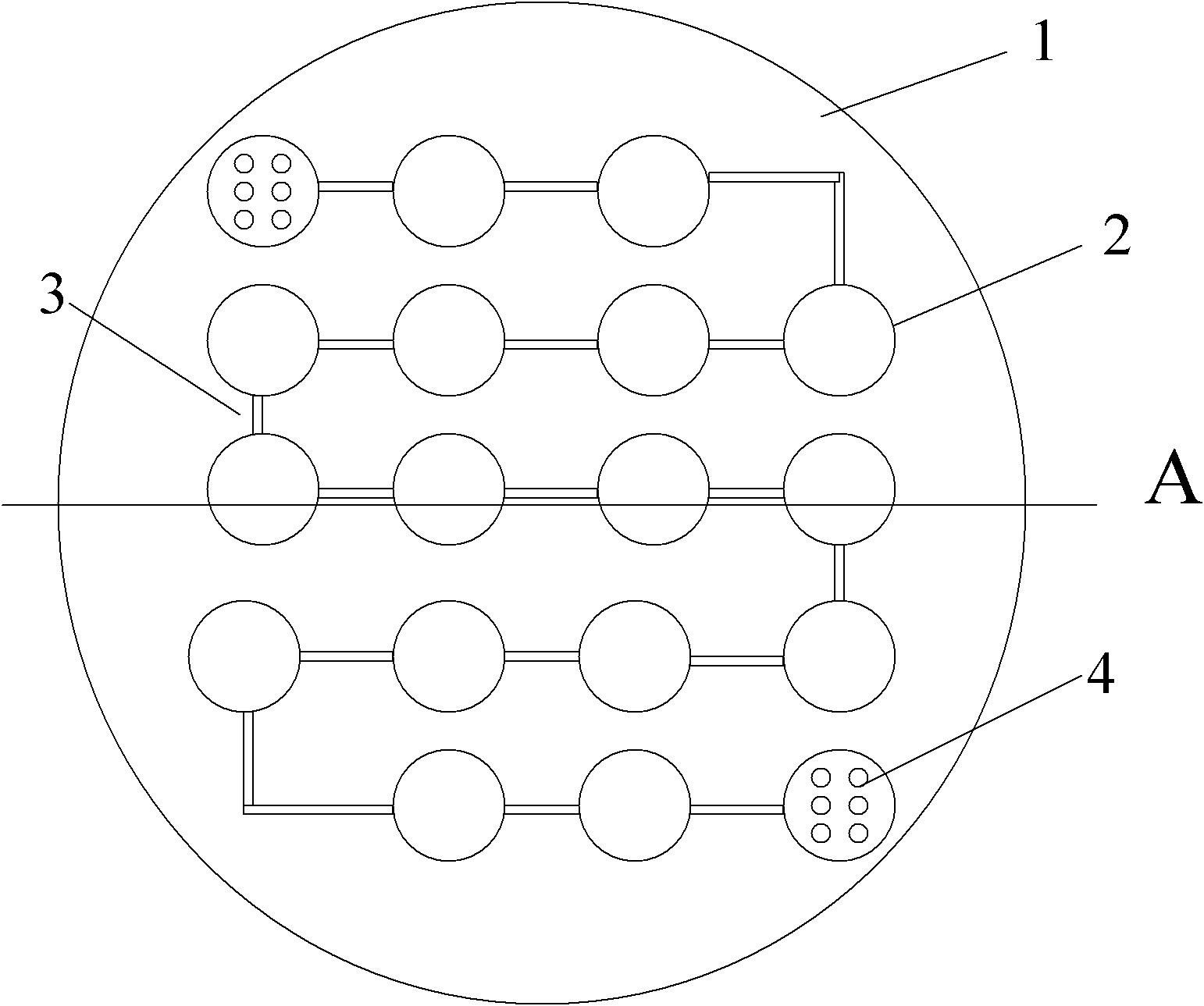

Pipe type membrane assembly coated with cascaded structure on inner wall

The invention discloses a pipe type membrane assembly coated with a cascaded structure on an inner wall, belonging to the technical field of membrane separation. The pipe type membrane assembly comprises a pipe shell, a set of pipe type membranes and two pairs of flanges, wherein the inner walls of the pipe type membranes are coated with separation layers; each pair of the flanges is composed of a fixed flange and a runner flange; each fixed flange is provided with through holes with section shapes, quantities and positions which correspond to those of the pipe type membranes; the runner flanges are provided with runner grooves; openings of the two pipe type membranes are formed in the runner grooves and are matched with the runner grooves so as to form the cascaded structure. Compared with the prior art, the pipe type membrane assembly has the advantages that small-batch online pervaporation dehydration can be realized; the contact area between organic solvent material liquid and the membrane assembly is large and the mobility of separated substances is good; the sealing performance, the temperature resistance and the solvent resistance are good; the dehydration efficiency is high and the time requirements on developing green economy are met.

Owner:宁波信远膜工业股份有限公司 +1

Socket and spigot type pipeline connector with anchoring structure

The invention relates to a socket and spigot type pipeline connector with an anchoring structure. The socket and spigot type pipeline connector with the anchoring structure is used for continuous nodular cast iron pipes. By means of the socket and spigot type pipeline connector, anchoring reliability can be improved, structural service life can be prolonged, pipeline maintaining cost can be reduced, optimization and simulation of the connector structure can be performed easily, and pipeline transporting capacity is improved. The socket and spigot type pipeline connector comprises a socket, a spigot and a sealing piece which is arranged between the socket and the spigot and used for sealing and locking the pipeline connector. The socket comprises an annular groove which is formed by sequentially connecting a first annular vertical wall, a conical wall, a cylindrical inner wall and a second annular vertical wall in a defined manner. The sealing piece comprises an elastic material ring and a plurality of anchoring pieces embedded in the elastic material ring. Each anchoring piece comprises a head and a plurality of meshing teeth. Each anchoring piece is provided with a rotating circle center. The portion, connected with the annular groove in an abutting manner, of each head is an arc supporting face. The abutting joint area of each arc supporting face and the annular groove is located on the joint of the first annular vertical wall and the conical wall.

Owner:XINXING DUCTILE IRON PIPES CO LTD

Method for preparing wafer-level uniform-dimension glass microcavity by positive pressure thermal forming

ActiveCN101905859ANot easy to expandLow costPrecision positioning equipmentSoldering apparatusPhysical chemistrySilicon

The invention discloses a method for preparing a wafer-level uniform-dimension glass microcavity by positive pressure thermal forming. The method comprises the following steps of: etching an array consisting of microgrooves on a silicon wafer, and etching microchannels connecting the microgrooves, wherein the minimum groove width of the microgrooves is 5 times more than the runner width; and putting a proper amount of thermal outgassing agent into at least one microgroove, correspondingly bonding the plurality of microgrooves to form a sealed cavity by using a glass wafer, heating to soften the glass, making the thermal outgassing agent heated to release gases to generate positive pressure, acting the positive pressure on the softened glass corresponding to the plurality of microgrooves which are connected through the microchannels so as to form a spherical microcavity with uniform dimension, and cooling the microcavity. By connecting the same microgrooves through the microchannel, the inside air pressure of the microgrooves is substantially consistent, and the formed glass microcavity has uniform dimension. When the dimension of the microgrooves is far greater than that of the microchannel, the microchannels with smaller radius hardly expand due to higher additional pressure. Therefore, the glass corresponding to the microchannels can keep smooth.

Owner:SOUTHEAST UNIV

Method for sealing heat pipe

A method for sealing a heat tube with one open end and one closed end features that said open end is radiated by the ionized light beam in inertial gas for activating it, and then squeezed by two pressing parts to become a sealed end. Its advantages are high strength and no leakage.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

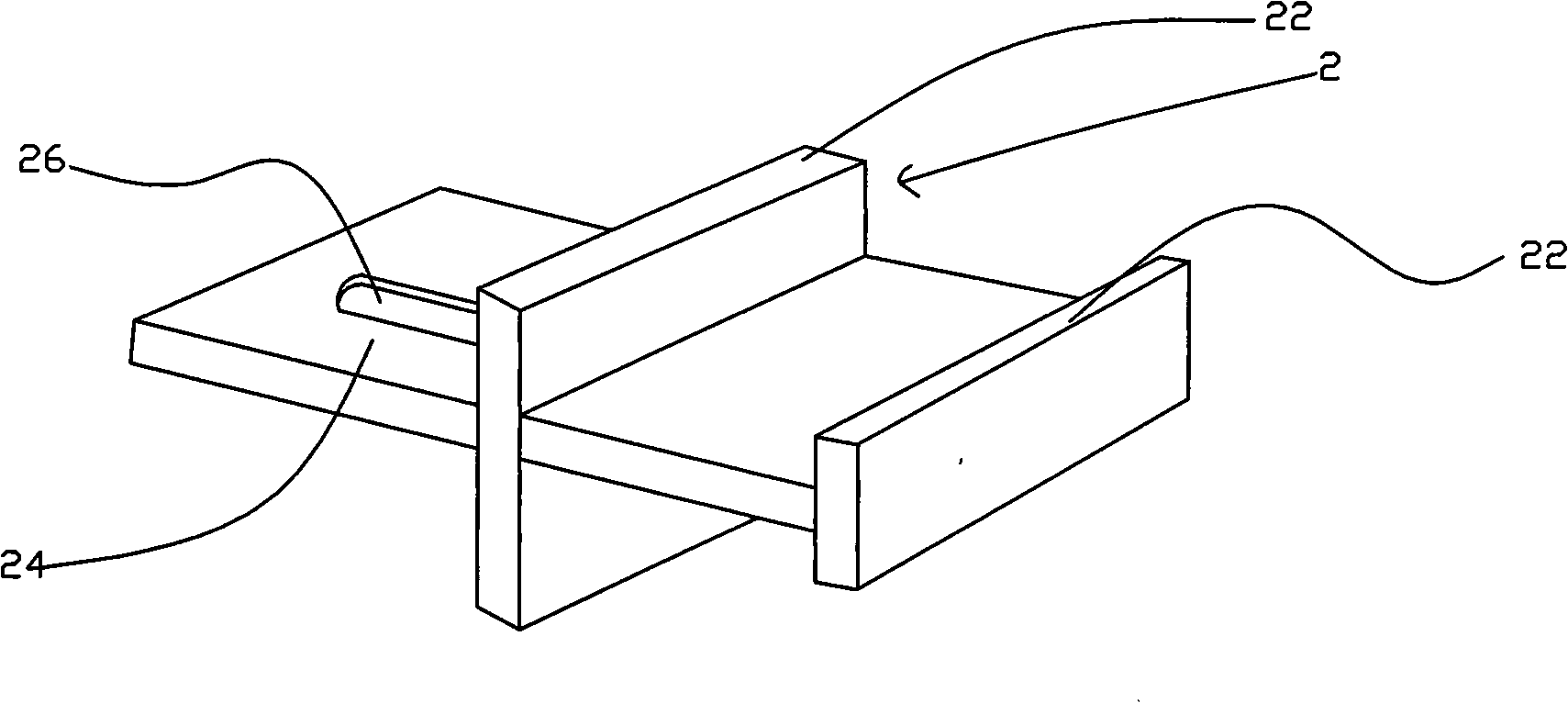

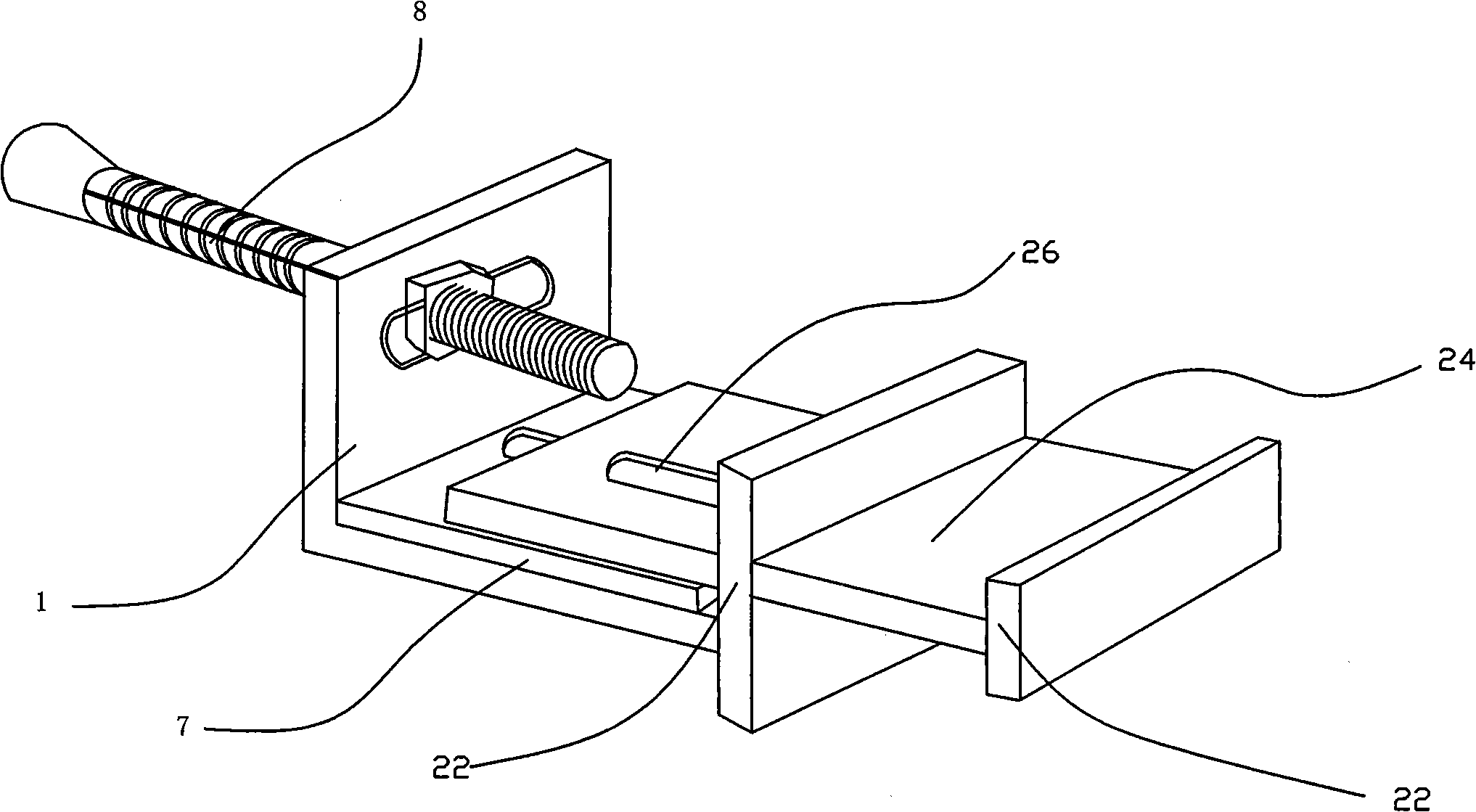

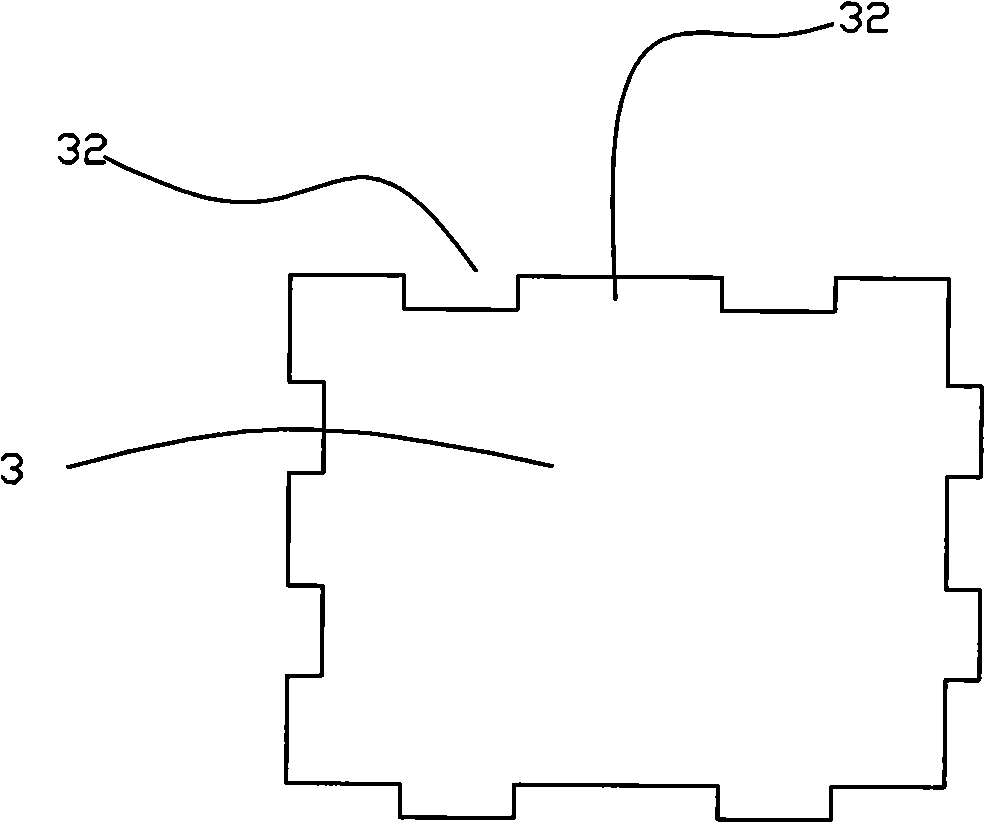

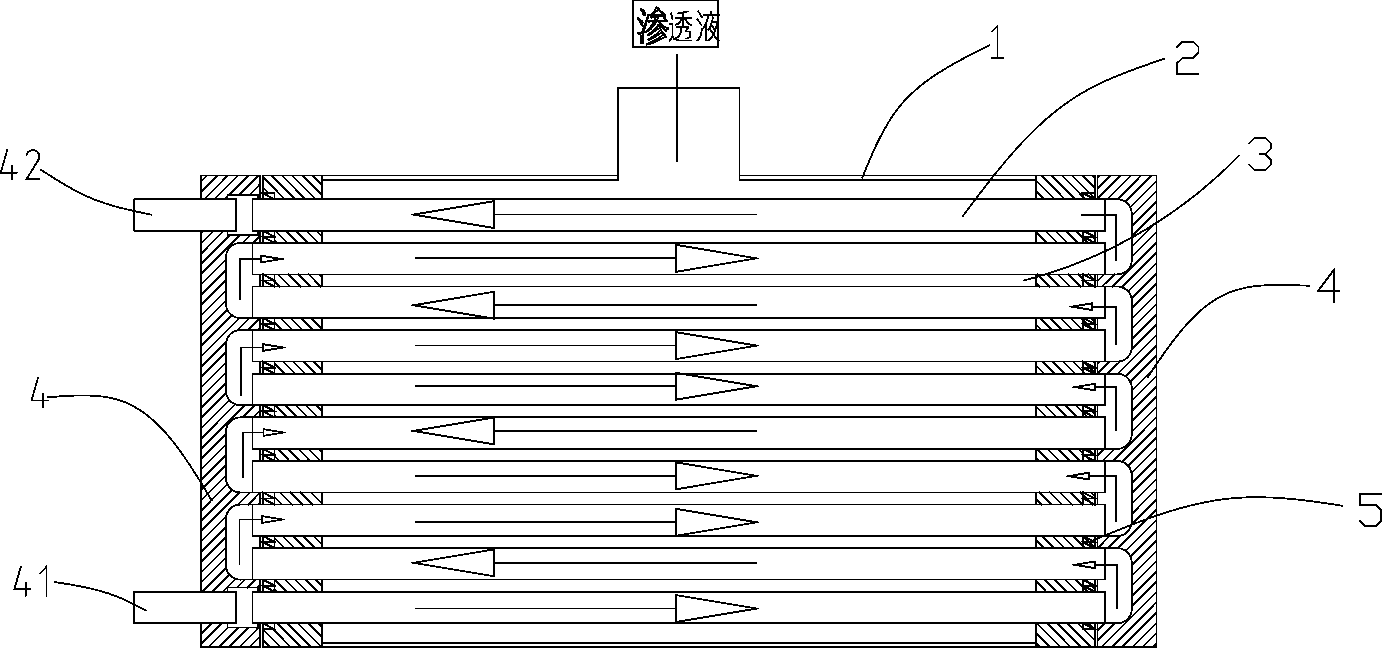

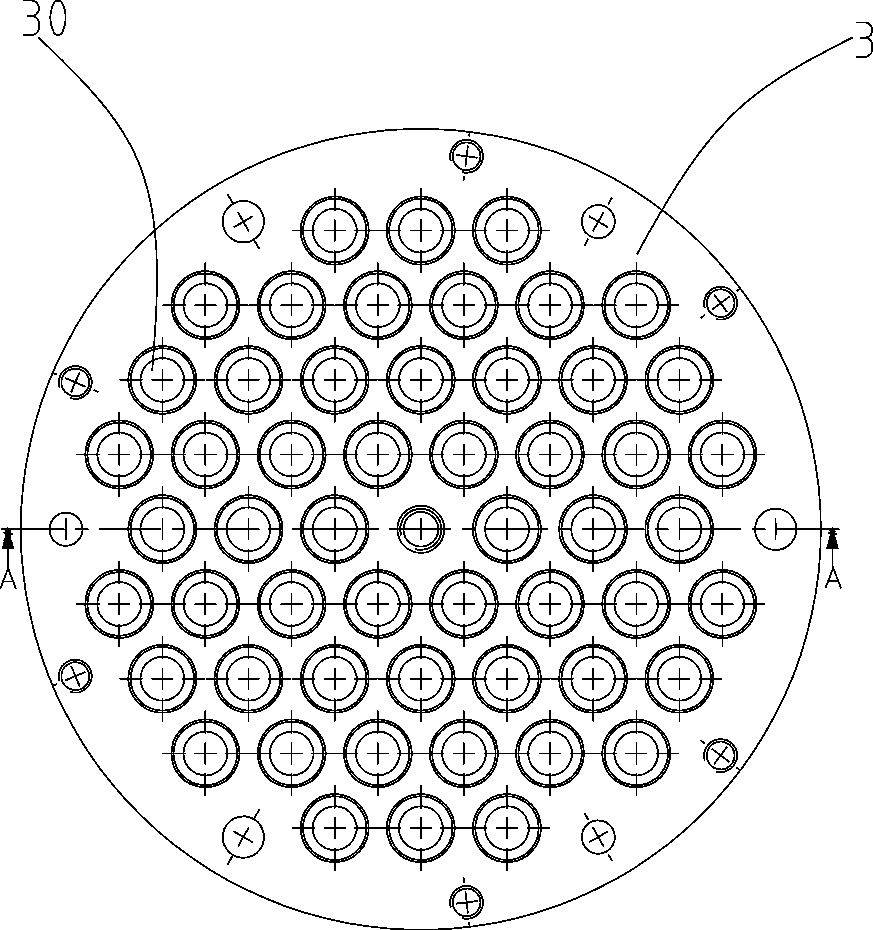

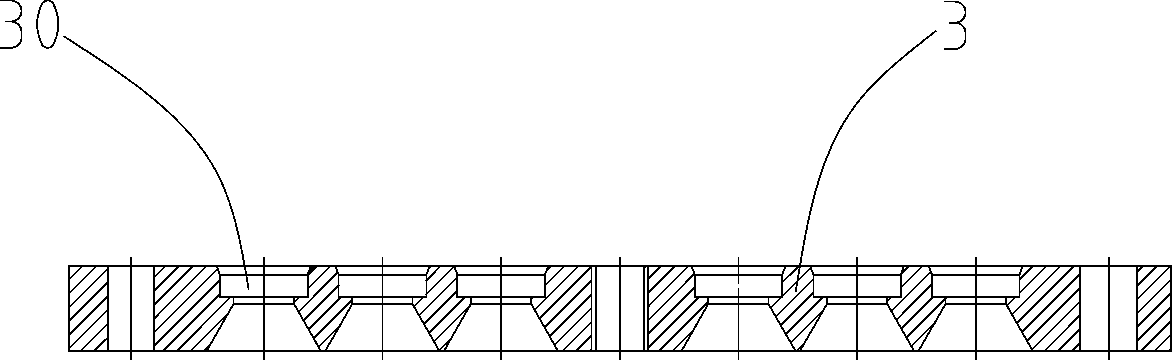

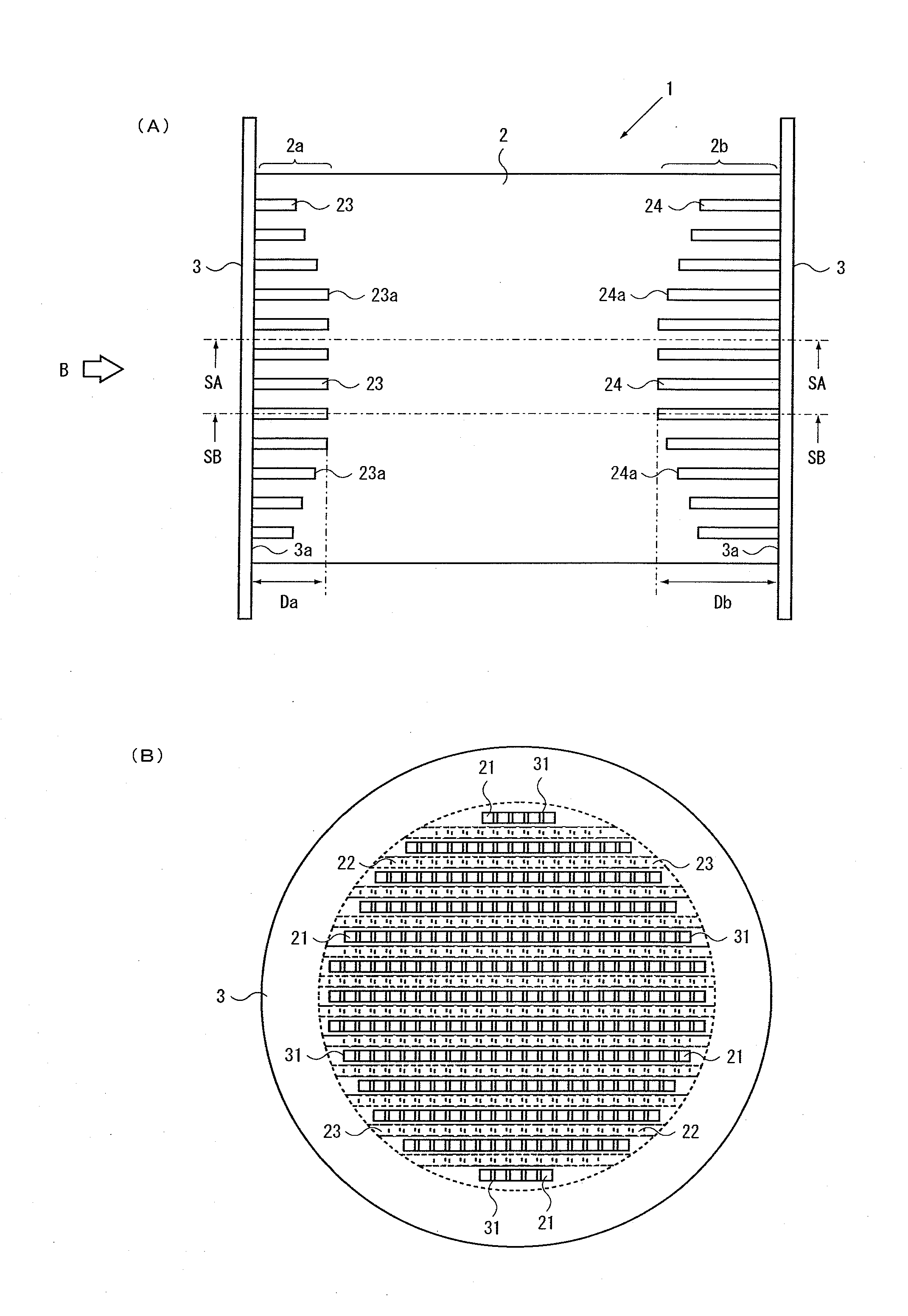

Ceramic heat exchanger and method of producing same

InactiveUS20120048524A1Reduce jointsEasy to produceMetal-working apparatusStationary tubular conduit assembliesInlet channelMetallurgy

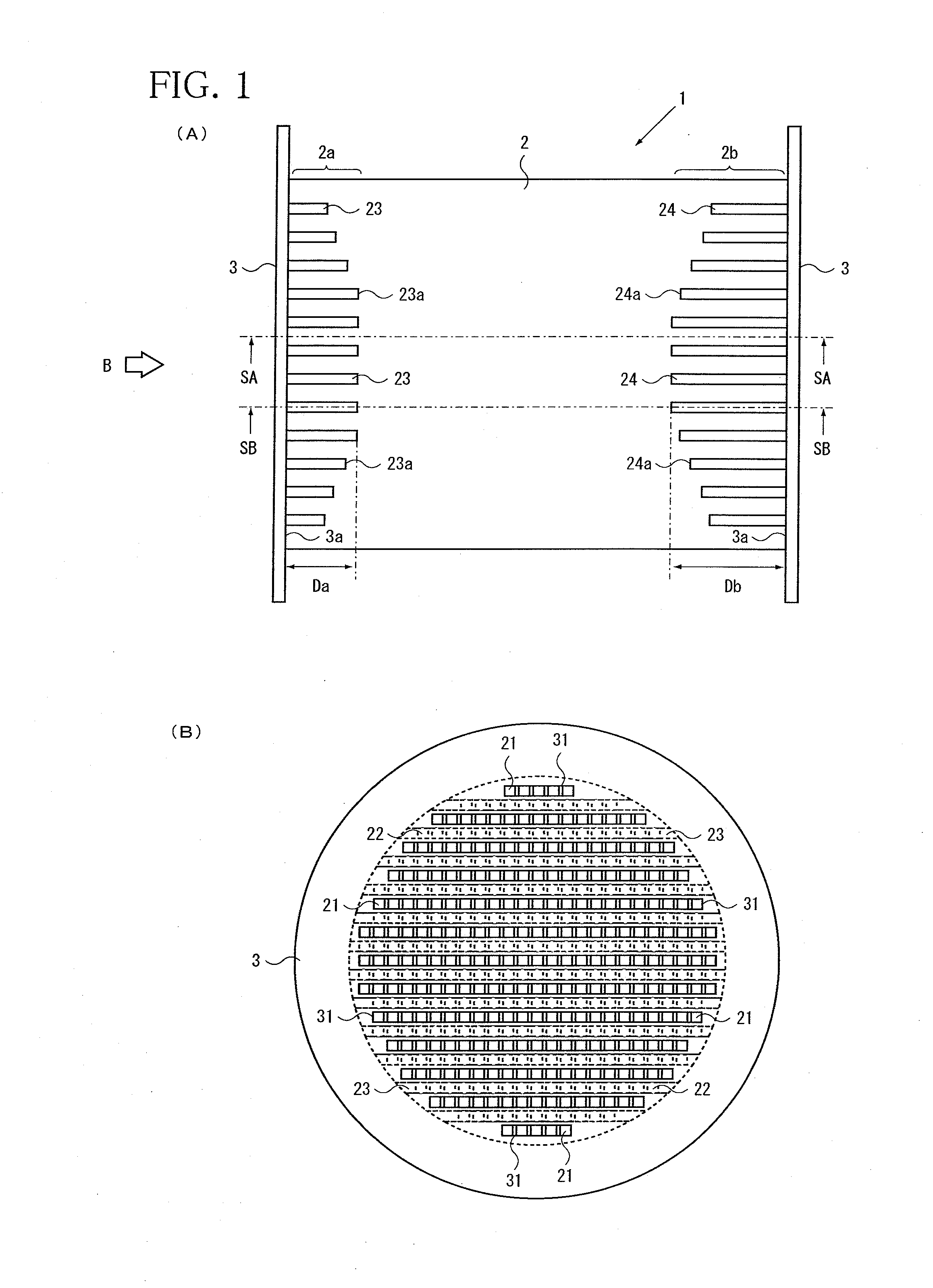

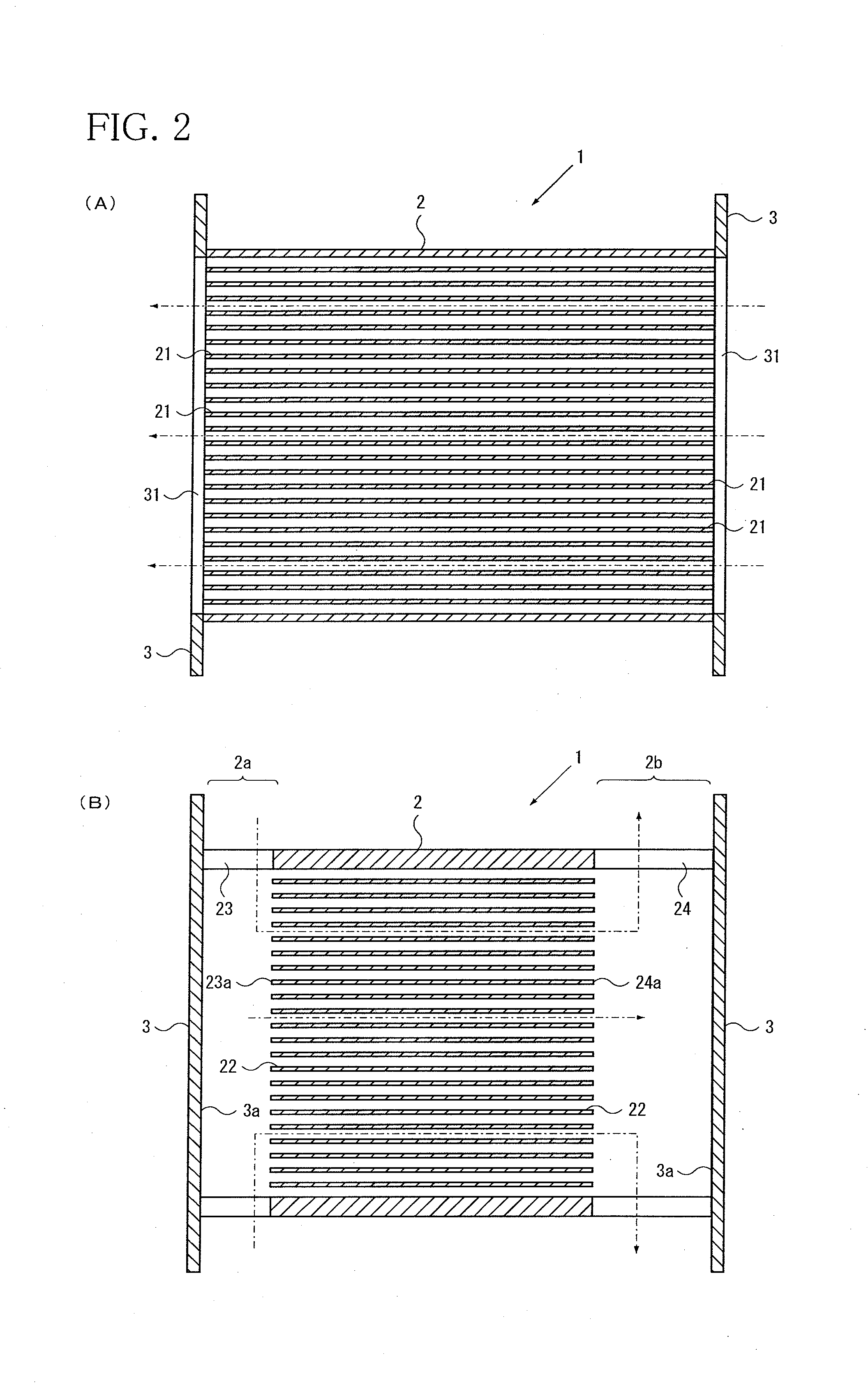

To provide a ceramic heat exchanger which has reduced joints, and thus, is easy to produce and less likely to leak and a method of producing same.The ceramic heat exchanger 1 according to the present invention comprises a body 2 having first channels 21 for a high-temperature medium to flow and second channels 22 for a low-temperature medium to flow, and lids 3 each having openings 31, joined to the body 2 at opposite ends 2a, 2b with the openings 31 connected to the first channels 21, the body 2 further having inlet channels 23 formed in a first channel 21 outlet-side end portion 2a to allow the low-temperature medium to enter the body at a side thereof and flow into the second channels 22, and outlet channels 24 formed in a first channel 21 inlet-side end portion 2b to allow the low-temperature medium to flow out of the second channels 22 and leave the body at the side thereof.

Owner:IHI CORP +1

Liquid-metal thermal interface material with self-packaging function and preparation method thereof

The invention relates to a liquid-metal thermal interface material with a self-packaging function and a preparation method thereof, and belongs to the technical field of thermal interface materials. In the thermal interface material, liquid metal accounts for 70 vol%-99 vol%; and high thermal conductivity filler accounts for 1 vol%-30 vol%. The liquid metal is formed by mixing two or more kinds of liquid metal with different melting points. The preparation method comprises the following steps that raw materials are cleaned, mixed, and then put into an ultrasonic processor, deionized water is added, ultrasonic treatment is carried out, and then filtering and drying are carried out; and then, the mixture is subjected to hot-pressing into a sheet shape, and finish rolling is carried out to obtain the sheet-shaped thermal interface material. According to the liquid-metal thermal interface material, at a use temperature, the high-melting-point part is in a solid state, the low-melting-point part is in a liquid state, the solid-phase part limits flowing of the liquid phase, the self-packaging effect is achieved, and the liquid-metal thermal interface material has a state of softening paraffin and has high flexibility and no fluidity. In addition, the liquid-metal thermal interface material has a high thermal conductivity (greater than 60 W / mK) and good processability. 60 W / mK) and good processability.

Owner:GRIMAT ENG INST CO LTD

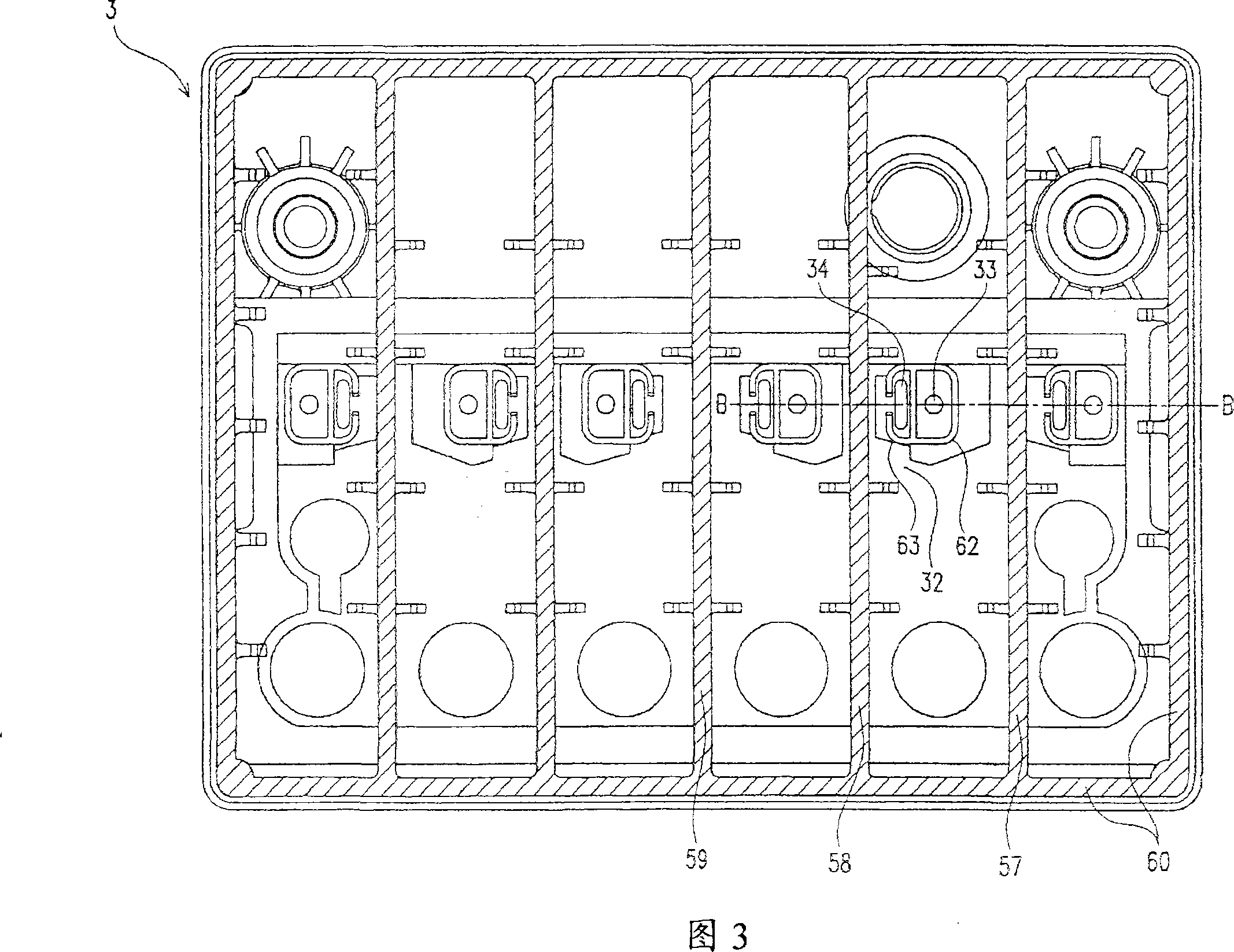

Lead accumulator

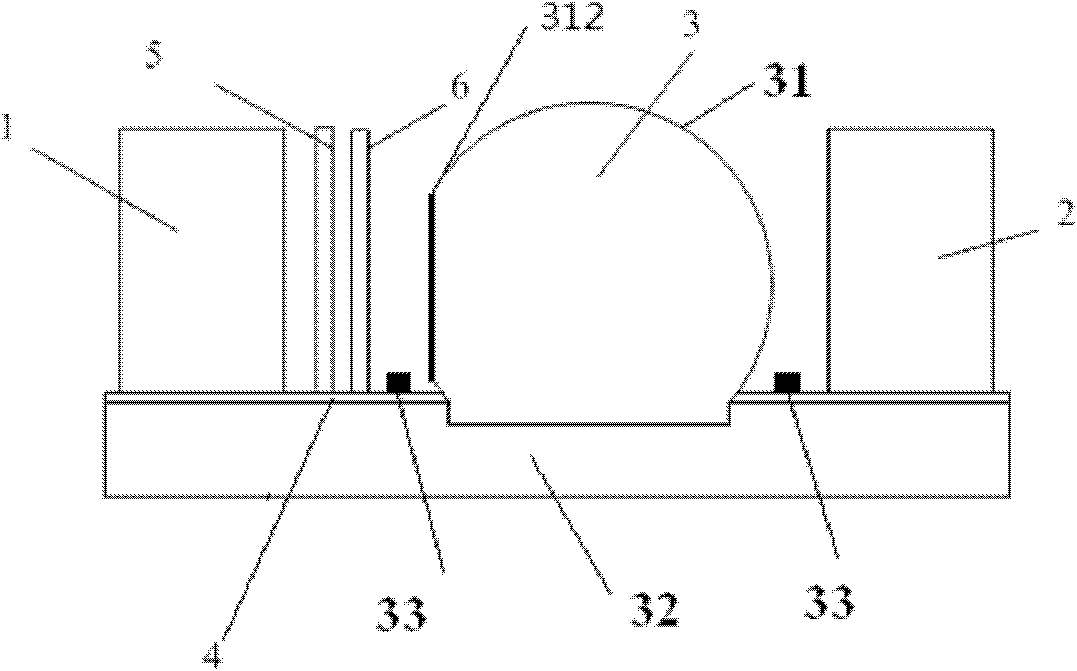

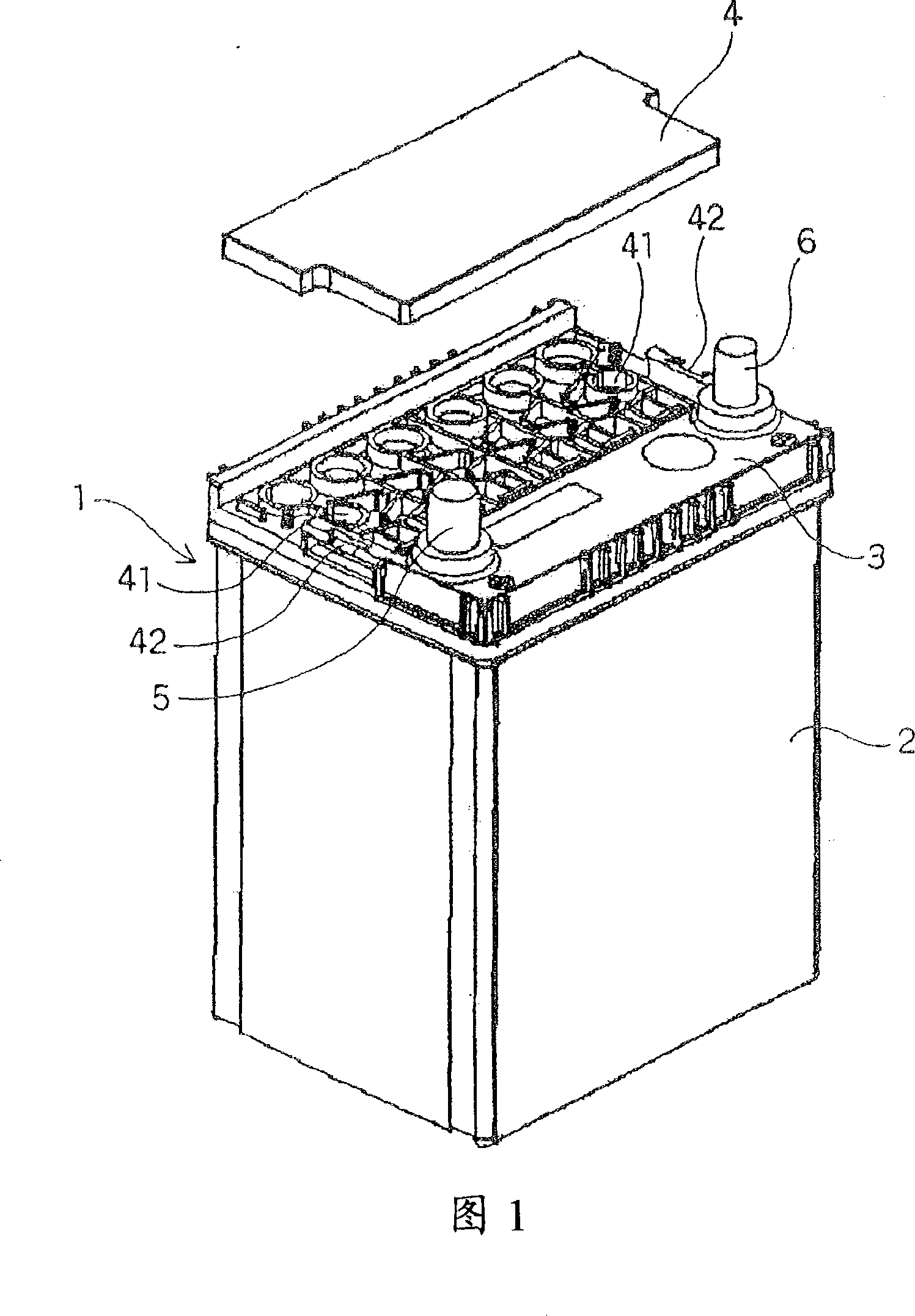

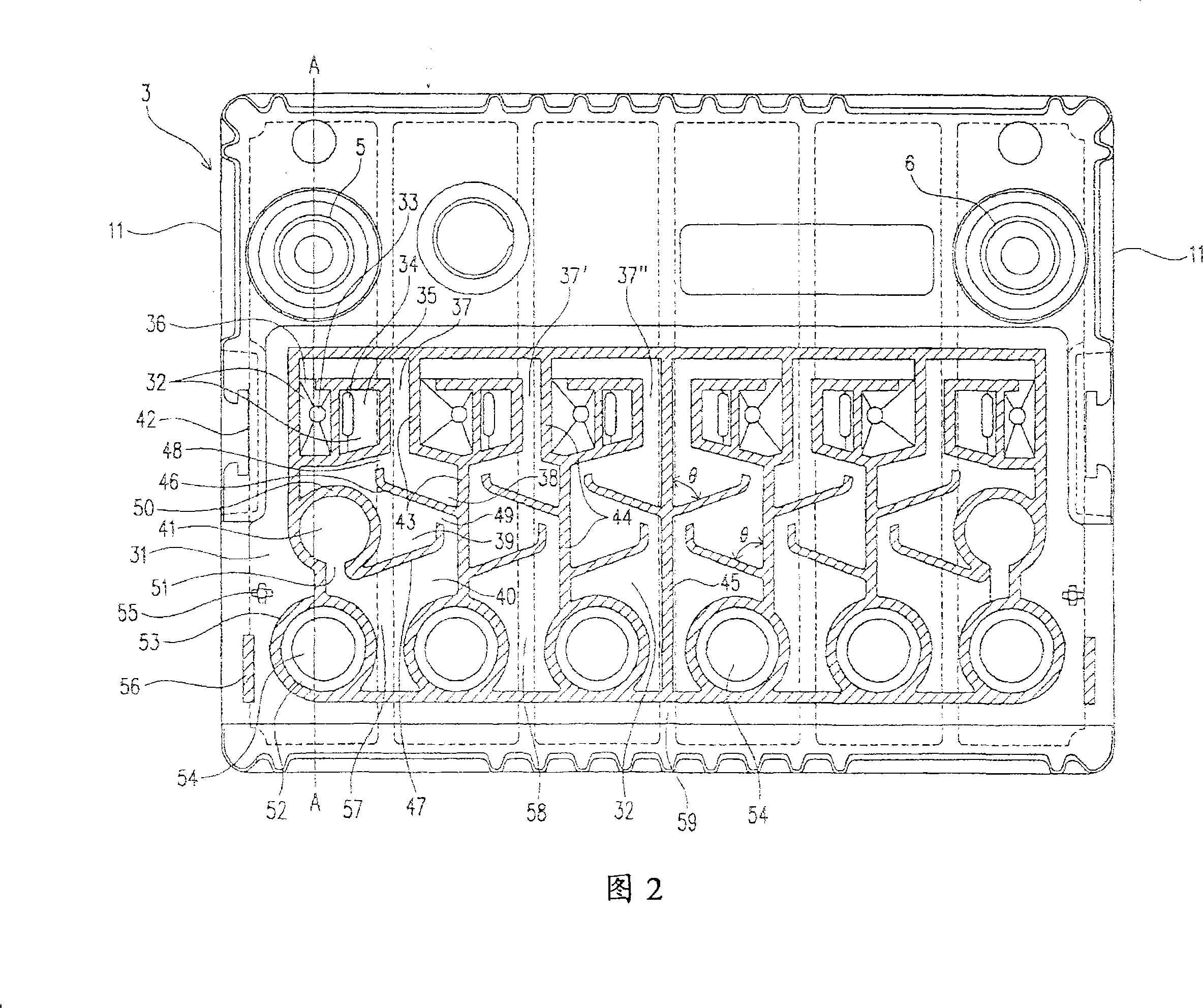

ActiveCN101185183ALess likely to leakExcellent separation functionElectrolyte moving arrangementsLead-acid accumulatorsEngineeringElectrolyte

A lead battery employing a collective exhaust system and exhibiting excellent gas exhaust function and electrolyte leakage preventive function in which the electrolyte does not leak even when the battery turns sideways. In the lead battery equipped with a collective exhaustion mechanism, a partition wall is arranged to surround an opening consisting of an electrolyte circulation opening (33) and a gas exhaust opening (34), a cell communicating subchamber (35) sectioned from exhaust chambers (37, 37', 37'') by the partition wall is provided, and the cell communicating chamber (35) is communicated with the exhaust chambers (37, 37', 37'') through a cut (36) provided on the partition wall, and the cell communicating subchamber (35) is isolated from the exhaust chambers (37, 37', 37'') by the partition wall excepting the cut (36).

Owner:GS YUASA INT LTD

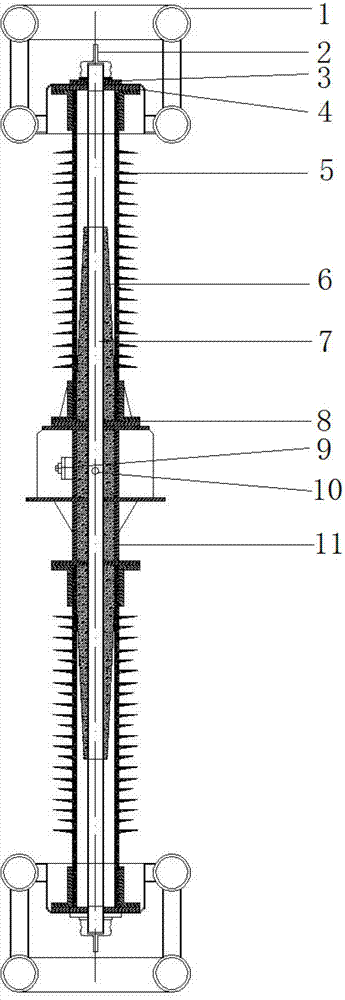

Resin impregnated paper capacitance type extra-high-voltage alternating current-direct current wall bushing

InactiveCN103500967AStrong anti-pollution flashover abilityReduce weightPartially enclosed bus-bar installationsInsulating bodiesCapacitanceEngineering

The invention introduces a resin impregnated paper capacitance type extra-high-voltage alternating current-direct current wall bushing which is provided with a conducting rod (7), wherein the conducting rod (7) is provided with a terminal board (2), a capacitance core (6) in a resin impregnated paper structure is sheathed in a middle section of the conducting rod (7), a sleeve (11) is sheathed on the capacitance core (6), insulating coatings (5), cross sections of which are in multilayer umbrella skirt shapes, are sheathed on both sides of the sleeve (11), and a test tap (9) and an SF6 gas pressure gage (10) are radially connected to the capacitance core (6). The bushing has the advantages that (1) the anti-pollution flashover capability is strong; (2) the civil engineering cost is reduced, and cool leakage of a phytotron is reduced; (3) the influence of heating of a conducting tube of the bushing is favorably reduced; (4) installation and overhaul are convenient; (5) an operating state of the bushing can be monitored in real time; (6) gas leakage is not likely to appear; (7) the grade of design voltage is high, and the application prospect is wide.

Owner:STATE GRID CORP OF CHINA +2

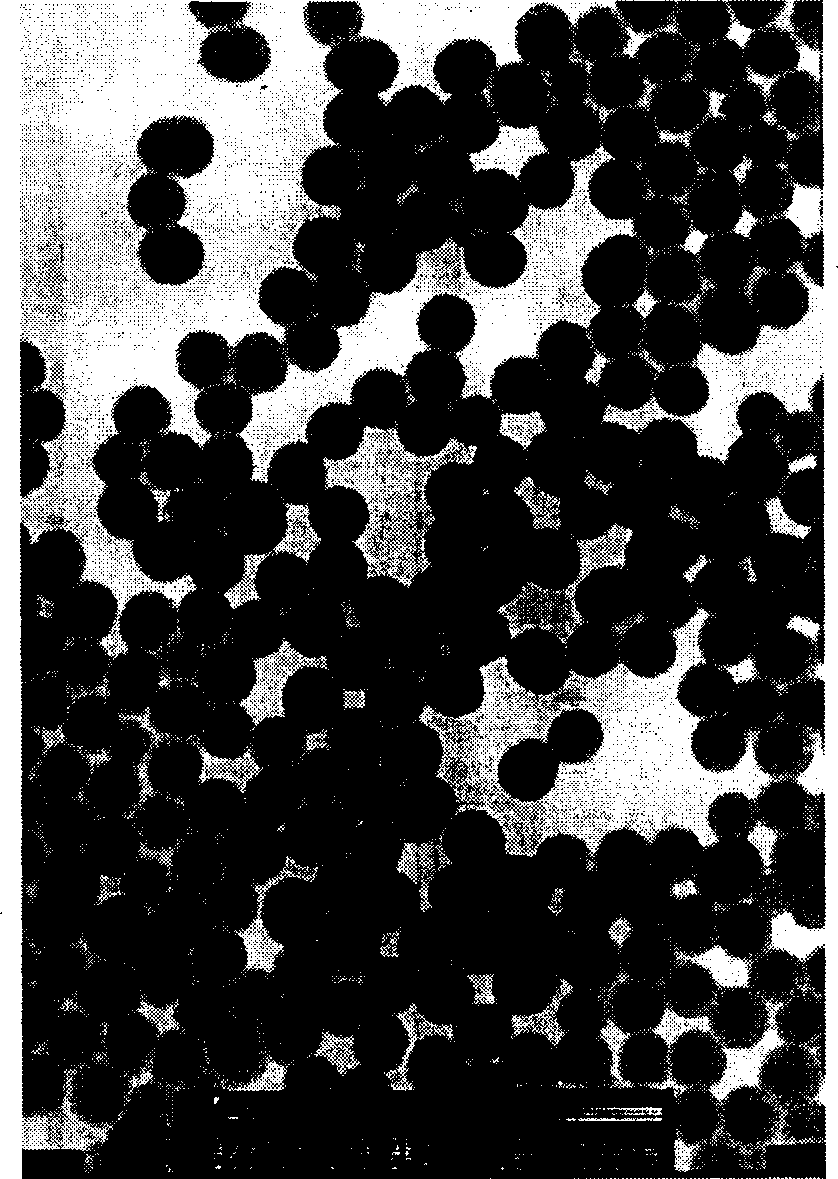

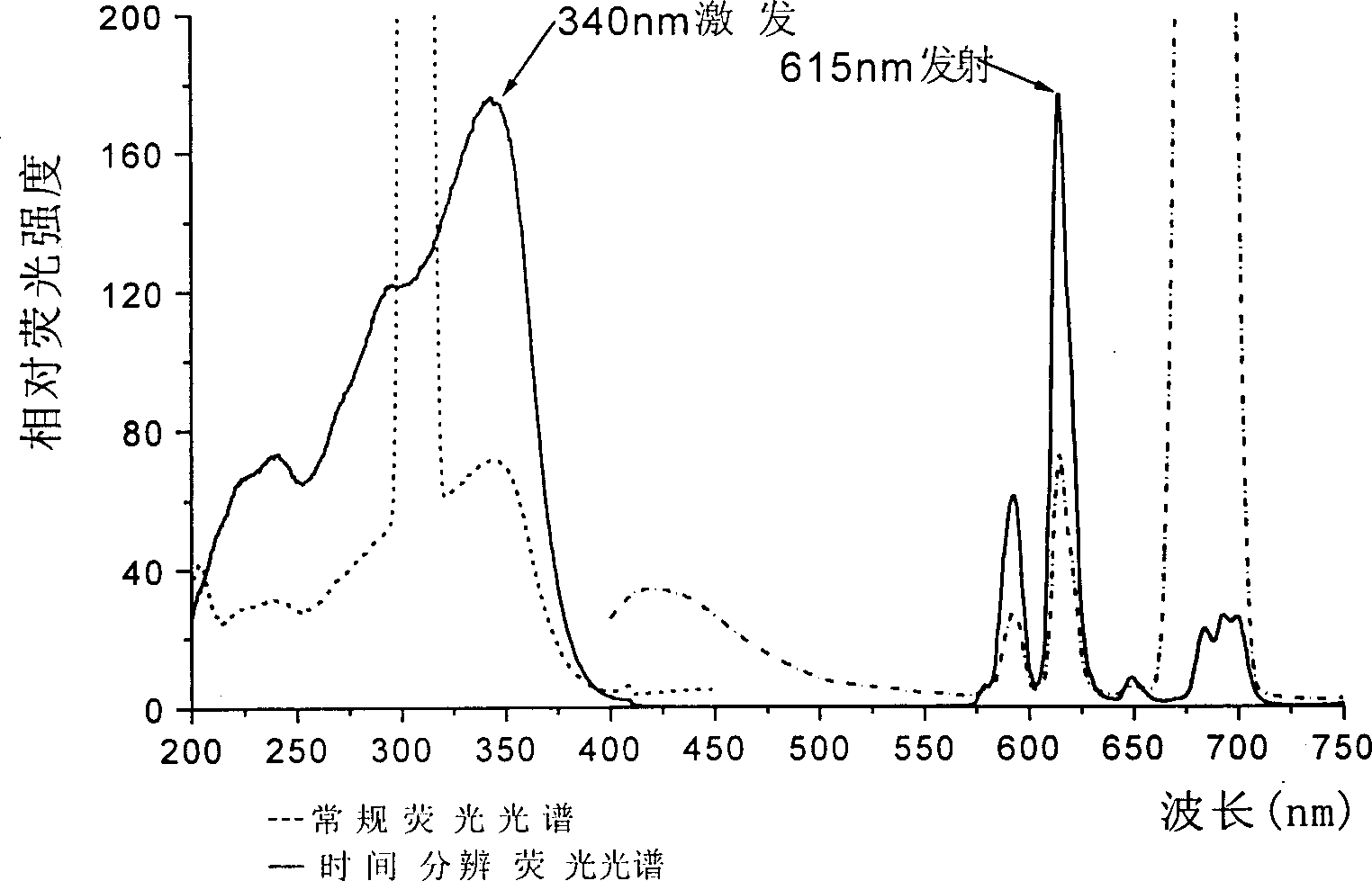

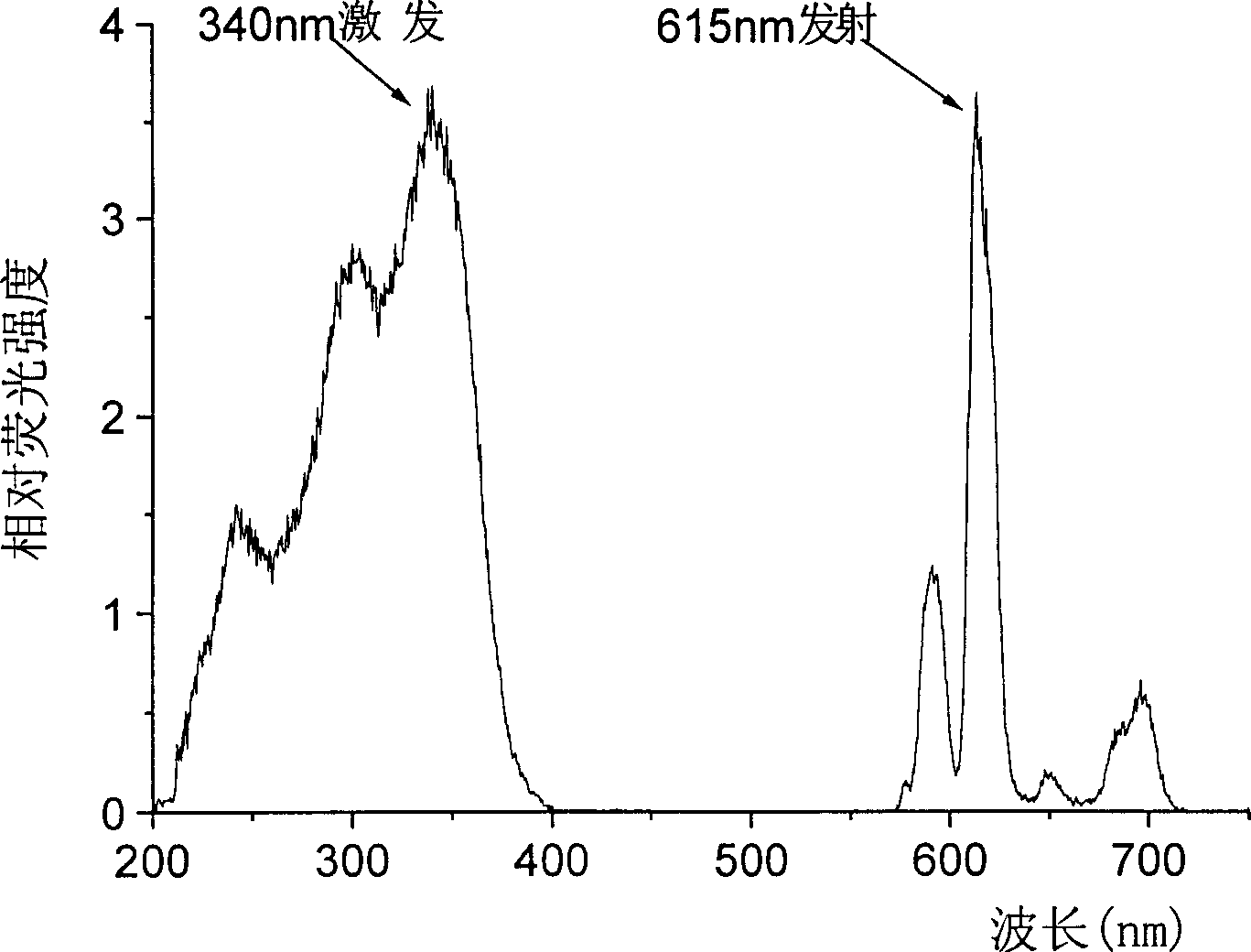

Functional nano-rare earth fluorescent micro particle and its preparation and application

InactiveCN1298807CSolve problems with very strong stray lightElimination of Assay EffectsLuminescent compositionsNanoparticleLanthanide

A functional lanthanide fluorescence nanoparticle (LFNP) is prepared from the strong-fluorescent RE matches as luminous center through chemically wrapping by silica gel. Its advantages are long fluorescence lift, big stoke shift, narrow emitting peak and strong specific signal. It can be used as the fluorescent marker for biological detection.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Methods of administering (4ar,10ar)-1-n-propyl-1,2,3,4,4a,5,10,10a-octahydrobenzo [g] quinoline-6,7-diol and related compounds across the oral mucosa, the nasal mucosa or the skin and pharmaceutical compositions thereof

Disclosed are pharmaceutical compositions and methods for the administration of (4aR,10aR)-1-n-propyl-1,2,3,4,4a,5,10,10a-octahydro-benzo[g]quinoline-6,7-diol or a pharmaceutically acceptable salt thereof and related compounds for the treatment of neurological disorder such as Parkinson's disease and restless leg syndrome.

Owner:H LUNDBECK AS

Nitrobenzene washing and separating system

ActiveCN103664629AReduce energy consumptionImprove securityOrganic chemistryOrganic compound preparationNitrationNitrobenzene

The invention belongs to the technical field of chemical washing and separating equipment, and relates to a nitrobenzene washing and separating system. After nitration reaction, nitration products and waste acids enter into a nitration separator to separate, separated organic phases enter into a neutralizing washer and a water-washing washer for alkaline washing and water washing, and obtained organic phases enter into a coalescing separator to further remove sodium salt and phenoxide in the organic phases, and subsequence treatment is carried out. The coalescing separator is mainly a static separator such as a fiber filter element separator, a plate separator or a combined separator. According to the method provided by the invention, nitrobenzene is washed and separated, so that sodium salt and phenoxide in coarse nitrobenzene can be further removed. The nitrobenzene is fully washed, and the content of phenoxide in washed coarse nitrobenzene is lower, so that the safety of the production system is improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

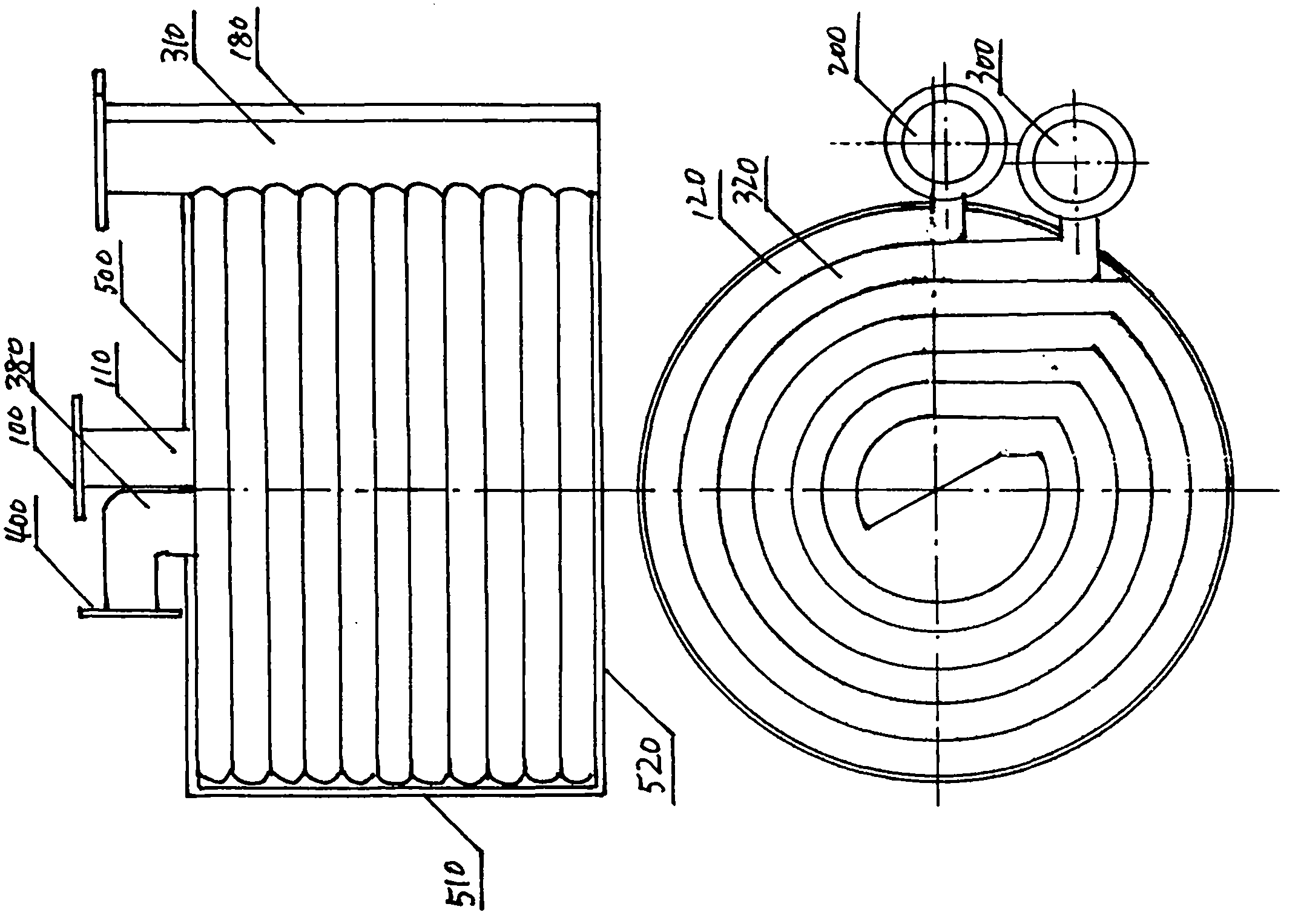

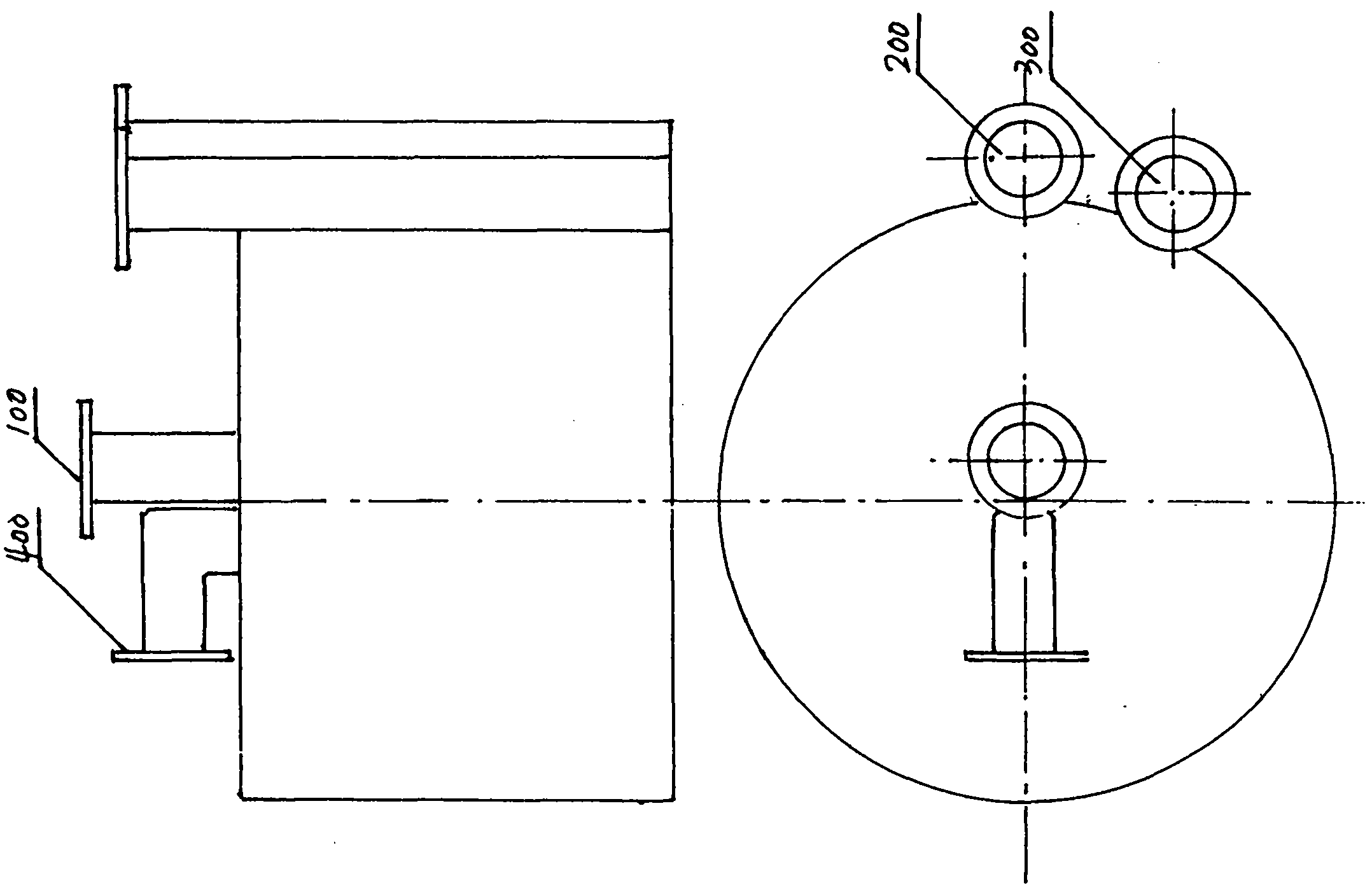

Spiral flow channel heat exchanger

InactiveCN104279895AWon't clogStable jobChemical industryStationary plate conduit assembliesWater flowEngineering

The invention provides a spiral flow channel heat exchanger. The spiral flow channel heat exchanger is in a circular table shape in appearance, and internally comprises a hot water flow channel, a cold water flow channel and a shell. The hot water flow channel comprises a hot water spiral flow channel. The cold water flow channel comprises a cold water spiral flow channel. The hot water spiral flow channel and the cold water spiral flow channel are arranged in a horizontally-spirally-spaced mode. The spiral flow channel heat exchanger is characterized in that the hot water spiral flow channel is composed of spiral pipe rows formed by connecting a plurality of horizontal spiral pipes in parallel in an up-down-stacked mode. The section of the spiral pipes is in a circular pipe or an oval pipe or a square pipe shape. The hot water passes through a hot water inlet, horizontally flows into the hot water spiral flow channel formed by the spiral pipe rows, and flows horizontally and spirally along the spiral lines from inside to outside. The flowing radius is gradually increased, and finally the hot water flows out of a hot water outlet after passing through a hot water outlet header. The cold water spiral flow channel is formed between two layers of the hot water spiral flow channel. The cold water flows horizontally and spirally along the spiral lines from outside to inside. The flowing radius is decreased gradually, and finally the cold water flows out of a cold water outlet after passing through a cold water outlet header in the center.

Owner:黑龙江省金永科技开发有限公司

New energy automobile water-cooled condenser

PendingCN108709342AFast coolingLess power consumptionEvaporators/condensersTubular elementsThermal energyNew energy

The invention discloses a new energy automobile water-cooled condenser which comprises a condenser body and a draught fan assembly. The condenser body comprises an outer pipe and an inner pipe which are fixedly installed in a sleeve manner, a refrigerant flowing channel is formed in an inner cavity of the inner pipe, a water flowing channel is formed in a space between the inner pipe and the outerpipe, the two ends of the outer pipe are provided with a water inlet connector and a water outlet connector, the two ends of the inner pipe are provided with a refrigerant inlet connector and a refrigerant outlet connector, the water inlet connector and the water outlet connector both communicate with the water flowing channel, the refrigerant inlet connector and the refrigerant outlet connectorboth communicate with the refrigerant flowing channel, heat conduction fins are arranged outside the outer pipe, and the draught fan assembly is arranged on one side of the condenser body to be used for blowing air to or sucking air from the condenser body. By means of the water-cooled condenser, the inner pipe and the outer pipe which are installed in the sleeve manner are used for achieving heatexchange between medium water and a high temperature refrigerant, heat in the high temperature refrigerant is conveniently recovered, utilization of thermal energy in a new energy automobile is morereasonable, and the aim of energy saving is achieved.

Owner:苏州赛普瑞新能源科技有限公司

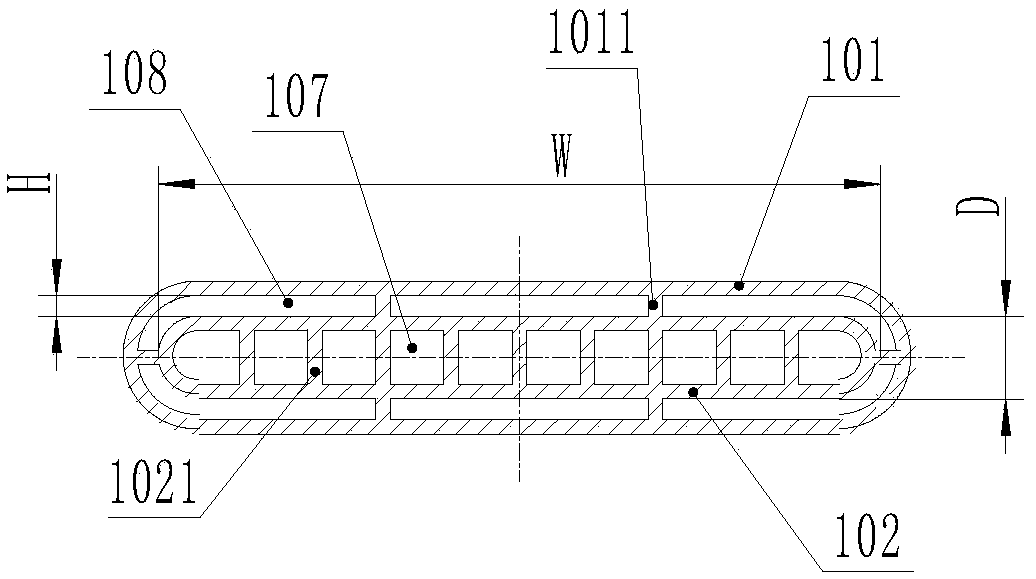

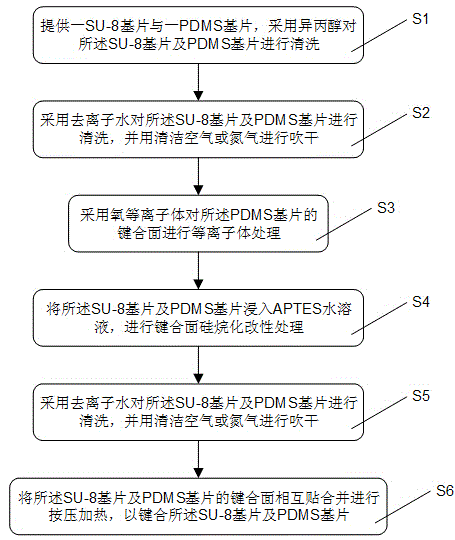

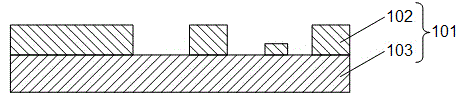

Microfluidic chip bonding method using SU-8 photoresist and PDMS as substrates

ActiveCN104627953ALess likely to leakImprove controllabilityDecorative surface effectsChemical vapor deposition coatingOxygen plasmaCorona discharge

The invention provides a microfluidic chip bonding method using an SU-8 photoresist and PDMS as substrates. The microfluidic chip bonding method comprises the following steps: firstly providing an SU-8 substrate and a PDMS substrate, cleaning the SU-8 substrate and the PDMS substrate by using isopropyl alcohol and deionized water, and then performing oxygen plasma treatment on the bonding surface of the PDMS substrate; performing silanization modification treatment on the bonding surfaces of the SU-8 substrate and the PDMS substrate by using an aqueous solution of APTES; and finally, enabling the bonding surfaces of the SU-8 substrate and the PDMS substrate to get close and carrying put press heating to bond the SU-8 substrate and the PDMS substrate to form a complete microfluidic chip. The microfluidic chip bonding method has the following beneficial effects that: 1) the bonding surface of the PDMS substrate can be modified by using an ordinary low-power plasma machine or a corona discharge instrument and other low-cost equipment; 2) the operation process is simple, the controllability, stability and repeatability of the process are high, the bonding strength and the yield are high, and the leakage does not easily occur; 3) the bonding of the SU-8 substrate and the PDMS substrate is helpful for realizing the precision multifunctional microfluidic chip with and complicated structure.

Owner:SOUTHEAST UNIV

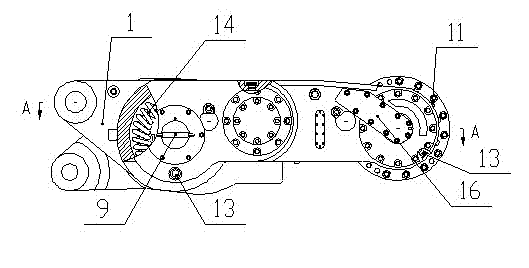

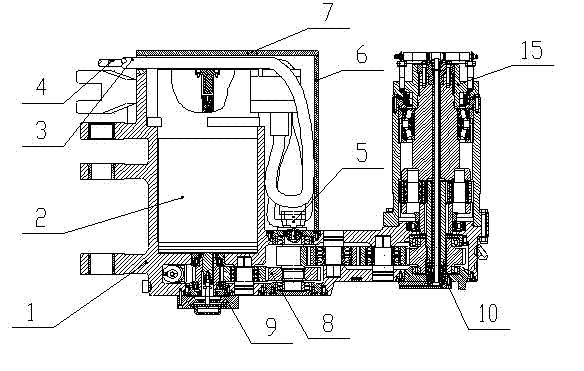

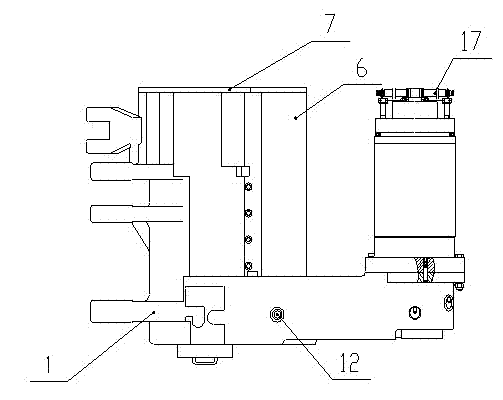

Cantilever type coal cutter rocking arm

The invention discloses a cantilever type coal cutter rocking arm, and belongs to the technical field of coal cutters. The cantilever type coal cutter rocking arm comprises a rocking arm shell, a cutting motor, a height adjusting gear pump, a gear transmission system, a clutch, an inner fog system, an outer fog system, a motor protective cap and a motor protecting cover, wherein the cutting motor is fixed on the rocking arm shell through a bolt, and the cutting motor is connected with the gear transmission system through the clutch; the height adjusting gear pump is arranged on the gear transmission system, the motor protective cap and the motor protecting cover are arranged outside the cutting motor, a cable, an oil pipe and the height adjusting gear pump; and a water channel of the inner fog system is a rigid channel, and oil drain holes are formed in the side surface and the bottom surface of the rocking arm. The cantilever type coal cutter rocking arm provided by the invention has the beneficial effects that the overall structure is compact, the change and disassembly and assembly of the motor are convenient, the inner and outer fog systems are safe and reliable, the temperature of a rocking arm gear box can be effectively reduced, and the oil drain is convenient; and the height adjusting gear pump is placed on the rocking arm, the length of a coal cutter is effectively reduced, the support is easy, and a water pipe is prevented from being damaged.

Owner:国科中迈(徐州)能源科技有限公司

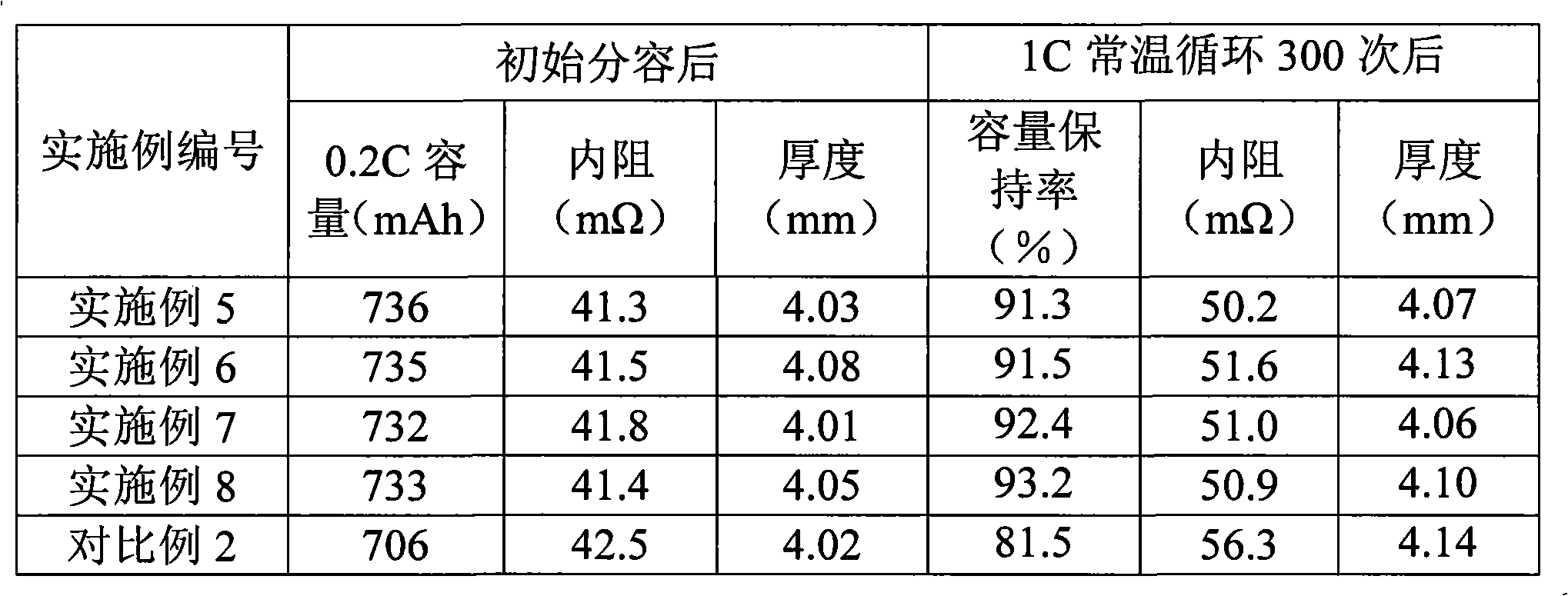

Preparation method of polymer lithium ion battery

InactiveCN101599557ALess likely to leakSmooth ion pathwayFinal product manufactureSecondary cellsLithium-ion batteryHeating temperature

The invention provides a preparation method of a polymer lithium ion battery, comprising the following step: plasticizing a precursor of the polymer lithium ion battery, wherein the plasticization comprises heating and the cooling the precursor of the battery, the temperature in a shell of the precursor of the battery is between 30 DEG C and 60 DEG C due to heating, the shell of the precursor of the battery is placed under the heating temperature for 0.1-10 hours, the temperature in the shell of the precursor of the battery is between 0 DEG C and 40 DEG C below zero due to cooling, and the shell of the precursor of the battery is placed under the cooling temperature for 0.1-10 hours. The preparation method achieves the better plasticizing effect of a polymer film by heating and cooling the precursor of the battery in the plasticizing process, thereby obviously enhancing the circulation performance and the safety performance of the obtained polymer lithium ion battery.

Owner:BYD CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Methods of administering (4ar,10ar)-1-n-propyl-1,2,3,4,4a,5,10,10a-octahydrobenzo [g] quinoline-6,7-diol and related compounds across the oral mucosa, the nasal mucosa or the skin and pharmaceutical compositions thereof Methods of administering (4ar,10ar)-1-n-propyl-1,2,3,4,4a,5,10,10a-octahydrobenzo [g] quinoline-6,7-diol and related compounds across the oral mucosa, the nasal mucosa or the skin and pharmaceutical compositions thereof](https://images-eureka.patsnap.com/patent_img/dab03a3d-6671-4f02-b204-4df54ac35b1c/US20120077836A1-20120329-D00001.png)

![Methods of administering (4ar,10ar)-1-n-propyl-1,2,3,4,4a,5,10,10a-octahydrobenzo [g] quinoline-6,7-diol and related compounds across the oral mucosa, the nasal mucosa or the skin and pharmaceutical compositions thereof Methods of administering (4ar,10ar)-1-n-propyl-1,2,3,4,4a,5,10,10a-octahydrobenzo [g] quinoline-6,7-diol and related compounds across the oral mucosa, the nasal mucosa or the skin and pharmaceutical compositions thereof](https://images-eureka.patsnap.com/patent_img/dab03a3d-6671-4f02-b204-4df54ac35b1c/US20120077836A1-20120329-D00002.png)

![Methods of administering (4ar,10ar)-1-n-propyl-1,2,3,4,4a,5,10,10a-octahydrobenzo [g] quinoline-6,7-diol and related compounds across the oral mucosa, the nasal mucosa or the skin and pharmaceutical compositions thereof Methods of administering (4ar,10ar)-1-n-propyl-1,2,3,4,4a,5,10,10a-octahydrobenzo [g] quinoline-6,7-diol and related compounds across the oral mucosa, the nasal mucosa or the skin and pharmaceutical compositions thereof](https://images-eureka.patsnap.com/patent_img/dab03a3d-6671-4f02-b204-4df54ac35b1c/US20120077836A1-20120329-D00003.png)