Spiral flow channel heat exchanger

A spiral flow channel and heat exchanger technology, applied in the field of heat exchange, can solve the problems of difficult processing of shell-and-tube heat exchangers, heavy opening and welding workload, poor processing quality assurance, etc., so that it is not easy to leak, Less welding workload and less resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

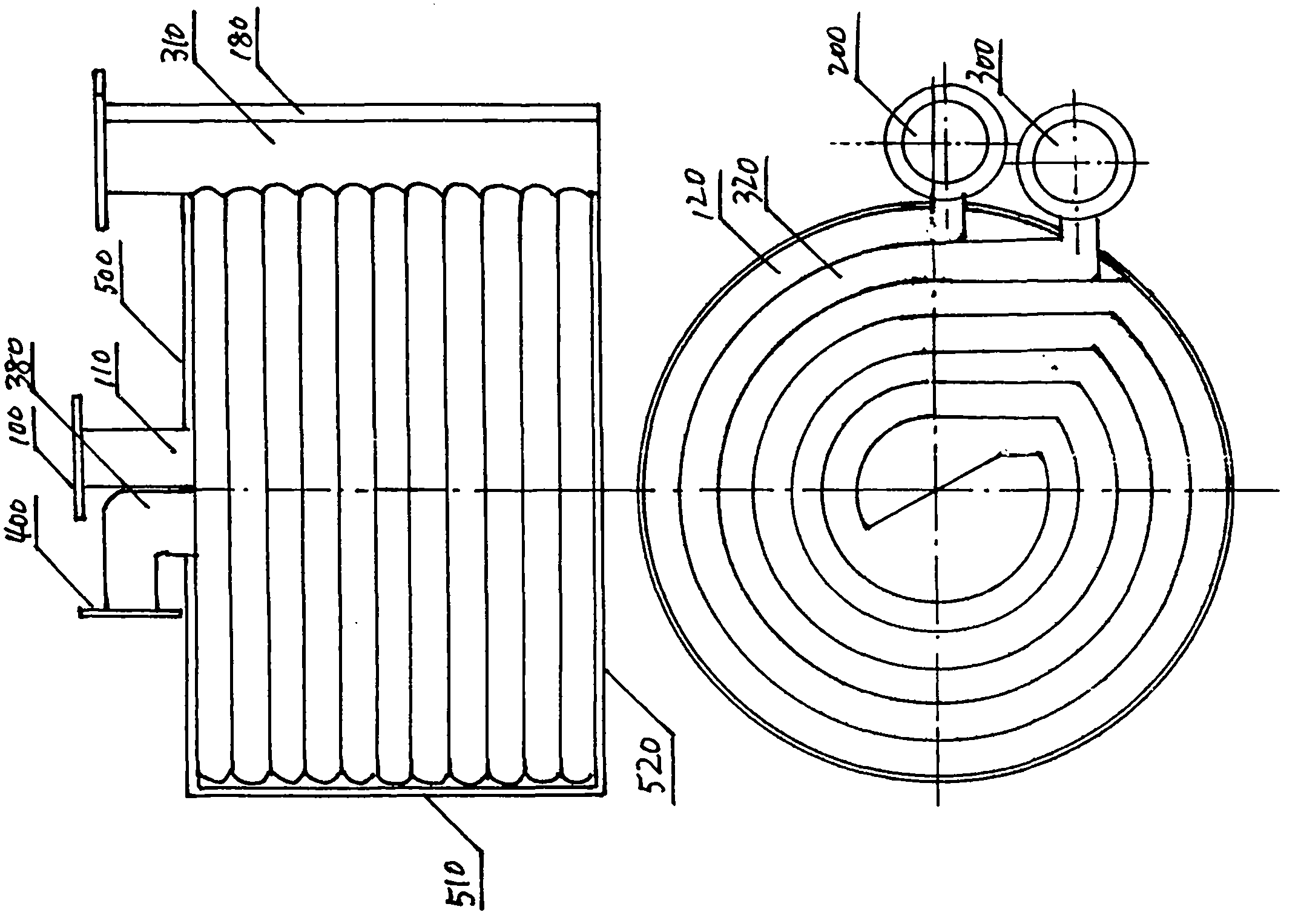

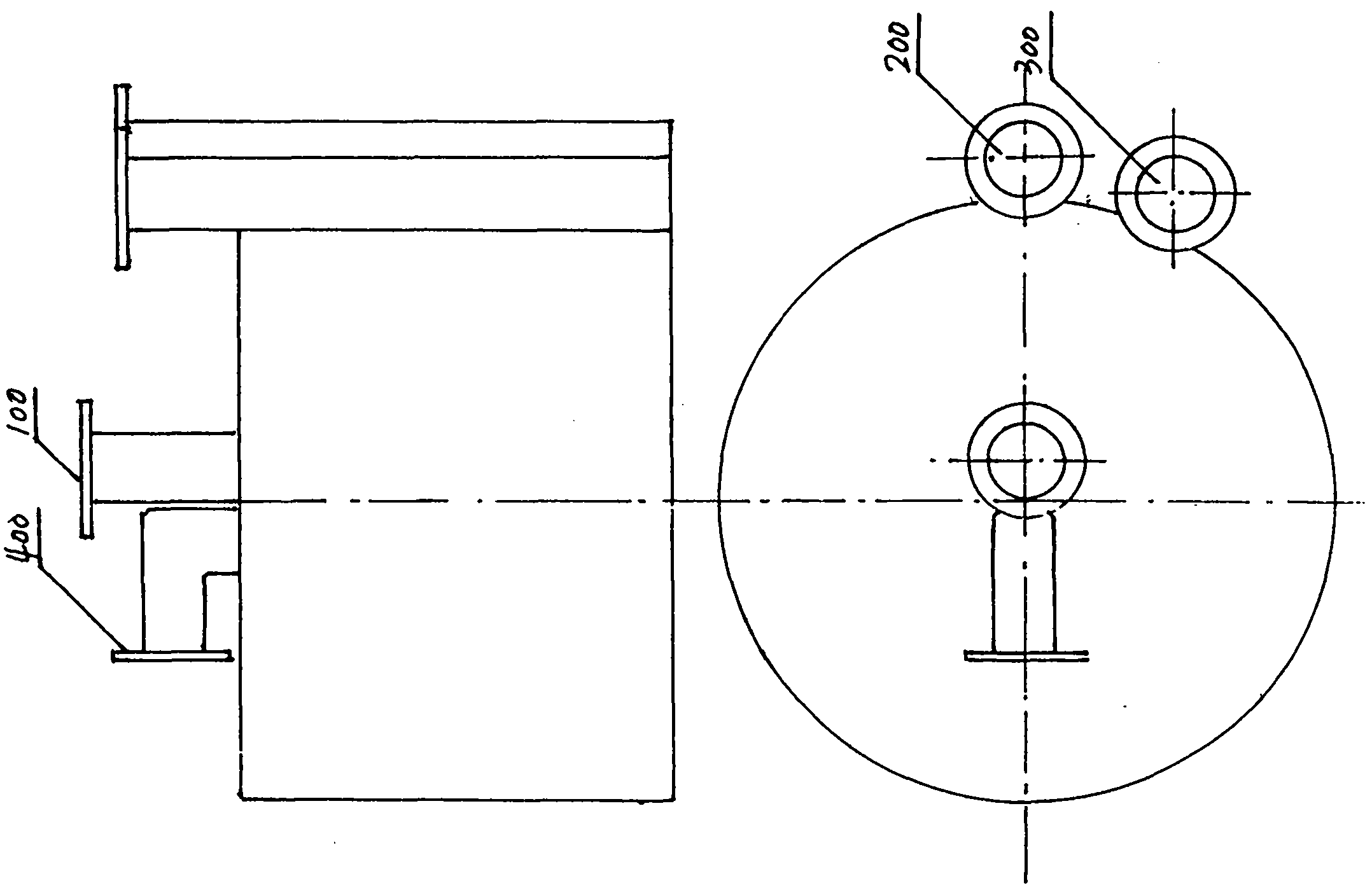

[0027] figure 1 The internal structure diagram of the embodiment of the spiral channel heat exchanger of the present invention is given.

[0028] The embodiment of the spiral channel heat exchanger of the present invention is composed of three parts: a hot water channel, a cold water channel, and a shell.

[0029] in:

[0030] The hot water flow channel is a spiral flow channel composed of a number of spiral pipe rows, including: hot water inlet 100, hot water inlet header 110, hot water spiral flow channel 120, hot water outlet header 180 and Hot water outlet 200. Hot water passes through the inlet flange of the hot water inlet 100, and enters a thick vertical pipe in the center, which is the hot water inlet header 110, and then flows horizontally into the hot water spiral flow channel 120 composed of spiral pipe rows, along the spiral Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com