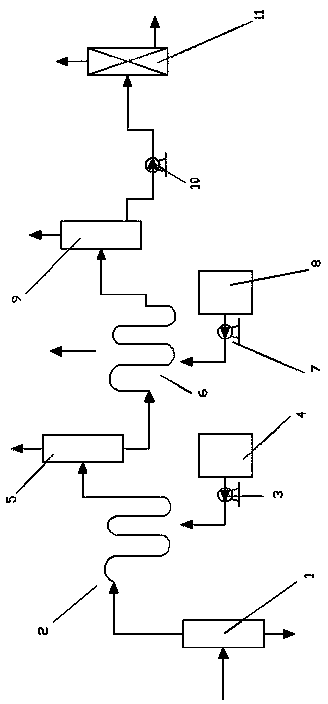

Nitrobenzene washing and separating system

A separation system and nitrobenzene technology, applied in the preparation of organic compounds, organic chemistry, chemical instruments and methods, etc., can solve the problems of inoperability, small operation flexibility, high energy consumption, etc., to improve safety, not easy to leak, The effect of low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1, the volume ratio of nitrobenzene and alkaline water entering the neutralization scrubber is 10:1, and the volume ratio of nitrobenzene and water entering the washing scrubber is 2:1.

[0025] After Example 1, the indicators before and after nitrobenzene enters the coalescence separator are shown in Table 1 below:

[0026] Table 1 Indicators before and after nitrobenzene enters the coalescence separator in Example 1

[0027] before washing after washing Moisture, ppm 3183 1909 Na + , ppm (in Na + count) 5.0 1.5 Phenol content, ppm (as 2,4-dinitrophenol) 2.3 1.0

Embodiment 2

[0028] Embodiment 2, the device structure is roughly the same as that of Example 1, the difference is that the coalescence separator adopts plate packing, the volume ratio of the nitrobenzene and alkaline water entering the neutralization scrubber is 15:1, and the nitrobenzene entering the washing scrubber is 15:1. The volume ratio of benzene to water is 2.5:1.

[0029] After Example 2, the indicators before and after nitrobenzene enters the coalescence separator are shown in Table 2 below:

[0030] Table 2 Indicators before and after nitrobenzene enters the coalescence separator in Example 2

[0031] before washing after washing Moisture, ppm 3546 2136 Na + , ppm (in Na + count) 4.8 1.6 Phenol content, ppm (as 2,4-dinitrophenol) 3.6 1.2

Embodiment 3

[0032] Embodiment 3, the structure of the device is roughly the same as that of Embodiment 1, the difference is that the coalescing separator adopts a plate type and a fiber filter core combined filler, and the volume ratio of nitrobenzene and alkaline water entering the neutralization scrubber is 20:1, and the water is washed and washed The volume ratio of nitrobenzene to water is 3:1.

[0033] After Example 3, the indicators before and after nitrobenzene enters the coalescence separator are shown in Table 3 below:

[0034] Table 3 Indicators before and after nitrobenzene enters the coalescence separator in Example 3

[0035] before washing after washing Moisture, ppm 3782 2208 Na + , ppm (in Na + count) 4.2 1.3 Phenol content, ppm (as 2,4-dinitrophenol) 4.1 1.4

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com