Pipe type membrane assembly coated with cascaded structure on inner wall

A series structure, tubular membrane technology, applied in the field of membrane separation, can solve the problems of difficulty in realizing small batch on-line pervaporation dehydration, poor sealing performance of the outer wall coating membrane tube, and low dehydration efficiency of a single membrane module. Simple, good sealing, not easy to leak

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

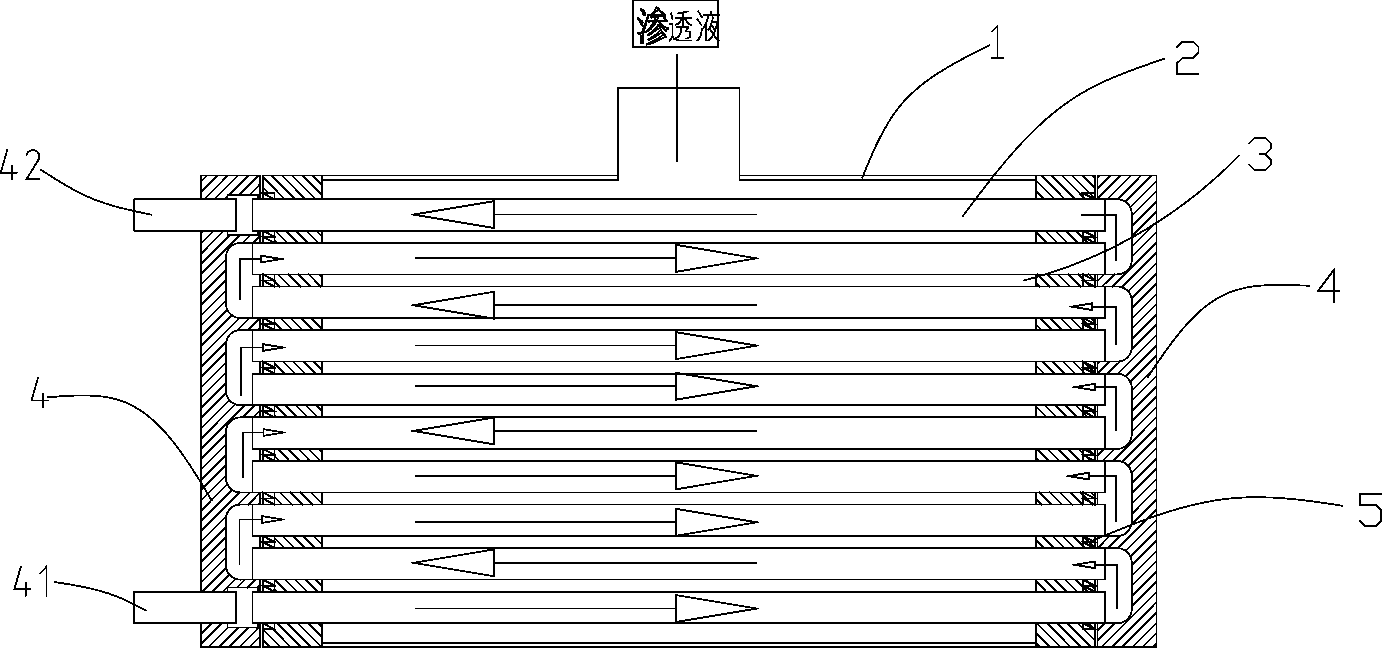

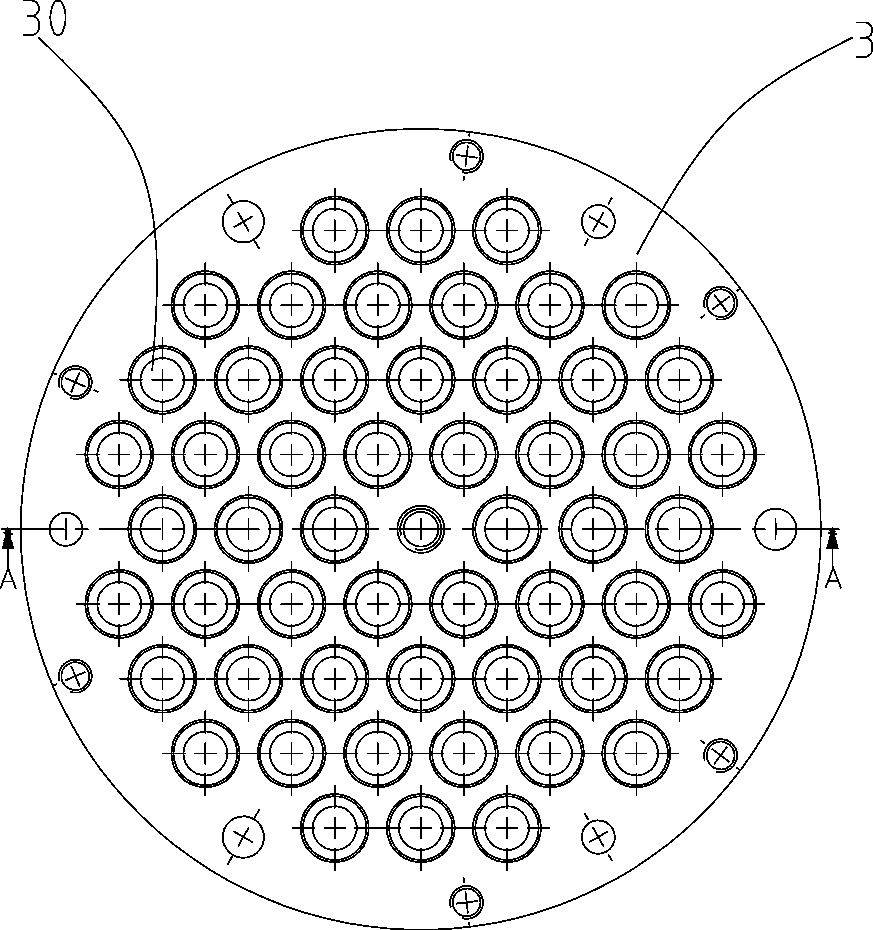

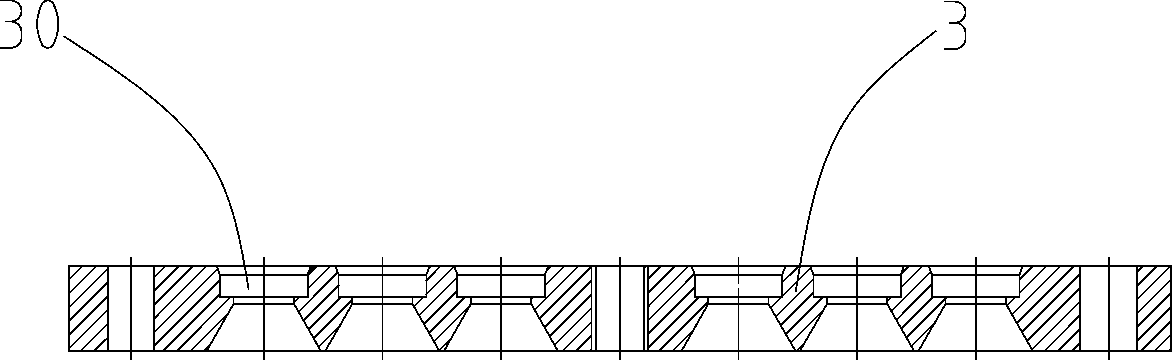

[0025] see Figure 1 to Figure 6 As shown, the inner wall of the present invention is coated with a series structure tubular membrane module mainly a shell 1, a group of tubular membranes 2, two pairs of flanges 3, 4 and seals 5, and the shell 1 covers all the tubular membranes. film2.

[0026] The inner wall of the tubular membrane 2 is coated with a separation layer. Compared with the sealing structure of the outer wall tube, the sealing structure with a separation layer on the inner wall is simpler and has better sealing reliability. It is not easy to leak under the environment, and the sealing structure is more effective in the presence of vacuum pressure.

[0027] Two pairs of flanges are arranged symmetrically at both ends of the tubular membrane 2, and each pair of flanges is composed of a fixed flange 3 and a channel flange 4, and a plane is passed between the fixed flange 3 and the channel flange 4. Contact, under the pressure of the bolts to prevent leakage between...

Embodiment 2

[0035] see Figure 1 to Figure 6 As shown, the separation layer is a pervaporation membrane supported by ceramics, which is a pervaporation membrane coated with an inorganic membrane on a ceramic support body, and the rest of the technical solutions are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com