Microfluidic atom cavity, on-chip atomic clock chip and preparation method

An atomic cavity and microfluidic technology, applied in the field of MEMS manufacturing, can solve the problems of optical window pollution, influence, low performance of atomic cavity, etc., and achieve the effect of low cost and simple method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

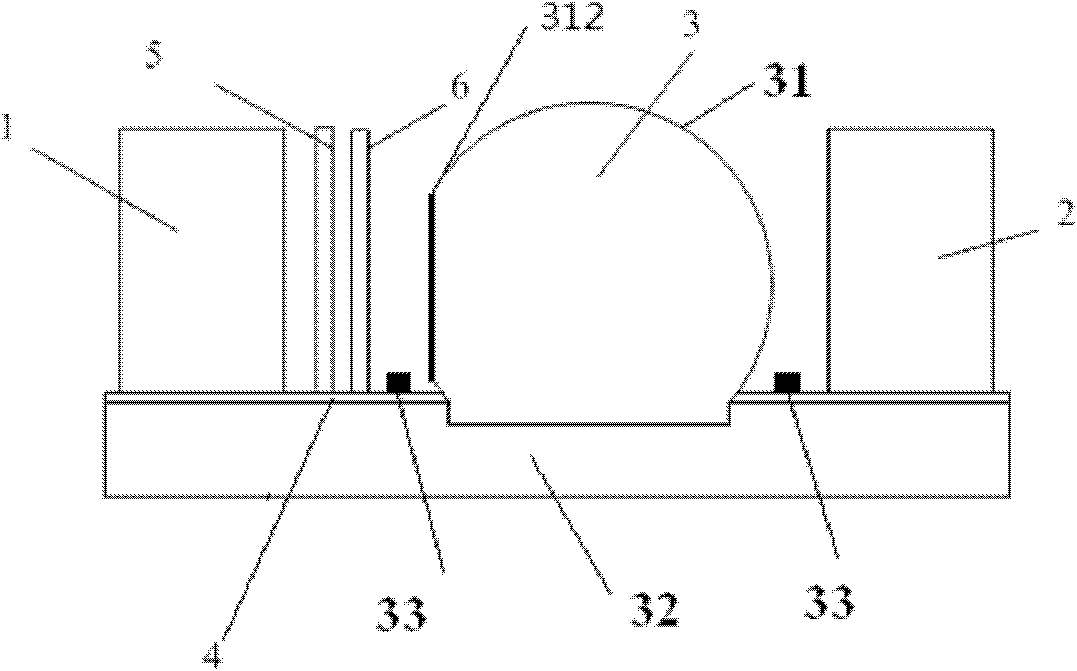

[0039] A microfluidic atomic cavity, a silicon substrate with a microfluidic groove and a borosilicate glass assembly wafer corresponding to the microfluidic groove to form a glass microcavity structure are bonded to form a closed system, the closed system includes a glass atomic cavity , The reactant blocks the micro-channel and the reactant micro-cavity, the reactant micro-cavity is placed with the reactant particles necessary for the generation of the atomic clock, the glass atomic cavity and the reactant micro-cavity are connected through the reactant-blocked micro-channel, bonding The caliber of the reactant glass microcavity on the surface is smaller than the caliber of the glass atomic cavity, the minimum width of the reactant blocking microflow channel is not greater than the minimum particle diameter of the reactant particle, and the glass atomic cavity is provided with a light incident plane.

[0040] In the above technical solution, the reactant blocking micro-channe...

Embodiment 2

[0042] A method for preparing a microfluidic atomic cavity, comprising the following steps: etching a microfluidic groove on a silicon substrate, which is composed of a reactant groove, a reactant blocking microfluidic path and an atomic groove, wherein the diameter of the reactant groove is smaller than The caliber of the atomic tank, the reactant tank and the atomic tank are connected through the reactant barrier micro-channel, the reactant particles are placed in the reactant tank, and then the above-mentioned silicon substrate etched with the micro-channel tank and borosilicate The glass assembly wafers are anodically bonded to form a sealed cavity; a silicon wafer mold is placed vertically on the surface of the borosilicate glass assembly wafer of the above-mentioned bonded wafers at a position corresponding to the microgroove, and then heated in the air to 820 °C ℃ ~ 900 ℃, keep warm for 10 ~ 20min, the reactant particles release gas so that the glass corresponding to the...

Embodiment 3

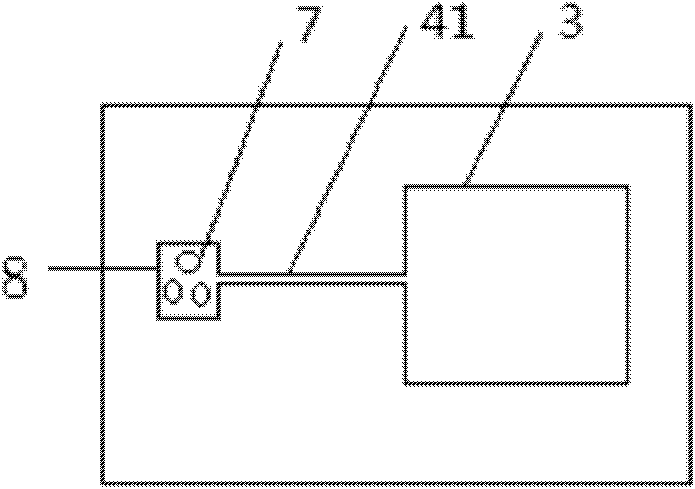

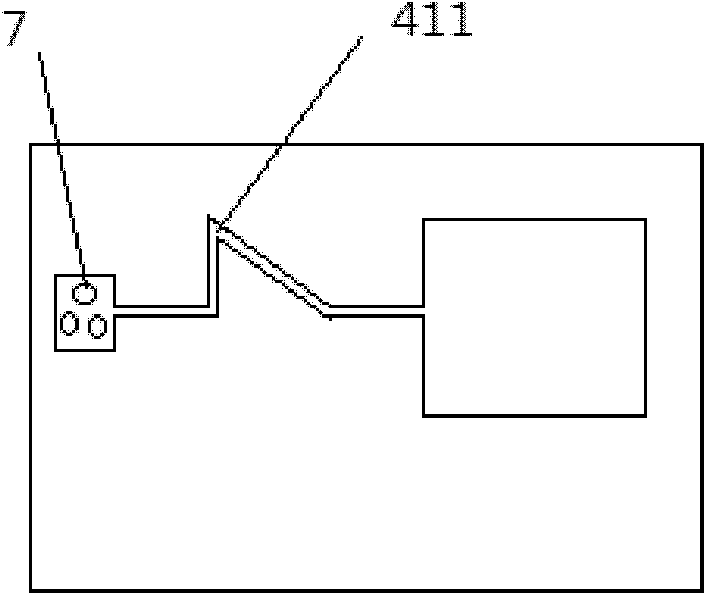

[0045] A miniature atomic clock chip, comprising a laser generator, a filter, a quarter wave plate, a laser detector and the miniature atomic cavity with a light incident plane described in Embodiment 1, a laser generator, a filter, a quarter wave plate A wave plate laser detector is assembled on a borosilicate glass assembly wafer, and their centers are located on the same optical axis as the center of the glass microcavity. The laser generator is located on the side of the airtight glass atomic cavity with a light incident plane. A filter and a quarter-wave plate are arranged sequentially between the laser generator and the light incident plane. The laser light emitted by the laser generator passes through the filter and the quarter-wave plate, and enters the airtight glass atomic cavity through the light incident plane. After being emitted again, it is detected by a laser detector, and a heater is arranged around the glass microcavity, and the above-mentioned heater, laser g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com