Parallel-flow heat exchanger and fabrication method thereof

A technology of parallel flow heat exchangers and headers, applied in the direction of refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problems of low waste rate of heat exchangers, difficulty in fixing, etc., achieve less leakage, wide application range, Flexible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

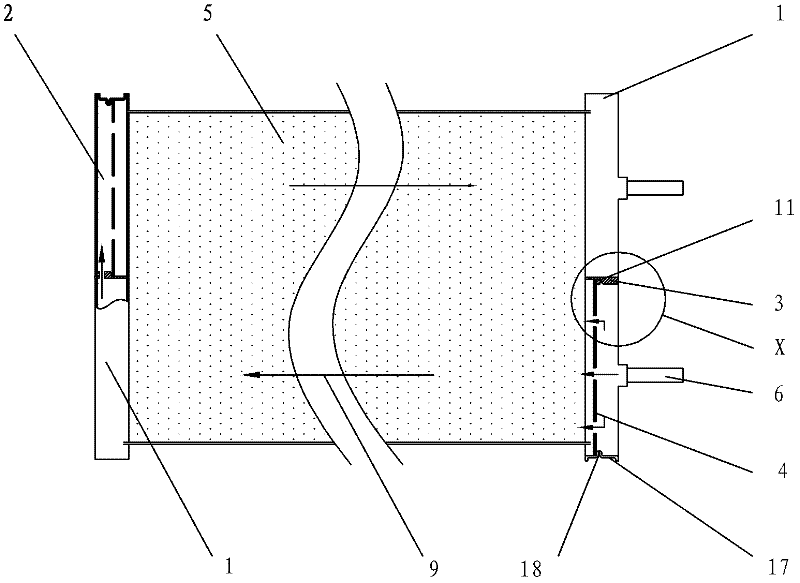

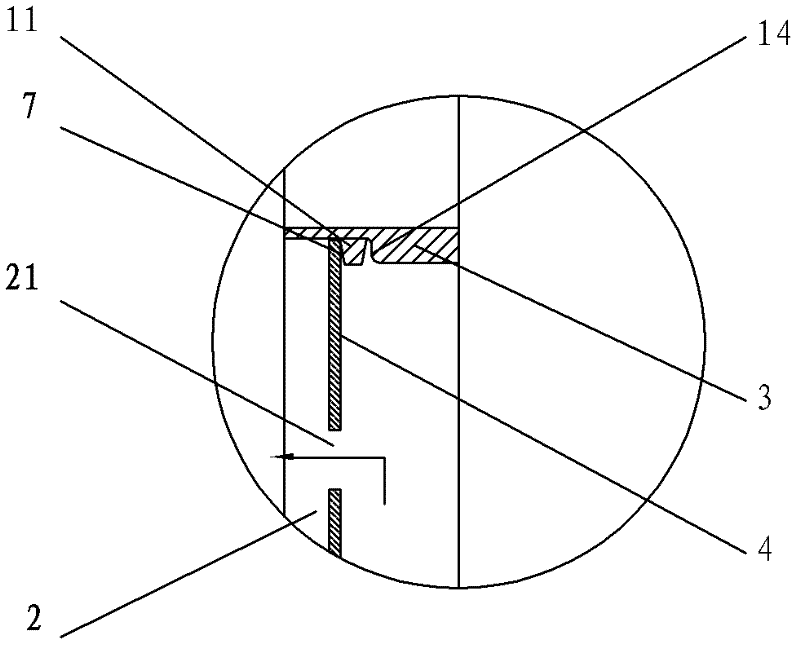

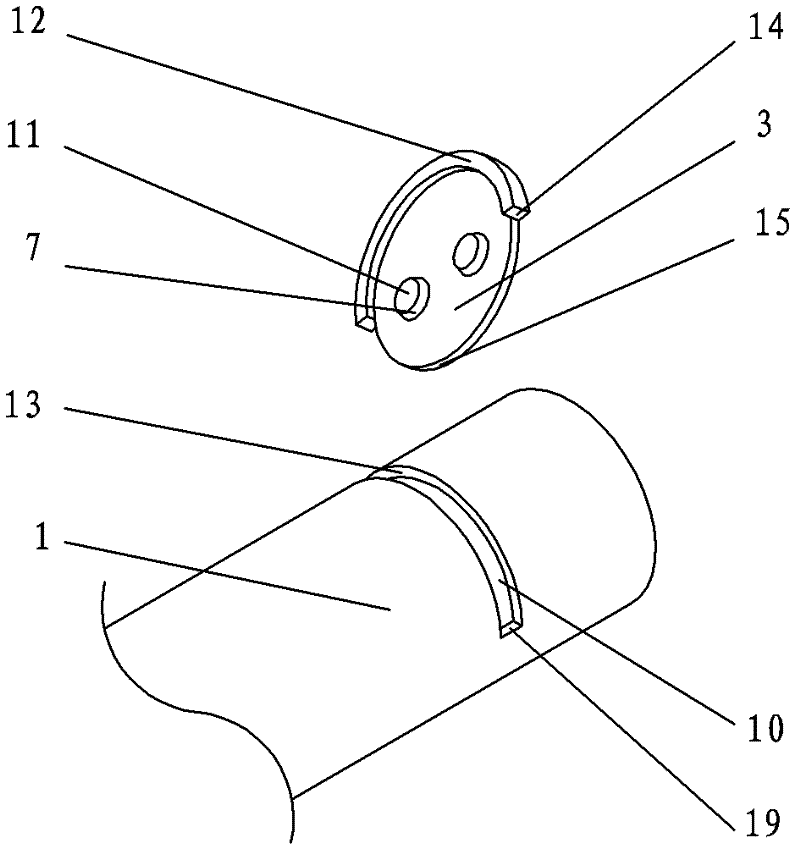

[0054] see Figure 1-Figure 6, this embodiment is a parallel flow heat exchanger with headers arranged vertically. The refrigerant enters the header 1 from the refrigerant pipe 6 below the right side. The inner wall of the flow tube 1 encloses the partition 2 of the collector. After the refrigerant passes through the flow equalizer 4 with the flow uniformity hole 21 set in the partition 2, it enters the flat tube 5 according to the direction of the process 9, and is collected to In the partition 2 located on the opposite side of the header 1 , the fixed partition 3 divides the cavities on both sides into disconnected, that is, the cavities on both sides become the partition 2 respectively. At this time, it is a disconnected partition.

[0055] In the present invention, process 9 refers to the header flowing from one side of the parallel flow heat exchanger through the flat tube to the other side of the header; specifically, it can be from the partition of a header through the...

Embodiment 2

[0074] see Figure 7 , The main difference between this embodiment and Embodiment 1 is that in this embodiment, H=18mm, α=45 degrees, L=33mm, M=15mm; M+H=15+18=33≤L=33 is established .

[0075] The end face of the flow sharing plate 4 pressed by the first crimping surface 7 of the fixed partition 3 is not a plane, but a positioning depression 20 is arranged on the end surface of the flow sharing plate 4, the shape of the positioning depression 20 is consistent with the first crimping The shapes of the surfaces 7 match each other, so that the contact area of the first crimping surface can be further enlarged, the stability after welding can be improved, and the leakage of the contact surface can be reduced.

[0076] See Embodiment 1 for the rest of the undescribed parts, and will not repeat.

Embodiment 3

[0078] see Figure 8 , the main difference between this embodiment and Embodiment 1 is that in this embodiment, H=3mm, α=1 degree, L=6mm, M=3mm; M+H=3+3=6≤L=6 is established .

[0079] The cross-section of the crimping protrusion 11 of the fixed partition 3 is a rectangle, and the bottom surface of the rectangle is a crimping surface, so the crimping protrusion 11 cooperates with the end surface of the planar structure of the flow equalizer 4, and there will be a relatively large pressure. Joint area, and the stability after welding is significantly improved.

[0080] See Embodiment 1 for the rest of the undescribed parts, and will not repeat.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com