System and method for enhancing heat transfer and online descaling of micro-channel heat exchanger

A micro-channel heat exchanger and heat transfer enhancement technology, applied in the field of flow heat transfer, can solve the problems of destroying the flow boundary layer and deposit fouling, and achieve the effect of stabilizing heat transfer performance and enhancing heat transfer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is described in further detail below in conjunction with embodiment.

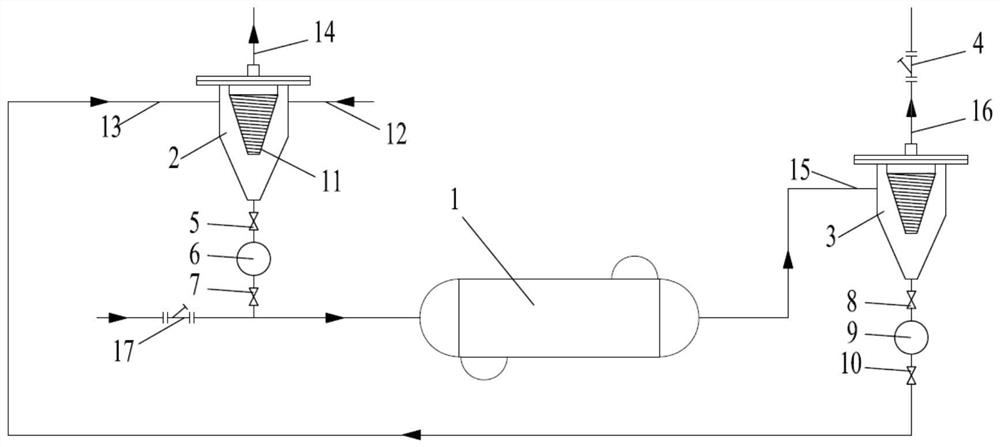

[0020] refer to figure 1 , a system and method for enhancing heat transfer and online descaling of a microchannel heat exchanger according to the present invention, including a particle feeding device, a particle separating device and a downstream filter 4 . The particle feeding device includes a particle separator one 2 , a valve one 5 , a particle storage tank one 6 and a valve two 7 , and the particle separator one 2 includes a return inlet 13 , a feed inlet 12 and a exhaust gas outlet 14 . The particle separation device includes a particle separator 2 3 , a valve 3 8 , a particle storage tank 2 9 and a valve 4 10 , and the particle separator 2 3 includes an inlet 15 and an outlet 16 . The first particle separator 2 and the second particle separator 3 are equipped with winding wires 11, the gaps of the winding wires are smaller than the particle size, and are used to filter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com