Ternary refrigerant mixture for pulsating heat pipe

A technology of pulsating heat pipes and mixed working fluids, applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve problems such as limited heat transfer capacity, and achieve the effects of strong heat transfer capacity, enhanced heat transfer, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with specific examples.

[0017] A ternary mixed working fluid for pulsating heat pipes is prepared by mixing two binary working fluids in a certain proportion. The two binary working fluids should meet the following basic requirements:

[0018] 1) The two binary working fluids are both water-based solutions;

[0019] 2) The binary working medium one is a nanofluid with high thermal conductivity, the larger the thermal conductivity of the metal nanoparticles, the better, and the smaller the particle size of the metal nanoparticles, the better;

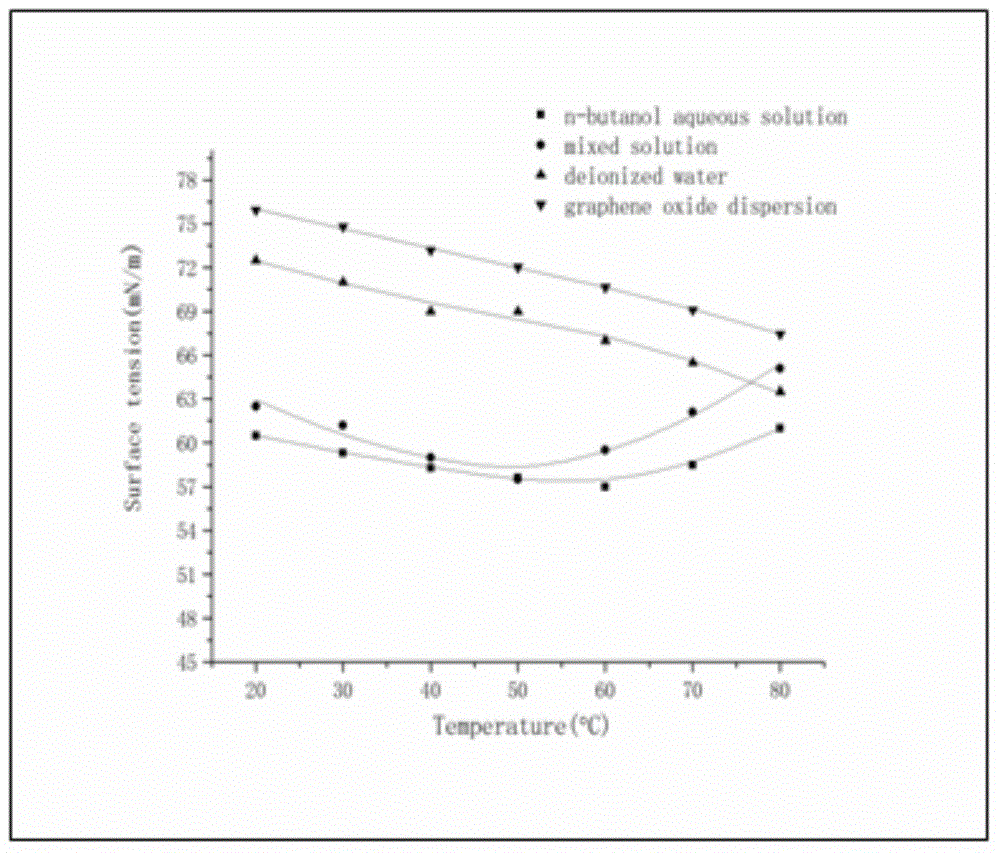

[0020] 3) The binary working medium 2 is a self-wetting fluid whose surface tension exhibits an inverse Marangoni effect at a certain temperature.

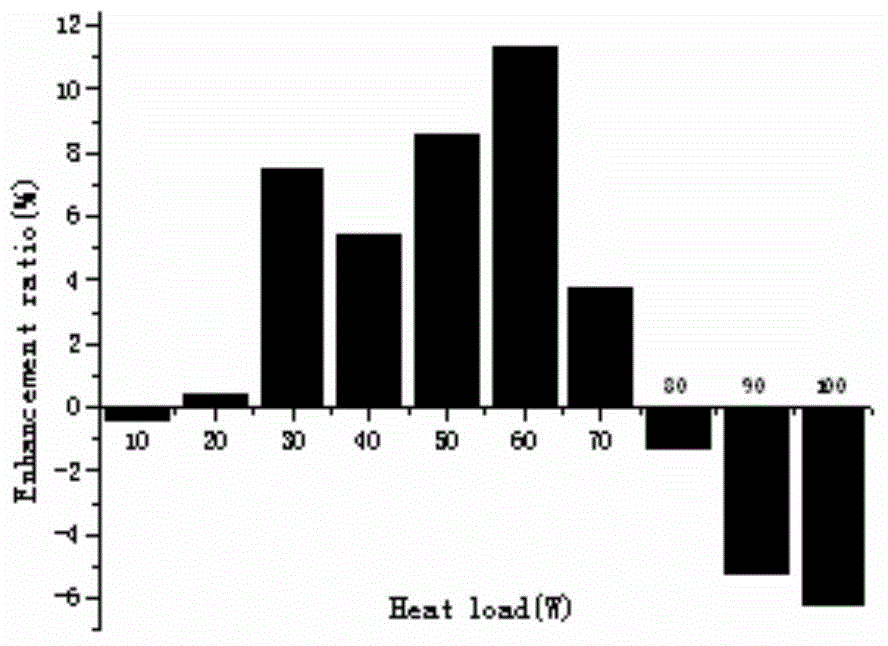

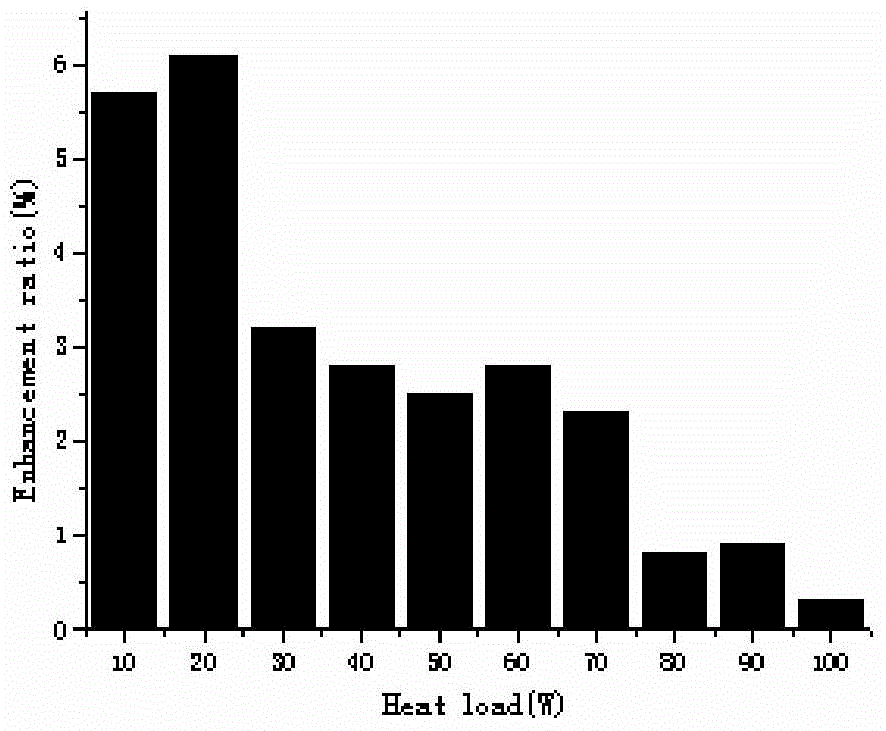

[0021] 4) Binary working fluid one nanofluid is the graphene oxide solution that concentration is 0.5mg / ml; Binary working fluid two is the n-butanol aqueous solution that mass fraction is 0.5%; Two kin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com