Aluminum spiral radiator

A heat-dissipating tube and spiral technology, applied in the field of spiral heat-dissipating finned tubes, can solve the problems of insufficient connection, shortened service life, corrosion of heat transfer tubes, etc., and achieve the effects of improving heat dissipation, prolonging service life and enhancing heat transfer capacity.

Inactive Publication Date: 2008-09-17

许雪峰

View PDF0 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Since the inner spiral fin guide vane is brazed on the inner wall of the heat transfer tube, the connection between the two is not tight enough, and the gap between the two is relatively large, resulting in poor thermal conductivity. At the same time, the gap between the spiral guide vane and the heat transfer tube It is easy to inject the circulating medium and cause the heat transfer tube to be corroded, greatly shortening the service life

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

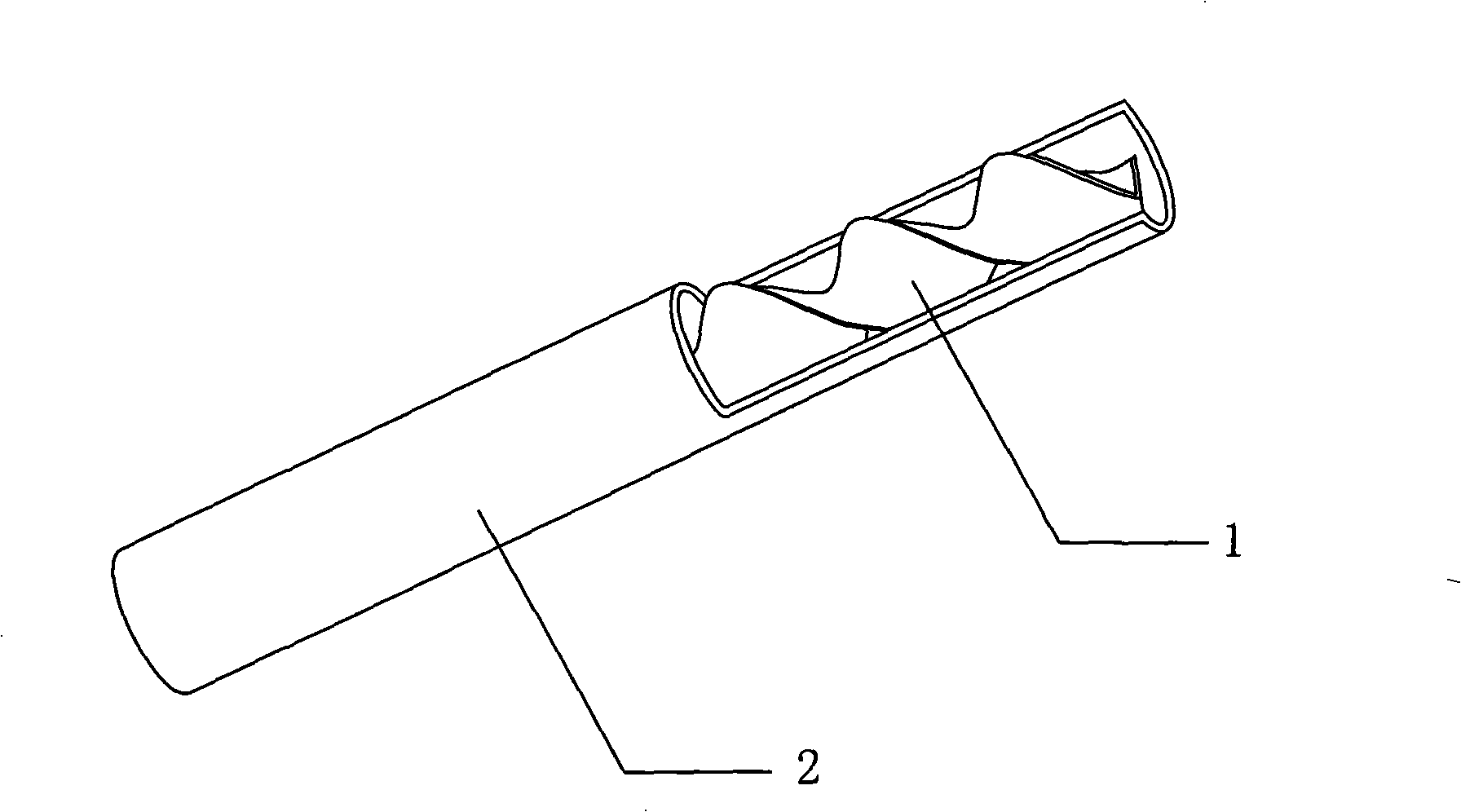

[0008] See figure 1 , the present invention includes a heat transfer tube 2 and an inner spiral fin 1, the heat transfer tube 2 and the inner spiral fin 1 are formed by hot extrusion, and the helical outer circumference of the fin 1 is directly extruded with the heat transfer tube 2 molding, and the two ends of the heat transfer tube 2 are open structures.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

Provided is an aluminum spiral radiating pipe having the advantages of simple structure, long service life, low flow contact thermal resistance and excellent heat-transfer capability. The radiating pipe includes heat transfer tube and spiral fin, characterized in that the spiral fin and the heat transfer tube are to become integrated by hot-extrusion.

Description

(1) Technical field [0001] The invention relates to a spiral cooling fin tube used in heat exchange equipment, in particular to an aluminum spiral cooling tube. (2) Background technology [0002] Generally, the structure of the inner spiral finned tube used in heat exchange equipment is composed of a heat transfer tube, an inner spiral fin guide vane arranged in the heat transfer tube, and an inner spiral fin guide vane provided at both ends of the heat transfer tube to prevent Slide out of the jam pose. Since the inner spiral fin guide vane is brazed on the inner wall of the heat transfer tube, the connection between the two is not tight enough, and the gap between the two is relatively large, resulting in poor thermal conductivity. At the same time, the gap between the spiral guide vane and the heat transfer tube It is easy to inject the circulating medium and cause the heat transfer tube to be corroded, which greatly shortens the service life. (3) Contents of the inven...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): F28F1/40

Inventor 许雪峰

Owner 许雪峰

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com