Combined cooling and power system and refrigeration, power generation and combined cooling and power method based on combined cooling and power system

A technology of combined cold and power supply and steam generator, which is applied in the fields of combined cold and power supply system, refrigeration, power generation and combined cold and power supply, can solve the problems of energy waste, environmental pollution, difficulty in achieving satisfaction, etc., and achieves low cost and reduced cost. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

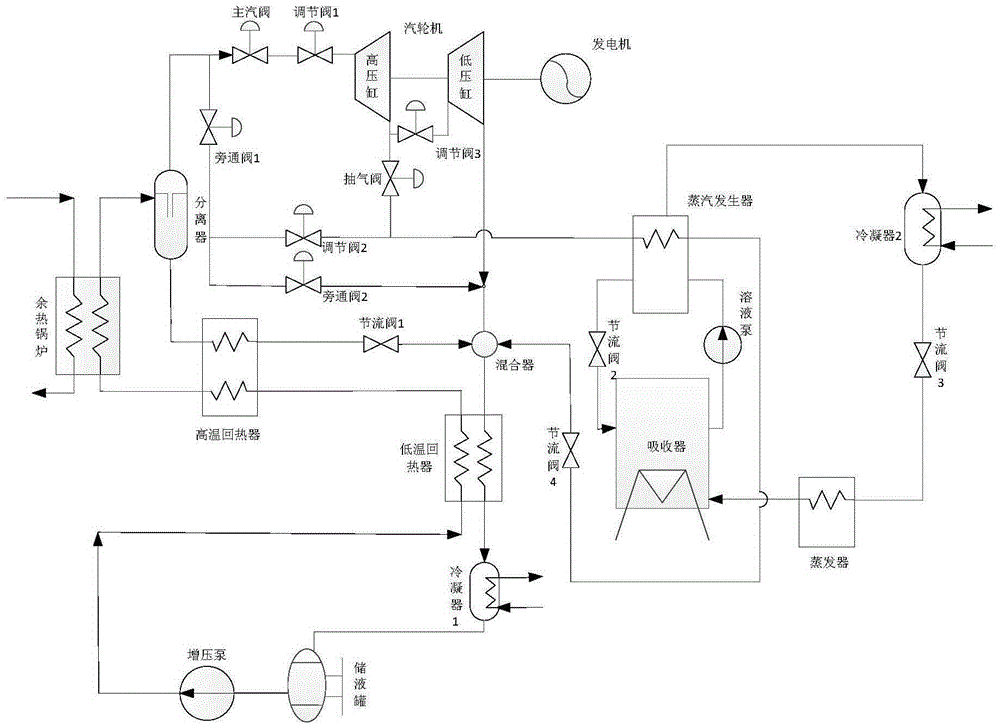

[0028] see figure 1 As shown, it is a flowchart of a combined cooling and power system based on the recovery and utilization of low-grade heat sources in the present invention. The system includes liquid storage tank, evaporator, waste heat boiler, separator, steam turbine, generator, condenser, booster pump, solution pump, low temperature regenerator, high temperature regenerator, steam generator, absorber and several regulators valve, throttle valve, bypass valve. A variety of joint supply modes can be realized according to the needs of different working conditions.

[0029] Implementations fall broadly into three categories:

[0030] 1. Combined cooling and power supply mode

[0031] 1) Cold electricity cycle under rated working conditions: the main steam valve is opened, bypass valve 1 and bypass valve 2 are closed, regulating valve 2 is closed, and regulating valve 1 and regulating valve 3 are opened. The ammonia water basic solution in the liquid storage tank is pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com