New energy automobile water-cooled condenser

A new energy vehicle and condenser technology, which is applied in the direction of evaporator/condenser, refrigerator, refrigeration components, etc., can solve the problems of poor air cooling effect, unreasonable use of heat, waste of heat, etc., to improve battery life , Reasonable use of heat energy, fast cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

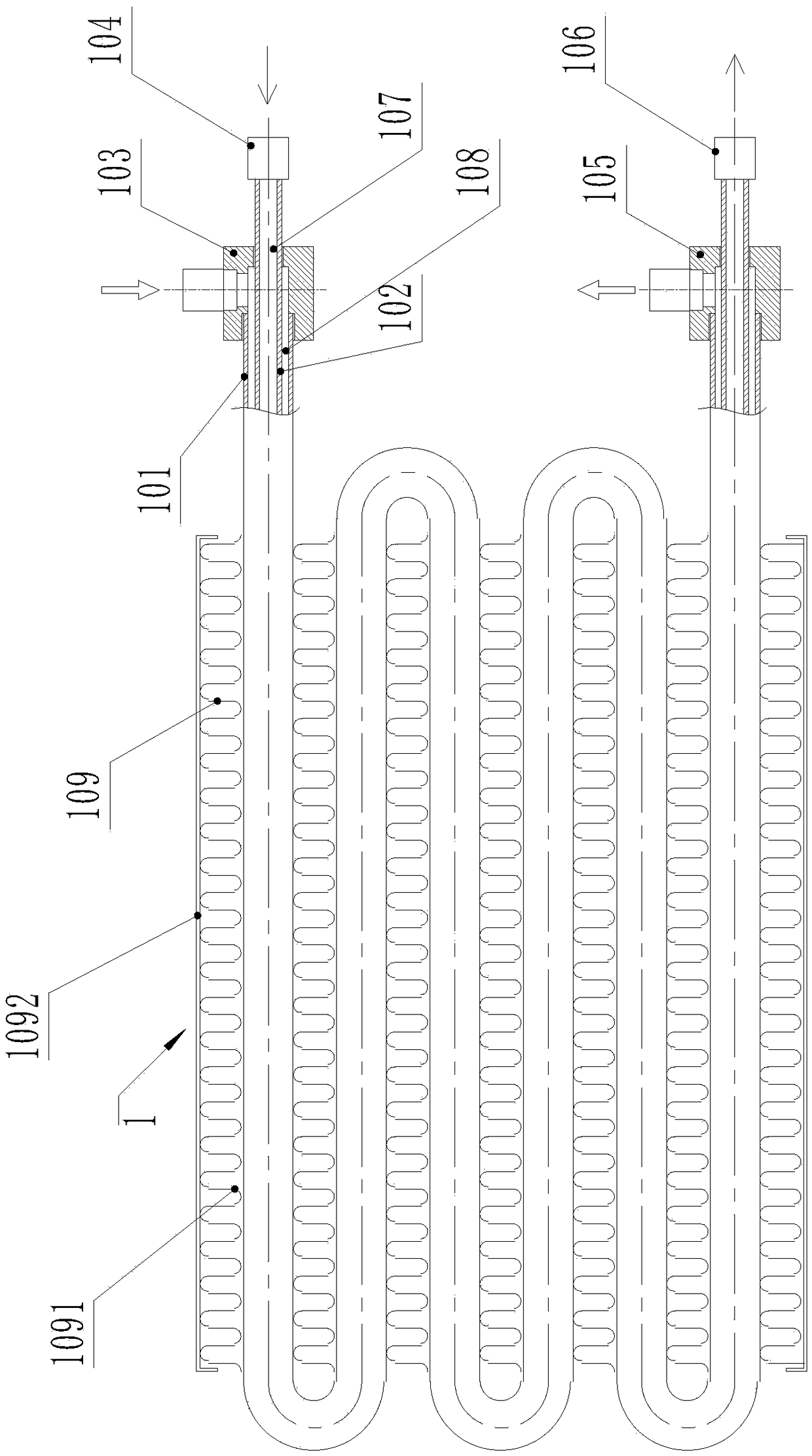

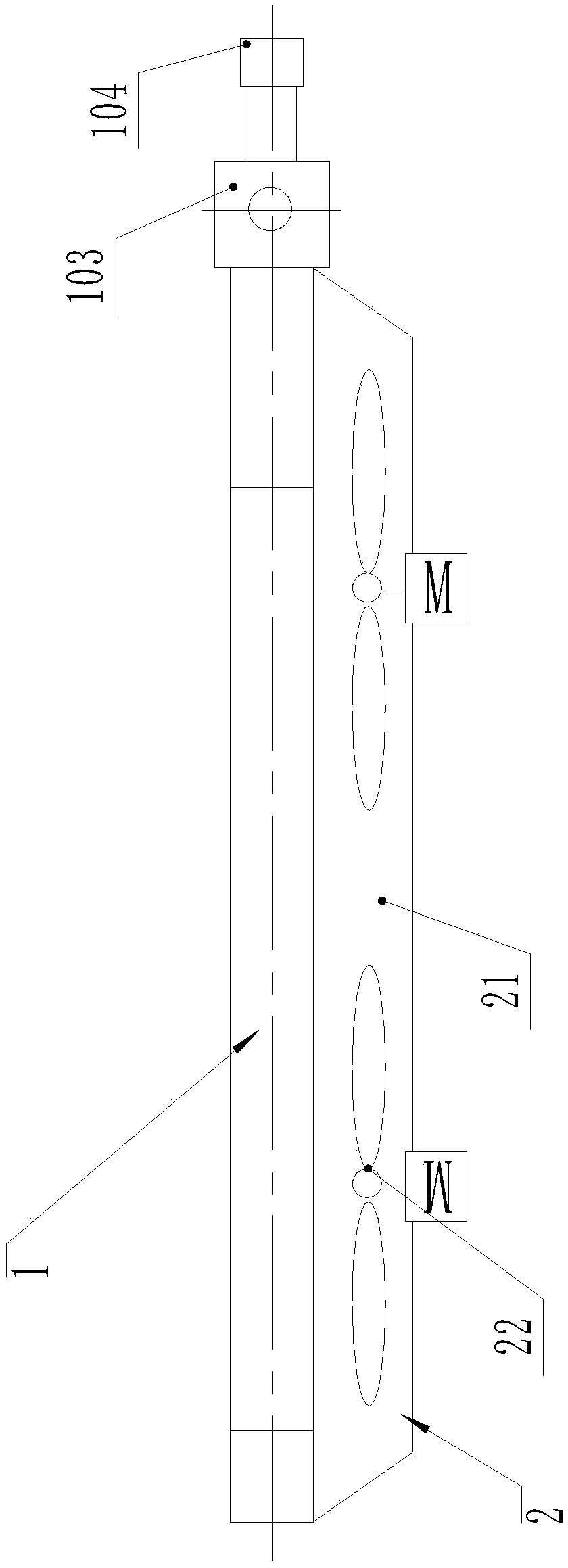

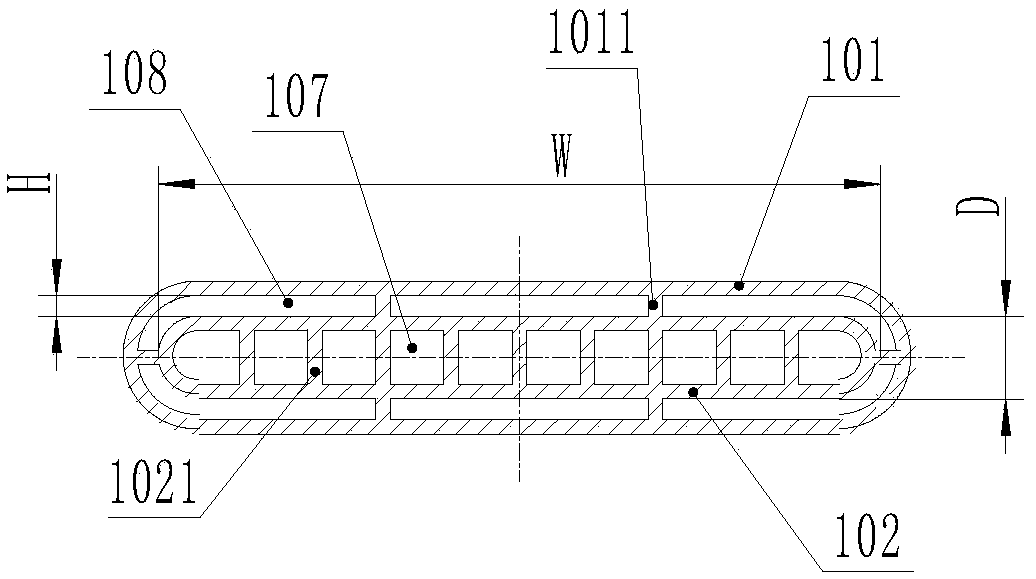

[0037] Such as Figure 1 to Figure 8 As shown, a water-cooled condenser for a new energy vehicle includes a condenser body 1 and a fan assembly 2. The condenser body 1 includes an outer tube 101 and an inner tube 102 that are mutually fitted and fixed, and the inner tube 102 is The cavity forms a refrigerant flow channel 107, and the space between the inner tube 102 and the outer tube 101 forms a water flow channel 108, and the refrigerant flow channel 107 and the water flow channel 108 are independent of each other.

[0038] The two ends of the outer pipe 101 are respectively provided with a water inlet joint 103 and the water outlet joint 105, and the two ends of the inner pipe 102 are respectively provided with a refrigerant inlet joint 104 and a refrigerant outlet joint 106, and the water inlet joint 103 and the water outlet joint 105 are connected with the water flow channel 108, the refrigerant inlet joint 104 and the refrigerant outlet joint 106 are both communicated wi...

Embodiment 2

[0050] Such as Figure 9 with Figure 10 As shown, the structure of this embodiment is basically the same as that of Embodiment 1, except that the structure of the condenser body 1 is changed. The inner tube 102 and the outer tube 101 in Embodiment 1 are formed into a coil structure, while this embodiment In the example, the number of inner tubes 102 and outer tubes 101 is multiple and all are straight tubes, the heat conducting fins 109 are arranged between adjacent straight tubes, the water inlet joint 103, the water outlet joint 105, the refrigerant The inlet joint 104 and the refrigerant outlet joint 106 are tubular structures and are respectively provided with a water inflow main channel, a water outflow main channel 1051, a refrigerant inflow main channel and a refrigerant outflow main channel. Figure 9 It can be seen from the figure that in the partial cross-sectional view of the water outlet joint 105, the water outlet joint 105 is a tubular structure, and the water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com