Preparation method of polymer lithium ion battery

A technology of lithium-ion batteries and polymers, applied in secondary batteries, circuits, electrical components, etc., can solve problems such as liquid leakage, uneven interface current distribution, and affecting battery safety performance, so as to improve cycle performance and safety performance, The effect of uniform distribution of interface current and smooth ion pathway

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

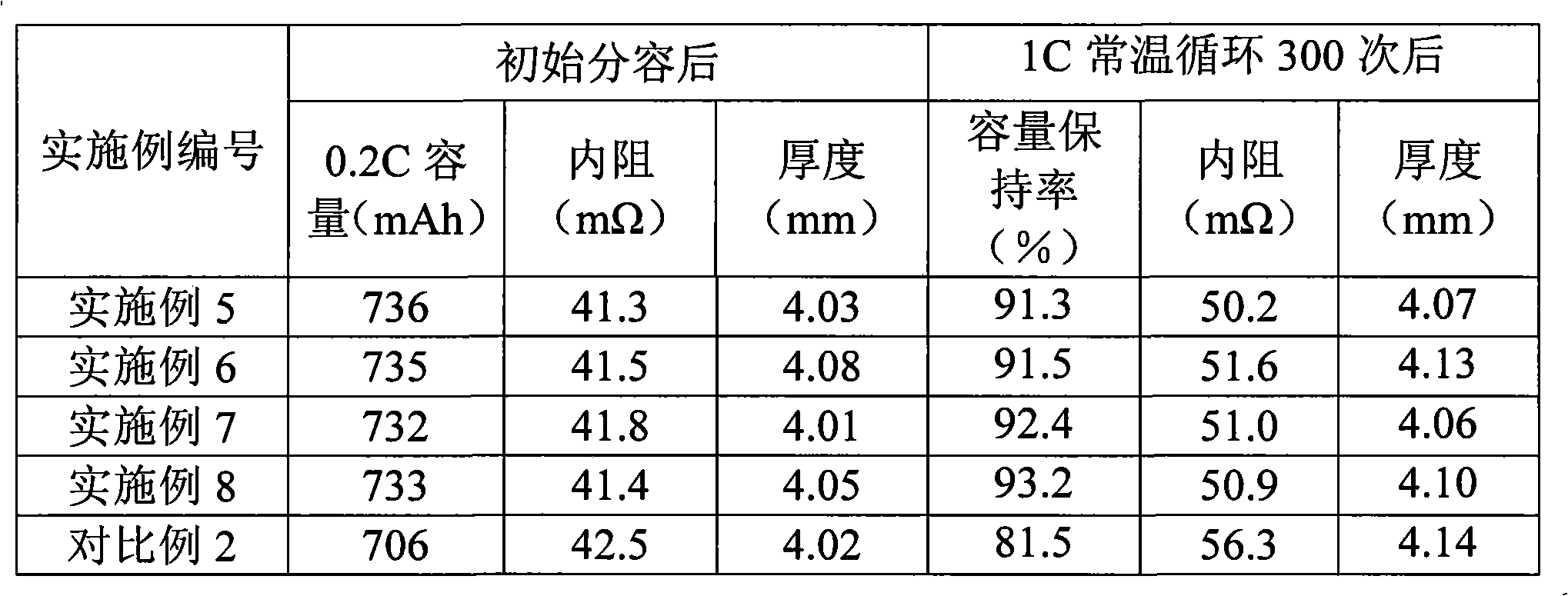

Examples

preparation example Construction

[0020] The preparation method of the battery precursor is well known to those skilled in the art. For example, the method may include: preparing the positive electrode sheet and the negative electrode sheet of the battery; coating the polymer slurry on the surface of the positive electrode sheet and the negative electrode sheet to form a polymer film; disposing a separator between the positive electrode sheet and the negative electrode sheet to form a pole core ; The pole core is accommodated in the battery case, injected with electrolyte and packaged.

[0021] The polymer slurry contains polymer, solvent, plasticizer and inorganic filler; in the polymer slurry, the content of polymer, solvent, plasticizer and inorganic filler can be changed in a wide range, preferably Next, based on the total weight of the polymer slurry, the content of the polymer is 1-20% by weight, the content of the solvent is 50-90% by weight, and the content of the plasticizer is 1-20% by weight. 30% b...

Embodiment 1

[0044] This example is used to illustrate the preparation method of the polymer lithium ion battery provided by the present invention.

[0045] (1) Preparation of polymer lithium-ion battery precursor

[0046] 1) Preparation of positive electrode sheet

[0047] Dissolve 30 grams of polyvinylidene fluoride (PVDF) in about 500 grams of N-methylpyrrolidone (NMP) solvent to prepare a binder solution, and then mix 940 grams of LiCoO 2 Add 30 grams of acetylene black powder as a conductive agent to the above solution, stir and mix well to obtain a positive electrode slurry; use a pulper to evenly coat the positive electrode slurry on both sides of an aluminum foil with a thickness of 18 microns, and make the coating The layer density is 23.5 mg / cm2. After heating and drying under vacuum at 125°C for 1 hour, roll forming by a twin-roller mill, and cutting into pieces to obtain a positive electrode of 360 mm (length) × 43.5 mm (width) × 130 microns (thickness), each positive electro...

Embodiment 2

[0061] This example is used to illustrate the preparation method of the polymer lithium ion battery provided by the present invention.

[0062] (1) Preparation of polymer lithium-ion battery precursor

[0063] 1) Preparation of positive electrode sheet

[0064] Dissolve 30 grams of polyvinylidene fluoride (PVDF) in about 500 grams of N-methylpyrrolidone (NMP) solvent to prepare a binder solution, and then mix 940 grams of LiCoO 2 Add 30 grams of acetylene black powder as a conductive agent to the above solution, stir and mix well to obtain a positive electrode slurry; use a pulper to evenly coat the positive electrode slurry on both sides of an aluminum foil with a thickness of 18 microns, and make the coating The layer density is 23.5 mg / cm2. After heating and drying under vacuum at 125°C for 1 hour, roll forming by a twin-roller mill, and cutting into pieces to obtain a positive electrode of 360 mm (length) × 43.5 mm (width) × 130 microns (thickness), each positive electro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com