Method for sealing heat pipe

A heat pipe and sealing technology, which is applied in the field of heat pipe sealing at room temperature, can solve the problems of easy cracks, affecting the fusion effect, and difficult to combine into one body, so as to achieve the effect of not easy to leak and tight and solid.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

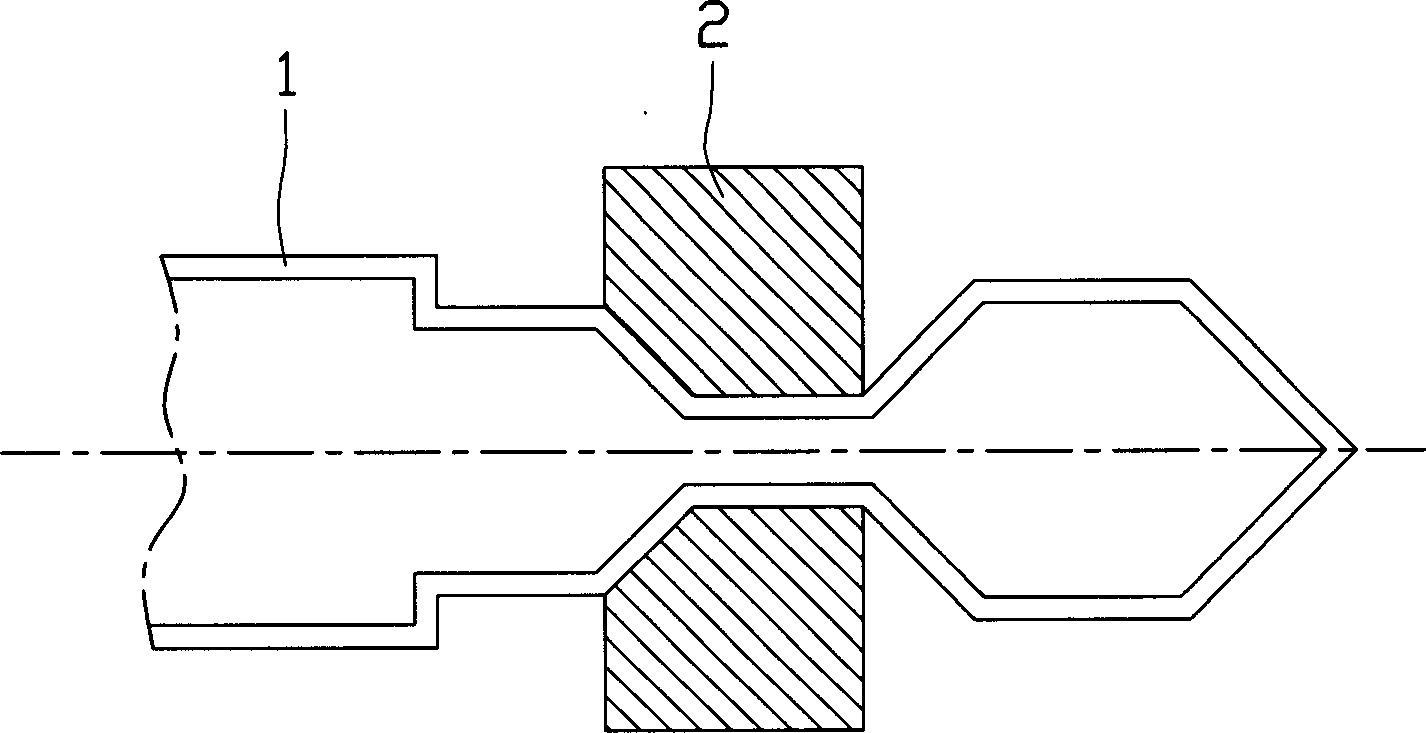

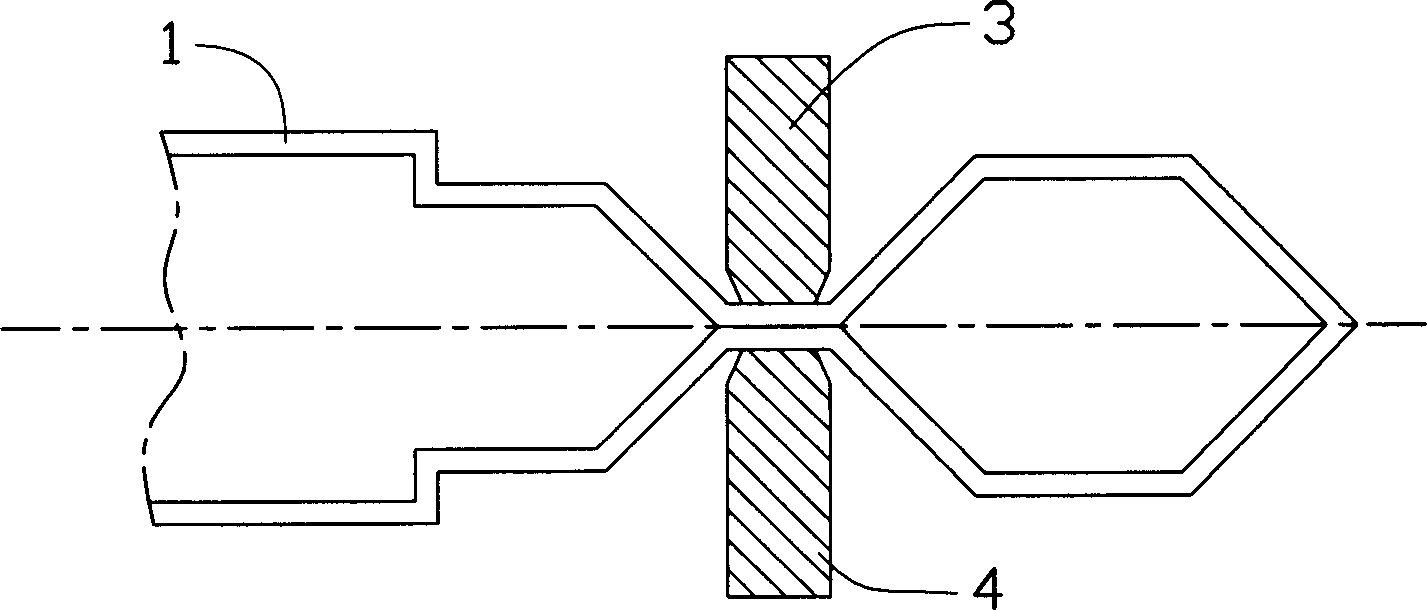

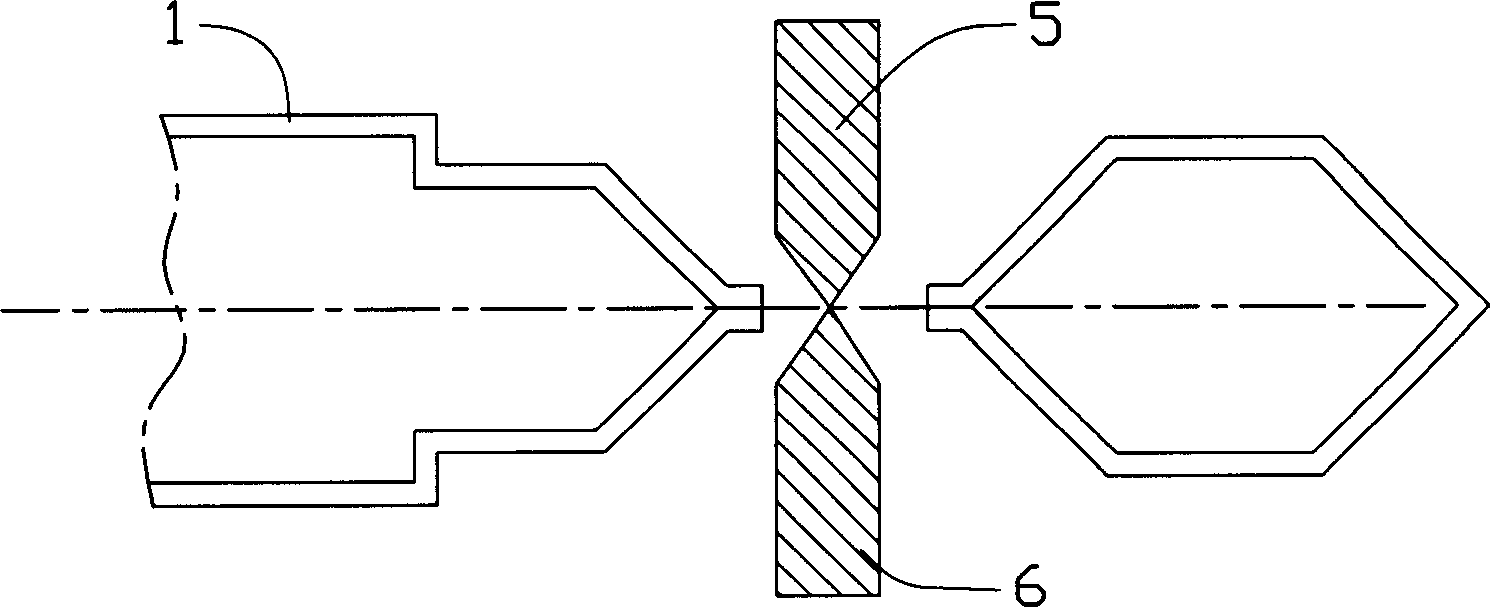

[0012] Please refer to Figure 2A ~B, the heat pipe sealing method of the present invention is: provide a liquid-filled pipe body 10, one end of this pipe body 10 is closed, and the other end is a desired sealing end 12 having a desired joint surface 14, and the desired joint surface 14 is a smooth surface; The ion beam 20, in the normal temperature and vacuum state, the argon ion beam 20 rotates corresponding to the periphery of the end 12 of the tube body 10 to irradiate the surface 14 to be jointed, and at this time the argon ions continuously hit the surface 14 to be jointed. Under the impact, the oxide layer and adsorption layer of the metal surface layer are excited, the surface to be joined 14 is activated, and the surface layers such as the oxide layer and the adsorption layer of the surface to be joined 14 are removed to form a clean active interface. It is an unstable active ion state, and it is easy to join with another active interface; two mechanical extrusion par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com