Patents

Literature

96results about How to "Reduce disassembly steps" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

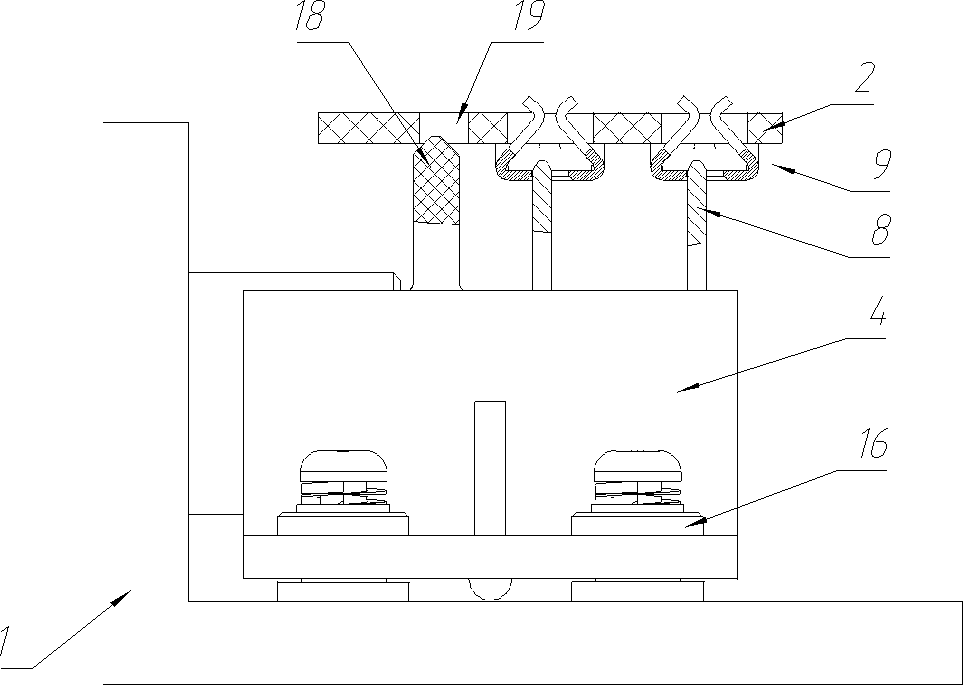

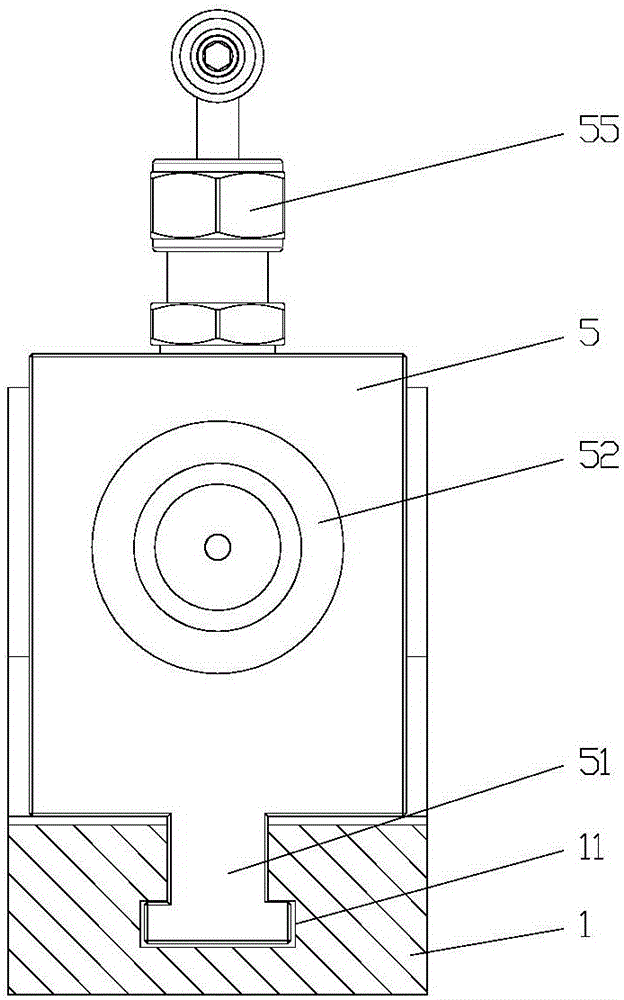

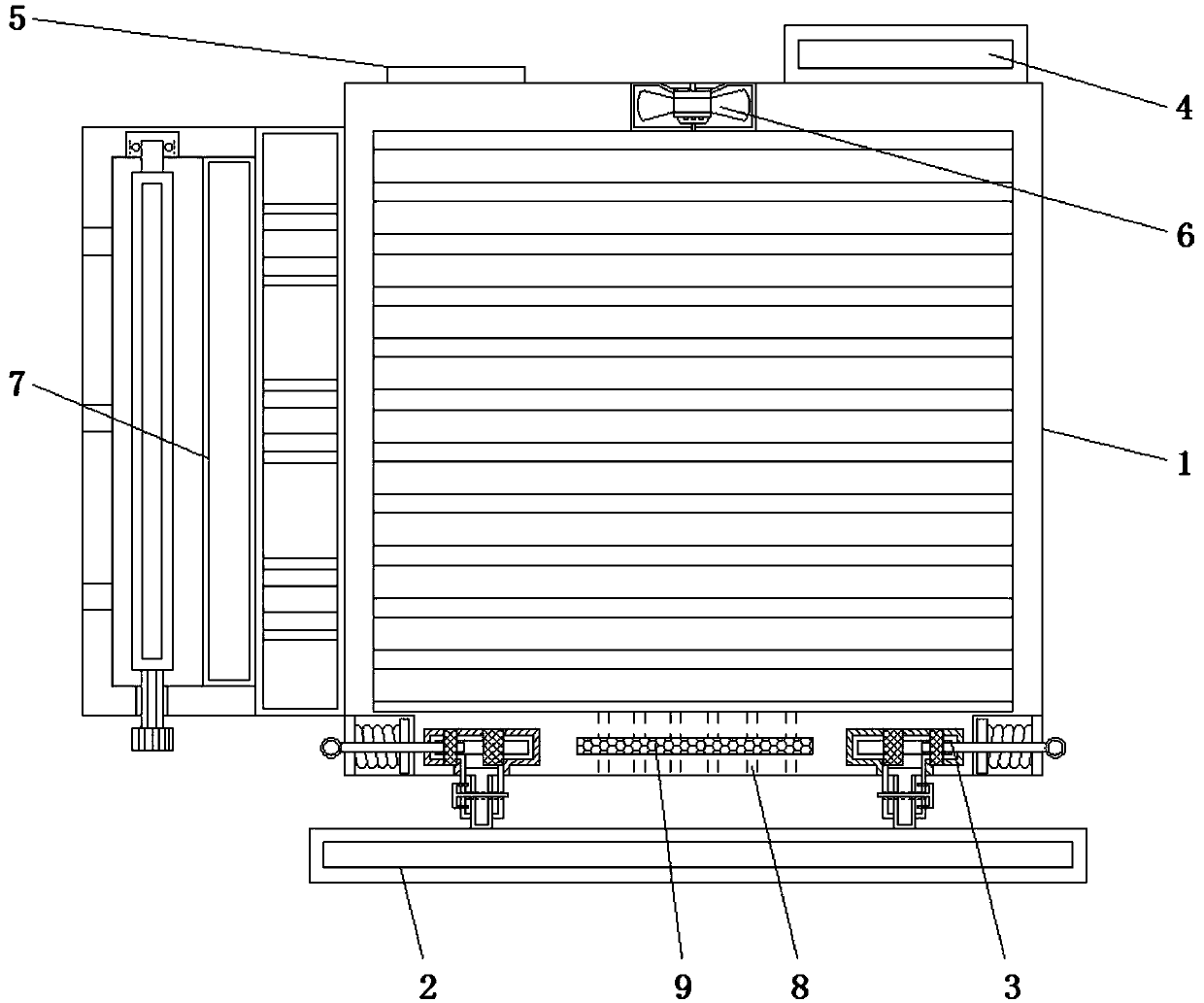

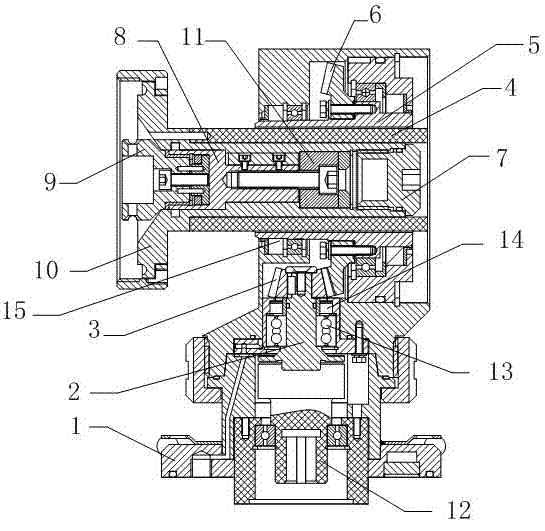

Water purifier

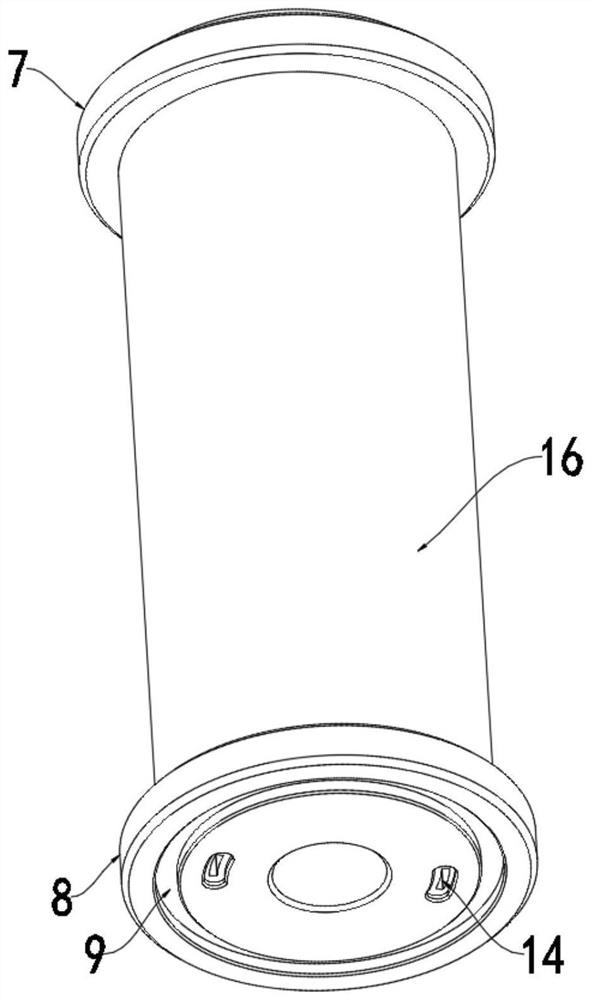

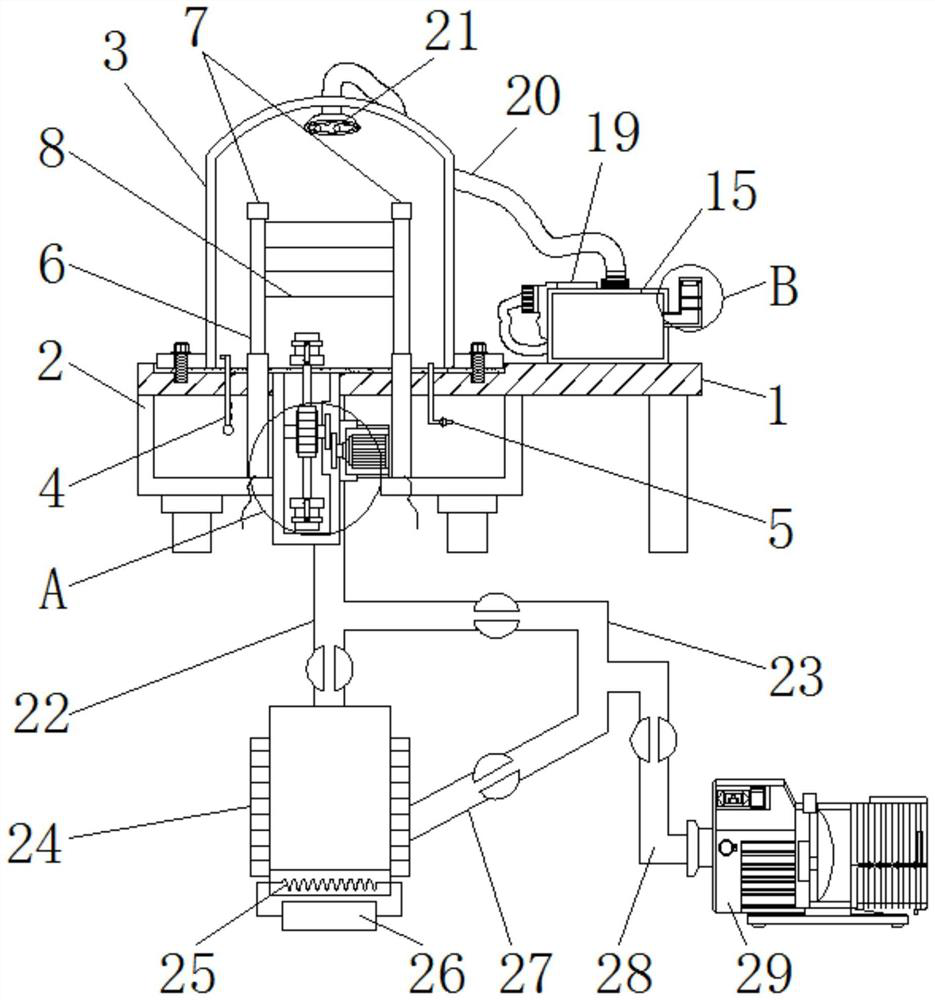

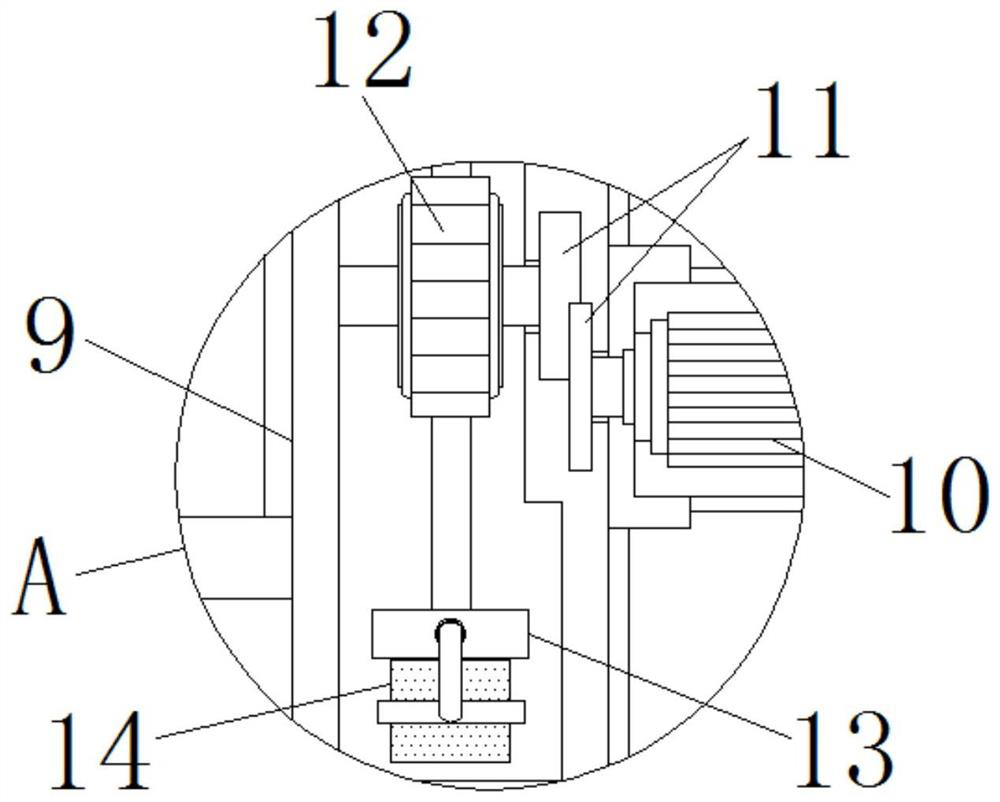

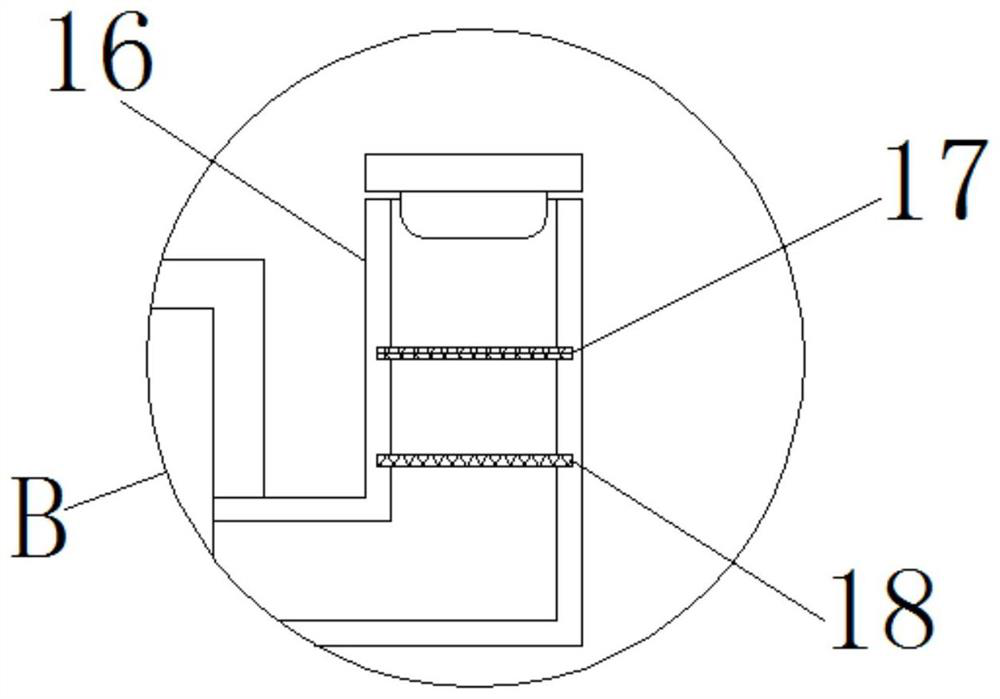

ActiveCN105521652AReduce installationReduce disassembly stepsTreatment involving filtrationFiltration separationWater leakageLocking mechanism

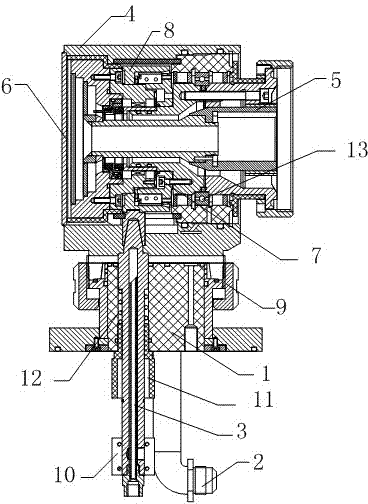

The invention provides a water purifier. The water purifier comprises a filter bottle mechanism, a rotating seat mechanism and a mounting seat mechanism, and the rotating seat mechanism is arranged on the mounting seat mechanism in a rotating manner; the rotating seat mechanism is provided with a connecting position used for connecting or dismounting the filter bottle mechanism and a positioning position corresponding the position of the filter bottle mechanism in a working state; the water purifier also comprises a locking mechanism used for locking the filter bottle mechanism in the position in the working state; and the connecting end of the filter bottle mechanism is plugged in the filter bottle cap of the rotating seat mechanism in a fit manner, and a sealing ring is arranged between the connecting end and the filter bottle cap to make the connecting end compact the sealing ring through the end surface when the filter bottle mechanism rotates to the position in the working state. The water purifier has the advantages of saving of labor consumed in the mounting and dismounting process, and difficult water leakage.

Owner:魏斯瓦瑟环境技术(嘉兴)有限公司

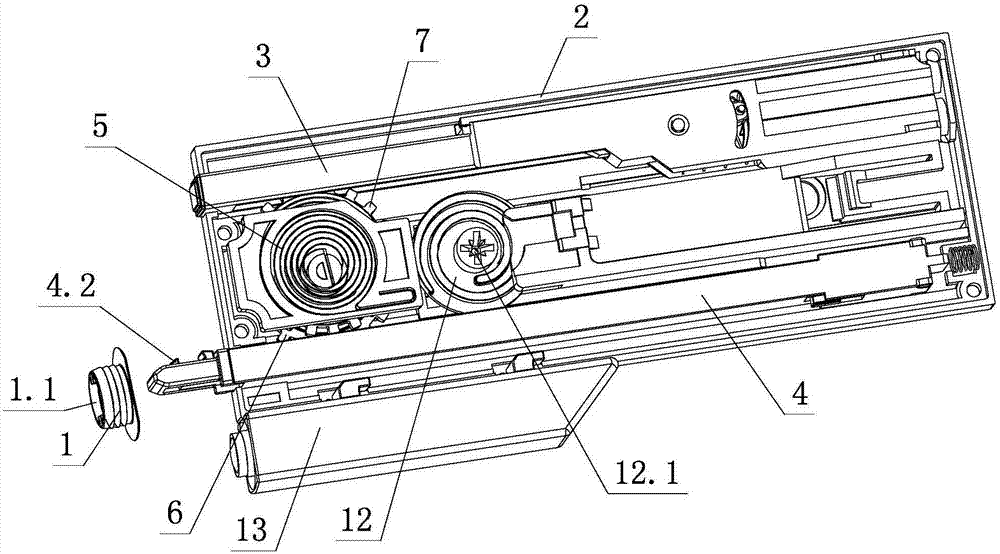

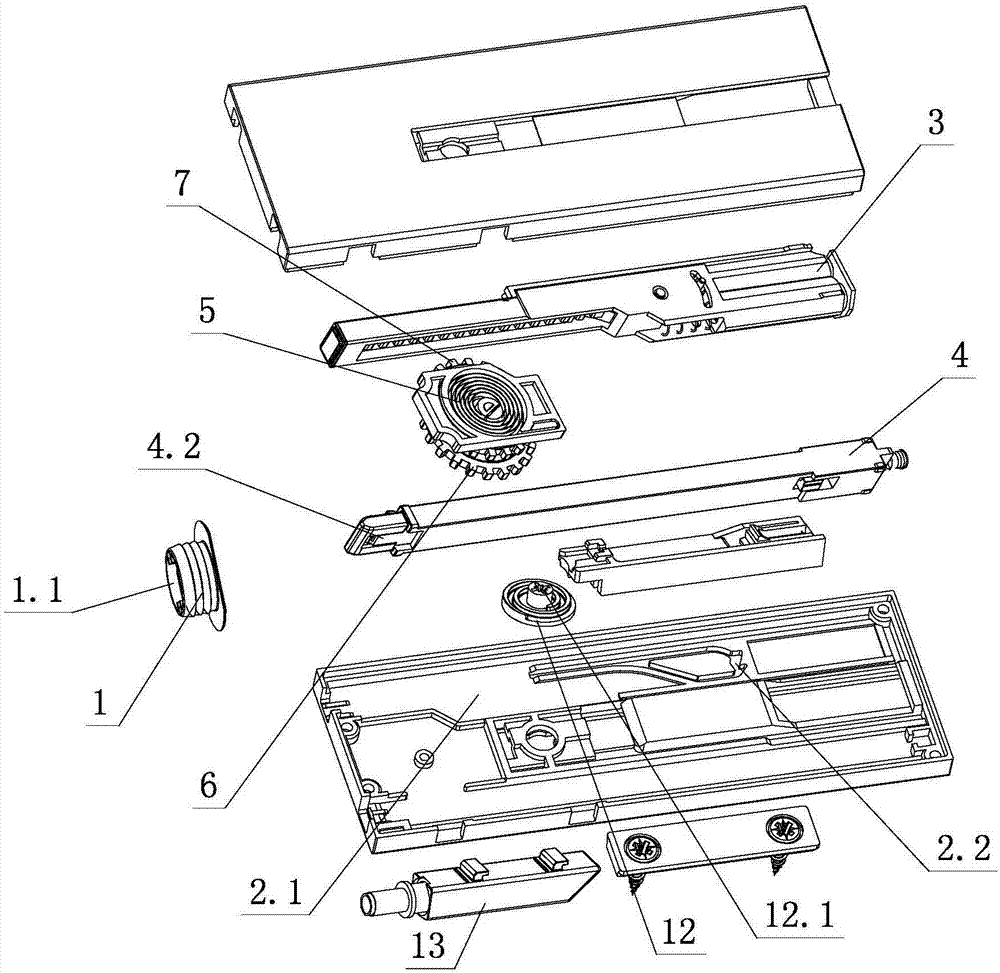

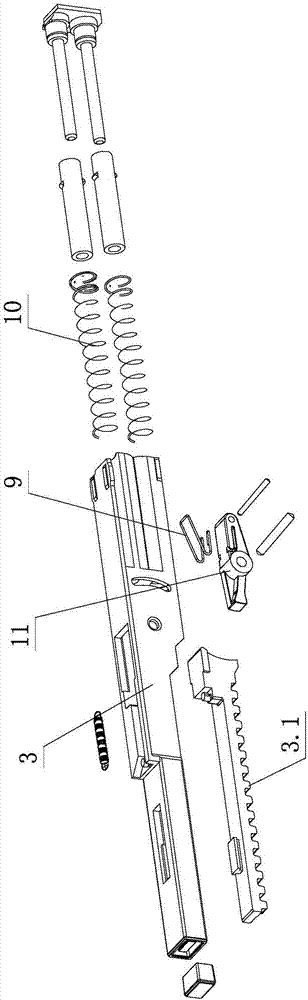

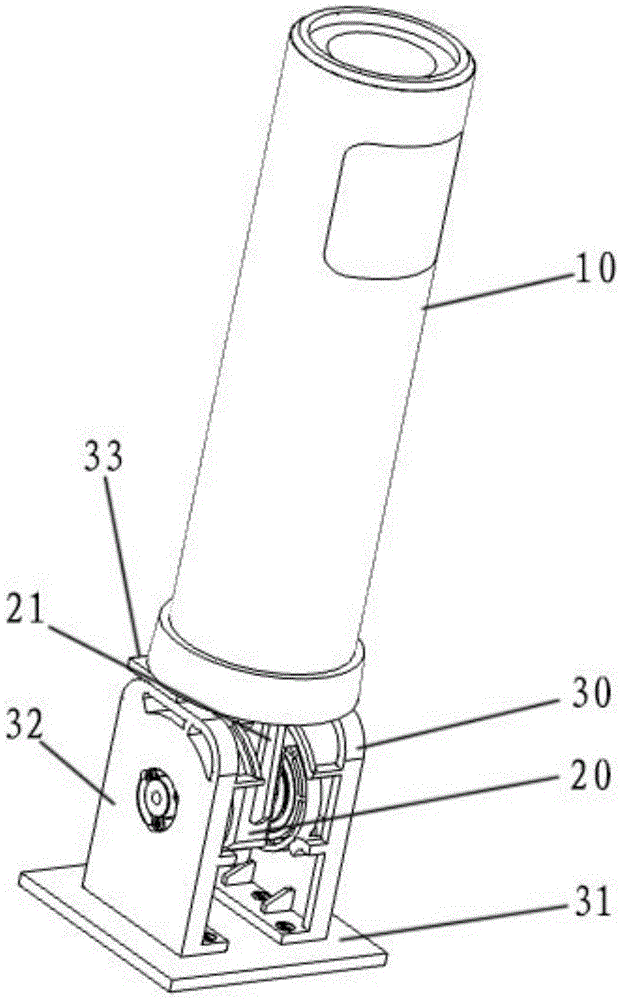

Sensor mounting box, air conditioner leak detecting device and sensor

InactiveCN104089383AReduce disassembly stepsEasy to disassembleMechanical apparatusSpace heating and ventilation safety systemsEngineeringPower cord

The invention discloses a sensor mounting box, an air conditioner leak detecting device and a sensor. The sensor mounting box comprises a box body. A sensor mounting base is arranged in the box body. A signal wire, a power supply wire and a ground wire or a null line are connected to the box body. The sensor arranged in the sensor mounting base is connected to the signal wire, the power supply wire and the ground wire or the null line correspondingly. According to the sensor mounting box, for an air conditioner with the leak detecting sensor which needs to be replaced at regular intervals, only the leak detecting sensor needs to be detached from the sensor mounting box, other parts do not need to be detached, the detaching steps of the leak detecting sensor can be reduced, a detaching process is simplified, and manpower cost is lowered.

Owner:GREE ELECTRIC APPLIANCES INC

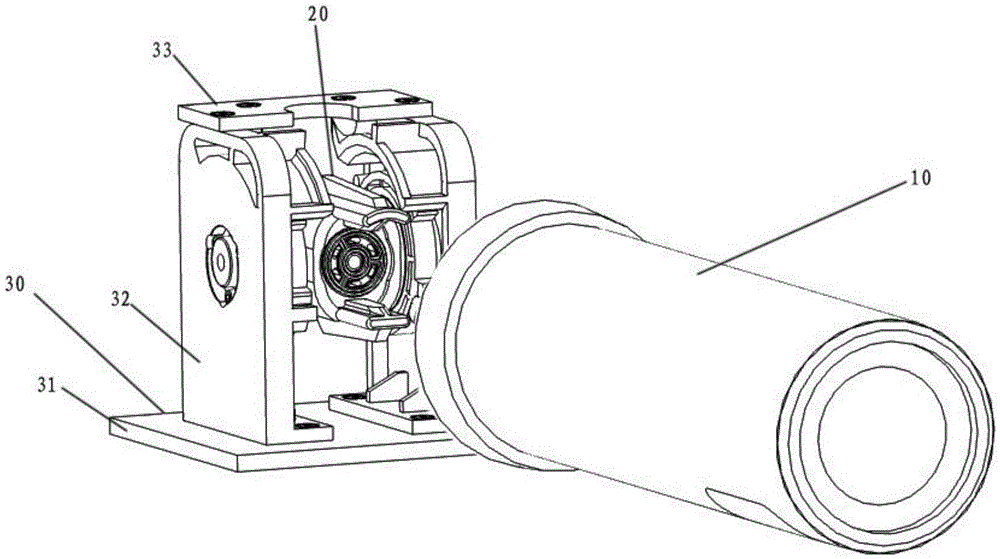

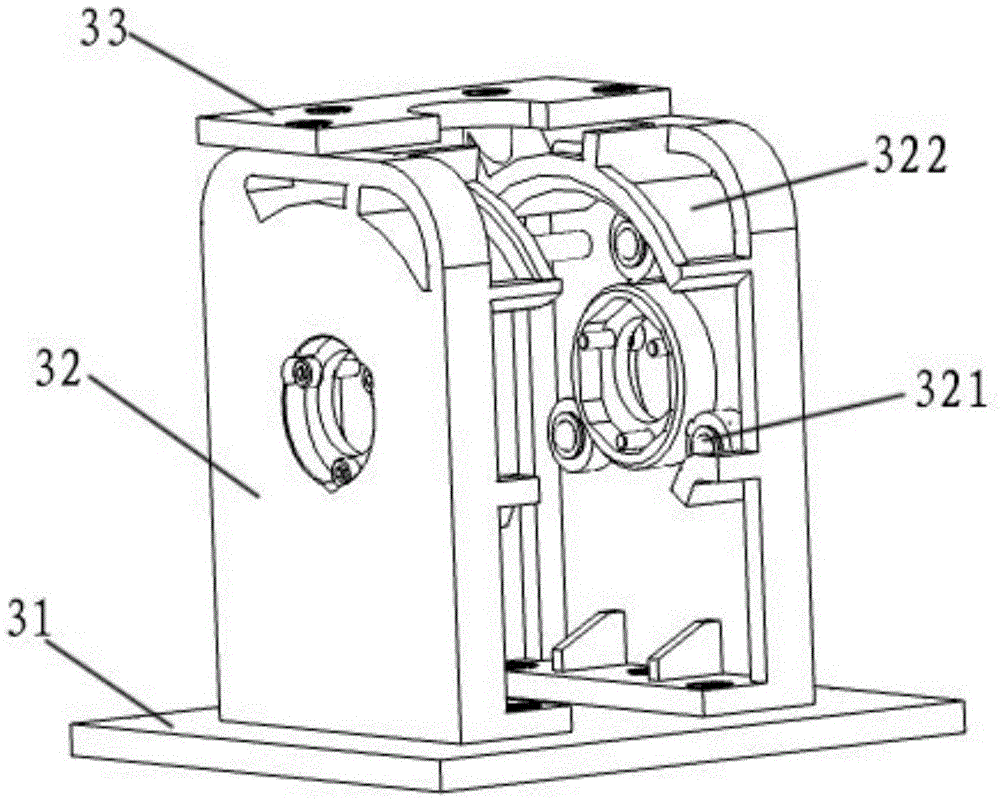

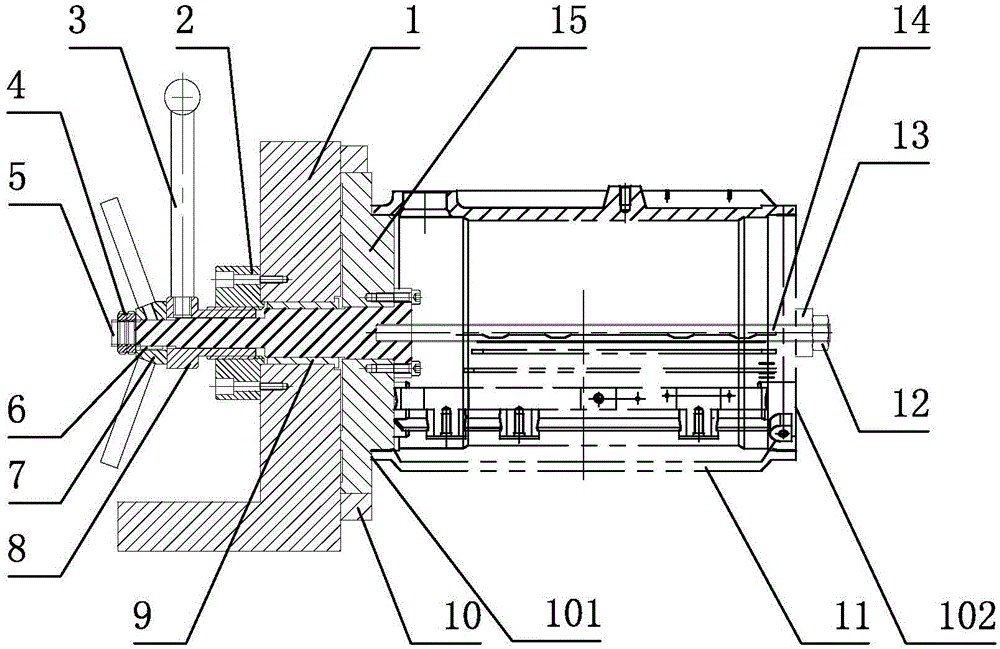

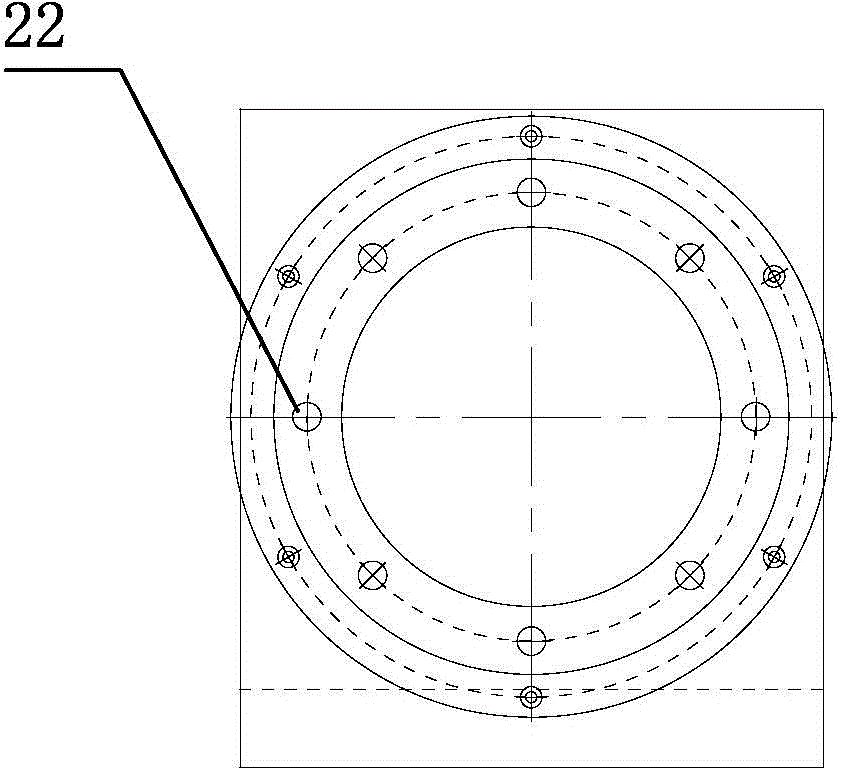

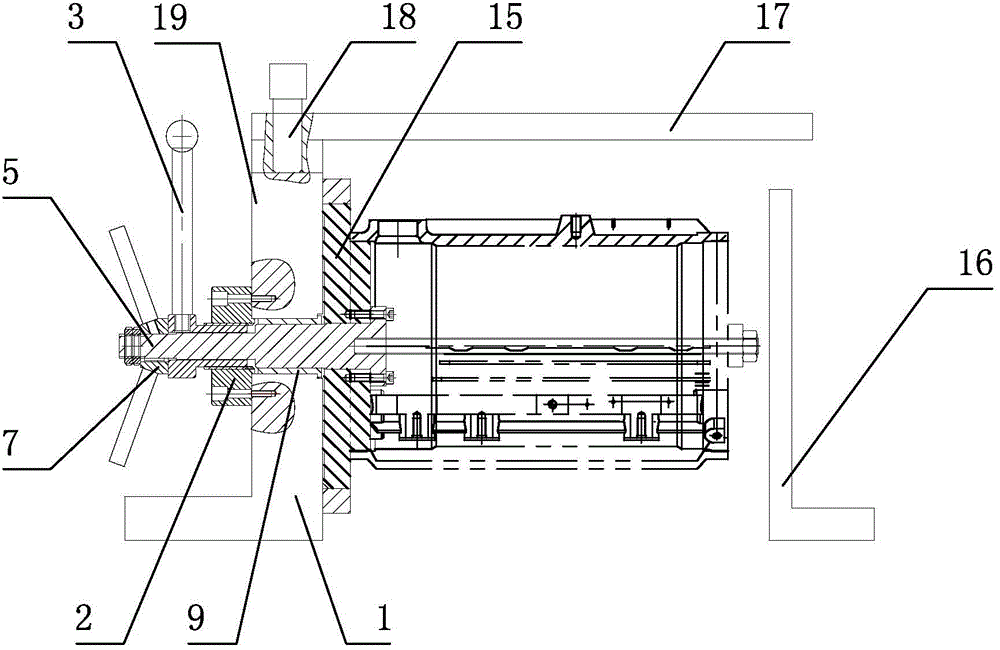

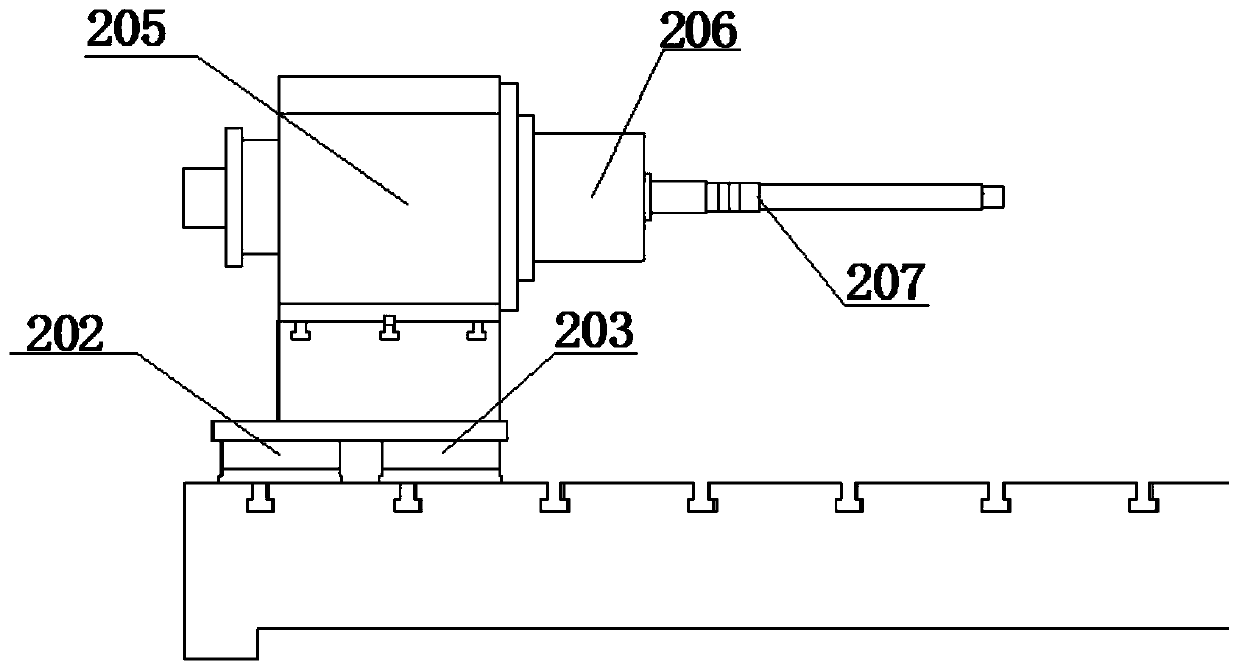

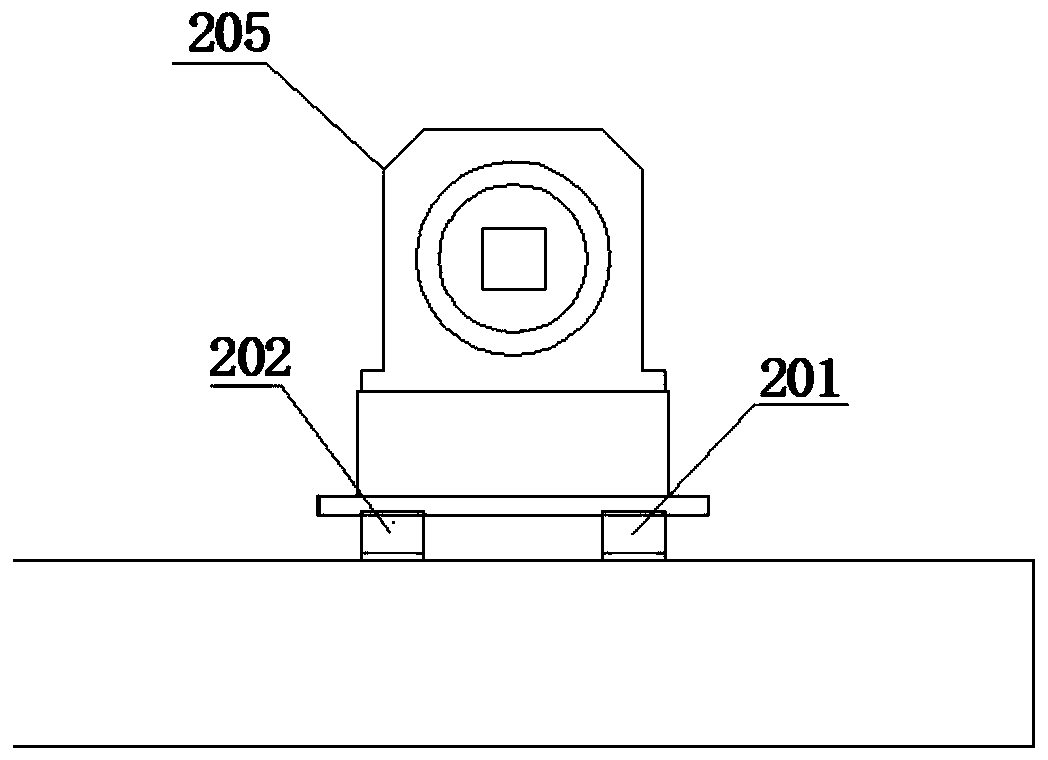

Anti-explosion motor casing processing device and processing technology

ActiveCN104607973AReduced lack of locking travelMake up for the lack of locking strokePositioning apparatusDrill jigsEngineeringDrill

The invention relates to an anti-explosion motor casing processing device and processing technology, and belongs to the technical field of anti-explosion motor casing processing. The anti-explosion motor casing processing device and processing technology comprise milling tools and drilling tools; the milling tools comprise a positioning mandrel, and the positioning mandrel is provided with a positioning plate, an L-shaped base plate, T-shaped nuts, a T-shaped threaded rod and a counter nut in sequence in a sleeved mode from back to front; on the basis of the milling tools, a horizontal drill plate is added to the drilling tools, one end of the drill plate is arranged on the upper end of the L-shaped base plate through an adjusting block, the other end of the drill plate is supported through a movable supporting seat, and drilling positioning holes are formed in a plane of the drill plate. The anti-explosion motor casing processing device and processing technology have the advantages that the usage is convenient, the disassembly frequency of the tools is greatly reduced, the work efficiency is improved, and the processing accuracy is guaranteed.

Owner:SHANDONG YUANTONG MASCH CO LTD

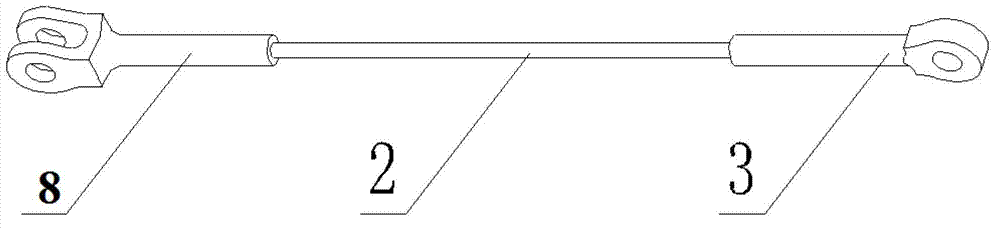

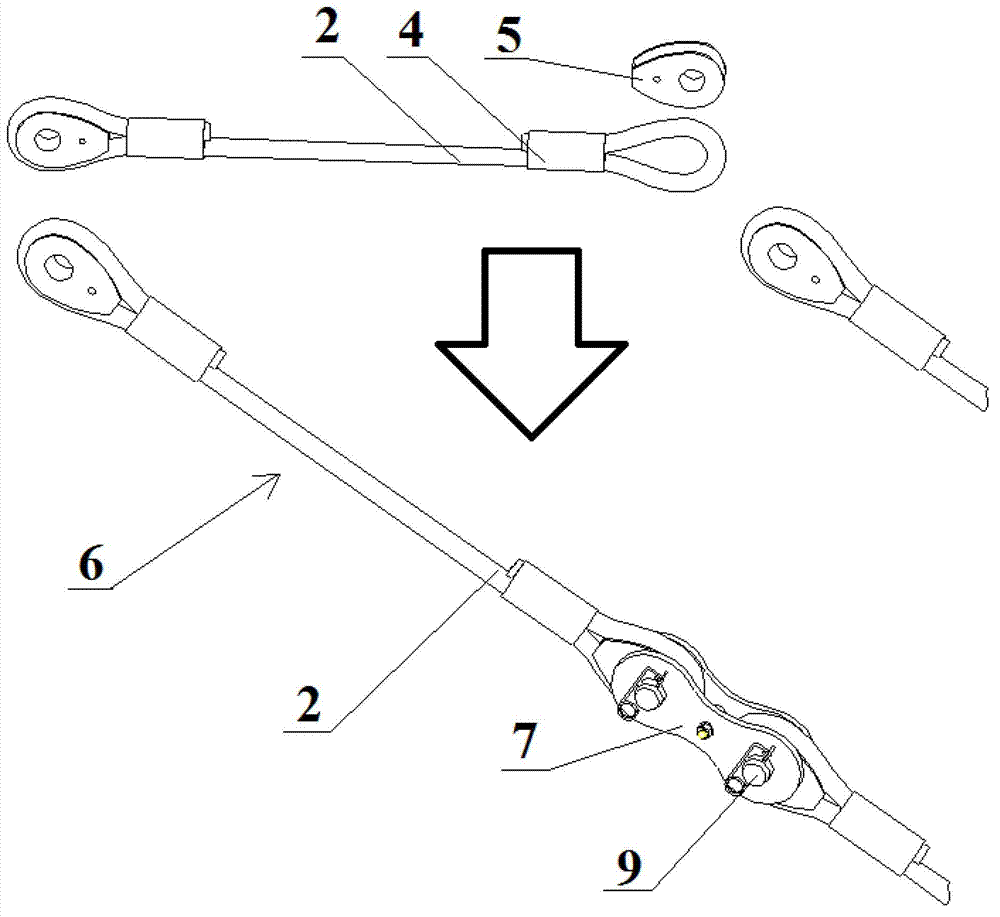

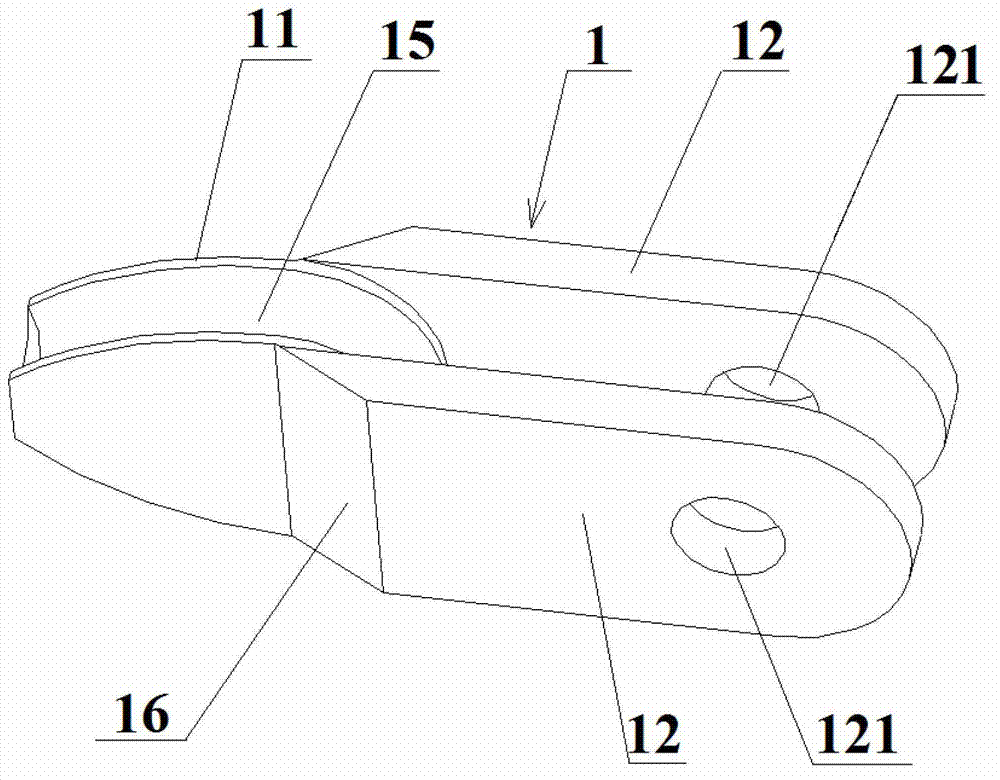

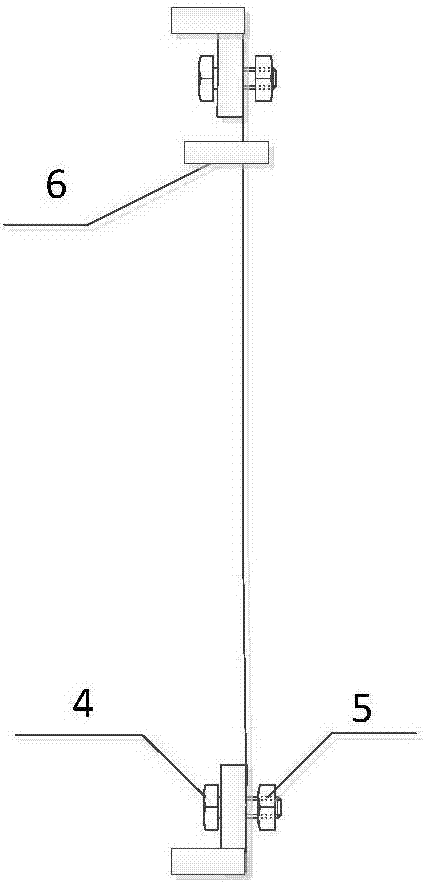

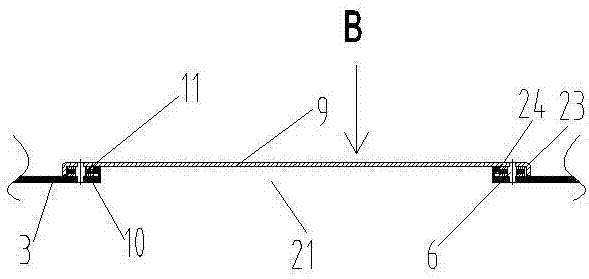

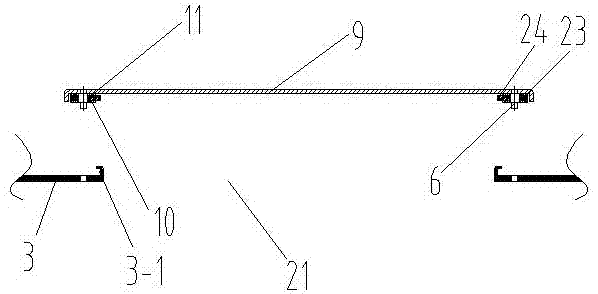

Lantern ring and inhaul cable structure

ActiveCN103089917AReduce disassembly stepsGood disassembly effectRopes and cables for vehicles/pulleyTextile cablesState of artLantern

The invention discloses a lantern ring and an inhaul cable structure and relates to the technical field of engineering machinery. The lantern ring and the inhaul cable structure solve the technical problems of inconvenient combination and low dismantling and assembling efficiency in the prior art. The lantern ring comprises a first connection part and two second connection parts, wherein the two second connection parts are respectively arranged on two opposite sides of the first connection part. A gap exists between the two second connection parts. Through holes are formed in the first connection part and in the two second connection parts. The first connection part and the two second connection parts are mutually fixedly connected, or the first connection part is integrated with the two second connection parts. The inhaul cable structure comprises a first lantern ring, a rope body, a first sleeve pipe, a second sleeve pipe and a second lantern ring, wherein the second lantern ring is the lantern ring mentioned above. The lantern ring is used for improving dismantling and assembling efficiency of the inhaul cable structure.

Owner:XCMG CONSTR MACHINERY

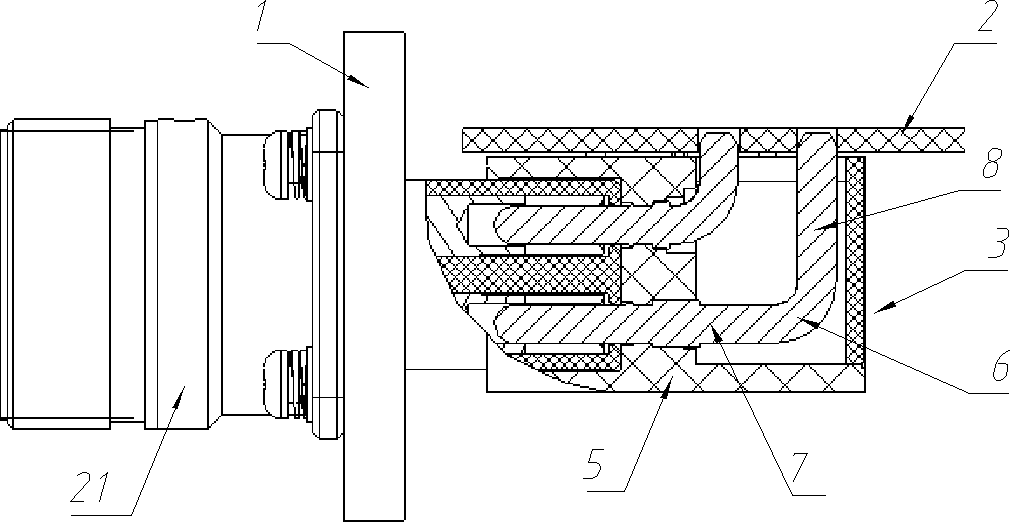

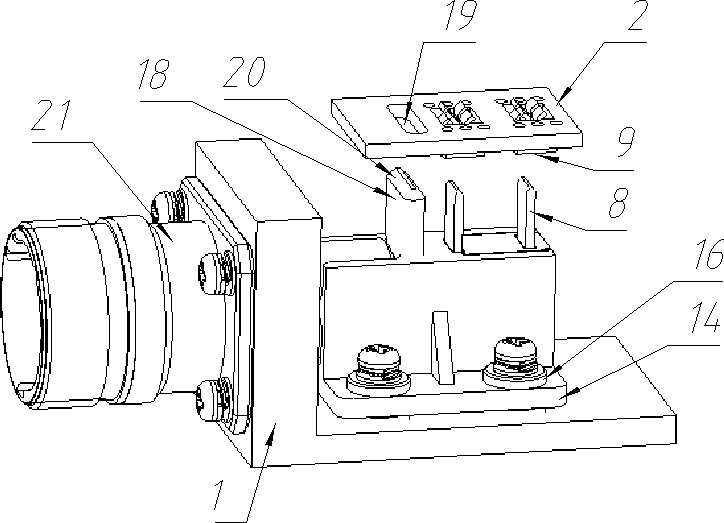

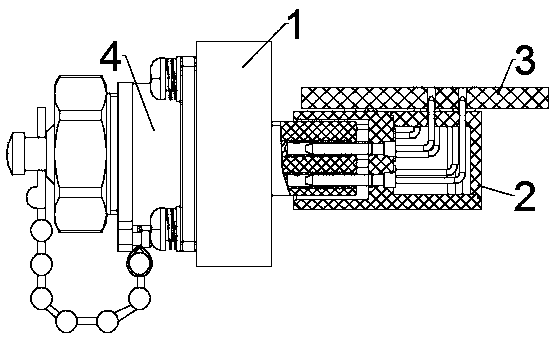

Adapter connector, printed board connector and base station remote unit

ActiveCN109149176AAchieve conductionEasy assembly and maintenanceCoupling device connectionsEngineeringPrinted circuit board

The invention relates to an adapter connector, a printed board connector and a base station remote unit. Wherein the printed board connector includes an insulator and a contact disposed within the insulator, the contact includes a printed board connection portion for conducting with the printed board and a socket connection portion for plugging with the box connector, The printed circuit board connector further includes a plug conductor for fixing to the printed circuit board and conducting with a circuit on the printed circuit board, the plug conductor having a plug structure for plug-matingwith a printed circuit board connection portion of the contact member in an extending direction of the printed circuit board connection portion. The adapter connector is the part other than the plug conductor in the printed circuit board connector. As the structure is adopted, the box connector can be installed first and then the printed board can be installed, and the printed board can be directly removed when the printed board is disassemble. Compared with the prior art, the assembly and maintenance of the printed board are convenient, the specific sequence is not required, the disassembly steps can be reduced, and the operation efficiency can be improved.

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

Method for dismounting transformer

The invention discloses a method for dismounting a transformer and belongs to the technical field of large power transformers. The method for dismounting the transformer specifically comprises the steps: performing oil drainage of an old main transformer; dismounting three side leads, all of accessories and secondary lines; checking a gas relay and an instrument of a novel main transformer; disassembling an old main transformer body and installing a novel main transformer body; installing a novel main transformer radiator, an oil return pipeline and a rubber mat; performing nitrogen explosion of the novel main transformer body; installing a novel main transformer captive test (CT) ascending base, a fan and a thermometer; installing a novel main transformer oil conservator; installing a novel main transformer on-load voltage regulation switch; performing oil return of the novel main transformer body, manufacturing the three side leads and connecting the secondary lines; installing a gas relay of the novel main transformer, performing oil filling of the novel main transformer oil conservator and adjusting oil level; performing oil filling of the on-load voltage regulation switch; checking up the connecting condition of the secondary lines and performing a transmission test; performing cleaning and paint spraying; and connecting the three side leads of the novel main transformer to finish installation of the novel main transformer. By means of the method, working steps of some complicated processes can be omitted, the working time can be saved, and the work efficiency can be improved.

Owner:STATE GRID CORP OF CHINA +1

Novel textile cloth winding device for textile

InactiveCN108529275AEasy to disassembleDisassembly does not hinderMechanical cleaningPressure cleaningFixed frameEngineering

The invention provides a novel textile cloth winding device for textile, and relates to the field of textile machines. The novel textile cloth winding device for textile comprises a base plate, supporting legs are fixedly connected to the four corners of the bottom of the base plate, storing plates are fixedly connected among the four supporting legs, the left side of the top of the base plate isfixedly connected with a damping cushion and a fixing frame, the top of the damping cushion is fixedly connected with a rotating motor, an output shaft of the rotating motor is fixedly connected witha reel, and one side of the reel penetrates through one side of the fixing frame and extends to the right side of the fixing frame. According to the novel textile cloth winding device for textile, through cooperative using of a lead screw, a second bearing, a threaded sleeve and a second fixing plate, the position of the lead screw can be adjusted while the lead screw rotates, the position of a connecting plate is moved along with moving of the position of the lead screw, moving of the connecting plate drives a limiting sliding column and a movable limiting block to move, thus the movable limiting block is disengaged from the reel, and a roll is in a loosening state, so that the roll is disassembled.

Owner:刘州豪

Screen levelness adjusting mechanism and projection display device

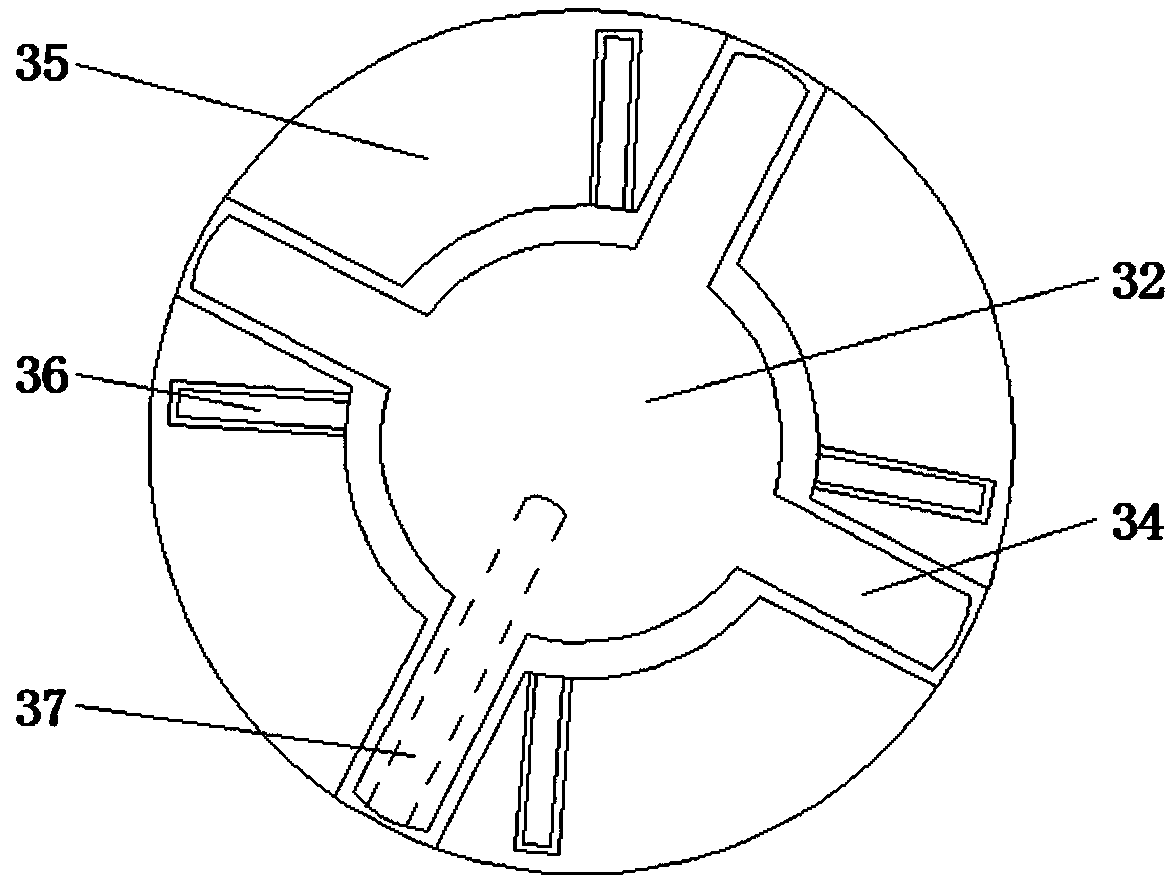

The invention discloses a screen levelness adjusting mechanism and a projection display device, relates to the technical field of display, and aims to solve the problem of low screen levelness adjusting efficiency. The screen levelness adjusting mechanism comprises a reference part, a support shaft, a cam and a support plate, wherein the reference part and the support shaft are arranged on the back surface of a screen, and are positioned on the two sides of the vertical centerline of the screen; a retractable pawl component is arranged on the support shaft; a shaft hole is formed in the rotating center of the cam; a plurality of ratchets are annularly arranged on the inner surface of the shaft hole; the cam is arranged on the support shaft through the shaft hole in a sleeving way; each ratchet and the pawl component form a pawl wheel mechanism; the support plate is arranged on a screen support body; the upper surface of the support plate is in contact with the contour surface of the cam to support the cam. The screen levelness adjusting mechanism is used for regulating the levelness of the screen when the screen is suspended on the screen support body.

Owner:HISENSE

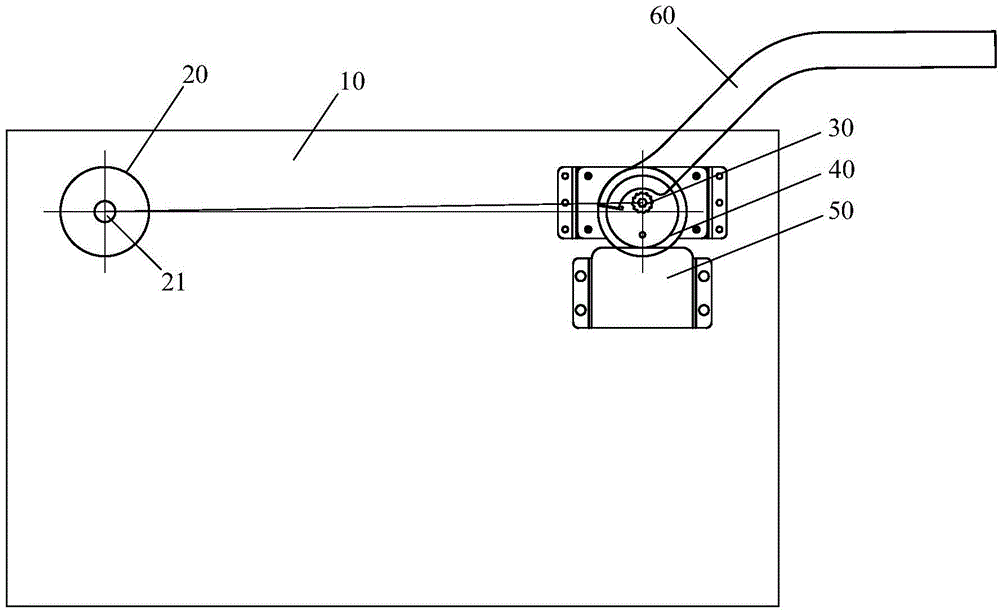

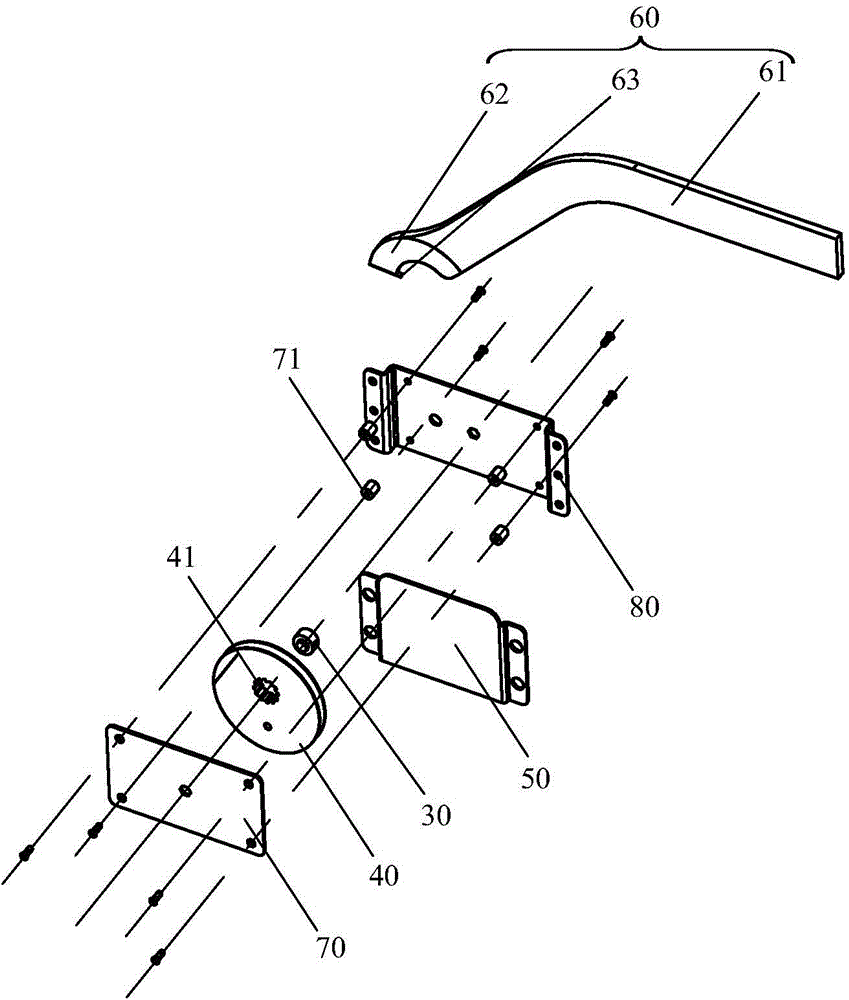

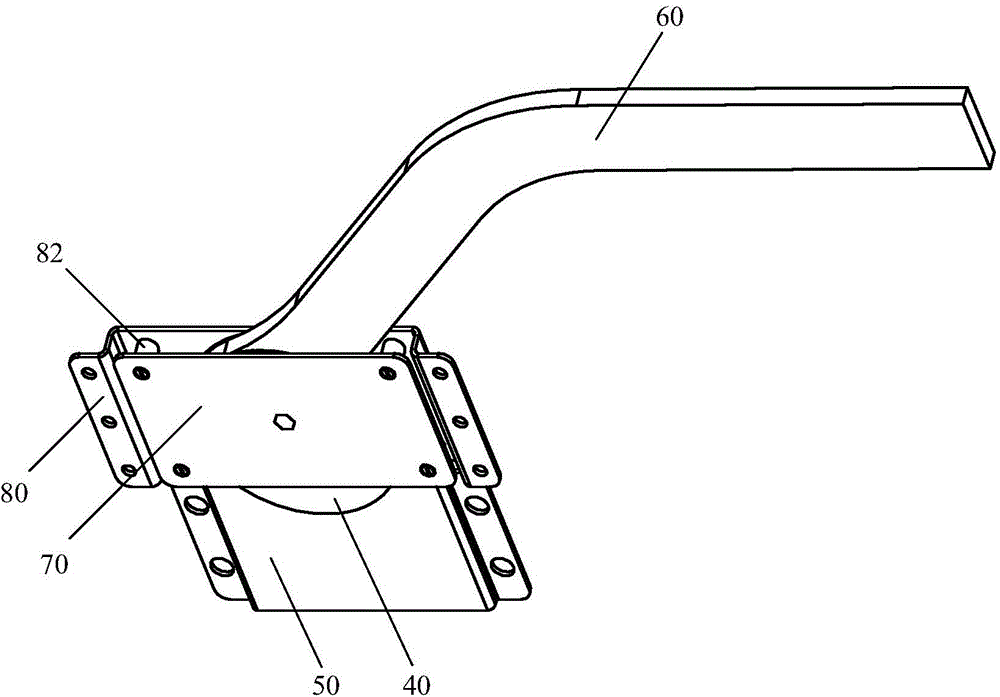

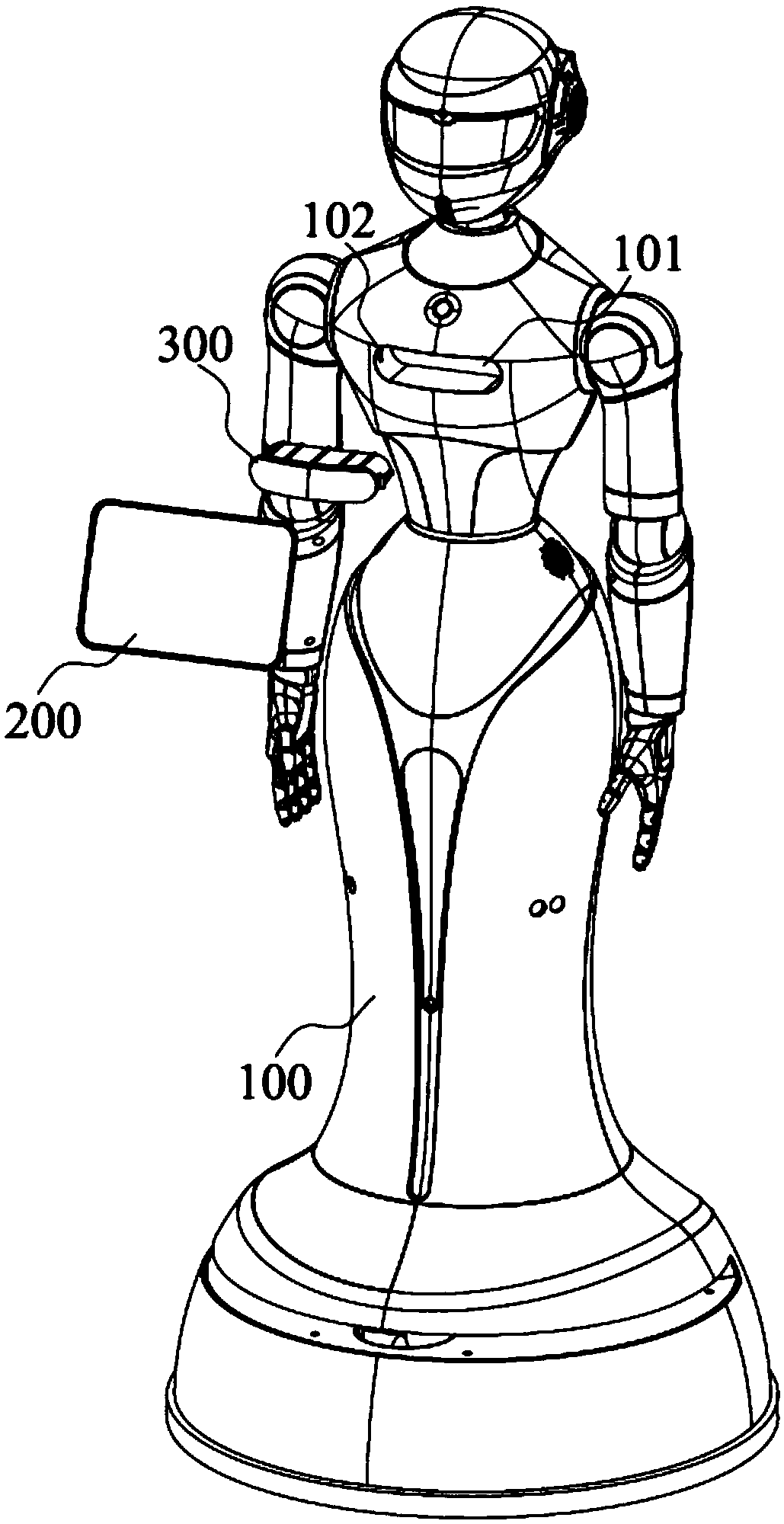

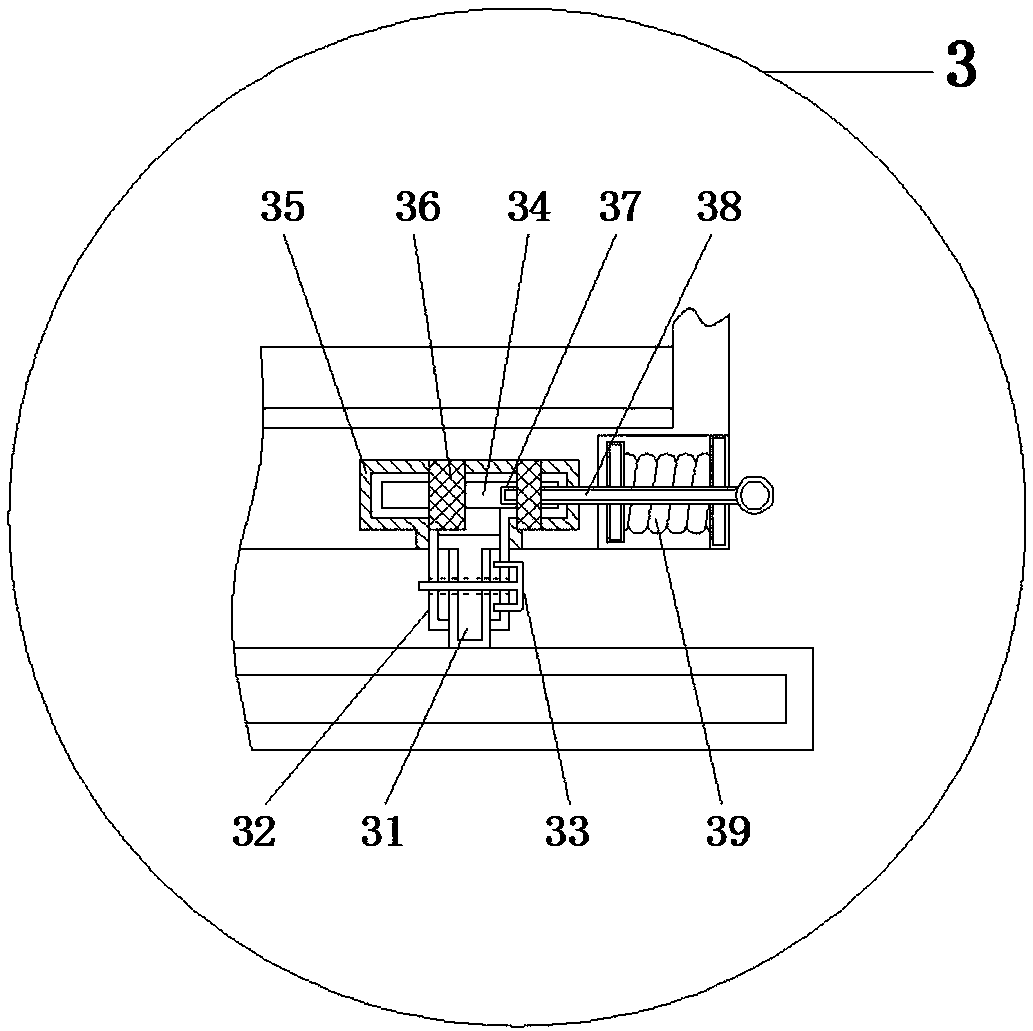

Rapid dismantling structure and robot

PendingCN108972587AEasy to disassembleQuick and easy disassemblyProgramme-controlled manipulatorEngineeringRobot

The invention discloses a rapid dismantling structure and a robot, and relates to the technical field of robots. The rapid dismantling structure comprises a shell, a lock block and an unlocking assembly; the lock block is telescopically arranged in the shell, the lock block can extend out of the shell, the unlocking assembly comprises a key telescopically arranged in the shell, the telescopic direction of the key is perpendicular to the telescopic direction of the lock block, the front end of the key penetrates the shell, the rear end of the key is connected with the lock block, the key can drive the lock block to retract to the shell, the lock block in the rapid dismantling structure extends out of the shell, and can be matched with a locking hole in a structure to be mounted for locking,when dismantling is needed, the key in the unlocking assembly is pressed, the lock block can be driven to retract into the shell, and unlocking is achieved, so that the rapid dismantling structure isdismantled from the structure to be mounted. Dismantling is convenient and rapid, the dismantling and mounting steps are reduced, and the replacement efficiency is improved.

Owner:SUZHOU BOZHON ROBOT CO LTD

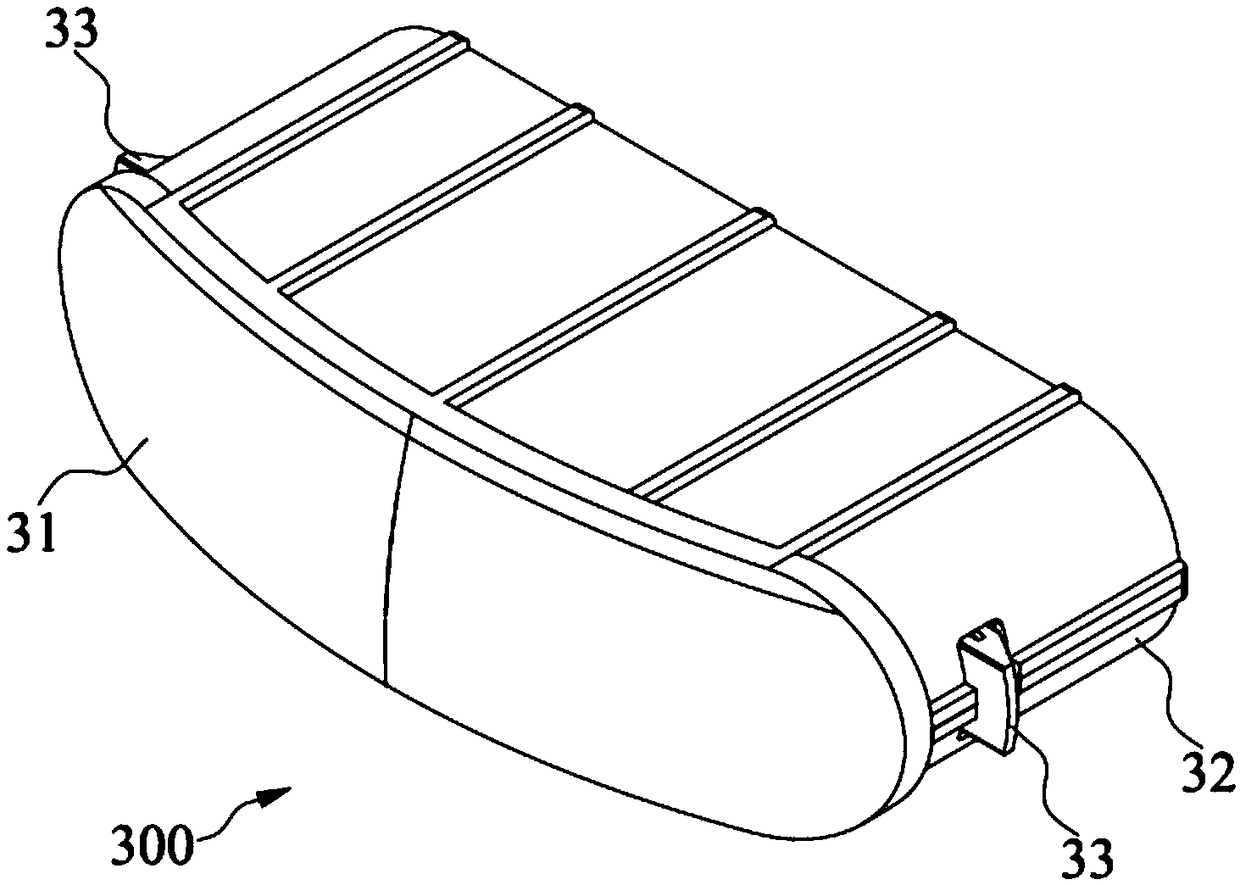

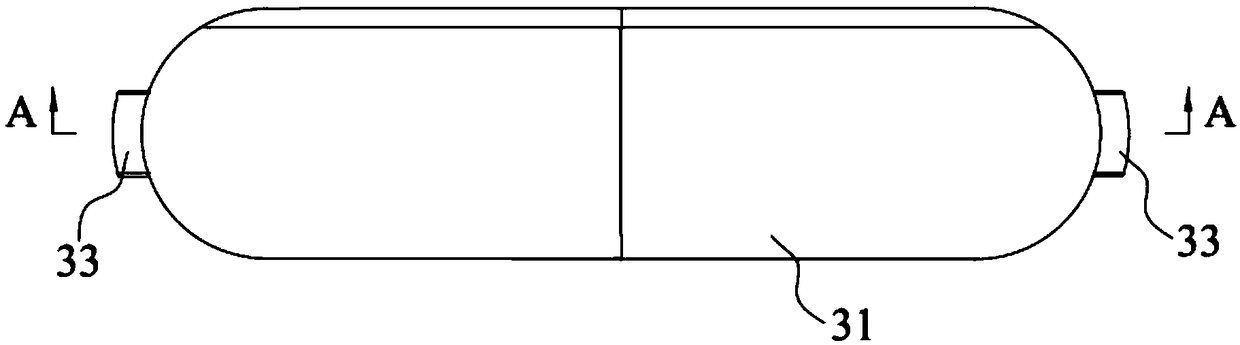

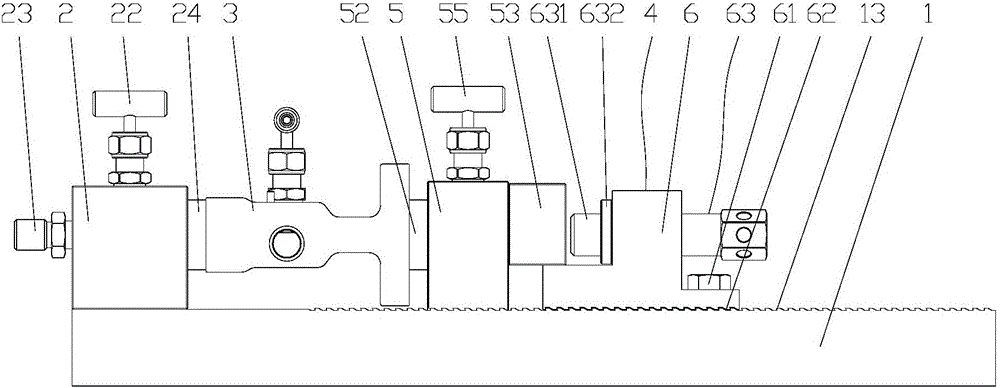

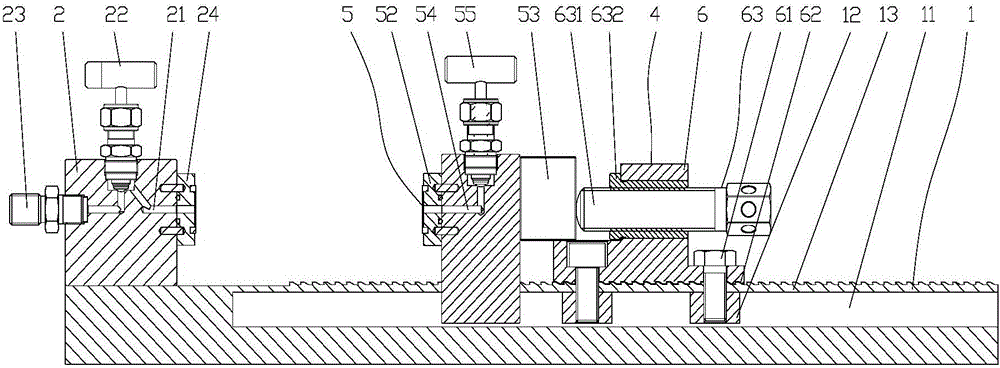

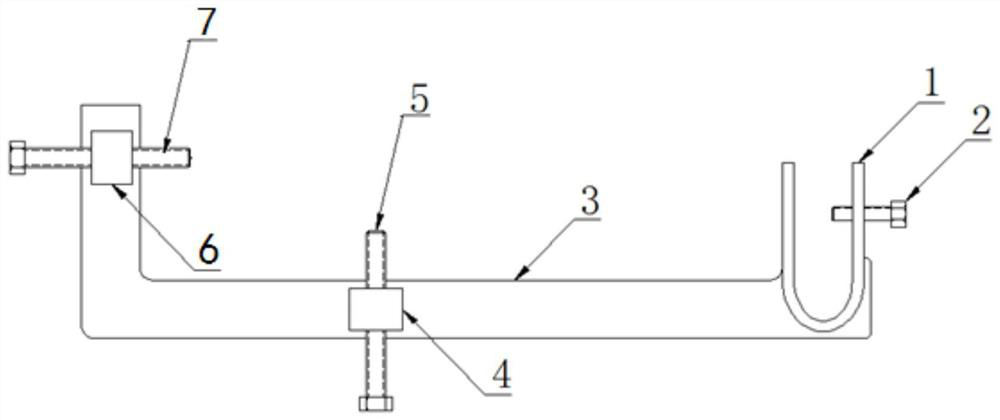

Flange instrument valve sealing testing device

ActiveCN105699018AJudgment of water tightnessDisassembly safetyDetection of fluid at leakage pointEngineeringFlange

The invention relates to a flange instrument valve sealing testing device which comprises a base. A stationary clamp seat which is internally provided with a pressure conveying channel is fixedly arranged at one end of the base. The other end of the vase is provided with a movable clamping seat. The base is provided with a T-shaped rail. At least one T-shaped slide block is embedded into the T-shaped rail. The upper surface of the base is provided with a sawtooth-shaped rail. The movable clamping seat comprises an abutting supporting seat and a movable supporting seat. The movable supporting seat is arranged between the stationary clamp seat and the abutting supporting seat. The bottom of the movable supporting seat is provided with a T-shaped part which is slidably connected with the T-shaped rail. One end of the movable supporting seat is provided with a first sealing cover assembly which is used for sealing the outlet of the instrument valve. The abutting supporting seat is connected with the T-shaped slide block through a fastener. The abutting supporting seat is fixed on the base. The lower surface of the abutting supporting seat is provided with unidirectional stopping sawteeth which are connected with the sawtooth-shaped rail, thereby preventing movement of the abutting supporting seat to the other end of the base. The abutting supporting seat is provided with a pushing mechanism which is used for pushing the movable supporting seat for making the instrument valve abut against the stationary clamp seat.

Owner:FUJIAN WIDE PLUS PRECISION INSTR

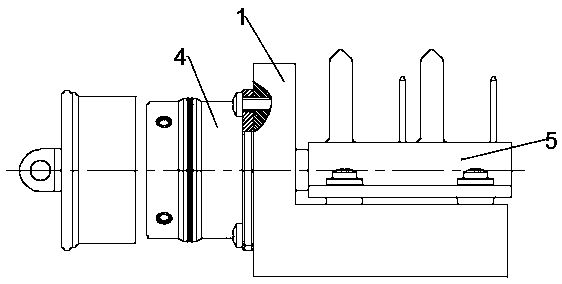

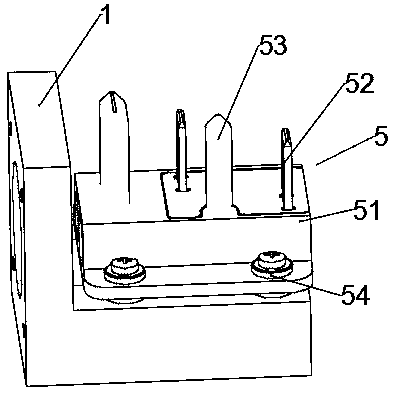

Connector and PCB socket component thereof

PendingCN109888542AReduce space guide distanceSpace guide distance shortenedCoupling contact membersCouplings bases/casesState of artEngineering

The invention relates to a connector and a PCB socket component thereof. The lower end of the PCB socket component is defined as an insertion end; the PCB socket component comprises a PCB and a PCB contact piece welded and conducted to the PCB; the PCB socket component also comprises a socket insulator arranged on the lower-side board face of the PCB; the PCB is provided with a contact piece installing hole, and the PCB contact piece is installed in the contact piece installing hole in a penetrating mode; and the socket insulator is provided with a lower guide hole which is parallel to the axis of the installing hole and used for being in guide insertion fit with a guide column on a plug insulator. Since the plug insulator is arranged and is provided with a floating structure, an adaptiveplug can be connected with an RU socket first, then the PCB socket component is moved to make the PCB contact piece connected with an adaptive contact piece, and then connection of the PCB and the RUsocket can be completed; when the PCB is detached, the PCB can be directly taken down; and compared with the prior art, assembling and maintenance are convenient, a specific order is not needed, detaching steps can be reduced, and operation efficiency is improved.

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

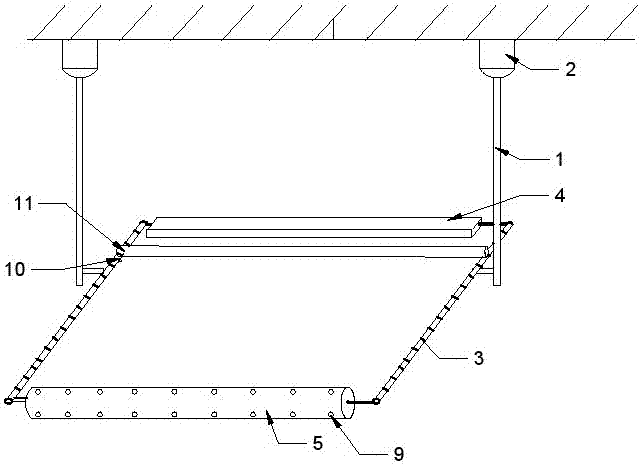

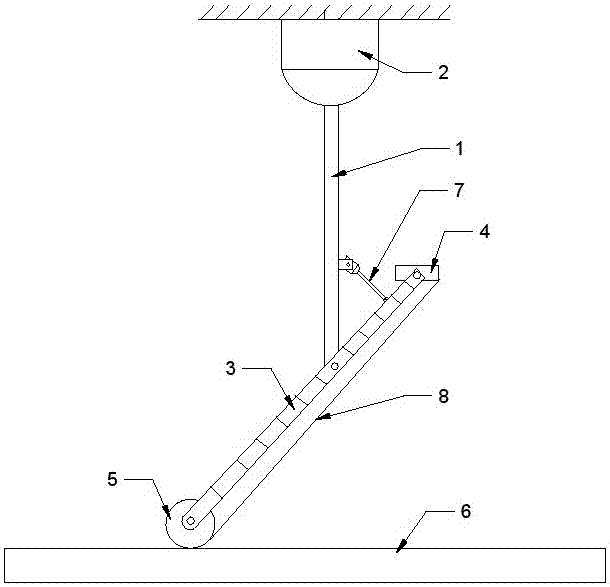

Wind tunnel inner sensor mounting device and method

The invention discloses a wind tunnel inner sensor mounting device and method. The wind tunnel inner sensor mounting device comprises a fixing component, a mobile control component and a sealing component, wherein the fixing component comprises a fixing supporting part, the fixing supporting part is provided with at least one fixing sensor part, and each fixing sensor part is used for fixing a corresponding wind tunnel inner sensor; the fixing supporting part is connected with the mobile control component, the mobile control component is used for controlling the fixing supporting part to moveaccording to a preset speed or a mode, and further the wind tunnel inner sensor is driven to move in a corresponding mode at a preset speed; and the sealing component is arranged at a preset wind tunnel position to ensure building of a predetermined air flow field in the wind tunnel. The sealing requirements of the wind tunnel can be met, and the device and the method have the advantages that thespace occupied by the sensor can be reduced maximally, impacts on the air flow are reduced, the sensor moves regularly and freely, convenience and flexibility are achieved, the cost is low, and the efficiency is high.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Convenient-to-disassemble transformer

InactiveCN109102993APromote repairEasy to disassembleTransformers/reacts mounting/support/suspensionTransformers/inductances coolingPulp and paper industryTransformer oil

The invention discloses a convenient-to-disassemble transformer, which includes a transformer body, a mounting carrier is mounted below the transformer body, fixing devices are arranged between the two sides of the bottom end of the transformer body and the two sides of the top end of the mounting carrier, a transformer oil tank is installed on one side of the top end of the transformer body, an operation button is installed on the side of the top end of the transformer body away from the transformer oil tank, a fan is installed at the middle position of the top end of the transformer body, ahole is uniformly arranged at the bottom end of the transformer body, and a filter screen is installed in the inner wall of the bottom end of the transformer body on the hole. The invention realizes the purpose of convenient and rapid maintenance by rapidly disassembling the transformer body for maintenance, reduces the disassembly steps, increases the disassembly efficiency, facilitates the maintenance by the maintenance personnel, and does not need to stop the transformer body from working when the transformer oil tank is repaired with minor problems.

Owner:TIANJIN XIANGYUAN ANGAO INTERMEDIATE FREQUENCY POWER TRANSFORMER CO LTD

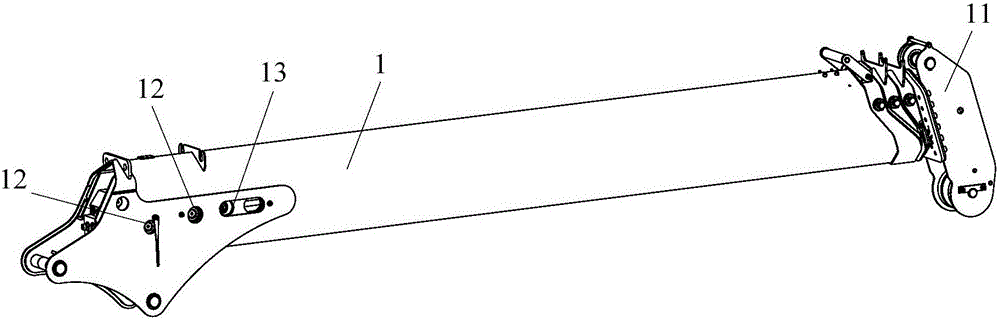

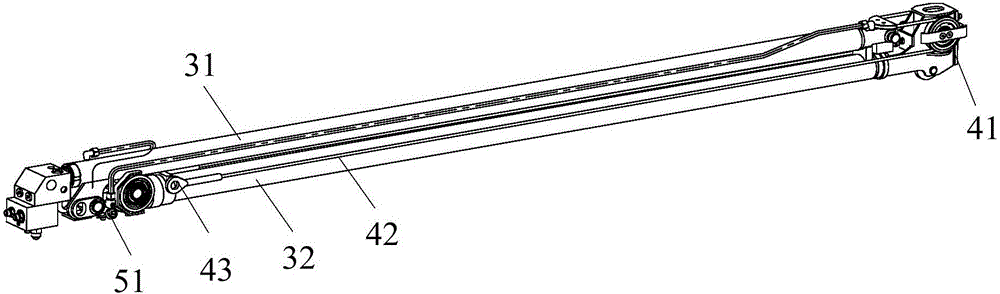

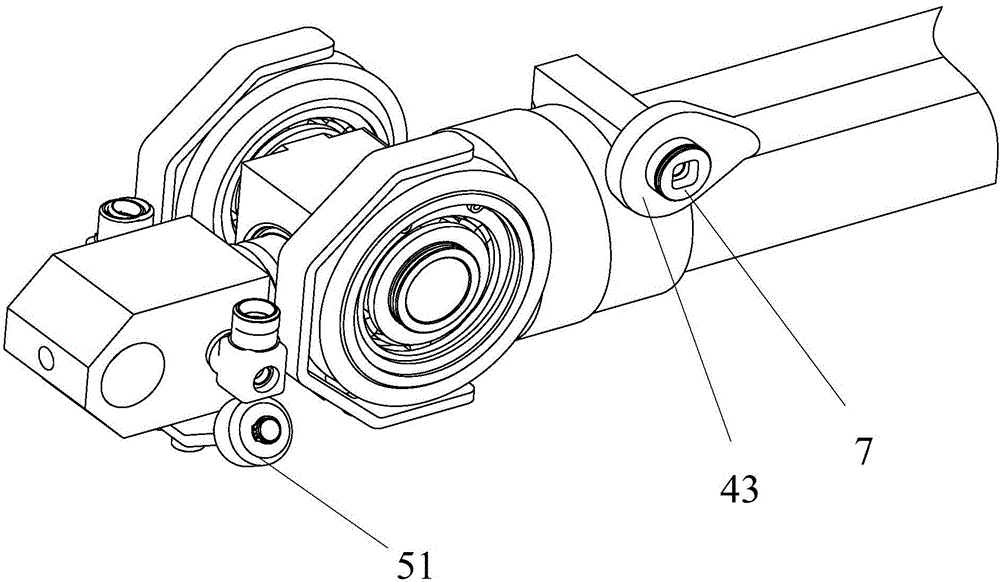

Telescopic arm barrel and crane boom

ActiveCN106744388AReduce disassembly stepsShorten the timeCranesArchitectural engineeringCrane Equipment

The invention provides a telescopic arm barrel and a crane boom and relates to the technical field of crane equipment. The invention aims to solve the problem that the detaching process of the crane boom is relatively complicated, and the maintenance efficiency is relatively low. The telescopic arm barrel comprises a plurality of knuckle arms which successively sleeve from outside to inside in a telescopic manner, wherein a telescopic device mounting hole for mounting a telescopic device is formed in one or more knuckle arms, a telescopic device through hole is correspondingly formed in each knuckle arm which sleeves the outer side of the knuckle arm provided with the telescopic device mounting hole, and when each knuckle arm is in a full shrinking state, the corresponding telescopic device mounting hole and the telescopic device through hole are aligned to each other. The telescopic arm barrel is applied to the crane boom so as to improve the maintenance efficiency of the crane boom.

Owner:SANY PALFINGER SPECIAL VEHICLE

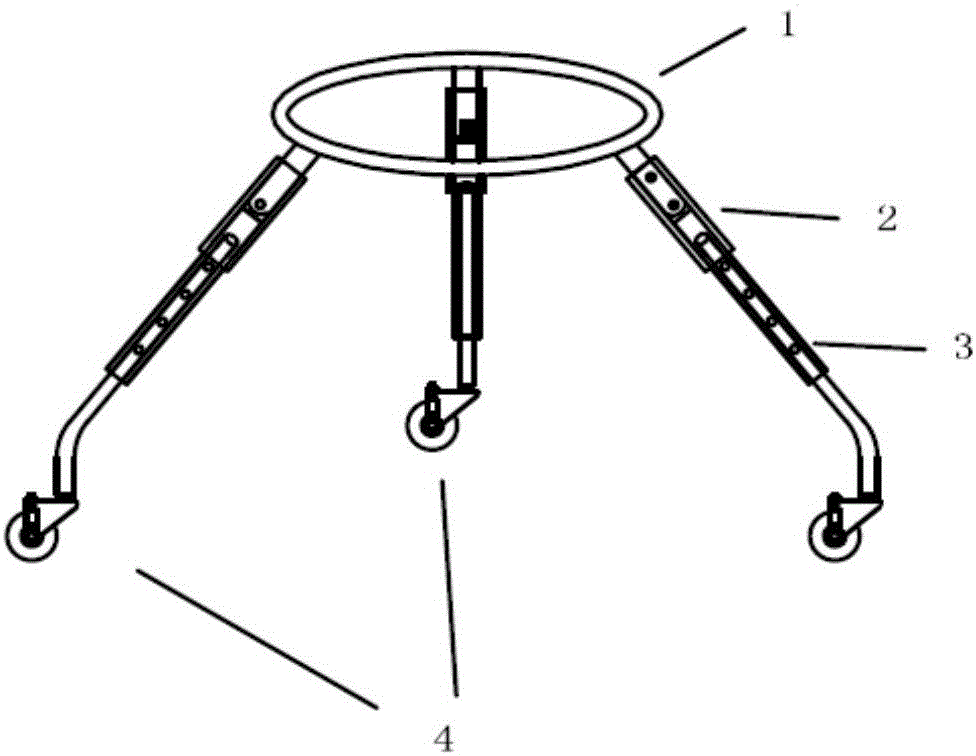

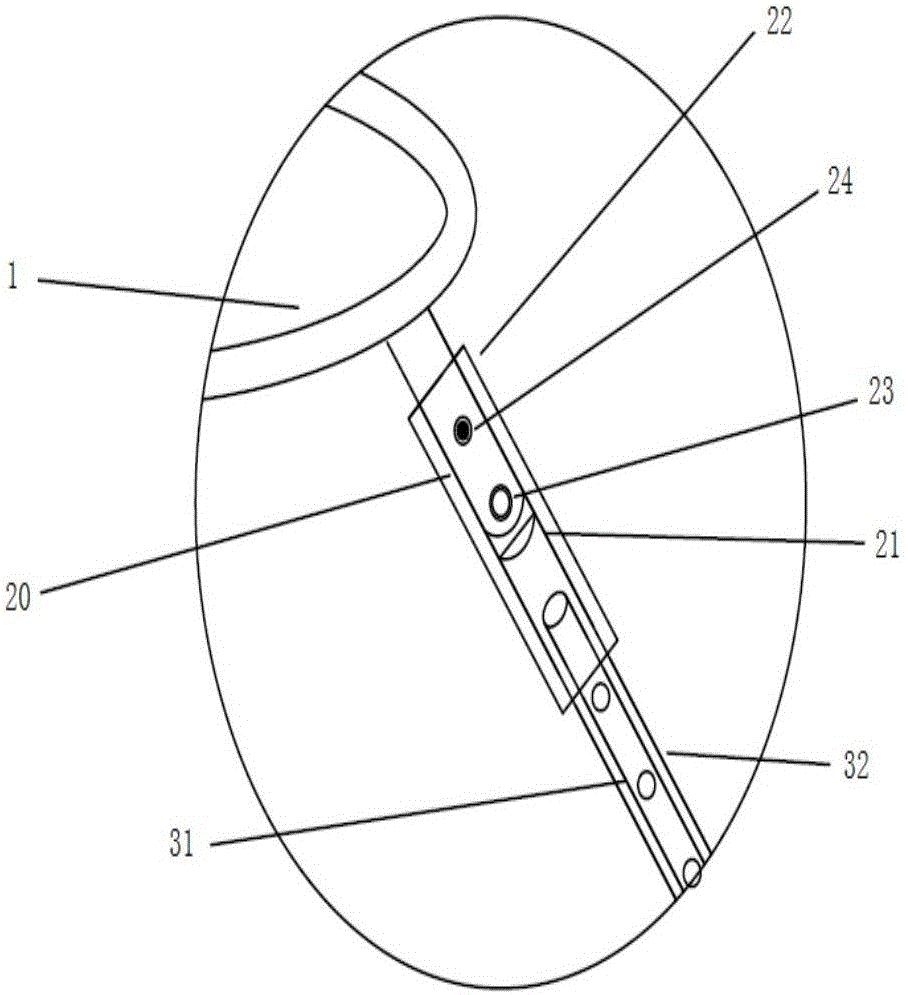

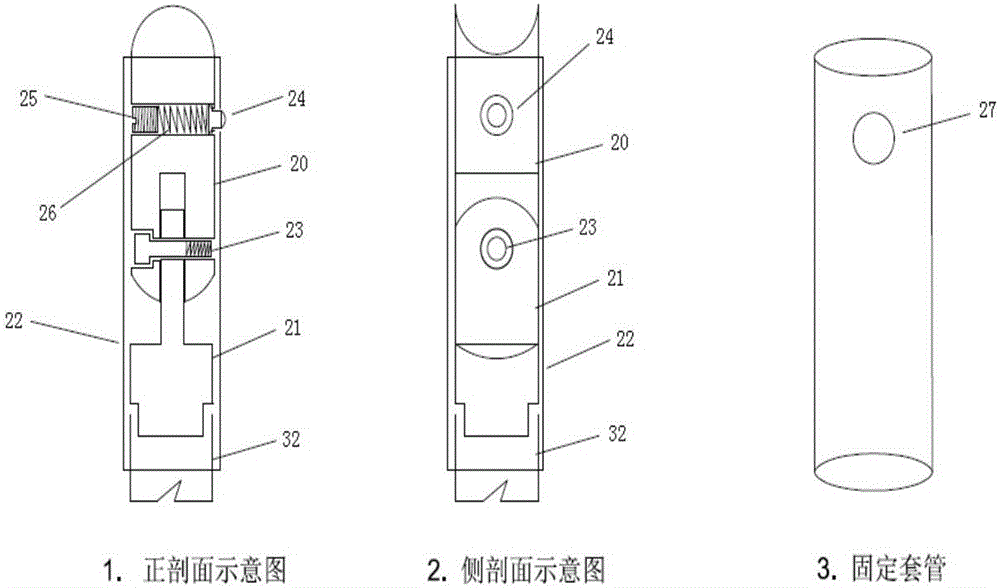

Folding roller skating learning assistor

InactiveCN106693337AAvoid insecurityReduce riskSport apparatusRoller skatingAgricultural engineering

The invention provides a folding roller skating learning assistor. The folding roller skating learning assistor is composed of a metal handle, supports, folding mechanisms and universal castors. The metal handle is of a circular ring structure and is connected with the upper ends of the supports through the folding mechanisms; each support is composed of an inner steel pipe, an outer steel pipe and a height adjusting mechanism, wherein the diameter of the outer steel pipe is larger than that of the inner steel pipe, and the inner steel pipe and the outer steel pipe are fixed through a press type round-head-shaped metal fastener to adjust the height. The universal castors are connected with nuts welded to the bottom ends of the inner steel pipes of the supports through fixed threaded rods, and a gravity brake device is arranged on each universal castor. By adopting the folding structure, the roller skating learning assistor is convenient to unfold and fold, convenient and fast to use and higher in safety and saves space.

Owner:卢霖

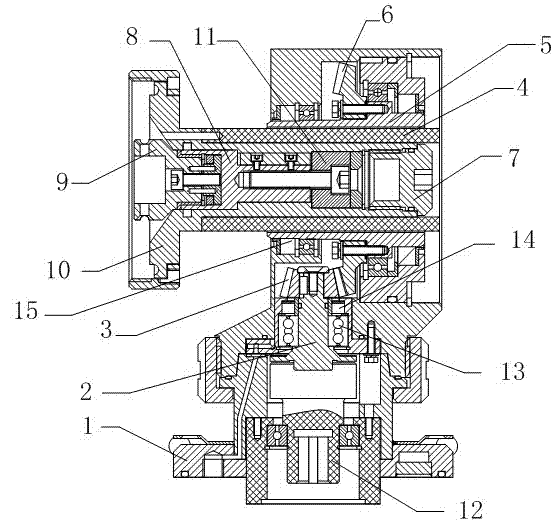

Driving tip device for rotating target

InactiveCN102268647AGuaranteed stable workReduce disassembly stepsVacuum evaporation coatingSputtering coatingPinionMechanical engineering

The invention relates to a driving tip device for rotating a target. The driving tip device comprises a substrate, and is characterized in that: the substrate is provided with a cross shaft; the top of the cross shaft is provided with a pinion; a driving end of the pinion is connected with a reducing sleeve; a hexagonal sleeve is arranged at the periphery of the reducing sleeve, and is provided with a gearwheel; and a driving component is arranged in the reducing sleeve. Therefore, when the target is replaced, disassembly steps can be effectively reduced. Most importantly, the cross shaft is matched with the reducing sleeve, so that the driving rotary force can be effectively transferred and the target is facilitated to work smoothly.

Owner:黄峰

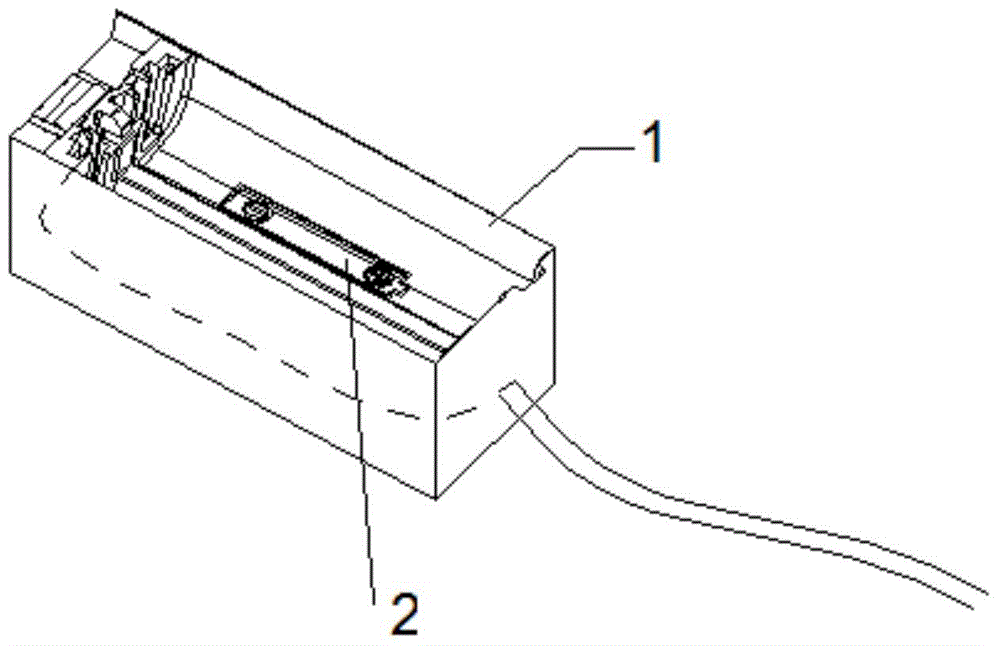

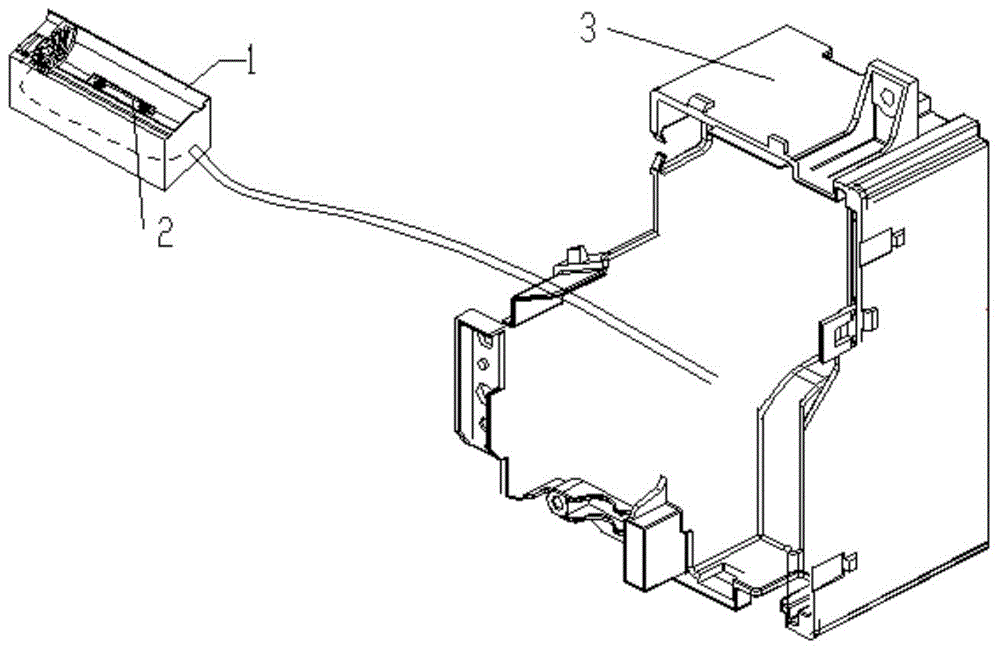

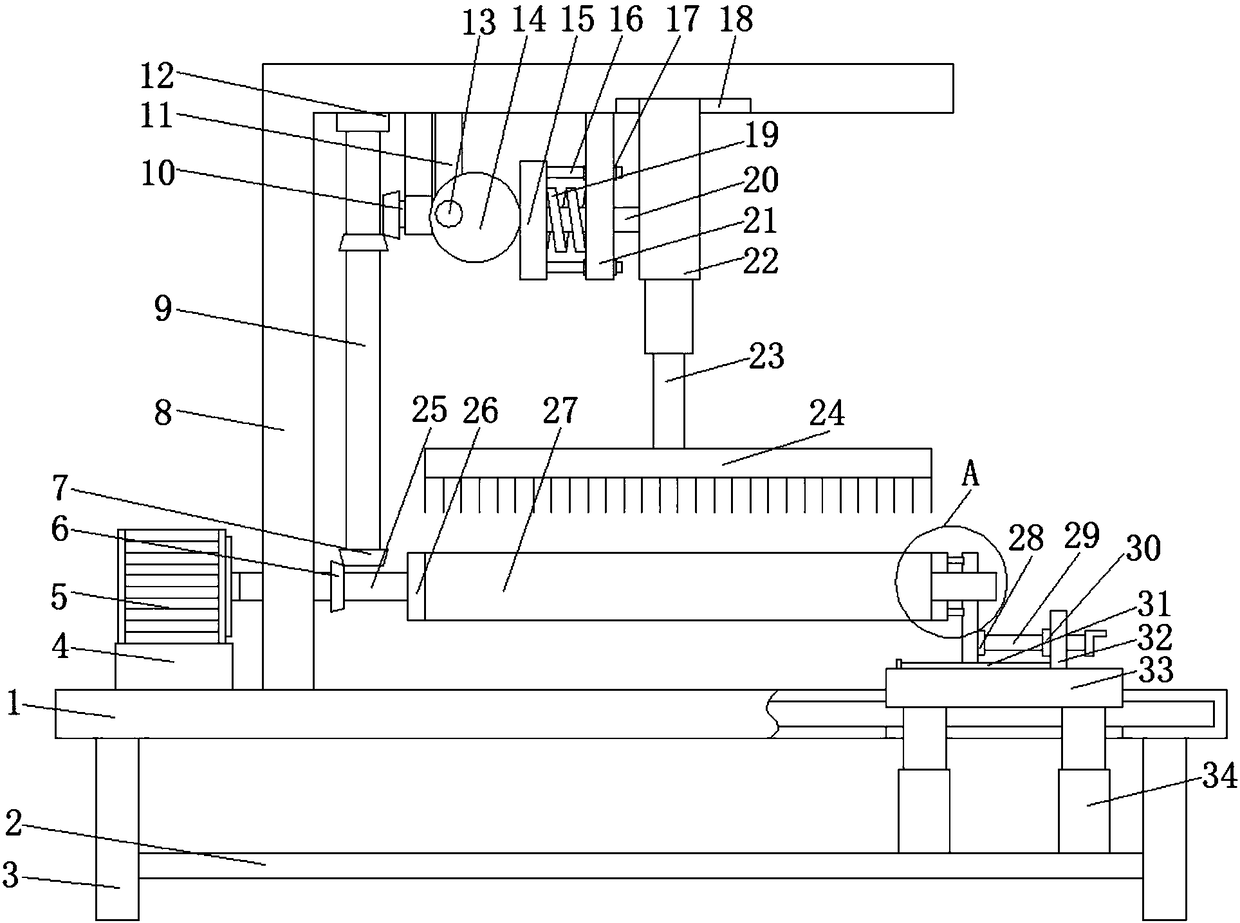

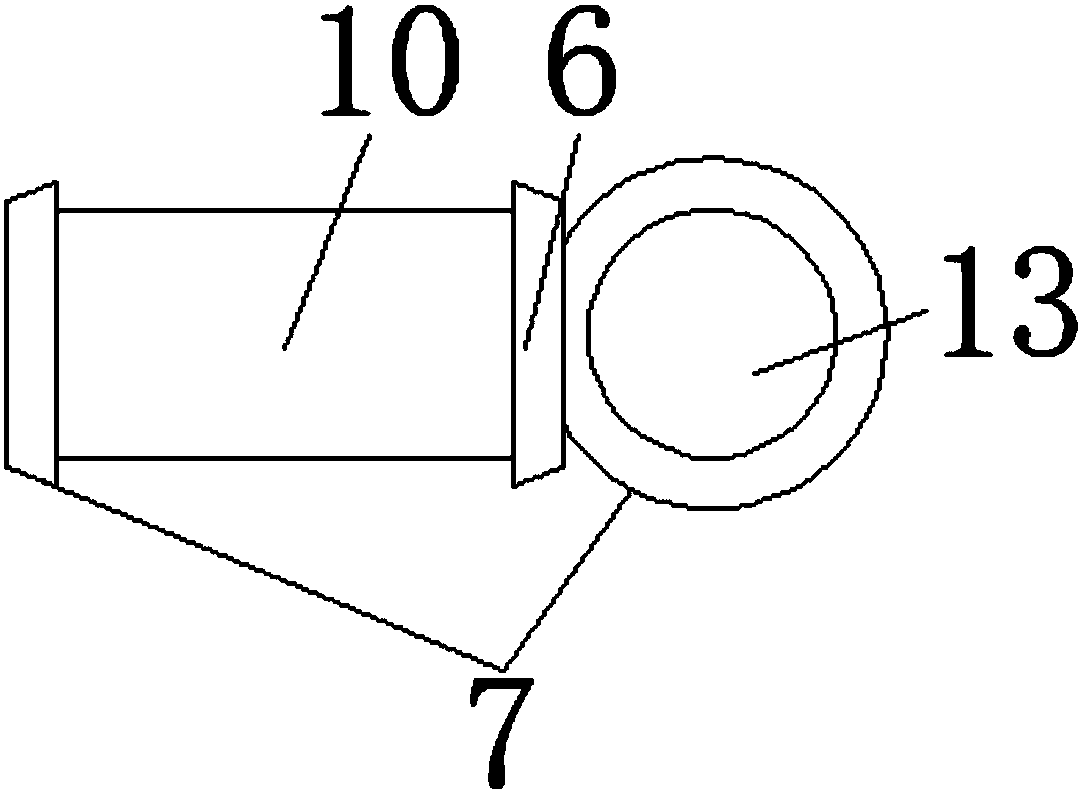

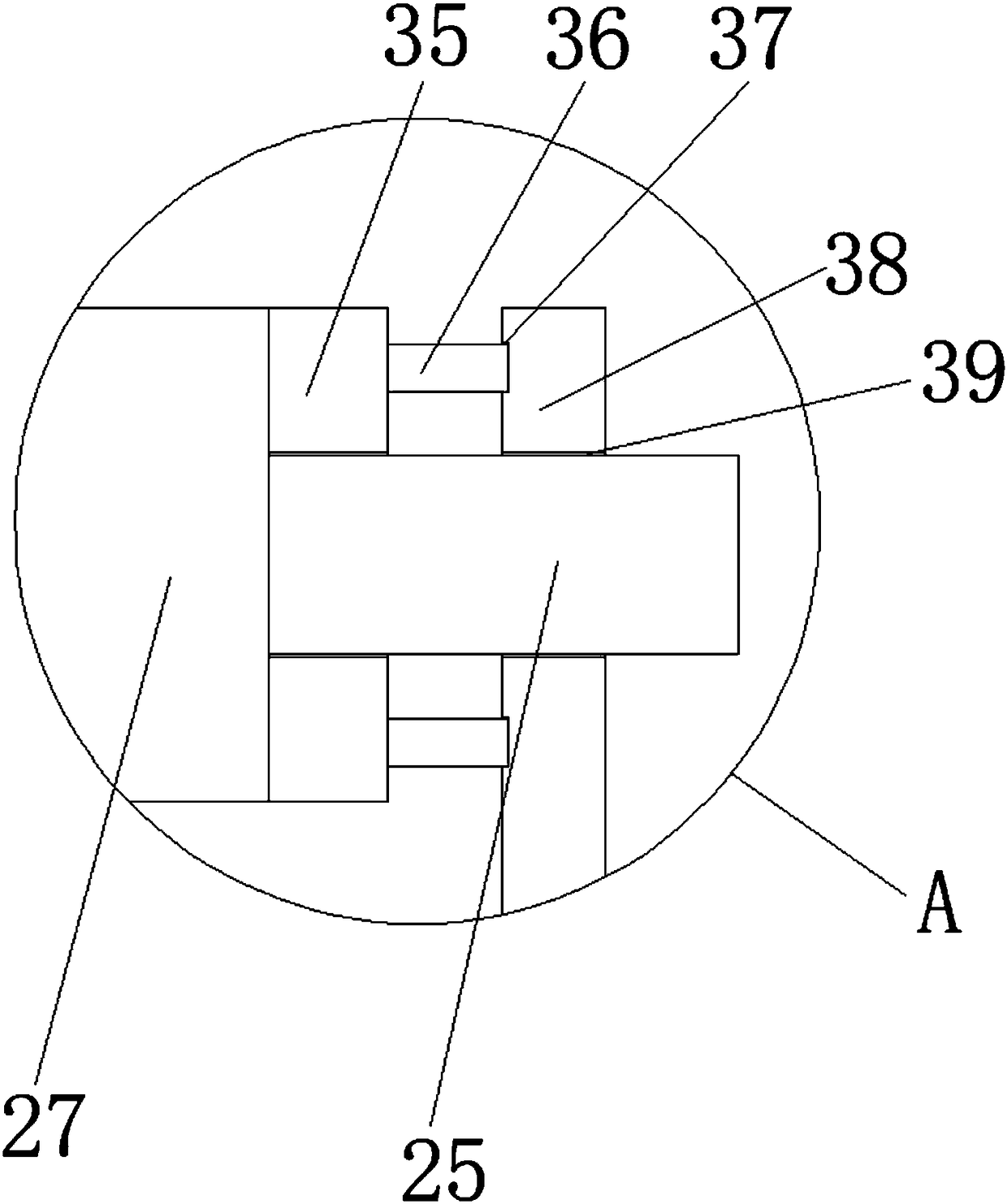

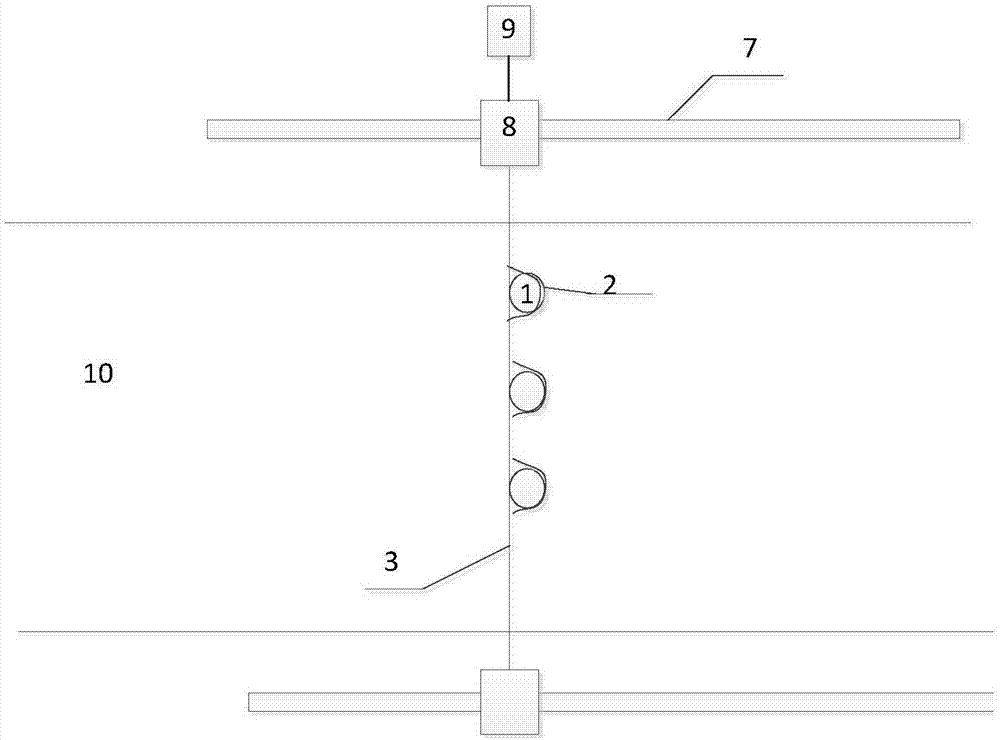

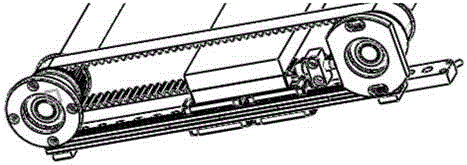

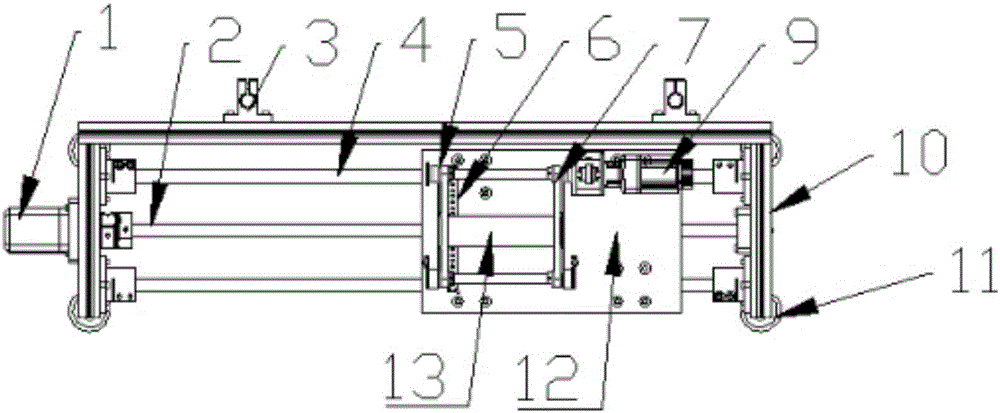

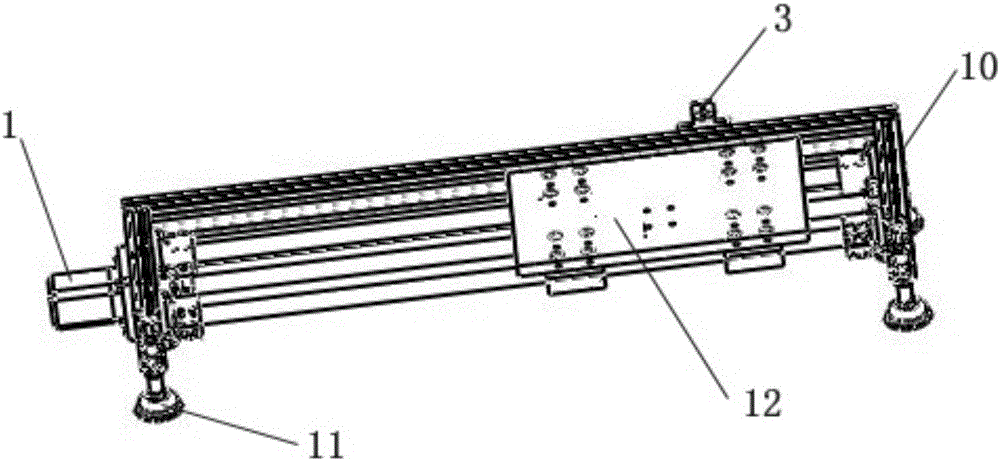

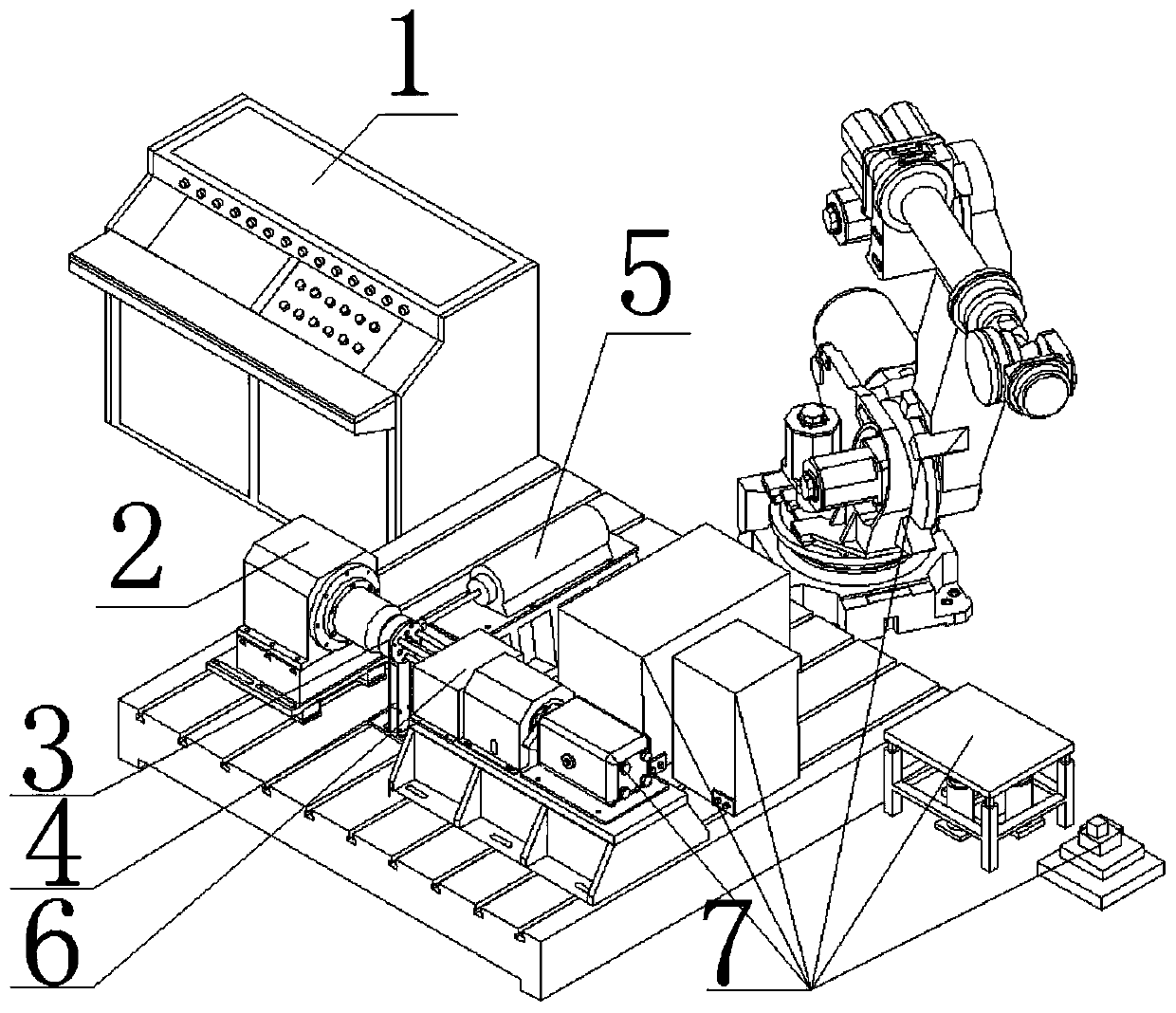

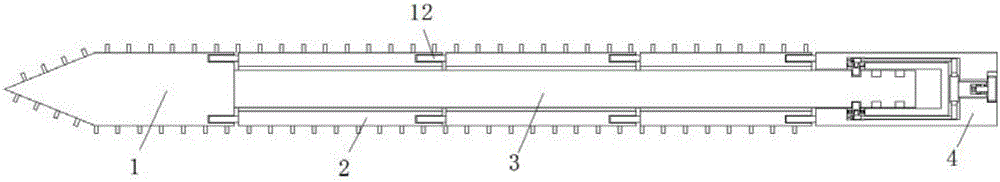

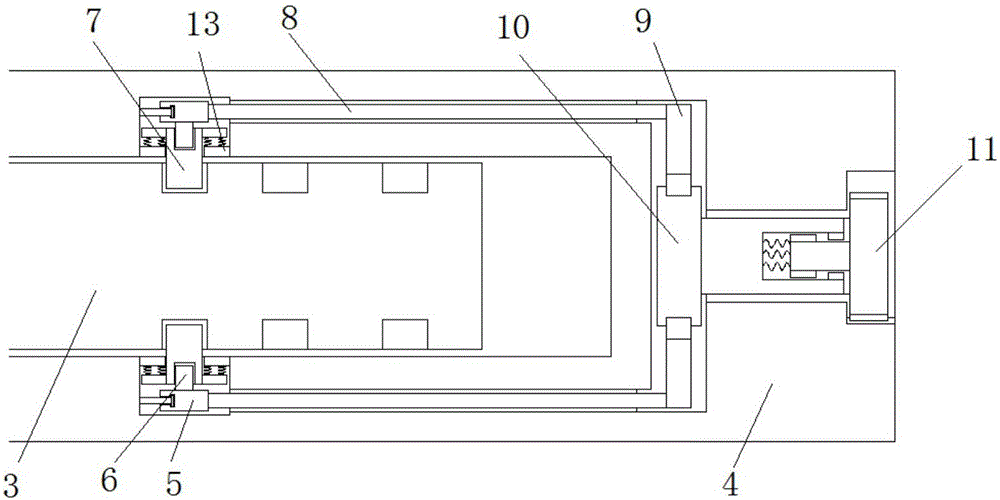

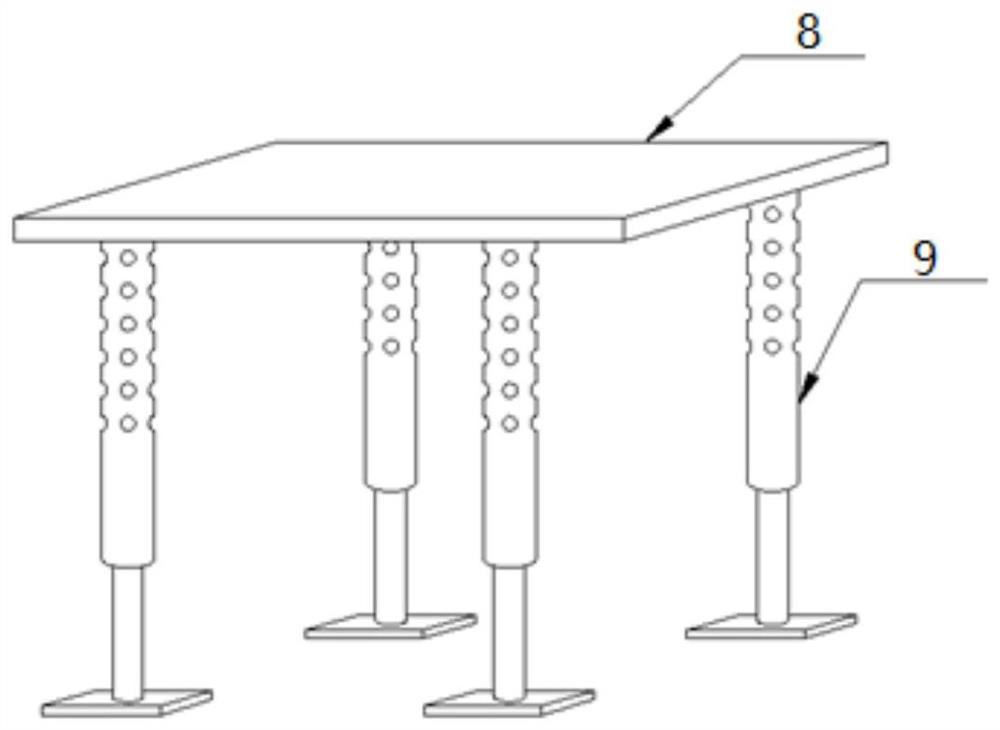

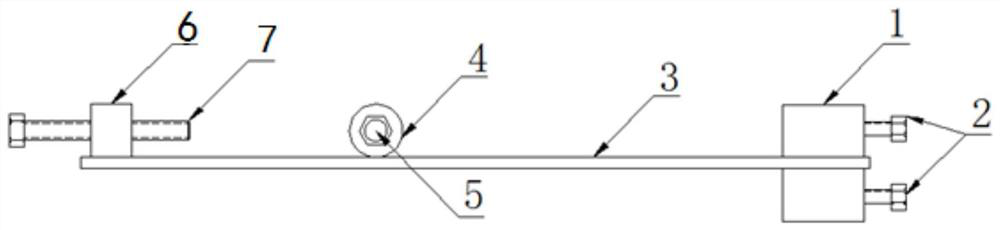

Multidirectional control platform for composite material ultrasonic cutting

ActiveCN105965588ARealize multi-directional controlAchieve precisionRadiation pyrometryMetal working apparatusGratingReciprocating motion

The invention belongs to the technical field of composite material ultrasonic cutting equipment, and particularly relates to a multidirectional control platform for composite material ultrasonic cutting. The multidirectional control platform comprises a machine frame (10), a driving shaft (2), a mobile platform (12), a carrier platform (13), a drive mechanism and a grating sensor (6). The machine frame (10) is provided with the rotating driving shaft (2). The driving shaft (2) is provided with the movable mobile platform (12). The mobile platform (12) is provided with the drive mechanism. The drive mechanism drives the carrier platform (13). The grating sensor (6) is arranged below the carrier platform (13) and used for sensing the displacement amount of the carrier platform (13). According to the multidirectional control platform, the problem of unicity of a reciprocating motion structure of a cutting platform is solved, the grating sensor is adopted for achieving motion direction and displacement accuracy of the cutting platform; the composite material ultrasonic cutting temperature is accurately measured; and the structure is simple, cutting efficiency is improved, and the multidirectional control platform has a remarkable popularization significance.

Owner:HANGZHOU DIANZI UNIV

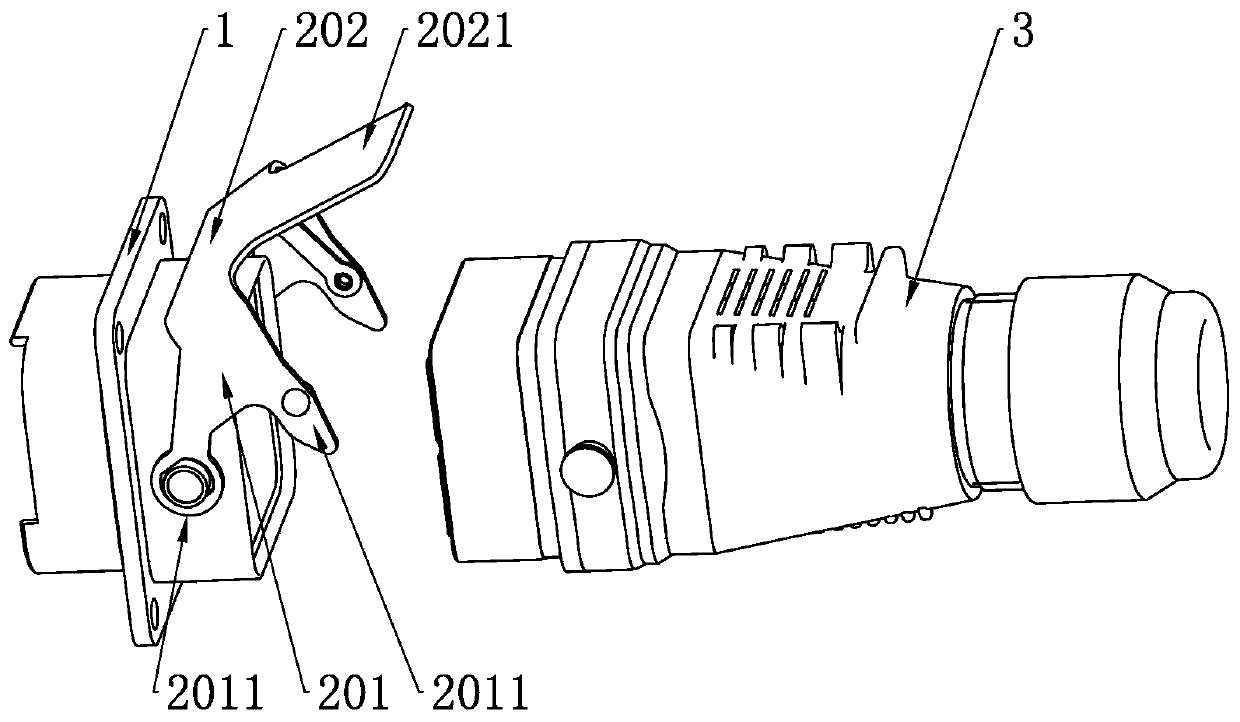

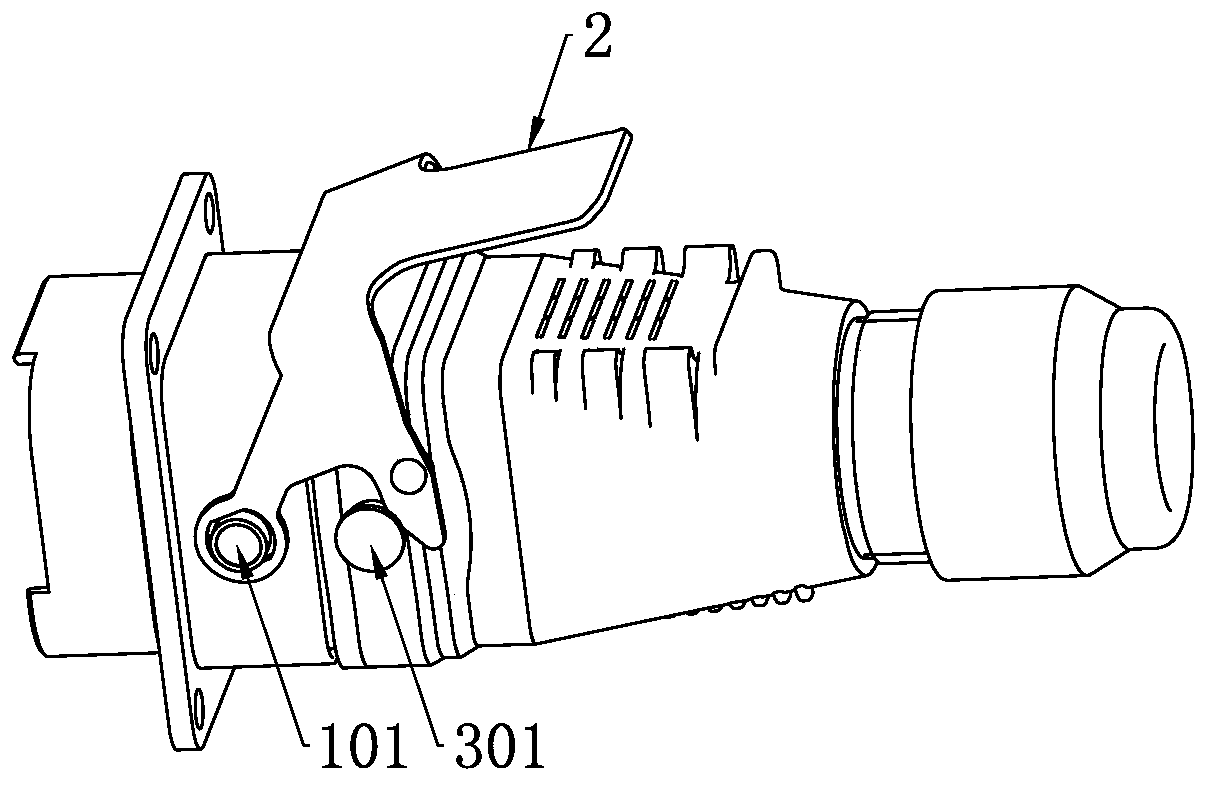

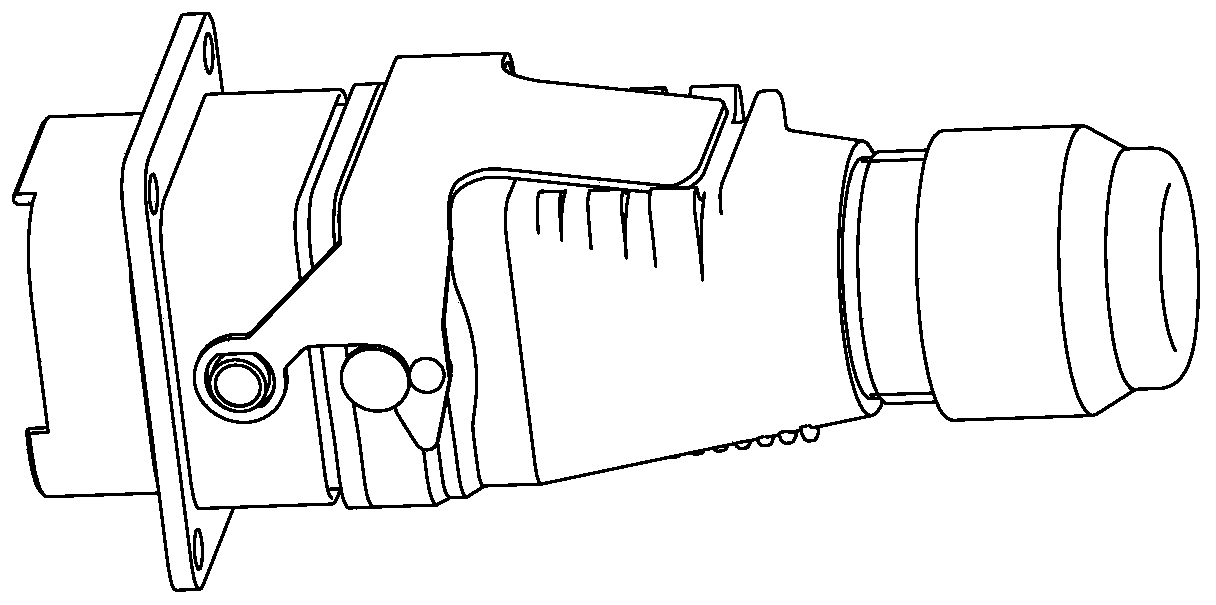

Locking sheet, push-and-pull locking mechanism and connector with push-and-pull locking mechanism

ActiveCN110086052ASimple and fast operationReduce disassembly stepsCoupling device detailsTwo-part coupling devicesPush and pullLocking mechanism

A push-and-pull locking mechanism comprises a locking sheet, a movement member, a protruded part, an elastic member and a limiting member. The locking sheet is mounted on a socket casing or a plug casing in a rotatable connection manner; the movement member mounted on the socket casing or the plug casing and capable of moving horizontally relative to the socket casing or the plug casing; the protruded part is arranged in the end portion of the movement member, cooperates with an inclined surface of a cooperation part by abutting, and enables the locking sheet to rotate when a socket is separated from a plug; one end of the elastic member is connected with the locking sheet, the other end of the elastic member is connected with the socket casing or plug casing, and the elastic member enables the locking sheet to return to the original position automatically after rotation; and the limiting member is mounted on the socket casing or plug casing, and limit horizontal movement of the movement member. When the push-and-pull locking mechanism is used to lock the socket and plug, it is only required to insert the plug into the socket, and when the socket is separated from the plug, it is only required to pull the movement member; and compared with the prior art, operation is simple, dismounting steps can be reduced, and the working efficiency is improved. The locking sheet and movementmember can both return the original positions after operation.

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

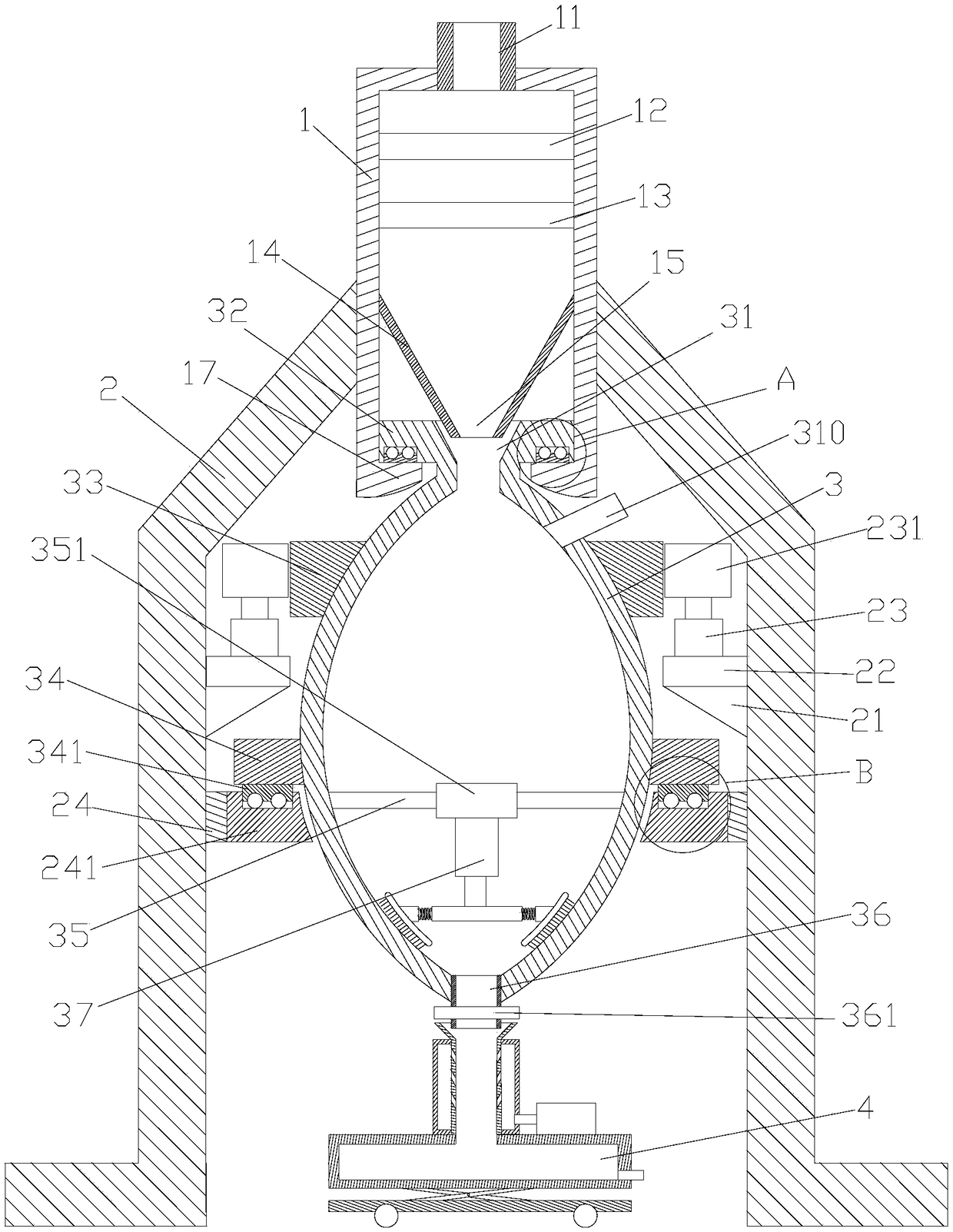

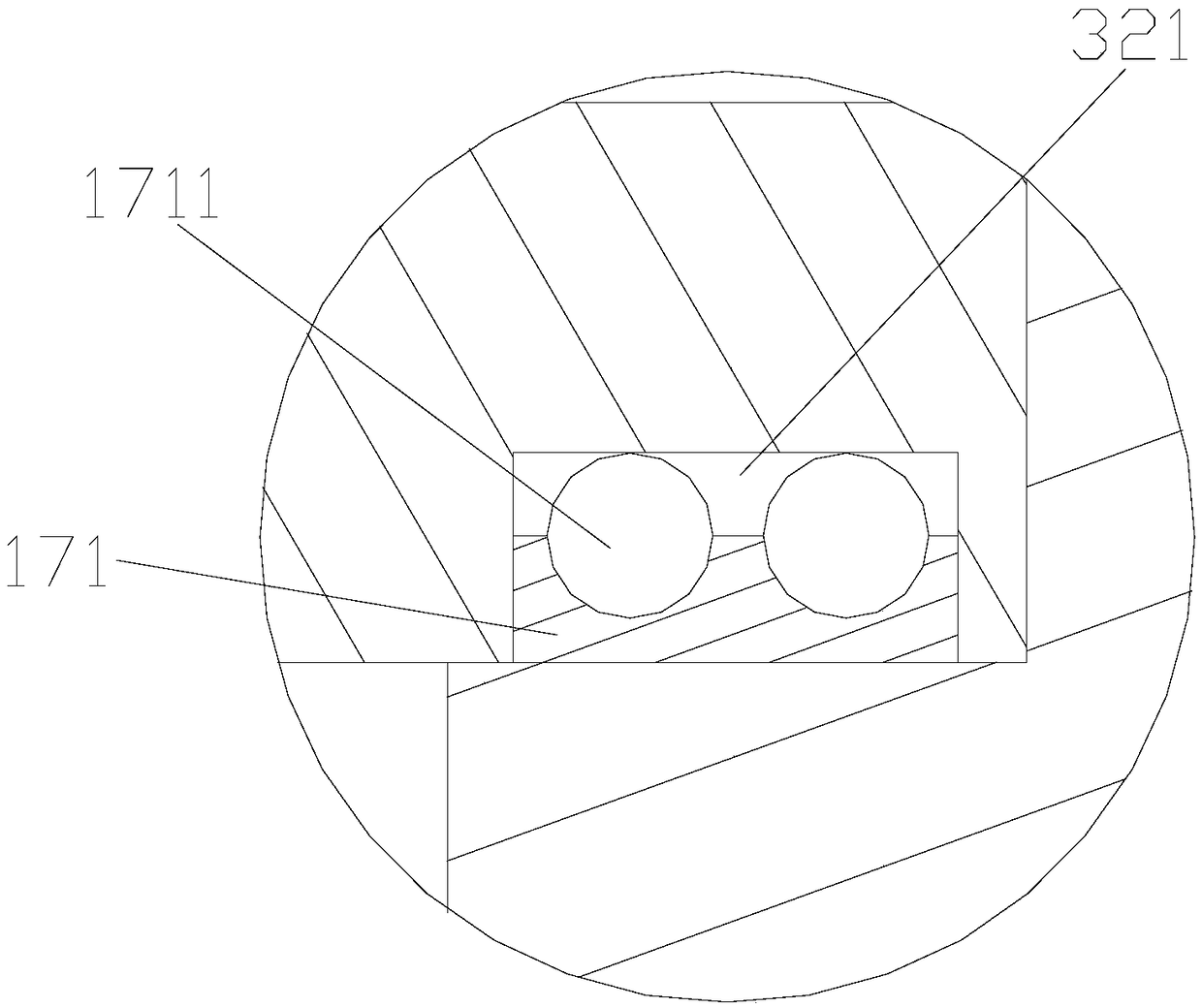

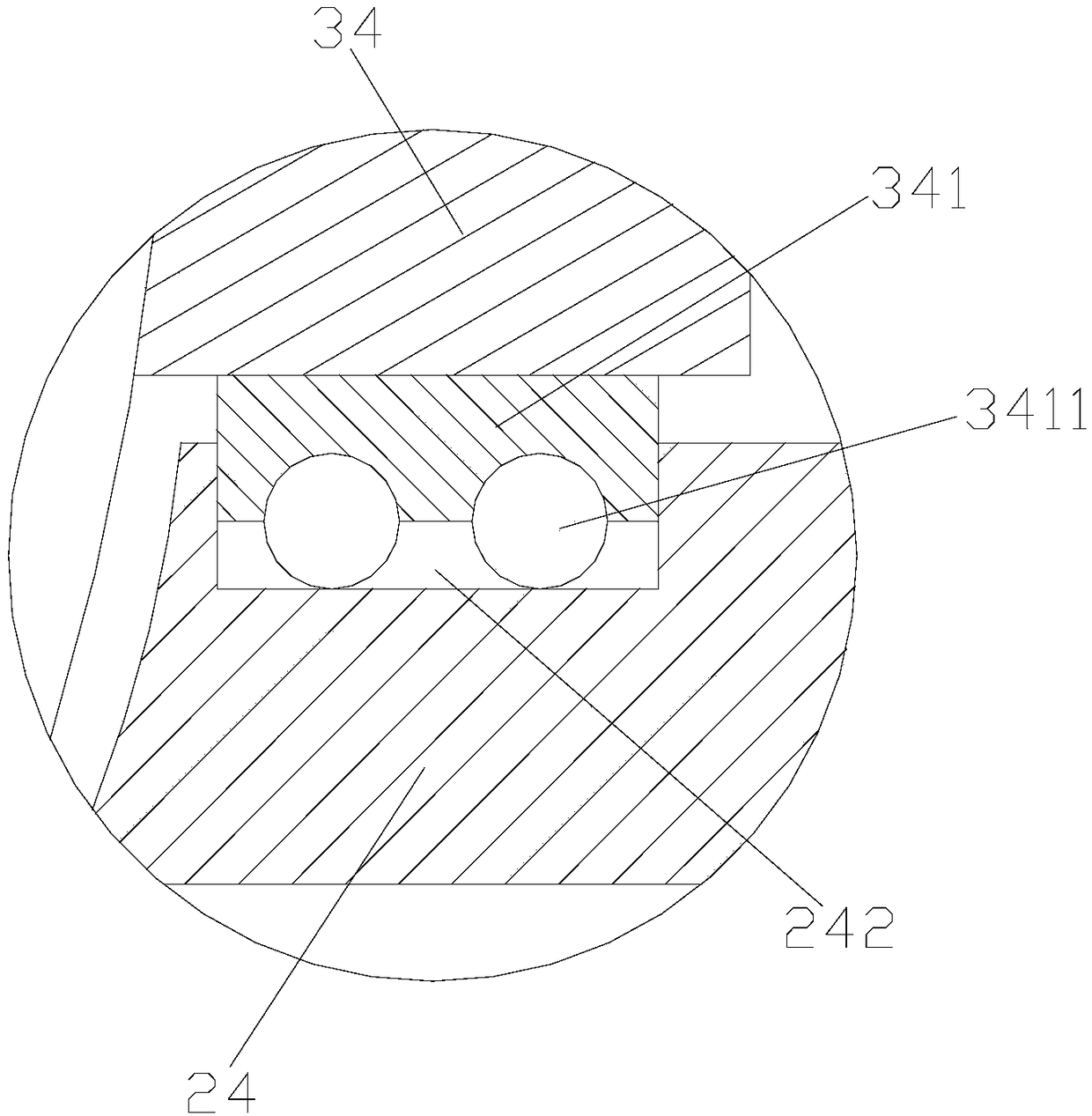

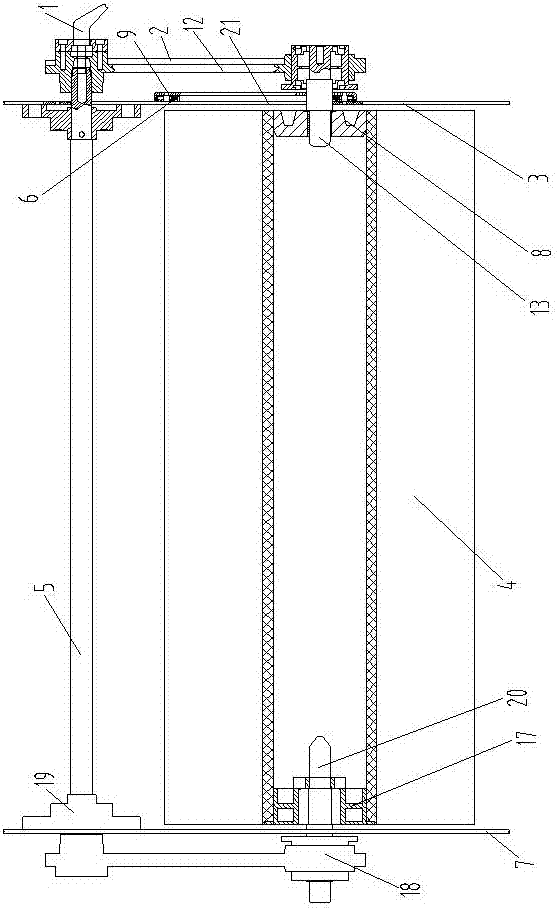

Electric spindle reliability test device based on synchronous hydraulic cylinder drive loading

PendingCN111238810ANo eccentricityAvoid failureMachine part testingHydraulic cylinderNumerical control

The invention discloses an electric spindle reliability test device based on synchronous hydraulic cylinder drive loading. The device comprises a main shaft clamping part, a loading unit part, a loading unit supporting part, a main radial loading part, an axial loading part and a torque loading part, the main shaft clamping part comprises a dowel bar; the loading unit part comprises a loading unitmain body and spherical grooves from No.1 to No.5; the loading unit supporting part comprises a first loading head; the main radial loading part comprises a No.2 loading head; the axial loading partcomprises loading heads from No.3 to No.5; and the torque loading part comprises a hydraulic pump and a torque transmission testing device. the electric spindle reliability test device is suitable fortwo common spindles in the reliability test of the numerically-controlled machine tool spindle, the test cost is reduced, and the device has universality; and axial, radial and torque loading can becarried out in a sequential, and separate and synchronous loading manners are performed, which is closer to the actual working condition of the main shaft, so that the steps of disassembling and assembling the test bed due to different loading are reduced, and the time is saved.

Owner:JILIN UNIV

Film removing method for high light plate piece

ActiveCN107054801AAvoid problems with detachment from the mucosal plateAchieve environmental protection effectUnpacking by cuttingElectrical and Electronics engineering

The invention relates to a film removing method for a high light plate piece. A rack, a film stripping mechanism and a bracket horizontally and slidably connected on the rack are included; one end of the bracket is connected with a reciprocating transmission mechanism, and the other end of the bracket is connected to the film stripping mechanism; the film stripping mechanism comprises a film pasting plate, a counterweight drum and two telescopic shafts hinged to the bracket; transmission air cylinders are connected between the bracket and the telescopic shafts; the film pasting plate and the counterweight drum are parallelly mounted between the two telescopic shafts and are rotatably connected on the two telescopic shafts; a negative pressure cavity is formed in the counterweight drum; communicating holes communicating with the negative pressure cavity are formed in the counterweight drum; film cutting cutters are mounted at the ends, close to the film pasting plate, of the telescopic shafts; and the movement tracks of the film cutting cutters are parallel to the film pasting plate. Through implementation of the technical scheme, the effects of environmental protection and high efficiency in the film removing process is guaranteed.

Owner:徐州博枫木业有限公司

Hydroelectric end connecting device for rotating target

InactiveCN102230161BGuaranteed stable workReduce disassembly stepsVacuum evaporation coatingSputtering coatingMechanical engineeringWater pipe

The invention relates to a hydroelectric end connecting device for a rotating target; and the hydroelectric end connecting device for the rotating target comprises a seat core and is characterized in that a water pipe and an electric-conductive rod are respectively mounted on the seat core and the seat core is connected with a shell module. Moreover, a shaft retainer ring is arranged at one end of the shell module; and a sealing cover is arranged at the other end of the shell module. A framework type oil seal module is arranged at the tail end of the shaft retainer ring. Meanwhile, an electric-conductive rod head is sleeved on the periphery of the framework type oil seal module. Therefore, while a target material is replaced, the assembling and disassembling steps can be effectively reduced. More importantly, the shaft retainer ring is mutually matched with a base closing piece so that the rotation force of the driving can be effectively transmitted to facilitate the smooth working ofthe target material.

Owner:黄峰

Floor brush and cleaning device

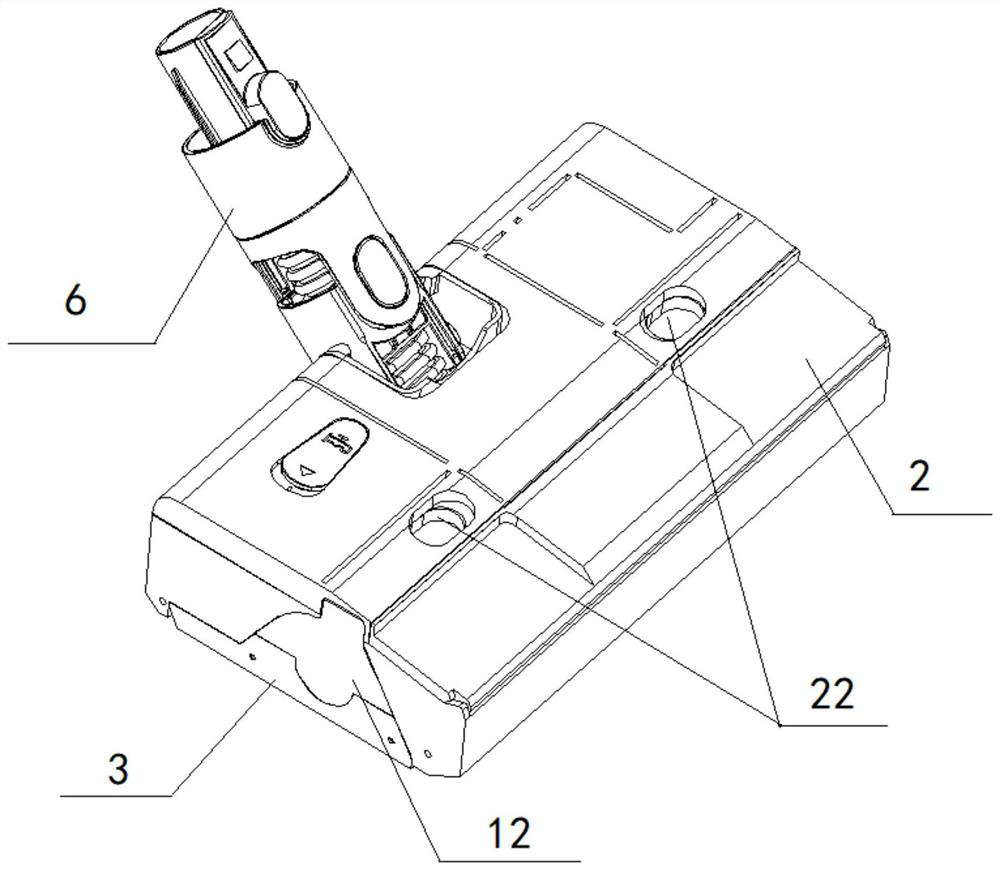

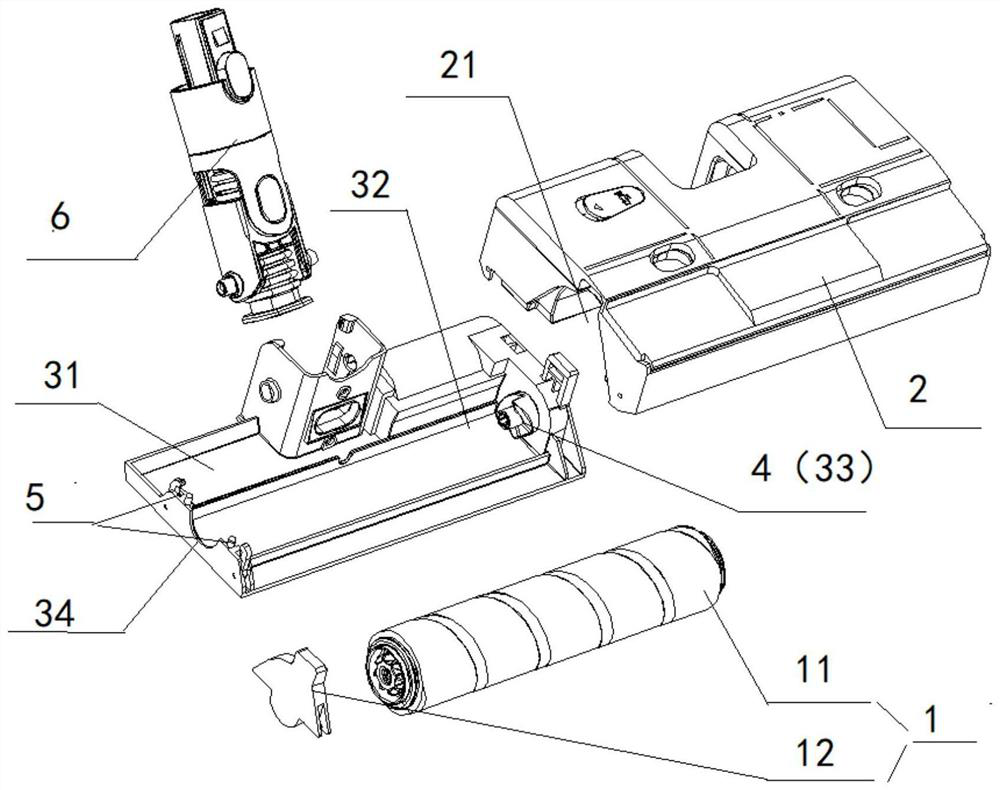

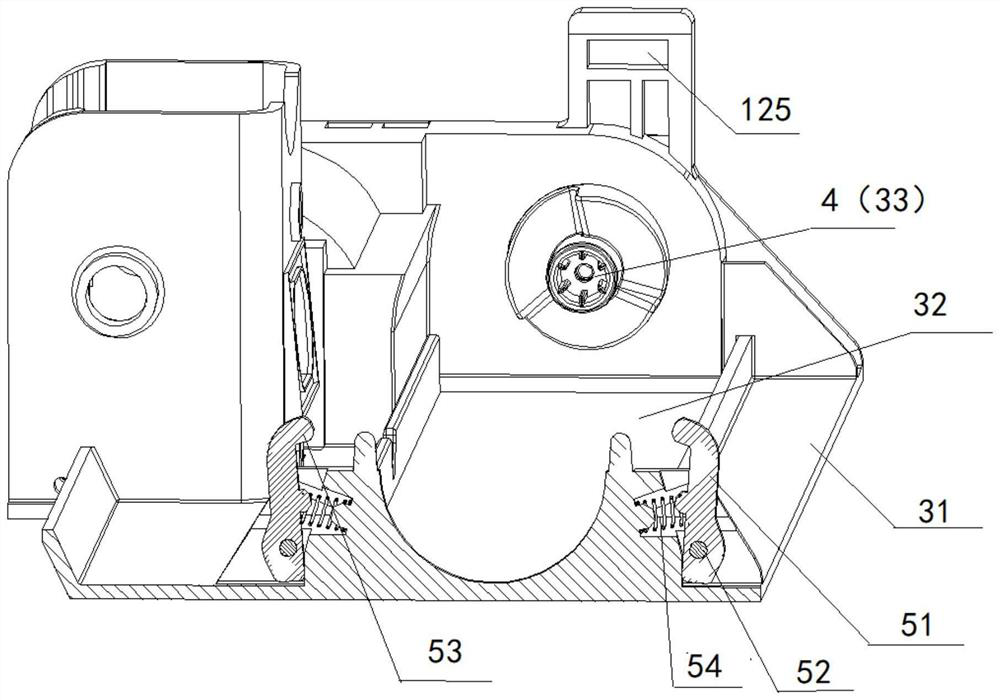

PendingCN113768425ARealize automatic unlockSimplify disassembly stepsCarpet cleanersFloor cleanersStructural engineeringMechanical engineering

The invention provides a floor brush and a cleaning device. The floor brush comprises a rolling brush assembly; a water tank assembly arranged on the upper side of the rolling brush assembly and suitable for supplying water to the rolling brush assembly and cleaning the rolling brush assembly; a support assembly, wherein a power part and a lock catch assembly are arranged on the support assembly, the support assembly is suitable for bearing the rolling brush assembly and the water tank assembly, and the lock catch assembly has a working position where the lock catch assembly is connected with the rolling brush assembly in a clamping mode at least under the pressure of the water tank assembly and enables the rolling brush assembly to rotate under the driving of the power part and a dismounting state where the lock catch assembly is separated from the pressure of the water tank assembly under the action of external force and is far away from the working position. By means of the arrangement, the step of manually unlocking the lock catch assembly is omitted, the disassembly and assembly steps of the rolling brush assembly and the water tank assembly are greatly simplified, the rolling brush assembly and the water tank assembly can be disassembled from the floor brush only through two steps, the disassembly and assembly steps are few, and disassembly and assembly are convenient. The defects that in the prior art, the process steps of upwards taking out a rolling brush assembly of a floor brush are many and the user experience is poor can be overcome.

Owner:GREE ELECTRIC APPLIANCES INC

Conveniently-replaced machine barrel screw for injection molding device

The invention discloses a conveniently-replaced machine barrel screw for an injection molding device. The conveniently-replaced machine barrel screw comprises a screw head, screw branch cylinders, a middle pillar and a connecting head. The multiple screw branch cylinders are arranged, and through holes are formed in the screw branch cylinders and the connecting head. One end of the middle pillar is fixed and welded to one end of the screw head. The screw branch cylinders are arranged on the outer side of the middle pillar in a sleeving manner. The connecting head is connected with the end, away from the screw head of the middle pillar. Multiple sets of clamping grooves are formed in a pillar body of the middle pillar. Side grooves are formed in the inner wall of the through hole of the connecting head, and rotation pillars are rotationally connected to the inner wall of the sides, close to the screw head, of the side grooves. Adjusting rods are connected to the sides, close to each other, of the rotation pillars. The ends, close to each other, of the adjusting rods are connected with clamping rods in a contact manner. By means of the conveniently-replaced machine barrel screw for the injection molding device, the demounting step is omitted, the production efficiency is improved, meanwhile, a large amount of different types of machine barrel screws are not needed in a production workshop, the production cost is reduced, and the use requirement of people in production and life is met.

Owner:宁波金亿精密机械有限公司

Installation method of vertical guide rail of ship elevator

The invention discloses an installation method of a vertical guide rail of a ship elevator. The installation method comprises the following steps that 1, a bottom support is manufactured; 2, a cross center line of a flat plate is marked on the bottom support; 3, each section of a vertical guide rail is sequentially hoisted in place from bottom to top; 4, adjusting is carried out on the vertical guide rail through an adjusting device, so that the corresponding faces of all sections of the guide rail are kept aligned; 5, total thickness measuring is carried out on a welding gasket and an adjusting gasket by using a caliper; 6, after thickness measuring of the gaskets is finished, the welding gasket is installed; 7, the vertical guide rail is hoisted back from bottom to top according to the serial number, the thickness of the adjusting gasket is adjusted through the caliper, spot welding is conducted on the adjusting gasket installed in place, and a fastening bolt is installed; and 8, positioning pins and set screws are installed, and a base plate between the adjusting device and the vertical guide rail is dismantled. The method can be operated without special training, extra cost isnot needed, and the training and operation cost is almost zero.

Owner:HUDONG ZHONGHUA SHIPBUILDINGGROUP

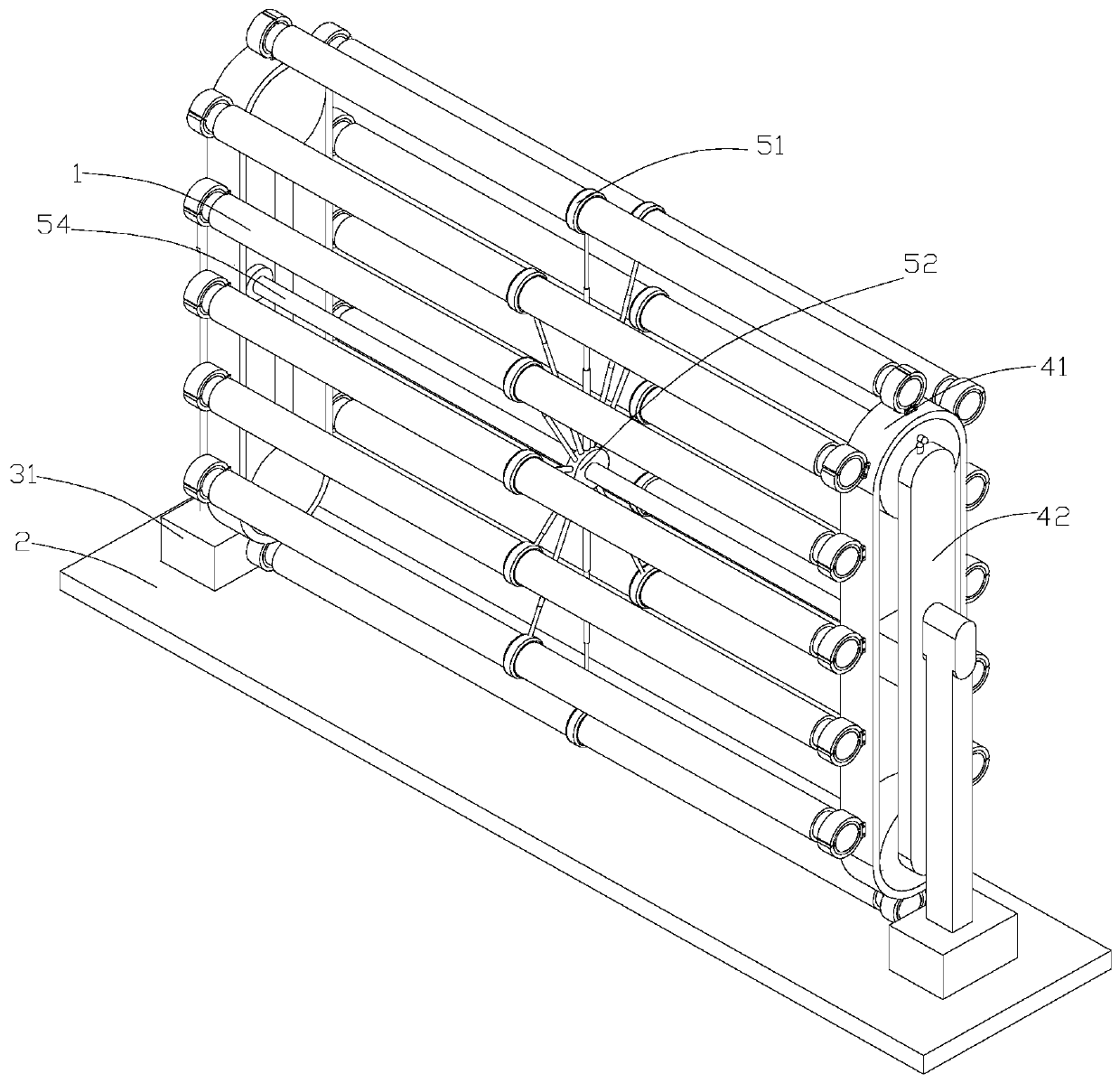

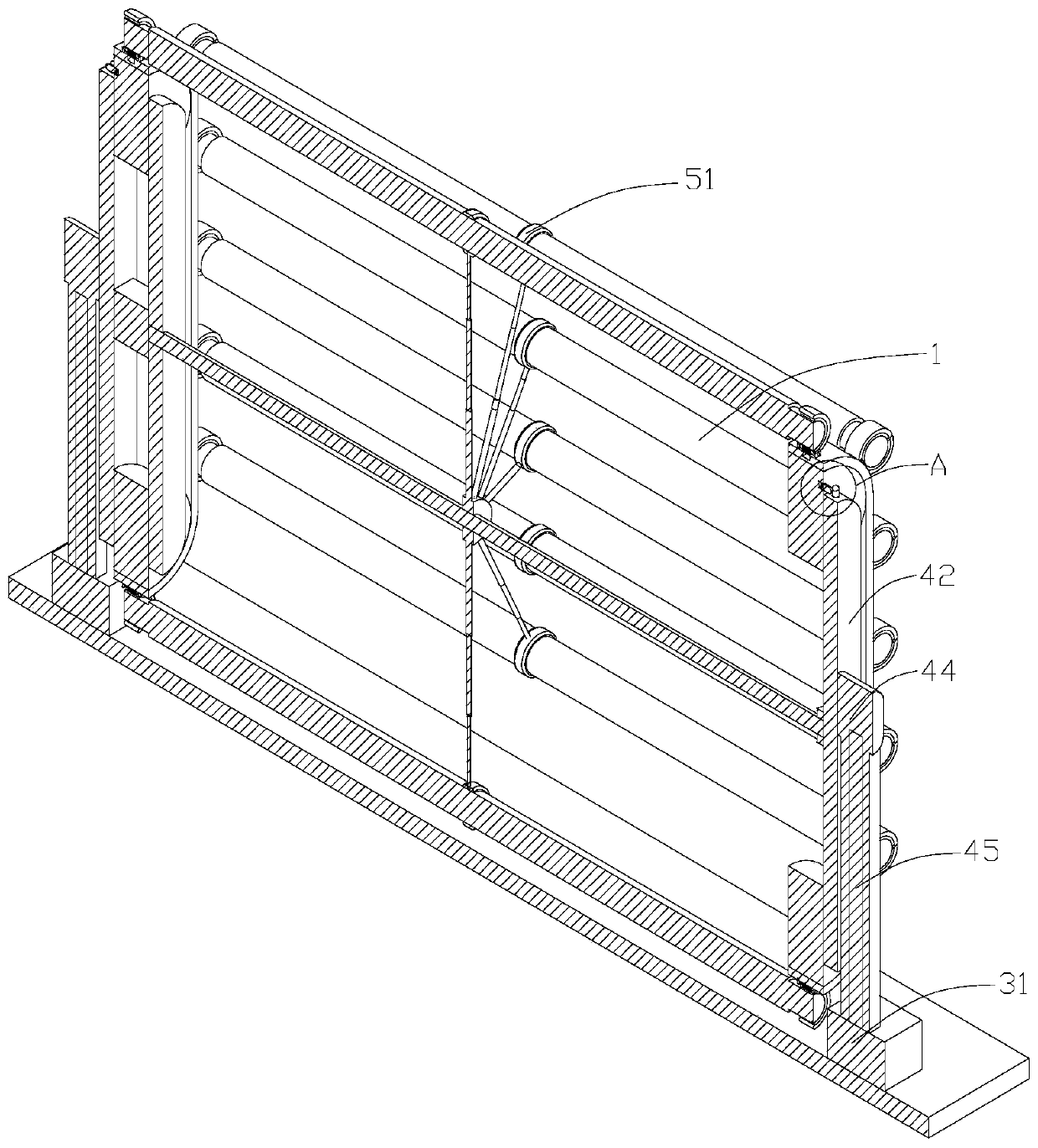

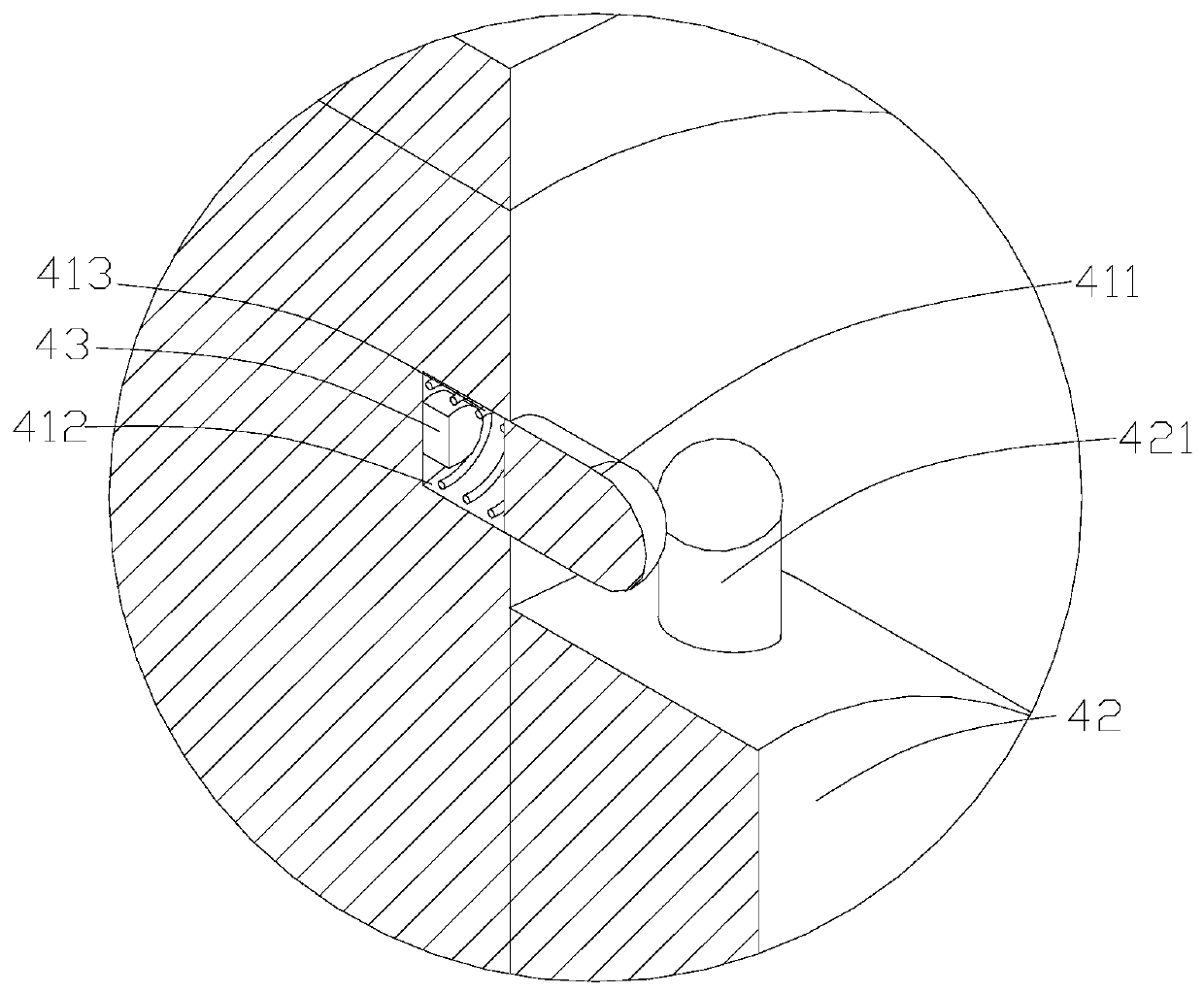

Open channel type ultraviolet disinfection equipment for sewage treatment

ActiveCN111517409AAvoid damageEasy to fixWater/sewage treatment by irradiationSpecific water treatment objectivesUv disinfectionSewage

The invention discloses open channel type ultraviolet disinfection equipment for sewage treatment which comprises a plurality of ultraviolet disinfection lamps for sterilizing and disinfecting sewageand a plurality of supporting bases for supporting the equipment, a first driving piece for controlling an ultraviolet disinfection lamp to do lifting motion, a fixing device which is used for clamping and fixing the ultraviolet disinfection lamp, two vertical conveying belts which are used for driving the fixing device to drive the ultraviolet disinfection lamp to rotate, and a cleaning device which is used for automatically cleaning the ultraviolet disinfection lamp are arranged on each supporting base. Through the arrangement of the structure, the ultraviolet disinfection lamps can be effectively cleaned; the ultraviolet disinfection lamps are prevented from scaling to influence ultraviolet irradiation, the irradiation effect of the ultraviolet disinfection lamps is effectively guaranteed, the ultraviolet disinfection lamps can be efficiently replaced through the arrangement of the fixing devices, and damaged ultraviolet disinfection lamps can be replaced more easily in a labor-saving mode.

Owner:中科华鹿(合肥)环保科技有限公司

Biopharmaceutical extraction equipment convenient for replacing filter layer

ActiveCN109107268AEasy to take outExtended service lifeFiltration circuitsBiochemical engineeringPore diameter

The invention discloses biopharmaceutical extraction equipment convenient for replacing a filter layer. The biopharmaceutical extraction equipment comprises a preliminary filter box, support seats arranged on two sides of the preliminary filter box, a secondary filter barrel arranged below the preliminary filter box, and a loading vehicle arranged below the secondary filter barrel, wherein a firstfeed port is formed in the top of the preliminary filter box; a first filter layer is arranged in the preliminary filter box; a second filter layer is arranged below the first filter layer; the porediameter of the filter pores of the first filter layer is greater than the pore diameter of the filter pores of the second filter layer; the first filter layer and the second filter layer are detachably connected with the preliminary filter box; the first filter layer comprises a first filter layer left part and a first filter layer right part; the first filter layer left part and the second filter layer right part are in detachable fit. Through detachable connection, the filter layer can be conveniently removed from the interior of the filter box to be changed, thus the steps of dismantling the filter layer are reduced, and the dismantling cost of the filter layer is reduced.

Owner:南京润力生物科技有限公司

Main brush structure of sweeping machine

PendingCN107354894AReduce disassemblyReduce disassembly stepsRoad cleaningStructural engineeringBrush

The invention provides a main brush structure of a sweeping machine, and relates to a sanitation facility. The main brush structure includes a left side plate, a right side plate, a main brush and a synchronizing shaft, a left end enclosure is connected with the inner side of the left end of the main brush, the left end enclosure is connected with a driven shaft, a right end enclosure is connected with the inner side of the right end of the main brush, the right end enclosure is connected with an active shaft, and the active shaft is supported on the right side plate; a main brush replacement port is formed in the left side plate of the main brush, and a main brush baffle is installed on the main brush replacement port; a left connecting arm assembly is arranged on the side, back facing the left side plate, of the main brush baffle, and a right connecting arm assembly is arranged on the side, back facing the main brush, of the right side plate, and the structure of the left connecting arm assembly is the same as the structure of the right connecting arm assembly, the upper end of the left connecting arm assembly is fixed with the left end of the synchronous shaft through a synchronous shaft bolt handle, the lower end of the left connecting arm assembly is support on the driven shaft, the driven shaft is arranged on the main brush baffle in a penetrating mode and connected with the left end enclosure; the upper end of the right connecting arm assembly is fixed with the right end of the synchronizing shaft, and the lower end of the right connecting arm assembly is supported on the active shaft. According to the main brush structure of the sweeping machine, the main brush can be quickly replaced.

Owner:NANTONG MINGNUO ELECTRIC TECH CO LTD

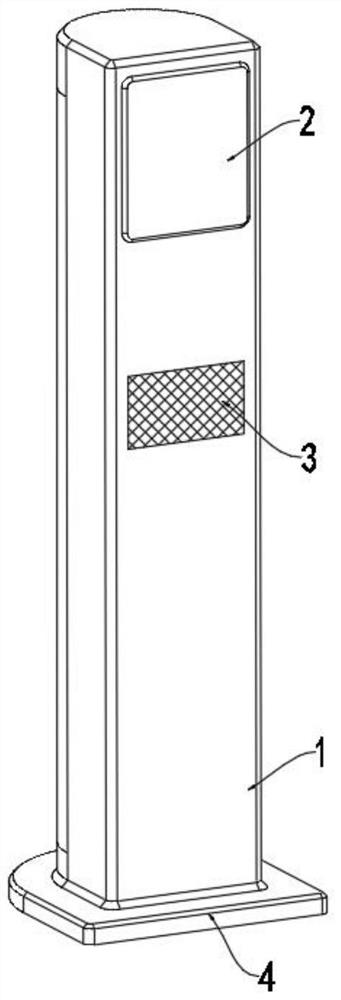

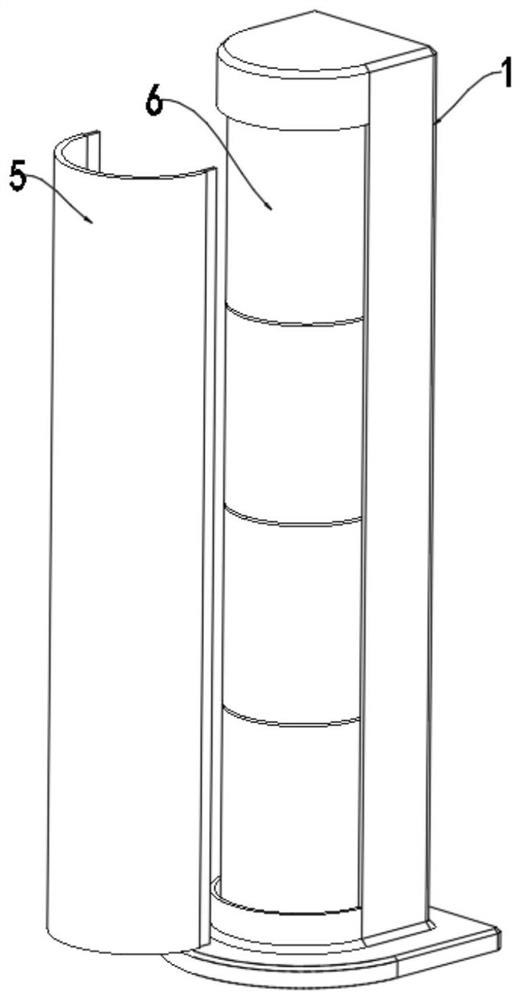

Pedestrian warning stand column all-in-one machine convenient to maintain

ActiveCN112361240AEasy to disassemble and repairReduced disassembly stepsElectric circuit arrangementsElectric lightingElectrically conductiveStructural engineering

The invention discloses a pedestrian warning stand column all-in-one machine convenient to maintain, which comprises a shell, wherein a fixed base is fixedly installed on the lower surface of the shell, an external protective shell is fixedly installed on one side of the shell, a combined lamp post is arranged in the shell, the combined lamp post comprises an upper cover, a lower cover, a connecting bottom groove, an outer ring, conductive pins, an inserting hole, a lamp post, conductive grooves, a lamp wick and a lampshade, the lamp post is fixedly installed in the lampshade, the upper coveris arranged on the upper surface of the lamp post, the lower cover is arranged on the lower surface of the lamp post, the outer ring is arranged on the upper surface of the upper cover, the connectingbottom groove is formed in the lower surface of the lower cover, two conductive pins located on the upper surface of the upper cover are symmetrically arranged on the inner side of the outer ring, the conductive grooves located in the lower surface of the lower cover are symmetrically formed in one side of the connecting bottom groove, and the lamp wick is arranged on the outer surface of the lamp post. When the device is maintained in the later period, the operation is convenient, and the installation is rapid.

Owner:苏州地枢新材料科技有限公司

A vacuum coating machine

ActiveCN109930128BContinuous operationReasonable designVacuum evaporation coatingSputtering coatingLiquid storage tankElectric machinery

The invention discloses a vacuum coating machine. The vacuum coating machine comprises a bottom plate, a diffusion pump and a mechanical pump, wherein supports are fixedly arranged on the left side and the right side of the lower end surface of the bottom plate, a vacuum meter is arranged on the left side of the interior of a cover body, a vent valve is arranged on the right side of the interior of the cover body, electric telescopic rods are arranged on the left side and the right side of the interior of the cover body, the outer surfaces of the upper ends of the electric telescopic rods arefixedly connected with to-be-plated metals at equal intervals, frame bodies are arranged on the inner sides of the electric telescopic rods, motors are fixedly arranged on the right side surfaces of the frame bodies, a fixed disc is arranged on a linkage structure, and a liquid storage tank is fixedly arranged on the right side of the upper surface of the bottom plate. According to the vacuum coating machine, the vacuum state in the cover body can be known and controlled through the vacuum meter, moreover, a cleaning device for the cover body is arranged, so that the coating efficiency is high, the cover body is not required to be repeatedly opened, so that the sealing performance of the machine is good, moreover, assembly and disassembly are convenient, and the design of the cooperative mechanism between the diffusion pump and the mechanical pump is reasonable.

Owner:南阳清水科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com