Driving tip device for rotating target

A technology of rotating target and tip, applied in the field of driving tip device for rotating target, can solve the problems of increasing production cost, being unable to adapt to different types of targets, affecting use, etc., reducing disassembly and assembly steps, and facilitating smooth work. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

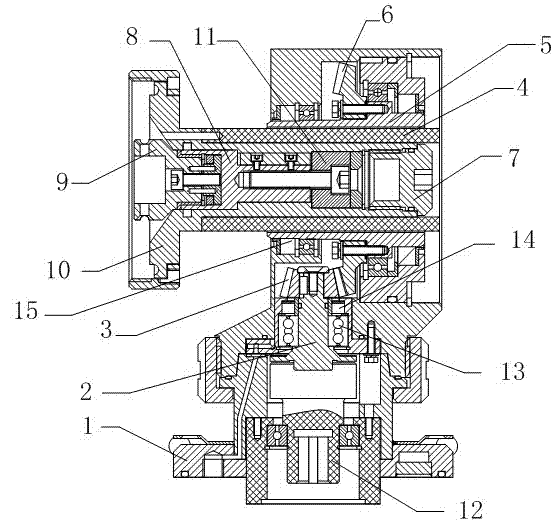

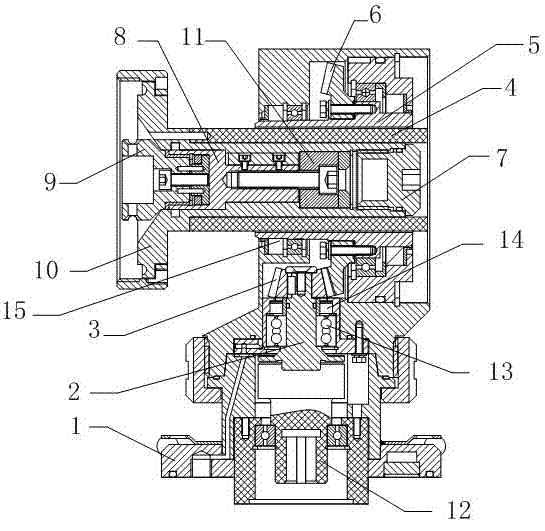

[0015] Such as figure 1 The driving end device for the rotating target shown includes a base 1, which is different in that: a cross shaft 2 is installed on the base 1 used in the present invention, and a pinion 3 is arranged on the top of the cross shaft 2 . Moreover, in order to improve the smooth operation of the pinion 3, an adapter sleeve 4 is connected to the driving end of the pinion gear 3. A hexagonal sleeve 5 is arranged on the periphery of the adapter sleeve 4, and a large gear 6 is installed on the hexagonal sleeve 5. Moreover, a driving assembly is arranged in the adapter sleeve 4 .

[0016] In view of a preferred embodiment of the present invention, in order to facilitate the correct transfer of driving operation, the drive assembly adopted in the present invention includes a head nut 7 , and a transition shaft 8 is provided at the top of the head nut 7 . At the same time, a shaft head 9 is arranged on the top of the transition shaft 8 , and a hexagonal main sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com