Purifying system for high power output and low-temp tail gas discharge of IC engine

A purification system and high-power technology, which is applied in the fields of exhaust emission purification of automobiles, high power output of internal combustion engines, and low-temperature exhaust emission purification systems, can solve problems such as high cost, unsatisfactory purification effect, and no substantial contribution to the output power of internal combustion engines. Achieve the effects of low production cost, suppression of noise and vibration rate, and increase of effective output power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

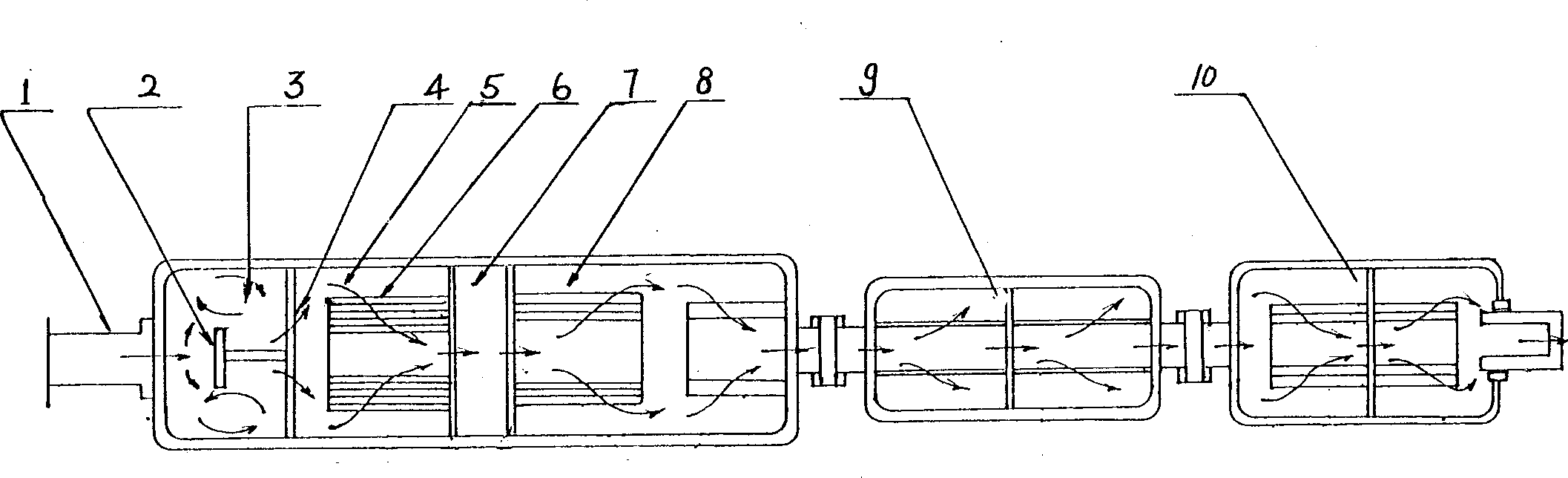

[0040] Example 1: Combining Figure 1 to Figure 5 , a gasoline engine internal combustion engine high power output, exhaust gas low temperature emission purification system, comprising a temperature raising and holding pressure vortex device, an air storage chamber 7, a filter, a muffler cooler 8, a decompression adsorber 9 and a muffler 10.

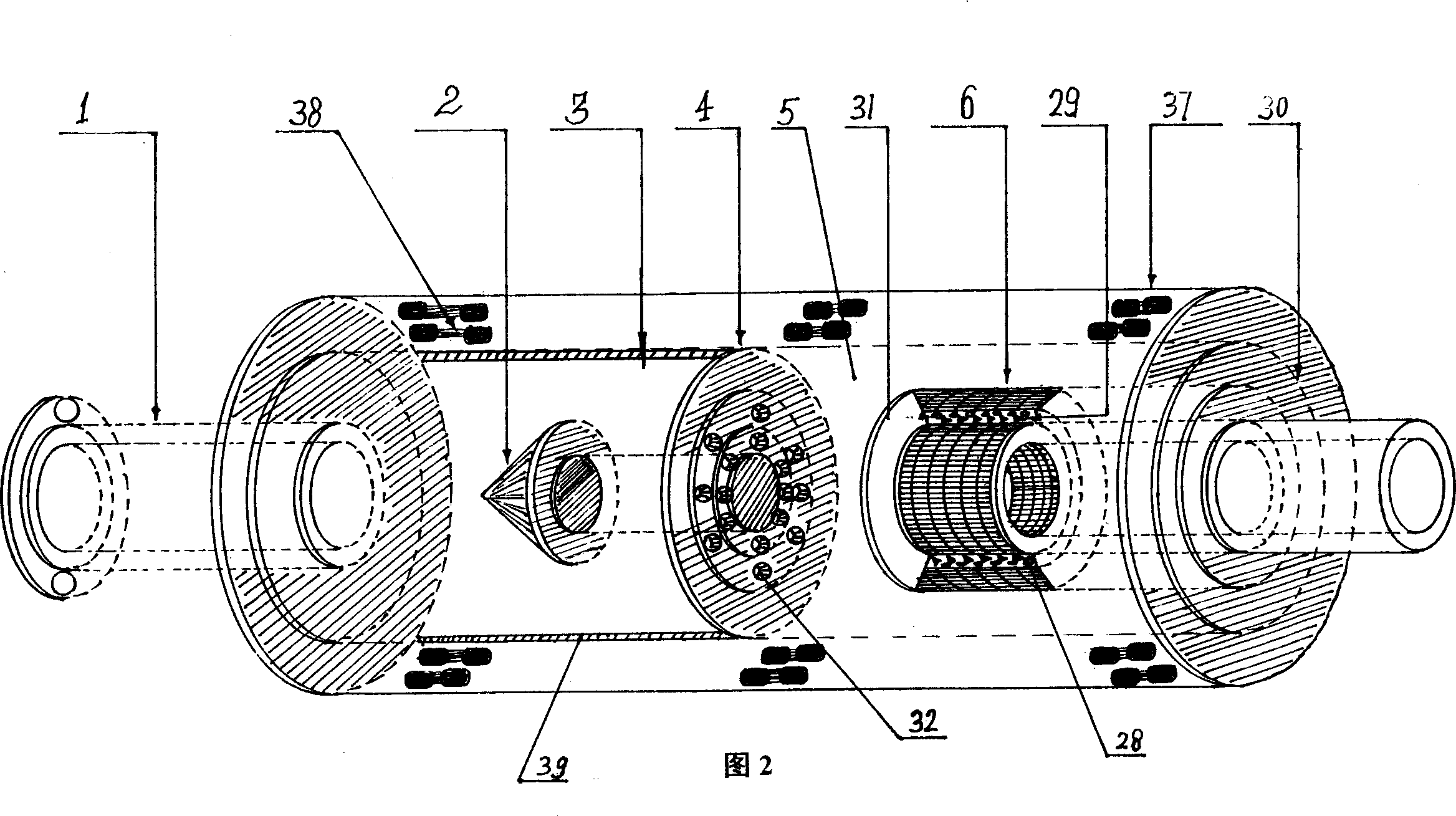

[0041] In Fig. 2, the temperature-raising and pressure-holding vortex device is composed of a vortex chamber 3, an airflow guide cone 2 and a restrictor plate 4. The airflow guide cone 2 is a conical, spherical or hemispherical metal body, facing the outlet of the engine exhaust manifold 1. The airflow guiding cone 2 is fixed at the center of the flow limiting plate 4, and the airflow guiding cone 2 is connected with the limiting plate 4 by electric welding, on the inner wall of the vortex chamber 3 or the limiting plate 4 or on the inner wall of the vortex chamber 3 and the limiting plate 4 A metal catalyst is fixed. Among them, the me...

Embodiment 2

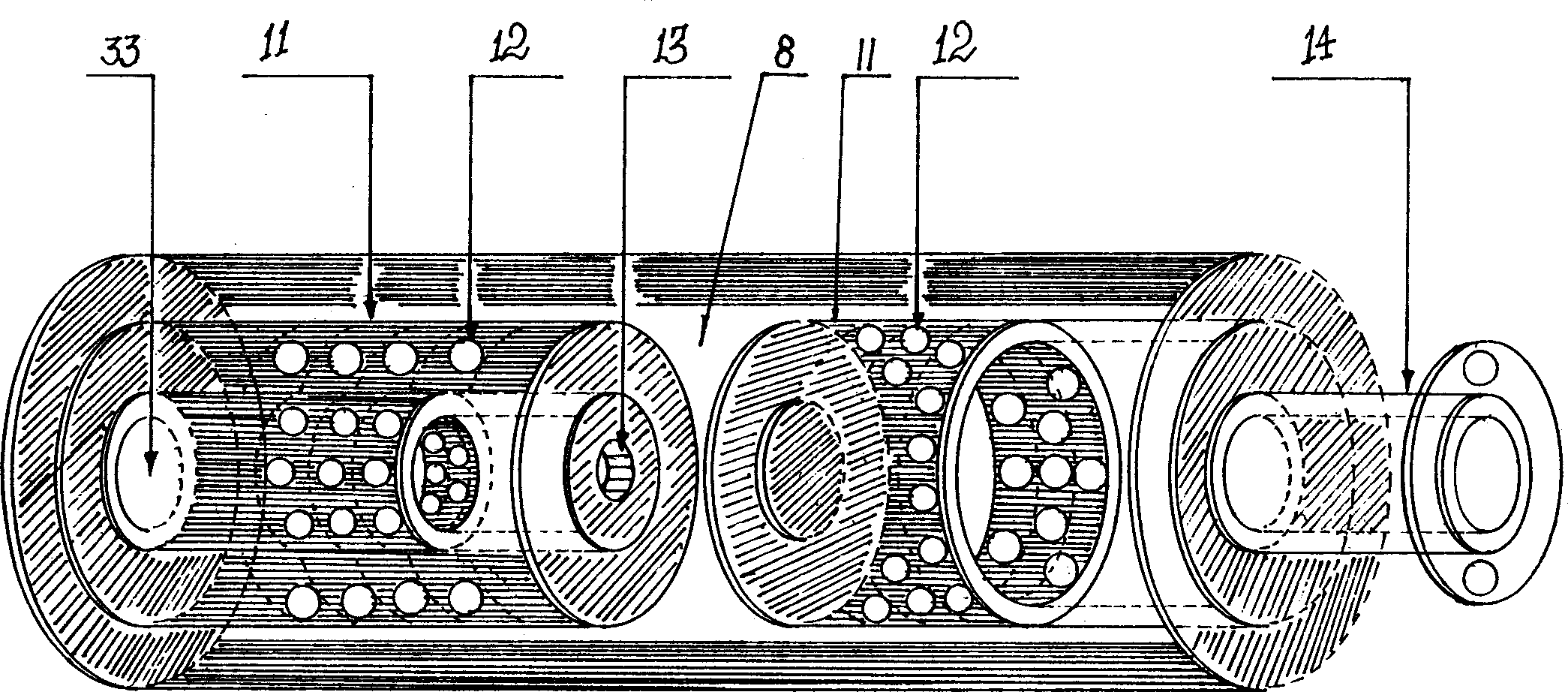

[0052] Embodiment two: in conjunction with Fig. 2~4, Figure 6~7 , a diesel engine internal combustion engine high power output, exhaust gas low temperature emission purification system, comprising a temperature raising and pressure holding vortex device, a filter 5, a muffler cooler 8, a decompression adsorber 9 and an exhaust gas filter 10. Among them, such as Image 6 , Figure 7 As shown, the exhaust gas filter 10 includes a connecting pipe 21, a housing 23, a decompression buffer head 22, a primary filter element 24 and a secondary filter element 25, the decompression buffer head 22 is a conical or spherical metal body, the primary filter element 24 and the secondary filter element 25. The secondary filter element 25 is a paper air filter element, the connecting pipe 21 communicates with the inner cavity of the housing 23, the inner cavity of the housing 23 is provided with a decompression buffer head 22, the rear of the decompression buffer head 22 is provided with a pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com