Patents

Literature

42results about How to "Increase effective output power" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

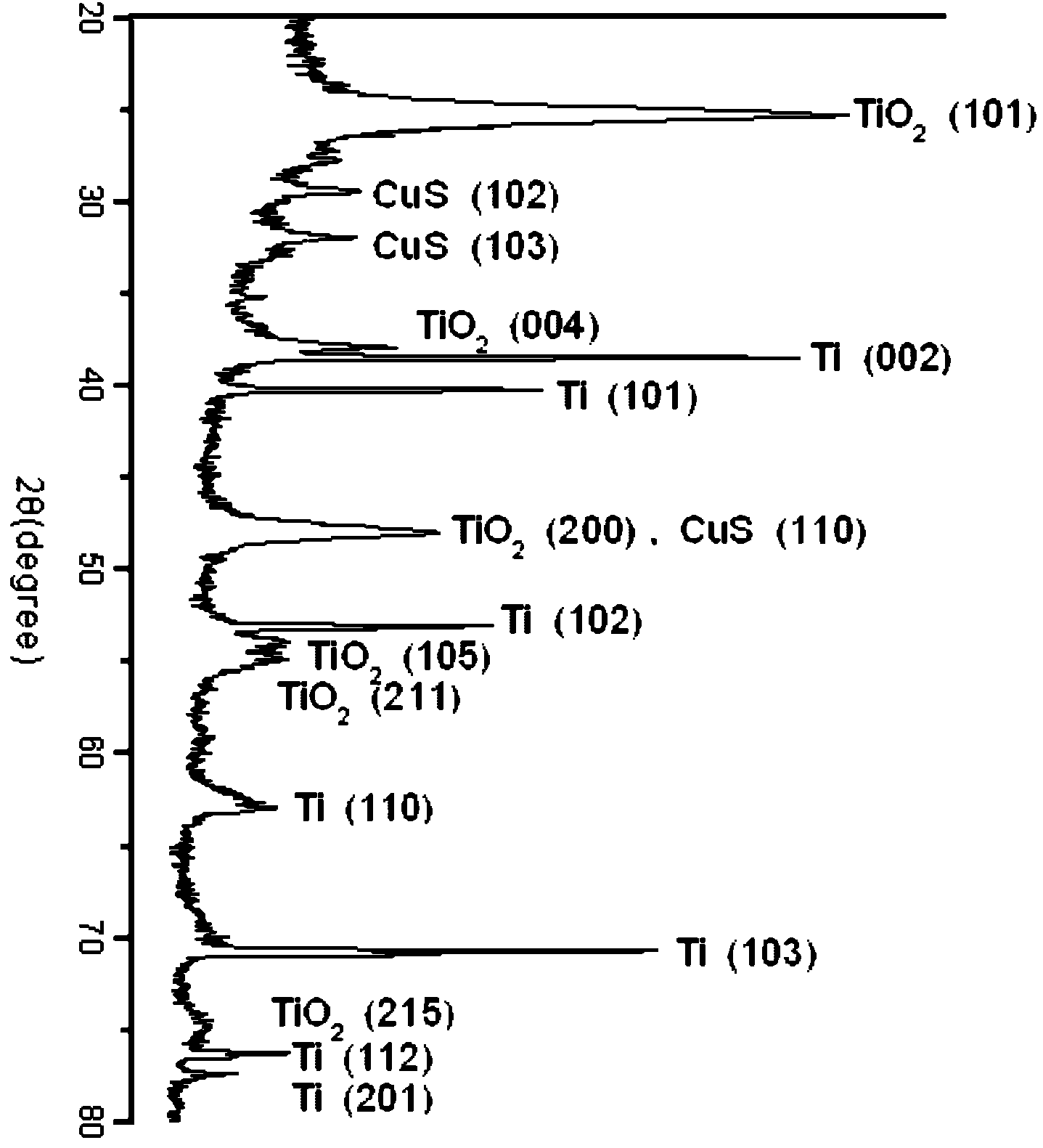

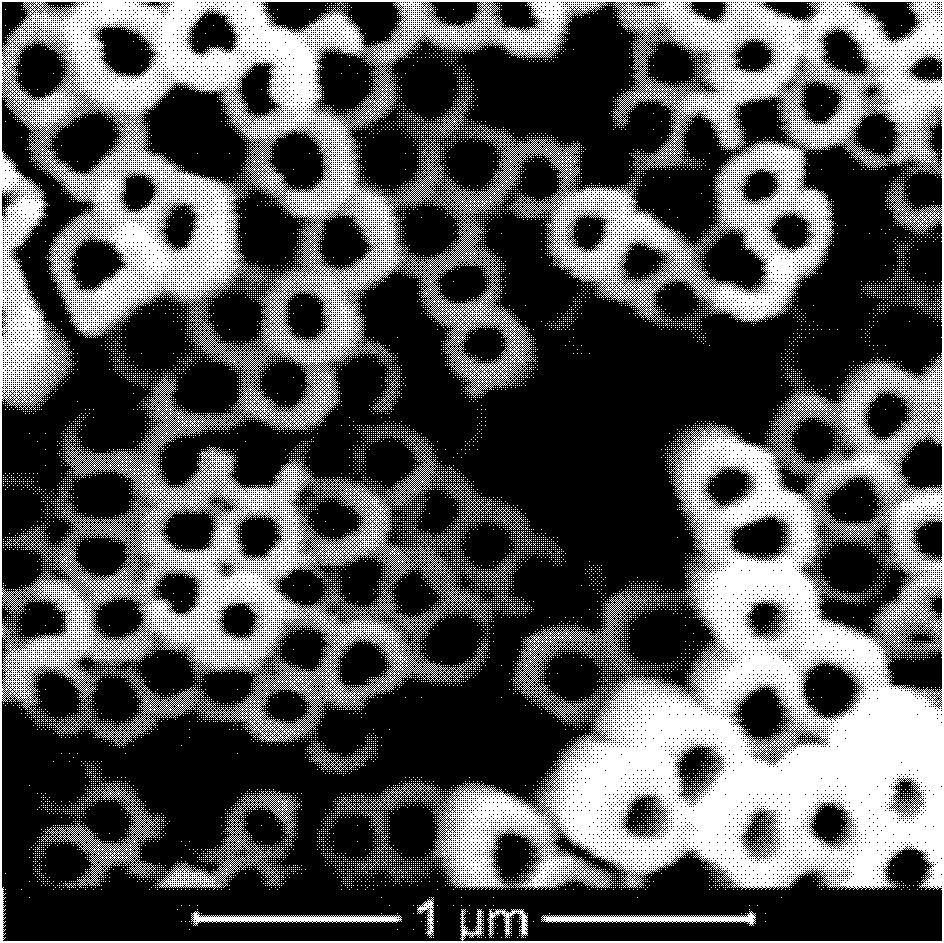

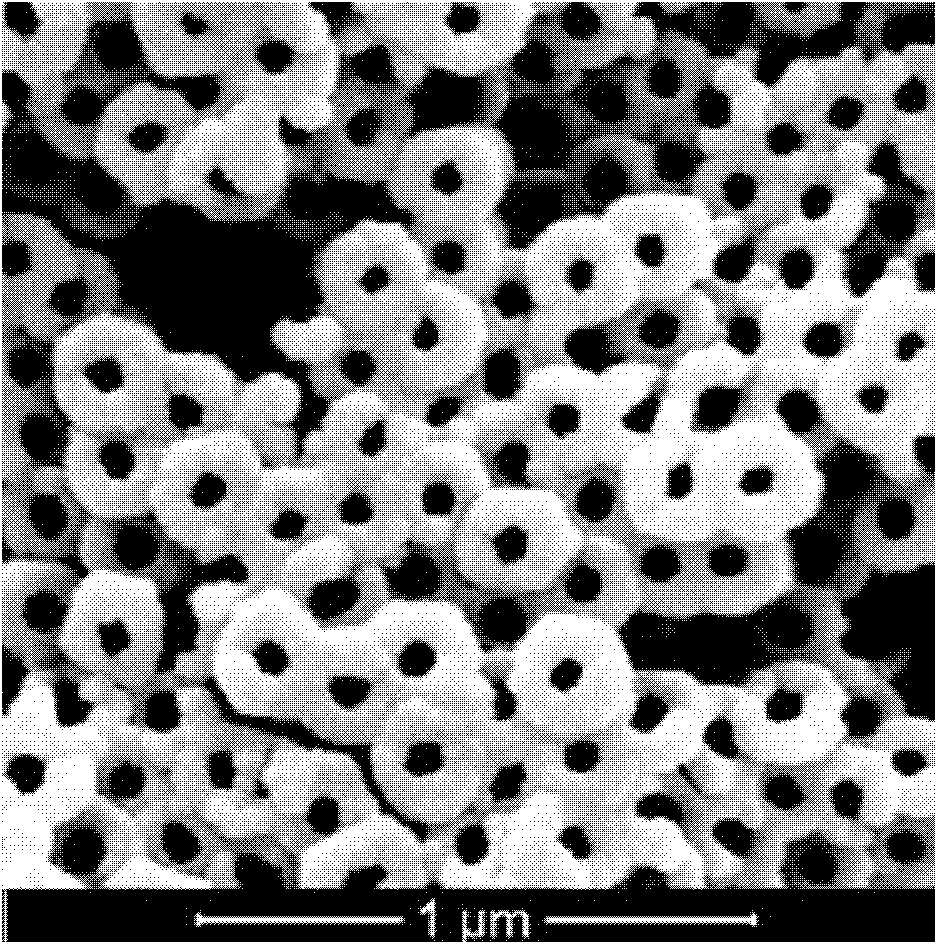

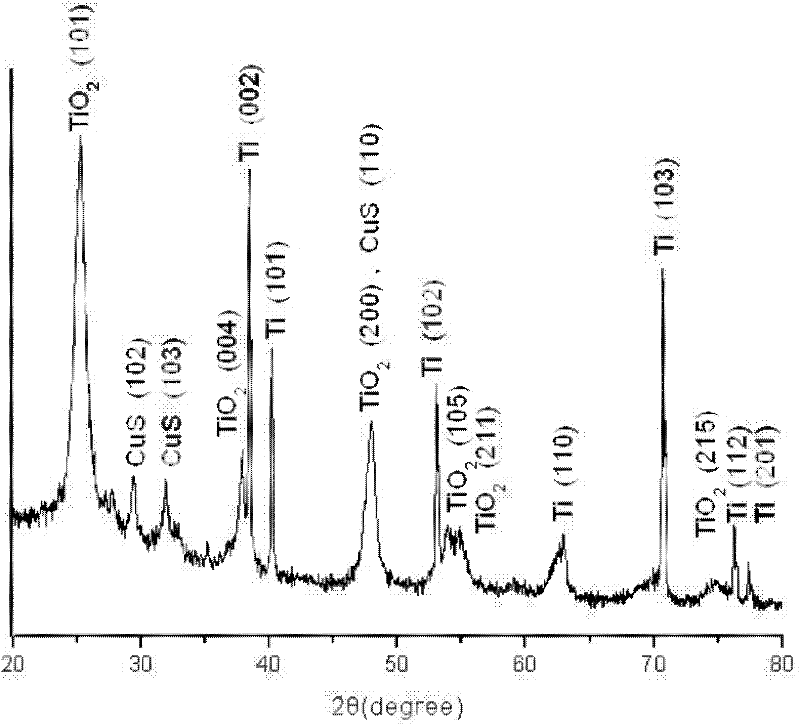

Method for preparing composite material of copper sulfide and titanium dioxide nano-tube

InactiveCN101899701APromote absorptionImprove utilizationSurface reaction electrolytic coatingSolar cellCopper sulfide

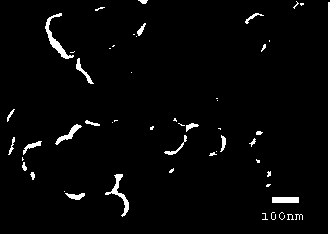

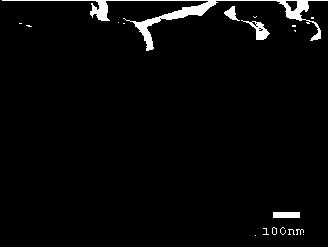

The invention provides a method for preparing a composite material of a copper sulfide and titanium dioxide nano-tube. The method comprises the following steps of putting a sanded titanium plate in acetone or absolute ethanol for ultrasonic cleaning, and is rinsed and aired with deionized water; anodizing a platinum plate serving as a cathode and the treated titanium plate serving as an anode in ethylene glycol solution with 0.25 weight percent of ammonium fluoride, namely a titanium dioxide nano-tube array grows on the surface of the titanium plate; putting the titanium plate growing the titanium dioxide nano-tube array in mixed solution filled with copper chloride and sodium thiosulfate, wherein molar concentrations of the copper chloride and the sodium thiosulfate in the mixed solution are the same, and are between 0.0025 and 0.01mol / L; and sealing the solution with an autoclave, heating the autoclave to the temperature of between 60 and 120 DEG C, and preserving the temperature for 12 to 24 hours. The nano composite material prepared by the method has high sunlight absorbing and utilizing capability, has good application prospect in the field of solar cells, and has simple manufacture process, low equipment requirement and low preparation cost.

Owner:SOUTHWEST JIAOTONG UNIV

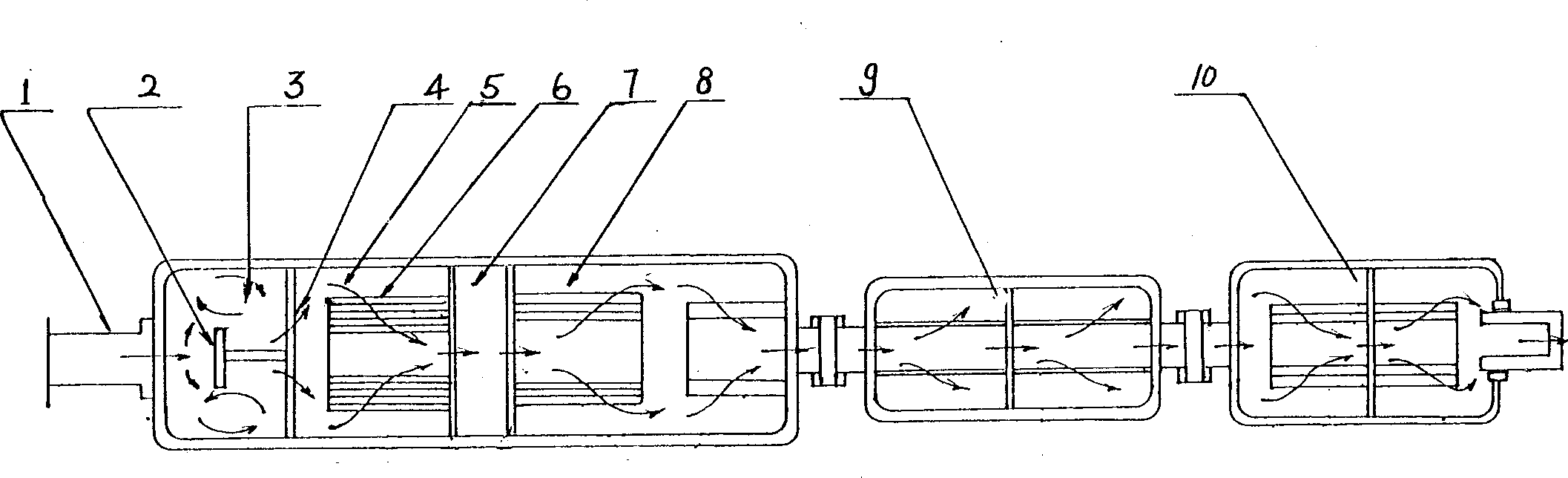

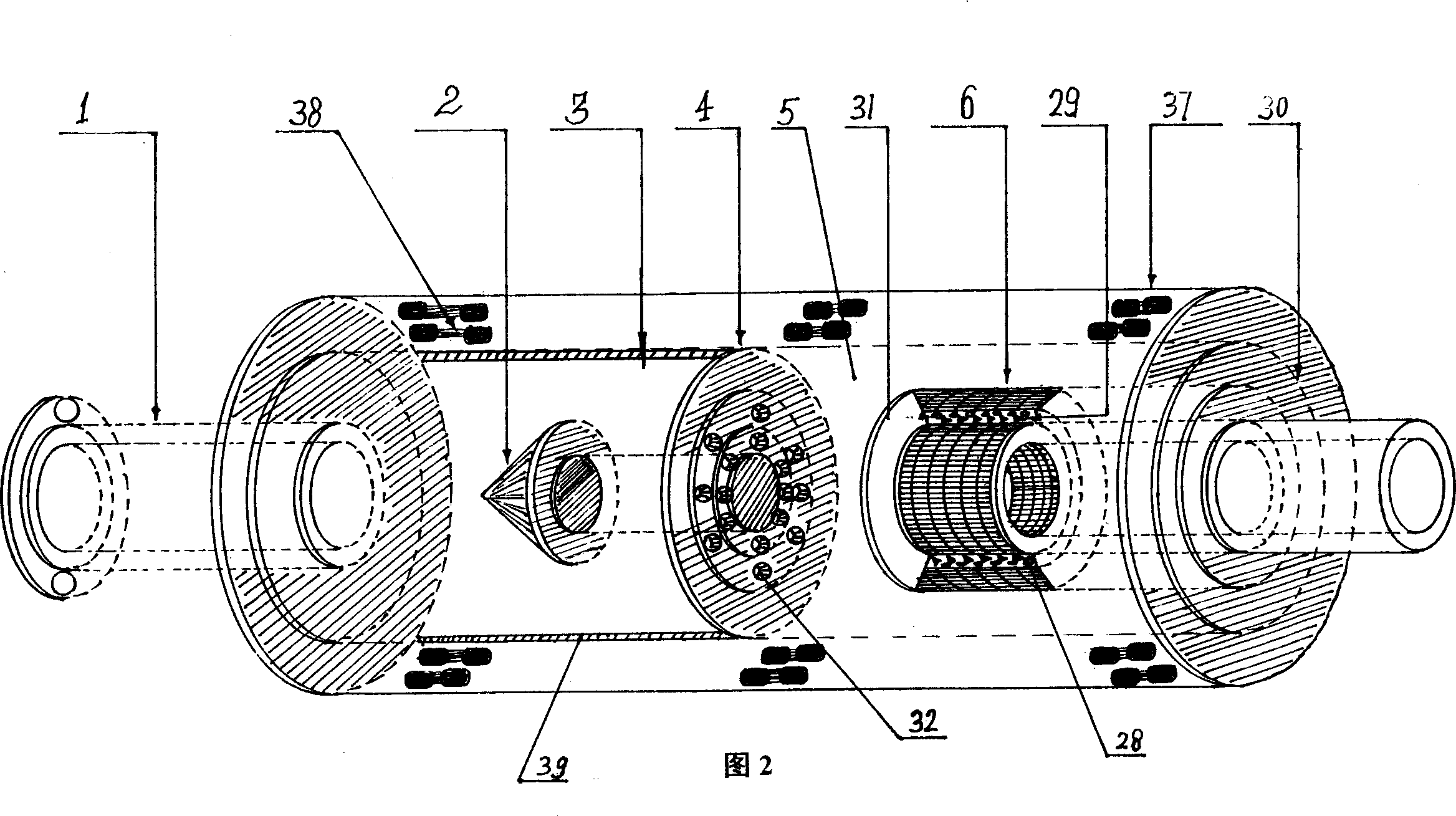

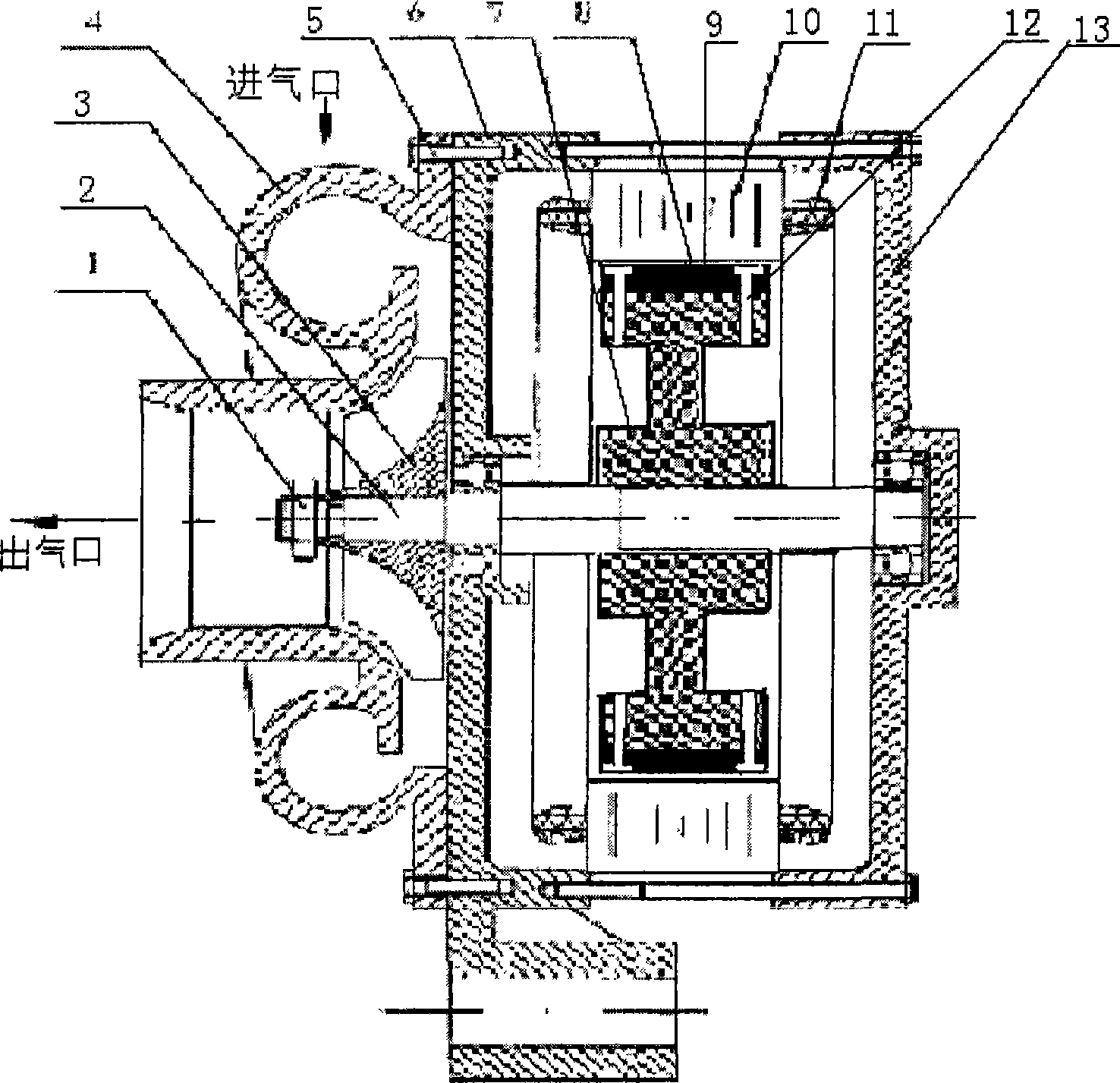

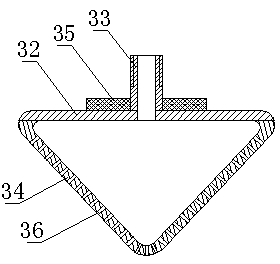

Purifying system for high power output and low-temp tail gas discharge of IC engine

InactiveCN1360139AReduce ingredient contentEasy to recycleExhaust apparatusDispersed particle separationActivated carbonLow noise

A system for higher power output and low-temp exhaust and cleaning of tail gas for IC engine is composed of temp-raising pressure-retaining swirler, filter, silencing cooler and vacuum adsorber. Saidswirler consists of swirl chamber, airflow guide cone, and flow limiting plate. Said silencing cooler comprises internal and external silencing cooling tubes with silencing holes. Said vacuum adsorber has internal and external metallic tubes with exhaust holes, activated carbon between two tubes and flow barrier. Its advantages are low cost, high output power, low noise and temp of exhausting tail gas, and tail gas cleaning function.

Owner:李树胜

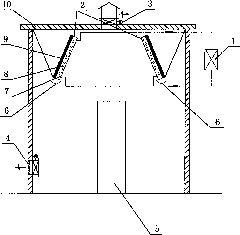

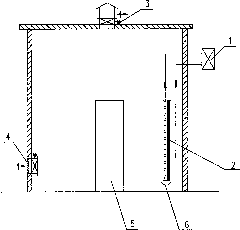

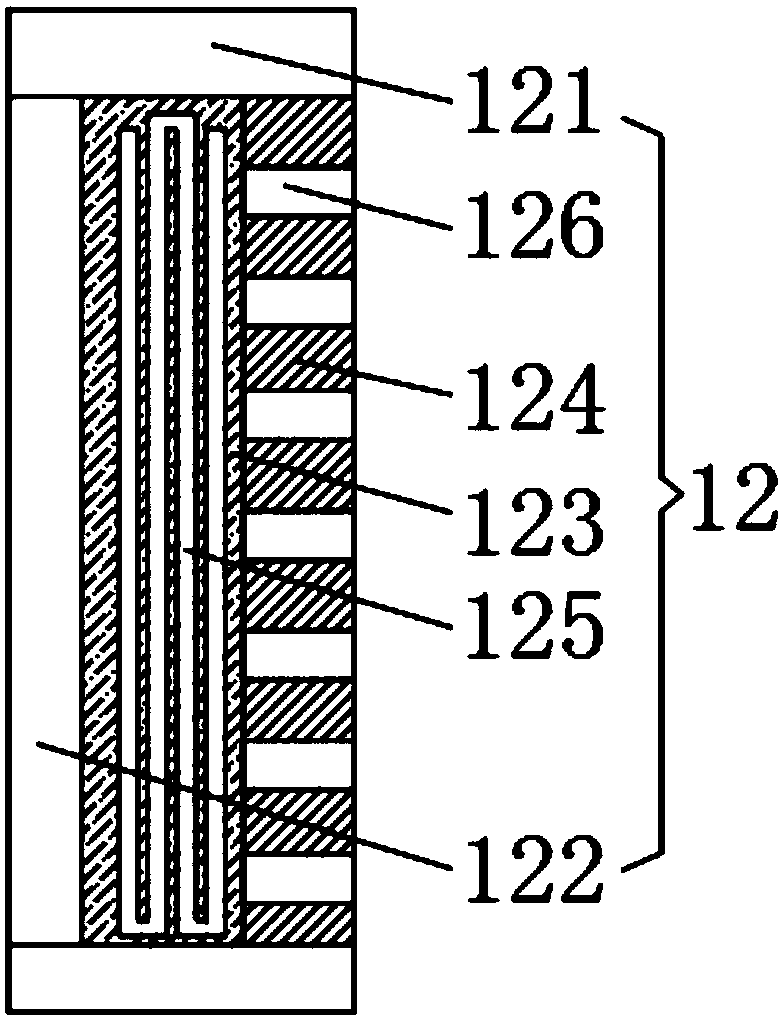

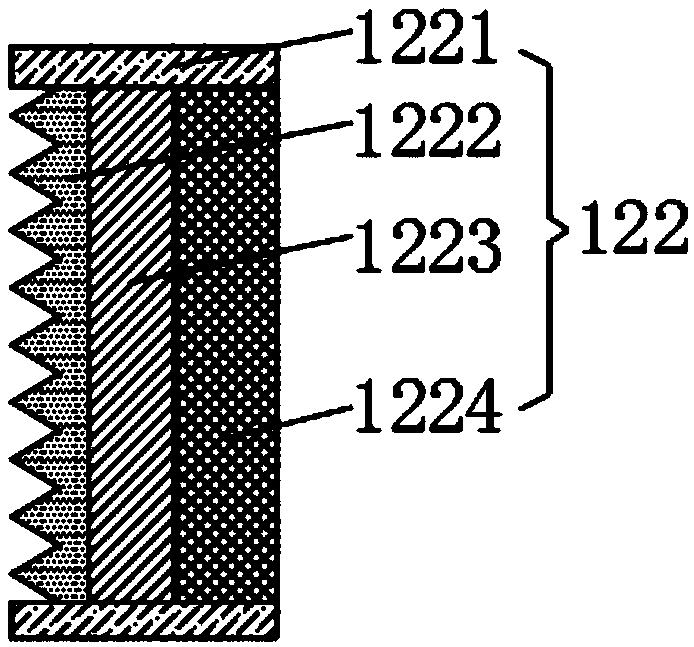

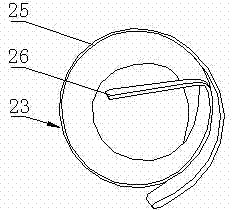

Special air conditioner for base station with separate type radiation plate evaporator

ActiveCN101825319AReduce the temperatureReduce power consumptionSpace heating and ventilation safety systemsLighting and heating apparatusThermal insulationClosed loop

The invention relates to a special air conditioner for a base station with a separate type radiation plate evaporator, which comprises a machine room, an outdoor unit and the radiation plate evaporator, wherein the radiation plate evaporator comprises refrigerant pipes, a radiation plate, an internal radiation finned plate and a thermal insulation material, the refrigerant pipes are connected with the internal radiation finned plate and arranged between the radiation plate and the thermal insulation material, and the refrigerant pipes of the evaporator are mutually communicated through connecting pipes; and the radiation plate evaporator forms the closed-loop connection with a compressor, a condenser and an expansion valve through the connecting pipes, and electric control valves are respectively arranged at an air inlet and an air outlet of the machine room. The special air conditioner for the base station with the separate type radiation plate evaporator can carry out direct radiation heat exchange on a heat source, quickly and effectively reduce the temperature and lead components to work at lower temperature; as the surface temperature of the component is reduced, the working efficiency is improved, the effective output power is increased, and the actual calorific value is reduced, thereby gradually reducing the power consumption of the air conditioner, forming the virtuous circle, further effectively reducing the power consumption of the air conditioner and saving electric energy and electricity fee.

Owner:珠海燕通环境科技股份有限公司

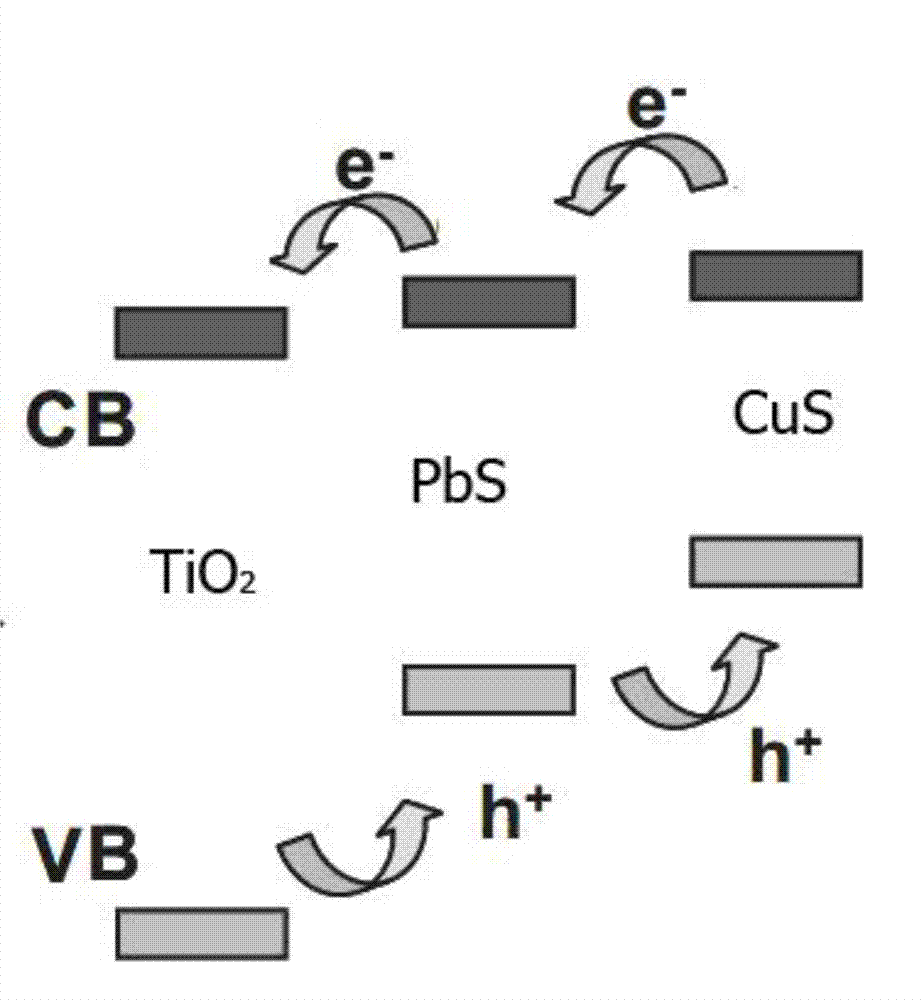

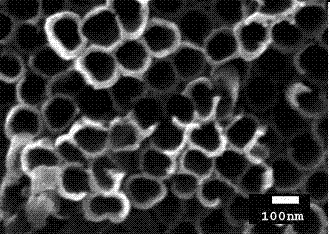

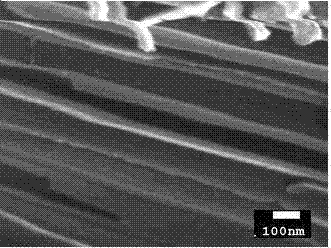

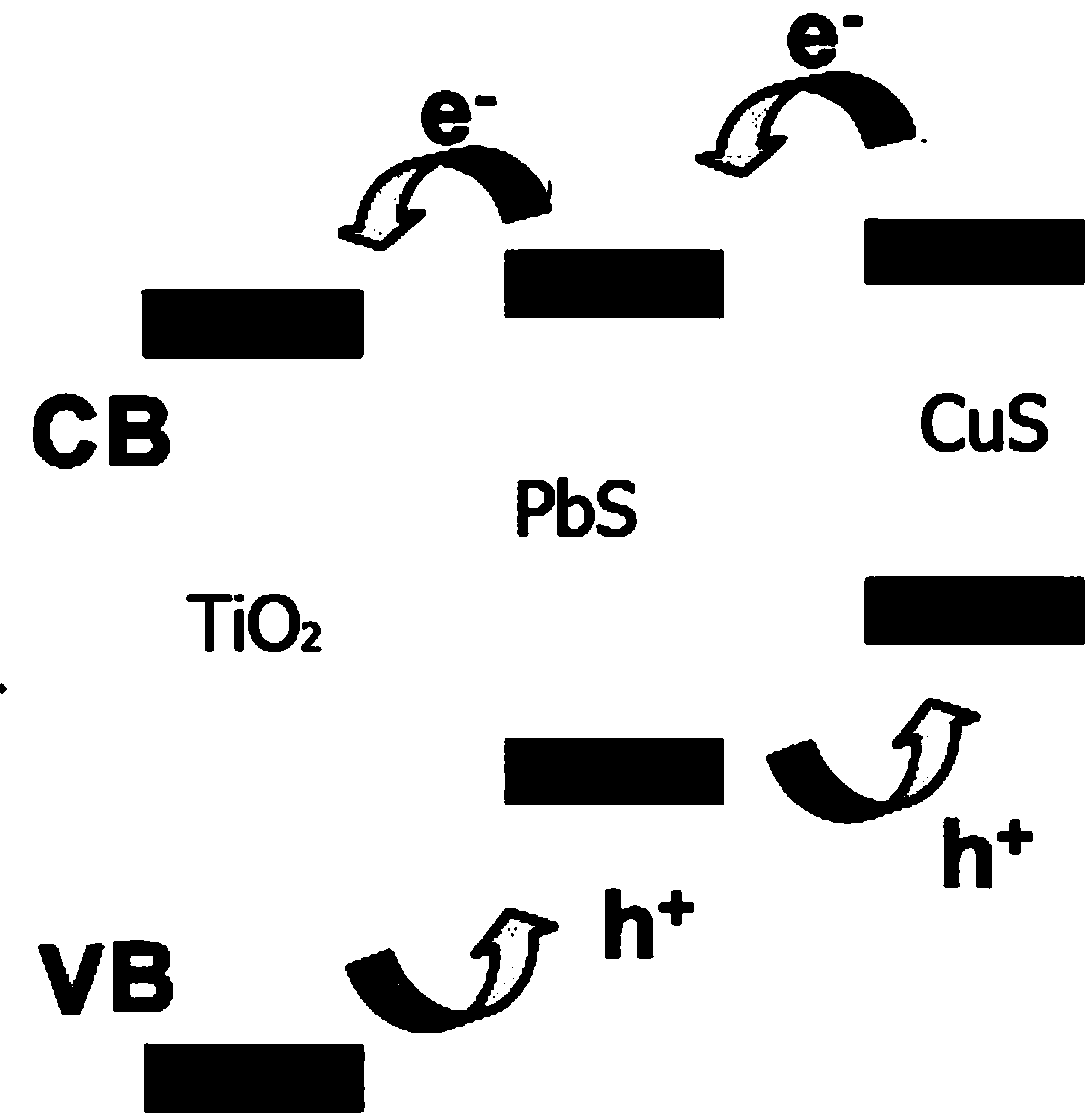

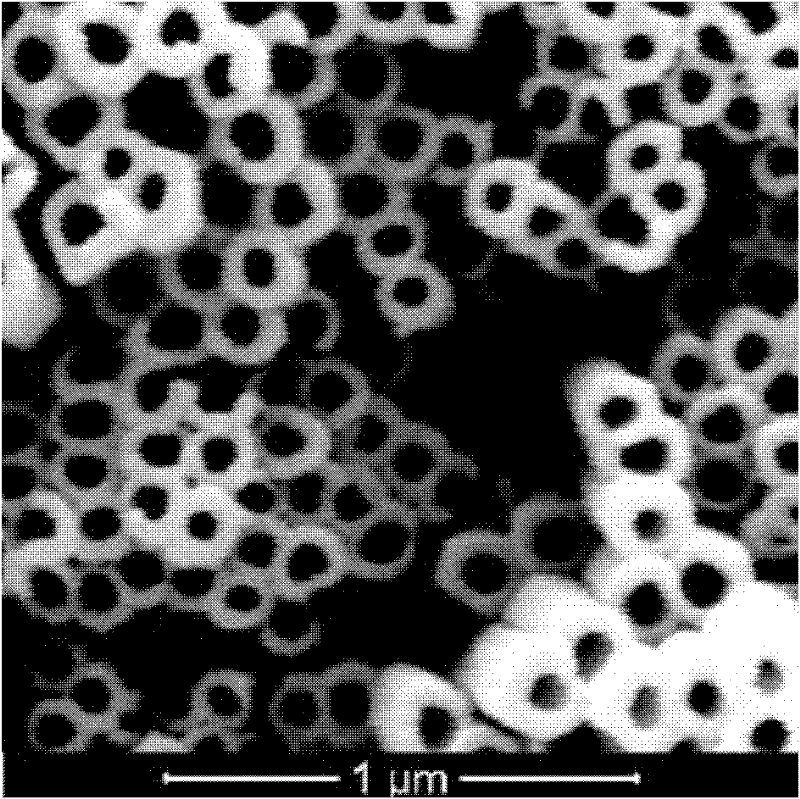

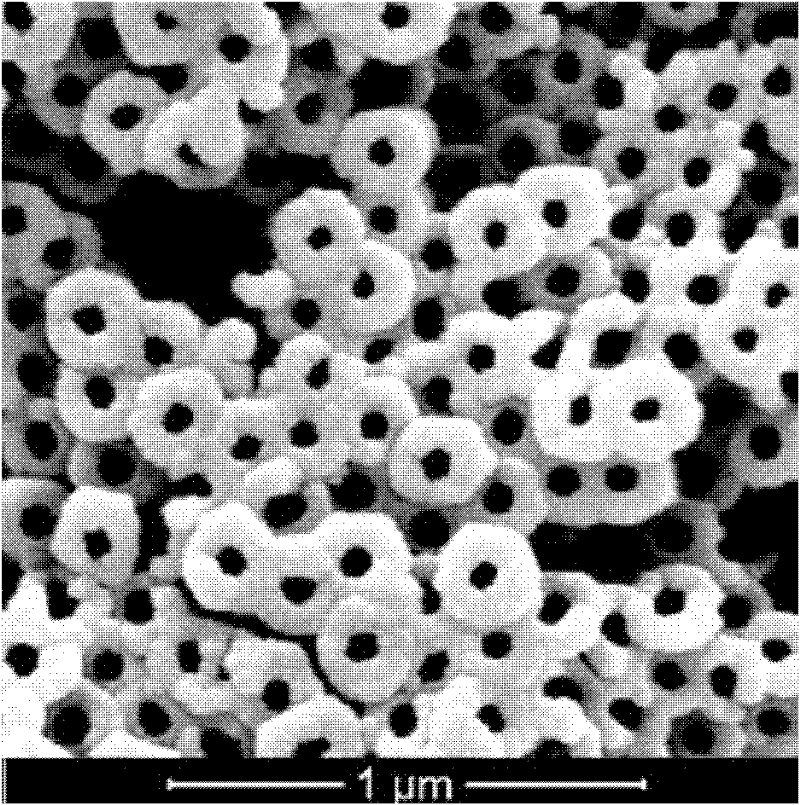

Preparation process of TiO2 nanotube/PbS/CuS nanocomposite

InactiveCN102776513ASimple materialSimple processSuperimposed coating processNano structuringTio2 nanotube

The invention relates to a preparation process of a multiple TiO2 nanotube / PbS / CuS nanocomposite used for quantum dot sensitized solar cells. The multiple TiO2 nanotube / PbS / CuS nanocomposite is prepared mainly by combining a chemical bath method and a hydrothermal method. The method comprises the following steps: shearing and grinding a titanium plate and carrying out ultrasonic cleaning and decontamination in acetone or anhydrous ethanol solution; flushing the cleaned titanium plate with deionized water, and air-drying; placing cleaned titanium plate in the well prepared electrolyte for carrying out electrochemical anodizing; and placing anodized sample of the semi-wall type titanium dioxide nanotube array in the hydrogen peroxide solution for soaking for certain time, and sequentially compounding nanoparticles of PbS / CuS with titanium oxide nanotube by adopting chemical bath method and the hydrothermal method. The method is simple in process, the prepared multi-nano structure is novel, and the conversion efficiency of the solar cell prepared through the structure is improved greatly, thus being beneficial to improvement of performances of quantum dot sensitized solar cells.

Owner:SOUTHWEST JIAOTONG UNIV

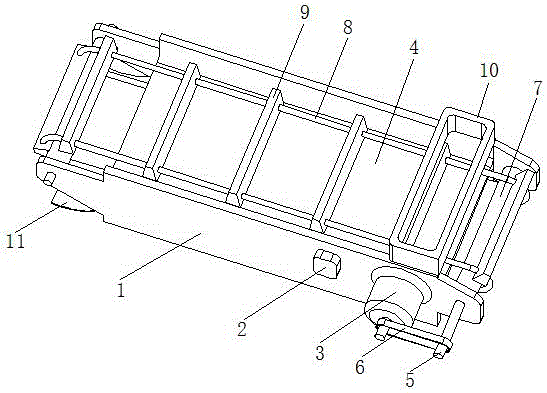

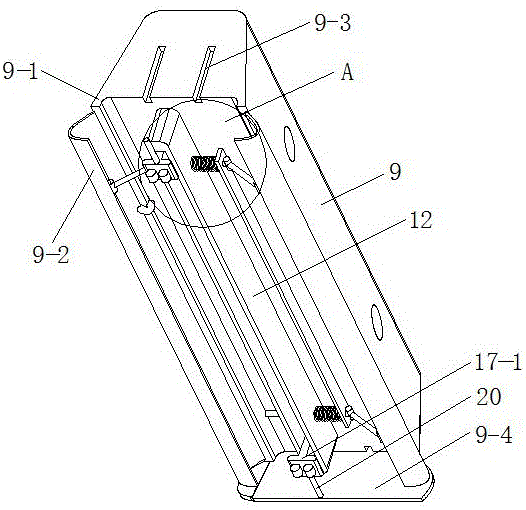

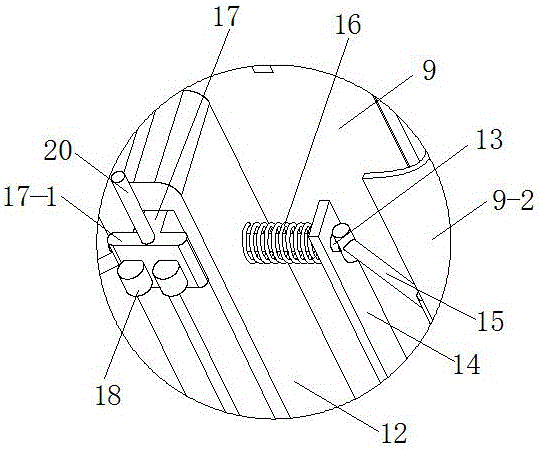

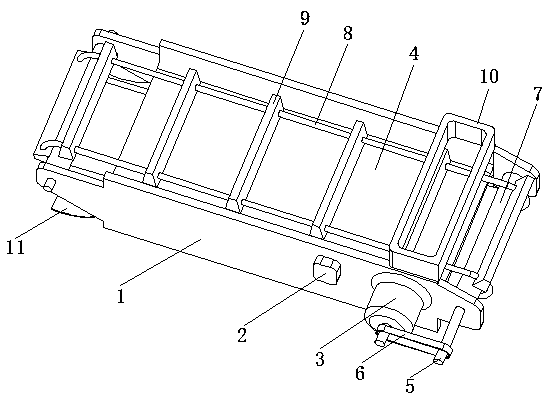

Scraper conveyor with float coal cleaning device

The invention discloses a scraper conveyor with a float coal cleaning device. The scraper conveyor comprises a bracket a feed hopper is arranged on one side of the bracket; a discharge hopper is arranged on the other side of the bracket; and multiple scrapers for pushing coals from the feed hopper to the discharge hopper and a transmission mechanism for driving the multiple scrapers are arranged in the bracket. The trapezoidal scraper structure is stable, and is more durable compared with a sheet shape; an elastic plate and a side cover plate are convenient to stop float coals, so that no float coals are below the scrapers; when the scrapers are suffered from the pressure, a spring I and a spring II are compressed, so that the scrapers move in the direction of a wear resisting baseplate; meanwhile, a movable shaft moves to the inner side; the bending degree of the elastic plate is increased; a gap between the elastic plate and the wear resisting baseplate is smaller; the float coals are stopped on the outer side of the elastic plate; when the pressure suffered by the scrapers is weakened or not generated, the deformation of the elastic plate is recovered, the float coals remained between the elastic plate and the wear resisting baseplate are ejected out for cleaning; and the effective output power of a speed reducing motor is directly enhanced through rolling friction of a rubber wheel.

Owner:JIANGSU VOCATIONAL INST OF ARCHITECTURAL TECH

Novel motor

InactiveCN103151869AImprove effective controlEnsure consistencySupports/enclosures/casingsModularityMetallic materials

The invention relates to a novel motor which comprises an end cover and a shell connected with the end cover. Modularization is massively adopted, and the motor has the functions of automatic heat dissipation, automatic air exhaust, automatic closing and flux leakage preventing efficiency. The motor has the advantages that assembly is simple and direct and size is small due to the massive adoption of modularization; the weight is light, the flux leakage preventing efficiency is high and the power is greater due to the massive adoption of non-metal materials; and heat dissipation is automatic, the reverse wind speed impedance of a rotor is reduced, the output power is effectively increased, and the quality is more stable and more reliable.

Owner:张孟荣

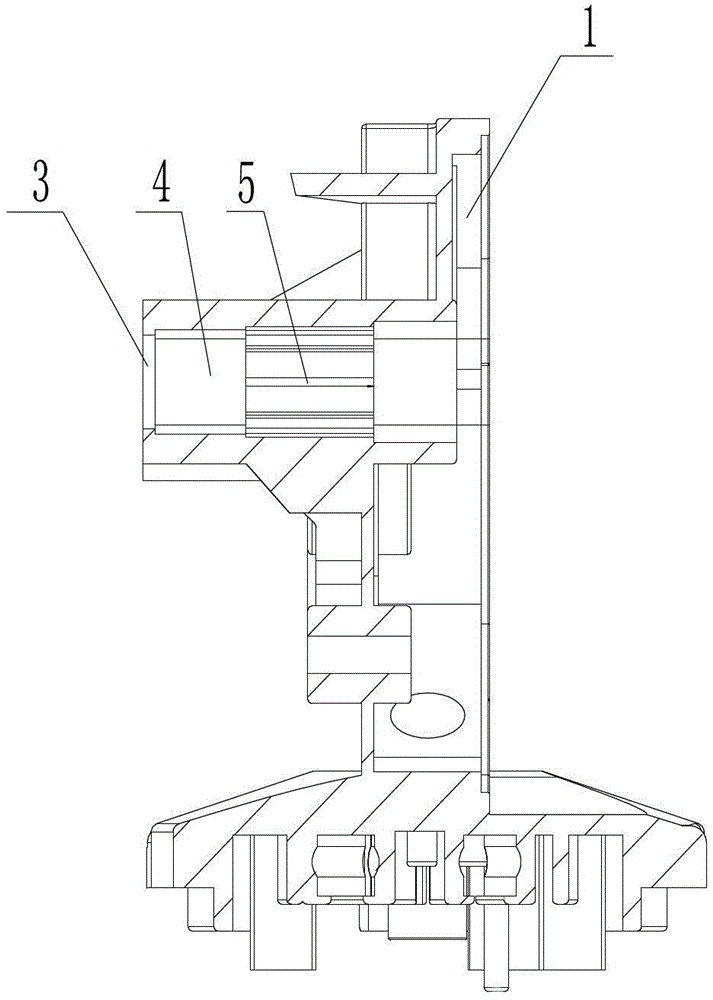

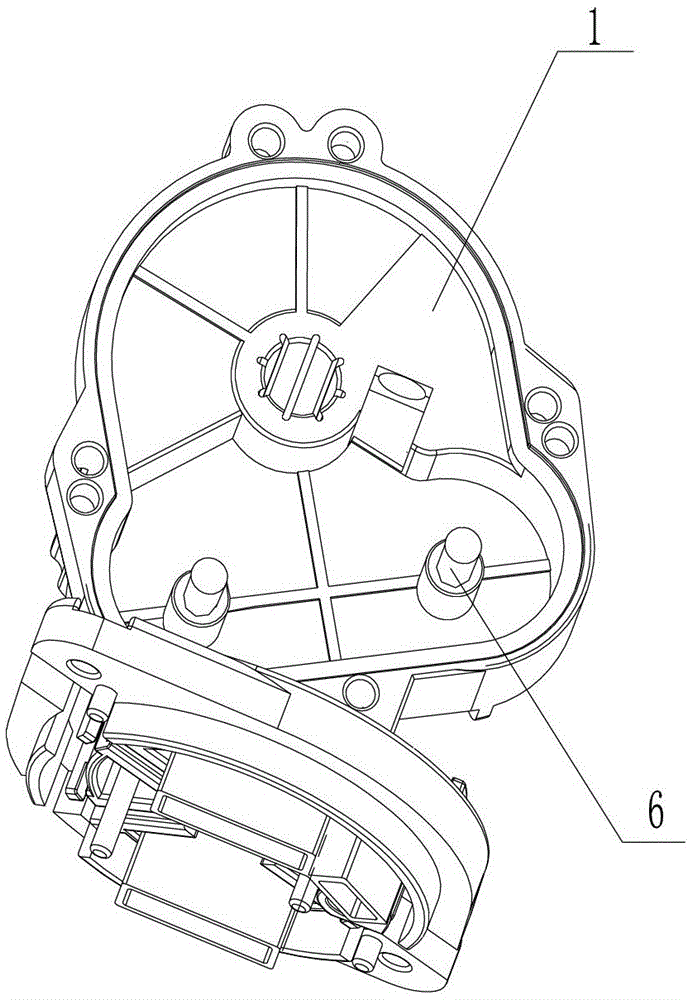

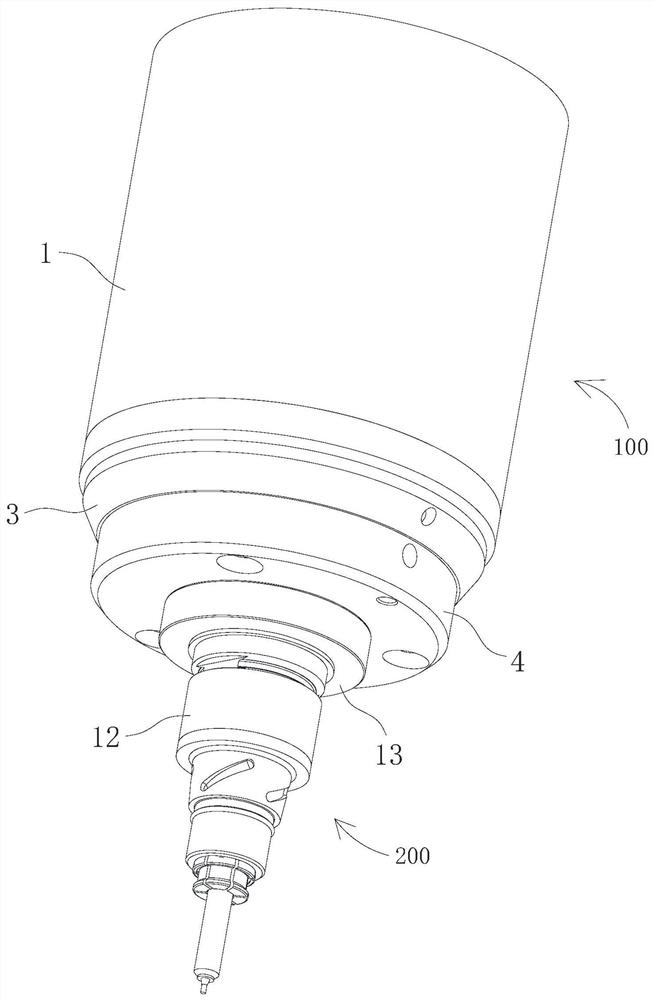

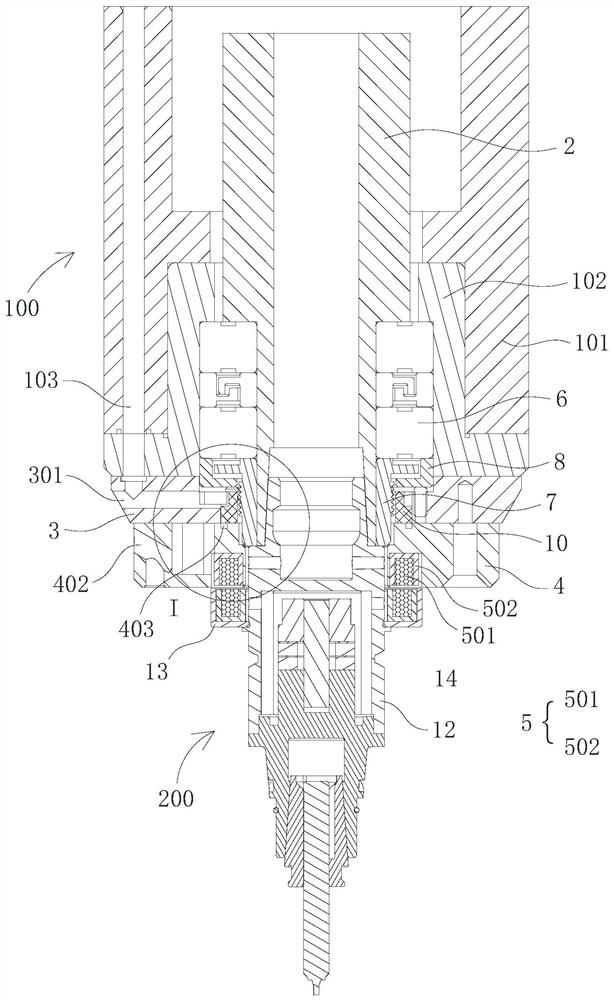

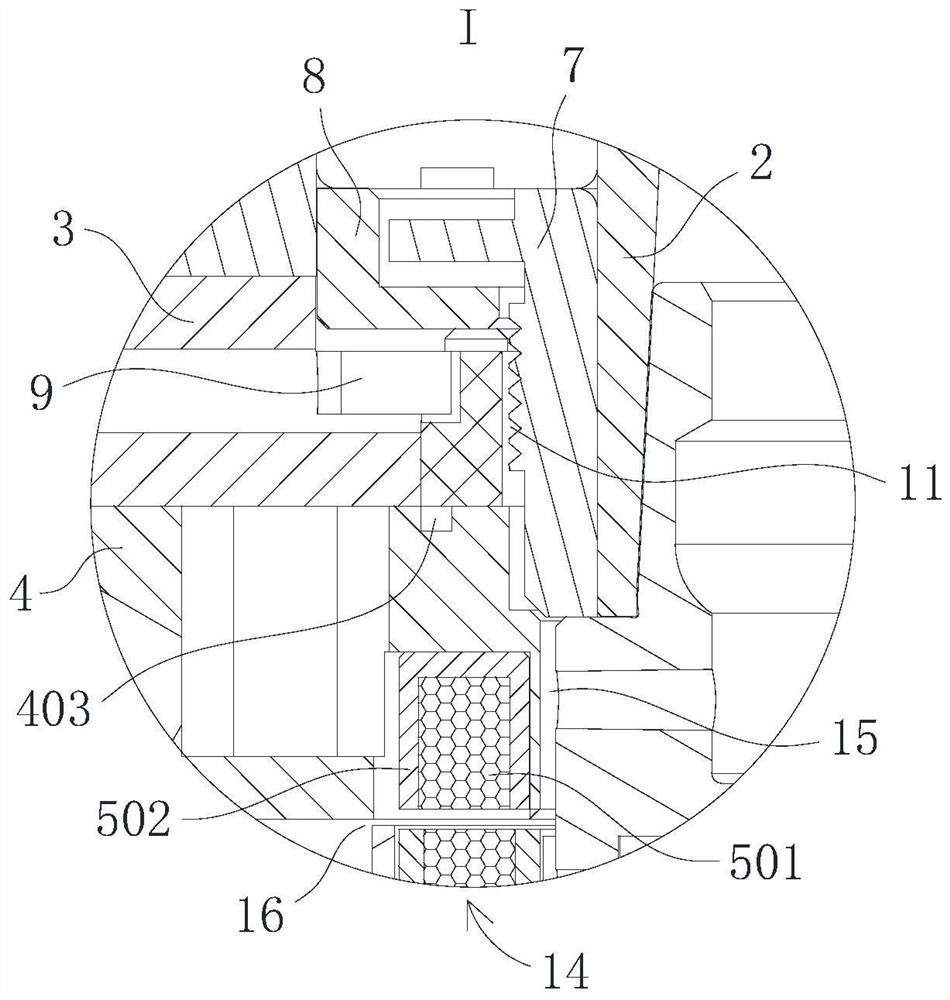

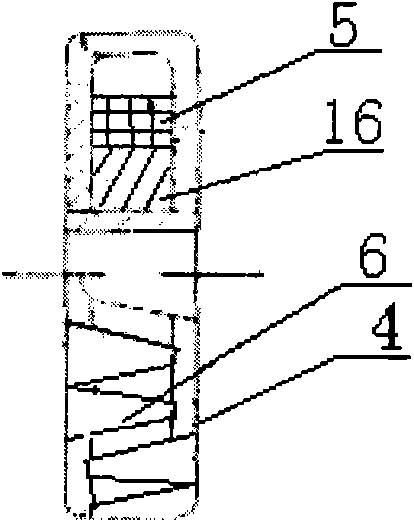

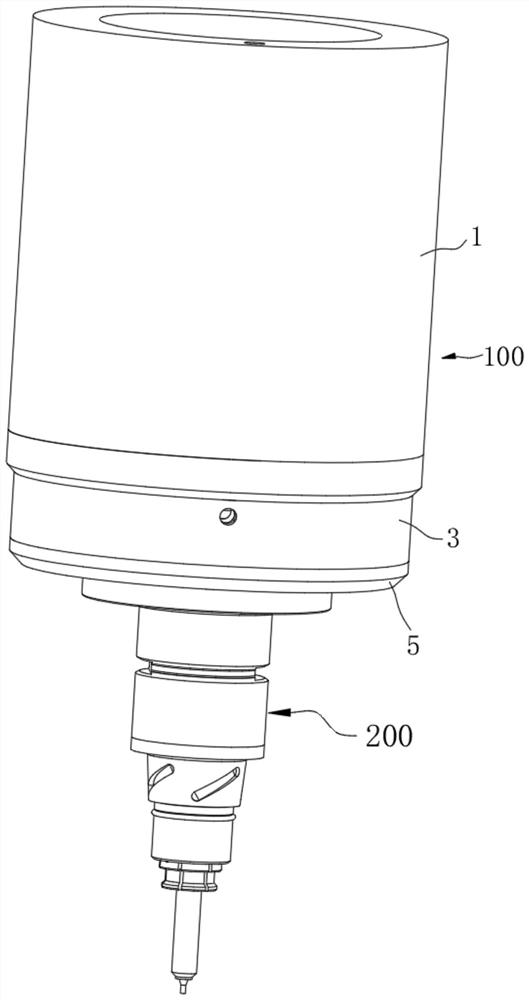

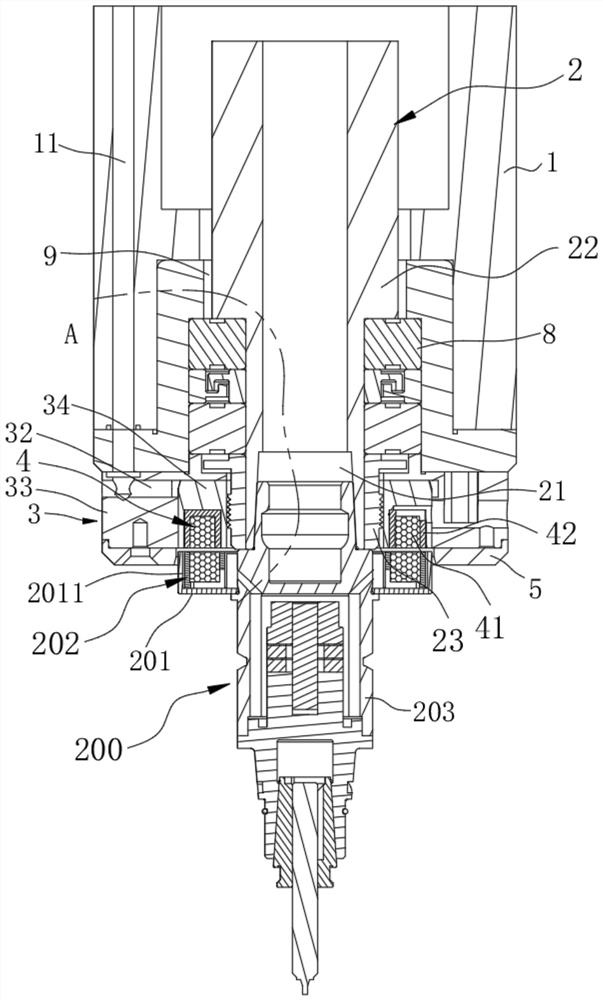

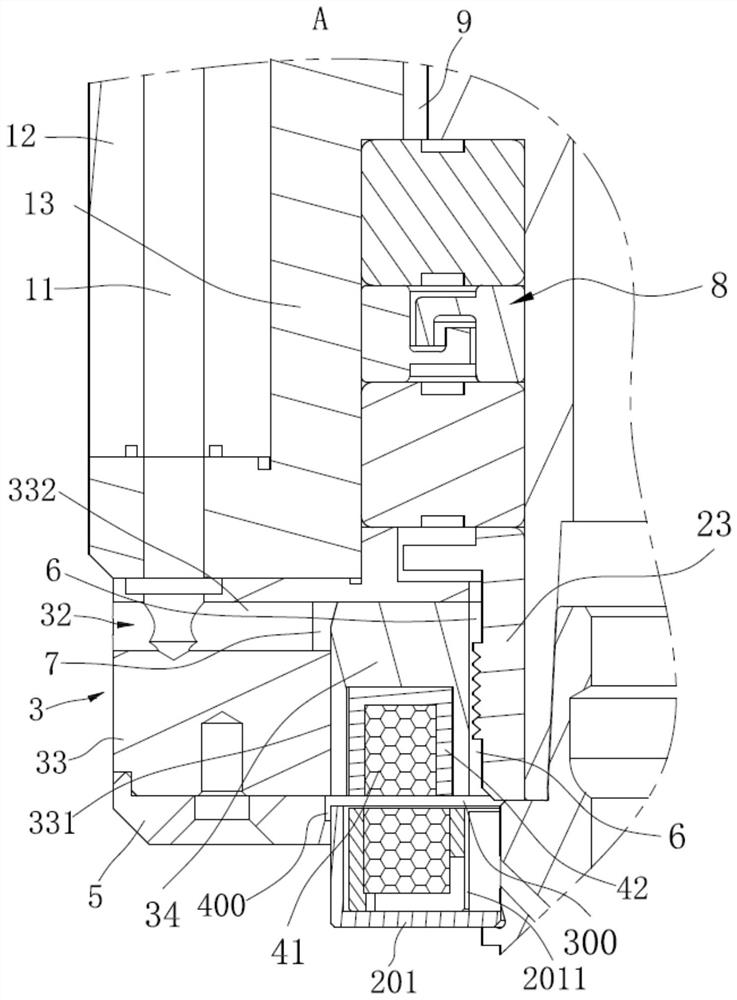

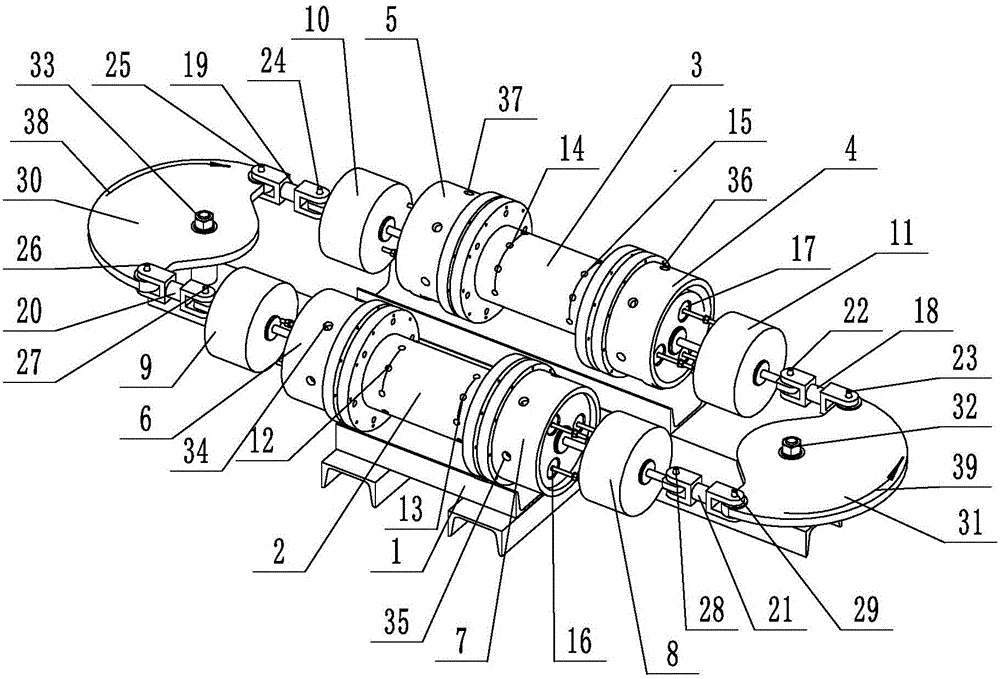

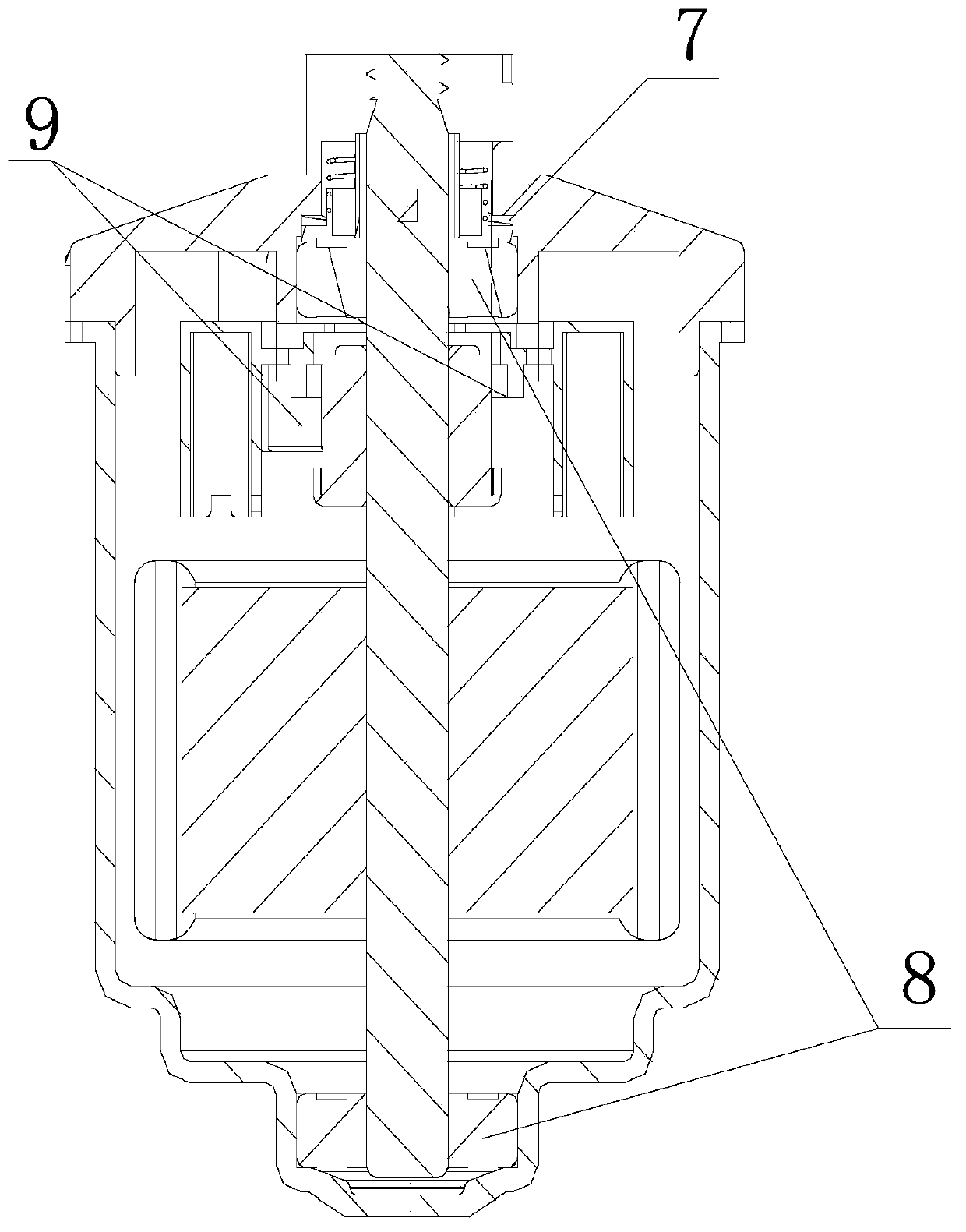

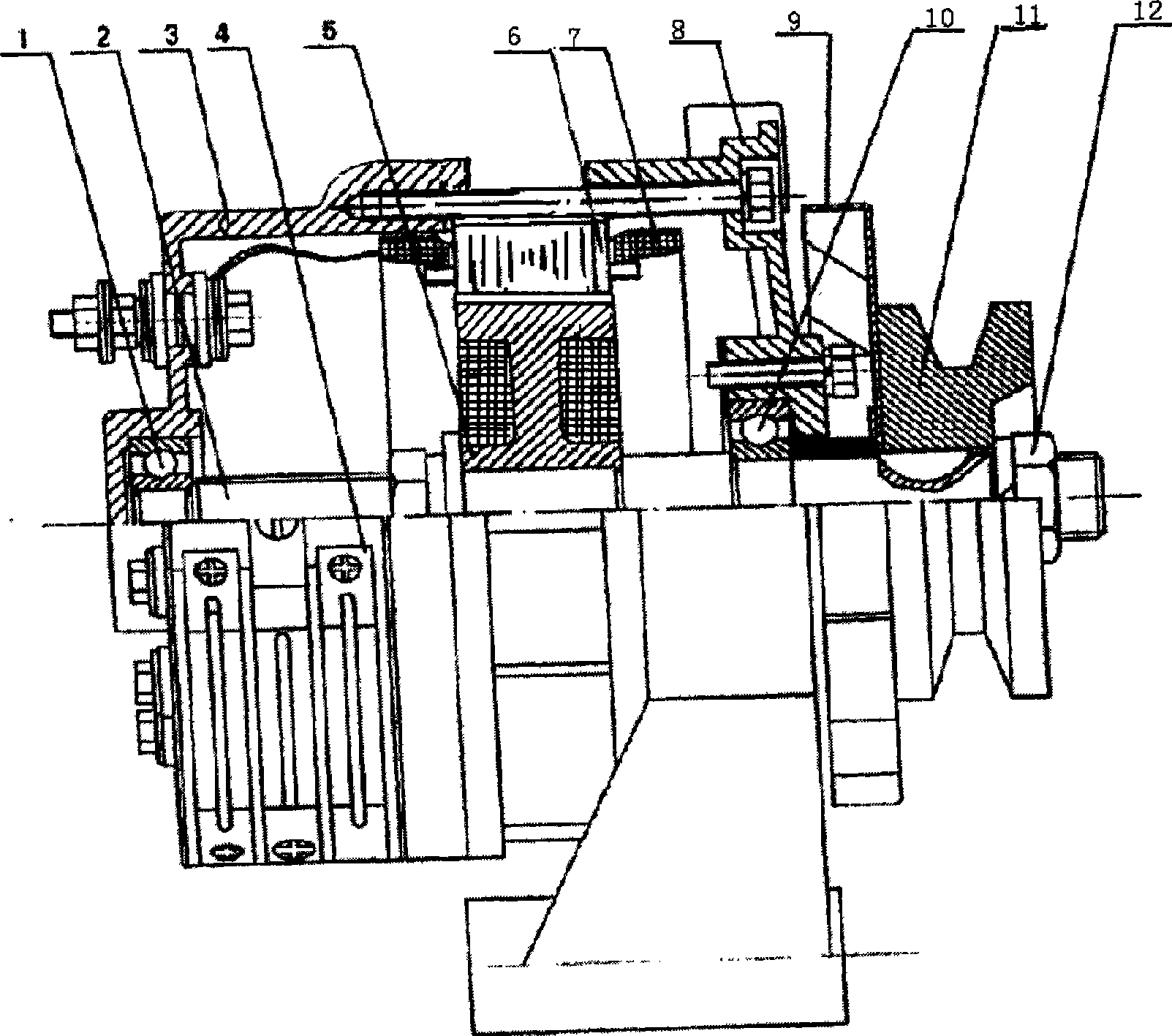

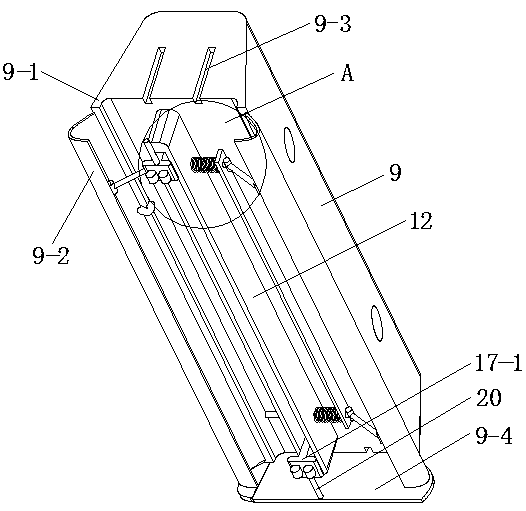

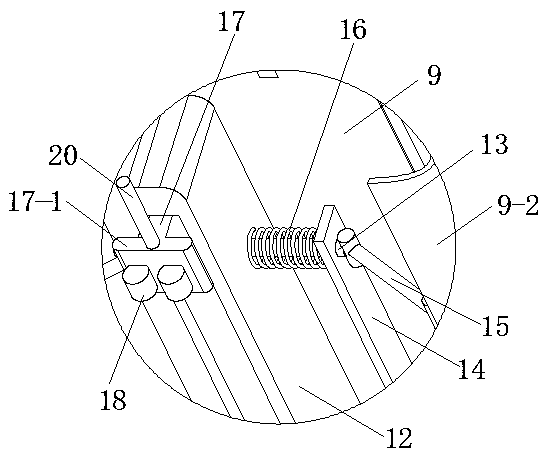

Ultrasonic machining equipment and ultrasonic spindle thereof

ActiveCN112317775ANot easy to interfereImprove installation accuracyLarge fixed membersMaintainance and safety accessoriesTransmitter coilRotational axis

The invention discloses an ultrasonic spindle. The ultrasonic spindle comprises a spindle shell, a rotating shaft, a front end cover, a transmitting frame and an ultrasonic wireless transmitting device. The rotating shaft is rotatably arranged in the spindle shell in a penetrating mode, and a mounting hole is formed in the front end face of the rotating shaft. The front end cover is arranged at the front end of the spindle shell and surrounds the rotating shaft. The transmitting frame is directly installed on the front end face of the front end cover and surrounds the rotating shaft, and a first containing groove surrounding the rotating shaft is formed in the front end face of the transmitting frame. The transmitting frame is connected with the front end cover through a bolt so as to be convenient to disassemble and assemble. The ultrasonic wireless transmitting device is arranged in the first containing groove and comprises a transmitting coil arranged around the rotating shaft and atransmitting ferrite used for containing the transmitting coil. Compared with the prior art, the ultrasonic spindle is excellent in performance, good in machining effect, wide in application range, capable of machining multiple materials and long in service life; and in addition, the invention further discloses ultrasonic machining equipment adopting the ultrasonic spindle.

Owner:CONPROFE MACHINE TOOLS CO LTD +1

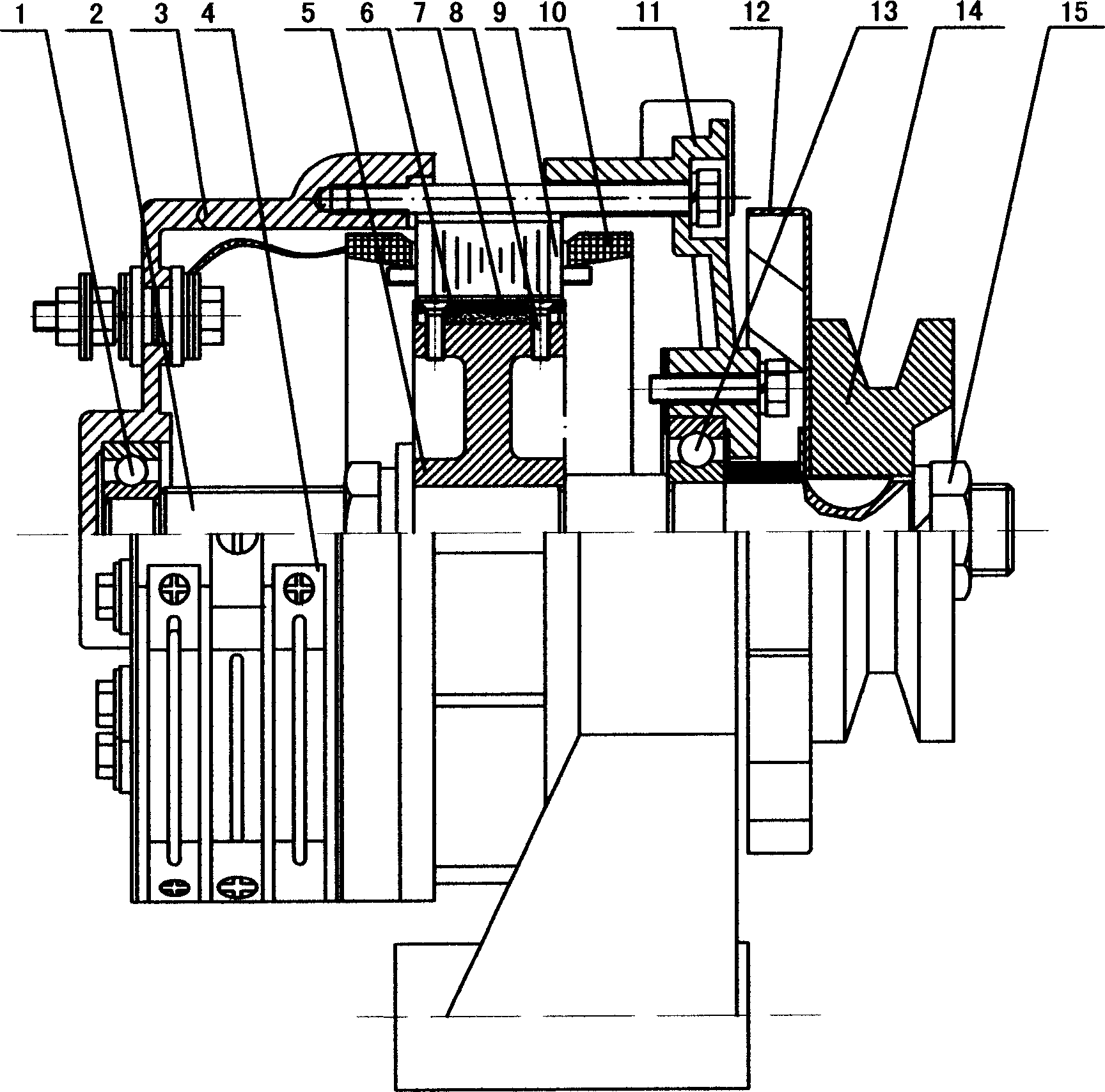

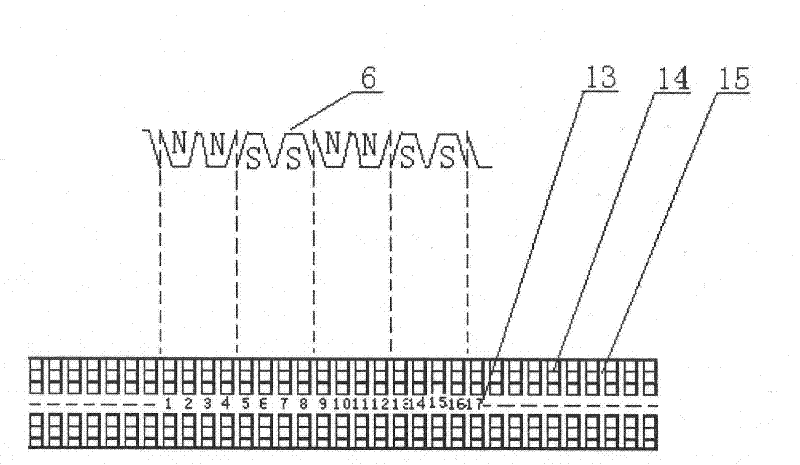

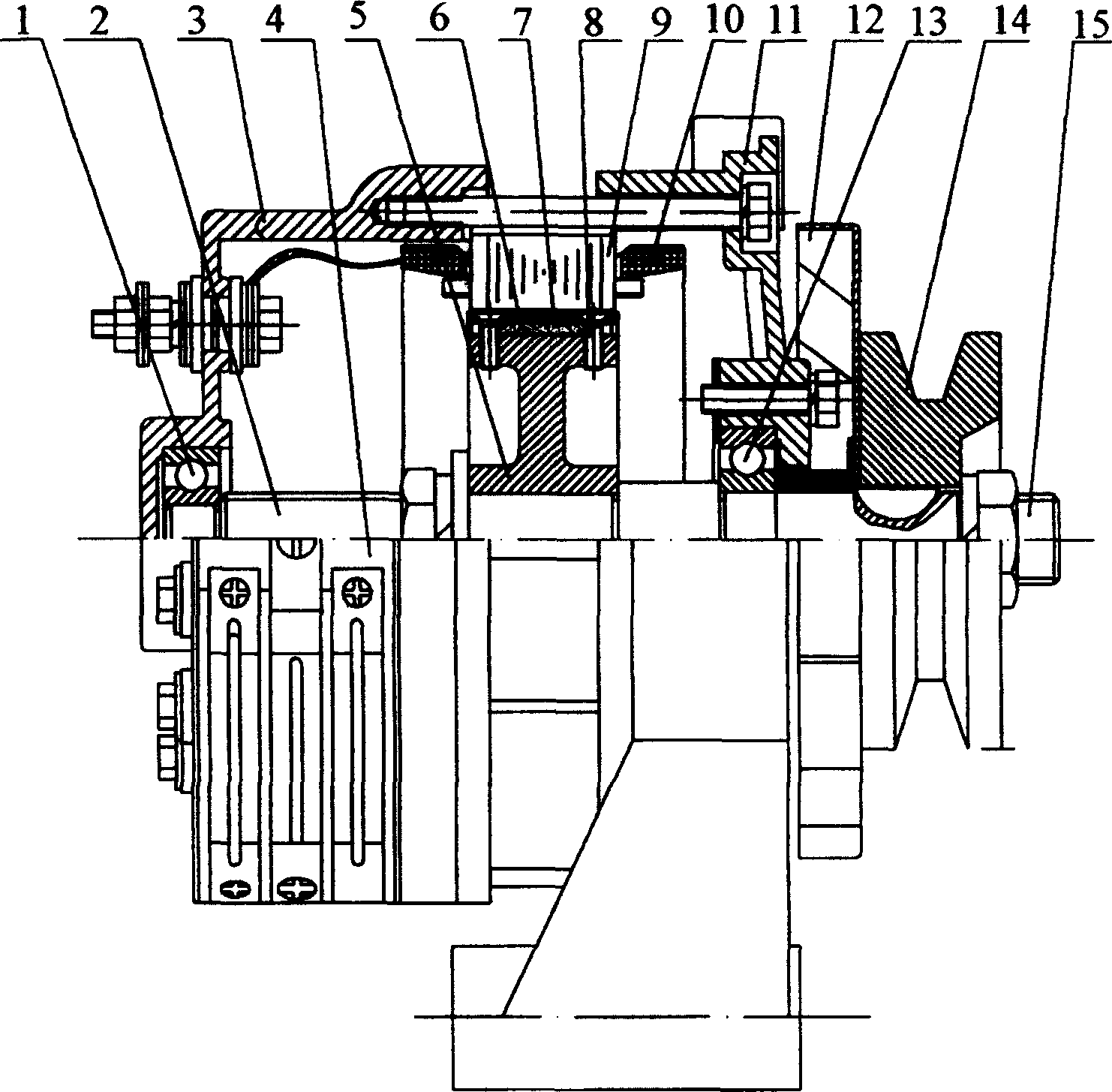

Five-phase Nd-Fe-B permanent-magnetic generator for vehicle

InactiveCN1885686ACompact structureSmall footprintMagnetic circuit rotating partsSynchronous machine detailsStatorEngineering

The provided five-phase Nd-Fe-B permanent-magnetic generator for vehicle comprises: the pole shoe, some permanent magnets with opposite polarity between near ones for N-S space array and every opposite to five poles on stator core, a rotor with iron core and shaft, and the stator composed by all of an iron core, a coiling, and a front / back cap. This invention has less wattless loss, compact structure for small room, and convenient to assemble for different vehicles.

Owner:SHANDONG UNIV OF TECH

Dual-claw polar multi-phase excitation generator

InactiveCN102185404AIncrease the number ofReduce manufacturing costMechanical energy handlingWindings conductor shape/form/constructionPhase differenceConductor Coil

The utility model provides a dual-claw polar multi-phase excitation generator belonging to the field of automobile electric apparatus. The dual-claw polar multi-phase excitation generator is mainly characterized in that armature windings are n-phase identical armature windings; each phase of the n phases spans n poles on a stator core respectively and is embedded with wires in sequnce; the phase difference of the armature windings is 360 / n degree, wherein n is an integer more than or equal to 4; and every two adjacent claw poles on each flange correspond to every n poles on a stator core. The dual-claw polar multi-phase excitation generator has the advantages that a rectifier has little heating quantity, long service life, simple and reliable voltage stabilizing and low cost, the generator is claw pole shaped, can be machined simply, can be magnetized uniformly, has high utilization degree, low whole-machine cost, and the like.

Owner:邓素华

Ultrasonic machining device and ultrasonic spindle thereof

ActiveCN112317774AImprove stabilityImprove assembly accuracyLarge fixed membersMaintainance and safety accessoriesRotational axisTransmitter coil

The invention relates to the technical field of ultrasonic machining, and discloses an ultrasonic machining device and an ultrasonic spindle thereof. The ultrasonic machining device comprises a spindle shell, a rotating shaft assembly, a front end cover and an ultrasonic wireless transmitting device, wherein the rotating shaft assembly is rotationally arranged in the spindle shell, the front end of the rotating shaft assembly protrudes out of the front end face of the spindle shell, and a mounting hole is formed in the front end face of the rotating shaft assembly; the front end cover is installed at the front end of the spindle shell and is annularly arranged on the periphery of the rotating shaft assembly, the rear end face of the front end cover is attached to the front end face of thespindle shell, and a first containing groove annularly formed in the rotating shaft assembly is formed in the front end face of the front end cover; and the ultrasonic wireless transmitting device isarranged in the first containing groove and comprises a transmitting coil and a transmitting ferrite. According to the ultrasonic machining device and the ultrasonic spindle thereof, the device has good machining precision and machining efficiency, the device is suitable for machining working conditions in a larger range, and more materials can be machined.

Owner:CONPROFE MACHINE TOOLS CO LTD +1

Horizontally-opposed-cylinder, horizontally-opposed-piston and two-stroke homogeneous compression-ignition engine and generators

ActiveCN106285934ACompact structureHigh failure rateMachines/enginesElectricityHomogeneous charge compression ignition

The invention discloses a horizontally-opposed-cylinder, opposed-piston and two-stroke homogeneous compression-ignition reciprocating engine and linear generators. Two pistons are arranged inside each of two parallel cylinders for doing work oppositely; four blast pump pistons, of which the effective area is 2-3 times greater than that of the work-doing pistons, are arranged behind the four pistons, and are used for supplying pressurized mixed fuel gas to the cylinders; four coaxial linear generators are arranged behind four blast pumps; shaft heads behind the four generators are connected with two interconnecting fulcrums of two semicircular rocker mechanisms fixed to central vertical shafts at the two ends of the two cylinders; when the two pistons in one cylinder move towards a combustion chamber, which is shared by the two pistons, in the center of the cylinder, the two pistons in the other cylinder move oppositely to the two ends of the cylinder; when the two pistons in one cylinder move up to 5-10 degrees in front of an upper stopping point, mixed fuel catches fire and bursts out through compression ignition to force the two pistons to rapidly move towards a lower stopping point, push the coaxial blast pumps to blast air, push the generators to generate electricity and push the two semicircular rocker mechanisms to rotate in the reverse direction so as to push the two pistons in the other cylinder to do compression work on the upper stopping point at the center of the cylinder.

Owner:高阳

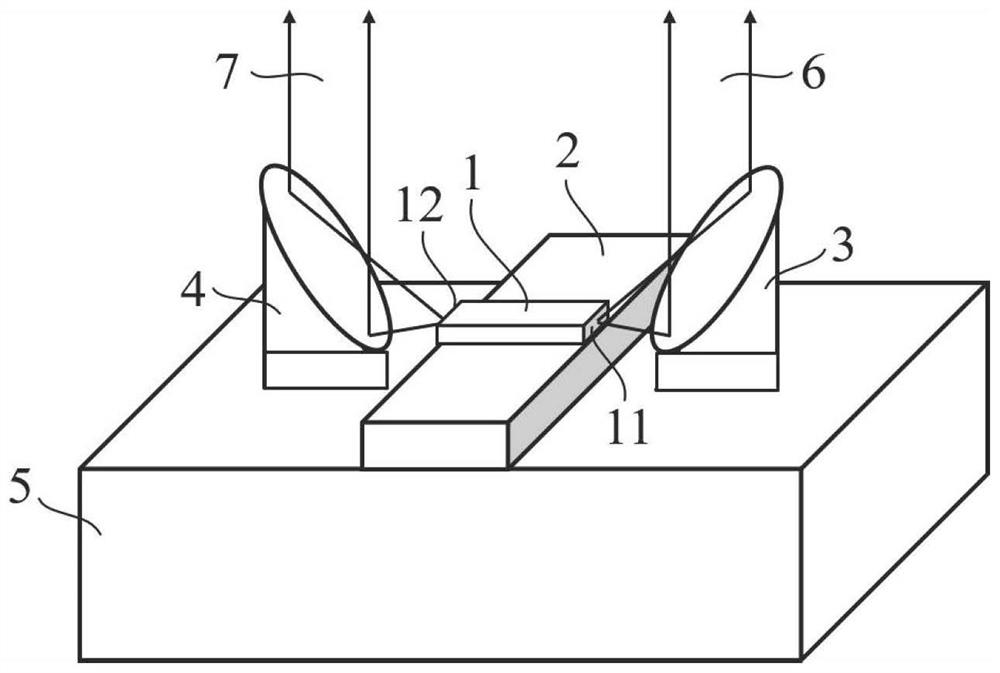

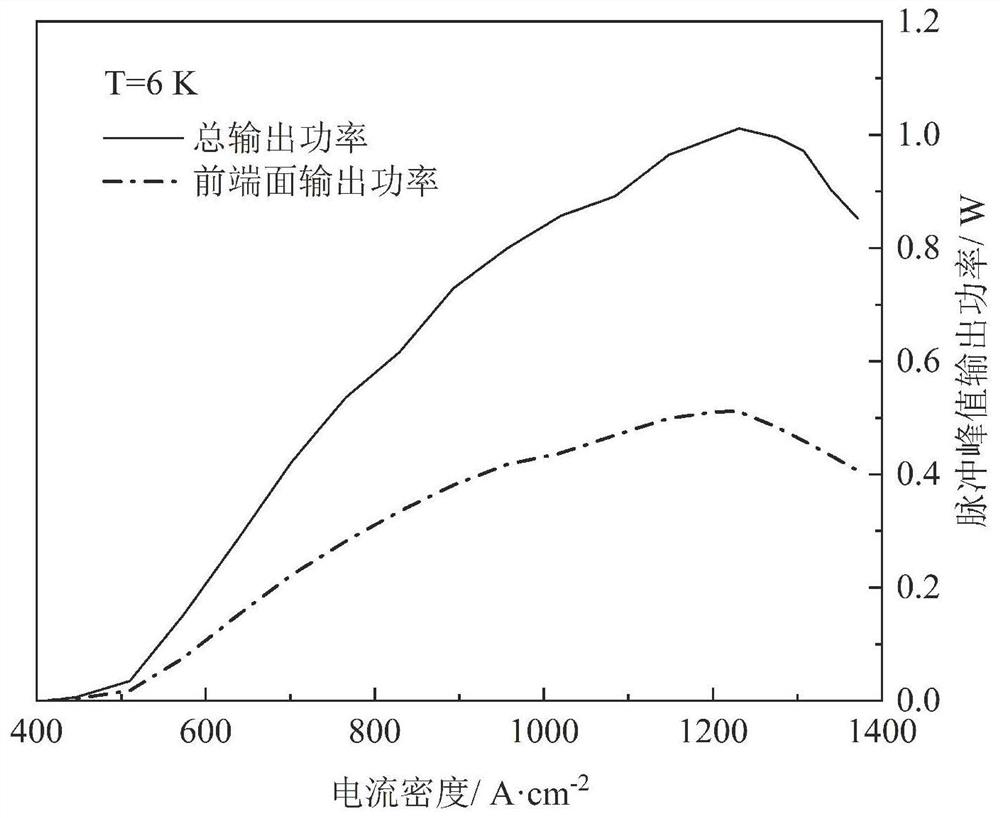

Coupling output structure of terahertz quantum cascade laser and packaging method of coupling output structure

PendingCN111952837AReduce reflection lossImprove coupling efficiencyLaser detailsLaser active region structureLight beamErbium lasers

The invention relates to a coupling output structure of a terahertz quantum cascade laser, and the structure comprises a terahertz quantum cascade laser, a first off-axis parabolic mirror and a secondoff-axis parabolic mirror; the focus of the first off-axis parabolic mirror is positioned in the front end surface of the terahertz quantum cascade laser, and the collimator is used for collecting and collimating laser emitted by the terahertz quantum cascade laser and forming a first quasi-parallel light beam; the second off-axis parabolic mirror is located in the rear end face of the terahertzquantum cascade laser and used for collecting and collimating laser emitted by the terahertz quantum cascade laser and forming a second quasi-parallel light beam. The invention further relates to a packaging method of the coupling output structure of the terahertz quantum cascade laser. According to the invention, double-end-surface laser high-efficiency coupling output can be realized.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

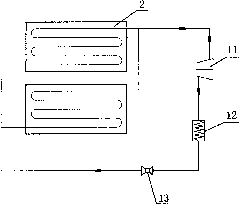

High-performance integrated special air conditioner for base station

InactiveCN109059127AReduce the temperatureReduce power consumptionLighting and heating apparatusSpace heating and ventilation detailsInsertion stentInlet valve

The invention discloses a high-performance integrated special air conditioner for a base station in the technical field of motors. A compressor is fixedly arranged at the top of a stent. A condenser is connected with the top of the compressor. An expansion valve is connected with the top of the condenser. An evaporator is connected with the top of the expansion valve. A dryer is connected with theright side wall of the evaporator. The bottom end of the dryer is connected with the compressor. An air inlet valve and a heat dissipation fan are respectively arranged at the bottom and the top of the right side wall of a machine body. A mounting block is fixed to the right side of the top of the inner cavity of the machine body. A heat exchanger is mounted at the bottom of the mounting block. Arefrigerant pipe is connected with the bottom of the left side wall of the heat exchanger. The other end of the refrigerant pipe is connected with the right side of the top of the compressor. According to the high-performance integrated special air conditioner for the base station, the temperature of components can be quickly and effectively reduced, so that the components in the machine body canwork in a relatively low temperature environment, thereby improving the working efficiency of the electronic device.

Owner:TAIZHOU GREEN ELECTRIC APPLIANCE MFG

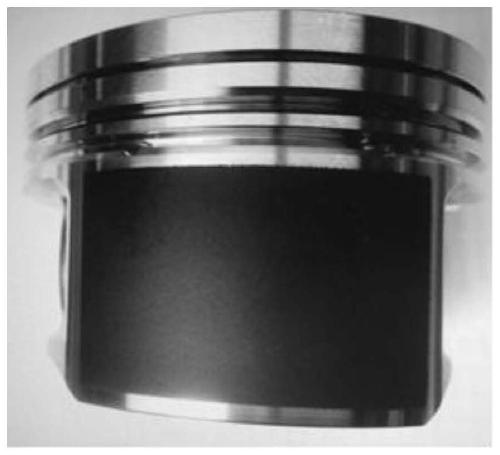

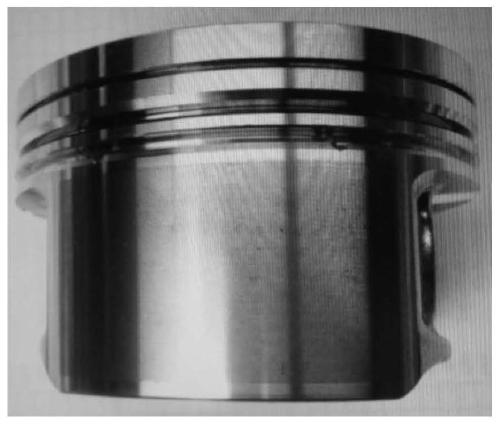

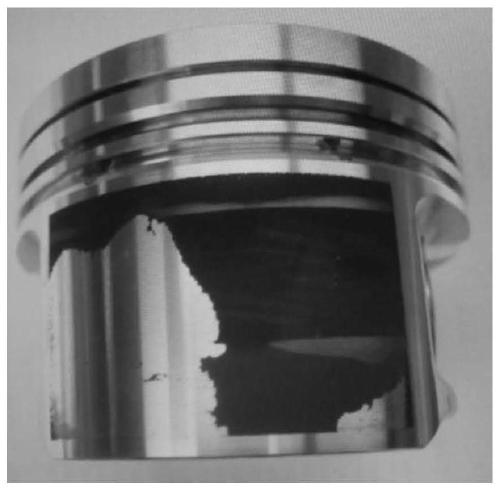

Printing solution of iron printing coating and method for preparing iron printing coating

InactiveCN110183937AExtend your lifeIncrease effective output powerEpoxy resin coatingsEpoxyScreen printing

The invention relates to a printing solution of an iron printing coating. The printing solution is prepared from raw materials as follows: high-temperature resistant resin, stainless steel powder, a diluent, curing agents and curing accelerators, wherein the high temperature resistant resin is epoxy resin E-44, the diluent is N-methyl pyrrolidone, the curing agents comprise dicyandiamide and dimethylformamide, and the curing accelerators comprise triethylenetetramine and tetraethylenepentamine. The iron printing coating is prepared from the printing solution by screen printing, environmental pollution is avoided, fewer materials are wasted, thickness of the iron printing coating is uniform, and adhesion is firm. The printing solution is completely suitable for aluminum pistons and cylinders to form an effective friction pair, and thus, the service life of an engine is prolonged while weight of the engine is reduced.

Owner:四川渝邻汽车零部件有限公司

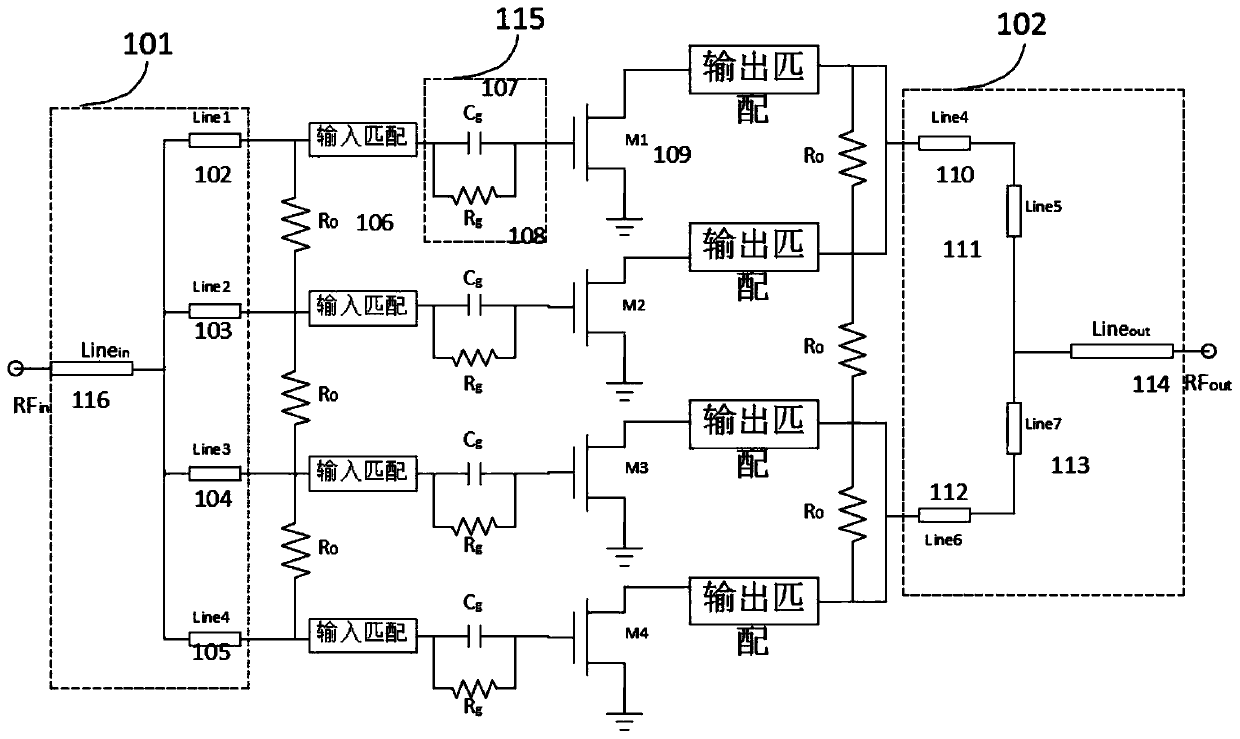

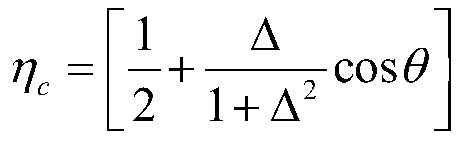

A radio frequency power amplifier applied to 5G millimeter wave mobile communication

ActiveCN109861651AHigh bandwidthLower Q valuePower amplifiersHigh level techniquesCapacitanceEngineering

The invention relates to the technical field of mobile communication, in particular to a radio frequency power amplifier applied to 5G millimeter wave mobile communication. The radio frequency power amplifier comprises a multi-path power synthesis power amplifier framework, a microstrip line and a capacitor are used for pre-matching, an output end is matched to 50 ohms through a multi-section power synthesis network, an input matching network adopts gain matching, and an output network adopts a harmonic tuning structure; The invention provides a radio frequency power amplifier applied to 5G millimeter wave mobile communication. a circuit structure combining broadband matching and power synthesis is provided, a domestic mature GaAs technology is adopted, the bandwidth performance of the power amplifier can be effectively improved, and therefore the technical scheme for solving the problems that the millimeter wave band power amplifier is insufficient in gain and low in efficiency is provided, and high creativity is achieved.

Owner:GUANGDONG UNIV OF TECH

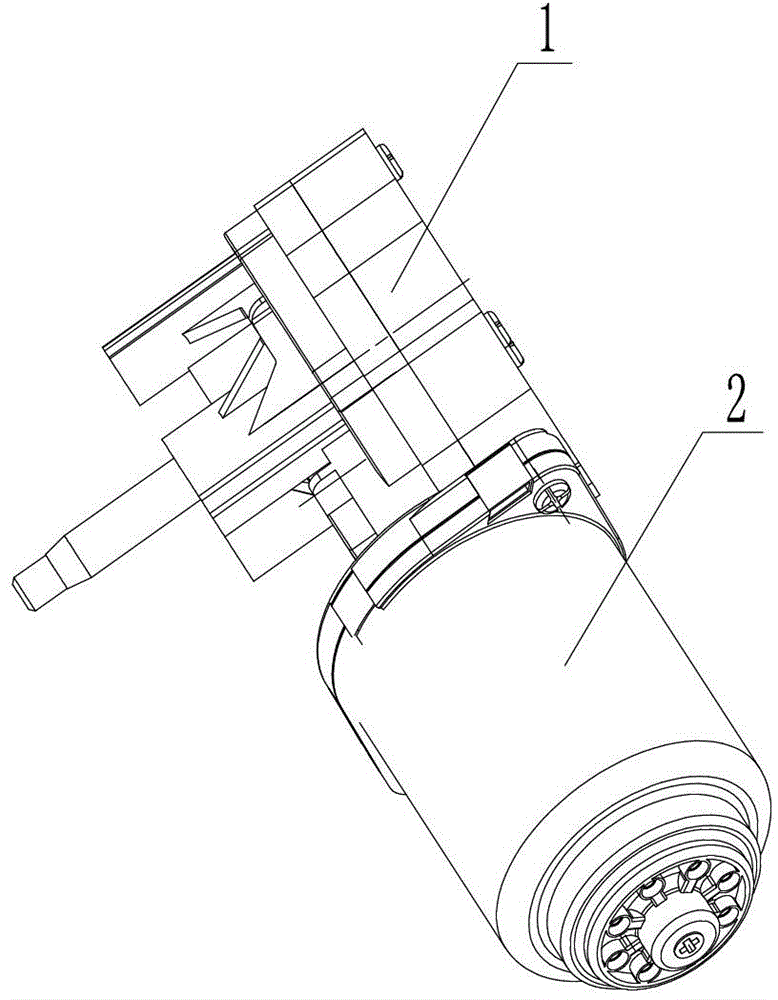

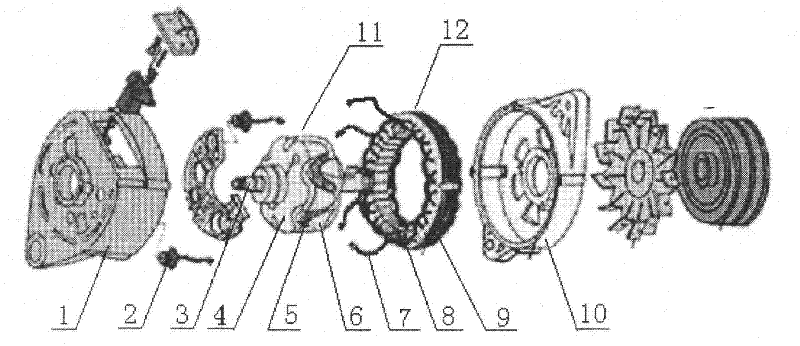

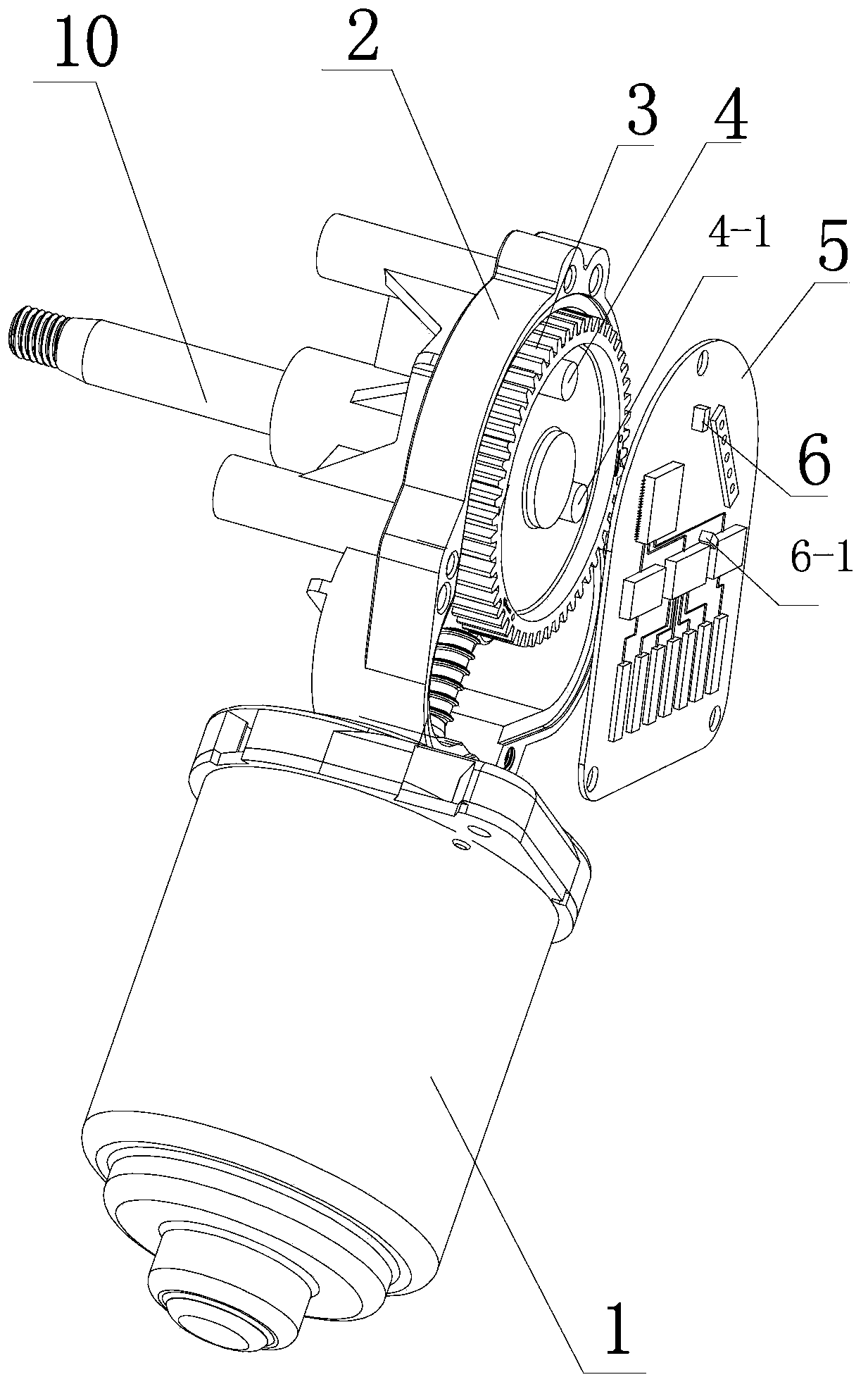

Electronic non-contact bidirectional rotary intelligent wiper motor

InactiveCN103427567AIncrease effective output powerLow costStructural associationMechanical energy handlingFailure rateElectric equipment

The invention relates to an electronic non-contact bidirectional rotary intelligent wiper motor (called NIM for short) based on a current international and domestic universal mechanical contact motor. The wiper motor overcomes the shortcomings that the mechanical contact motor is cumbersome in structure, short in service life, high in failure rate, unstable in quality, difficult to mount and the like for a long time, interferential radiation cannot be generated when the wiper motor runs, other electronic devices in an automobile are protected from interference, and a structure of a transmission assembly in a wiper assembly is particularly omitted, so that the wiper assembly is simpler in structure and lower in use cost. The wiper motor fills up international and domestic gaps of the field of an automobile wiper motor industry.

Owner:张岳峰 +2

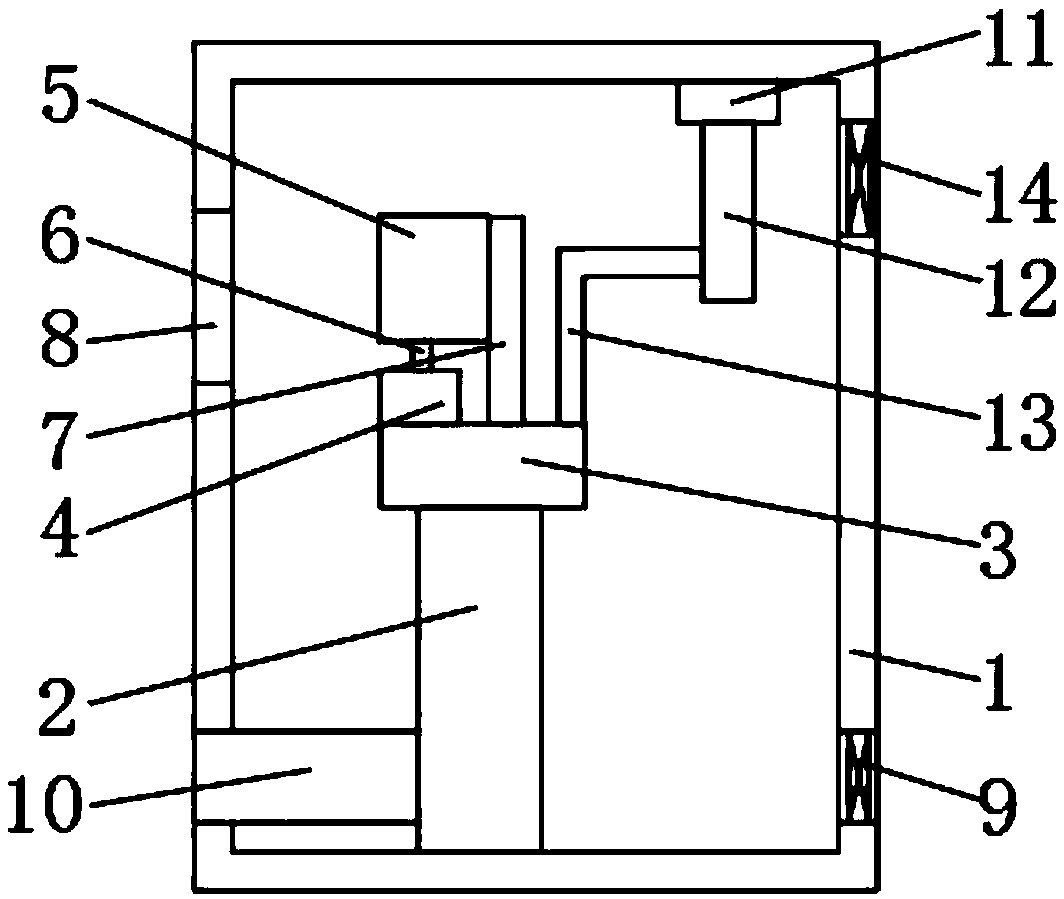

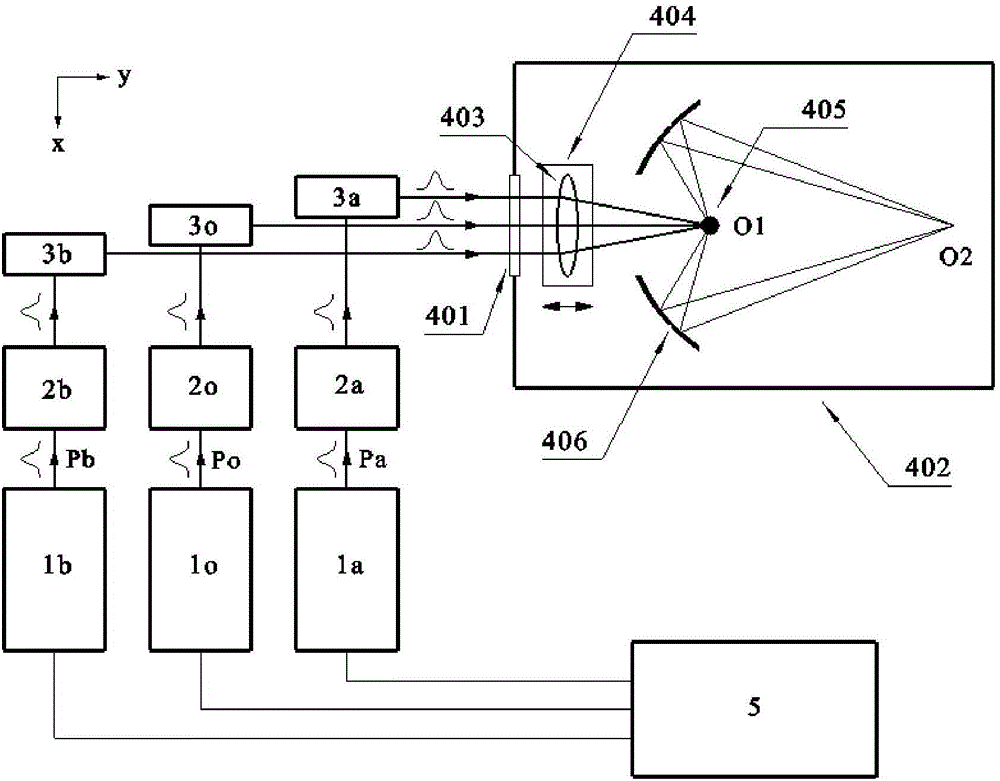

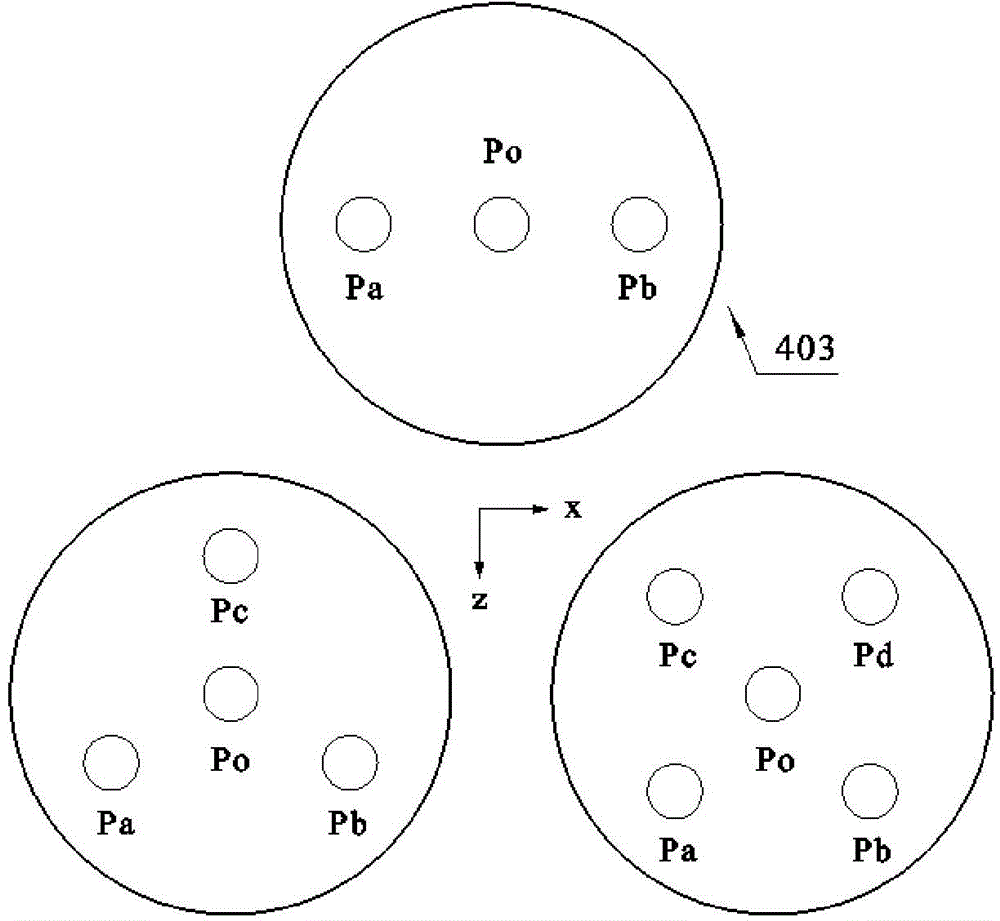

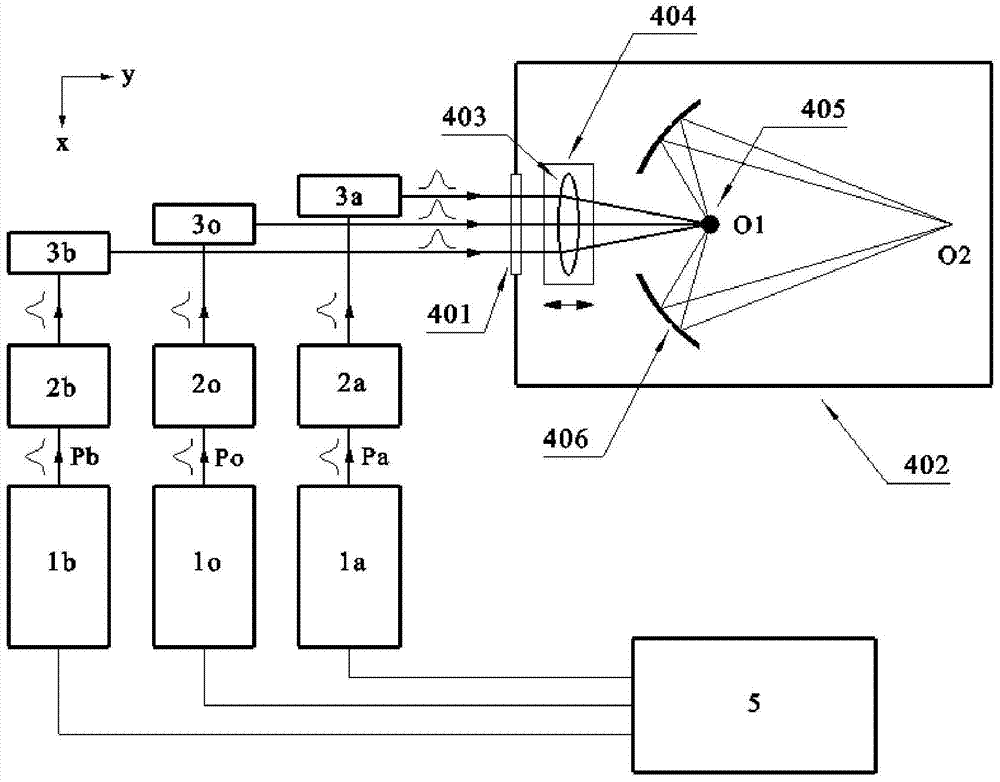

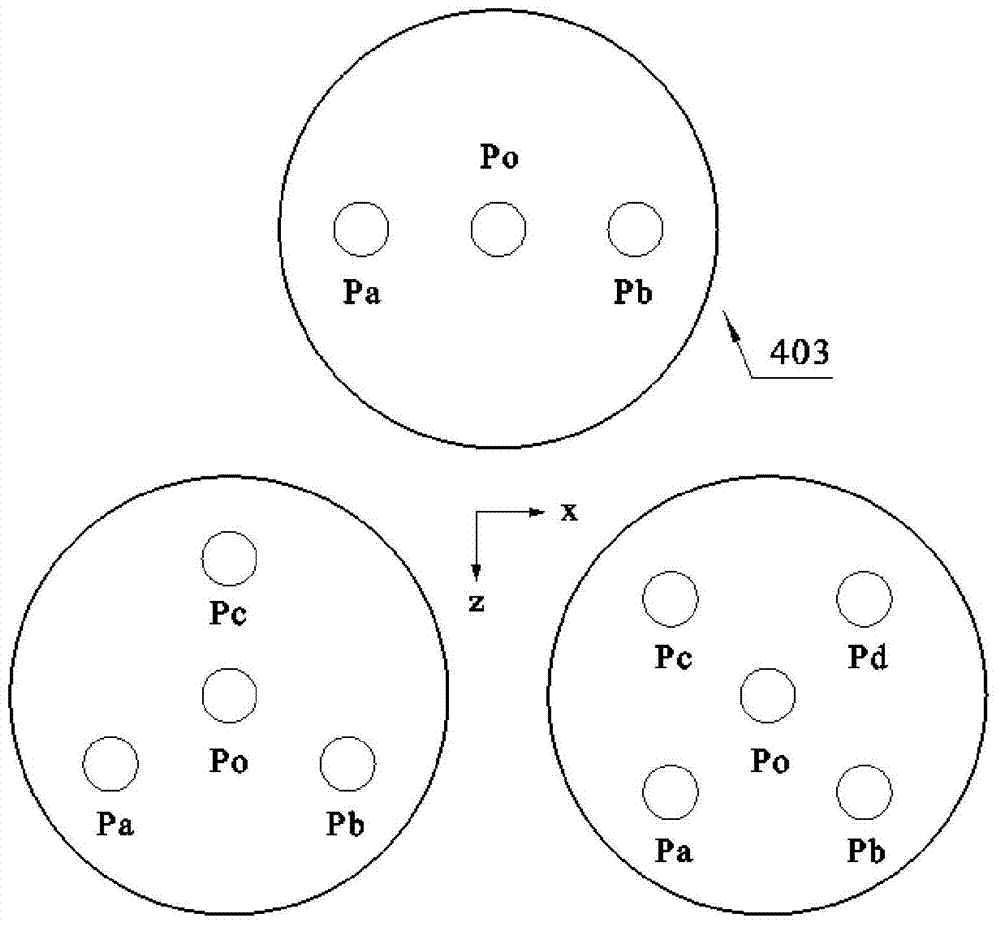

LPP-EUV (Laser-Produced Plasma-Extreme Ultraviolet Lithography) light source system for multi-pulse combined pump

ActiveCN104638503ASufficient laser powerIncrease effective output powerLaser detailsLight beamBeam direction

The invention discloses an LPP-EUV (Laser-Produced Plasma-Extreme Ultraviolet Lithography) light source system for a multi-pulse combined pump. The LPP-EUV light source system is composed of a pump laser pulse source group, a pulse delay regulation device group, a beam direction regulation device group, an LPP-EUV generation device and a synchronous signal controller. The pump laser pulse source group outputs pump pulses, a pulse combination is generated through the pulse delay regulation device group and the beam indication regulation device group; the pulse combination enters into the LPP-EUV generation device, and is acted on a target material; the triggering signal of each pump laser pulse source is generated by the synchronous signal controller. By employment of the LPP-EUV light source system for the multi-pulse combined pump, not only can the restriction that a single pulse pump laser source power is insufficient be overcome, but also the energy conversion efficiency can be optimized through regulating the pump pulse combination, thus the power output capacity of the LPP-EUV photoetching light source is improved.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

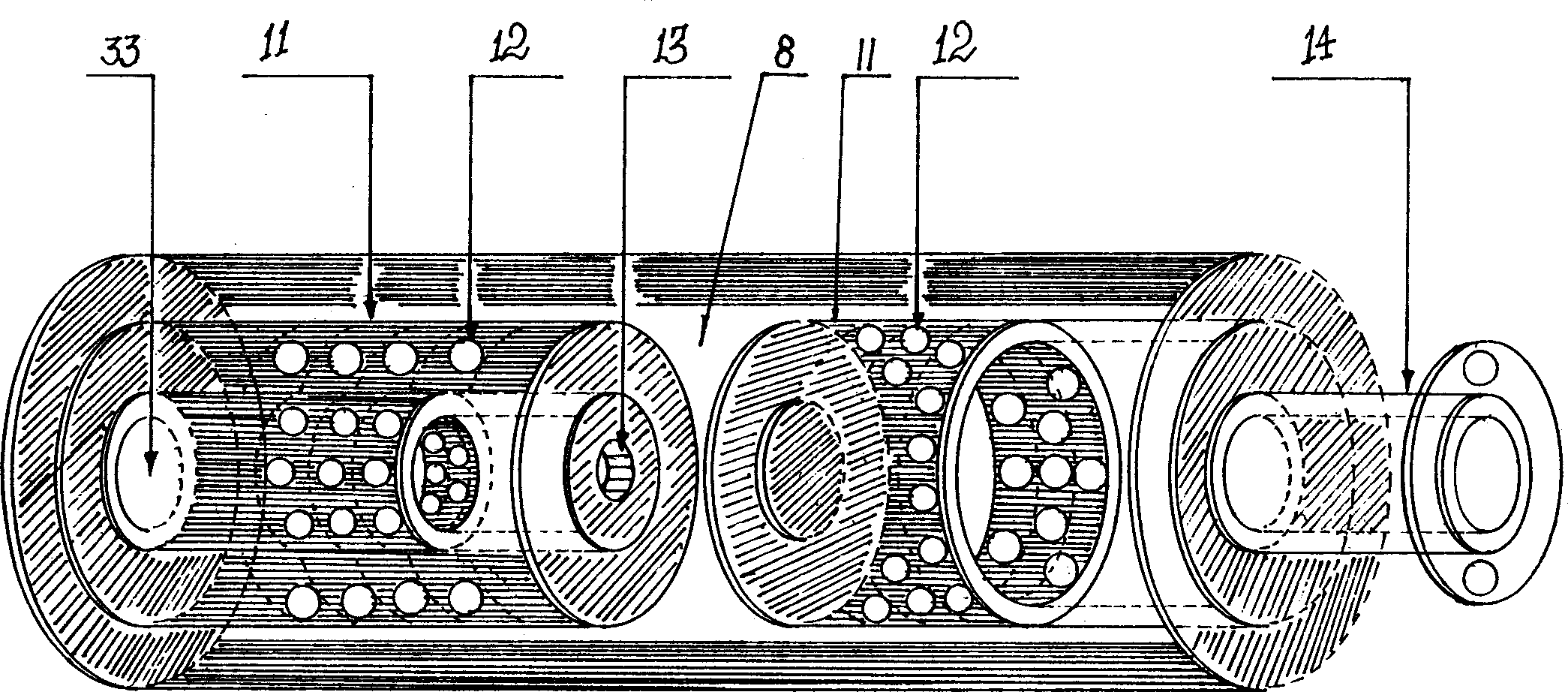

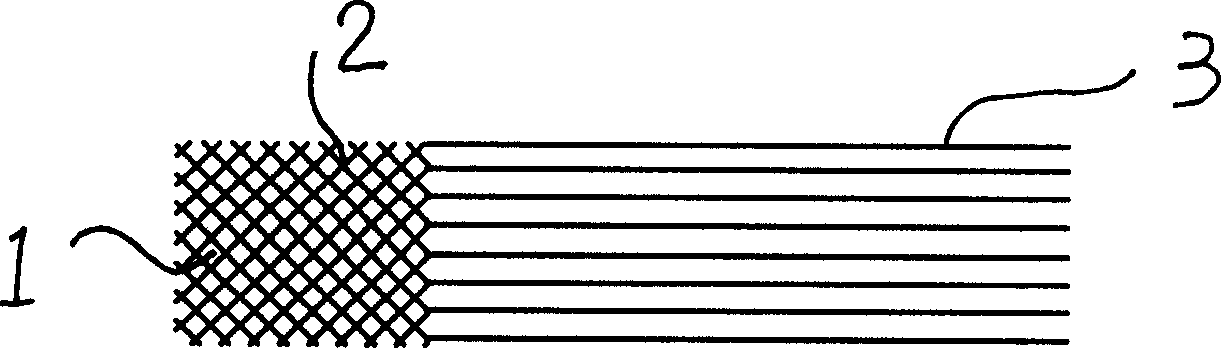

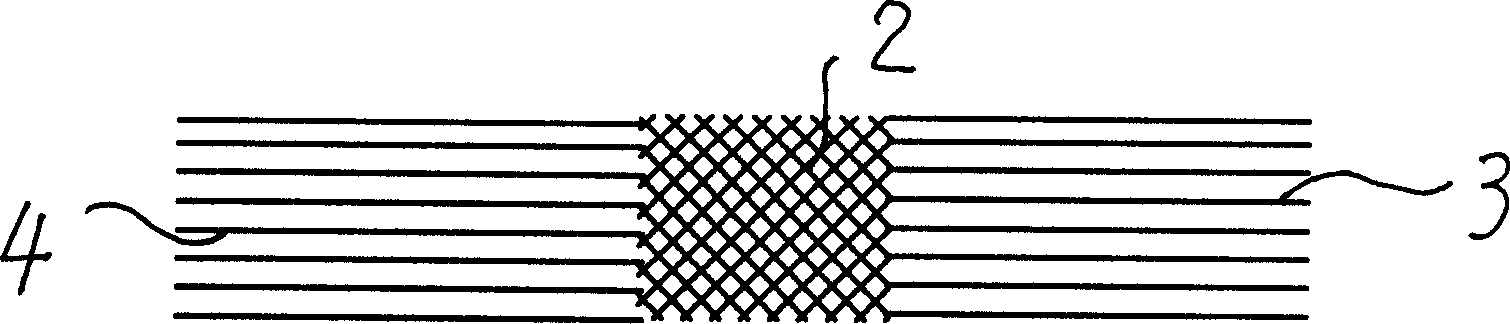

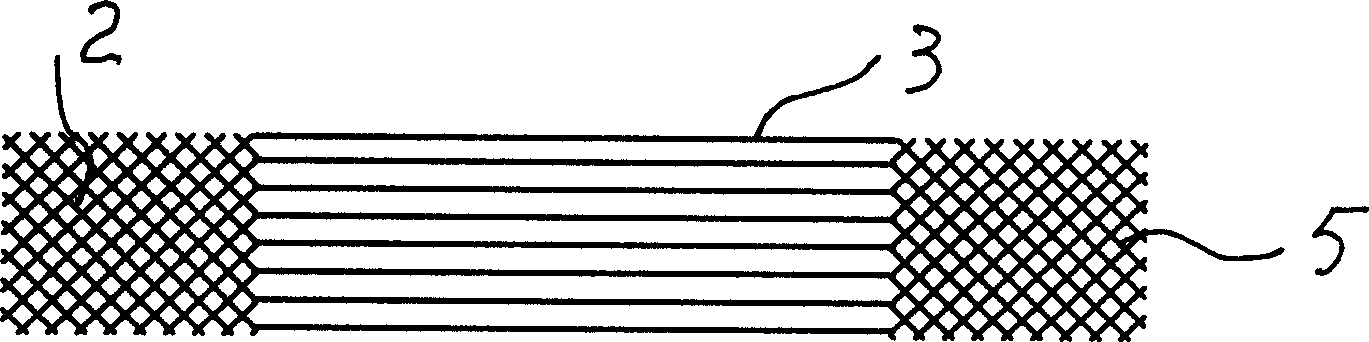

A net special for battery electrode and method for making same and dedicated device

InactiveCN1571199AReduce internal frictionGuarantee product qualityElectrode carriers/collectorsEngineeringUltimate tensile strength

The invention discloses a battery electrode special web and its preparing method and special preparing device, and its main technical project: using a working platform connected with metal plate feeding mechanism, the end of the working platform is a right-angled or obtuse-angled base, there is a special device composed of machine tool head and able to drive the mould to swing right and left and shake up and down on top side of the base, there is a special mould fixed on the special device, which can produce metal web plate with meshes and battery electrode special web connected with the metal web plate. The special web is carved of metal plate, therefore it has no contact resistance but high mechanical strength, uneasy to deform, thus able to largely reduce internal consumption of battery, raise effective output power of the battery and beneficial to assurance for battery product quality.

Owner:于朋涛

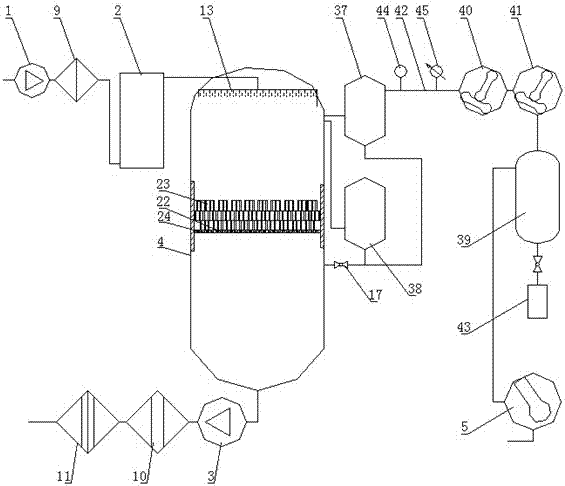

On-line vacuum gasification system

InactiveCN103691196AImprove filtering effectVaporization fastFiltration circuitsFiltrationProcess engineering

The invention discloses an on-line vacuum gasification system which comprises an oil liquid heater, a vacuum separating device, filters, condensers, roots pumps and a vacuum pump, wherein the vacuum separation device comprises a vacuum tank, an atomizer and a reaction rack; the filters comprises a primary filter, a secondary filter and a fine filter; an oil inlet pump, the primary filter, the oil liquid heater, the vacuum pump, an oil outlet pump, the secondary filter and the fine filter are sequentially connected; the atomizer comprises an oil inlet tube, a distributor and a nozzle; gas inlets of the condensers are communicated with a chamber between the atomizer and the reaction rack; gas outlets of the condensers are connected with the gas inlets of the roots pumps; the gas outlets of the roots pumps are connected with the gas inlet of the condenser III; the gas outlet of the condenser III is connected with the vacuum pump. An oil liquid firstly passes through the primary filter and is subsequently gasified in vacuum, and is finally filtered through the secondary filter and the fine filter, the filtration effect is good, condensation for water removal and drying treatment are performed through high-temperature vapor, and the service life of the vacuum pump is greatly prolonged.

Owner:重庆市合川区邓健萍摩托车配件加工厂

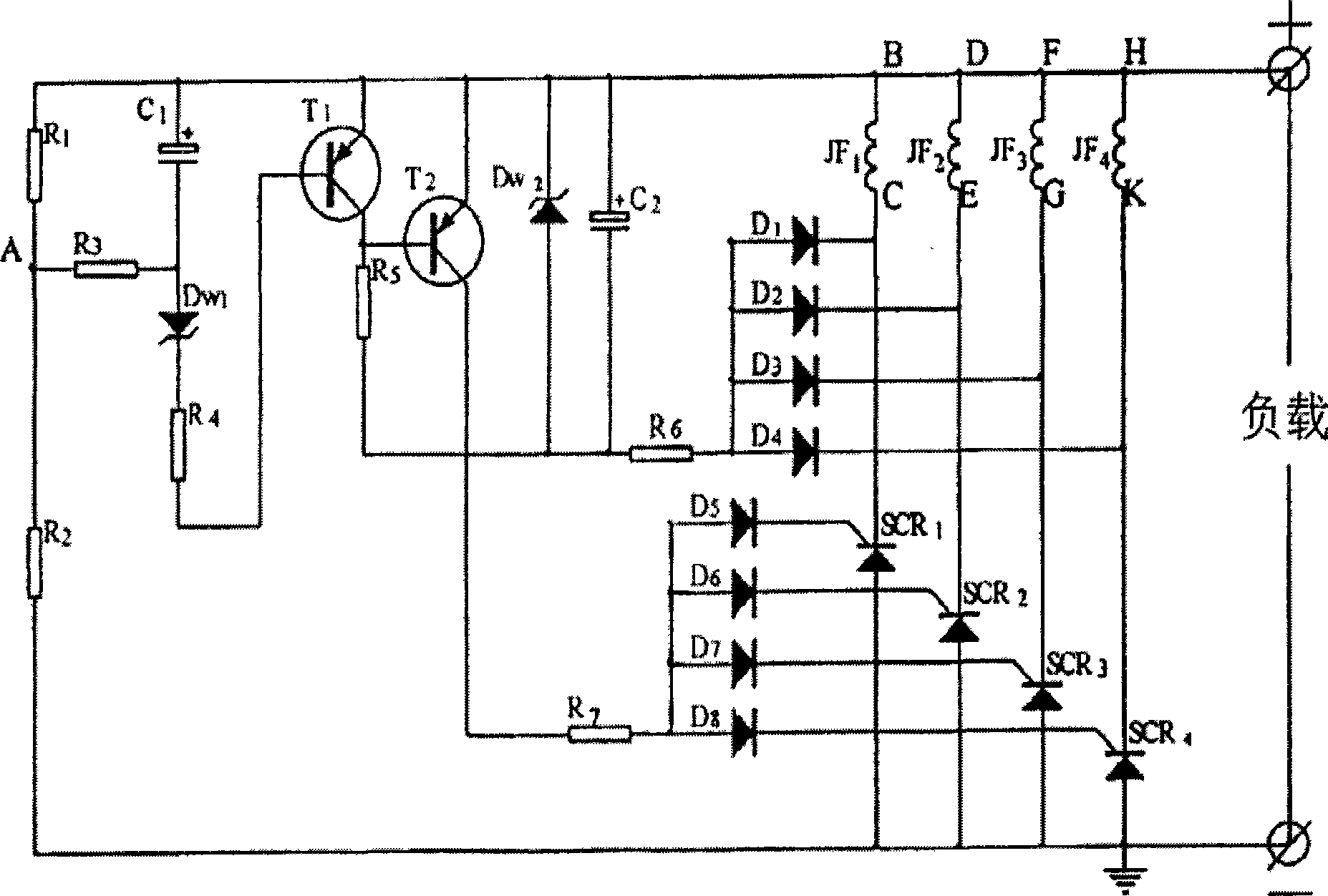

Novel use of four phase half-wave rectifying voltage regulator and apparatus

InactiveCN101483362AImprove bindingGood effectSynchronous generatorsBatteries circuit arrangementsCapacitancePhase difference

The present invention provides a new use of four-phased half-wave rectification voltage stabilizer and a electric generating apparatus utilizing the rectification voltage stabilizer, namely applying the rectification voltage stabilizer in four-phased excitation electric generating apparatus, wherein the four-phased excitation electric generating apparatus characterized in that each phase armature winding with four-phased identical stator armature winding strides over four poles of the stator core and insert line in series; the phase difference of the armature winding is 90 DEG; the head end of the armature winding is connected to the cathode output end of the electric generating apparatus; the tail ends of the armature windings are connected with input ends of the four-phased half-wave rectification voltage stabilizer respectively to constitute the four-phased excitation electric generating apparatus. When the electric generating apparatus works, constant electrical current is input into the rotor exciter winding to generate constant excitation field. Direct current output by the apparatus provided in the invention can directly supply power for electric appliance of vehicles, or charge a accumulator cell or a super capacitor.

Owner:柳小伟

Vehicle waste gas driving voltage-stabilizing generator

InactiveCN101503969ACompact structureSmall footprintMagnetic circuit rotating partsMagnetic circuit stationary partsBattery chargeElectric machine

The invention provides a voltage stabilizing generator driven by vehicle waste gas, which belongs to the field of electrical appliances of automotive motors. The voltage stabilizing generator consists of a rotator, a stator, a front end cover, a rear end cover, a turbine and a turbine scroll; an armature winding of the stator is an armature winding with four same phases; the armature windings in four phases respectively cross over three poles of a stator core and sequentially inserting wires; each permanent magnet on a permanent magnetic rotor corresponds to every four poles on the stator core; a four-phase armature structure and a rectifying voltage stabilizing device are used for stabilizing the voltage and outputs the current with stabilizing voltage, thereby directly supplying power to a vehicle direct current electrical appliance and charging a storage battery; in addition, the turbine is fixed on the rear end cover of the generator by a bolt; the turbine and the generation shares with the same shaft; and the voltage stabilizing generator has compact structure, small occupied space and convenient mounting, and is the waste gas exhausted by the generator, thereby saving energy and reducing the cost.

Owner:柳小伟

Preparation process of TiO2 nanotube/PbS/CuS nanocomposite

InactiveCN102776513BTake advantage ofImprove performanceSuperimposed coating processNano structuringTio2 nanotube

The invention relates to a preparation process of a multiple TiO2 nanotube / PbS / CuS nanocomposite used for quantum dot sensitized solar cells. The multiple TiO2 nanotube / PbS / CuS nanocomposite is prepared mainly by combining a chemical bath method and a hydrothermal method. The method comprises the following steps: shearing and grinding a titanium plate and carrying out ultrasonic cleaning and decontamination in acetone or anhydrous ethanol solution; flushing the cleaned titanium plate with deionized water, and air-drying; placing cleaned titanium plate in the well prepared electrolyte for carrying out electrochemical anodizing; and placing anodized sample of the semi-wall type titanium dioxide nanotube array in the hydrogen peroxide solution for soaking for certain time, and sequentially compounding nanoparticles of PbS / CuS with titanium oxide nanotube by adopting chemical bath method and the hydrothermal method. The method is simple in process, the prepared multi-nano structure is novel, and the conversion efficiency of the solar cell prepared through the structure is improved greatly, thus being beneficial to improvement of performances of quantum dot sensitized solar cells.

Owner:SOUTHWEST JIAOTONG UNIV

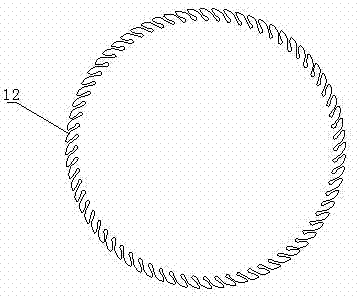

Oil on-line purification machine

The invention discloses an oil on-line purification machine which comprises an oil heater, a vacuum separator, a filter, a condenser, a Roots pump and a vacuum pump, wherein the vacuum separator comprises a vacuum tank, an atomizer and a reaction rack; the filter comprises a primary filter, a secondary filter and a fine filter; an oil inlet pump, the primary filter, the oil heater, the vacuum tank, an oil outlet pump, the secondary filter and the fine filter are sequentially connected; the atomizer comprises an oil inlet pipe, a distributor and a sprayer; the distributor comprises an upper cavity plate and a lower cavity plate; and the reaction rack comprises a supporting plate and a three-layer reaction ring. The oil passes through the primary filter, is subjected to vacuum vaporization and finally is filtered through the secondary filter and fine filter, so that the filtration effect is better; and the high-heat vapor in the vacuum tank is condensed, dehydrated and dried, thereby greatly prolonging the service life of the vacuum pump.

Owner:重庆市合川区邓健萍摩托车配件加工厂

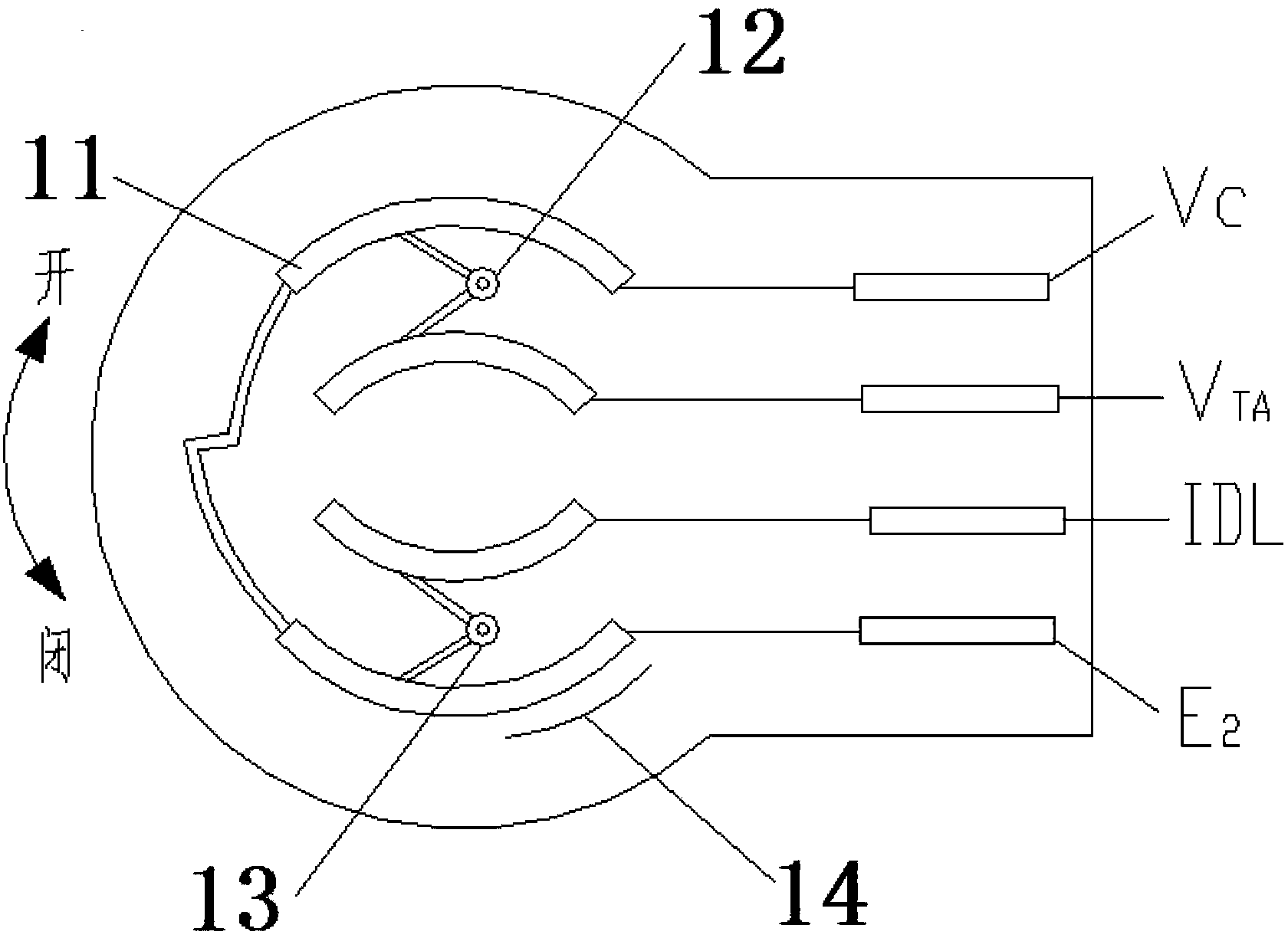

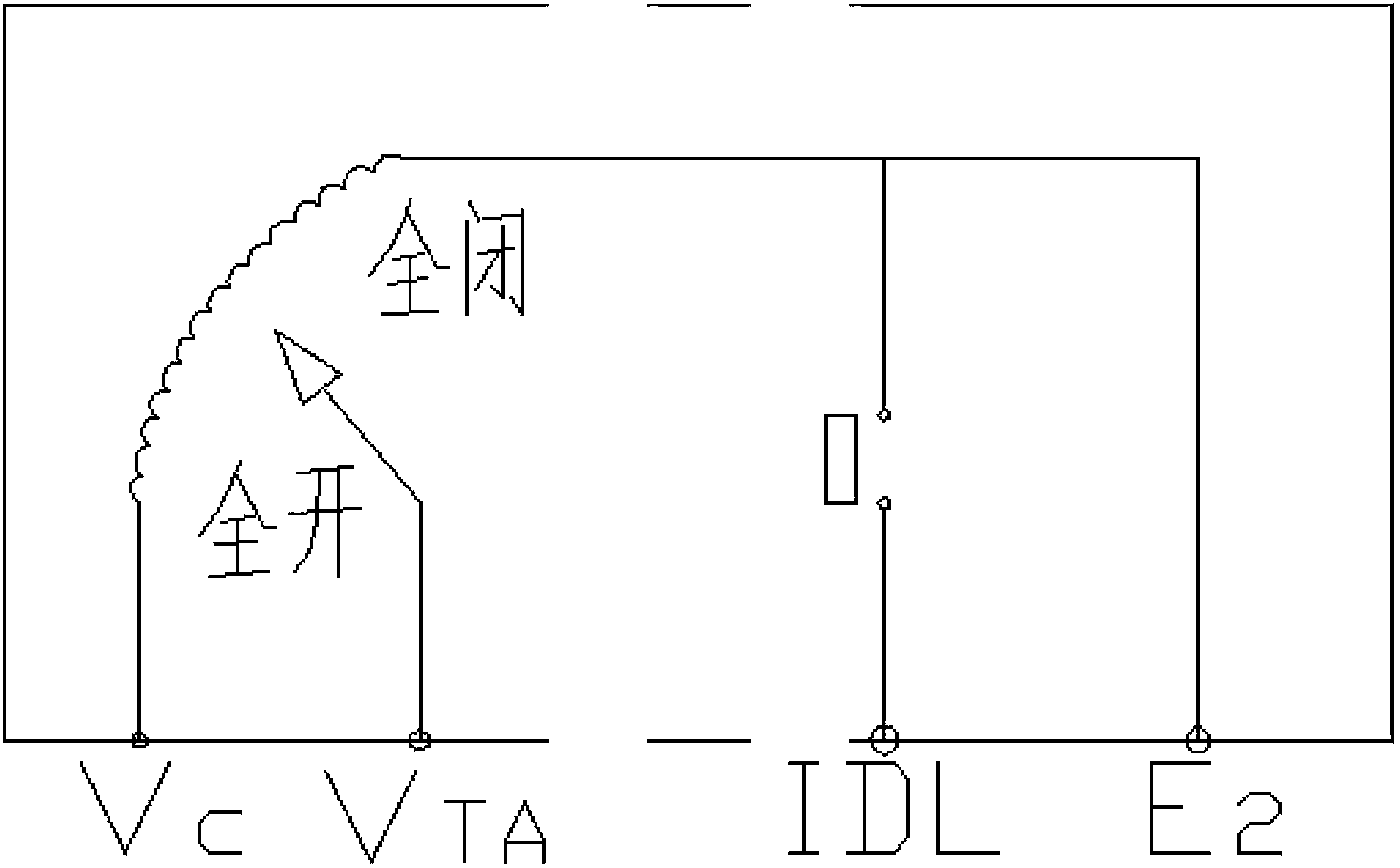

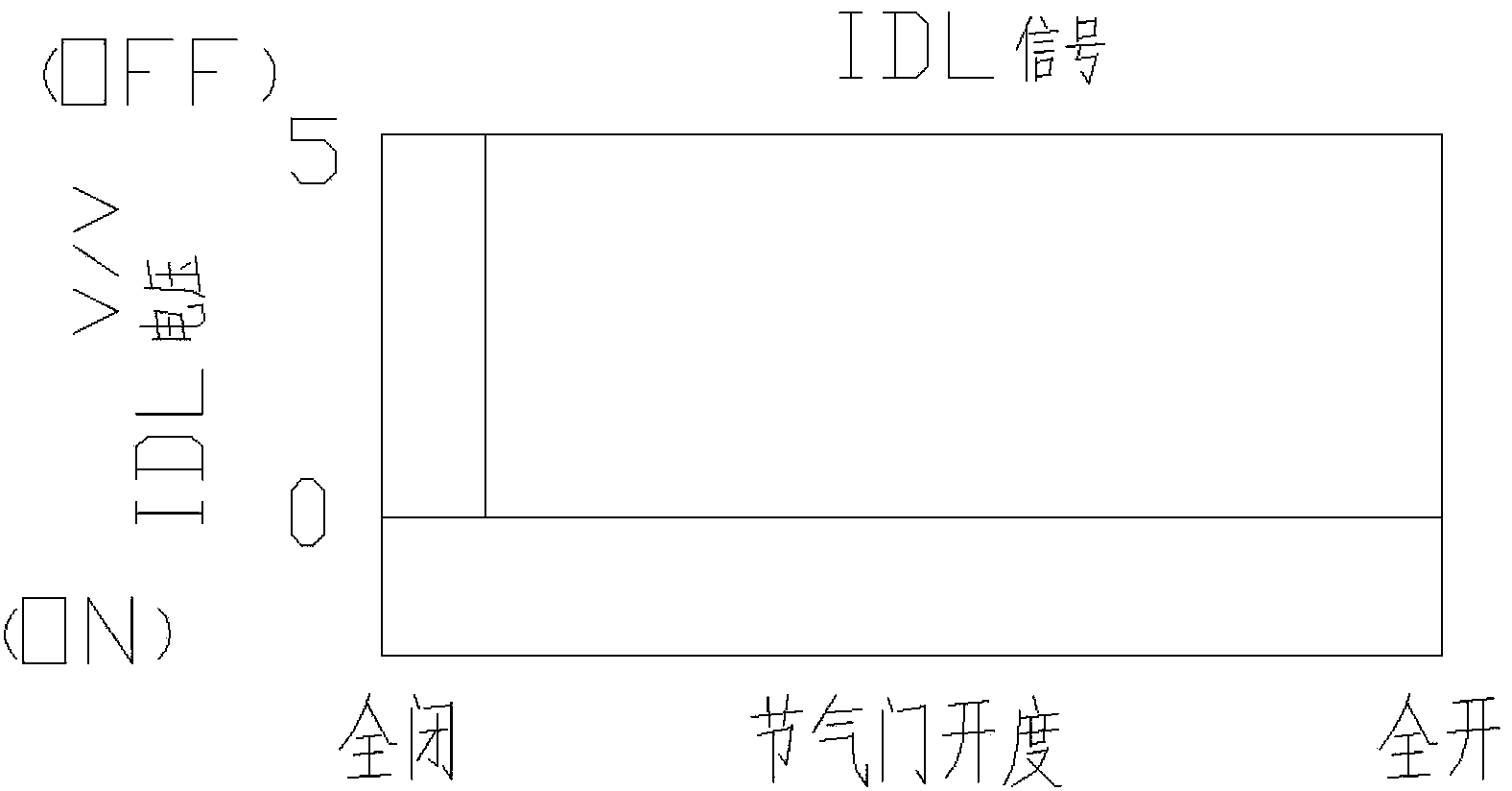

An engine load control system

ActiveCN102795176BIncrease effective output powerImprove use comfort performanceElectric/fluid circuitControl systemThrottle position sensor

Owner:CHERY AUTOMOBILE CO LTD

Method for improving effective powers of motor and generator and polymers thereof

InactiveCN102223031BIncrease exerciseJump fasterManufacturing dynamo-electric machinesPolyurea/polyurethane coatingsEffective powerPower equipment

Owner:张继先 +1

A scraper conveyor with floating coal cleaning device

The invention discloses a scraper conveyor with a float coal cleaning device. The scraper conveyor comprises a bracket a feed hopper is arranged on one side of the bracket; a discharge hopper is arranged on the other side of the bracket; and multiple scrapers for pushing coals from the feed hopper to the discharge hopper and a transmission mechanism for driving the multiple scrapers are arranged in the bracket. The trapezoidal scraper structure is stable, and is more durable compared with a sheet shape; an elastic plate and a side cover plate are convenient to stop float coals, so that no float coals are below the scrapers; when the scrapers are suffered from the pressure, a spring I and a spring II are compressed, so that the scrapers move in the direction of a wear resisting baseplate; meanwhile, a movable shaft moves to the inner side; the bending degree of the elastic plate is increased; a gap between the elastic plate and the wear resisting baseplate is smaller; the float coals are stopped on the outer side of the elastic plate; when the pressure suffered by the scrapers is weakened or not generated, the deformation of the elastic plate is recovered, the float coals remained between the elastic plate and the wear resisting baseplate are ejected out for cleaning; and the effective output power of a speed reducing motor is directly enhanced through rolling friction of a rubber wheel.

Owner:JIANGSU VOCATIONAL INST OF ARCHITECTURAL TECH

Method for improving effective powers of motor and generator and polymers thereof

InactiveCN102223031AIncrease exerciseJump fasterManufacturing dynamo-electric machinesPolyurea/polyurethane coatingsEngineeringPower equipment

The invention discloses a method for improving effective powers of a motor and a generator and polymers thereof, belonging to the application of novel auxiliary materials in the motor and the generator. The method specifically comprises the following steps of: 1, brushing a rotor sleeve and an inner wall of a shell of the motor or the generator by using the polymer, wherein the polymer is formed from nanoscale zinc crystal and polyurethane according to a special proportion; and 2, treating magnetic steel as an external coating installed on the motor or the generator until the magnetic steel is completely dried, wherein the polymer is formed from nanoscale potassium feldspar or albite crystal, C60 and polyurethane according to a special proportion. According to the method for improving theeffective powers of the motor and the generator, disclosed by the invention, the steps are simple, the output power of the motor can be effectively improved by above 20%, and the output voltage current of the generator can be improved by above 15%. The polymers can be used on various types of generators and motors, can be also used for brushing power equipment having the same theories and structures, and has wide application range.

Owner:张继先 +1

Four-phase permanent magnet generator for hybrid-power electric automobile

InactiveCN1264265CSmall synchronous reactanceMany phasesMagnetic circuit rotating partsElectric machinesPole pieceNon magnetic

Owner:张学义

Method for preparing composite material of copper sulfide and titanium dioxide nano-tube

InactiveCN101899701BPromote absorptionImprove utilizationSurface reaction electrolytic coatingSolar cellCopper sulfide

The invention provides a method for preparing a composite material of a copper sulfide and titanium dioxide nano-tube. The method comprises the following steps of putting a sanded titanium plate in acetone or absolute ethanol for ultrasonic cleaning, and is rinsed and aired with deionized water; anodizing a platinum plate serving as a cathode and the treated titanium plate serving as an anode in ethylene glycol solution with 0.25 weight percent of ammonium fluoride, namely a titanium dioxide nano-tube array grows on the surface of the titanium plate; putting the titanium plate growing the titanium dioxide nano-tube array in mixed solution filled with copper chloride and sodium thiosulfate, wherein molar concentrations of the copper chloride and the sodium thiosulfate in the mixed solutionare the same, and are between 0.0025 and 0.01mol / L; and sealing the solution with an autoclave, heating the autoclave to the temperature of between 60 and 120 DEG C, and preserving the temperature for 12 to 24 hours. The nano composite material prepared by the method has high sunlight absorbing and utilizing capability, has good application prospect in the field of solar cells, and has simple manufacture process, low equipment requirement and low preparation cost.

Owner:SOUTHWEST JIAOTONG UNIV

lpp‑euv light source system pumped by multi-pulse combination

ActiveCN104638503BSufficient laser powerIncrease effective output powerLaser detailsLithographic artistPulse energy

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com