Five-phase Nd-Fe-B permanent-magnetic generator for vehicle

A five-phase NdFeB permanent magnet generator technology, applied to synchronous motors with stationary armatures and rotating magnets, synchronous machine parts, magnetic circuit rotating parts, etc., can solve the problem of high cost, stable voltage and permanent The structure of the magnetic generator is complicated, etc., to achieve the effect of less reactive power loss, compact structure and large output power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

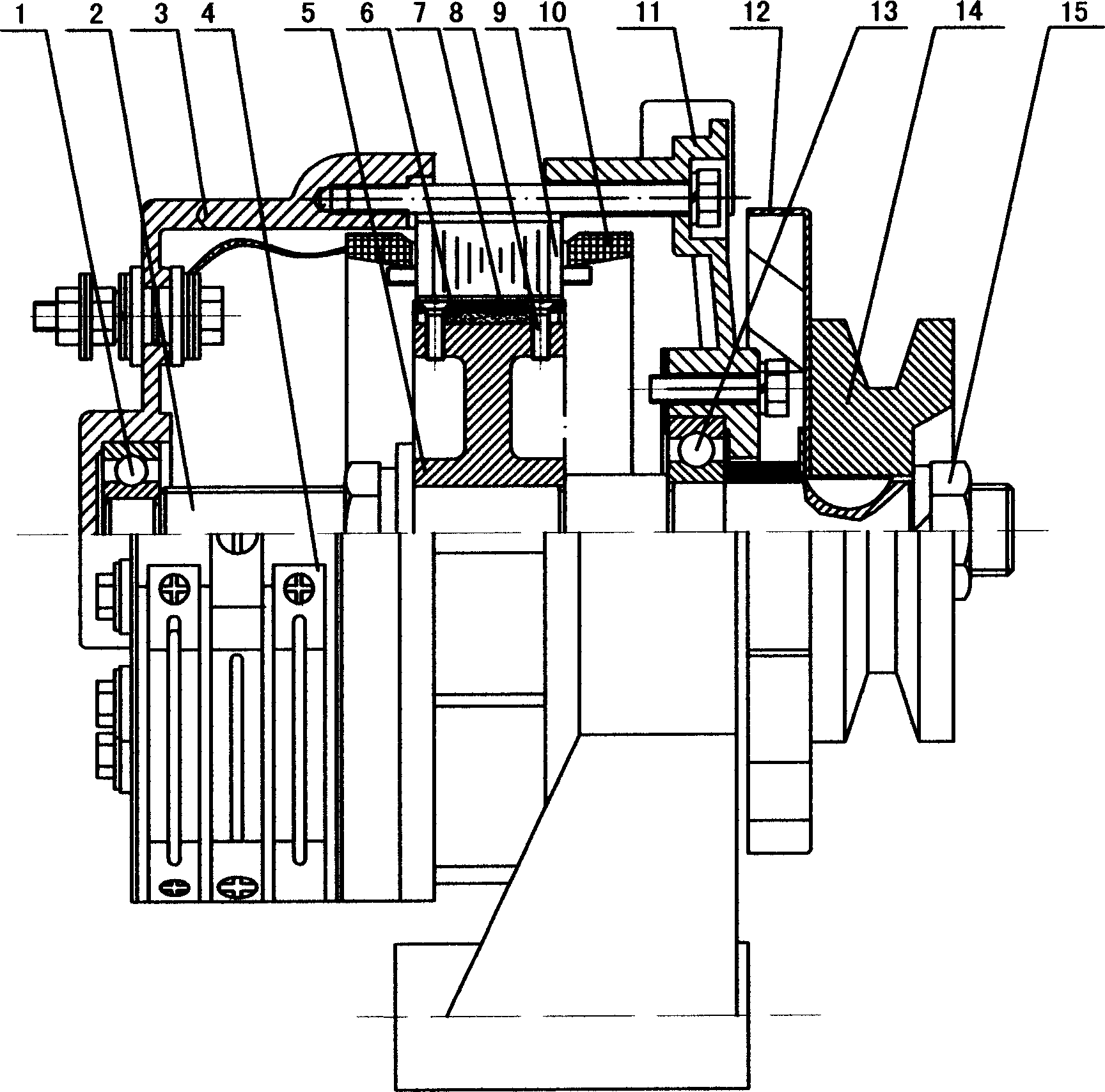

[0007] 1. Rear end bearing 2. Rotating shaft 3. Rear end cover 4. Electronic voltage stabilizer 5. Rotor core 6. NdFeB permanent magnet 7. Pole shoe 8. Non-magnetic screw 9. Stator core 10. Armature Winding 11. Front cover 12. Fan 13. Front bearing 14. Pulley 15. Nut

[0008] The present invention will be further described below in conjunction with accompanying drawing:

[0009] There are several poles on the stator core 9, and each phase of the armature windings 10 in the five identical armature windings 10 respectively straddles the five poles on the stator core 9 and inlays the wires sequentially, and the phase difference is 72° , the first end is connected to one point, which is the positive output end of the generator, and the tail end of each phase armature winding 10 is respectively connected to the input end of the five-phase half-wave controllable rectification and voltage stabilizing electronic voltage stabilizer 4 to form a five-phase In the NdFeB permanent magnet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com