lpp‑euv light source system pumped by multi-pulse combination

An LPP-EUV, light source system technology, applied in the field of plasma type EUV lithography light source, can solve the problem of insufficient pump laser power of the light source, and achieve the effect of optimizing energy conversion efficiency, improving effective output power, and improving output capability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below through the examples and accompanying drawings, but the protection scope of the present invention should not be limited by this.

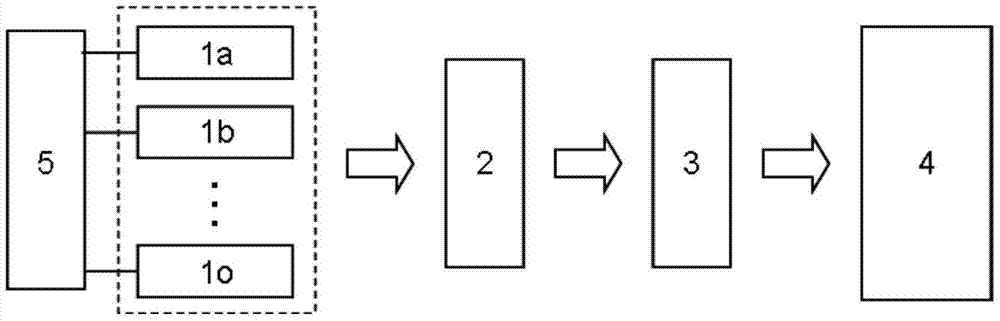

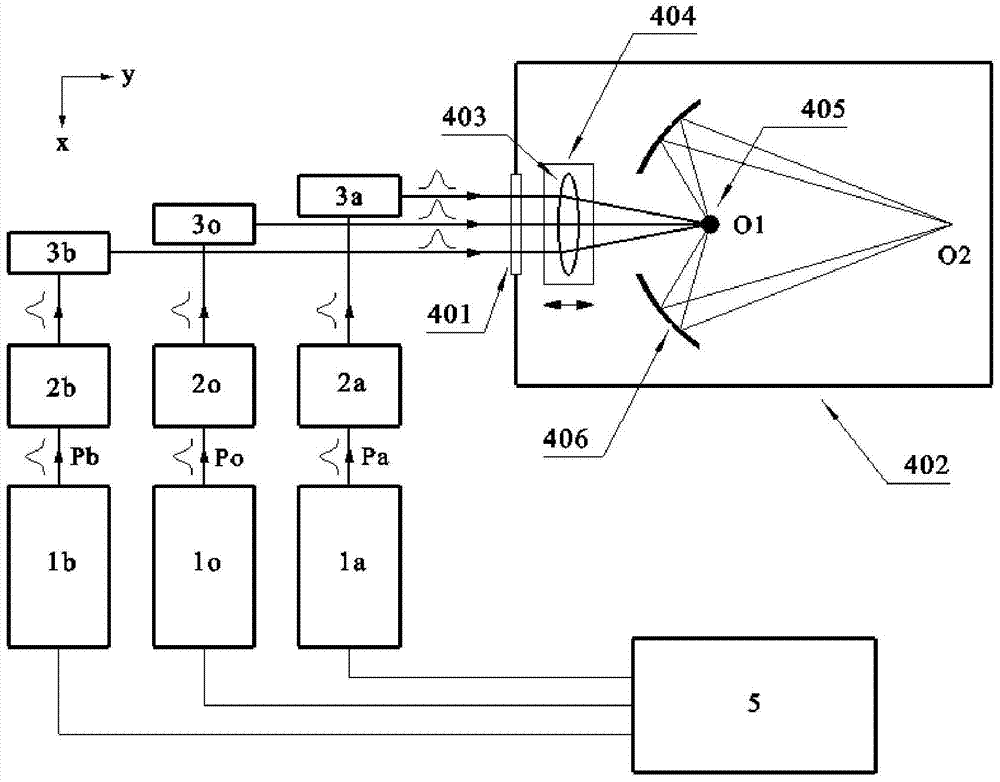

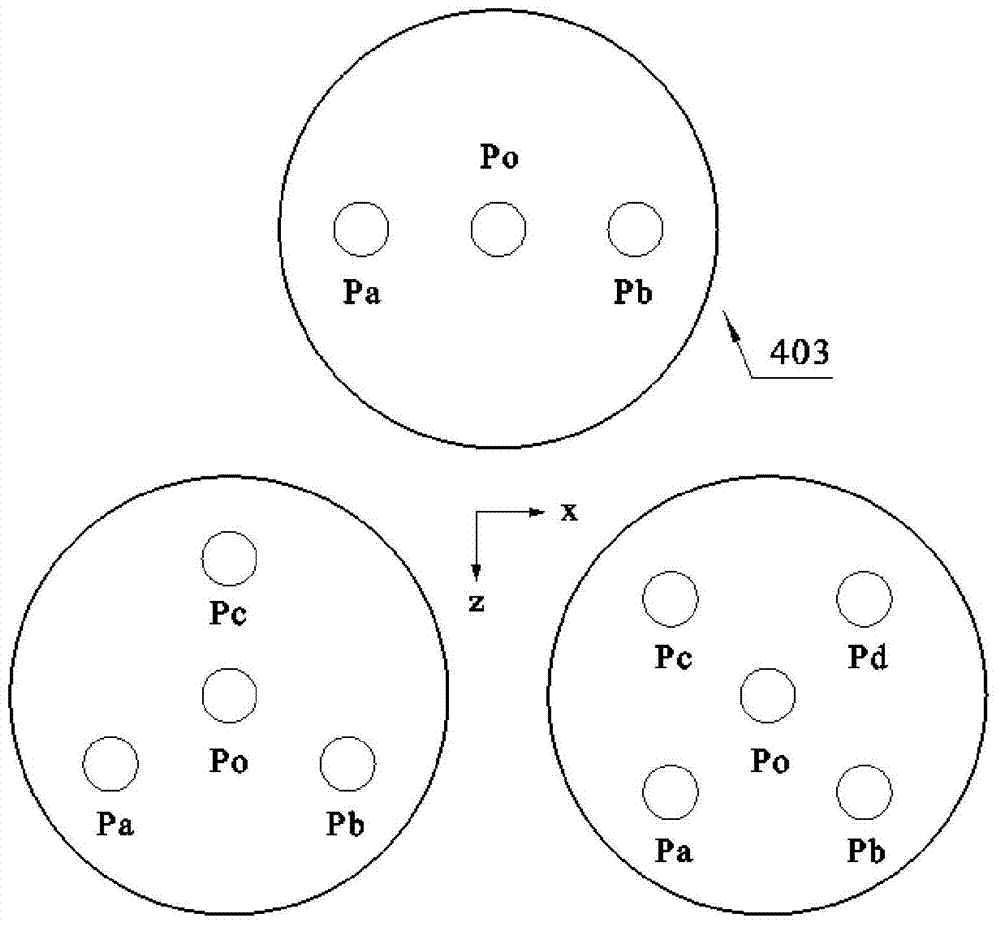

[0019] Please see first figure 1 , figure 1 It is a structural schematic diagram of the multi-pulse combined pump LPP-EUV light source system of the present invention. It can be seen from the figure that the composition of the multi-pulse combined pumping LPP-EUV light source system of the present invention includes a pump laser pulse source group 1, a pulse delay adjustment device group 2, a beam pointing adjustment device group 3, an LPP-EUV generating device 4 and a synchronous Signal controller 5. The pump pulses are output from the pump laser pulse sources 1a, 1b,..., 1o, and the pulse combination is generated by the pulse delay adjustment device group 2 and the beam pointing adjustment device group 3, and then enters the LPP-EUV generation device 4 to act on the target , the trig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com