Scraper conveyor with float coal cleaning device

A scraper conveyor and cleaning device technology, which is applied in the field of scraper conveyors, can solve the problems of lowering the transmission power, reducing the effective output power of the geared motor, and falling off, and achieves the advantages of easy cleaning, enhanced effective output power, and stable structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

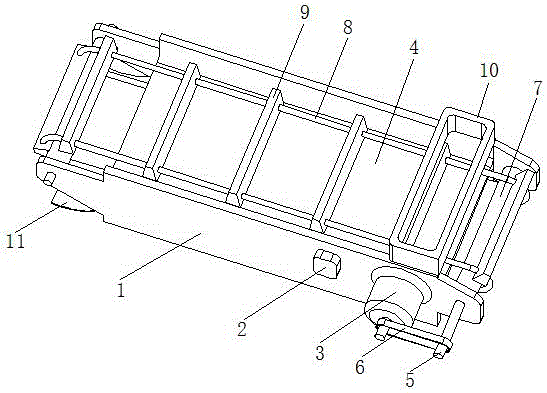

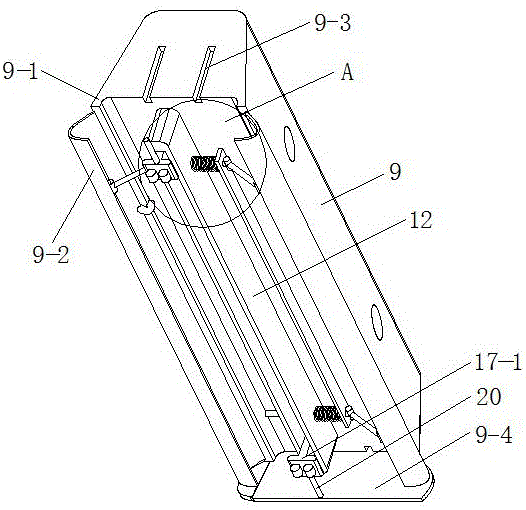

[0024] A scraper conveyor with a floating coal cleaning device, comprising two parallel side frame plates 1 and a wear-resistant bottom plate 4, the two side frame plates 1 are connected and fixed by a wear-resistant bottom plate 4 to form a U-shaped groove Structure; a feed hopper 10 is provided at the upper end of one side of the two side frame plates 1 , and a lower hopper 11 is provided at the lower end of the other side of the two side frame plates 1 .

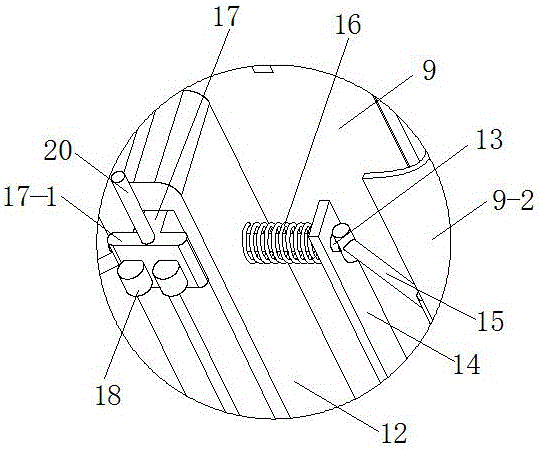

[0025] The shaft holes on the left and right sides of the side frame plate 1 are respectively provided with transmission shafts 5, and a roller 7 that is closely matched or integrally formed with it is arranged on the transmission shaft 5, and the two rollers 7 are connected by two chains 8. transmission, between the two chains 8 there are evenly arranged a plurality of scrapers 9 which are synchronously driven; the shaft end of the transmission shaft on the right side is connected with the output shaft of the reduction mo...

example example 2

[0031] A scraper conveyor with a floating coal cleaning device, comprising two parallel side frame plates 1 and a wear-resistant bottom plate 4, the two side frame plates 1 are connected and fixed by a wear-resistant bottom plate 4 to form a U-shaped groove Structure; a feed hopper 10 is provided at the upper end of one side of the two side frame plates 1 , and a lower hopper 11 is provided at the lower end of the other side of the two side frame plates 1 .

[0032] The shaft holes on the left and right sides of the side frame plate 1 are respectively provided with transmission shafts 5, and a roller 7 that is closely matched or integrally formed with it is arranged on the transmission shaft 5, and the two rollers 7 are connected by two chains 8. transmission, between the two chains 8 there are evenly arranged a plurality of scrapers 9 which are synchronously driven; the shaft end of the transmission shaft on the right side is connected with the output shaft of the reduction mo...

Embodiment 3

[0037]A scraper conveyor with a floating coal cleaning device, comprising two parallel side frame plates 1 and a wear-resistant bottom plate 4, the two side frame plates 1 are connected and fixed by a wear-resistant bottom plate 4 to form a U-shaped groove Structure; a feed hopper 10 is provided at the upper end of one side of the two side frame plates 1 , and a lower hopper 11 is provided at the lower end of the other side of the two side frame plates 1 .

[0038] The shaft holes on the left and right sides of the side frame plate 1 are respectively provided with transmission shafts 5, and a roller 7 that is closely matched or integrally formed with it is arranged on the transmission shaft 5, and the two rollers 7 are connected by two chains 8. transmission, between the two chains 8 there are evenly arranged a plurality of scrapers 9 which are synchronously driven; the shaft end of the transmission shaft on the right side is connected with the output shaft of the reduction mot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com