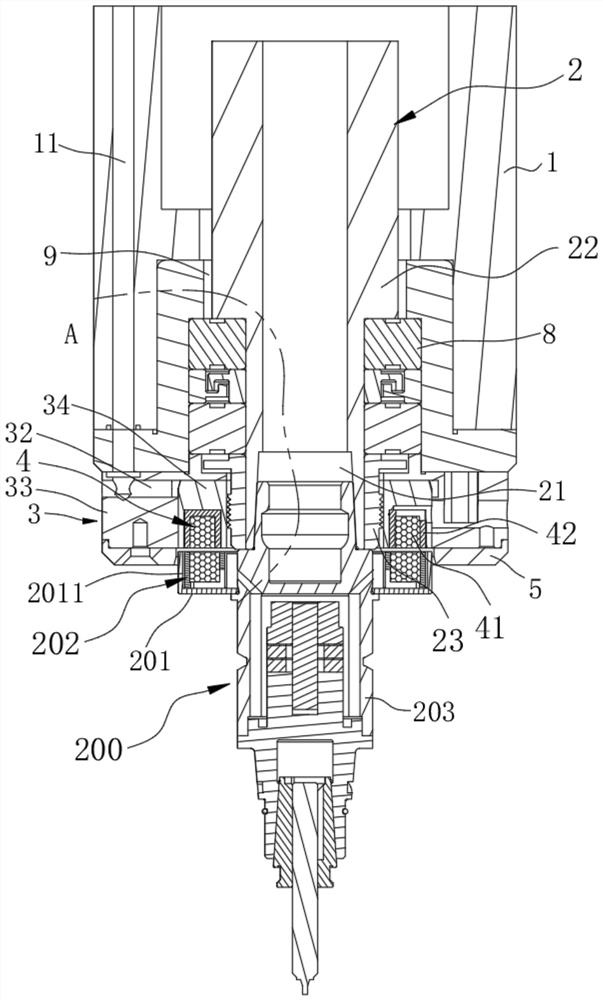

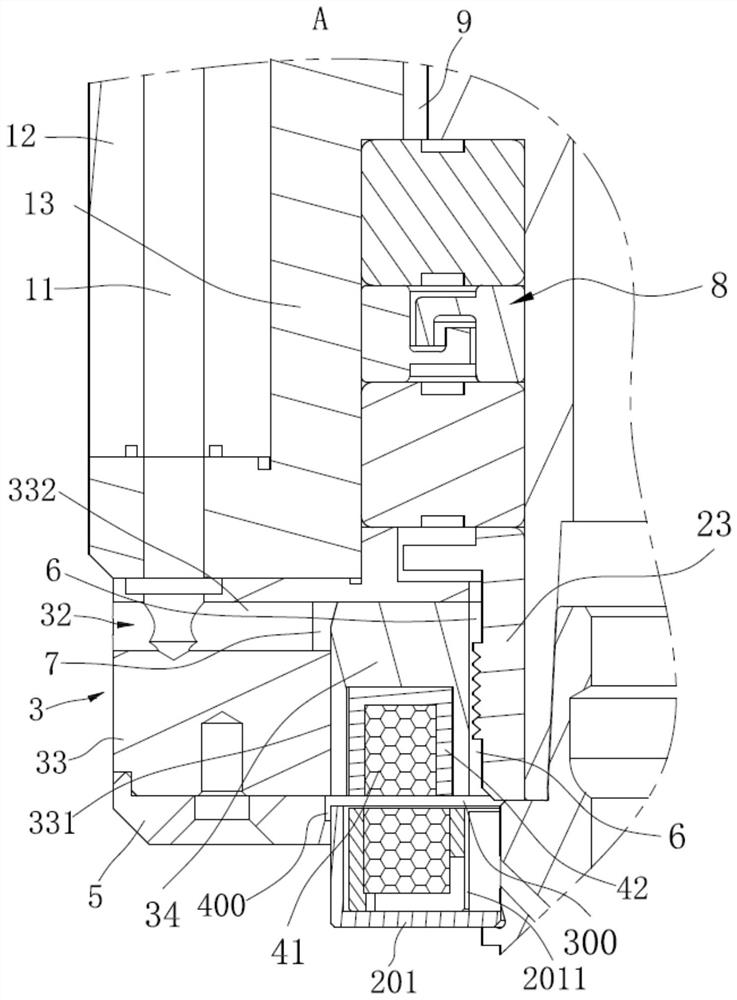

Ultrasonic machining device and ultrasonic spindle thereof

An ultrasonic and spindle technology, applied in the direction of metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve the problems of unstable electrical conduction, affecting the processing effect of tools, and low installation accuracy, so as to achieve stable electrical conduction Reliable, improve processing effect, improve the effect of assembly accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] Preferred embodiments of the present application will be described in detail below with reference to the accompanying drawings. Those skilled in the art will appreciate that these descriptions are only descriptive and exemplary, and should not be construed as limiting the protection scope of the present application.

[0059] First of all, it should be noted that the orientations of top, bottom, upward, and downward mentioned in this article are defined relative to the directions in each drawing, and they are relative concepts, and therefore can be It changes in different positions and different practical states. Accordingly, these or other orientations should not be construed as limiting terms.

[0060] It should be noted that the term "comprising" does not exclude other elements or steps, and "a" or "an" does not exclude a plurality.

[0061] In addition, it should also be noted that for any single technical feature described or implied in the embodiments herein, or ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com