On-line vacuum gasification system

A vacuum and vacuum tank technology, applied in the field of online vacuum vaporization system, can solve the problems of poor atomization effect, shortened vacuum pump life, poor filtering effect, etc., and achieve the effect of enhancing effective output power, better filtering effect, and improving vaporization effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

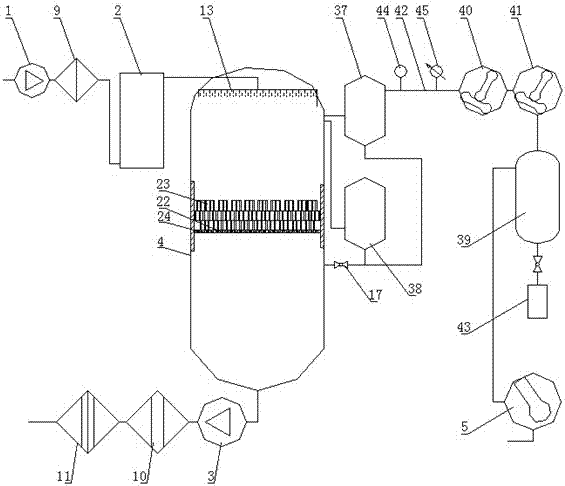

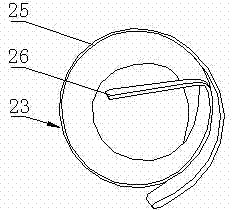

[0021] Such as figure 1 As shown, the online vacuum vaporization system includes oil inlet pump 1, oil heater 2, vacuum separation device, oil outlet pump 3, filter, condenser I37, condenser II38, condenser III39, Roots pump I40 and Roots pump II41. The vacuum separation device includes a vacuum tank 4 , an atomizer 13 and a reaction rack arranged in the vacuum tank, and a return valve 17 is arranged on the vacuum tank 4 and close to the bottom of the reaction rack.

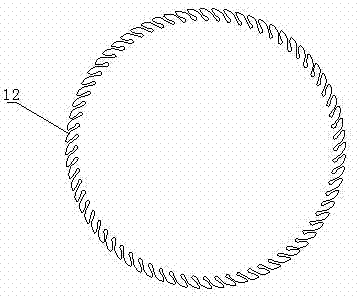

[0022] The filter includes a primary filter 9 , a secondary filter 10 and a fine filter 11 . The filter core of the primary filter 9 adopts a single-layer filter screen, and the filter core of the secondary filter 10 adopts a three-layer filter screen. The cross-section of the filter screen 12 of the fine filter 11 is a corrugated ring with alternating crests and trou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com