Special air conditioner for base station with separate type radiation plate evaporator

A plate-type evaporator and radiant plate technology, which is applied in the field of air conditioners, can solve the problems of easy condensation of ceiling-type air conditioners, and achieve the effects of improving work efficiency, increasing output power, and reducing power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

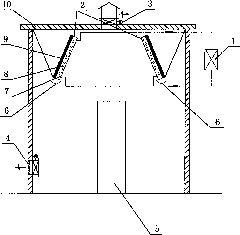

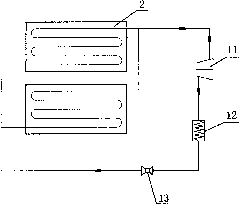

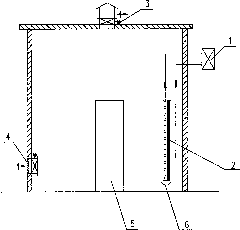

[0021] Such as figure 1 with figure 2 As shown, the base station dedicated air conditioner with a separate radiant plate evaporator includes a machine room 10, an outdoor unit 1, a radiant plate evaporator and a condensed water removal device arranged in the machine room 10, and the radiant plate evaporator is composed of several plate evaporators The plate evaporator 2 includes a refrigerant pipe 8, a radiant plate, an inner radiant fin and heat insulating material, the refrigerant pipe 8 is connected to the inner radiant fin, and the refrigerant pipe 8 and the inner radiant fin are arranged on the radiant plate 7 and the heat insulating material 9, the refrigerant pipes 8 of several plate evaporators 2 communicate with each other through connecting pipes; the outdoor unit 1 includes a compressor 11 and a condenser 12; It forms a cyclic closed-circuit connection with the expansion valve 13. The condensed water removal device includes a sump 6 and a drainpipe.

[0022] In ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com