Printing solution of iron printing coating and method for preparing iron printing coating

A printing liquid and coating technology, which is applied in the field of printing liquid for printing iron coating and preparation of printing iron coating, can solve the problems of difficult control of the adhesion between the printing iron coating and the substrate, uneven appearance of the printing iron coating, and shortening the life of the engine. , to achieve the effect of improving the effective output power, uniform thickness of the printed iron coating and reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

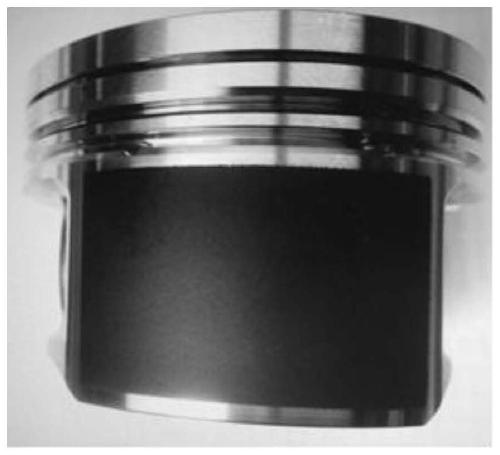

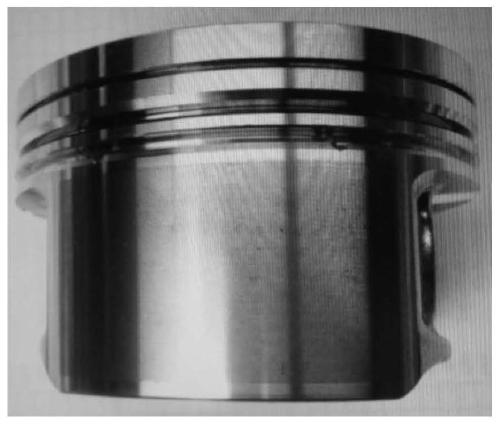

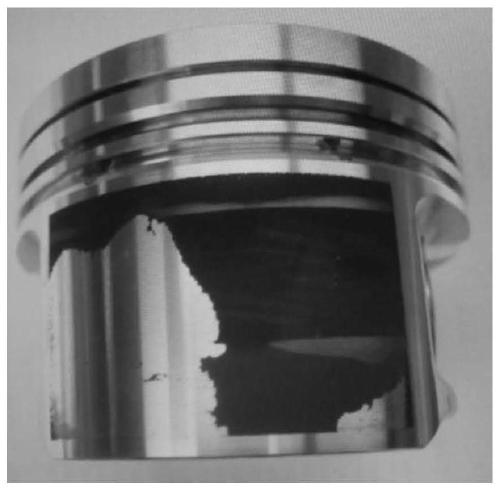

Image

Examples

Embodiment 1

[0030] The invention relates to a printing solution for iron printing coating on the surface treatment of piston skirt, and its raw materials include high temperature resistant resin, stainless steel powder, diluent, curing agent and curing accelerator. Prepare about 5kg of printing liquid, and its specific raw materials and dosage are as follows:

[0031]

[0032] Among them, 100% stainless steel powder particle size < 63 μm, 99.5% stainless steel powder particle size < 40 μm, the same below. According to the printing solution of the iron printing coating used for the surface treatment of the piston skirt of the present invention, the content of the stainless steel powder can be 10% to 15%.

[0033] Compared with printed graphite, due to the high density of iron (stainless steel powder) in the printed iron coating, it is easy to precipitate, and its bonding force with the aluminum substrate is not good. In order to overcome this difficulty, in the formula of the present in...

Embodiment 2

[0035] The invention relates to a printing solution for iron printing coating on the surface treatment of piston skirt, and its raw materials include high temperature resistant resin, stainless steel powder, diluent, curing agent and curing accelerator. Prepare about 5kg of printed iron materials, the specific raw materials and dosage are as follows:

[0036]

Embodiment 3

[0038] The invention relates to a printing solution for iron printing coating on the surface treatment of piston skirt, and its raw materials include high temperature resistant resin, stainless steel powder, diluent, curing agent and curing accelerator. Prepare about 5kg of printed iron materials, the specific raw materials and dosage are as follows:

[0039]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com