Preparation process of TiO2 nanotube/PbS/CuS nanocomposite

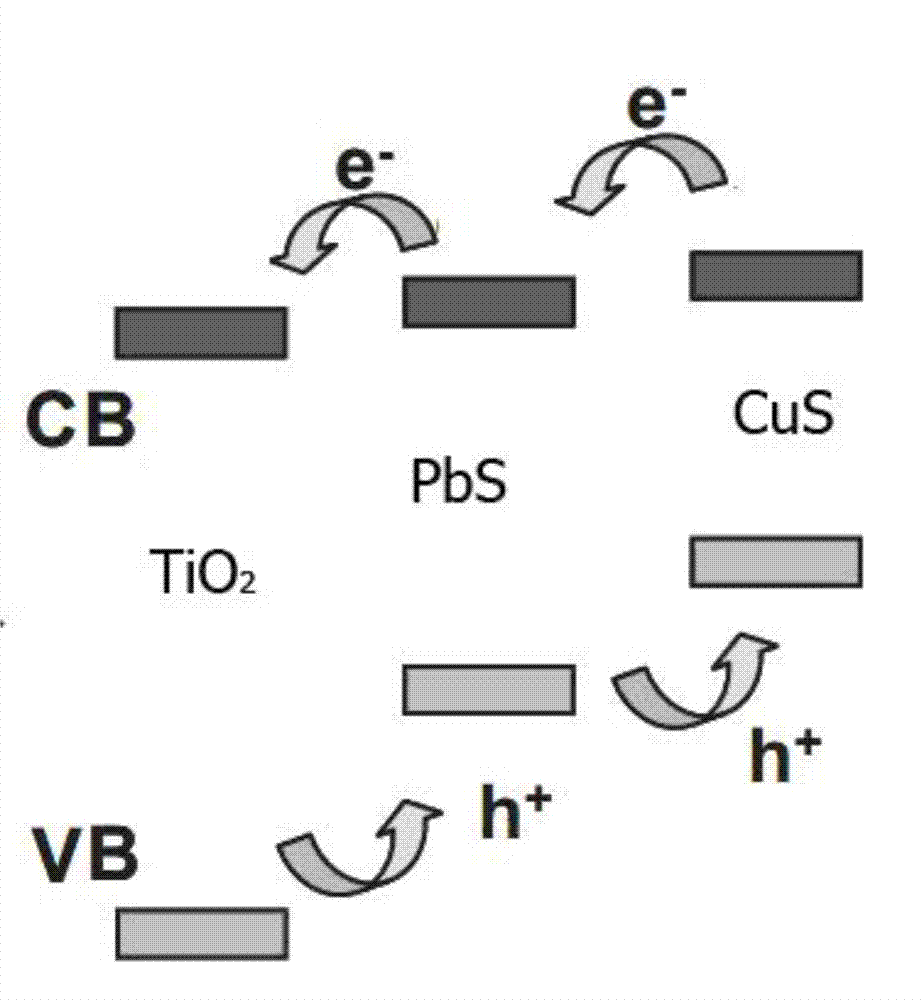

A nano-composite material and preparation process technology, which is applied in the field of preparation technology of multiple nano-structured composite materials, can solve the problems of difficulty in being fully utilized, weak light absorption, low photoelectric conversion efficiency, etc., and achieves simple materials, low preparation cost, and low technology simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A kind of TiO 2 The preparation process of nanotube / nano-PbS / nano-CuS multiple nanostructure composite material consists of the following steps:

[0034] a. Pretreatment of titanium sheet: grind the surface of titanium sheet with a purity of 98.0% until it is bright and traceless, put it into acetone or absolute ethanol for 15 minutes of ultrasonic cleaning, then rinse with deionized water and air dry ;

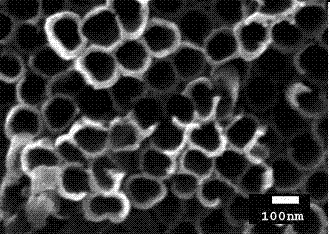

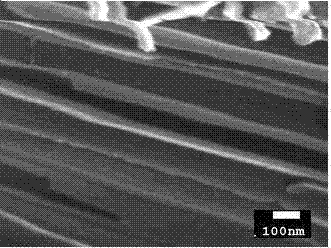

[0035] b. Electrochemical preparation of titanium dioxide nanotube arrays: the platinum sheet was used as the cathode, and the titanium sheet treated in step a was used as the anode, and anodic oxidation was carried out in 0.2% wt ammonium fluoride ethylene glycol solution, the oxidation voltage was 40v, and the oxidation After 20 hours, a titanium dioxide nanotube array with better morphology grows on the surface of the titanium sheet;

[0036] c. Preparation of titanium dioxide nanotube array and nano-lead sulfide particle composite thermal material: take the tita...

Embodiment 2

[0039] A kind of TiO 2 The preparation process of nanotube / nano-PbS / nano-CuS multiple nanostructure composite material is characterized in that it consists of the following steps:

[0040] a. Pretreatment of titanium sheet: After grinding the surface of titanium sheet with a purity of 99.0% until it is bright and traceless, put it in acetone or absolute ethanol for 20 minutes of ultrasonic cleaning, then rinse with deionized water and air dry ;

[0041] b. Electrochemical preparation of titania nanotube arrays: use the platinum sheet as the cathode and the titanium sheet treated in step a as the anode, and perform anodic oxidation in 0.3% wt ammonium fluoride ethylene glycol solution with an oxidation voltage of 50v. After 15 hours, a titanium dioxide nanotube array with better morphology grows on the surface of the titanium sheet;

[0042] c. Preparation of titanium dioxide nanotube array and nano-lead sulfide particle composite thermal material: take the titanium dioxide ...

Embodiment 3

[0045] A TiO2 nanotube / nano-PbS / nano-CuS multiple nanostructure composite material preparation process is characterized in that: it consists of the following steps:

[0046] a. Pretreatment of titanium sheet: grind the surface of titanium sheet with a purity of 99.5% until it is bright and traceless, put it in acetone or absolute ethanol for 20 minutes of ultrasonic cleaning, then rinse with deionized water and air dry ;

[0047] b. Electrochemical preparation of titania nanotube arrays: use the platinum sheet as the cathode, and the titanium sheet treated in step a as the anode, and perform anodic oxidation in 0.4% wt ammonium fluoride ethylene glycol solution with an oxidation voltage of 60v. After 10 hours, a titanium dioxide nanotube array with better morphology grows on the surface of the titanium sheet;

[0048] c. Preparation of titanium dioxide nanotube array and nano-lead sulfide particle composite thermal material: take the titanium dioxide nanotube array sample af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com