An engine load control system

A technology for engine load and control systems, which is applied to circuits or fluid pipelines, transportation and packaging, and vehicle components, etc. It can solve problems such as poor engine output power, poor low-speed torque, and low effective engine output power, and achieve improvement The effective output power and the effect of improving the comfort of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

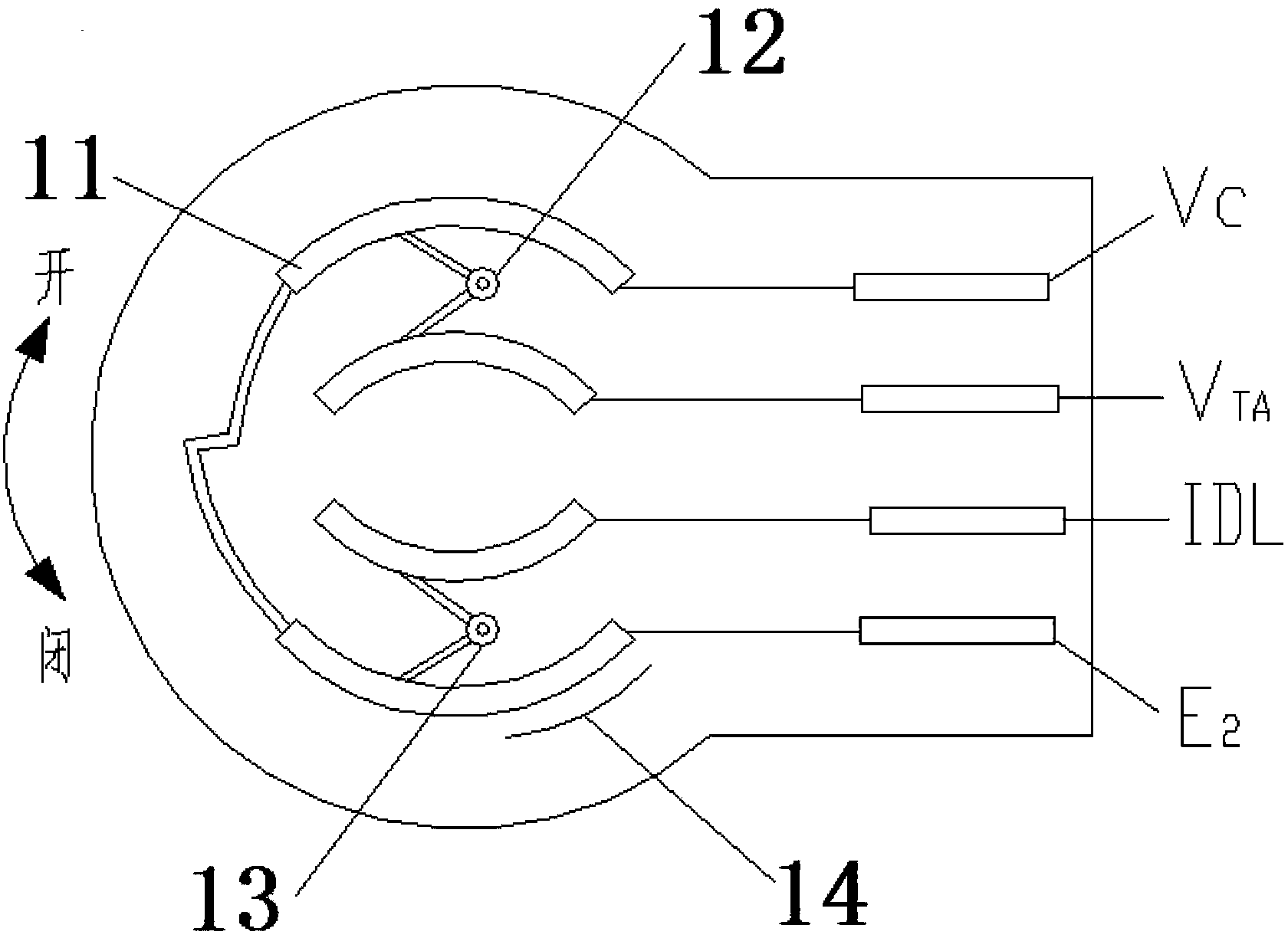

[0019] Throttle position sensor 1 as figure 1 , 2 As shown, a resistive film 11 is provided inside, and the throttle opening signal contact 12 and the idle speed signal contact 13 are located in the resistive film 11, and the throttle opening signal use movable contact 12 and the idle speed signal use movable contact The point 13 slides on the resistance film 11, detects the opening degree of the throttle valve and converts the opening degree signal into a voltage signal, and transmits it to the controller 1 body. Open the resistive film 11 and peripheral parts.

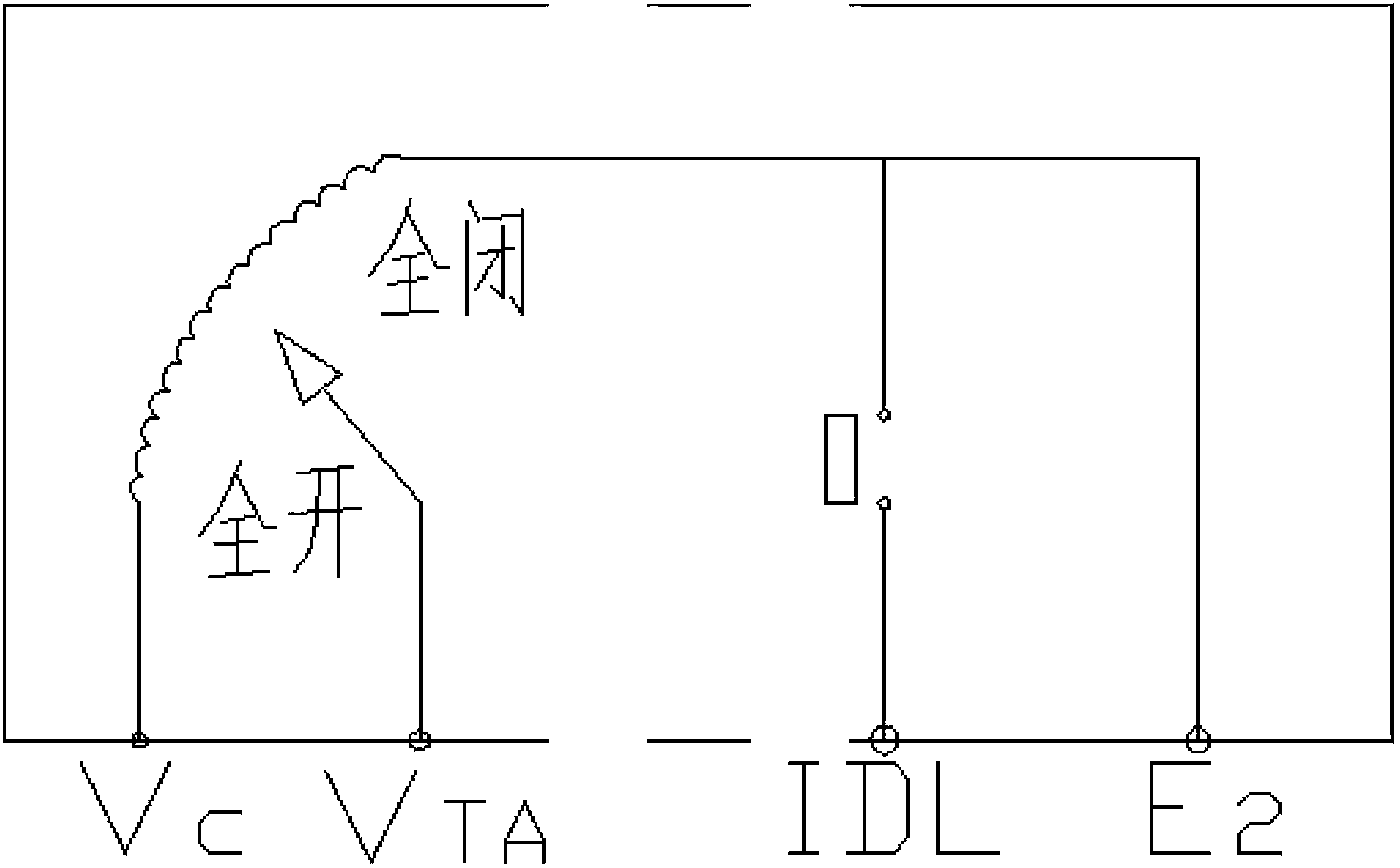

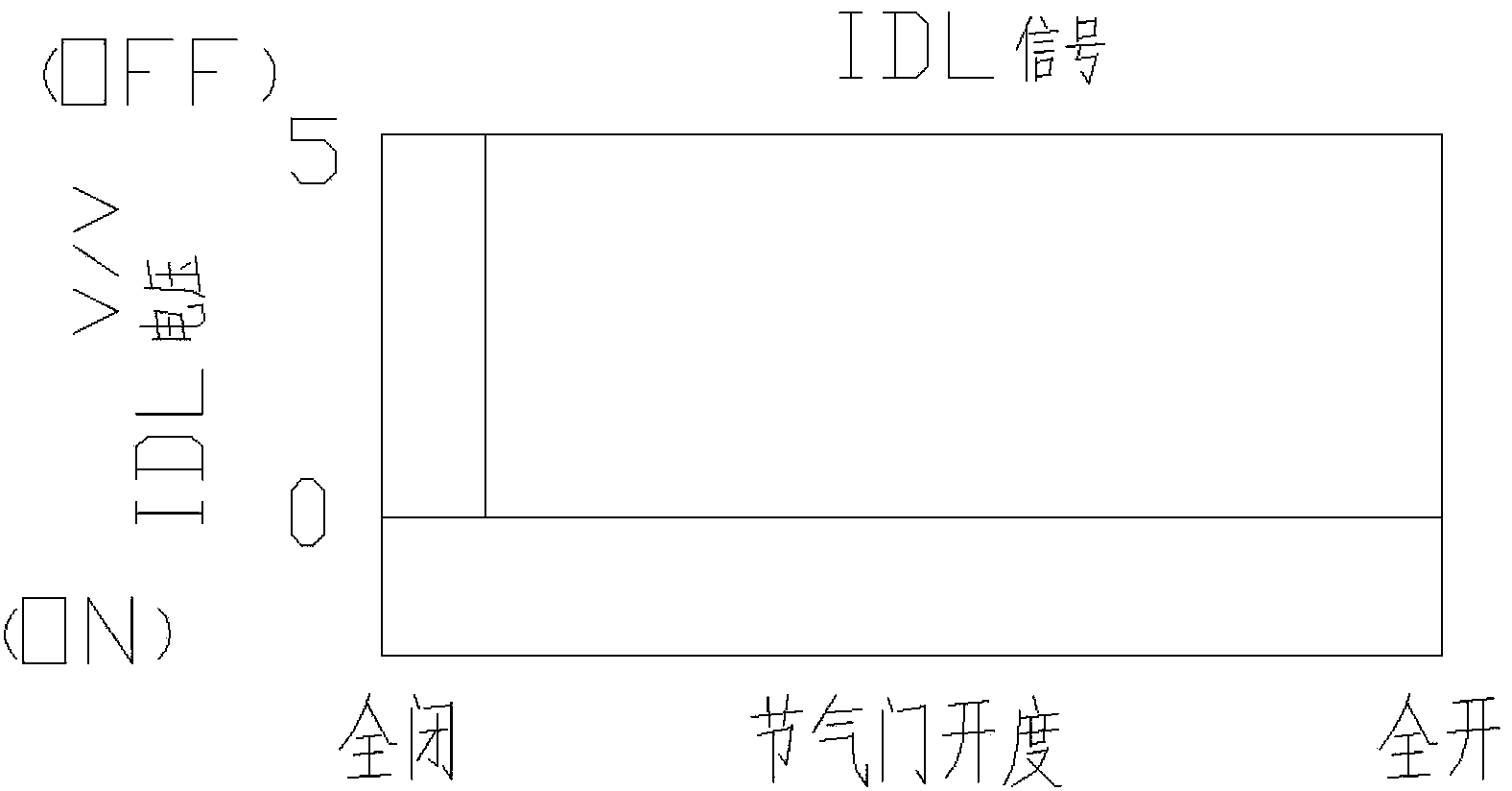

[0020] see image 3 , 4 It can be seen that a constant voltage of 5V is always applied to the VC terminal of the throttle position sensor 1, and the movable contact 12 for the throttle opening signal slides on the resistance film 11 according to the throttle opening, and there will be a voltage on the VTA terminal. Voltage output proportional to throttle opening. When the throttle valve is fully closed, the mova...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com