Method for detecting scrap steel constituent in stainless steel

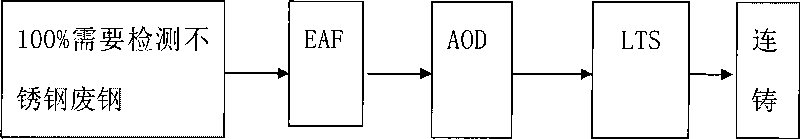

A technology for composition detection and stainless steel, applied in the field of stainless steel, can solve the problems of excessive inclusion content in molten scrap, shorten the smelting time, reduce the consumption of refractory materials, and avoid mismatches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] In order to reduce the oxidation of metal chromium, which is easily oxidized in melting furnaces, and improve the detection accuracy of stainless steel scrap components, the total silicon addition is strictly controlled (the total silicon addition is 8.5~12Kg / t), so as to reduce the oxidation of chromium in the mother liquor. The batching mode, power supply mode and operating points corresponding to the melting furnace are as follows:

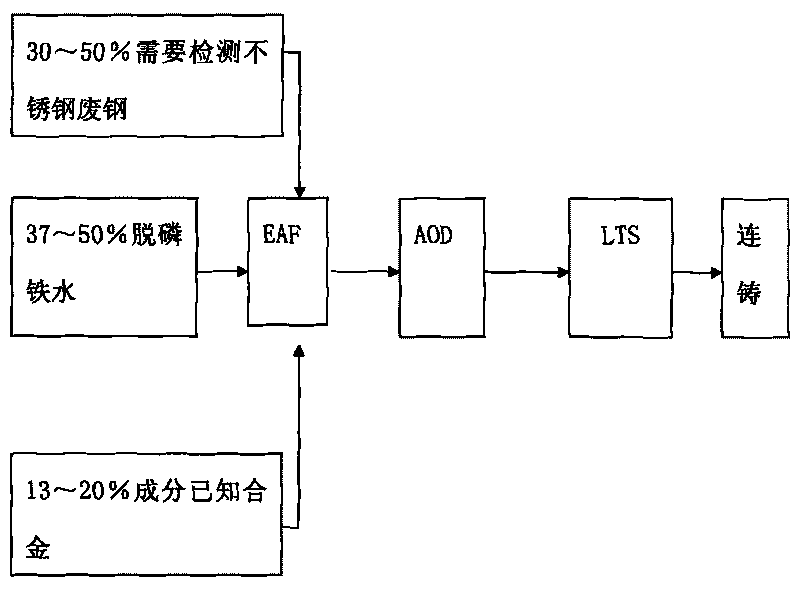

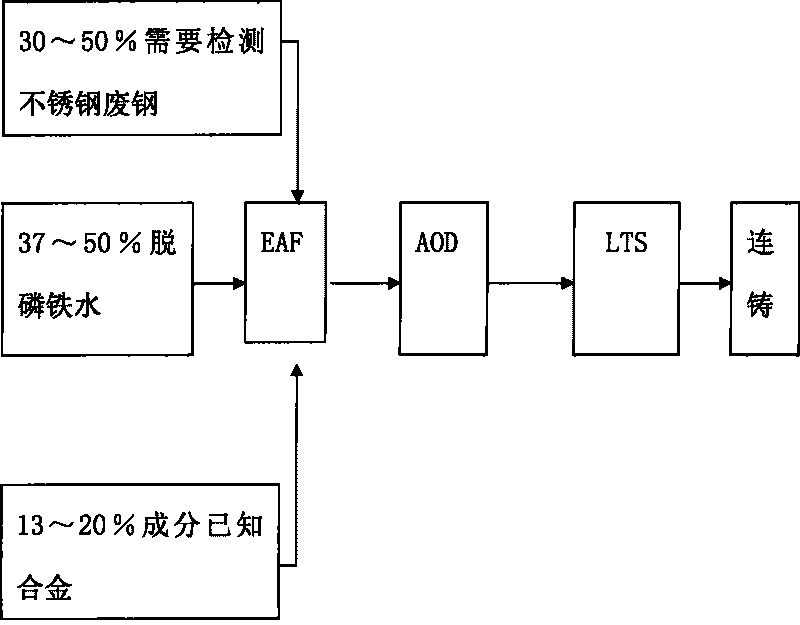

[0036] 1. Ingredients mode

[0037] Batching mode corresponding to melting furnace

[0038]

[0039] 2. Corresponding power supply mode

[0040]

[0041]

[0042] 3. Operation points corresponding to melting furnace times

[0043] 1) The added amount of total silicon is 9.2Kg / t (total metal added amount).

[0044] 2) When the power consumption is 202Kwh / t, the oxygen blowing volume is 4m 3 / t.

[0045] 3) When the power reaches 312Kwh / t (calculated according to the amount added), take a sample (slag sample) and start reduct...

Embodiment 2

[0053] In order to reduce the oxidation of metal chromium, which is easily oxidized in the melting furnace, and improve the detection accuracy of stainless steel scrap components, the batching is to strictly control the total silicon addition (the total silicon addition is 8.5-12Kg / t), and reduce the oxidation of chromium in the mother liquor. The second corresponding batching mode, power supply mode and operation points of the melting furnace are as follows:

[0054] 1. Ingredients mode

[0055] Batching mode corresponding to melting furnace

[0056]

[0057] 2. Corresponding power supply mode

[0058]

[0059]

[0060] 3. Operation points corresponding to melting furnace times

[0061] 1) The added amount of total silicon is 12Kg / t (total metal added amount).

[0062] 2) When the power consumption is 189Kwh / t, the oxygen blowing volume is 6m 3 / t.

[0063] 3) When the power reaches 286Kwh / t (calculated according to the amount added), take a sample (slag sample) a...

Embodiment 3

[0071] In order to reduce the oxidation of metal chromium, which is easily oxidized in melting furnaces, and improve the detection accuracy of stainless steel scrap components, the total silicon addition is strictly controlled (the total silicon addition is 8.5~12Kg / t), so as to reduce the oxidation of chromium in the mother liquor. The second corresponding batching mode, power supply mode and operation points of the melting furnace are as follows:

[0072] 1. Ingredients mode

[0073] Batching mode corresponding to melting furnace

[0074]

[0075]

[0076] 2. Corresponding power supply mode

[0077]

[0078] 3. Operation points corresponding to melting furnace times

[0079] 1) The added amount of total silicon is 8.5Kg / t (total metal added amount).

[0080] 2) When the power reaches 297Kwh / t (calculated according to the amount added), take a sample (slag sample) and start reduction. Add 1.5kg / t of ferrosilicon for reduction, and spray 2.0kg / t of ferrosilicon po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com