Patents

Literature

56 results about "Vacuum fusion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Vacuum fusion is an analytical chemistry technique, used for determining the oxygen, hydrogen, and sometimes nitrogen content of metals. While ineffective when used on alkali or earth metals, vacuum fusion remains a viable means when applied to almost all other metals.

Hyperbranched polyester modified acrylic resin and preparation method thereof

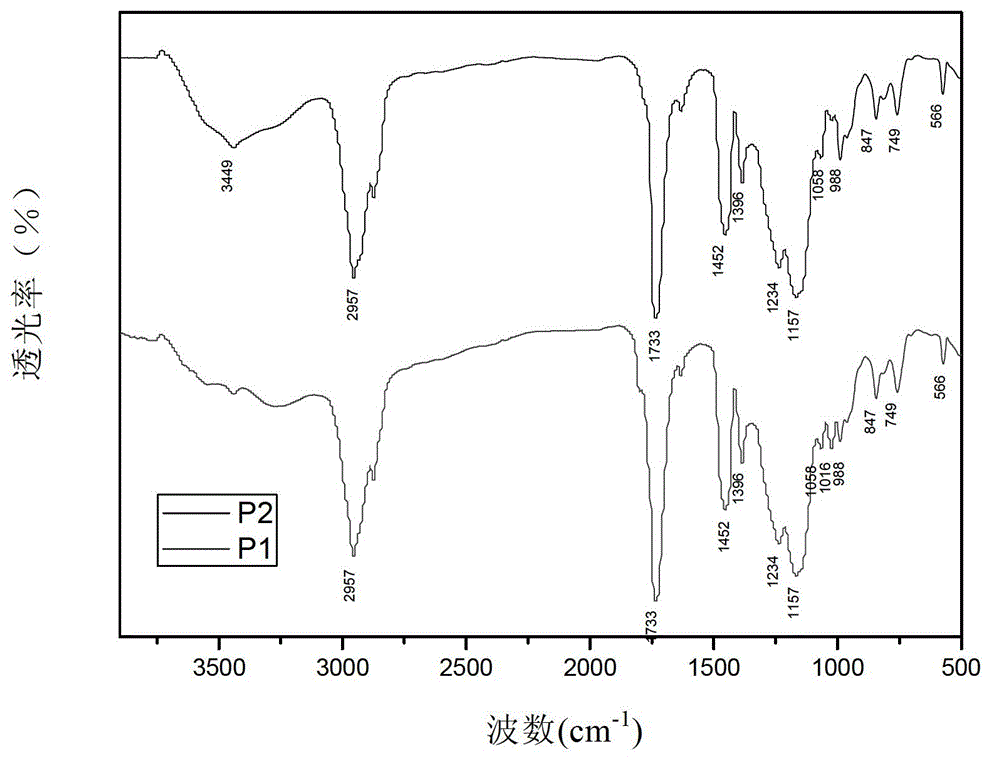

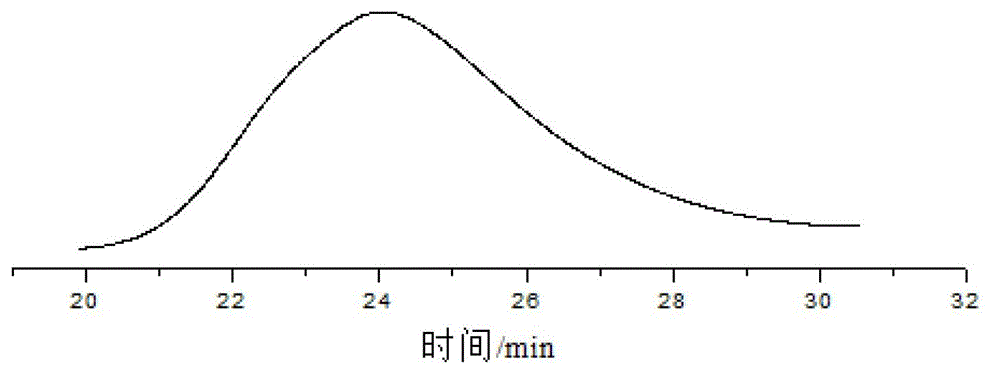

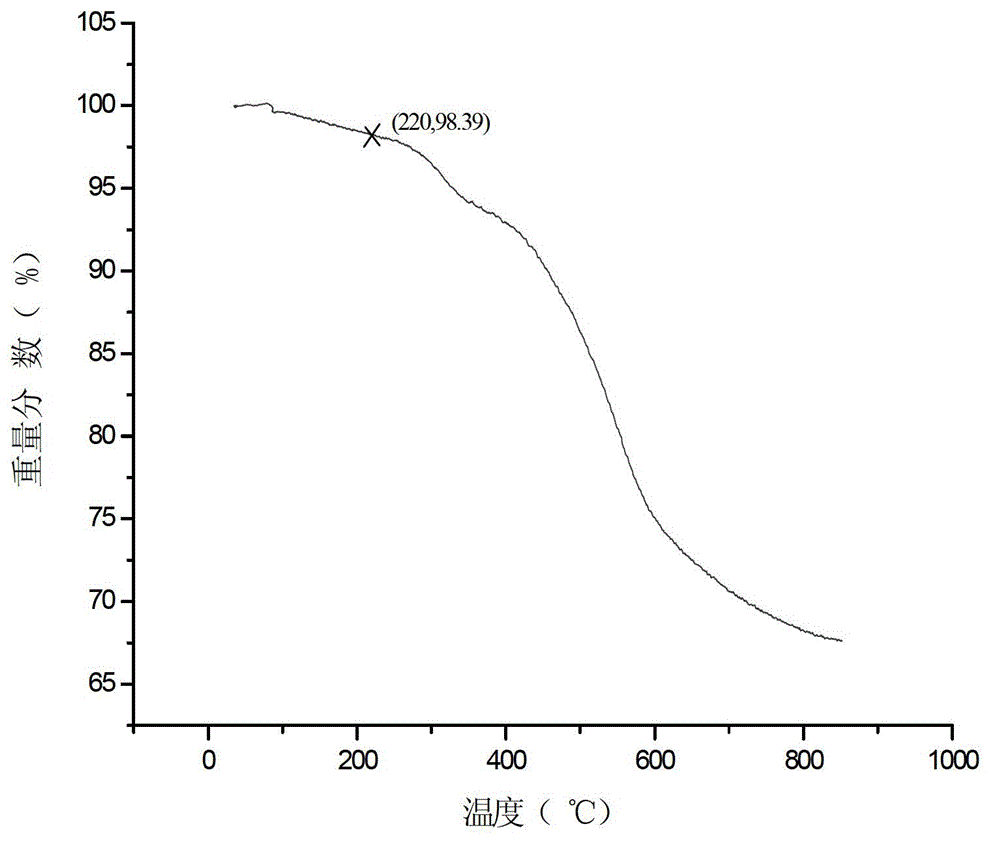

The invention relates to hyperbranched polyester modified acrylic resin and a preparation method thereof. Firstly, a By-type polyhydroxylated compound is taken as nuclear molecules (wherein B represents hydroxyl, and the degree of functionality y of B is larger than of equal to 2), ABx-type polyhydroxy acid is taken as divergence molecules (wherein A represents carboxyl, B represents hydroxyl and x represents the degree of functionality of hydroxyl and is larger than or equal to 2), a polyester-type hyperbranched polymer with hydroxyl at the terminal is obtained through a vacuum fusion polycondensation method, and esterification reaction is performed on prepared hyperbranched polyester and acrylic resin with carboxyl in the presence of a water-carrying agent to obtain hyperbranched polyester modified acrylic resin. Acrylate with hyperbranched polyester introduced enriches a great amount of hydroxyl, and is taken as a cross-linking group to greatly reduce the curing time of a coating film; and at the same time, hyperbranched polyester has excellent performance of dendritic polymer, molecular chains are not easily twisted, and hyperbranched polyester modified acrylic resin with high solidity and low viscosity can be obtained. According to the invention, the source of raw materials is wide, the price of the raw materials is low, the synthetic method is simple, the controllability is good, and the production cost is low.

Owner:ETERNAL CHEM (CHINA) CO LTD

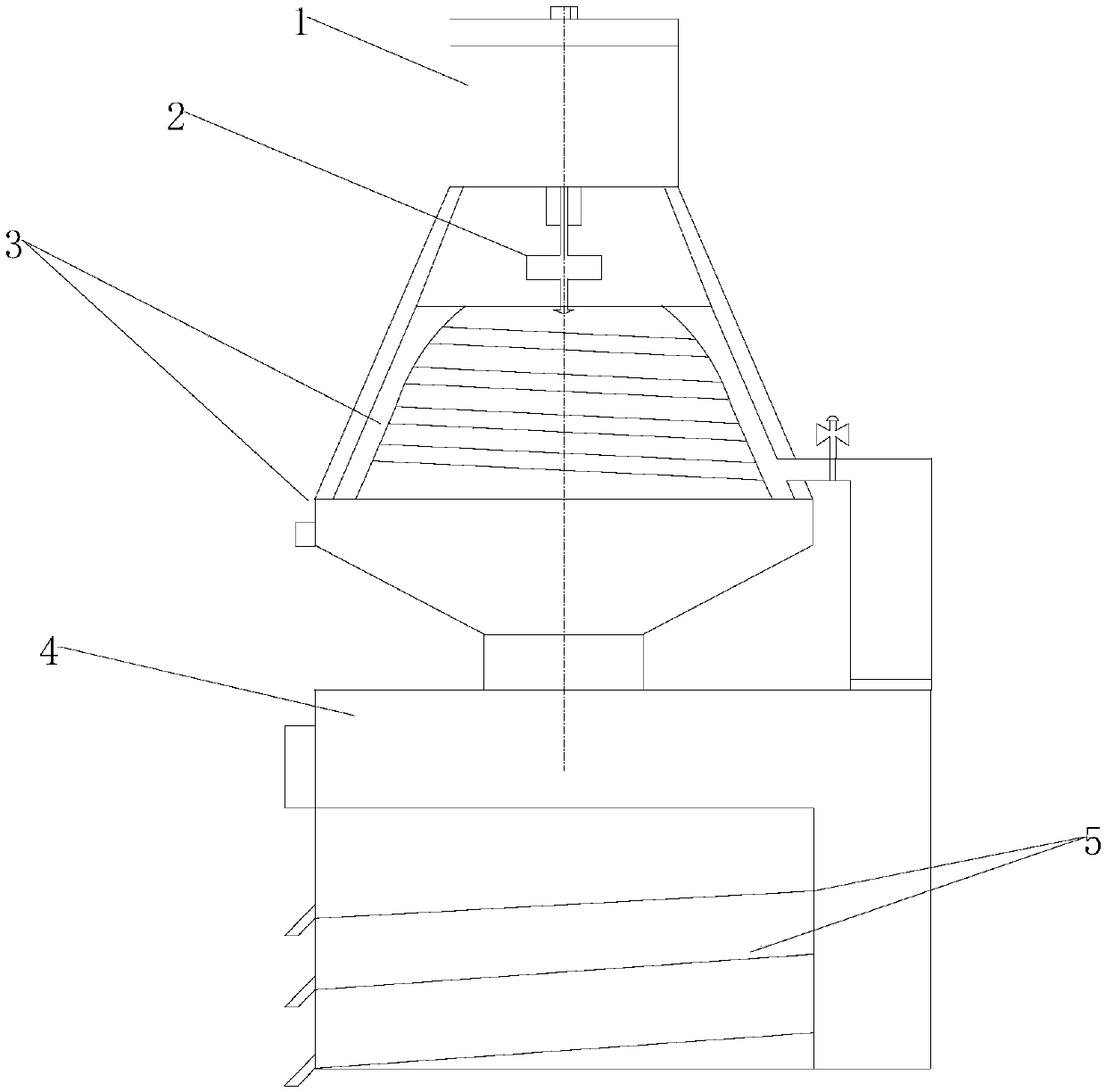

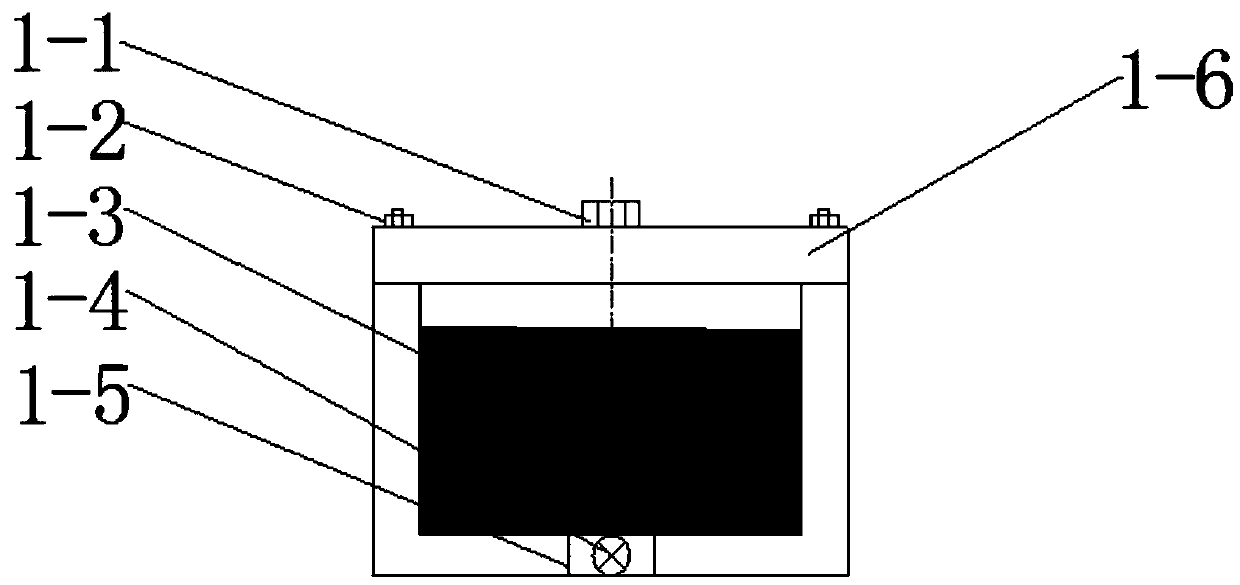

Device for preparing metal amorphous powder through ultrasonic atomization recooling method

The invention relates to an amorphous powder ultrasonic atomization device, in particular to novel ultrasonic atomization metal amorphous powder preparing equipment integrating fusion, ultrasonic atomization, a liquid nitrogen and water secondary recooling system, vacuum drying and discharging screening and collecting. A vacuum fusion crucible is used for fusing raw materials into metal fusion liquid. The metal fusion liquid becomes atomized globular liquid drops under the effect of an ultrasonic atomizer. The metal liquid drops are quickly cooled through liquid nitrogen and cooling water to form metal particles. The metal particles are dried through a vacuum drying oven. The dried metal particles are screened and collected. The amorphous powder preparing method is suitable for metal, quasicrystals and microcrystals.

Owner:CHANGZHOU UNIV

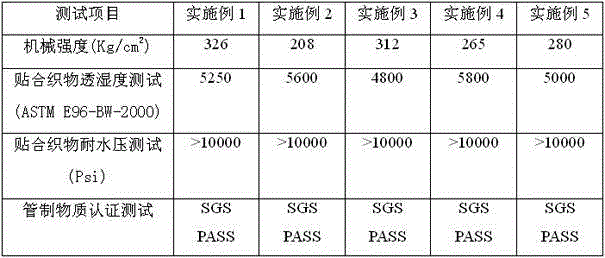

Water-proof moisture-permeable polyurethane thermoplasticity elastomer and preparation method thereof

The invention relates to the technical field of the thermoplasticity elastomer, in particular to a water-proof moisture-permeable polyurethane thermoplasticity elastomer and a preparation method thereof. The water-proof moisture-permeable polyurethane thermoplasticity elastomer is prepared from polyurethane colloidal particles, wherein the polyurethane colloidal particles are prepared from the following raw materials in parts by weight: 40-90 parts of polyester polyol or polyether polyol, 15-45 parts of diisocyanate and 3-12 parts of chain extender; the polyester polyol is obtained in a way that at least one of polyatomic acid and polyester and polyhydric alcohol are subjected to dealcoholization and dehydration condensation according to a mole ratio of 1to (1.01-1.2) in a vacuum fusion method, the hydroxyl value of the polyester polyol is 20-120mgKOH / g, and the acid value of the polyester polyol is 0.1-2mgKOH / g. The thermoplasticity elastomer has the advantages of good plasticization processing, high natural degradation speed and environmental protection, can be regulated according to the moisture-permeable requirements and can also resist bacteria and avoid dust mists.

Owner:东莞宏石功能材料科技有限公司

Preparation technique for cuprum peptide-cuprum nickel compensating conductor and alloy wire thereof

ActiveCN101231197AAmbient temperature is high and wideHigh compensation accuracyThermometers using electric/magnetic elementsUsing electrical meansElectrical conductorVacuum fusion

The invention relates to the technical field of temperature-measuring element, in particular to a compensation lead of copper titanic to copper nickel and a preparation process of alloy wires of the compensation lead, wherein, a positive pole conductor of the compensation lead is copper titanic alloy wires, and a weight percentage of the chemical composition is 0.3-1.5 percent of titanic, 0.04-0.06 percent of rare earth, impurities with a percentage no larger than 0.087 percent and excess copper; a negative pole conductor of the compensation lead is copper nickel alloy wires, and a weight percentage of the chemical composition of which is 16-18.5 percent of, 0.3-1.2 percent of manganese, 0.08-0.21 percent of silicon, 0.005-0.015 percent of carbon, 0.04-0.06 percent of rare earth, impurities with a percentage no larger than 0.107 percent and excess nickel. The copper titanic alloy wires and the copper nickel alloy wires have the technical process of raw material preparation, vacuum fusion, hot forging, hot rolling, annealing of hot rolling flan, a process from drawing to annealing with a repetition of three times, and finished product detection and package for leaving factories. The ambient temperature used by the invention is high and wide with a range from -55 DEG C to 300 DEG C, and the invention has the advantages of high precision compensation with a precision level, reduction of raw material cost of 60 percent.

Owner:袁勤华

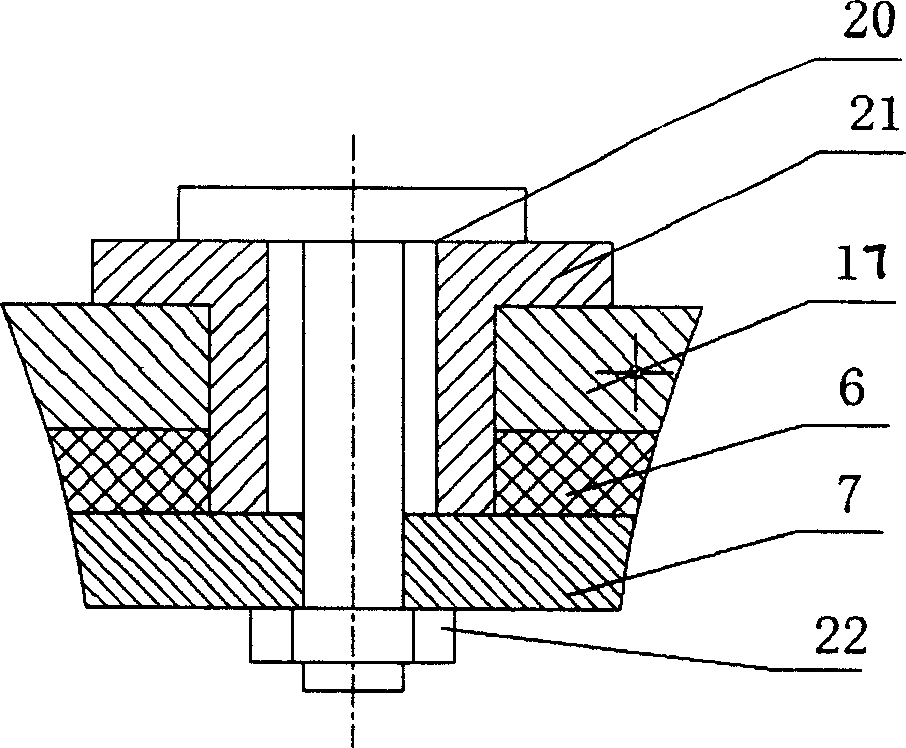

Vacuum fusion welding packaging method and packaging device

InactiveCN1951619AGuaranteed EncapsulationEasy to useResistance welding apparatusVacuum fusionNitrogen

The invention relates to a vacuum welding packing method and relative packing device. Wherein, said method comprises that: (1), putting the tube base (14) and tube cap (13) in vacuum chamber (5); vacuuming the vacuum chamber (5), or heating it to remove gas; (3), powering and welding to weld the tube base (14) and tube cap (13). And in inventive device, the movable electrode (3) is connected to the piston rod (21) of driving cylinder (1); the nitrogen tank (4) is around the vacuum chamber (5); the vacuum chamber (5) via vale (7) is connected to the nitrogen tank (4); the outer wall of chamber (5) is coiled with heating sheath (6); the vacuuming system (10) is through to the vacuum chamber (5); the ends of movable electrode (3) and stable electrode (9) are inserted into chamber (5). The invention has high package degree, short welding time and high vacuum degree.

Owner:甘志银

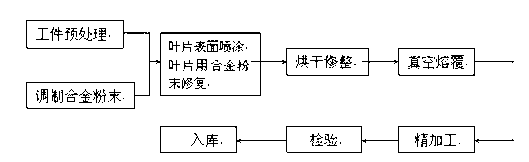

Fracturing pump valve body and valve seat vacuum fusion covering surface strengthening method

Provided is a fracturing pump valve body and valve seat vacuum fusion covering surface strengthening method. A vacuum fusion covering method is used, nickel-based self-fusion alloy powder is used as raw materials, WC hard strengthening phase powder is added, and a high-abrasion-resistance high-corrosion-resistance high-impact-resistance coating layer is manufactured on the surfaces of a valve body and a valve seat of a fracturing pump. The method comprises the processing steps of workpiece surface preprocessing, ball milling material mixing, slurry forming, workpiece surface coating, drying and vacuum sintering in sequence. The ingredient components comprise, by weight, 5%-30% of WC powder and 70%-95% of Ni-Cr-Mo-Fe-B-Si-C alloy powder. The prepared fusion covering coating layer is high in density and small in internal stress, the coating layer and a base body are well combined in a metallurgical mode, the abrasion resistance, the corrosion resistance, the impact resistance and the like of the surface of the fusion covering coating layer of the valve body and the valve seat are greatly improved, accordingly, the service life of the valve body and the valve seat is effectively prolonged, technology operation is easy, the raw material using rate is high, cost is low, processing property is stable, and the method is suitable for mass production.

Owner:UNIV OF SCI & TECH BEIJING

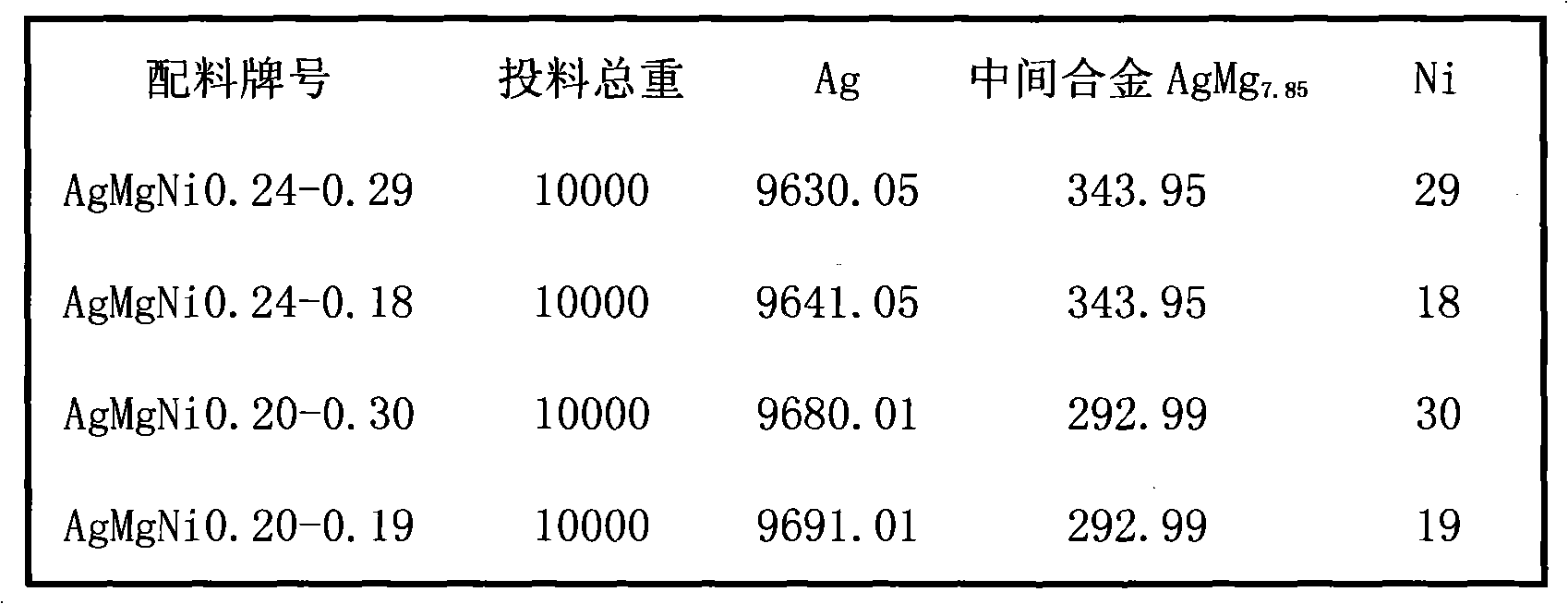

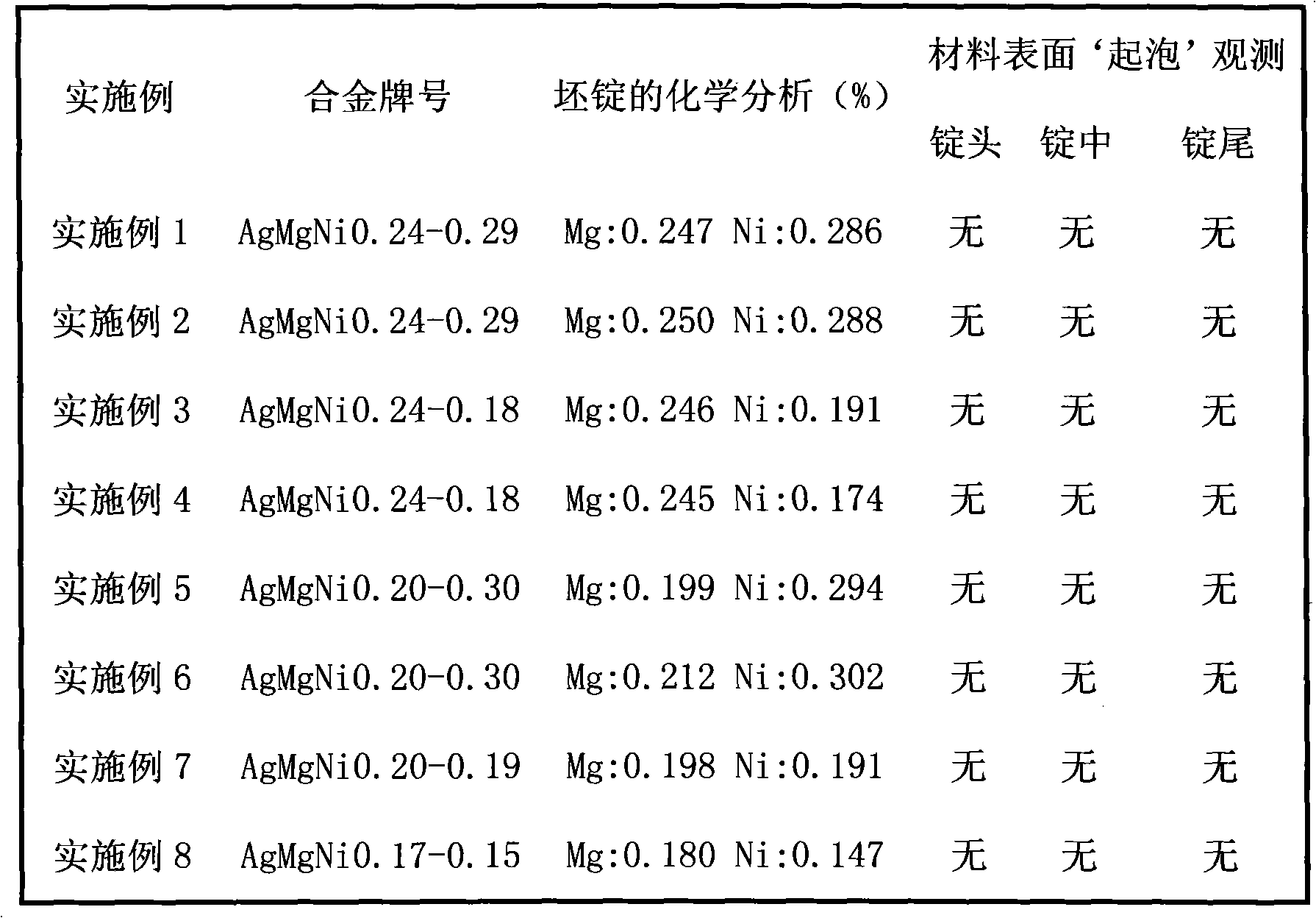

Method for preparing silver-magnesium-nickel alloy billets

The invention discloses a method for preparing silver-magnesium-nickel alloy billets, which comprises the following steps of: preparing silver-magnesium intermediate alloy from Ag and Mg alloy elements by adopting a vacuum fusion casting technique; and proportioning Ag and Ni alloy elements and the silver-magnesium intermediate alloy according to a component proportion of a silver-magnesium-nickel alloy mark, putting the silver-magnesium intermediate alloy and Ni into a multistage charging system by using a vacuum intermediate-frequency induction furnace capable of performing multistage charging in vacuum respectively, and preparing the silver-magnesium-nickel alloy billets by precision processes of degassing, refining, heat insulation and the like. The gas content of the Ag and the oxidation of the magnesium are effectively controlled, the billets prepared by casting molding are directly prepared into plates, sheets or strips by cold-rolling processing, internal oxidation (800 DEG C / 2h) is performed in air by using a resistance furnace, and 'bubbles' are not produced on the surface of the material. The method for preparing the silver-magnesium-nickel alloy billets solves the problems that the burning loss of a little amount of additive component Mg is not easy to control and the plates and the strips prepared from a casting blank by cold rolling produce 'bubbles' on the internal oxidation surface in the atmosphere, and provides stable process guarantee for subsequent use of the materials.

Owner:SINO PLATINUM METALS CO LTD

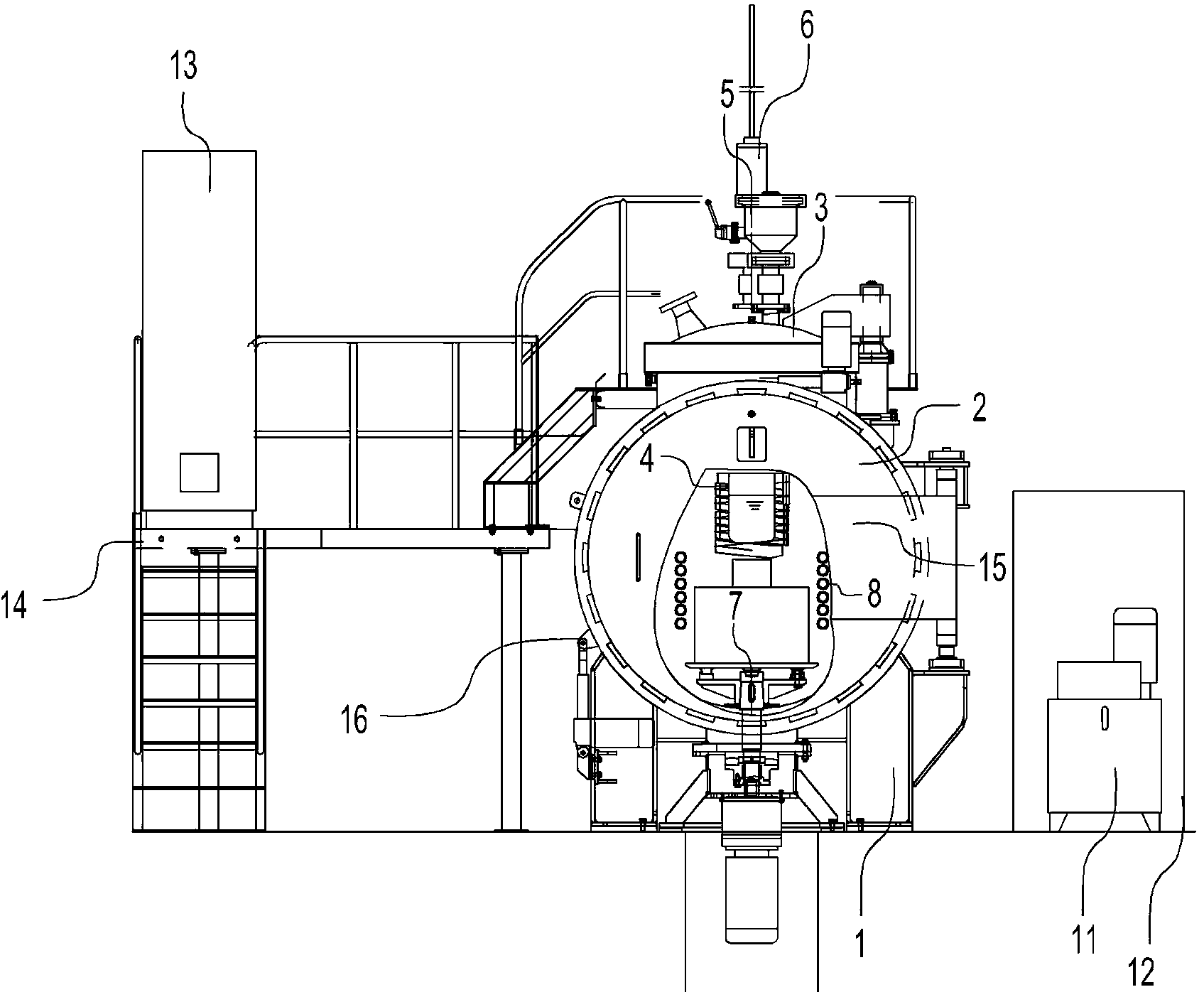

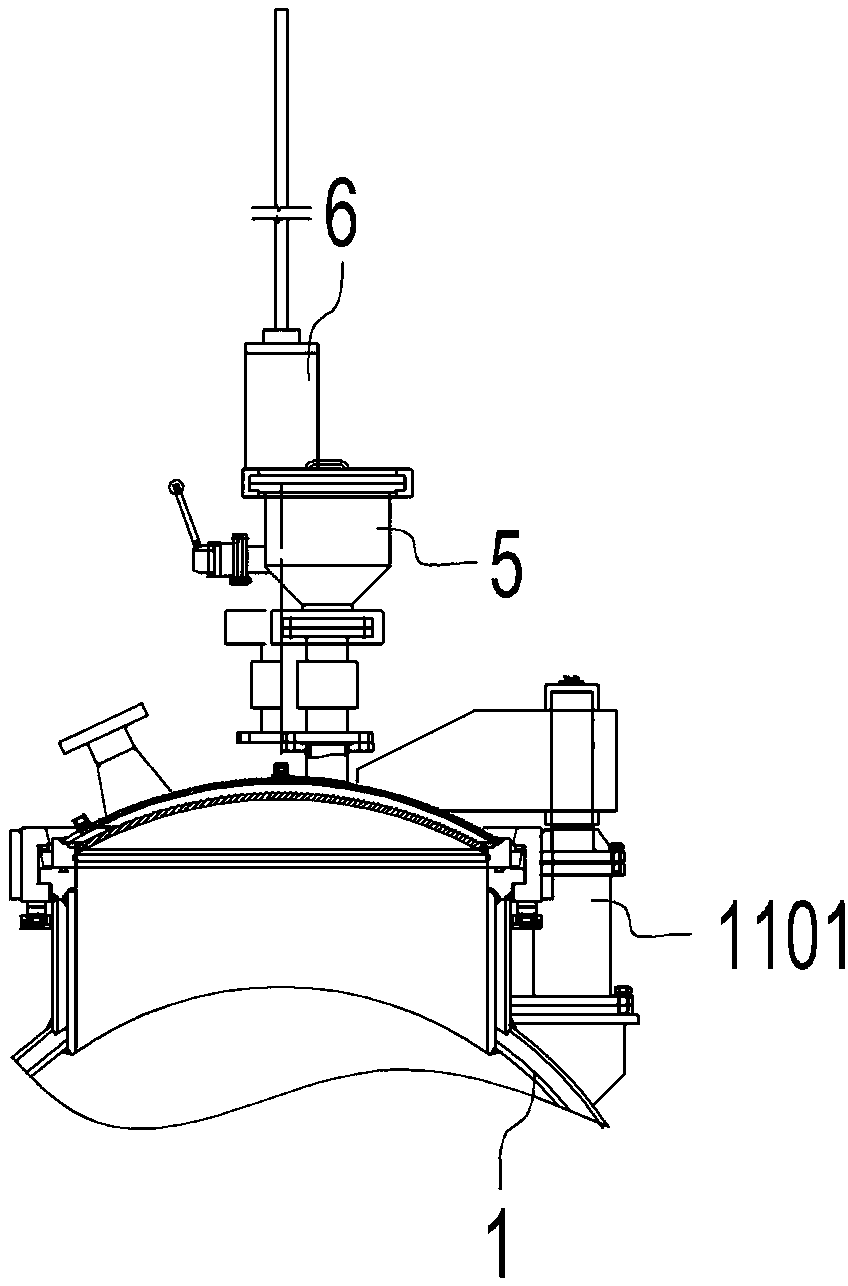

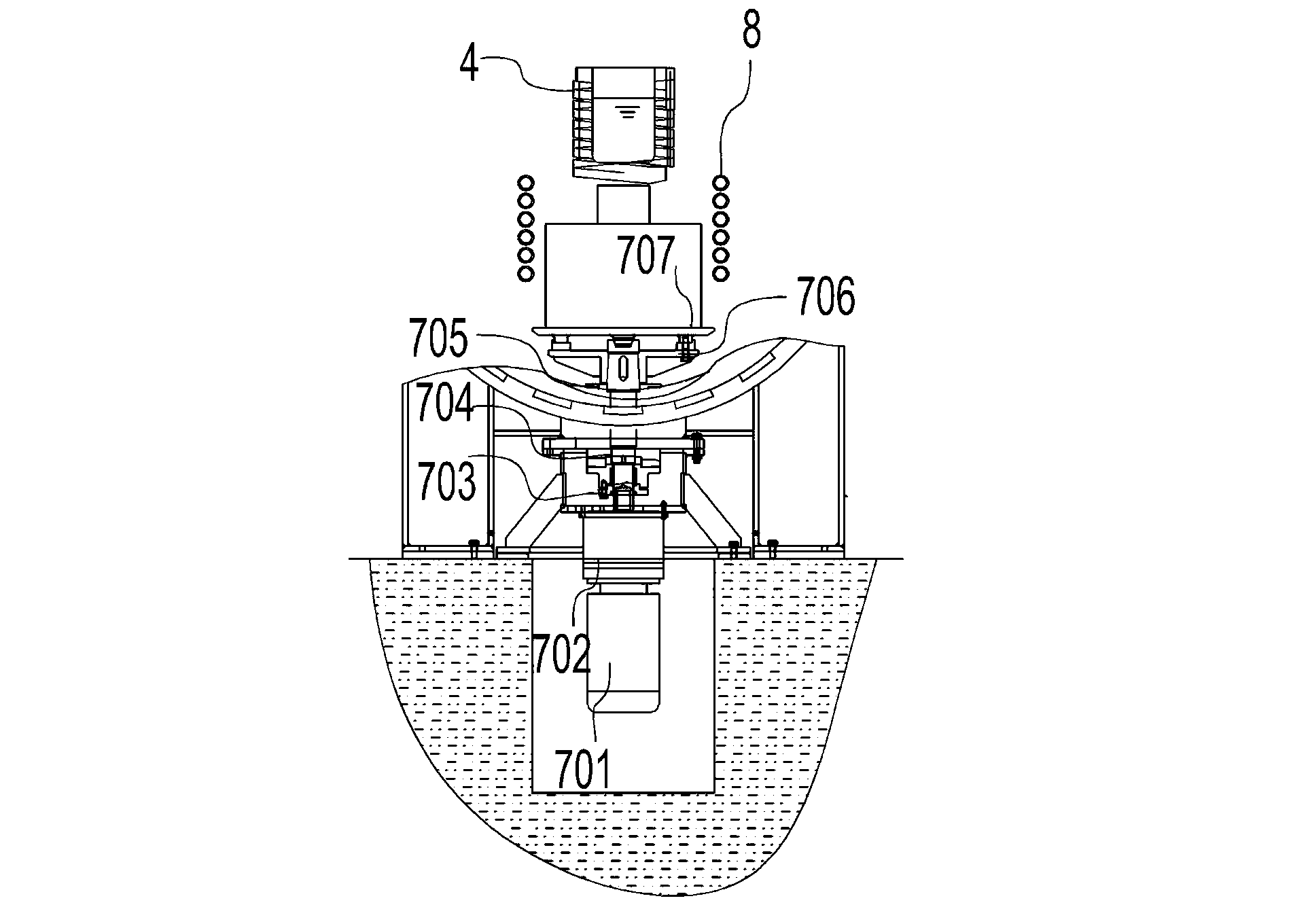

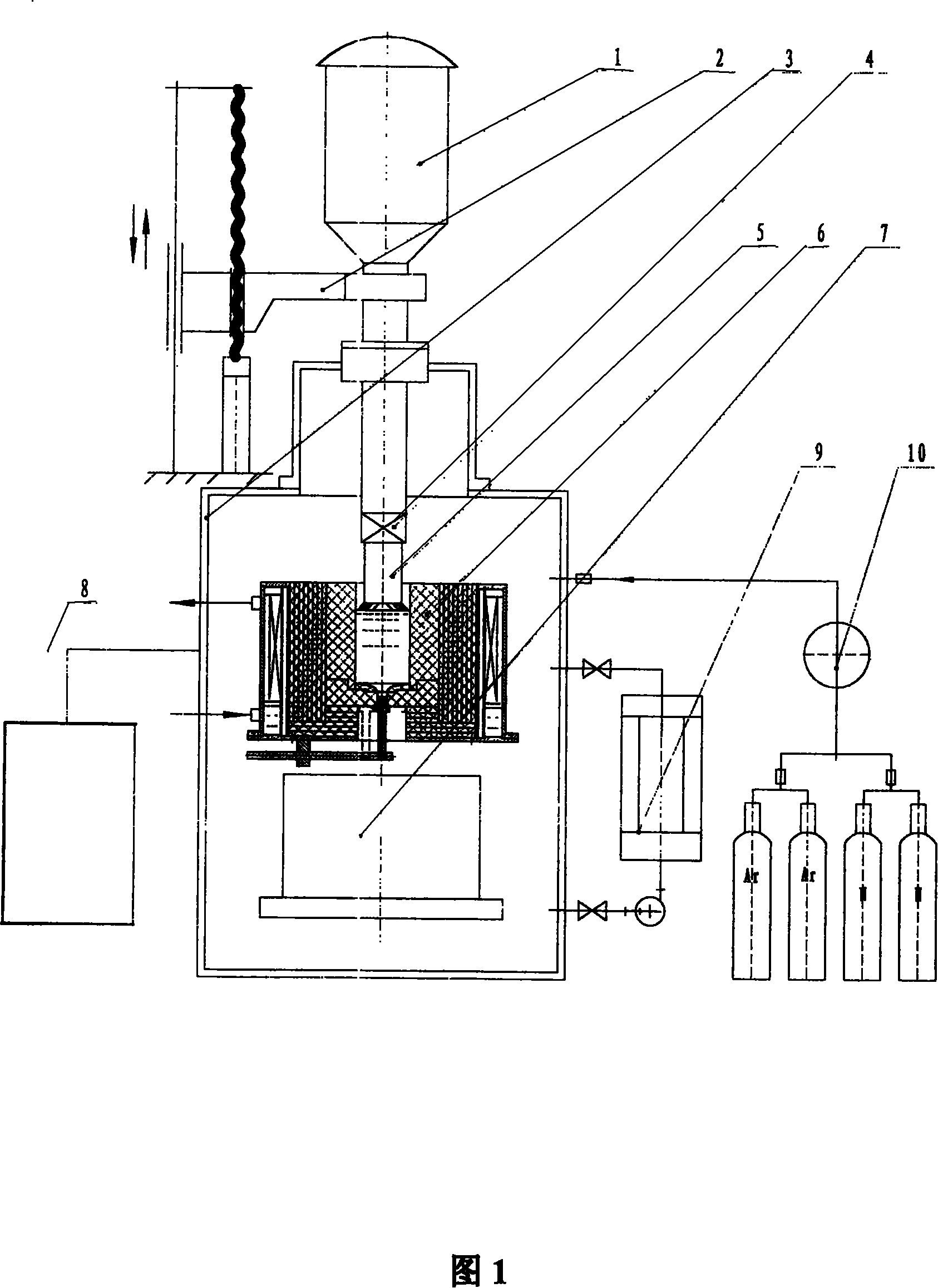

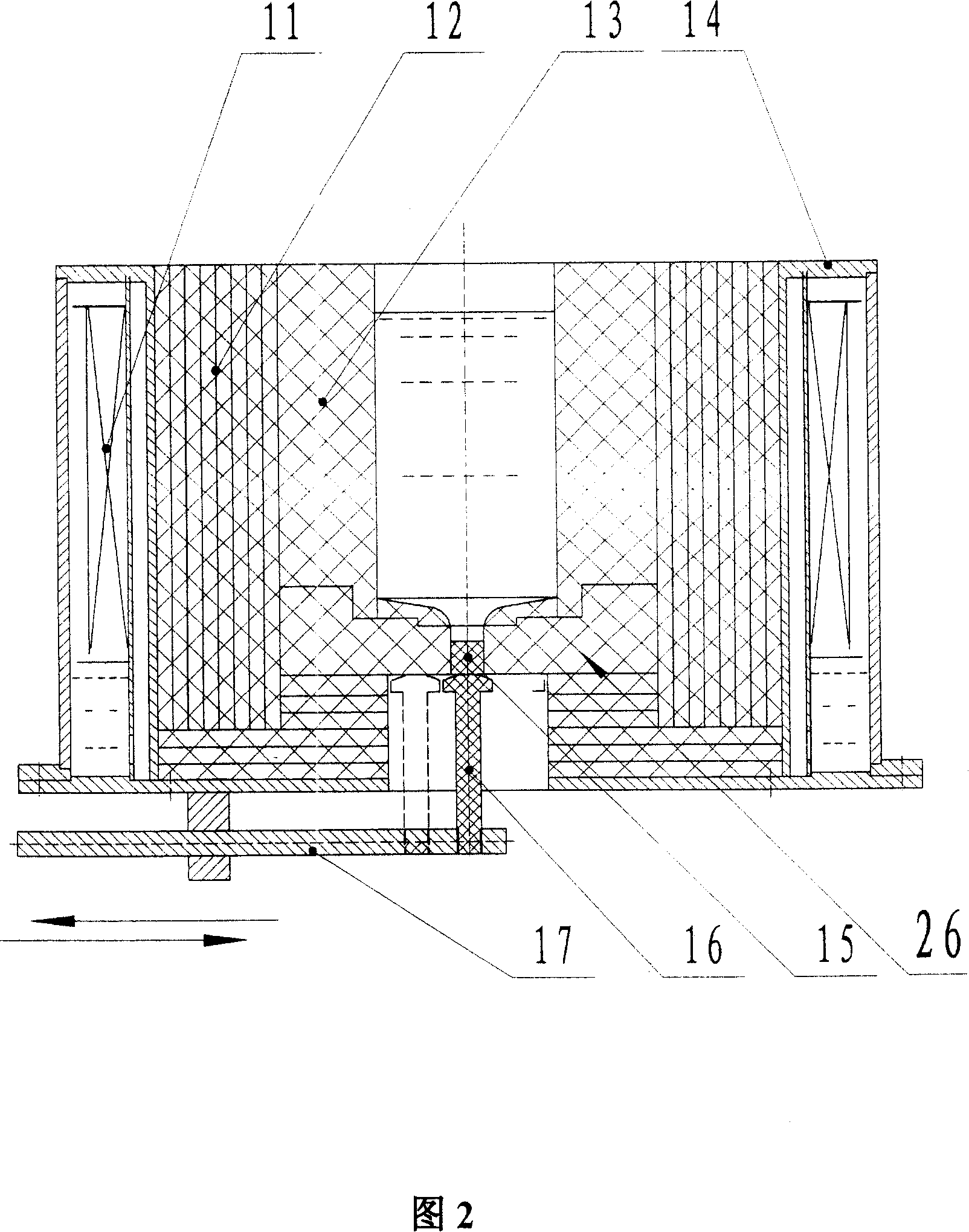

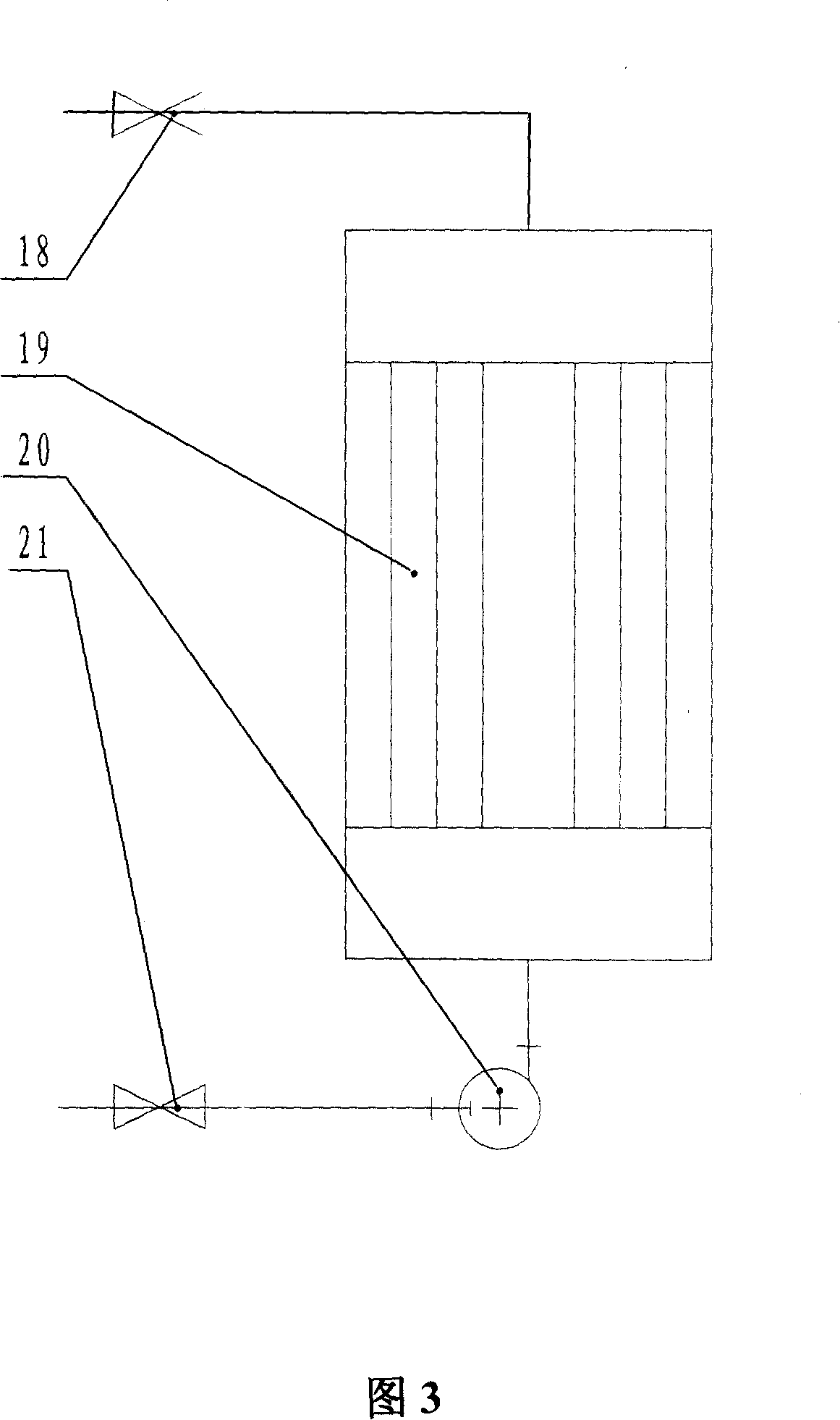

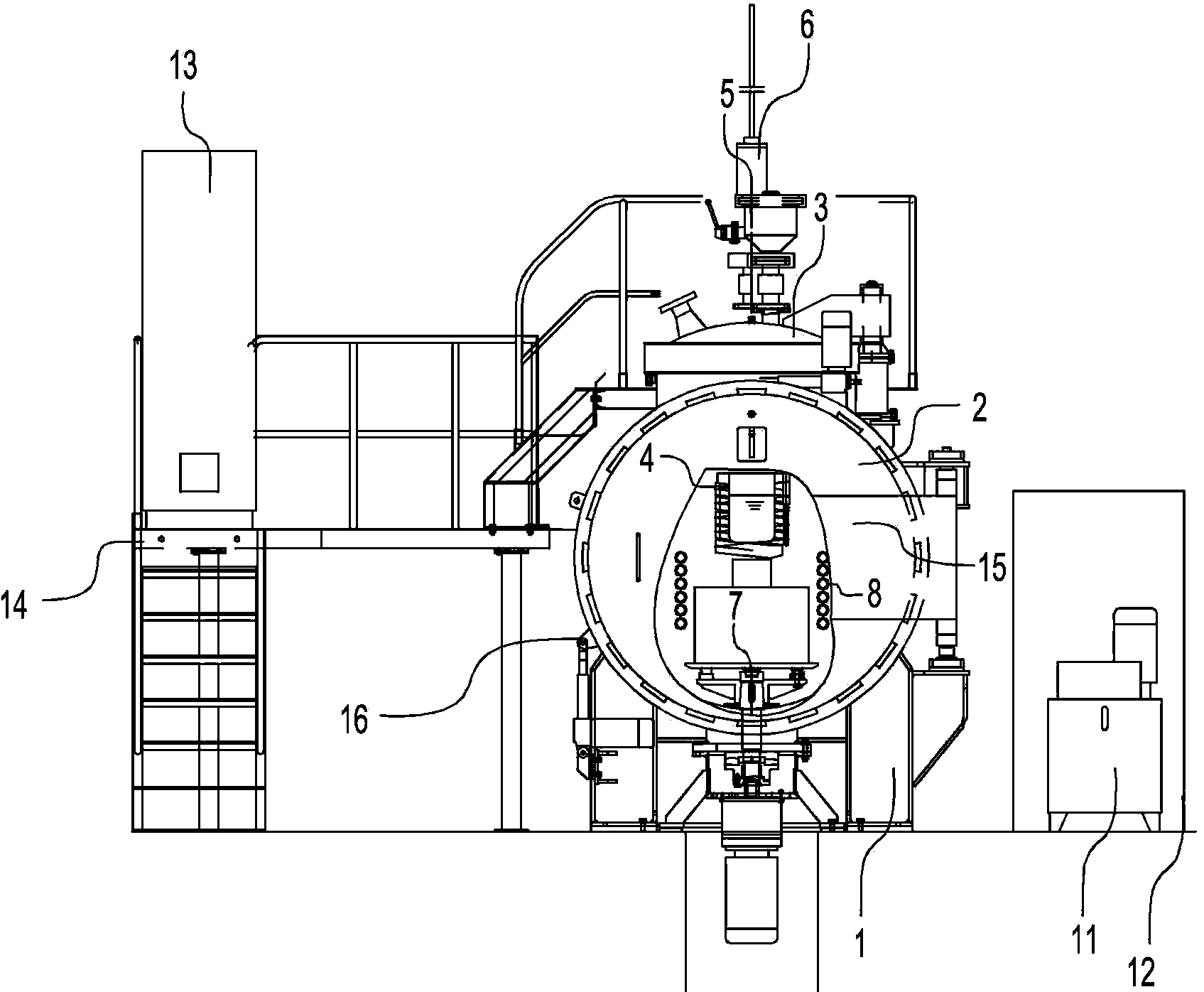

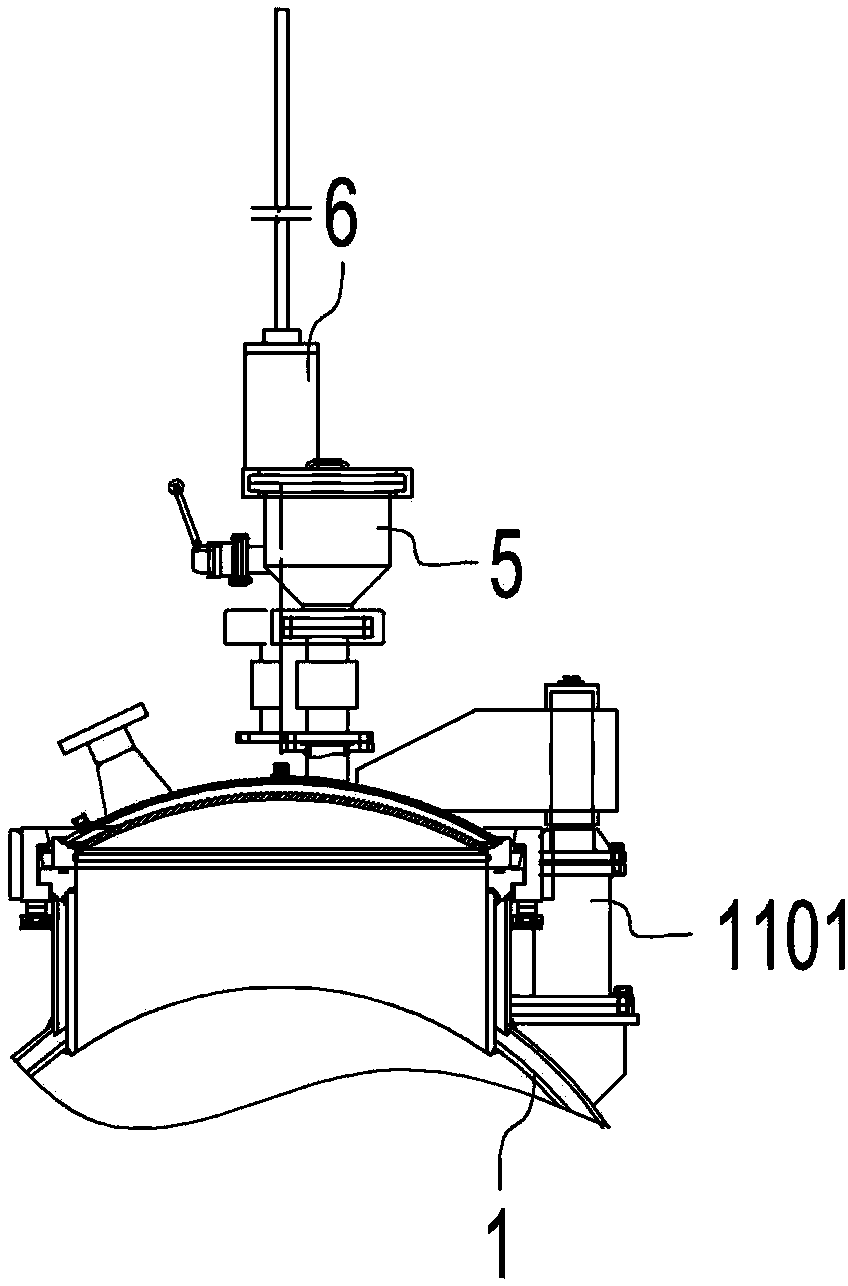

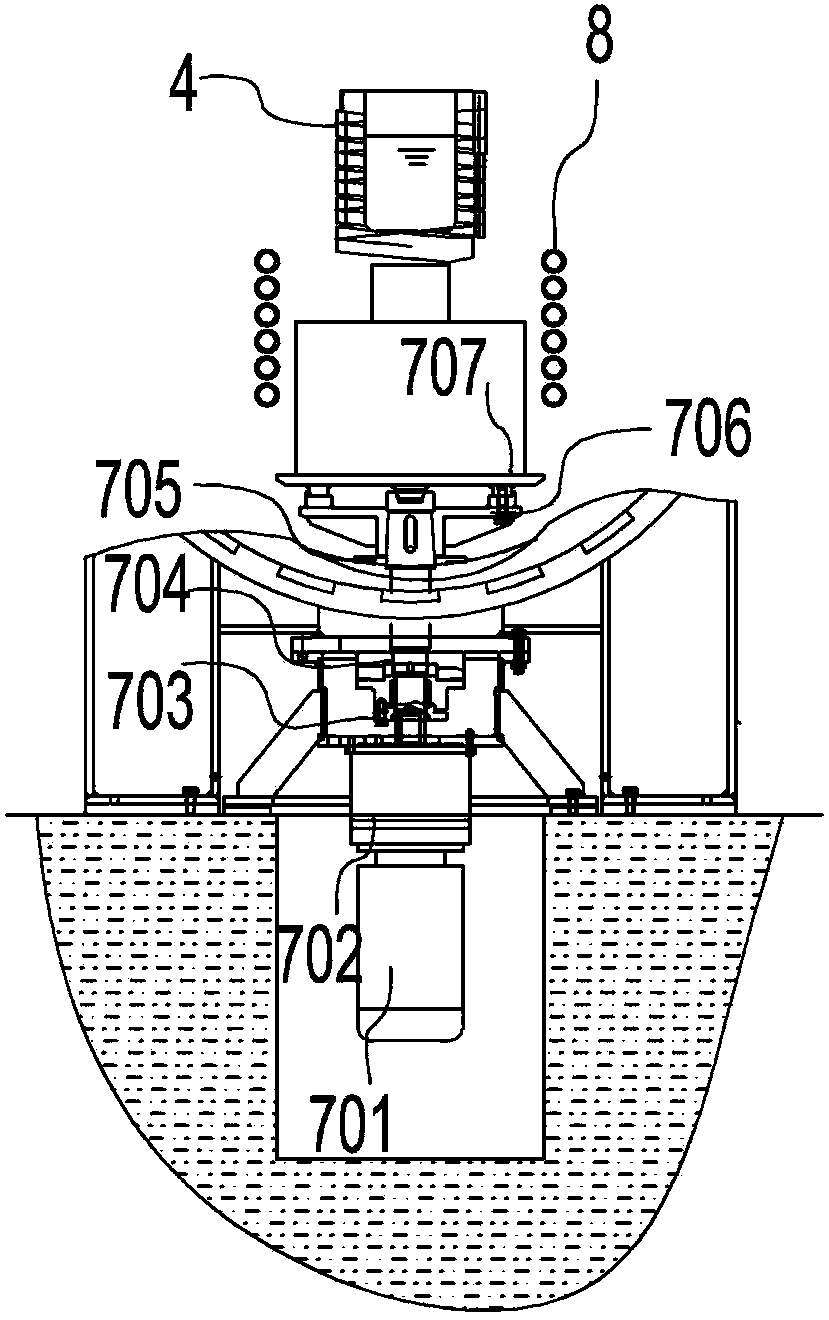

Electromagnetic-stirring pressurized centrifugal large-opening vacuum fusion casting furnace

ActiveCN103071784AMeet the requirements of nitrogen content (≥1.2%)Accurate ingredientsSteam pressureVacuum fusion

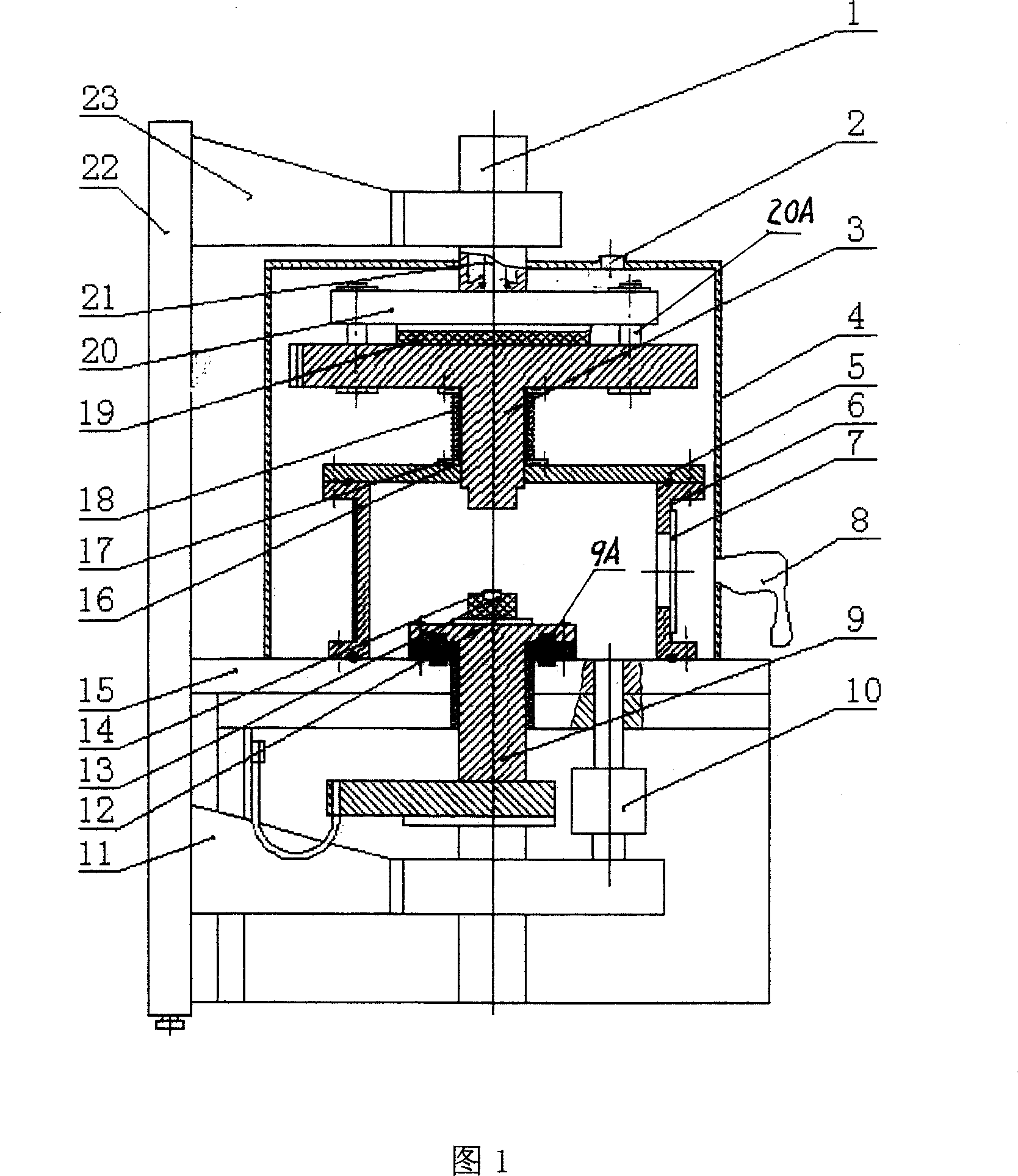

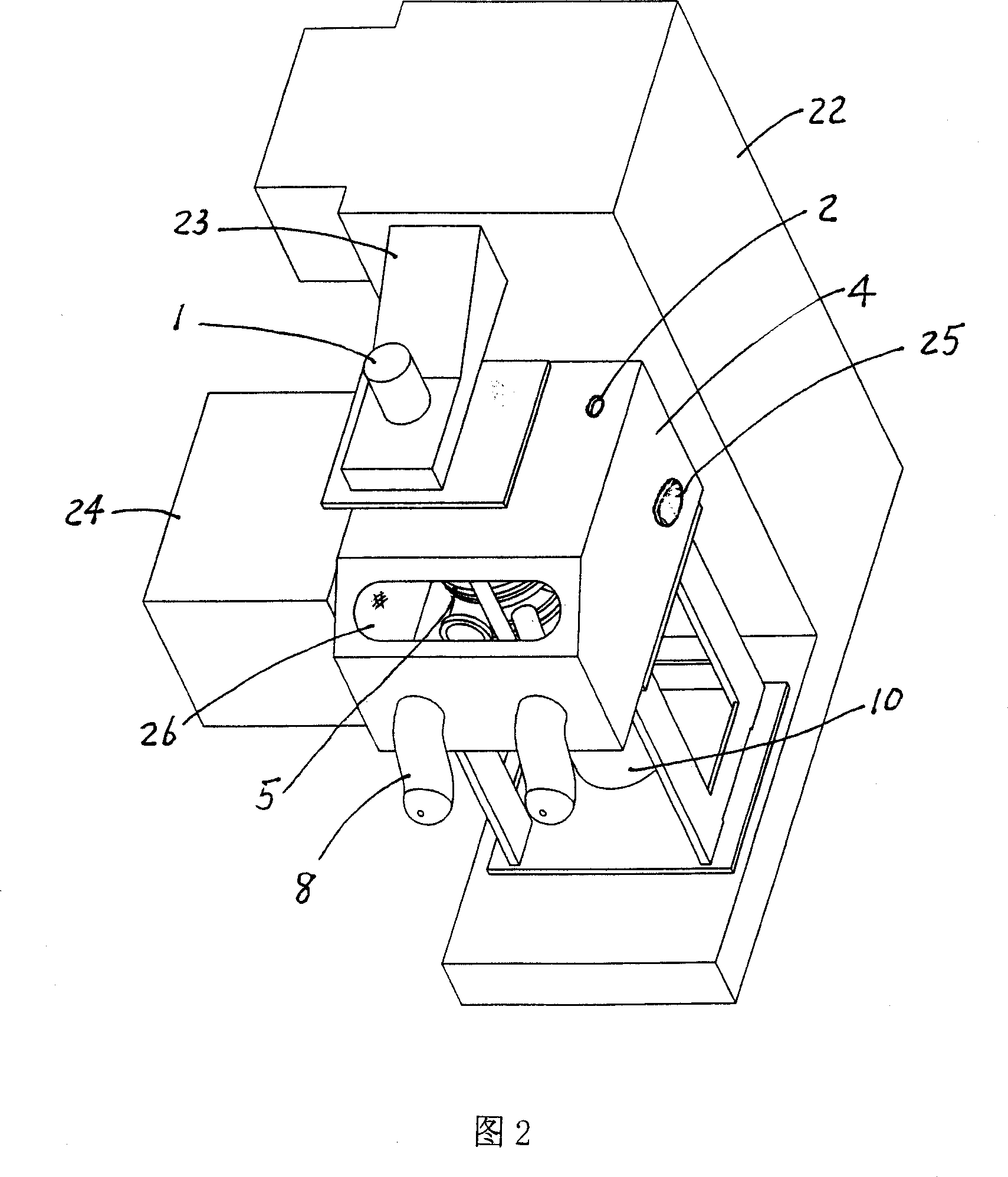

The invention discloses an electromagnetic-stirring pressurized centrifugal large-opening vacuum fusion casting furnace, which comprises a furnace body (1), a furnace door (2), a furnace cover (3), a sensor (4), a charging mechanism (5), a centrifugal rotating mechanism (7), an electromagnetic stirrer (8), a vacuum system (9), an inflating and pressurizing system (10) and a medium-frequency power supply (12), wherein the vacuum pumping pipe connecting port of the vacuum system (9) is communicated with the chamber of the furnace body (1); the sensor (4) is arranged in the chamber of the furnace body (1) and the power input end of the sensor (4) is connected with the power output end of the medium-frequency power supply (12); locking mechanisms are arranged on butting surfaces between the furnace body (1) and the furnace door (2) and between the furnace body (1) and the furnace cover (3); and the electromagnetic stirrer (8) is arranged around the rotating executing unit of the centrifugal rotating mechanism (7). The electromagnetic-stirring pressurized centrifugal large-opening vacuum fusion casting furnace has the advantages that the furnace can be used for producing cast ingots and precision castings made of high-nitrogen steel, high-temperature alloy and the like, the components of high-steam-pressure alloy elements can be guaranteed to be accurate, and the effects of mold filling and shrinkage compensation of special-shaped precision castings are ideal.

Owner:SHENYANG VACUUM TECH INST

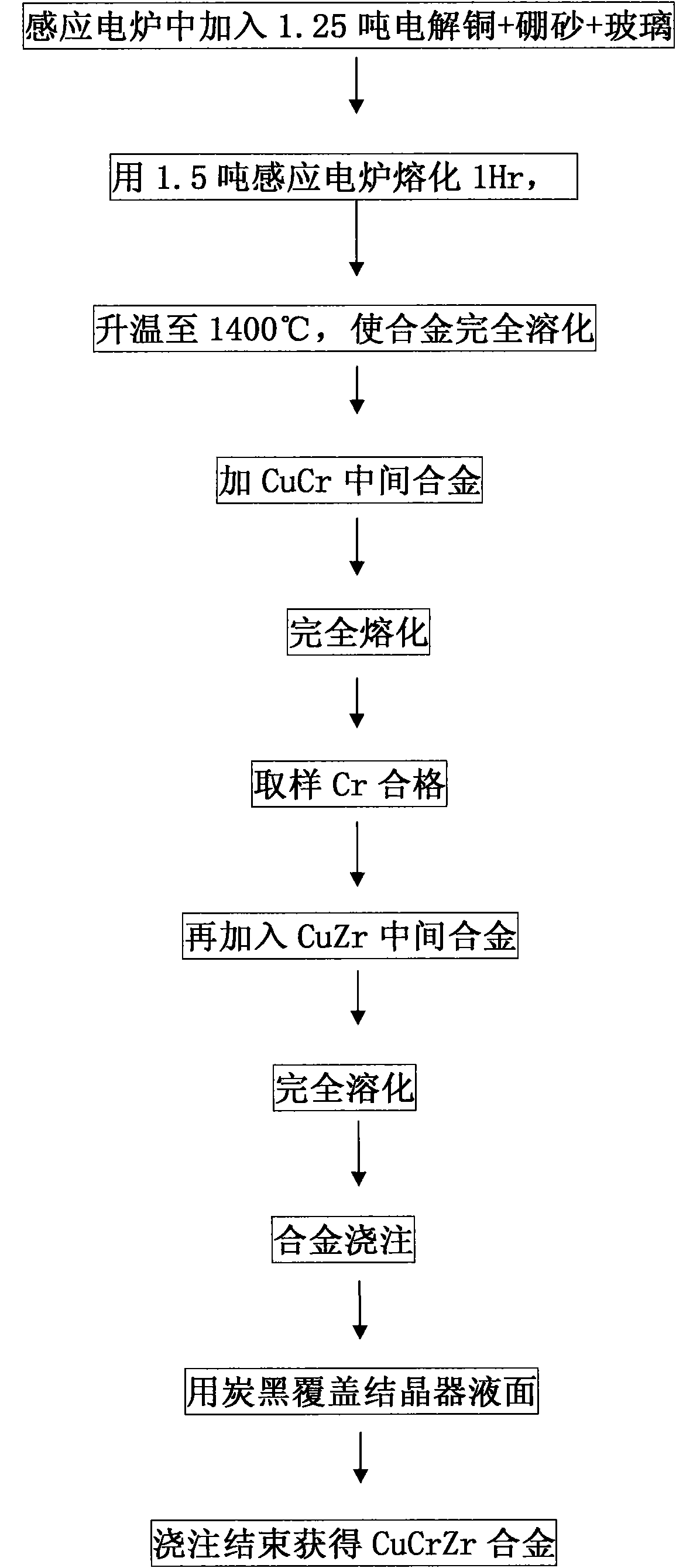

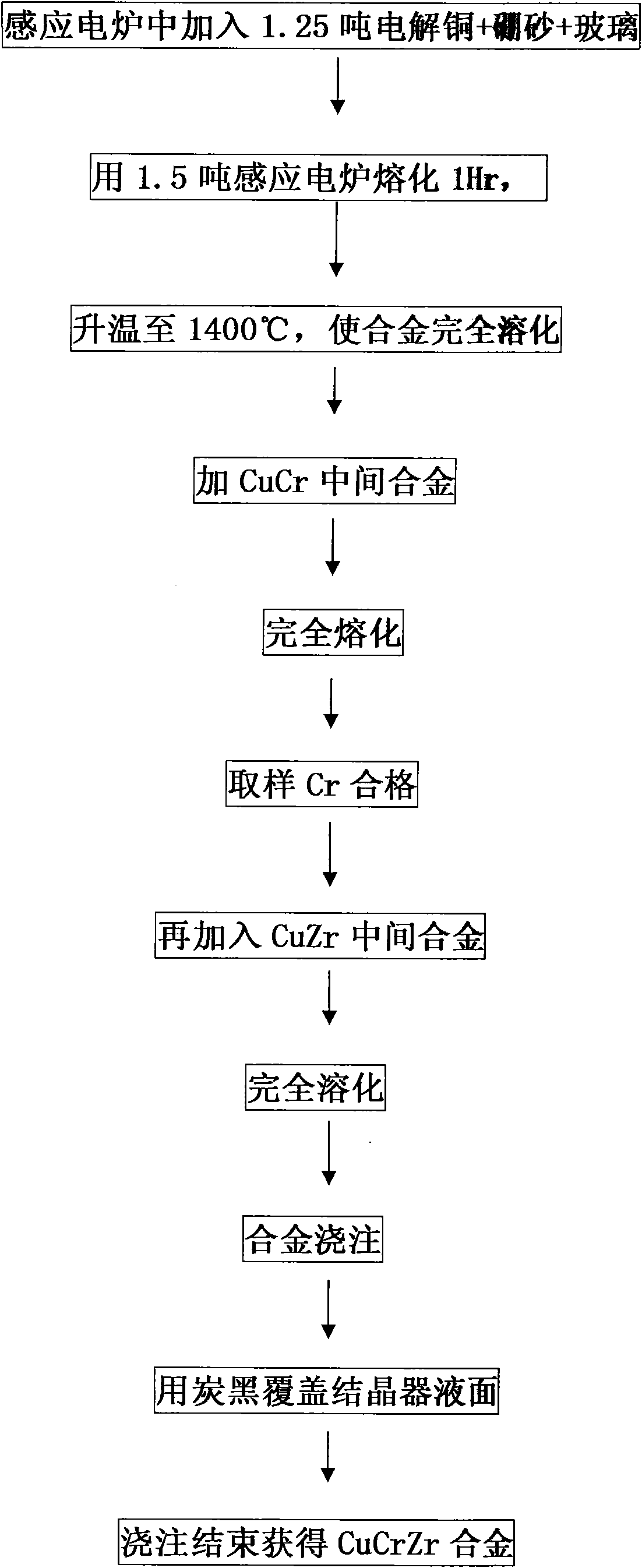

Non-vacuum smelting method of CuCrZr alloy

InactiveCN101906547ASolve the technical problems of being easy to oxidize and difficult to add to Cu meltSolve the costVacuum fusionCopper

The invention relates to a non-vacuum smelting method of a CuCrZr alloy, which is characterized by comprising the following steps of: manufacturing Cr and Zr into an intermediate alloy CuCr and an intermediate alloy CuZr to be used as the intermediate alloy addition materials for later use; sequentially adding electrolytic copper, an antioxidant and the intermediate alloy CuCr into an induction furnace according to the proportion in parts by weight in batches, electrifying to melt for 1 hour, and then increasing the temperature to 1400 DEG C to completely melt the mixture; then adding the intermediate alloy CuZr, then increasing the temperature to 1400 DEG C, pouring after being completely melted, covering a crystallizer with carbon black when pouring to obtain the CuCrZr alloy after finishing pouring. The invention solves the problems of complicated process, overhigh production cost and low production efficiency existing in traditional vacuum fusion casting process production, the input cost of non-vacuum fusion casting equipment is only about 1 / 10 as much as that of vacuum fusion casting equipment, and the production efficiency thereof is more than three times as much as that of a vacuum furnace with the same capacity.

Owner:JIUXING HLDG GRP

Method for producing product by combination of continuous fibre reinforced nylon and metal

The present invention relates to a continuous fiber reinforcing nylon and a metal parts preparation method. The method is that: a processed metal plate is placed at the bottom of a mold, the fiber with the same area with the metal plate is placed on the top of the metal plate; the mold is sealed and heated to the required temperature for the reacting of a monomer; the dehydrated caprolactam liquid is melted in the vacuum, or proper plasticizer is added into the vacuum, which is heated to a given temperature to be melted and mixed to get the mixed liquid. The mixed liquid is poured into the mold at certain temperature and kept reacting for 5 to 30 minutes, then the temperature is reduced, the mold is stripped, and the product is gained. Compared with the prior art, the present invention has the advantages of simple in technique, convenient and good interface mixing of the fiber and interface of the body.

Owner:鄂尔多斯市永杰科技有限公司

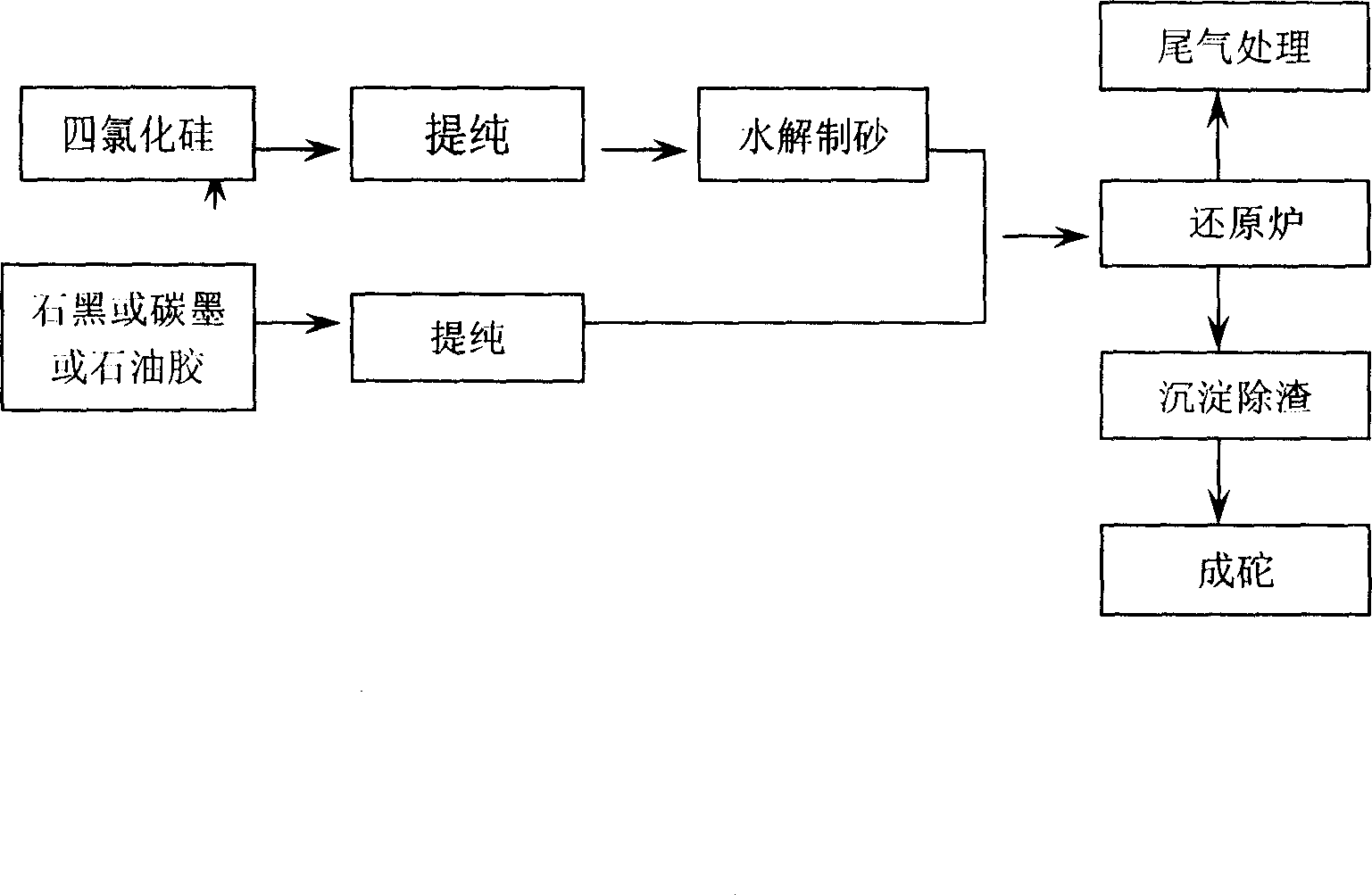

Production process of solar energy grade polysilicon

The invention discloses a manufacturing method of solar grade polycrystalline silicon, which comprises the following steps: sintering graphite or carbon black or oil in the vacuum at 1500-2000 Deg C; purifying; adding the high-purity quartz and purified high-purity graphite or carbon black or oil with molar rate at 1: 2 in the reduced furnace; making silicon product with lower impurity; fusing the silicon in the vacuum; controlling temperature according to the fusing point of silicon; filtering to remove slag; removing carbon, silicon carbide and silica powder; pouring fused silicon in the mould; solidifying directionally to obtain 6N-grade solar grade polycrystalline silicon.

Owner:JINZHOU NEW CENTURY QUARTZ GROUP CO LTD

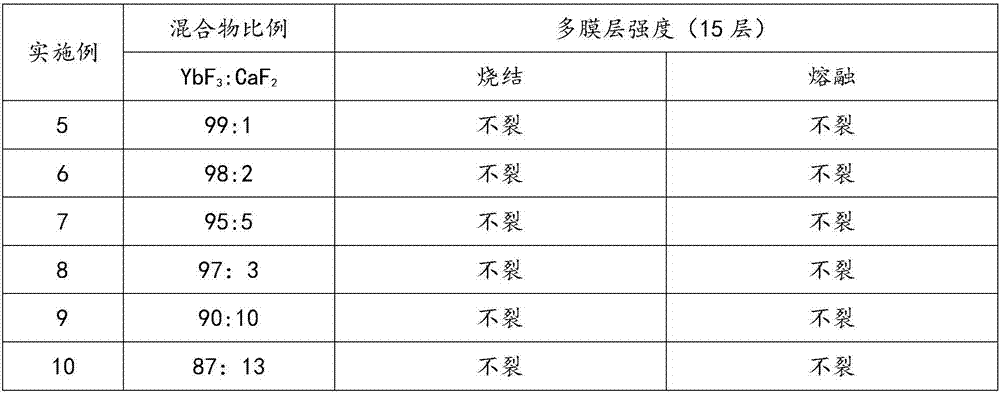

Low-refractive-index infrared optical coating material and preparing method thereof

ActiveCN107881467AEnsure stabilitySolve the problem of membrane ruptureVacuum evaporation coatingSputtering coatingYtterbium fluorideOptical coating

The invention relates to a low-refractive-index infrared optical coating material and a preparing method thereof, and belongs to the technical field of optical coating materials. According to the weight proportions of ytterbium fluoride and calcium fluoride, the ytterbium fluoride ranges from 85%-99.5%, the calcium fluoride ranges from 0.5%-15%, a ytterbium fluoride and calcium fluoride mixture obtained after proportioning is sintered, the sintering temperature is 700 DEG C-1250 DEG C, and the fusion step is executed; and the sintered sintering mixture is subject to vacuum fusion for 3 h to 6h at above 1260 DEG C, and a ytterbium fluoride and calcium fluoride fusion mixture is obtained. The low-refractive-index infrared optical coating material has the beneficial effects that in the ytterbium fluoride material, a certain amount of calcium fluoride is guided in, the ytterbium fluoride and the calcium fluoride evaporate at the same time and are deposited on the optical surface, due to the difference of crystalline forms of the calcium fluoride and the ytterbium fluoride, the directional growth condition in the original single ytterbium fluoride deposition process is prevented, and an even optical film layer with the small internal stress is formed; and as the internal stress is reduced, when a multi-layer film is plated, stability of the multi-layer film is guaranteed, and the problem of film cracking of the multi-layer film is solved.

Owner:凯永(固安)光电技术有限公司

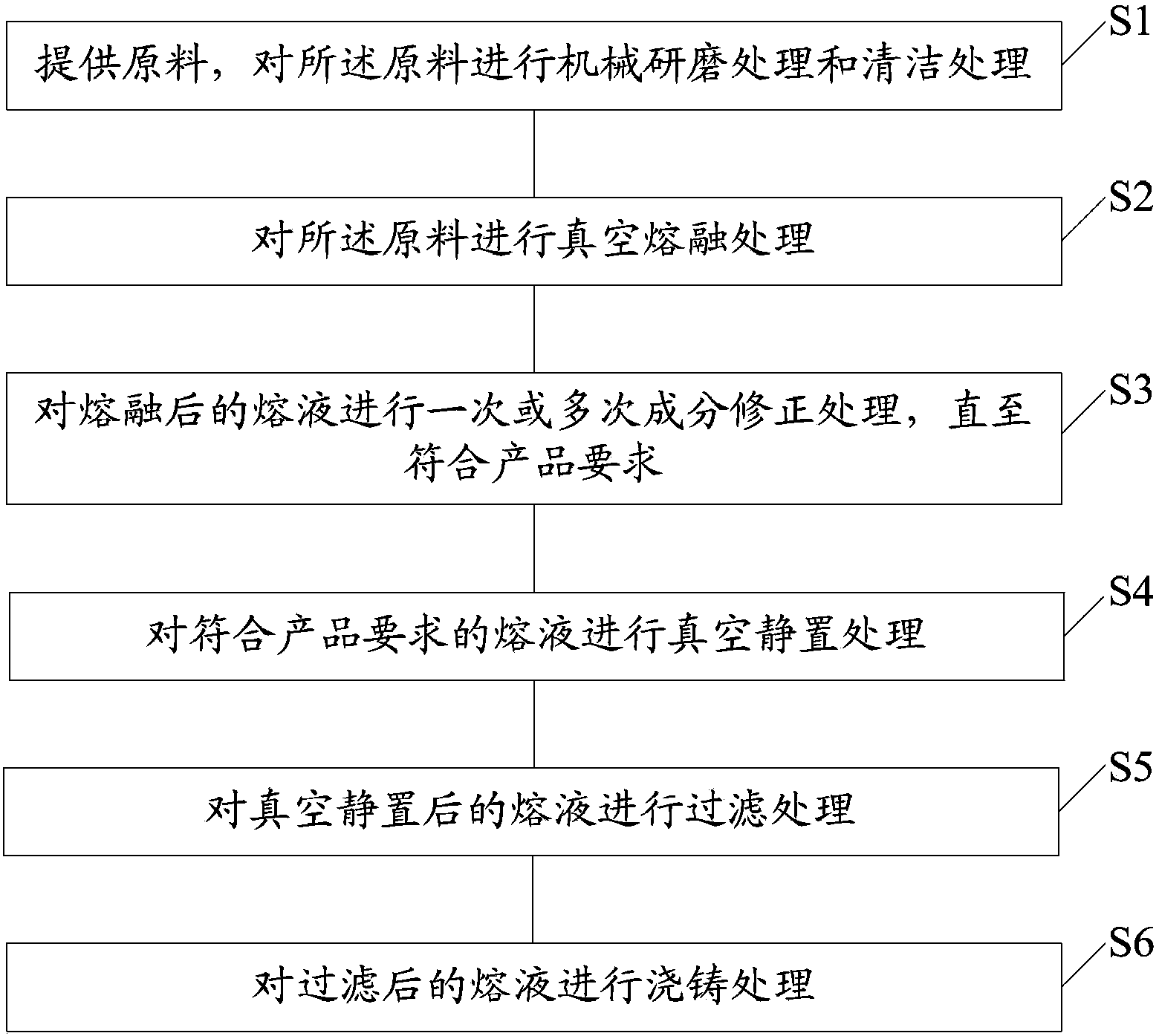

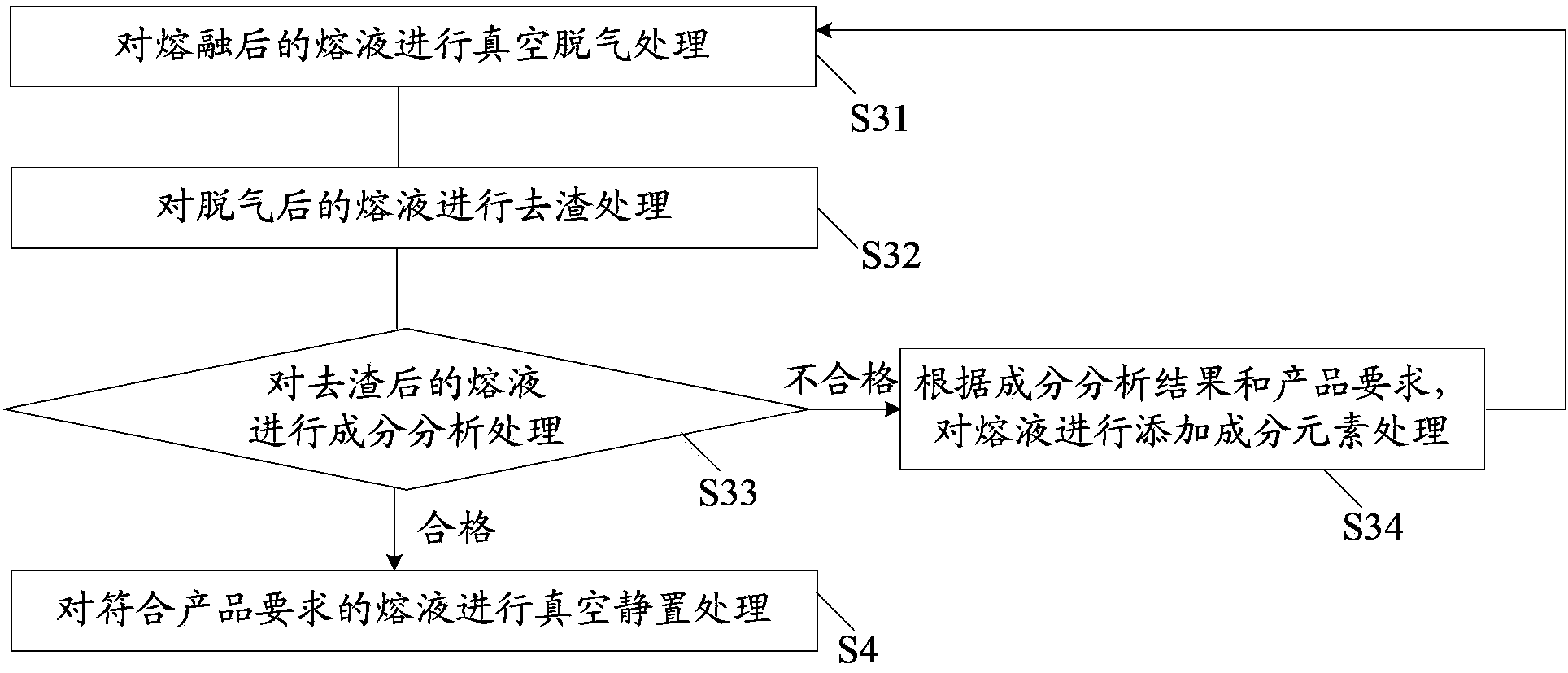

Aluminum alloy casting method

The invention discloses an aluminum alloy casting method. The aluminum alloy casting method comprises the following steps: raw materials are supplied; the vacuum melting treatment is performed for the raw materials; one or more times of component correction treatment is performed for the molten liquid until the product requirements are satisfied; the vacuum standing treatment is performed for the molten liquid satisfying the product requirements; and the filtering treatment and the casting treatment are performed for the molten liquid after the vacuum standing treatment. The aluminum alloy casting method can improve the aluminum alloy purity, and reduce the production cost.

Owner:宁波创润新材料有限公司

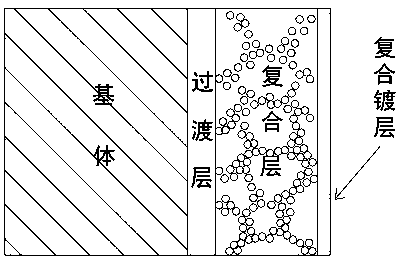

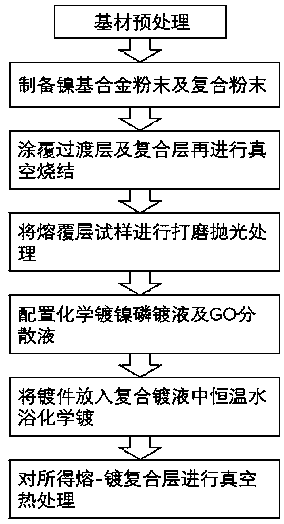

Structure of melted-plated compound coating by vacuum fusion covering+chemical plating and preparation method thereof

InactiveCN110438496ACorrosion-resistant, wear-resistant and high-temperature resistantLiquid/solution decomposition chemical coatingSuperimposed coating processChemical platingAdhesive

The invention relates to a structure of a melted-plated compound coating by vacuum fusion covering+chemical plating and a preparation method thereof. The structure of the coating is divided into a vacuum fusion covering nickel-based tungsten carbide compound layer, a transitional layer, a diffusion influence area and a chemical plated Ni-P-GO compound coating on the surface of a compound claddinglayer. The nickel-based tungsten carbide compound material coating is metallurgically bonded to a matrix, and WC hard particles are distributed among spherical nickel-based alloy particles to form a three-dimensional netty structure; a chemical compound coating is formed based on the compound cladding layer to obtain a comprehensive functional melted-plated compound coating. The method comprises the following steps: first, uniformly mixing nickel-based alloy powder with a self-made adhesive, coating the mixture to the surface of a carbon steel matrix to form the transitional layer, and coatingthe compound powder mixed with the adhesive to the surface of the transitional layer to obtain the compound cladding layer; and then preparing a nickel and phosphorus graphene oxide compound coatingby means of a chemical plating technology, and carrying out thermal treatment on the obtained melted-plated compound layer at 400-600 DEG C, wherein the chemical coating and the cladding layer are indiffused connection.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

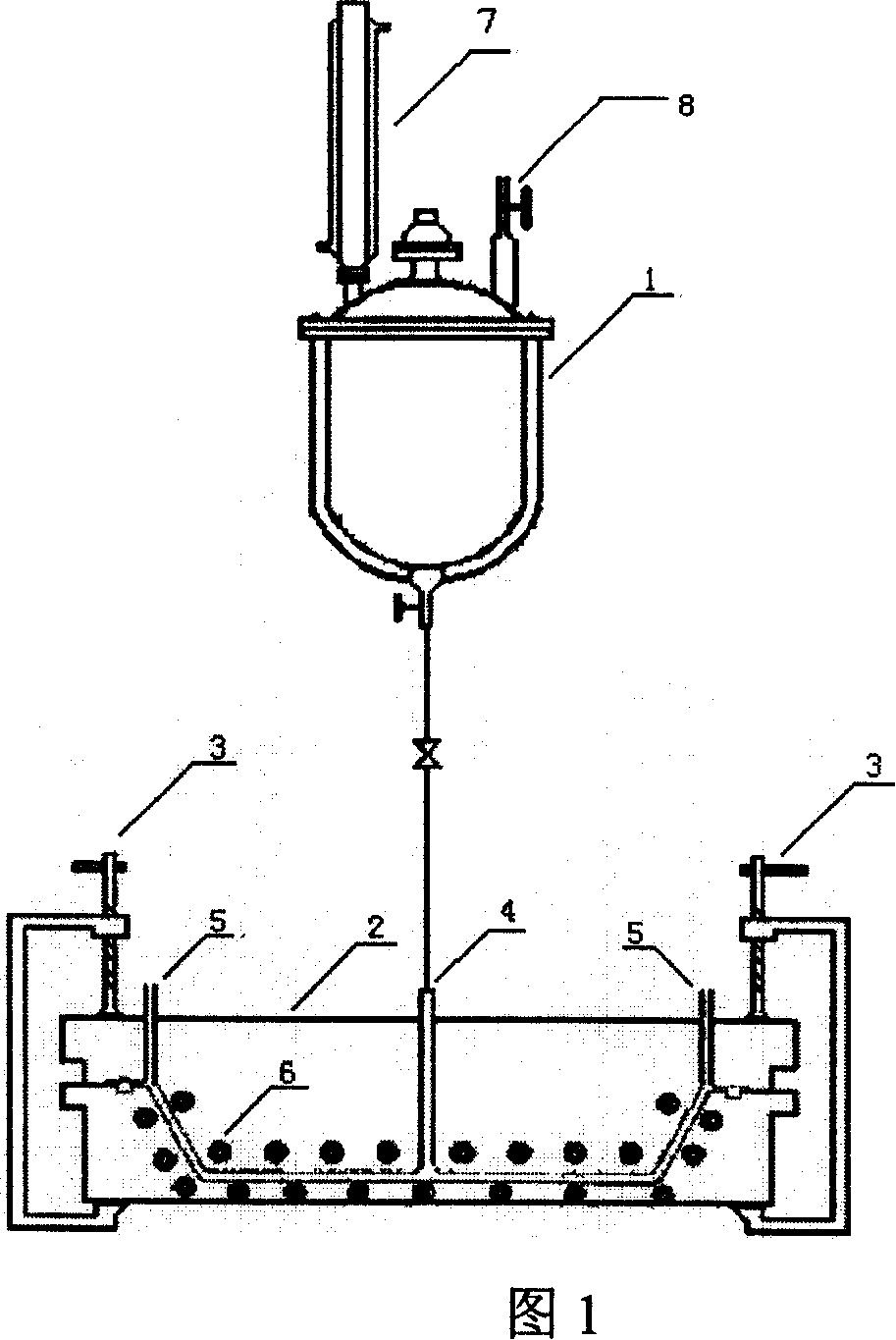

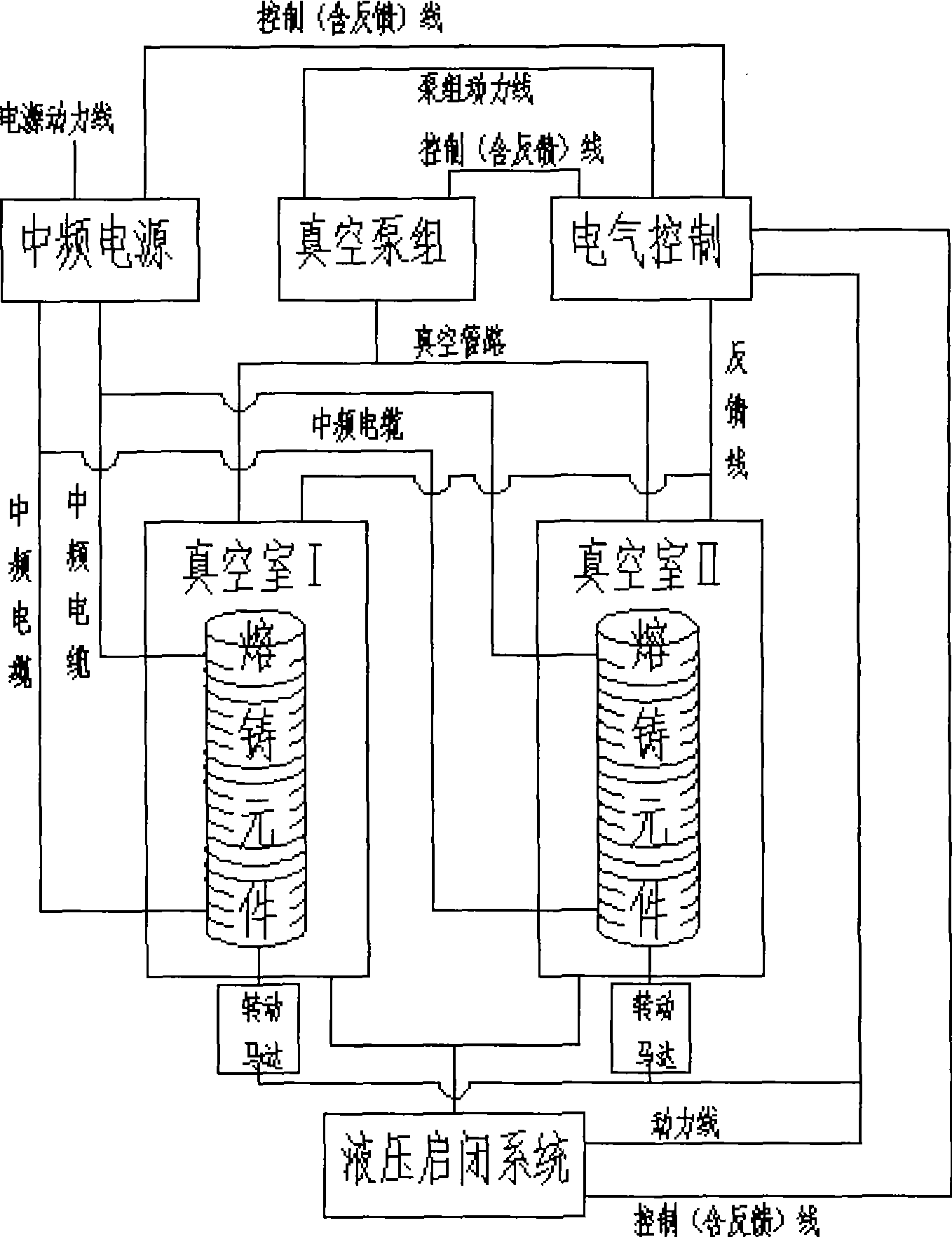

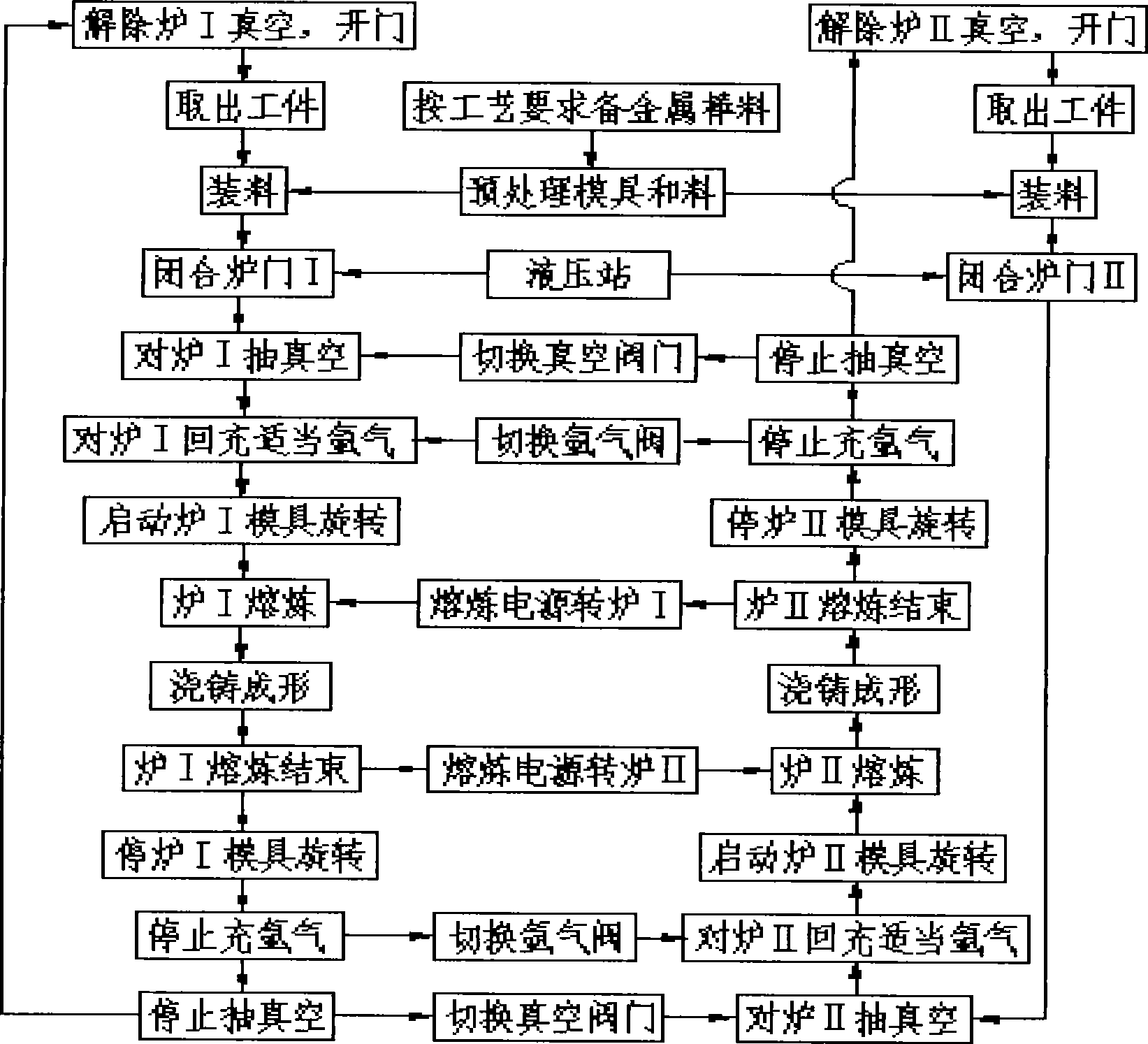

Metal material casting system and method

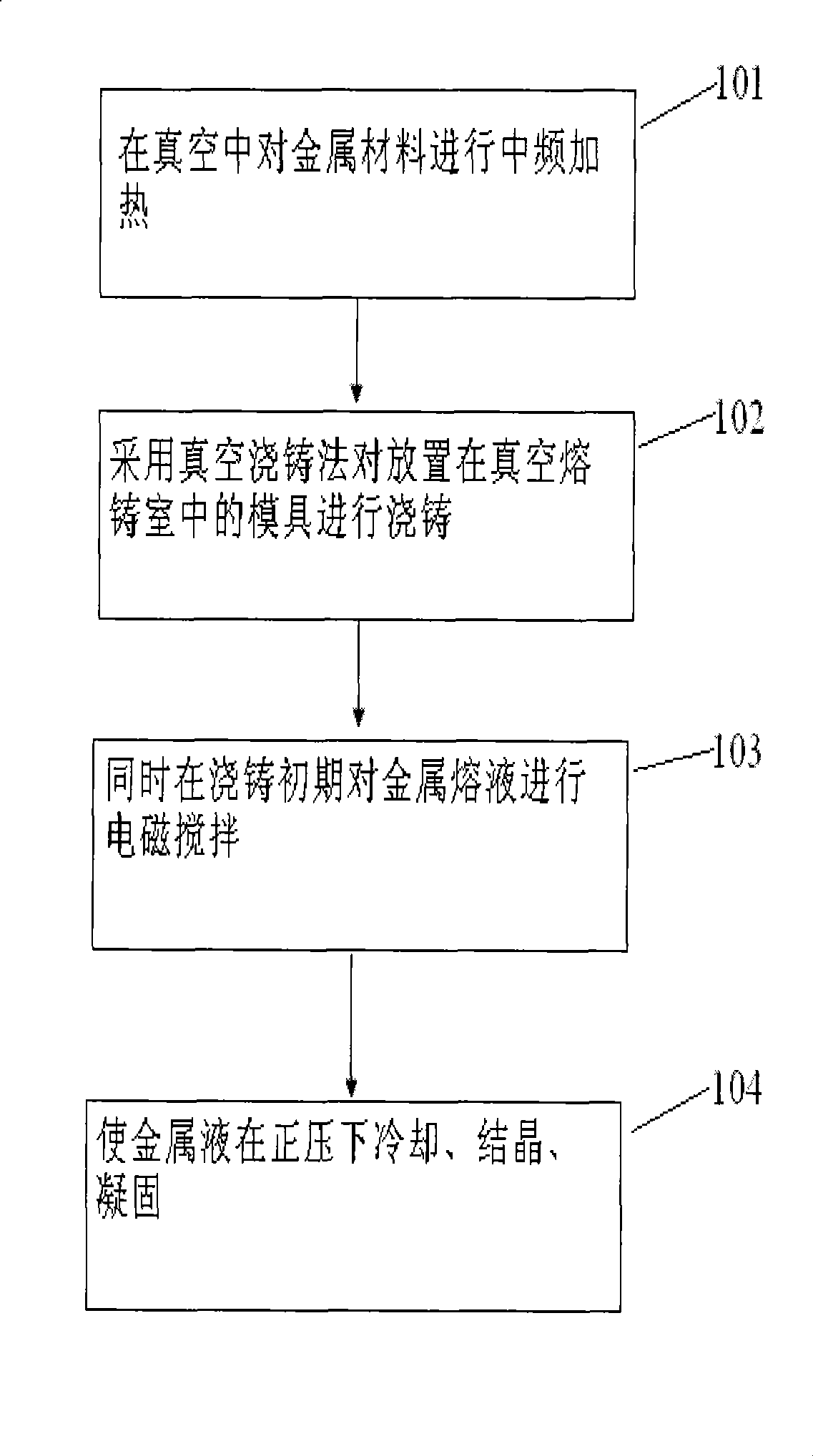

The invention relates to a system for metallic material fusion cast molding as well as a method thereof, wherein the system comprises: an intermediate frequency power supply, an electric control device, a hydraulic open and close device and a vacuum apparatus, and also includes a vacuum pumping set, a vacuum fusion cast chamber and a rotating motor. The vacuum fusion cast chamber adopts a crucibleless structure and is provided with an induction heating element for electromagnetic heating and agitation. The method for preparing castings comprises: implementing the intermediate frequency heating to metallic materials in vacuum, using a vacuum casting method to cast a die placed in the vacuum fusion cast chamber, meanwhile electromagnetically stirring the molten metal at the early stage of casting, and cooling, crystallizing and solidifying the molten metal under positive pressure. The adoption of the method and the system can eliminate the process of recasting by using a crucible, and the molten metal can be electromagnetically stirred and / or centrifugally moved while in intermediate frequency smelting and vacuum casting, so as to acquire castings with fine grains, compact tissues and excellent performances.

Owner:ZHONGSHAN TIANYUAN VACUUM EQUIP TECH CO LTD

Vacuum melting furnace for preparing fusion casting type production of molybdenum from worn-out molybdenum

InactiveCN101093141AImprove physical and chemical propertiesSolve the regeneration problemCrucible furnacesVacuum fusionAlloy

This invention relates to a vacuum fusion furnace preparing castable Mo products with waste Mo including a vacuum chamber and a pot set in it, in which a cast model is under the pot, a cast hole with a group casting strob is set at the bottom of the graphite pot, the outside wall and bottom of the pot are wrapped by an insulated heat preservation conduction material layer, the outer of which is a water-cooling jacket with arc stabilizing coil in it, which can guarantee the heat balance necessary for smelting waste Mo and increases density of the products while eliminating nitrogen, hydrogen and oxygen and alloy impurities at low melting point compared with products produced by a powder metallurgical method.

Owner:JILIN XUFENG LASER TECH

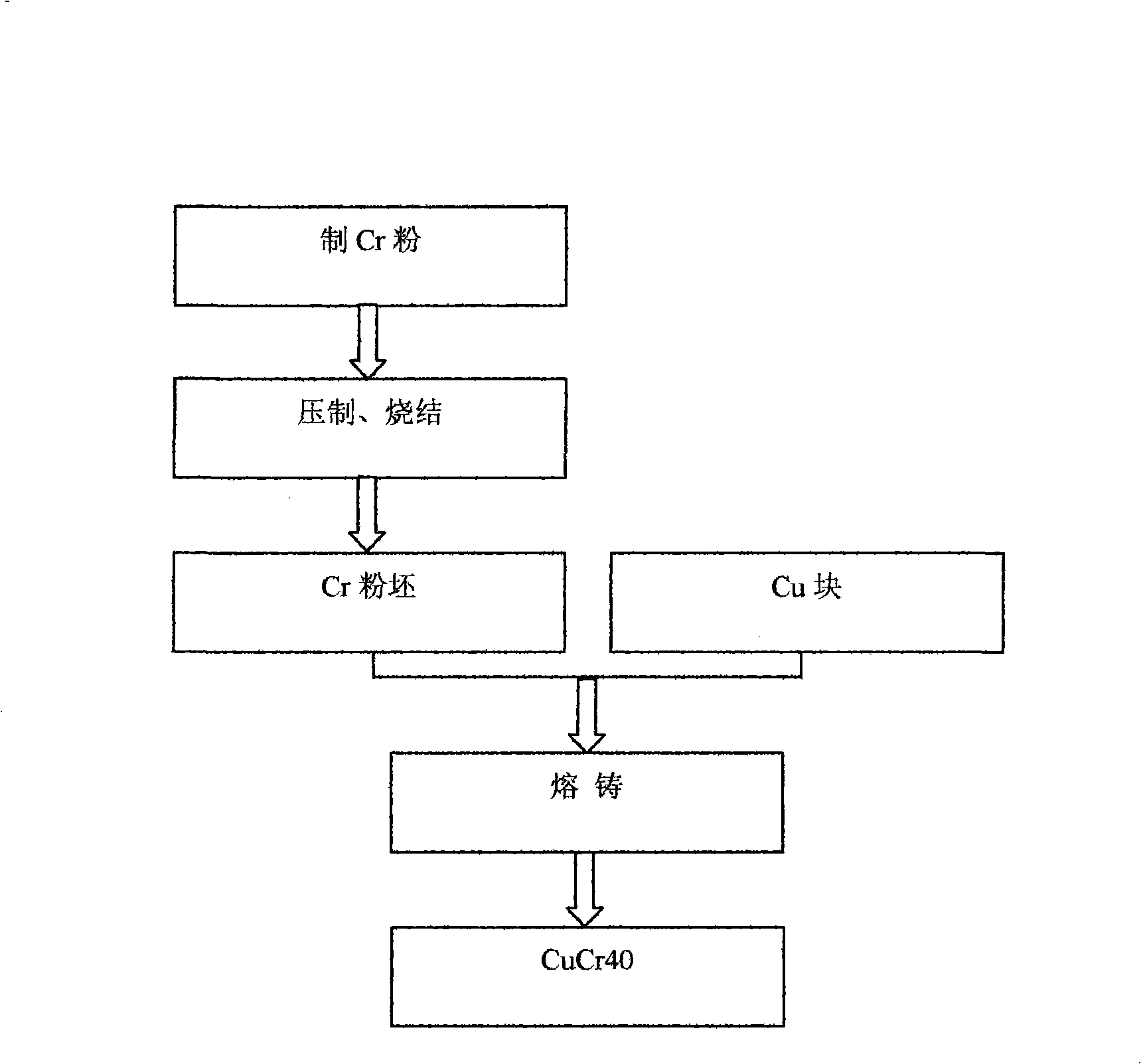

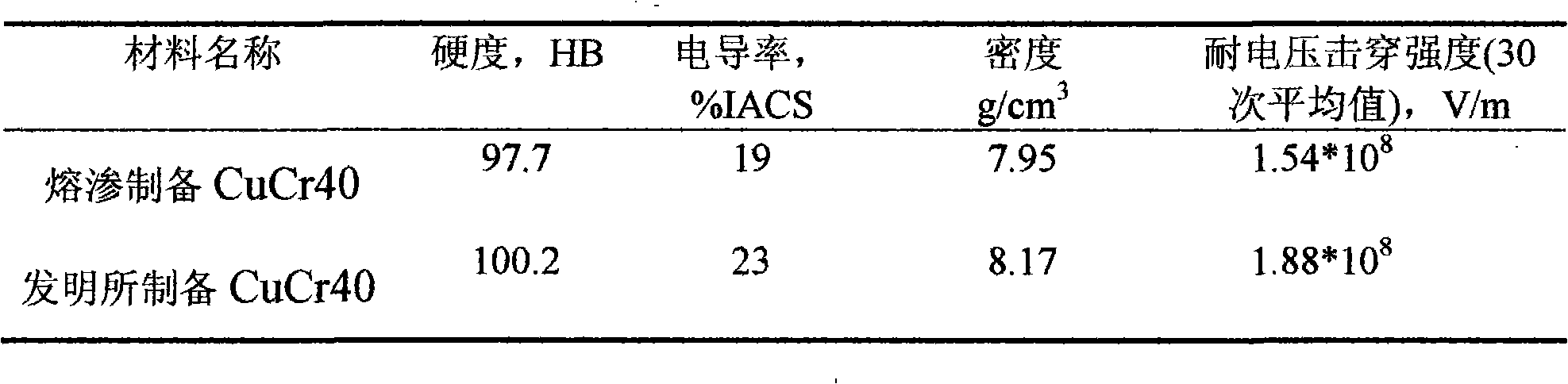

Method for producing CuCr40 contact material with vacuum fusion cast method

The invention discloses a method for preparing a CuCr40 electrical contact by adopting a vacuum fusion casting method, which belongs to the technical field of metal materials preparation. The CuCr40 electrical contact comprises the following compositions in percentage by weight: 40 percent of Cr, and the balance being Cu. The CuCr40 electrical contact is prepared by the following method: a Cr block is processed into Cr powder through a grinding crusher under the protection of low-temperature liquid; the Cr powder is pressed and then is sintered into a Cr powder billet; and then a Cu block and the Cr powder billet are placed into a vacuum furnace for heating, the casting is performed after the fusion, and a CuCr40 electrical contact material is obtained after cooling. The method has the advantages that the Cr block is crushed into the Cr powder, and the Cr powder is then pressed and sintered into the Cr powder billet, so as to reduce fusion temperature and shorten fusion time. The preparation method has simple process and low cost, and the prepared CuCr40 composite material has more excellent performance compared with a filtrated CuCr40 composite material prepared by infiltration.

Owner:SHAANXI SIRUI ADVANCED MATERIALS CO LTD

Alloy for impeller of aircraft gas compressor

The invention provides alloy for an impeller of an aircraft gas compressor. The alloy is prepared from the following raw materials in parts by weight: 86.0-95.0 parts of Al, 2.0-3.4 parts of Ni, 0.7-1.2 parts of Si, 0.7-1.0 part of Fe, 1.8-2.6 parts of Cu, 0.4-0.8 part of Mn and 0.4-0.8 part of Mg. The alloy has the following advantages: silicon nitride spraying material is adopted to spray a crucible before smelting to prevent the crucible from crack at a high temperature; vacuum fusion treatment is adopted to enable sufficient degassing of fused alloy, remove impurities and avoid pollution; an electron beam is adopted to smelt alloy so as to ensure high strength, high tenacity and high corrosion resistance of alloy; solution treatment, salt bath quenching and twice aging treatment are adopted to enable the alloy to have higher hardness, yield strength, tensile strength, impact toughness and fatigue strength in the complicated aircraft flight environment; hot isostatic pressure treatment is adopted to improve the overall mechanical property of alloy ingot; sampling analysis, an alloy meter and an ultrasonic harmless flaw detector are adopted to detect the alloy ingot so as to ensure quality of the alloy ingot.

Owner:NANJING LVZHICHENG PATENT TECH DEV CO LTD

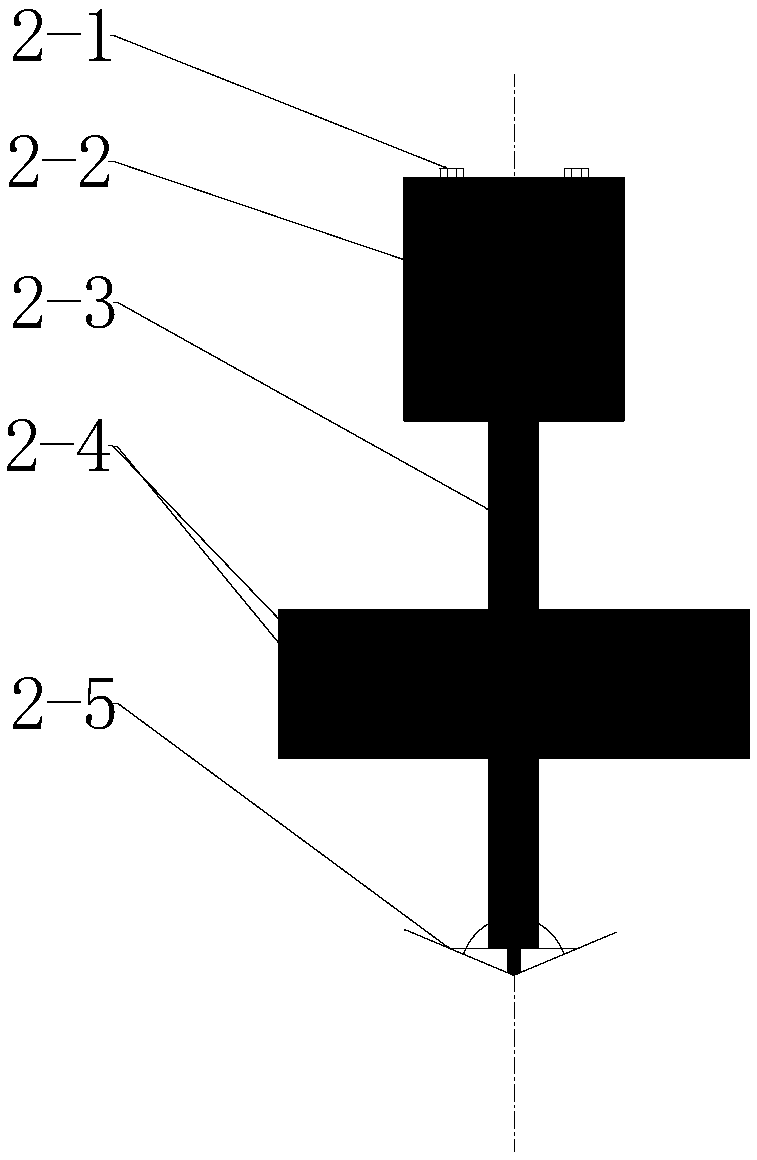

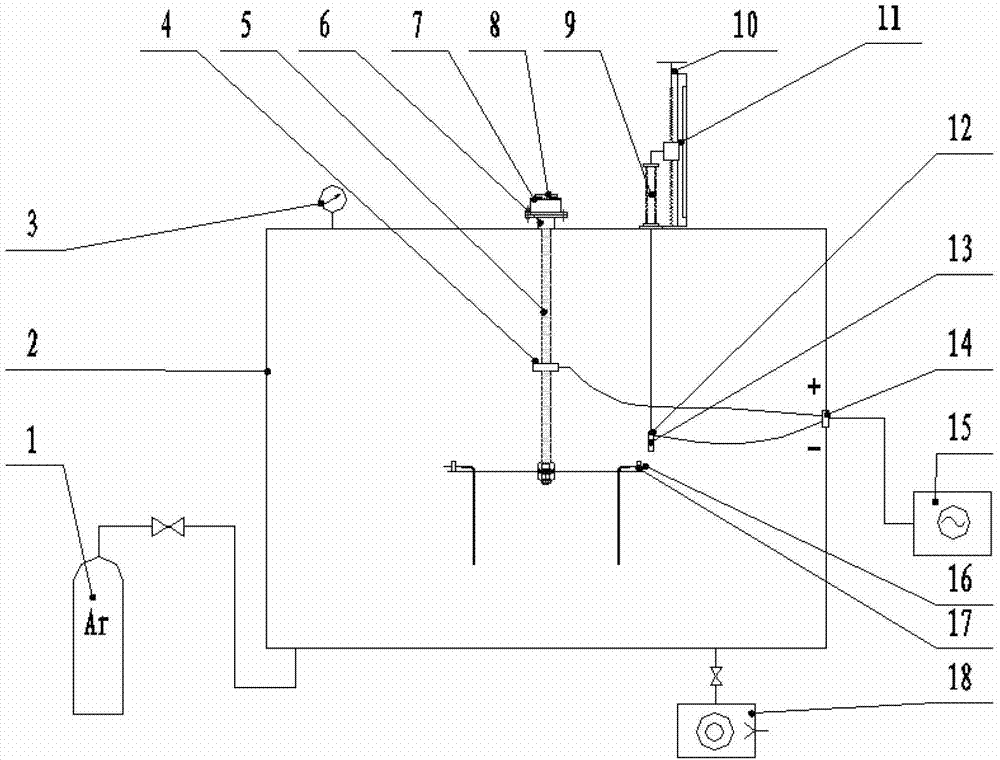

Thermocouple vacuum fusion welding system

InactiveCN103111766AImprove work efficiencyEasy to controlWelding/cutting auxillary devicesAuxillary welding devicesVacuum fusionButt joint

A thermocouple vacuum fusion welding system is capable of being used for fusion welding of thermocouple wires with various types in a vacuum environment, removing air by vacuumizing to eliminate a thermocouple wire oxidizing reaction which is possibly caused when fusion welding on a butt joint end of the thermocouple wires is conducted and improve pyroelectric effect performance of a thermocouple. The thermocouple vacuum fusion welding system is characterized by comprising a vacuum chamber. Thermocouple wire fixtures are arranged in the vacuum chamber. A fusion welding carbon rod is arranged in a corresponding position where each thermocouple wire fixture clamps the butt joint end of the thermocouple wire. The fusion welding carbon rod is connected with a feed movement device. The thermocouple wire fixture is connected with one pole of a fusion welding power supply, and the fusion welding carbon rod is connected with the other pole of the fusion welding power supply.

Owner:BEIJING DONGFANG MEASUREMENT & TEST INST

A making method of NdFeB magnetic powder

InactiveCN101055778AHigh energy productUniform magnetic compositionInductances/transformers/magnets manufactureMagnetic materialsVacuum fusionMagnetic energy

Owner:俞葵

Method for treating molten salt electrolysis cathode deposits through pyrogenic process

ActiveCN106702438AAvoid wastingReduce manufacturing costElectrolysis componentsElectrolysisVacuum fusion

The invention relates to a method for treating molten salt electrolysis cathode deposits through a pyrogenic process, and belongs to the technical field of electrochemical metallurgy. The method comprises the following steps of: firstly, crushing cathode deposits obtained by molten salt electrolysis, mixing the cathode deposits with a mixture of alkali metal chloride and alkali metal fluoride, and putting the mixture into a ceramic crucible, wherein a molar ratio of the cathode deposits is equal to that of the mixture; putting the ceramic crucible into a vacuum melting filtering tank, starting vacuum-pumping, heating, stopping vacuum-pumping when pressure is lower than 1-10<-3>Pa, stopping vacuum-pumping, continuously heating to 700-750 DEG C, and preserving heat; after preserving heat, charging argon gas, keeping micro positive pressure, melting molten salt electrolyte mixed up with the deposits, and dripping the molten salt electrolyte under a gravity condition; and collecting dripped molten salt electrolyte into a lower crucible, keeping metal in the ceramic crucible, taking out metal after cooling, and returning the collected molten salt electrolyte to an electrolysis process for use. The method is simple and safe to operate, guarantees continuous production processes through recycled electrolyte, reduces production cost, and has a relatively high application value and relatively good theoretical significance.

Owner:有研资源环境技术研究院(北京)有限公司

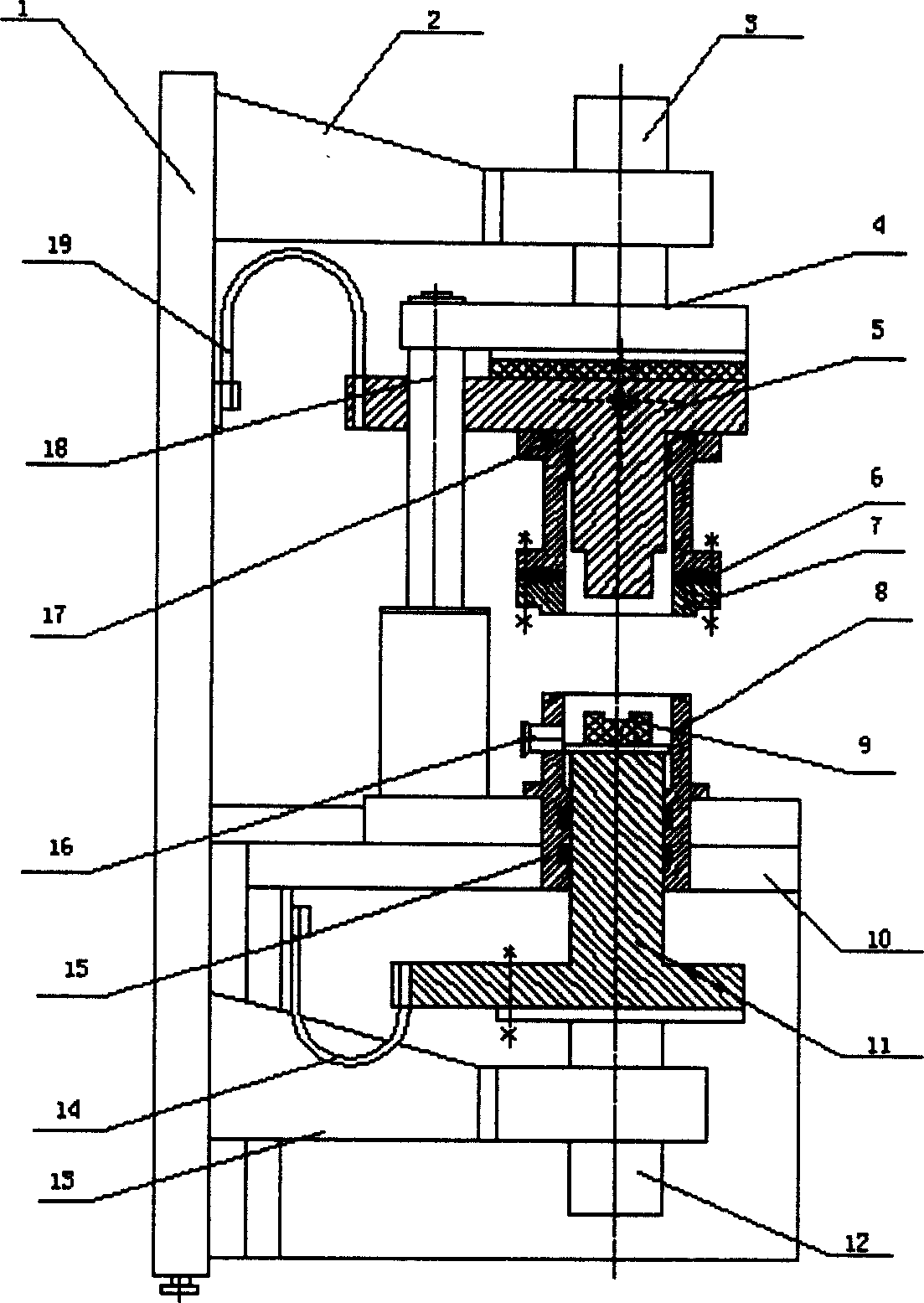

MEMS component vacuum fusion welding device

InactiveCN1686657AShort welding heating timeReduce welding distortionResistance electrode holdersVacuum fusionResonance

A vacuum fusion welding apparatus for the vacuum packageing of resonance device MEMS is composed of machine frame, upper supporting arm, upper sylinder, lower supporting frame with slide supporting frame linked with the slide arm driven by upper cylinder in slide mode, upper welding arm fixed to said slide arm, lower supporting arm with lower cylinder linked to lower welding arm, DC power supply, and upper and lower air chambers to be vacuumized.

Owner:HUAZHONG UNIV OF SCI & TECH

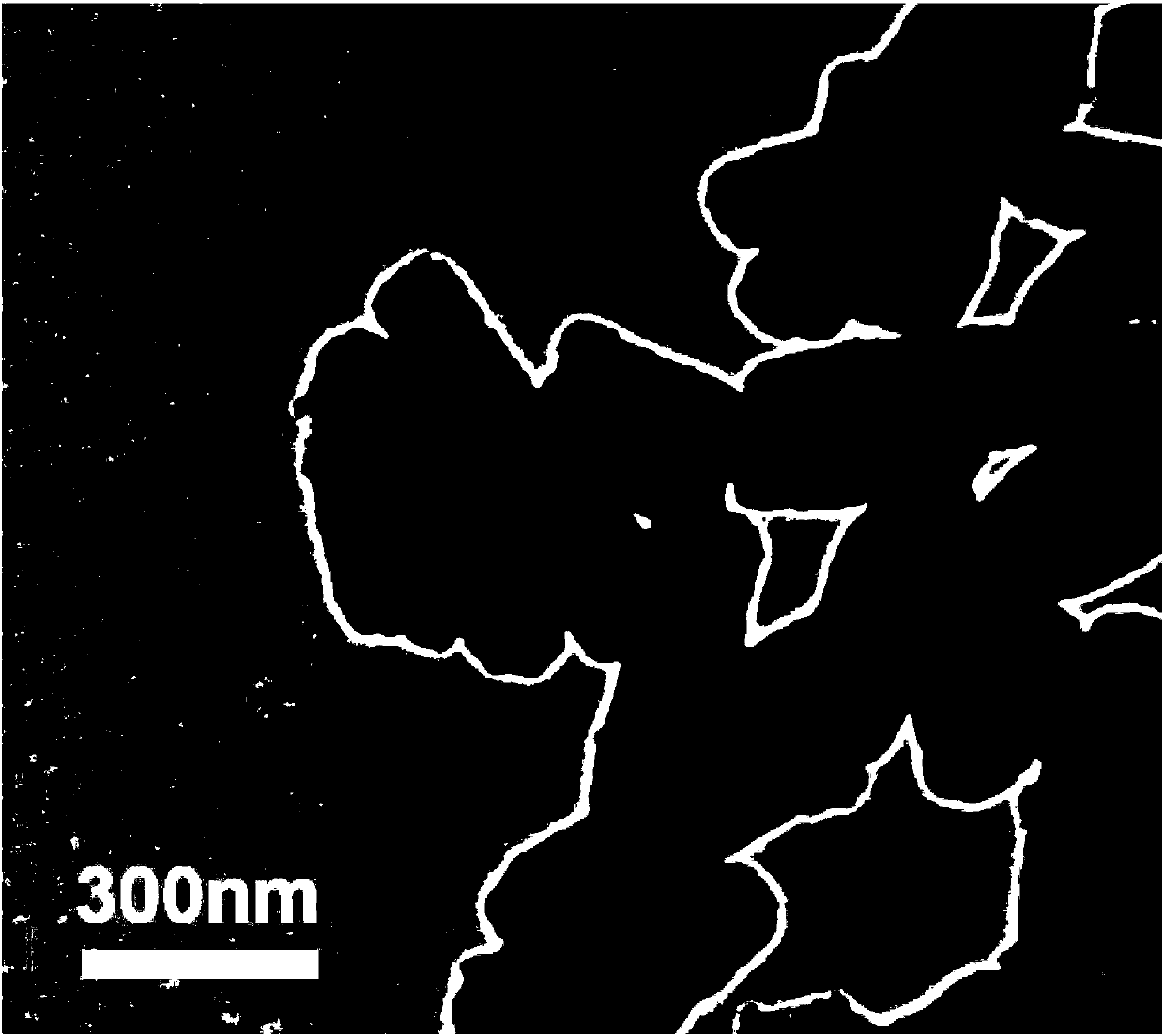

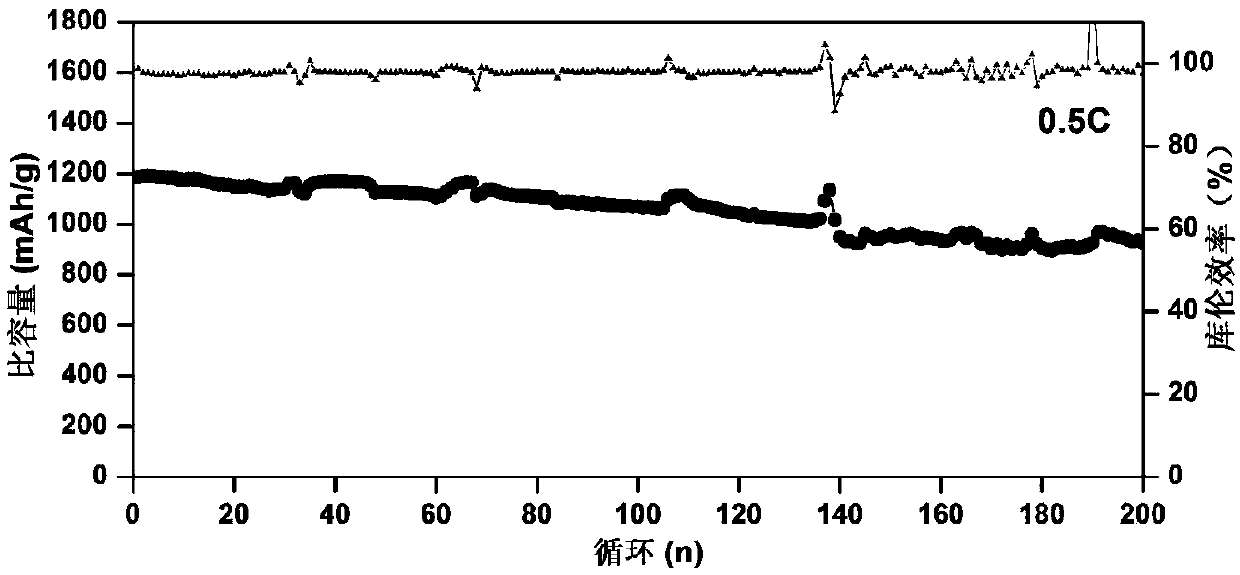

One-dimensional nitrogen-doped double-layer carbon shell/sulfur composite positive electrode material for lithium-sulfur battery and preparation method thereof

InactiveCN107732184ANovel structureImprove performanceMaterial nanotechnologyPositive electrodesVacuum fusionMicroparticle

The invention discloses a one-dimensional nitrogen-doped double-layer carbon shell / sulfur composite positive electrode material and a preparation method thereof. According to the material, an elongated double-layer carbon shell is prepared from a nitrogen-doped carbon material, and elemental-sulfur nanoparticles are dispersed in the carbon shell. According to the preparation method, the double-layer carbon shell is used as a sulfur-fixing precursor, and elemental sulfur is uniformly disperses in the double-layer carbon shell in the form of nanoparticles in virtue of a vacuum molten salt process. The size and content of sulfur particles are controlled via the one-dimensional size of the carbon shell, so the usage rate of sulfur is increased; the contact area between sulfur and an electrolyte is increased via the double-layer carbon shell, so the utilization rate of sulfur is improved; nitrogen-doped graphitized carbon is used for improving the electric conductivity of sulfur; and the loss of polysulfides and the cycle performance of the electrode material are improved in virtue of the hermeticity of the carbon shell, usage of a double-layer structure and chemical coordination between nitrogen and sulfur. The preparation method is simple in process and easy to operate; and the prepared composite positive electrode material has excellent properties, high specific discharge capacity, large rate and good long cycle performance, and has good application prospects in fields like mobile communications, portable electronic devices, energy storage devices, unmanned aerial vehicles and electric vehicles.

Owner:GUANGZHOU HKUST FOK YING TUNG RES INST +1

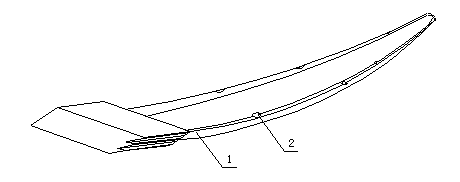

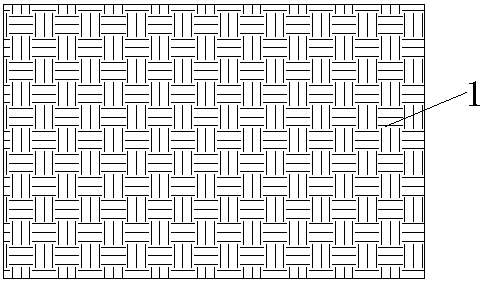

Wear resistant blade and processing method thereof

InactiveCN103158292AImprove wear resistanceImprove corrosion resistanceLamination ancillary operationsLaminationVacuum fusionWear resistant

The invention relates to the field of blades and especially to a wear resistant blade. The wear resistant blade is characterized in that a wearing layer is fixed on the inner wall of a blade body. Since vacuum fusion covering is employed for extrusion coating of the self-fluxing alloy powder on the external surface of the blade body, metallurgical bonding between the alloy powder and a cylinder barrel material is realized, and the blade with high wear resistance and high corrosion resistance is developed.

Owner:SHAANXI TIANYUAN MATERIALS PROTECTION TECH

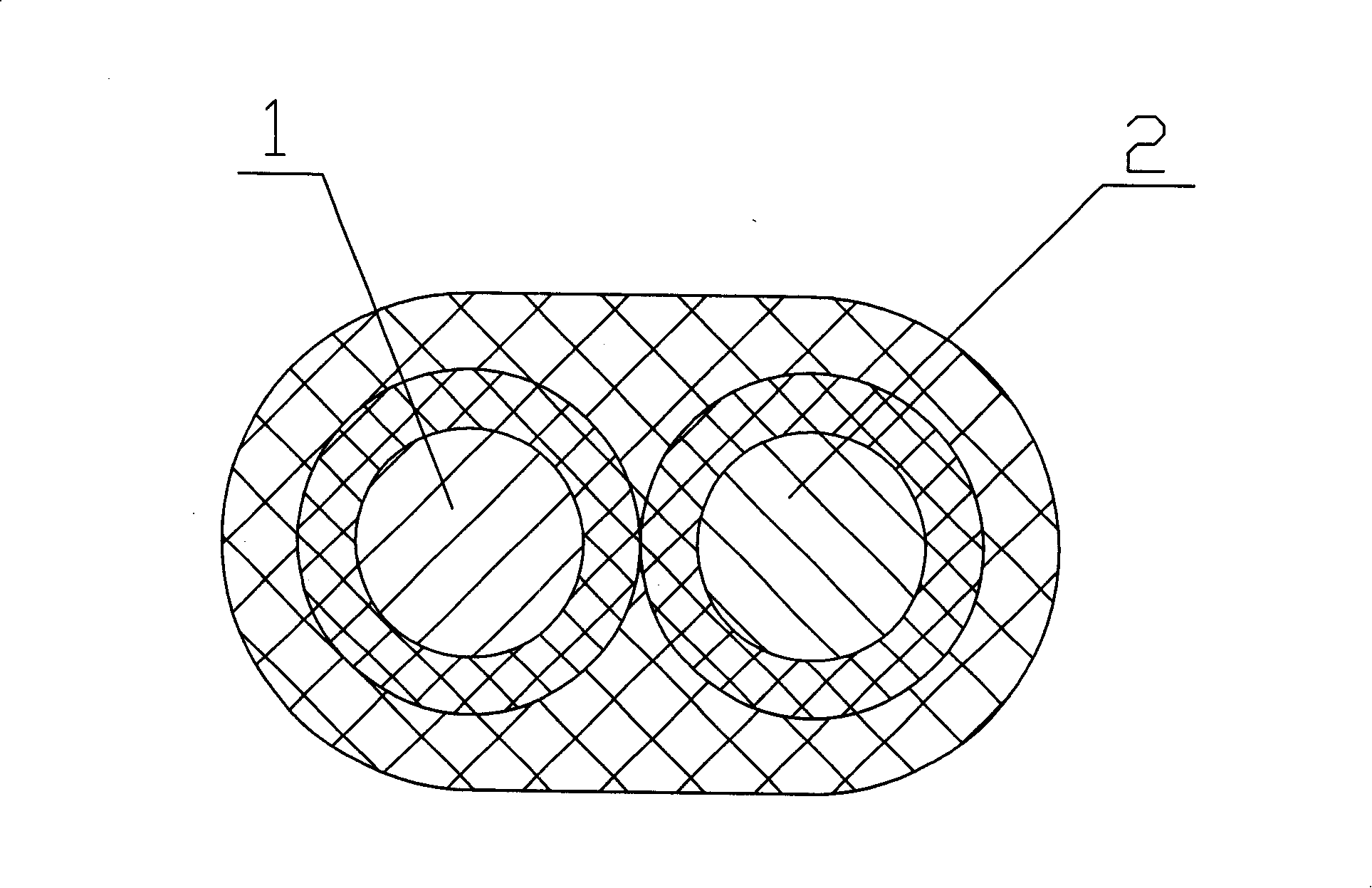

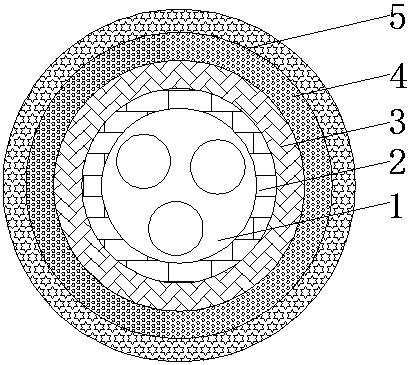

Graphene fiber insulating cable

ActiveCN107610823AImprove insulation performanceImprove securityInsulated cablesInsulated conductorsFiberEpoxy

The invention discloses a graphene fiber insulating cable. The graphene fiber insulating cable comprises a cable body; an insulating layer, a waterproof layer, a sunscreen layer and a wear-resisting layer are arranged on the surface of the cable body in sequence; the insulating layer is prepared from graphene fibers, a varnished cloth paint pipe and insulating immersed fibers in a mixing manner; the waterproof layer is prepared from polyvinyl chloride, acrylate, a polyurethane prepolymer and epoxy resin in a vacuum fusion manner; the sunscreen layer is prepared from ultra-thin glass wool and octyl salicylate through fine processing; and the wear-resisting layer is prepared by adding a nanometer additive to silicon carbide powder and a flexibilizer through high-temperature stirring. The invention relates to the technical field of the cable. By virtue of the graphene fiber insulating cable, the cable insulativity and the cable safety are improved, generation of an electric shock accidentcan be prevented, and a user can use the cable without any worry; and meanwhile, the cable has the multiple functions of waterproof property, sunscreen property and wear-resisting property, so that damage of the cable can be prevented, influence to use of the user caused by damage of the cable can be avoided, and property loss can be reduced at the same time.

Owner:加法电力设备(深圳)有限公司

Method for improving grade of titanium slag

ActiveCN110482603ARaise the gradeLow impurity contentTitanium dioxideVacuum fusionCalciums magnesium

The invention relates to a method for improving the grade of titanium slag, and belongs to the field of titanium slag smelting aftertreatment. The invention provides the method for improving the gradeof titanium slag. The method comprises the following steps: a, vacuum smelting: wherein 1.5%-2.5% w / w of a carbonaceous reducing agent is added into the titanium slag to obtain a mixture, and the mixture is subjected to vacuum smelting, wherein the vacuum degree is controlled to be -5 pa to 20 pa, the smelting temperature is controlled to be 1400 DEG C to 1550 DEG C, the smelting time is 10 min to 25 min, and the smelting power is controlled to be 15 kW to 25 kW, so that molten titanium slag is obtained for standby application; b, cooling and crushing the molten titanium slag; and c, carryingout magnetic separation on the titanium slag to obtain high-grade titanium slag. The method is easy to operate, conventional wet treatment equipment is reduced, the technological process is simplified, the titanium slag grade improving time is saved, the production cost of the boiling chlorinated titanium dioxide raw material is reduced, and a new method is provided for reducing the content of calcium and magnesium in the titanium slag, improving the titanium slag grade and providing a high-quality titanium-containing raw material for boiling chlorinated titanium dioxide.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Method for preparing TiAl alloy by adopting vacuum fusion casting method

The invention relates to a method for preparing a TiAl alloy by adopting a vacuum fusion casting method, comprising the following steps of: a, putting a graphite mold into an oven, drying the graphite mold at the temperature of 700-900 DEG C for 3-5 minutes, and putting the graphite mold into a vacuum fusion oven; b, feeding: adding metal Al and metal Ti into the vacuum fusion oven; c, evacuating: evacuating in the vacuum fusion oven below 2.0Pa; d,fusion casting: setting the heating rate to be12-18 DEG C / min and the fusion temperature to be 1400-1800 DEG C; and e, casting: after fusing the metal Al and the metal Ti, casting the metal Al and the metal Ti into the dried graphite mold to prepare the TiAl alloy material. The method for preparing a TiAl alloy by adopting a vacuum fusion casting method has simple process and low cost, and the prepared TiAl alloy material has high compactness and yield.

Owner:SHAANXI SIRUI ADVANCED MATERIALS CO LTD

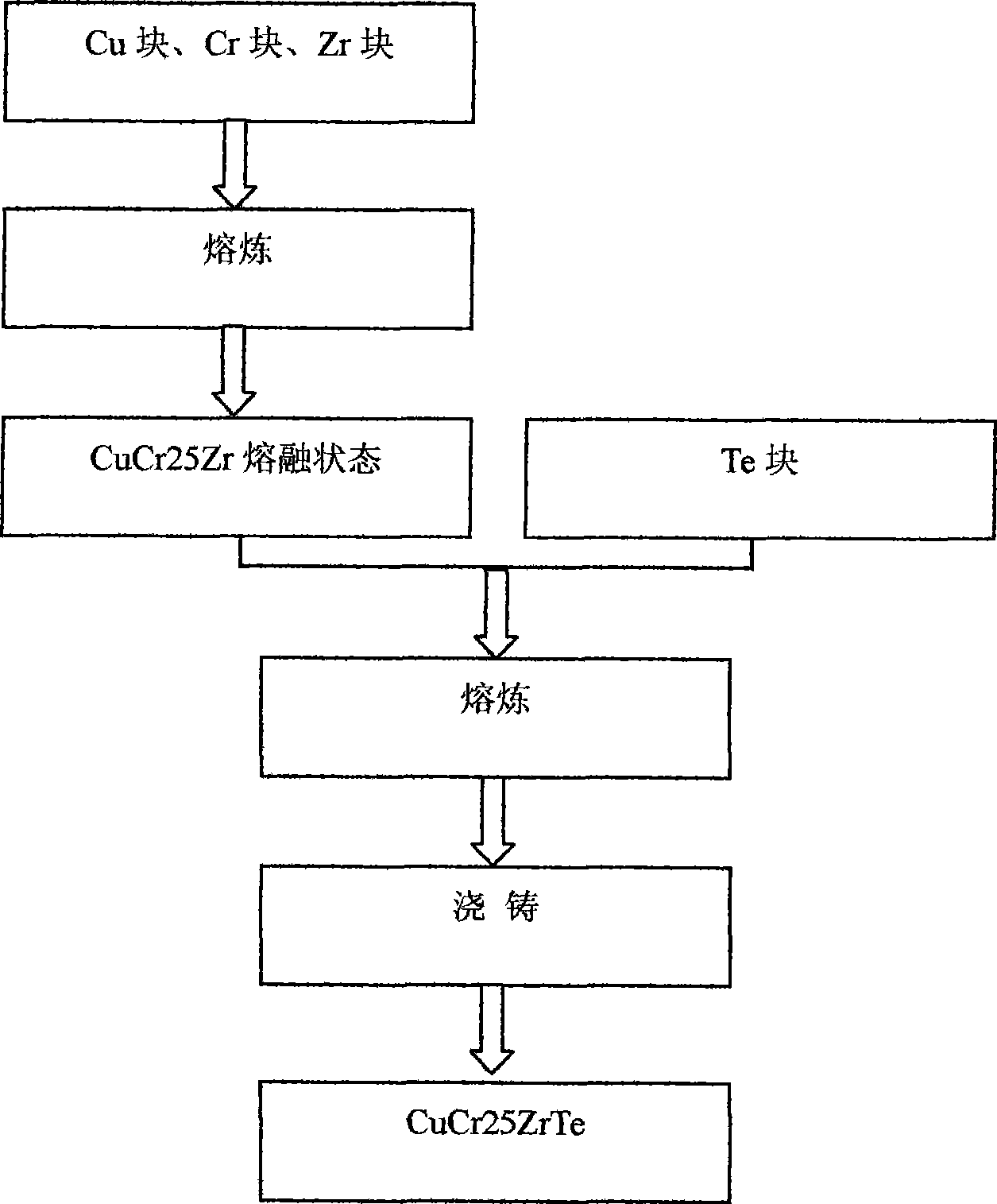

Method for preparing CuCr25ZrTe contact tip by vacuum casting process

ActiveCN101488406AReduce gas contentHigh voltage strengthElectric switchesVacuum fusionMetallic materials

The invention discloses a CuCr25ZrTe electrical contact prepared by using a vacuum fusion casting, belonging to the technical field of metallic material preparation. The components of the electrical contact are according to the percentage by weight: 25% of Cr, 0.01-0.3% of Te, 0.03-0.3% of Zr and the rest of Cu. The electrical contact is prepared by the following method: a Cu block, a Cr block and a Zr block are well mixed and put into a melting hearth; the melting is carried out in vacuum; after melting, the element Fe is added and casted after keeping a period of time; thereby CuCr25ZrTe electrical contact materials are obtained after cooling. The invention has the advantages that Zr is added into CuCr alloy, which reduces the gas content of the alloy and increases the wearing resistance of the alloy; the Te is added into CuCr alloy, which reduces the tensile strength of the alloy and increases the anti-melting welding performance. The preparation method of the invention has simple technique and low cost. Compared with CuCr25 composite materials, the prepared CuCr25ZrTe composite materials have more excellent performance.

Owner:SHAANXI SIRUI ADVANCED MATERIALS CO LTD

Electromagnetic-stirring pressurized centrifugal large-opening vacuum fusion casting furnace

ActiveCN103071784BMeet the requirements of nitrogen content (≥1.2%)Accurate ingredientsSteam pressureVacuum fusion

The invention discloses an electromagnetic-stirring pressurized centrifugal large-opening vacuum fusion casting furnace, which comprises a furnace body (1), a furnace door (2), a furnace cover (3), a sensor (4), a charging mechanism (5), a centrifugal rotating mechanism (7), an electromagnetic stirrer (8), a vacuum system (9), an inflating and pressurizing system (10) and a medium-frequency power supply (12), wherein the vacuum pumping pipe connecting port of the vacuum system (9) is communicated with the chamber of the furnace body (1); the sensor (4) is arranged in the chamber of the furnace body (1) and the power input end of the sensor (4) is connected with the power output end of the medium-frequency power supply (12); locking mechanisms are arranged on butting surfaces between the furnace body (1) and the furnace door (2) and between the furnace body (1) and the furnace cover (3); and the electromagnetic stirrer (8) is arranged around the rotating executing unit of the centrifugal rotating mechanism (7). The electromagnetic-stirring pressurized centrifugal large-opening vacuum fusion casting furnace has the advantages that the furnace can be used for producing cast ingots and precision castings made of high-nitrogen steel, high-temperature alloy and the like, the components of high-steam-pressure alloy elements can be guaranteed to be accurate, and the effects of mold filling and shrinkage compensation of special-shaped precision castings are ideal.

Owner:SHENYANG VACUUM TECH INST

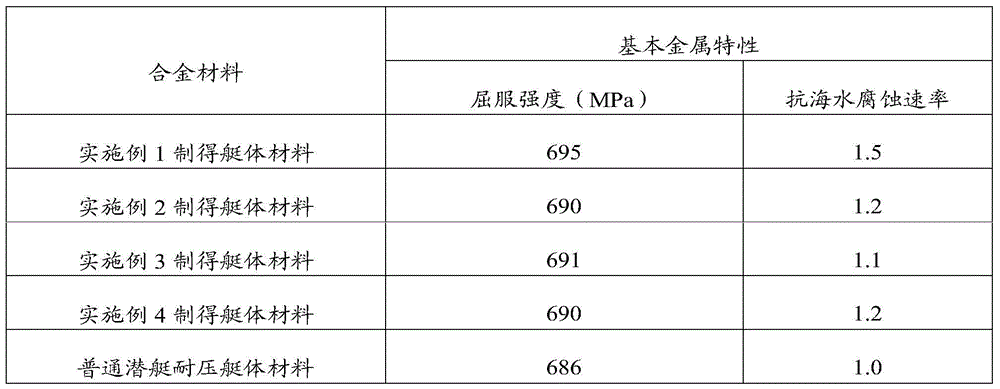

Pressure withstanding submarine body material for submarine and preparing method thereof

The invention discloses a pressure-resistant hull material for a submarine and a preparation method thereof. The specific steps of the preparation method include: (1) preparing raw materials, and the ratio by mass percentage is: carbon nanotubes 2%~5%, manganese 0.35%~ 0.65%, chromium 2.0%~2.75%, nickel 0.6%~1.0%, molybdenum 0.9%~1.2%, tungsten 2%~4%, rare earth elements 0.6%~0.9%, and the rest is iron; Raw materials such as iron, manganese, chromium, nickel, molybdenum, tungsten, ytterbium, rhenium, and cerium are added to the vacuum chamber, vacuumed, and melted in vacuum for 1 to 2 hours; (3) refill with argon, add carbon nanotubes, and keep warm for 40 minutes ~50min, the melting is uniform; (4) Keep the pressure down to room temperature at a cooling rate of 100°C / min~110°C / min, and obtain the finished submarine pressure hull material. The submarine pressure-resistant hull material prepared by the invention has excellent pressure resistance, friction resistance, corrosion resistance, high temperature resistance and high hardness.

Owner:福建海峡西岸知识产权研究院有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com