Vacuum fusion welding packaging method and packaging device

A packaging device and packaging method technology, applied in welding equipment, resistance welding equipment, metal processing equipment, etc., can solve the problems of hindering the vibration of the vibrator, reducing the quality of the product, and low welding yield, so as to achieve easy packaging operation and high yield , The effect of short welding time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

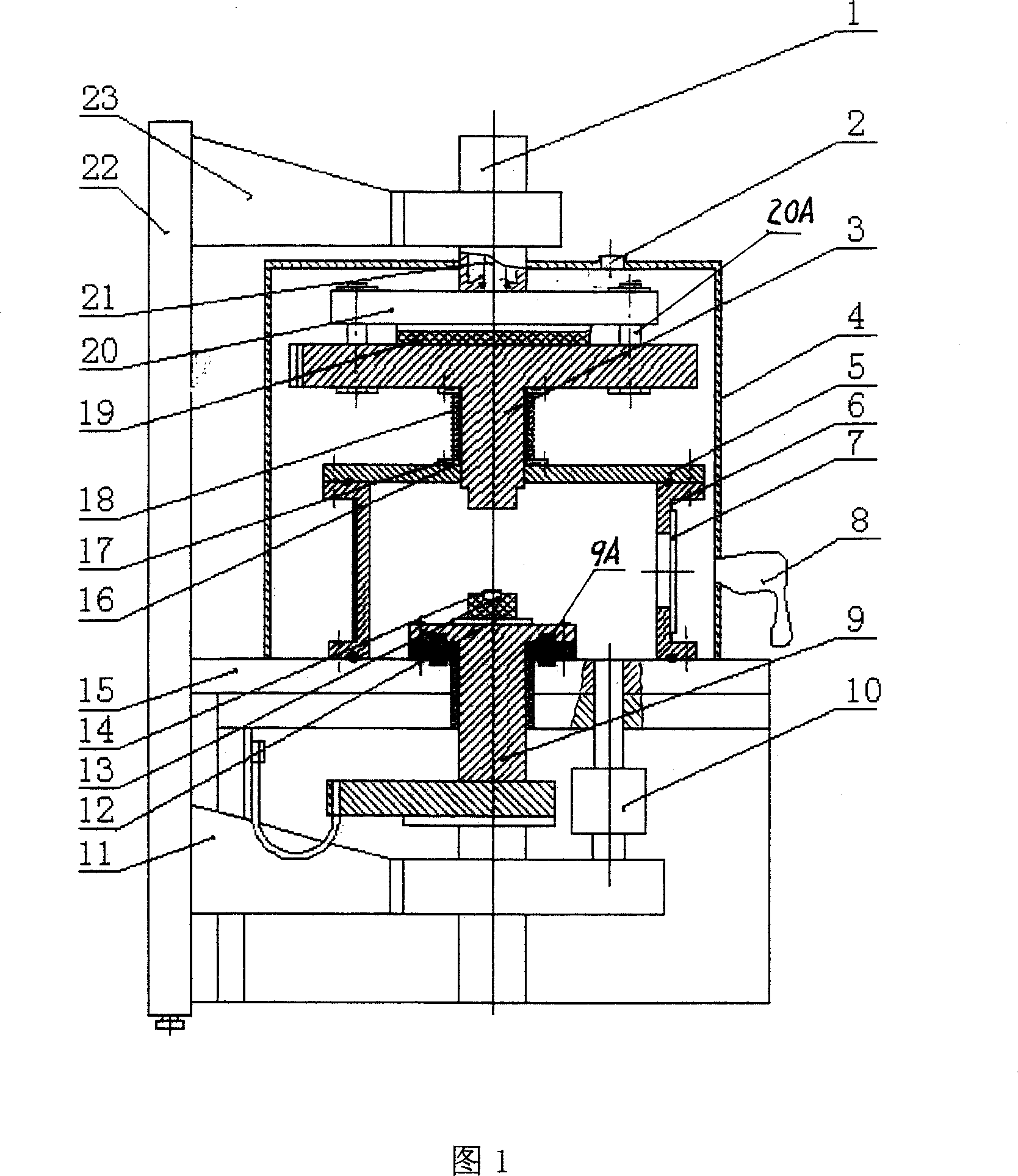

[0036] Embodiment 1. The vacuum fusion welding packaging method of the present invention comprises the following steps, as illustrated in FIG. 1:

[0037] (1), the pipe seat 14 and the pipe cap 13 to be welded are placed in the vacuum chamber 5,

[0038] (2), the vacuum chamber 5 is evacuated, and heated to degas simultaneously;

[0039] (3) The tube base 14 and the tube cap 13 located in the vacuum chamber 5 are welded and packaged together by electric welding.

Embodiment 2

[0040] Embodiment 2. Vacuum fusion welding packaging device

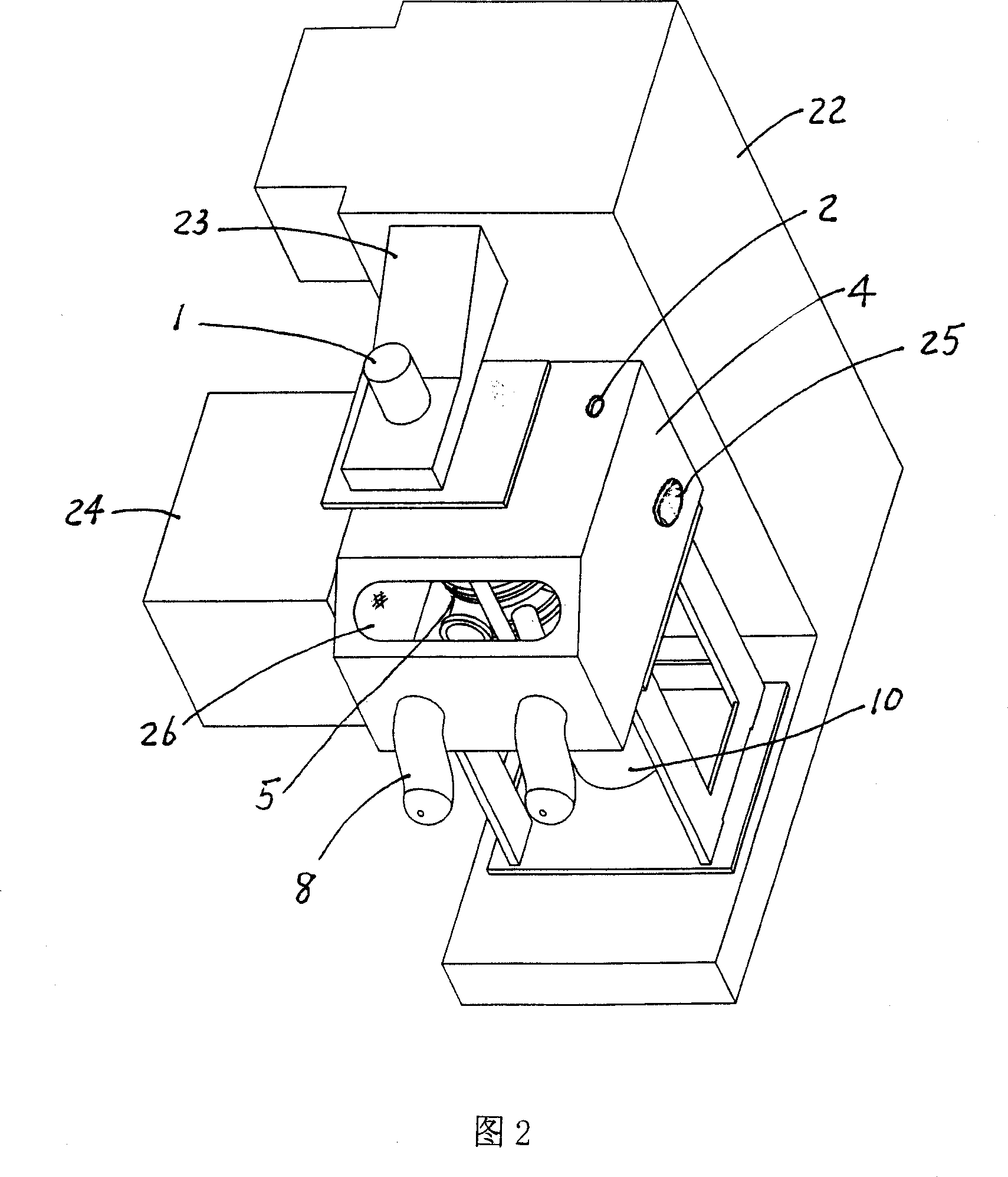

[0041] 1 and 2 are schematic diagrams of a vacuum welding packaging device, including a frame 22, a drive cylinder 1, a moving electrode 3, a static electrode 9, a nitrogen filling box 4, a vacuum chamber 5, and a vacuum pumping system 10;

[0042] The driving cylinder 1 is installed on the upper arm 23 of the frame 22; the moving electrode 3 is connected to the piston rod 21 of the driving cylinder 1; The nitrogen box 4 is surrounded by the vacuum chamber 5, and gloves 8 are installed on the nitrogen box 4; the vacuum chamber 5 has a valve 7, which communicates with the nitrogen box 4 through the valve 7, and the outer wall of the vacuum chamber 5 is wrapped with a heating jacket 6. The vacuum pumping system 10 is connected to the bottom of the vacuum chamber 5; the ends of the moving electrode 3 and the static electrode 9 extend into the vacuum chamber 5; between the moving electrode 3 and the vacuum chamber 5, a ...

Embodiment 3

[0047] Embodiment three, use a kind of operation method of this vacuum fusion welding packaging device, comprise the following steps, explain according to Fig. 1,2:

[0048] (1), preparation, the clamp 12 used during welding is cleaned before use, and the vacuum chamber 5 and the cleaned clamp 12 contained therein are preheated and degassed with the heating jacket 6;

[0049] (2), cleaning the tube base 14 and the tube cap 13 to be welded and packaged;

[0050] (3), the cleaned tube base 14 and tube cap 13 are put into a separate vacuum oven 24 (Fig. 2), and after heating and degassing, put into the vacuum chamber 5;

[0051] (4), put the tube base 14 and the cap 13 into the clamp 12 in the vacuum chamber 5 that is full of nitrogen (nitrogen is sent into by the hole 2 and the valve 7), close the valve 7, and vacuum the vacuum chamber 5 with the vacuum system 10 Vacuumize and heat with heating mantle 6;

[0052] (5) The tube base 14 and the tube cap 13 located in the vacuum cav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com