Preparation technique for cuprum peptide-cuprum nickel compensating conductor and alloy wire thereof

A technology for compensating wires and copper-titanium alloys, applied to metal/alloy conductors, thermometers using electrical/magnetic components that are directly sensitive to heat, using electromagnetic means, etc. major problems, to achieve the effect of cost reduction and high compensation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

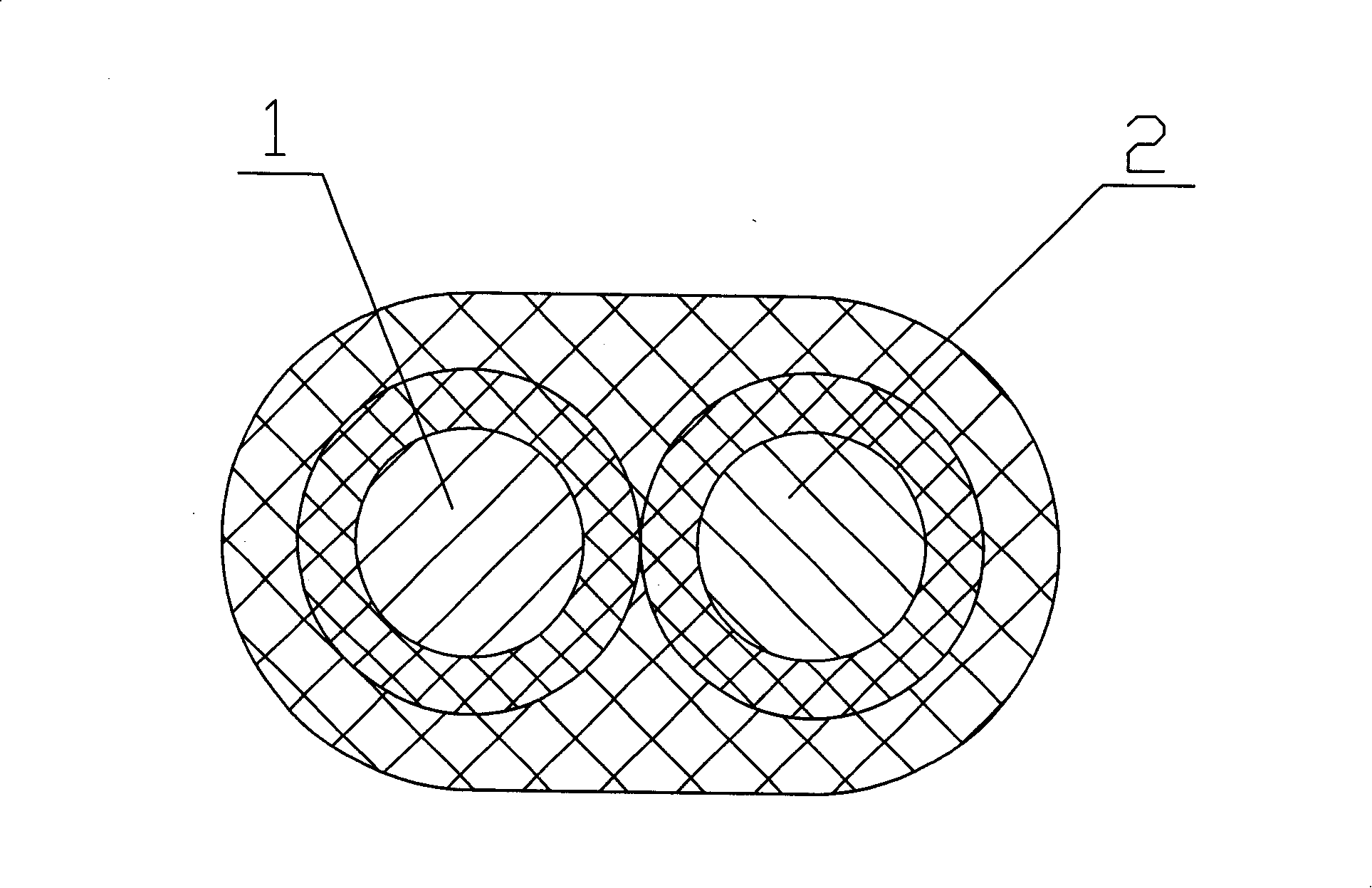

[0018] as attached figure 1 The illustration shows a compensation wire with a single strand of positive and negative conductors, and the present invention is also applicable to compensation wires with multiple strands of positive and negative conductors.

[0019] The first embodiment of the copper-titanium-copper-nickel compensation wire of the present invention:

[0020] Positive electrode conductor 1 is copper-titanium alloy wire, and its chemical composition weight percentage is 0.3% titanium, 0.04% rare earth, not more than 0.087% impurity and copper of the balance; Negative electrode conductor 2 is copper-nickel alloy wire, and its chemical composition weight percentage is The percentages are 16% copper, 0.3% manganese, 0.08% silicon, 0.005% carbon, 0.04% rare earth, no more than 0.107% impurities and the balance nickel.

[0021] The second embodiment of the copper-titanium-copper-nickel compensation wire of the present invention:

[0022] The positive electrode conduct...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com