Temperature compensation system and method for capacitance type micro-mechanical accelerometer

A technology of capacitive micro-mechanics and temperature compensation, which is applied in the direction of measuring acceleration, speed/acceleration/shock measurement, measuring devices, etc., can solve the problems of unreachable, temperature measurement value error, high compensation accuracy, etc., and achieve the reduction of temperature compensation cost, The effect of improving temperature compensation accuracy and avoiding temperature measurement error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

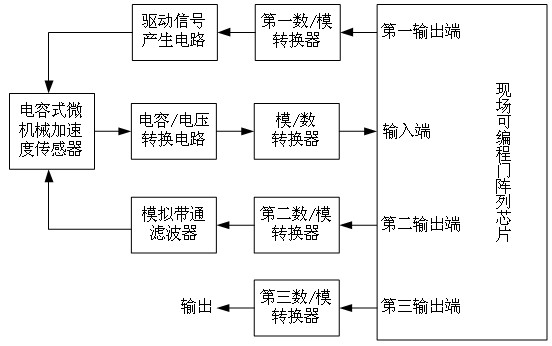

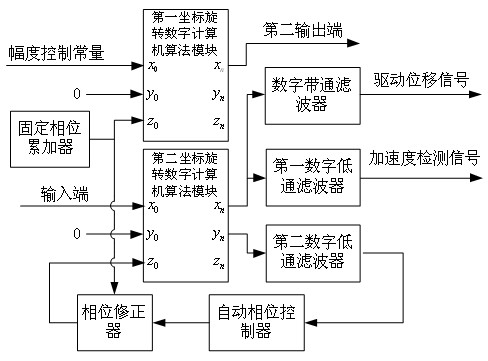

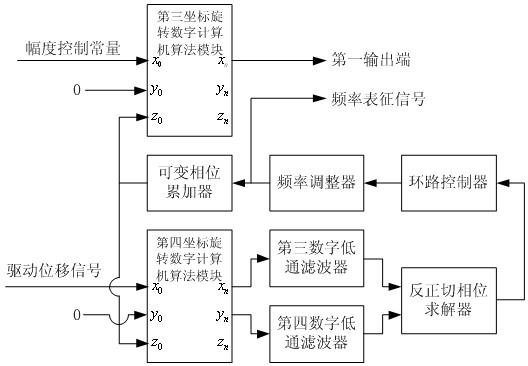

[0020] The capacitive micro-mechanical acceleration sensor is sensitive to the external acceleration signal, and converts the acceleration signal into a capacitance change, and converts the capacitance change inside the sensor into a voltage change through the capacitance / voltage conversion circuit, and then the input acceleration can be obtained through the subsequent processing circuit The size of the signal, so as to realize the detection of acceleration. Since the key unit of the capacitive micro-machined acceleration sensor is a capacitor, when the temperature changes, the capacitance of the capacitor will change, which will cause a change in the system's zero-bias output signal and affect the detection of the real acceleration signal by the capacitive micro-machined accelerometer system . In order to reduce the influence of temperature on the output signal of the capacitive micromachined accelerometer system, it is necessary to adopt an effective temperature compensation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com