Patents

Literature

32results about How to "Improved Temperature Compensation Accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Temperature compensation system and method for capacitance type micro-mechanical accelerometer

ActiveCN102435774AReduce temperature compensation costsEliminate the influence of compensation accuracyAcceleration measurementCapacitanceAccelerometer

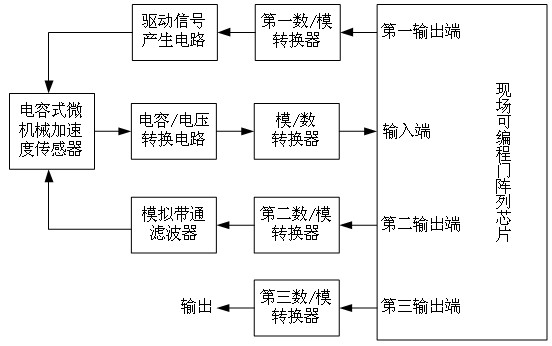

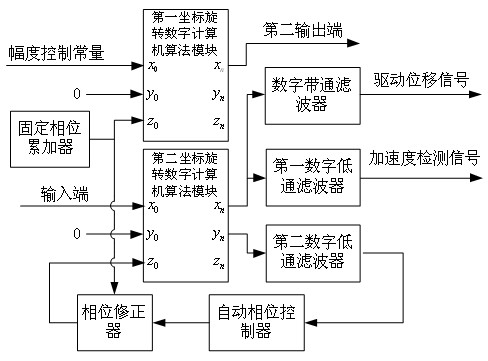

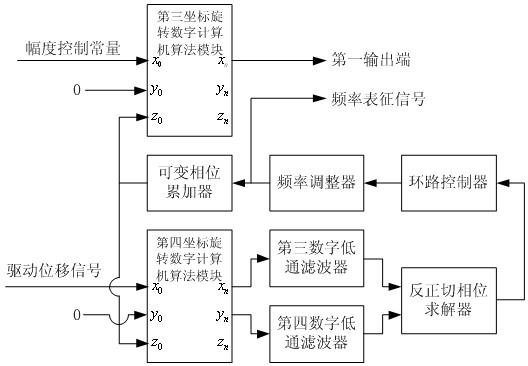

The invention discloses a temperature compensation system and a temperature compensation method for a capacitance type micro-mechanical accelerometer. The temperature compensation system for the capacitance type micro-mechanical accelerometer comprises a capacitance type micro-mechanical acceleration sensor, a driving signal generating circuit, a capacitance / voltage switching circuit, an analog band-pass filter, a first digital / analog (D / A) converter, an analog / digital (A / D) converter, a second D / A converter, a third D / A converter and a field programmable gate array chip. The temperature compensation method for the capacitance type micro-mechanical accelerometer comprises three steps of: carrier wave generating / synchronously demodulating, resonance frequency locking and zero offset temperature compensating. According to the invention, the temperature change of a capacitance type micro-mechanical acceleration sensor is detected by the means that the resonance frequency of the capacitance type micro-mechanical acceleration sensor changes along with the change of the temperature, and the temperature compensation system is used for compensating the temperature by the means that the resonance frequency is taken as a compensation reference signal of an output signal of a capacitance type micro-mechanical accelerometer system. Therefore, the temperature compensation cost is reduced, the influence of temperature measurement errors on compensation precision is eliminated, and the temperature compensation precision is improved.

Owner:ZHEJIANG UNIV

Temperature compensating device for micro-machined capacitive accelerometer

ActiveCN101858930ASimple structureLow costAcceleration measurementElectrical resistance and conductanceLow-pass filter

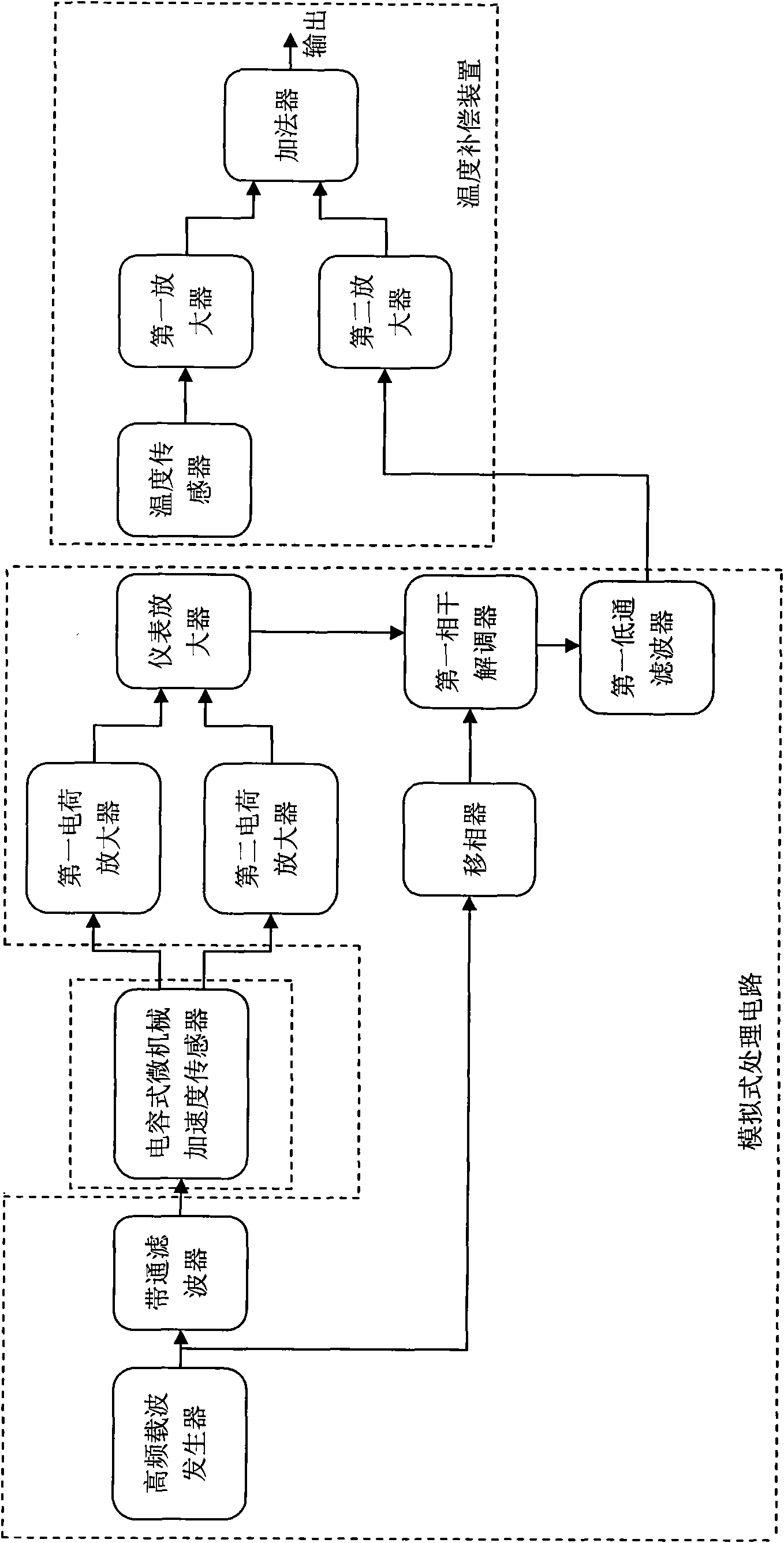

The invention discloses a temperature compensating device for a micro-machined capacitive accelerometer. The temperature compensating device mainly comprises a coherent demodulator, a low pass filter and a temperature compensating circuit, wherein an output end of the coherent demodulator is connected with an input end of the low pass filter; and the output end of the low pass filter is connectedwith the input end of the low temperature compensating circuit. By taking the internal capacitance which changes with the temperature of the micro-machined capacitive accelerometer as a compensating reference signal of an output signal of the accelerometer, the temperature compensating device does not need a thermistor or an integrated temperature sensor for measuring the temperature of an acceleration sensor, so the structure of the temperature compensating device is simplified, and the cost is reduced; the influence on compensating precision due to temperature measurement error is eliminated, and the temperature compensating precision is improved; and no temperature sensor is needed to be arranged and used on the micro-machined capacitive accelerometer, so a temperature measurement error due to a temperature gradient of a metal pipe shell of the acceleration sensor is avoided, and the temperature compensating precision is further improved.

Owner:ZHEJIANG UNIV

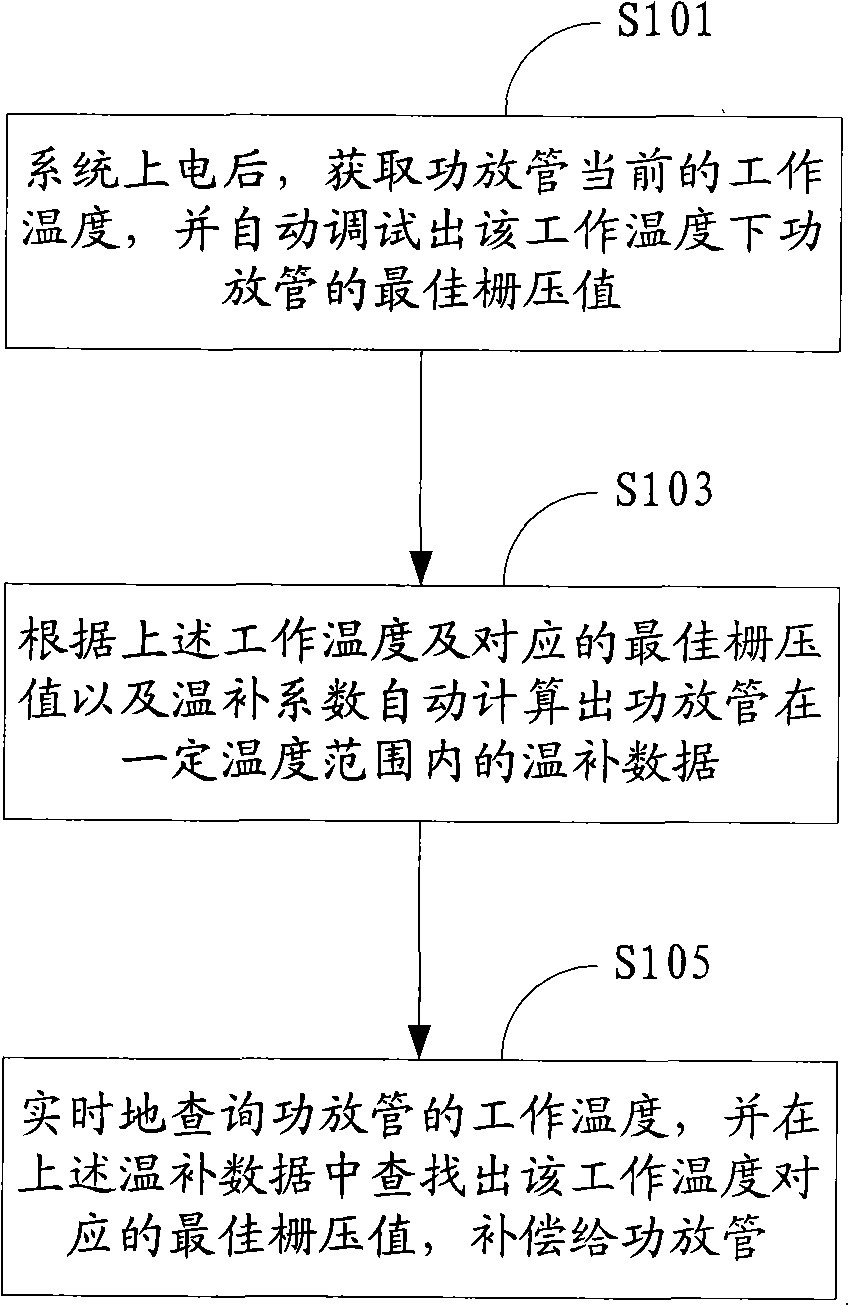

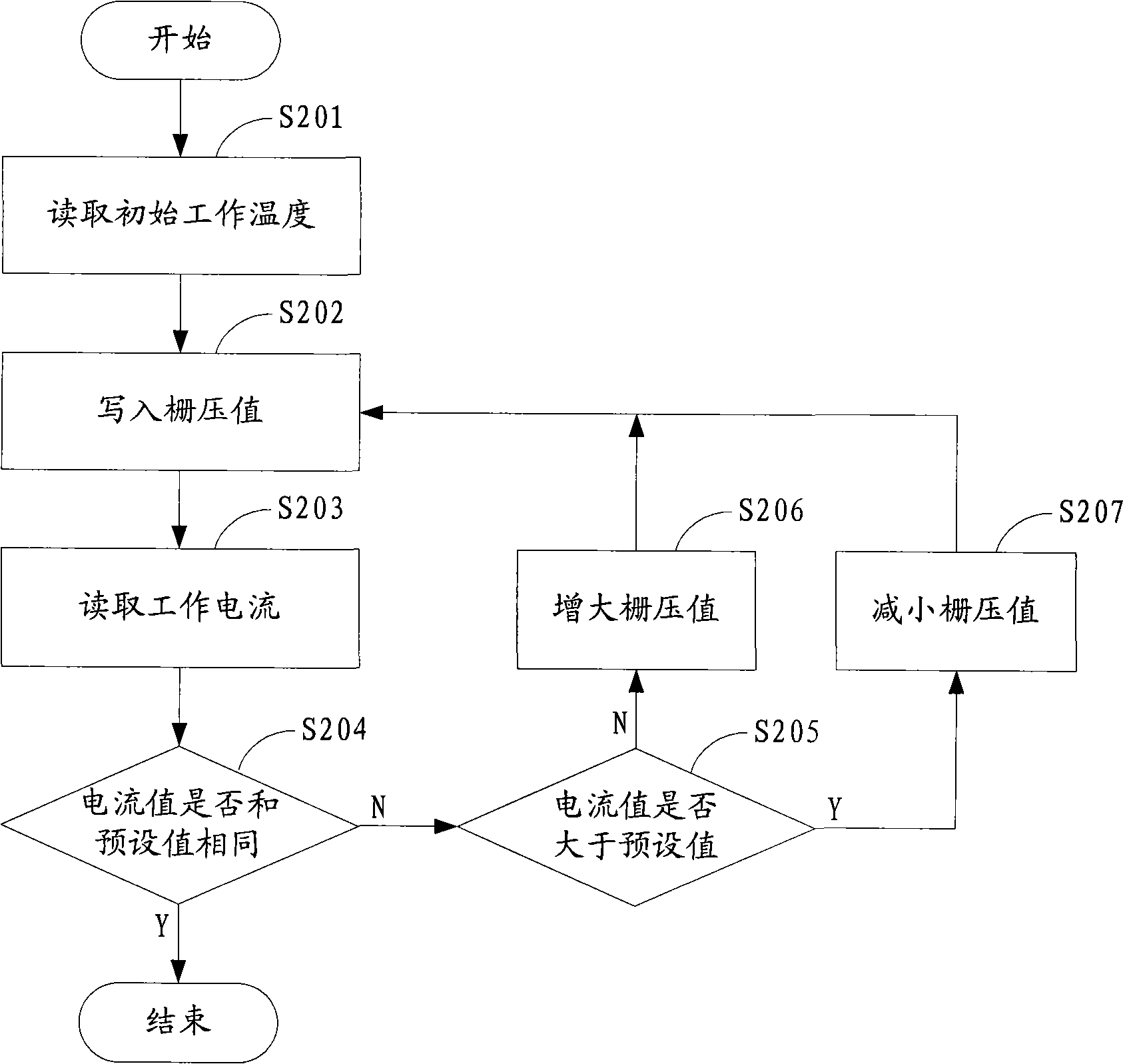

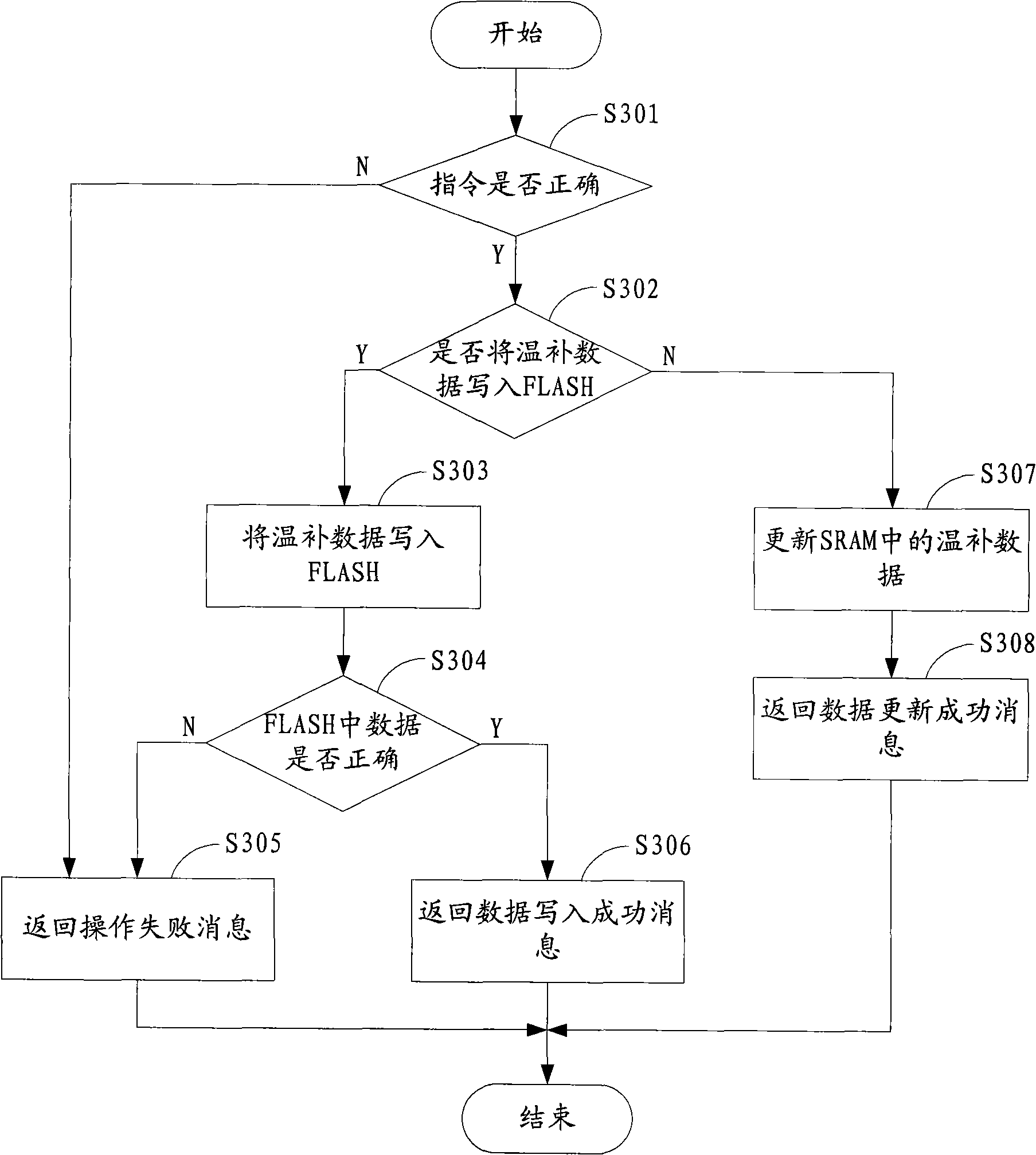

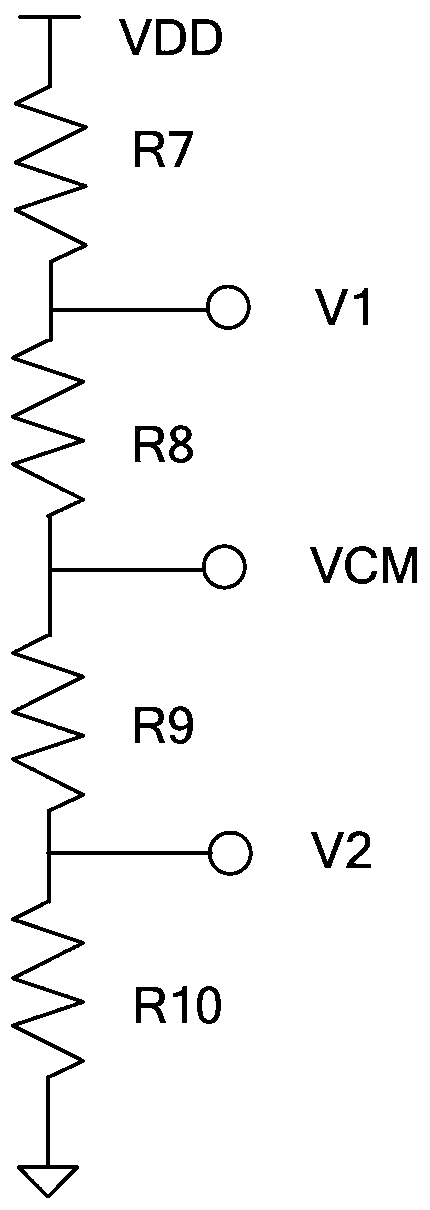

Method and apparatus system for compensating temperature of power amplifier

InactiveCN101299595AImproved Temperature Compensation AccuracyImprove anti-interference abilityAmplifier modifications to reduce temperature/voltage variationLDMOSAudio power amplifier

The invention is suitable for the electronic technology field, which provides a power amplifier temperature compensation method and a device system, wherein the method includes obtaining the current working temperature of the temperature compensated power tube, automatically adjusting the optimum grid voltage of the power tube under the current working temperature; computing the warming and invigouating data in a certain range according to the current working temperature and the optimum grid voltage; real-time detecting the working temperature of the power tube, looking for the corresponding offset data in the warming and invigouating data according to the working temperature, and performing the temperature compensation to the power tube by the offset data. The invention automatically matches the corresponding warming and invigouating data for the power tubes required for temperature compensation, and obtains the temperature information of the power tube through the digital temperature sensor, and adopts the separate reference voltage module to provide the reference voltage for the D / A modular converter, which advances the temperature compensation precision of the LDMOS power tube and enhances the interference immunity.

Owner:NTS TECH CHENGDU

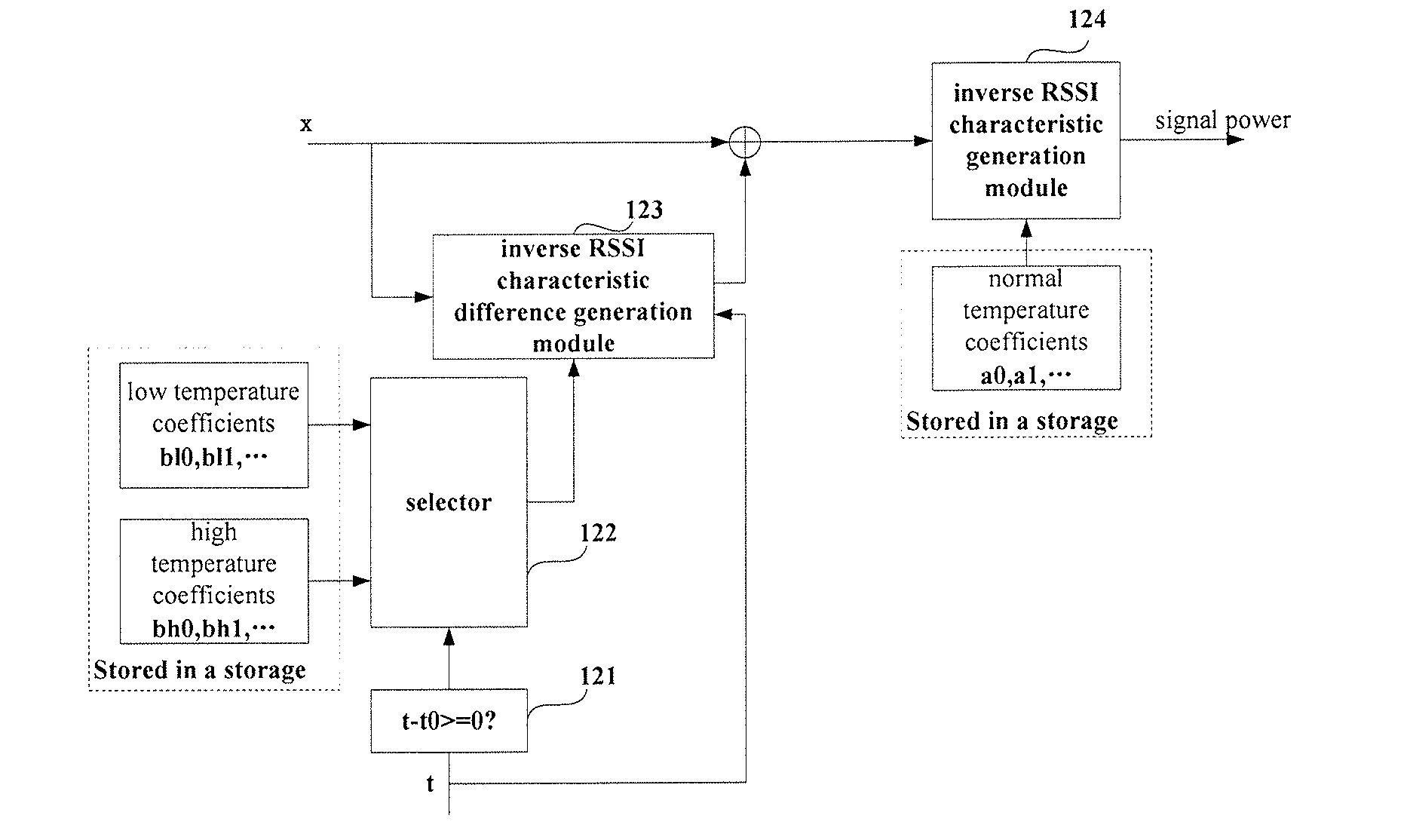

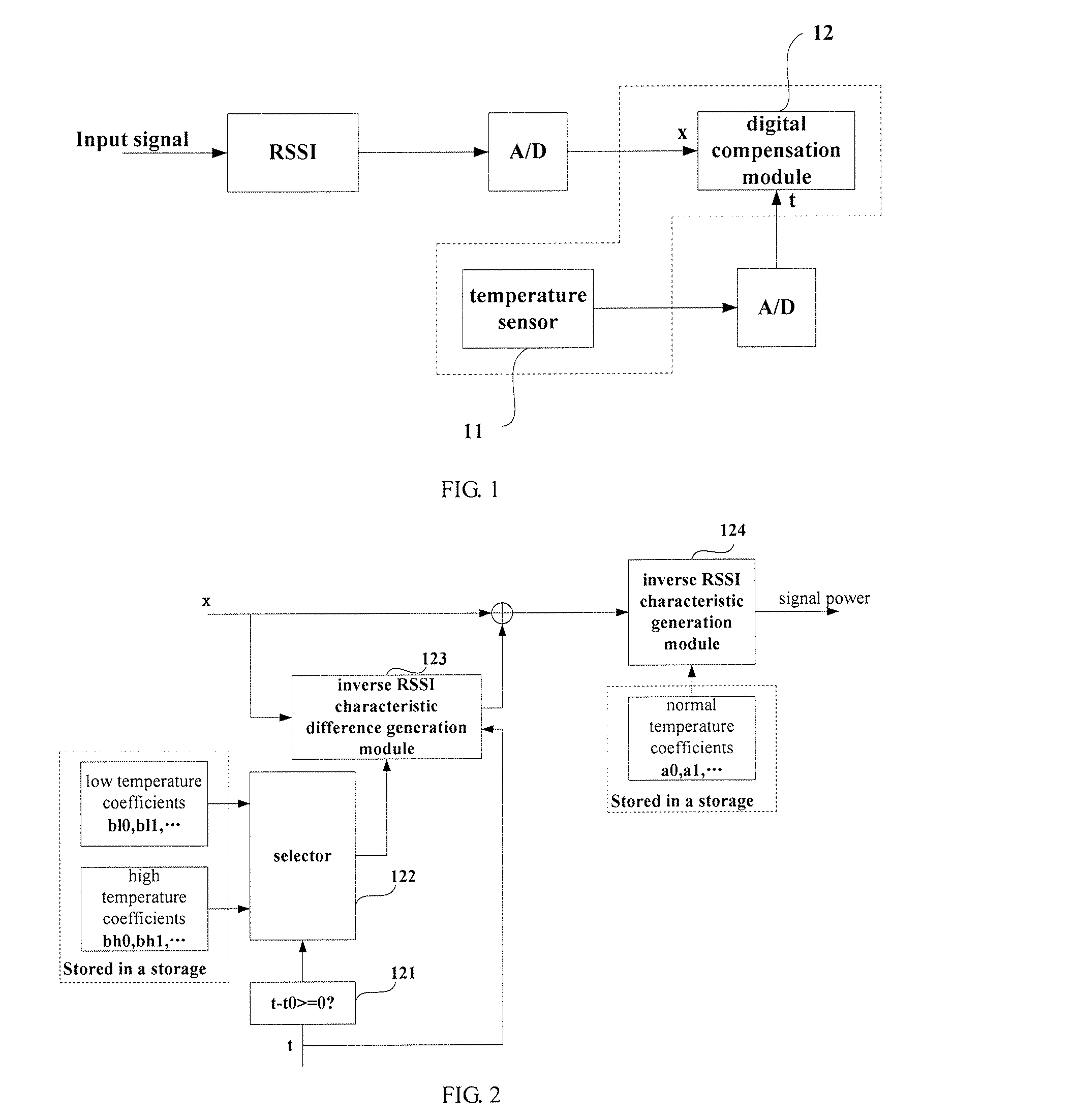

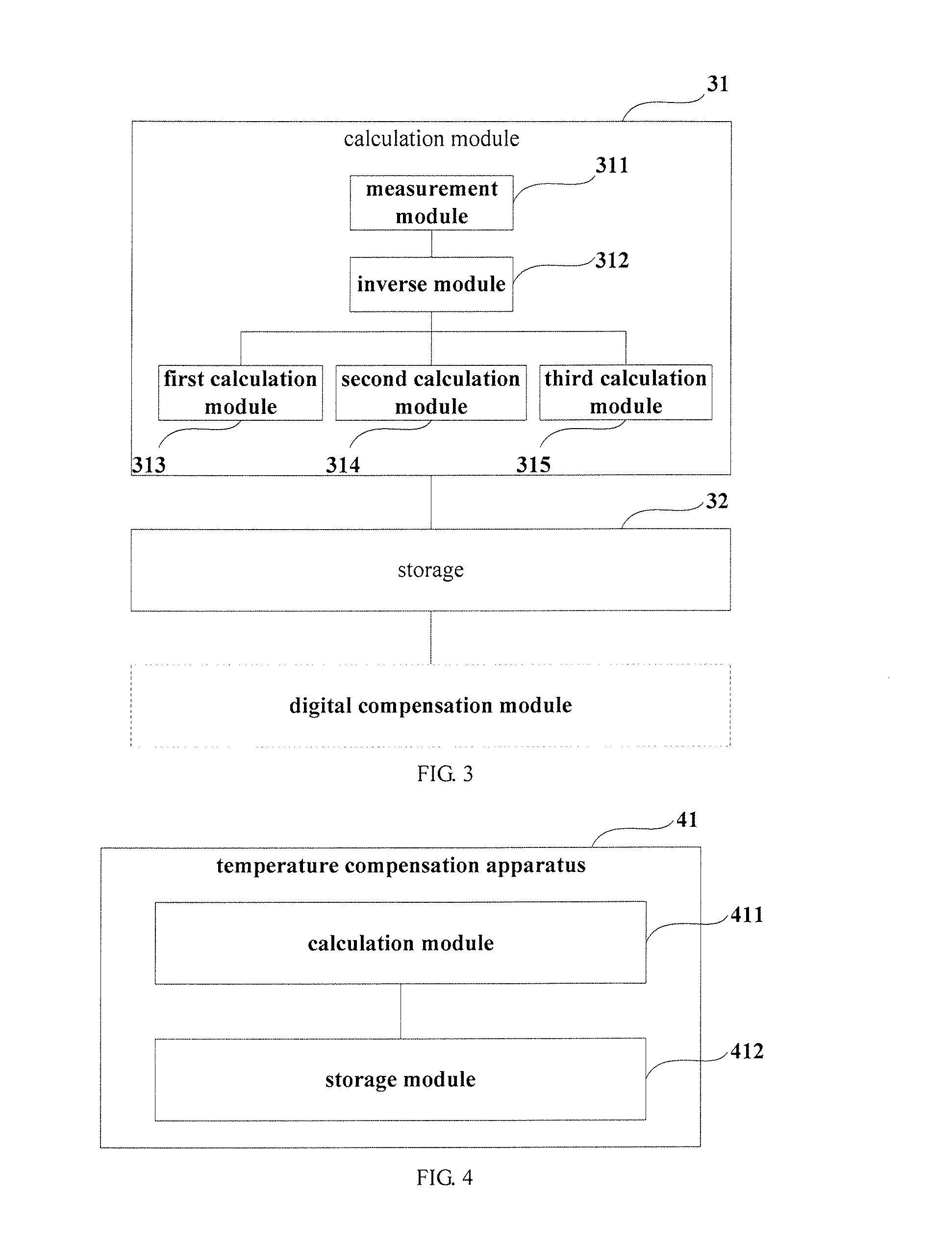

Temperature compensation method and apparatus for received signal strength indicator

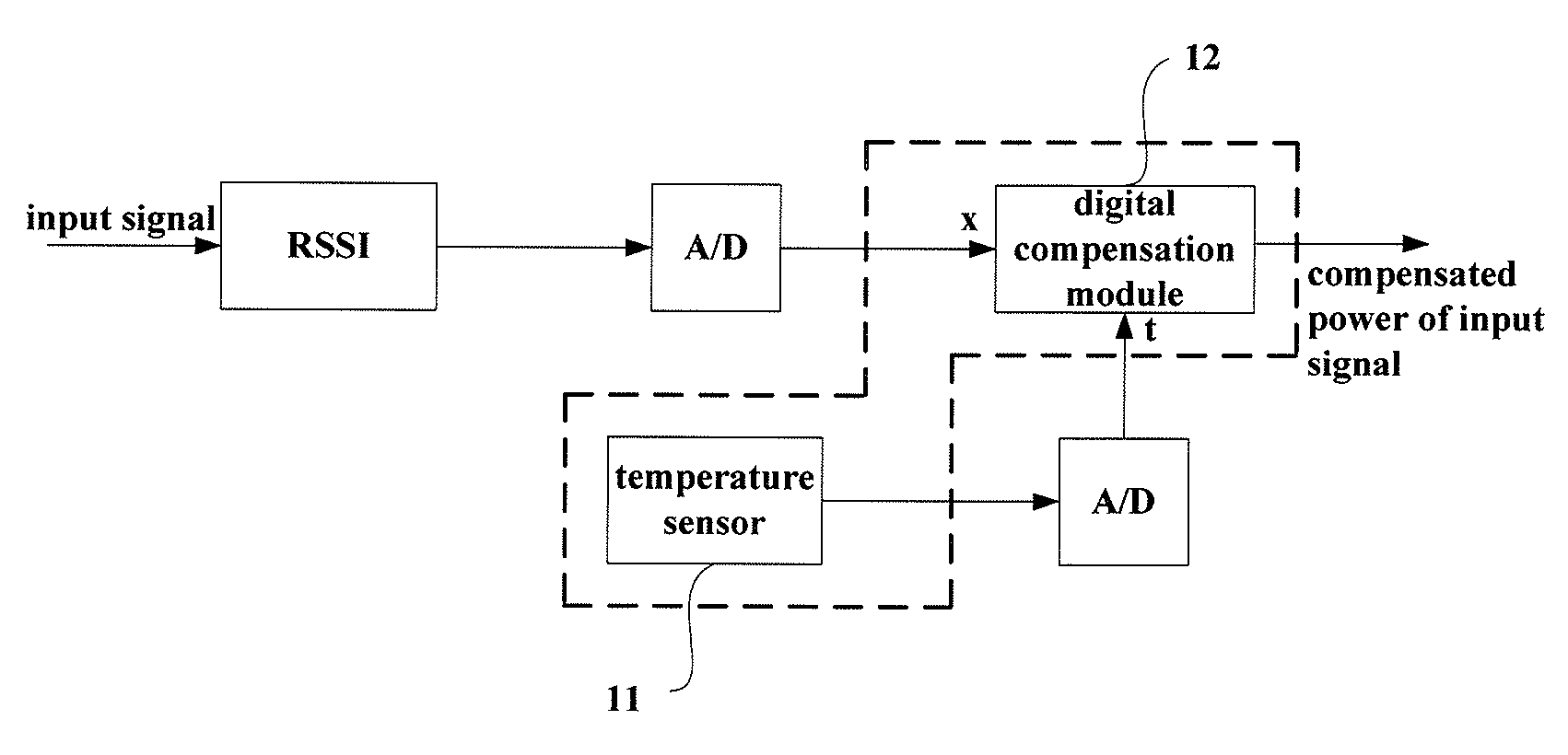

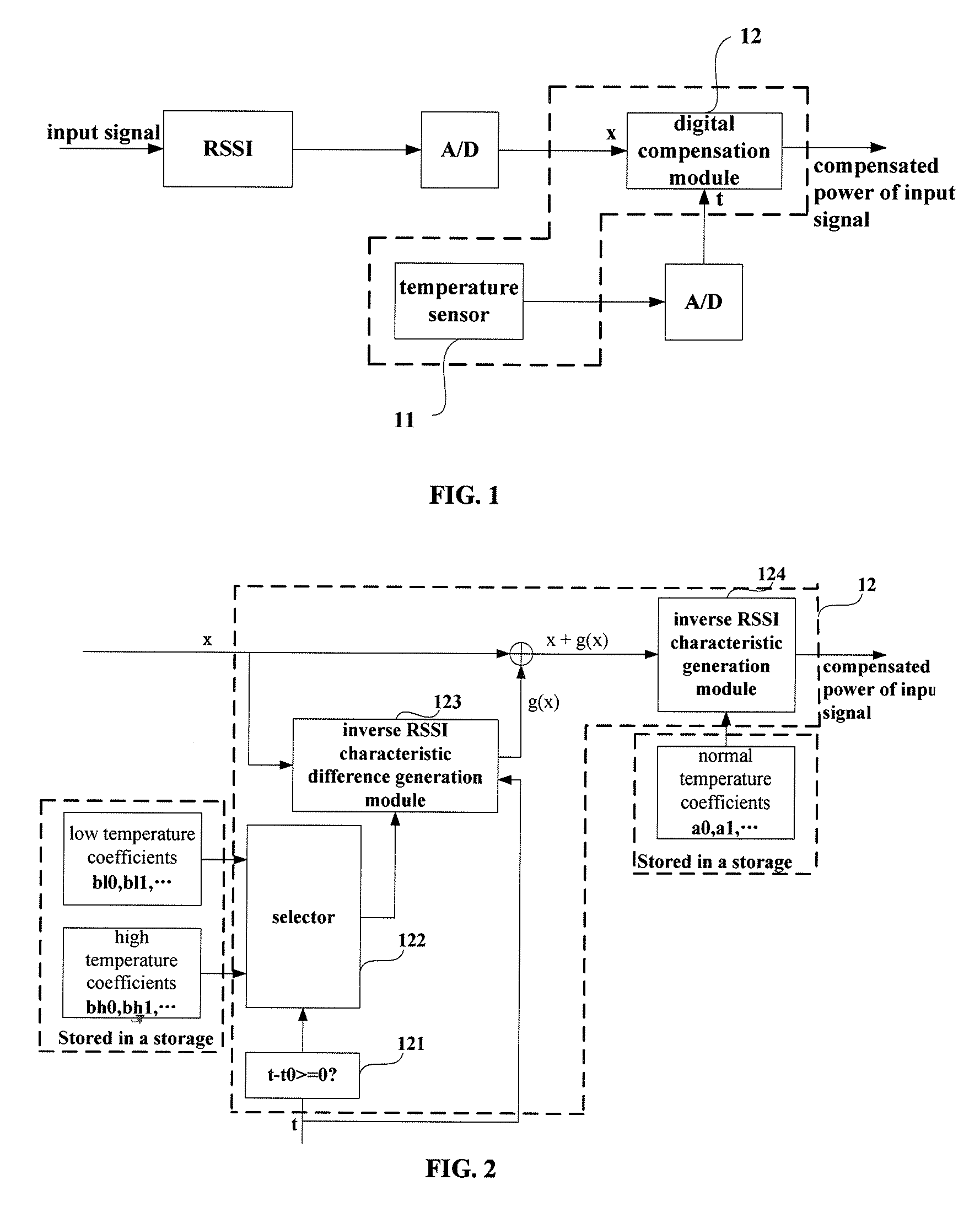

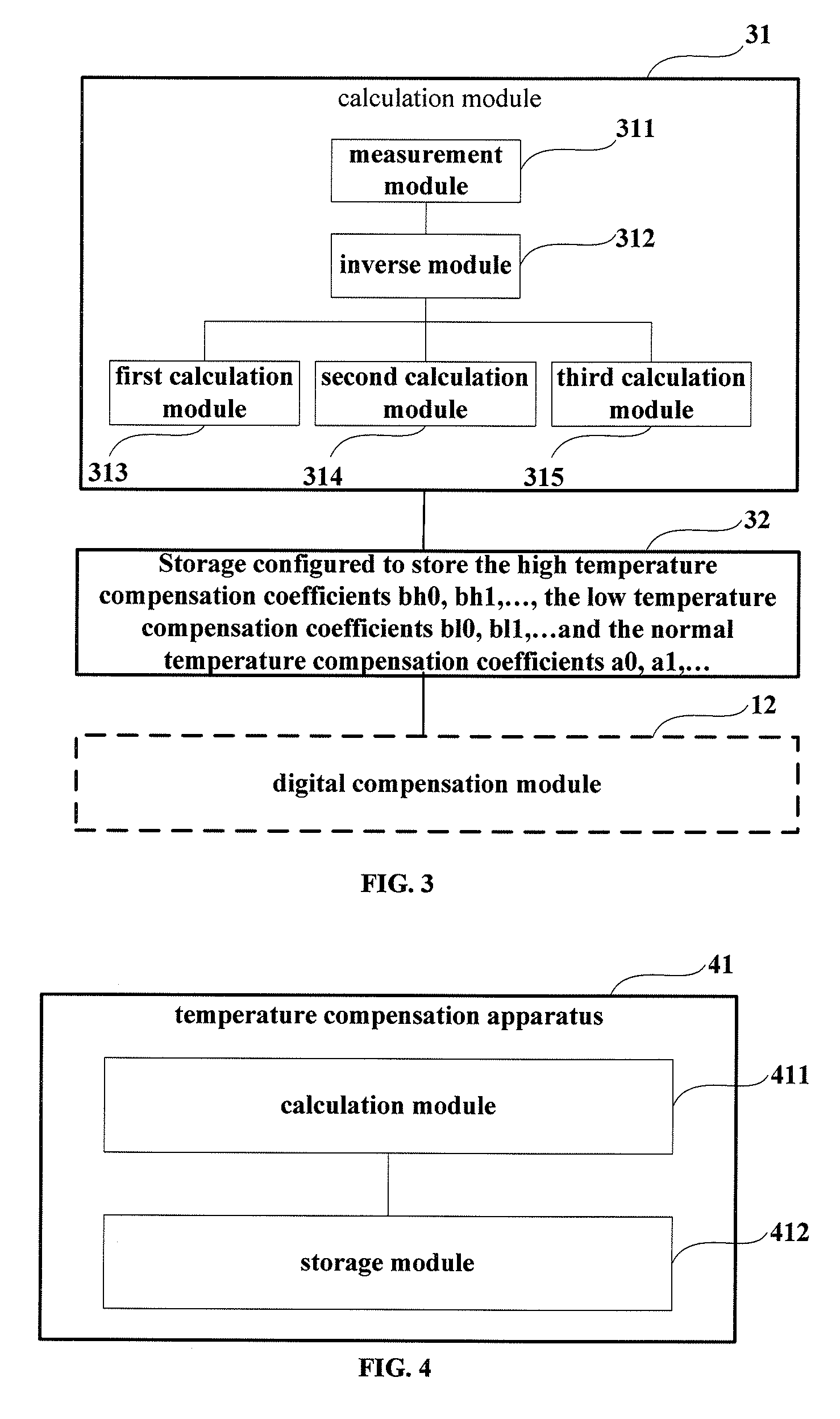

ActiveUS20140094133A1Improve accuracyReduce storage spaceReceivers monitoringElectromagentic field characteristicsReceived signal strength indicationEngineering

Embodiments of the present invention provide a temperature compensation method and apparatus for a received signal strength indicator. The apparatus comprises a temperature sensor configured to measure a current temperature; and a digital compensation module configured to select a temperature compensation coefficient from prestored temperature compensation coefficients corresponding to a normal temperature, a low temperature and a high temperature according to the current temperature, and perform temperature compensation on output signals of the RSSI according to the selected temperature compensation coefficient. With the method and apparatus of the embodiments of the present invention, the accurate power values of the input signals of the RSSI under any temperatures can be obtained by measuring the characteristics of the RSSI under the predefined three temperatures, and using an interpolation method to compensate for the temperature characteristics of the RSSI. In comparison with the relevant art, the size of the storage is decreased and the accuracy of temperature compensation is improved.

Owner:FUJITSU LTD

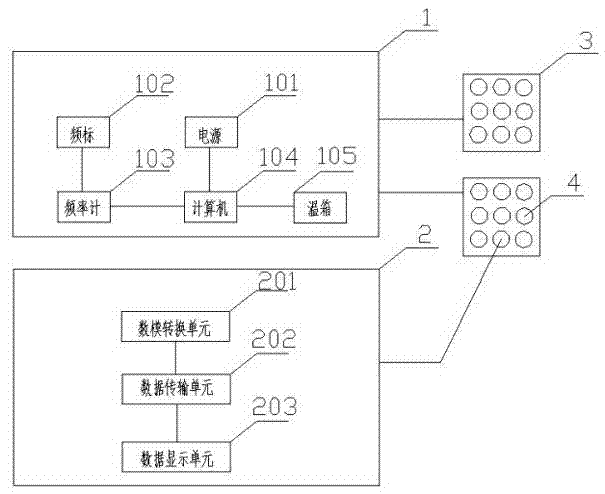

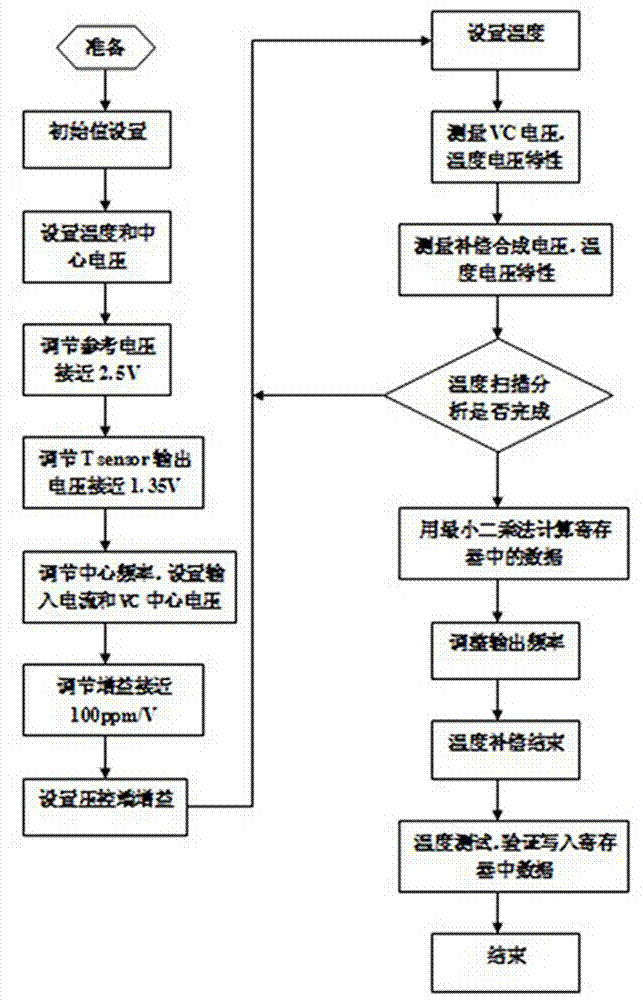

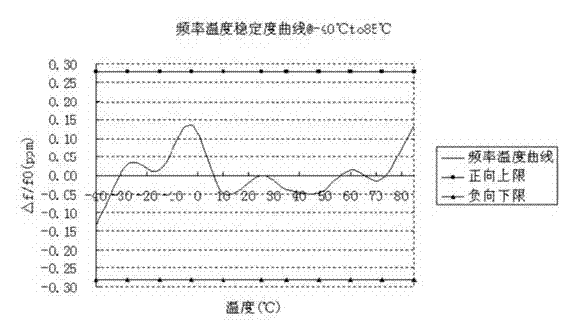

High-accuracy temperature compensation crystal oscillator system and operational method thereof

InactiveCN103036505AImproved Temperature Compensation AccuracyImprove work efficiencyOscillations generatorsCapacitanceInternal memory

The invention relates to a high-accuracy temperature compensation crystal oscillator system and an operational method of the high-accuracy temperature compensation crystal oscillator system. The high-accuracy temperature compensation crystal oscillator system comprises a computer, a power supply, an incubator, a frequency meter, a frequency-scaling and data-transporting and displaying unit, a data input and output (DIO) card used for driving the testing controlling board arranged on the computer mainboard in an inserting mode, and a general purpose interface bus (GPIB) card used for driving the incubator, the frequency meter, and the power supply. Software based on event-driving controls the power supply, the incubator and the frequency meter through the DIO card and the GPIB card, reads multiple sets of data of each set temperature point and stores the data inside a computer database. The multiple sets of data are synthesized into a plurality of five-order functions in a set temperature range, and a best curve is calculated by the software. Each coefficient of the best curve is extracted, and is converted into numbers inside the an internal memory of a crystal oscillator chip through an analog to digital (A / D) converter, and therefore the number of capacitors controlled by the memory is changed, and the purpose of high-accuracy temperature compensation of the crystal oscillator is achieved. The high-accuracy temperature compensation crystal oscillator system and the operational method of the high-accuracy temperature compensation crystal oscillator system can be produced in scale and are high in working efficiency.

Owner:TANGSHAN JINGYUAN YUFENG ELECTRONICS

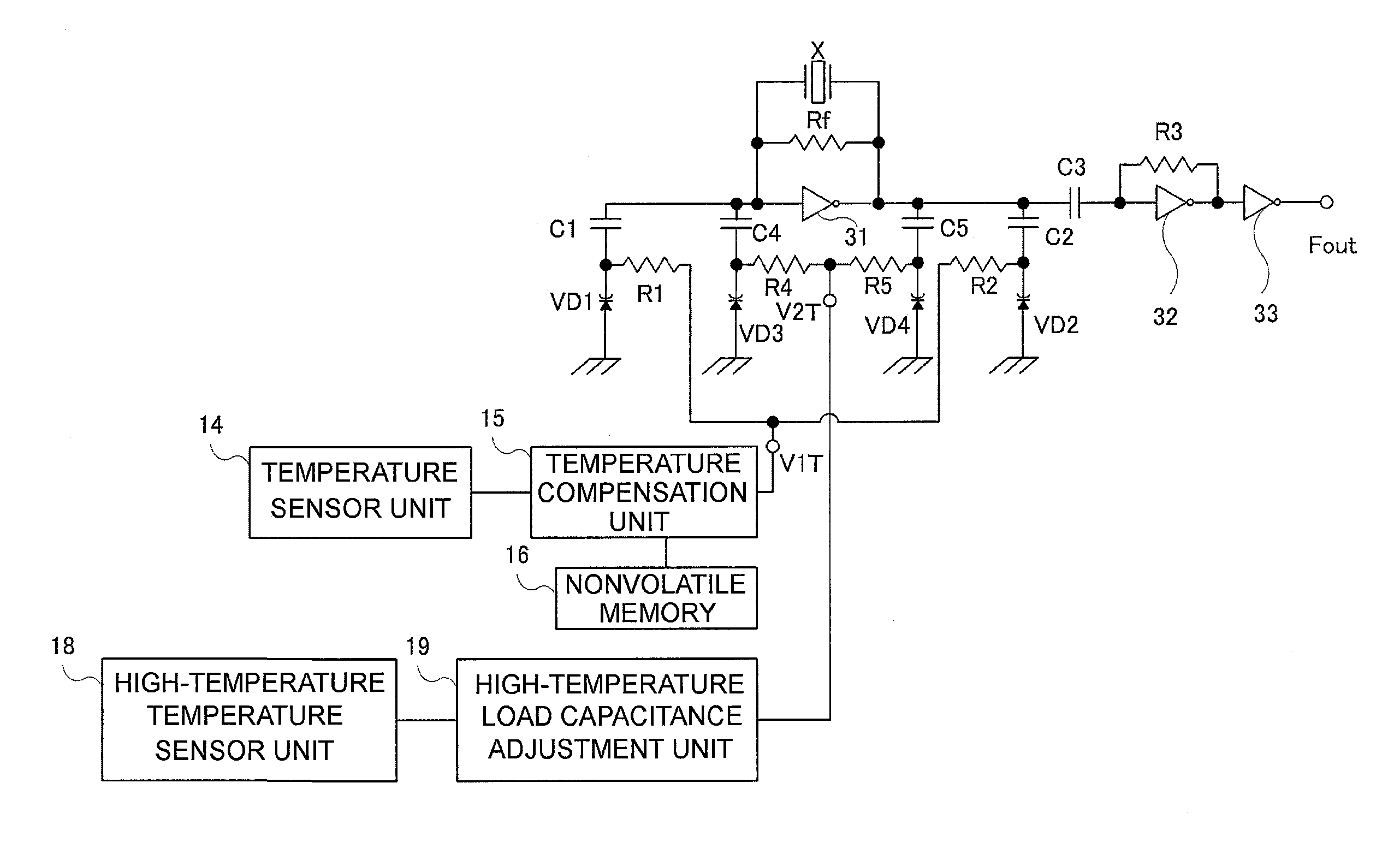

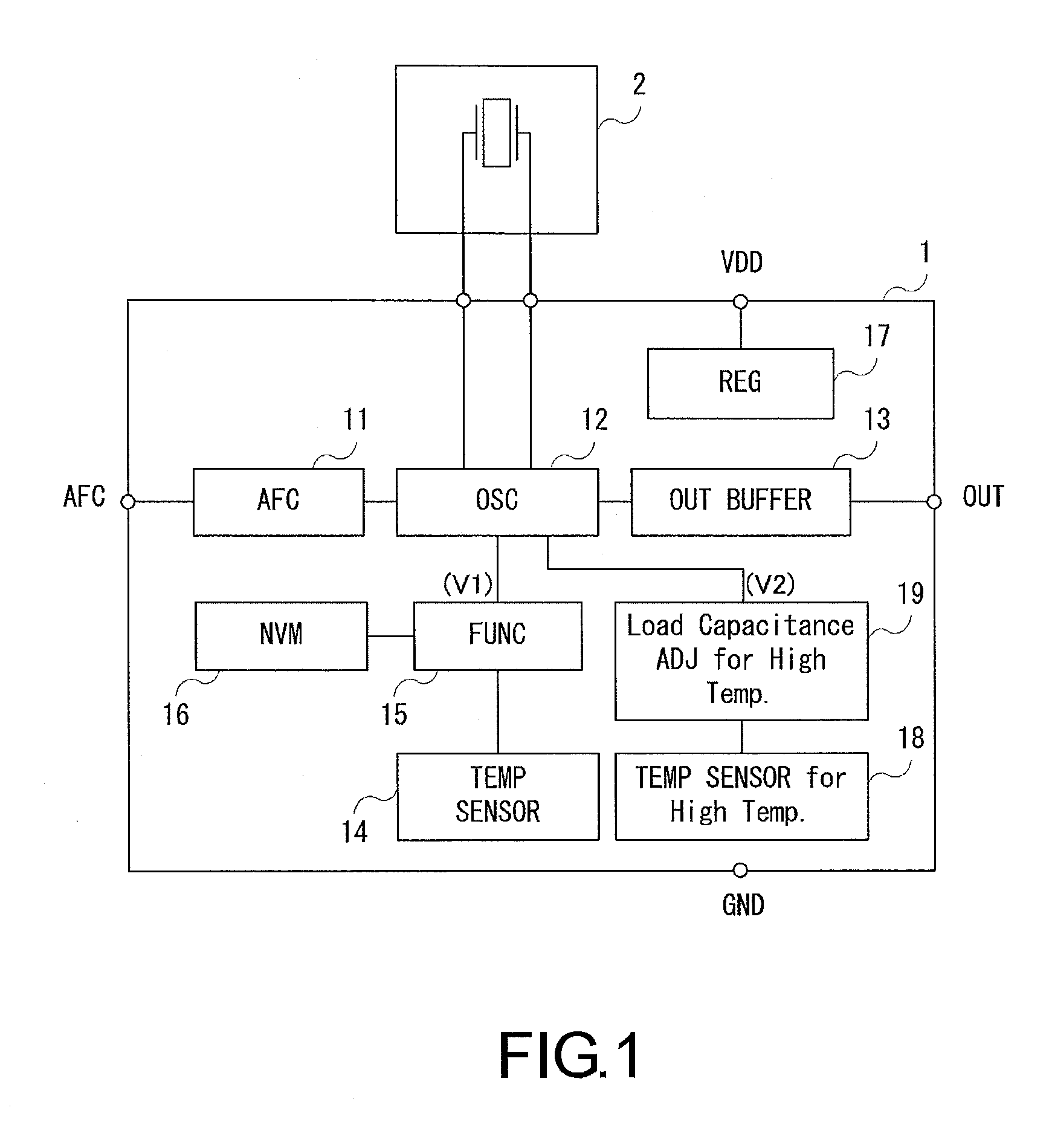

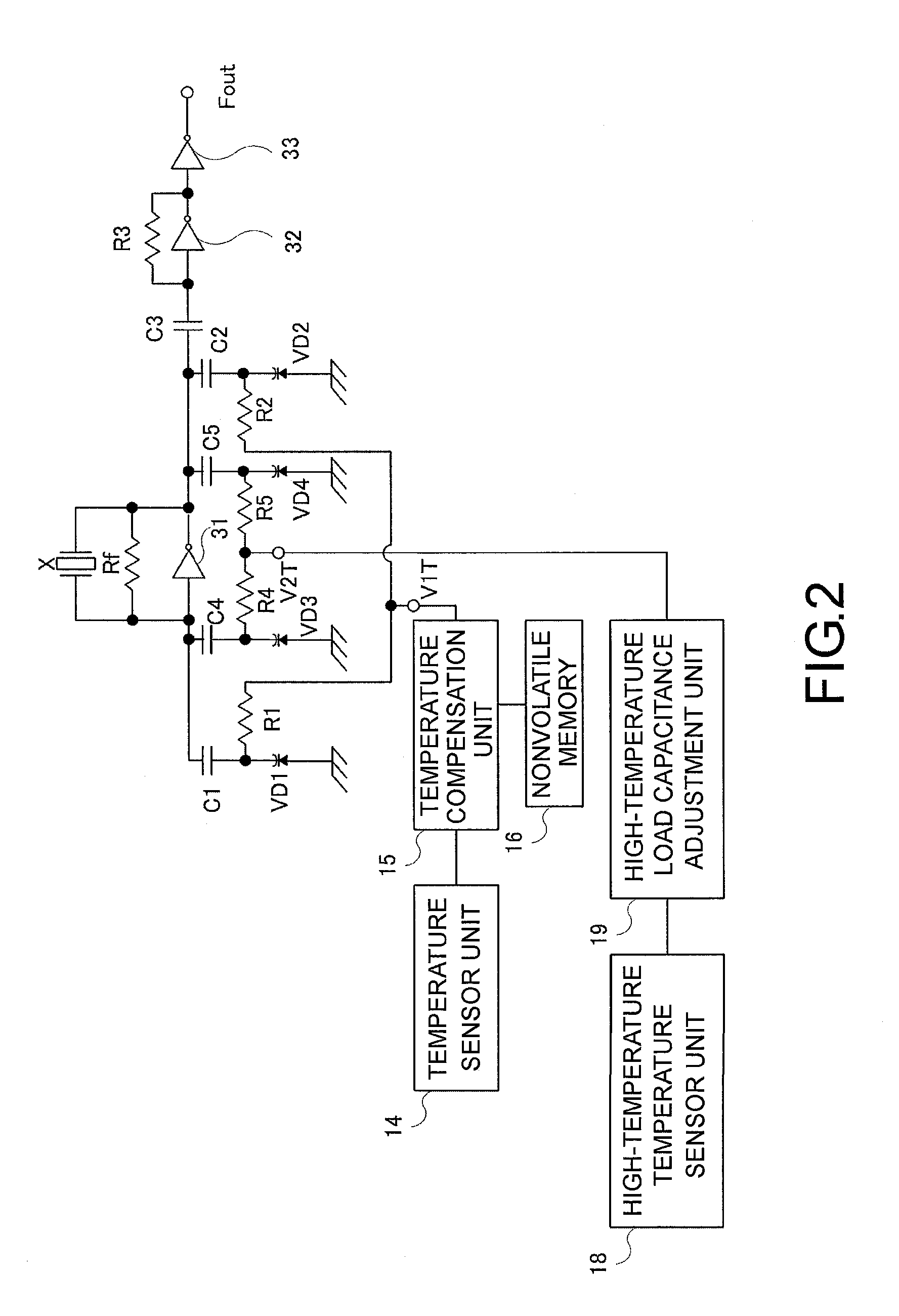

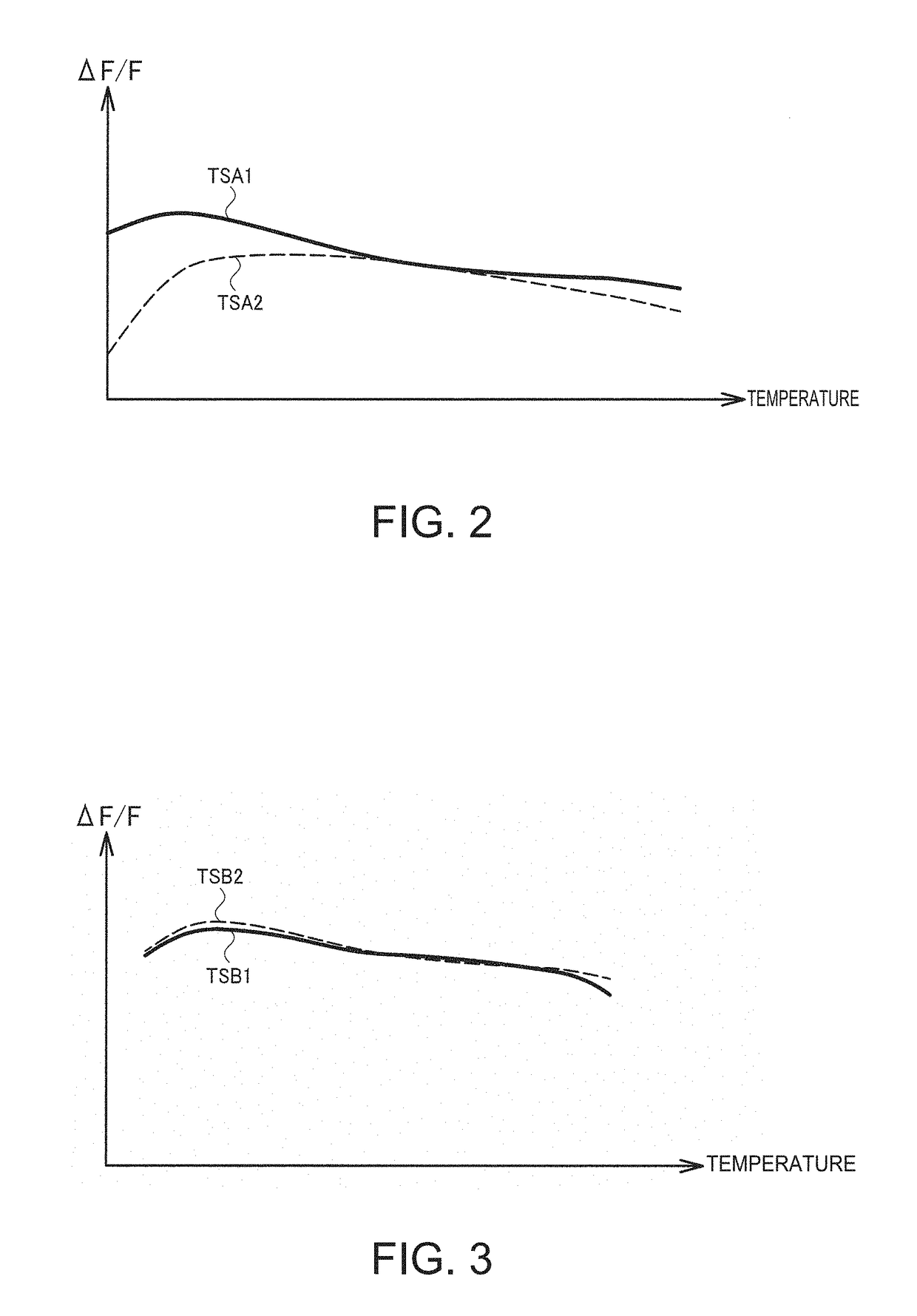

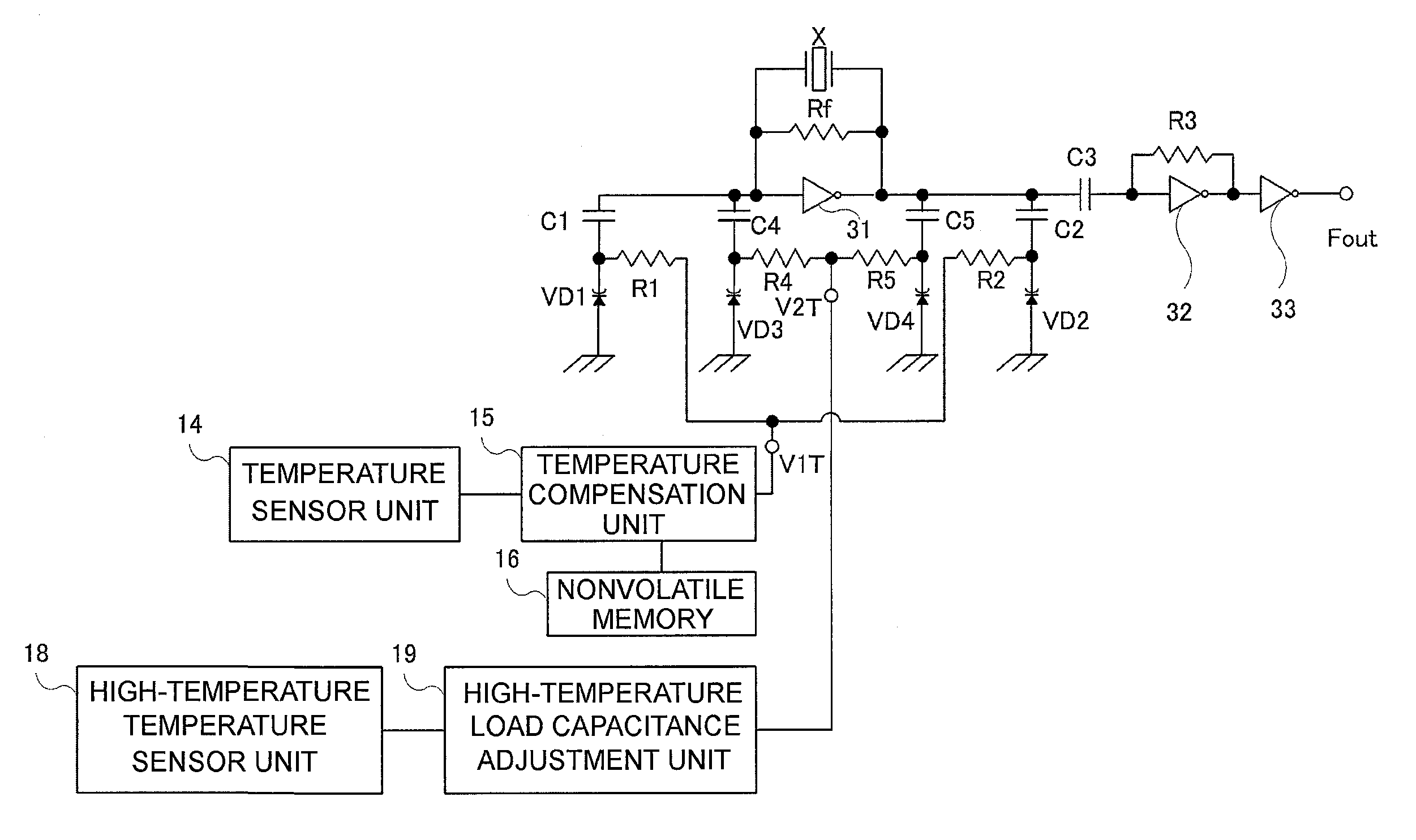

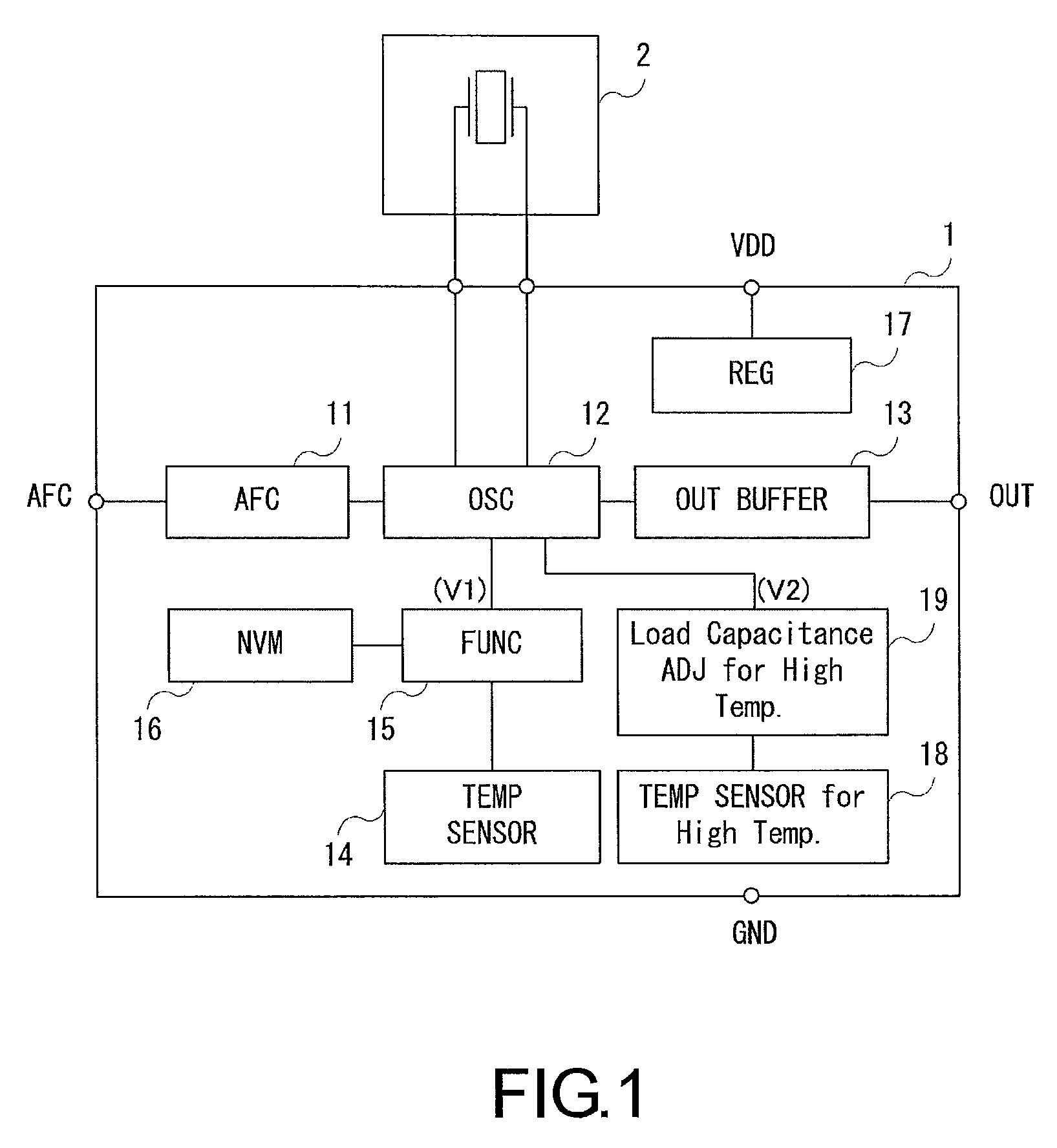

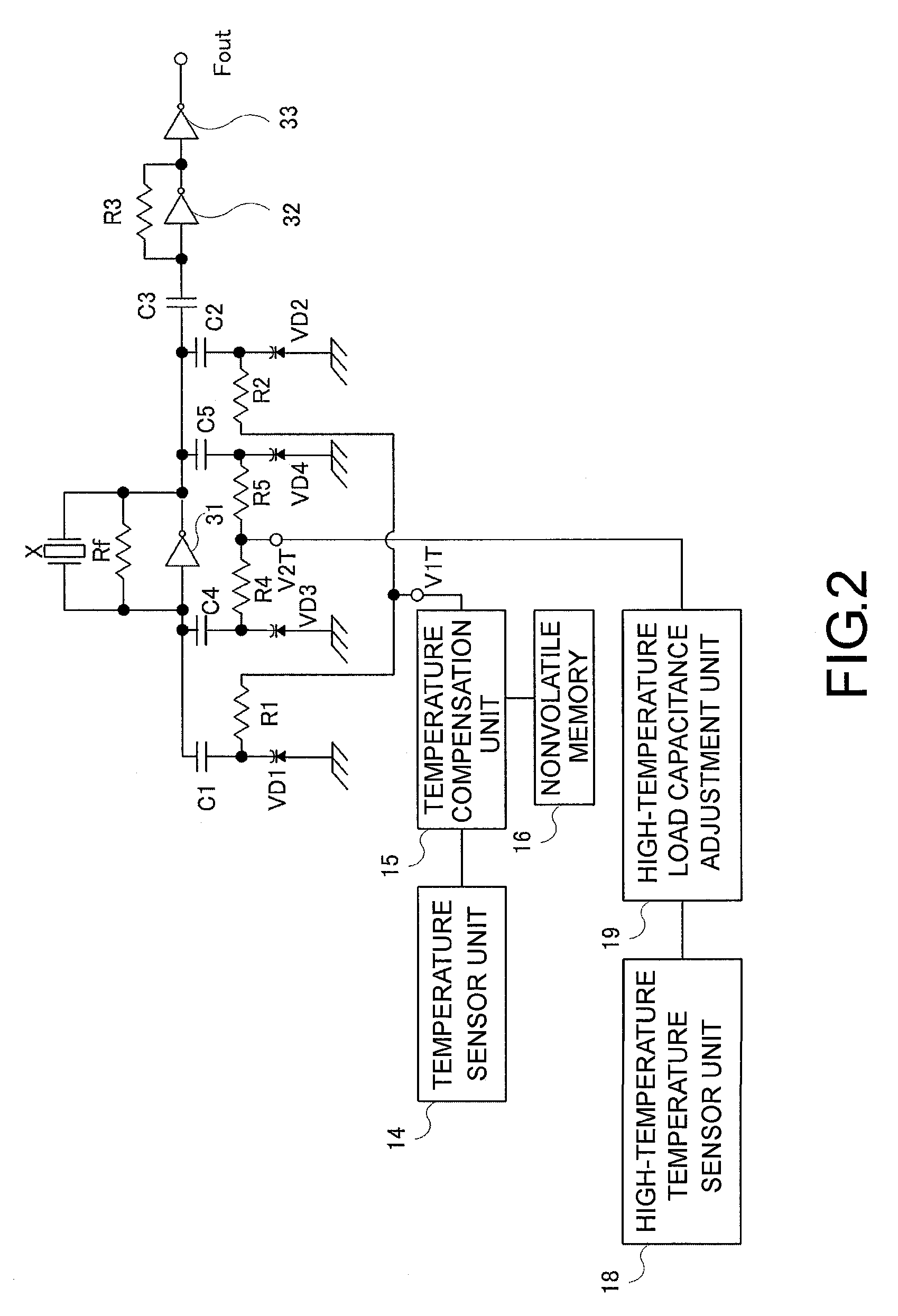

Temperature-compensated crystal oscillator

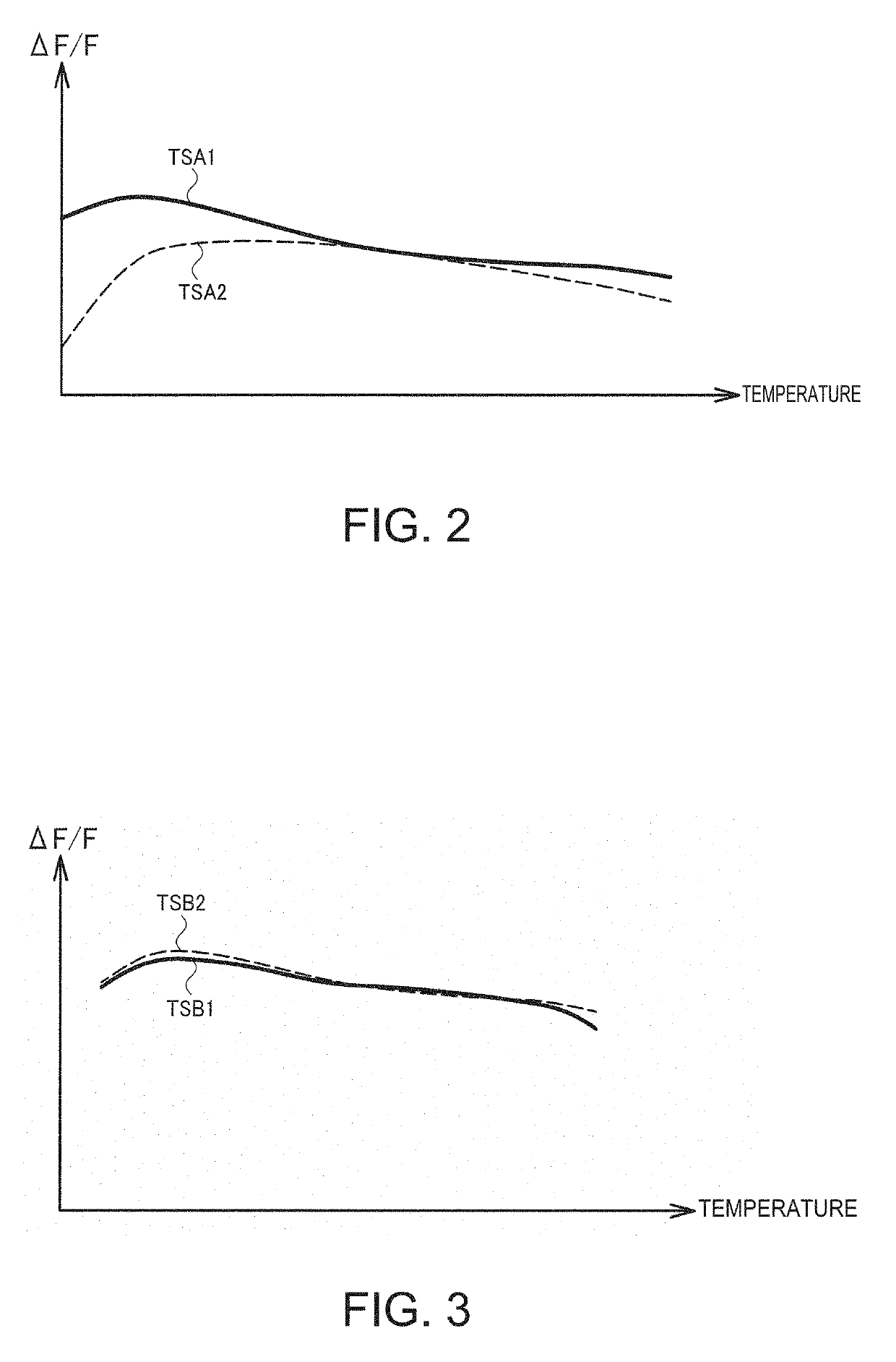

InactiveUS20130038400A1Improved Temperature Compensation AccuracyHigh sensitivityGenerator stabilizationOscillations generatorsCapacitanceEngineering

A temperature-compensated crystal oscillator includes a crystal resonator; and an oscillator circuit for performing temperature compensation. The oscillator circuit has a temperature sensor unit that measures an ambient temperature of the crystal resonator, a temperature compensation unit that outputs a first voltage for temperature compensation based on the measured temperature, a high-temperature load capacitance adjustment unit that outputs a second voltage for temperature compensation based on the temperature measured in a high temperature area exceeding a particular temperature range, an oscillator unit having first and second variable capacitance elements used for temperature compensation within a particular temperature range, third and fourth variable capacitance elements used for temperature compensation in the high temperature area, and an oscillation integrated circuit (IC) connected to the crystal resonator to perform an oscillation operation, and a buffer that amplifies the output from the oscillator unit.

Owner:NIHON DEMPA KOGYO CO LTD

Wide-temperature-range high-precision sputtering film pressure sensor and manufacturing method thereof

ActiveCN109238524AHigh precisionSolving Electrical Connection Reliability IssuesForce measurementSputteringFilm pressure

The invention relates to a wide-temperature-range high-precision sputtering film pressure sensor and a manufacturing method thereof. A sensitive element in the sensor comprises a transition layer, aninsulating layer and a circuit layer which are arranged at the end part of a pressure interface; the circuit layer is provided with a pressure measuring circuit and a temperature compensation circuit;an adapter base is fixedly arranged on the sensitive element; a plurality of electric connecting pieces are circumferentially and uniformly arranged on the adapter base; each electric connecting piece comprises an arc-shaped bonding pad and an inserting pin which are connected with each other; the arc-shaped bonding pads are horizontally arranged on the adapter base; the inserting pins are perpendicular to the adapter base, and the bottoms of the inserting pins are fixed through bumps; a leading-out signal of the sensitive element penetrates through the adapter base to be connected with the arc-shaped bonding pad; a protective plate is arranged above the bumps to cover the adapter base; the inserting pin penetrates through the protective plate to be welded with one end of a lead wire; andthe outer side of a whole after welding of the inserting pin and the lead wire is further subjected to contour welding reinforcement through a metal wire. The pressure sensor solves the technical problems that an existing pressure sensor is relatively narrow in using temperature range, inaccurate in pressure measurement and not suitable for application under severe conditions of strong vibration,large impact and the like.

Owner:XIAN AEROSPACE PROPULSION INST

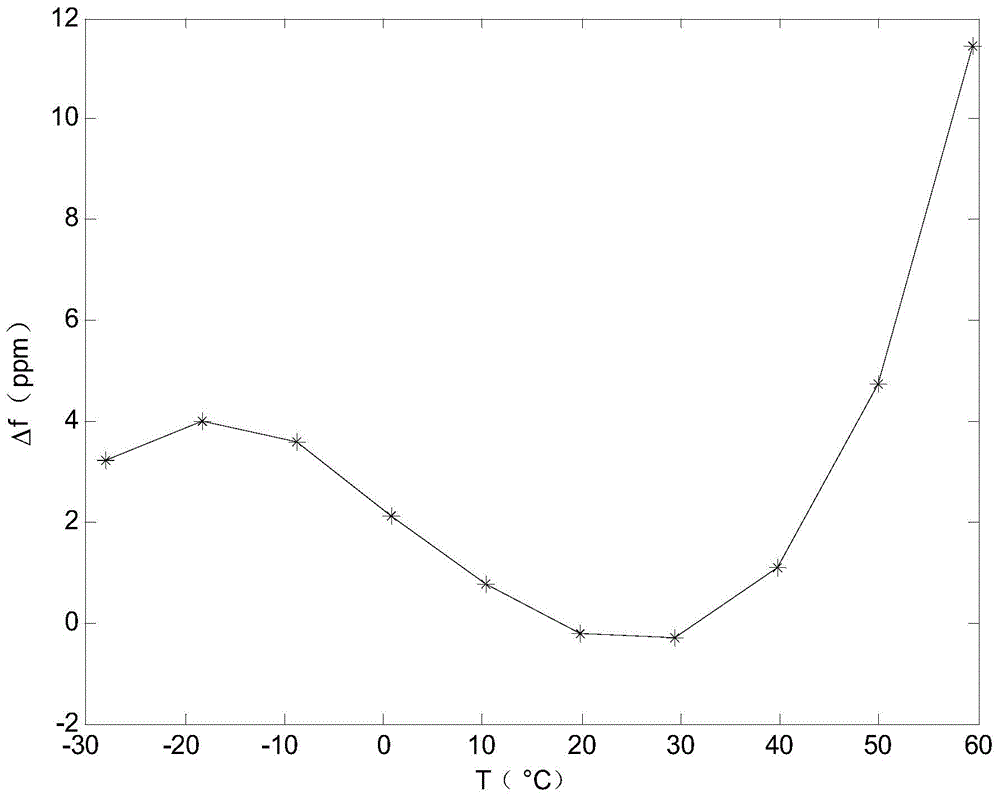

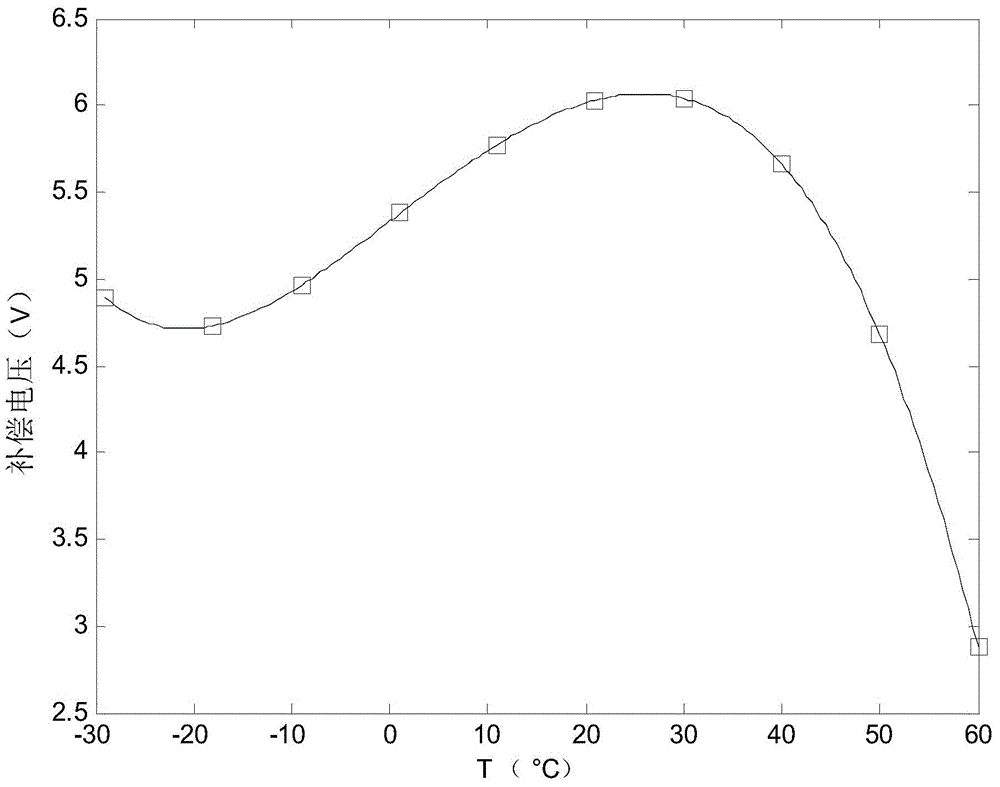

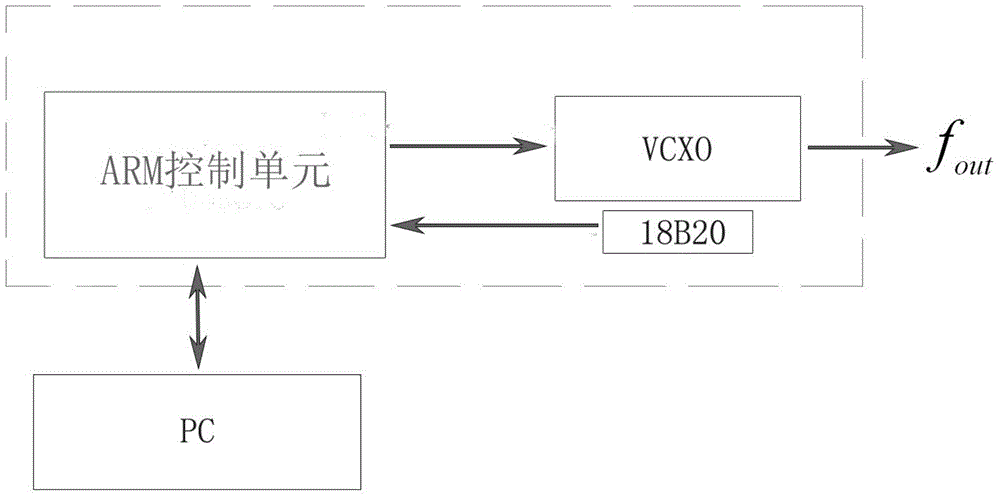

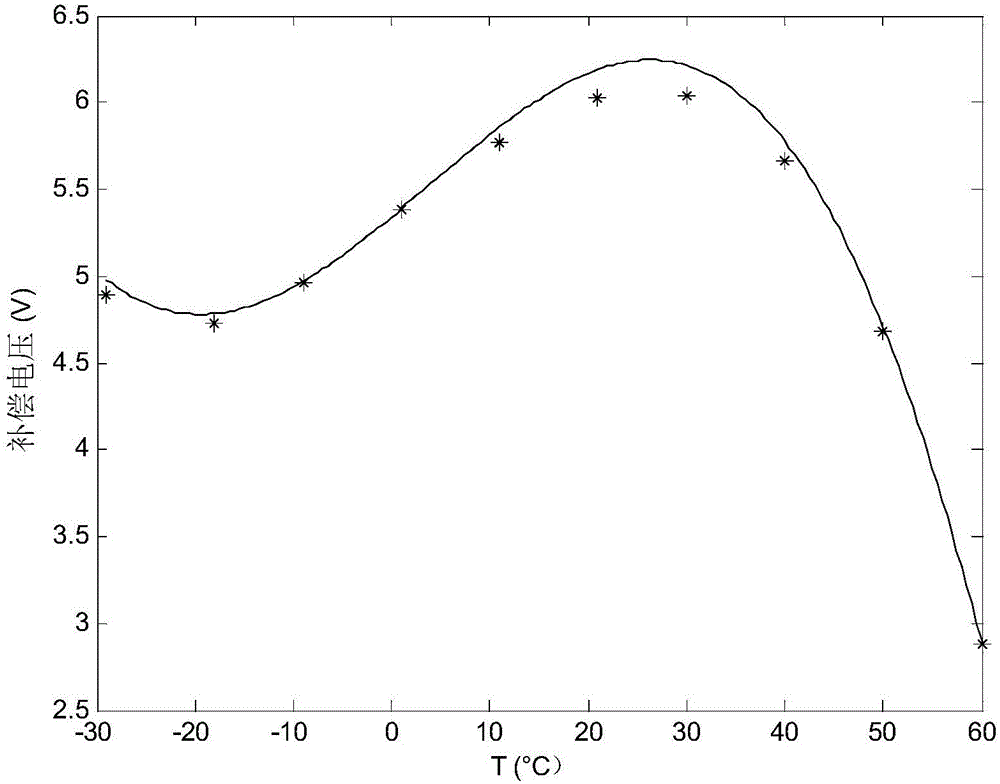

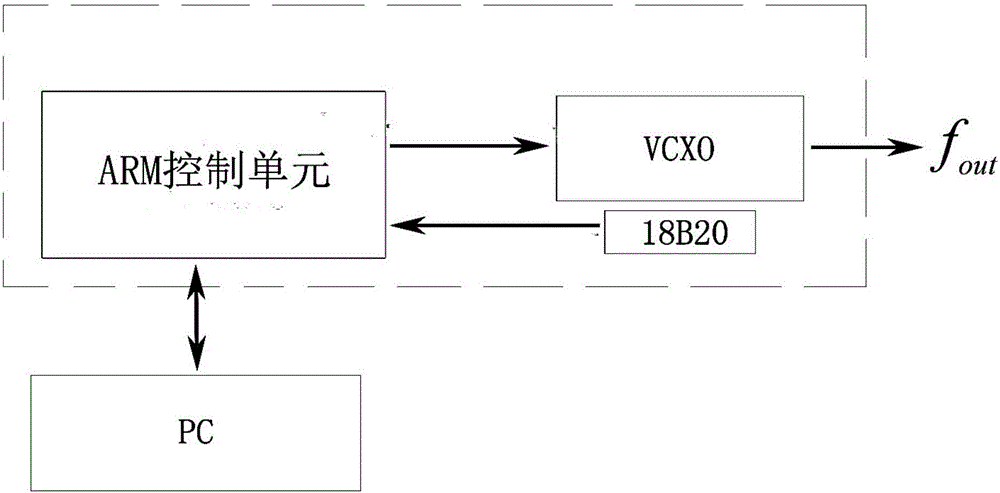

Temperature compensation system of crystal oscillator

InactiveCN104467816AImproved Temperature Compensation AccuracyGenerator stabilizationVoltage referenceControl unit

The invention discloses a temperature compensation system of a crystal oscillator. A Fourier function base is used for fitting. An experiment shows that the Fourier function base contains more abundant high-order information, so that under the condition that the Fourier function base is used for fitting a compensation curve, with the same number of parameters, more abundant high-order information can be contained, and higher temperature compensation precision can be obtained. In addition, according to the temperature compensation system of the crystal oscillator, real-time communication between an upper computer (PC) and an ARM control unit is achieved, the influence of an actual working state effect of a temperature compensation oscillator circuit and an effect that the precision internal reference voltage of the temperature compensation oscillator is insufficient to the control voltage obtained by the temperature compensation system is already taken into consideration.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

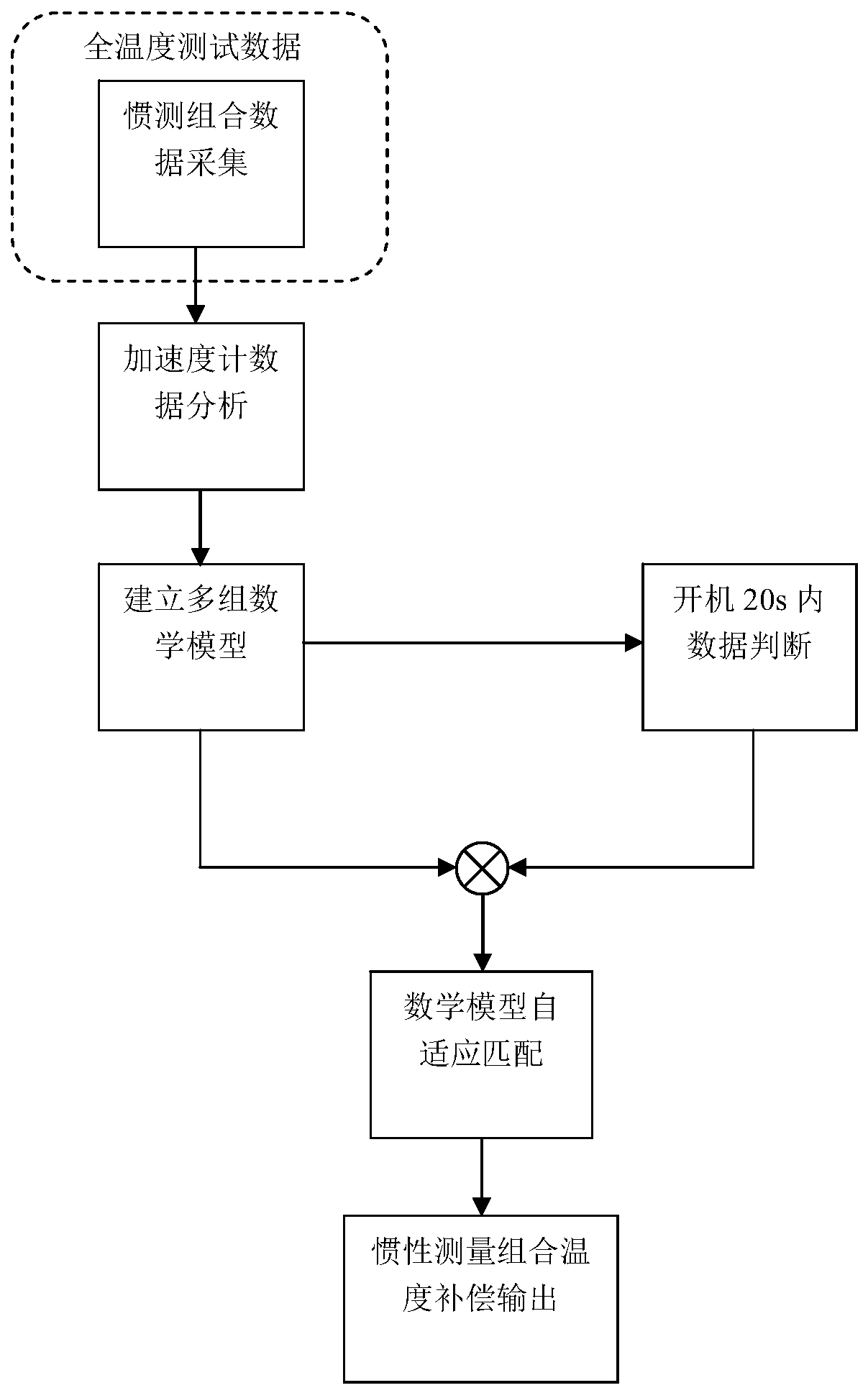

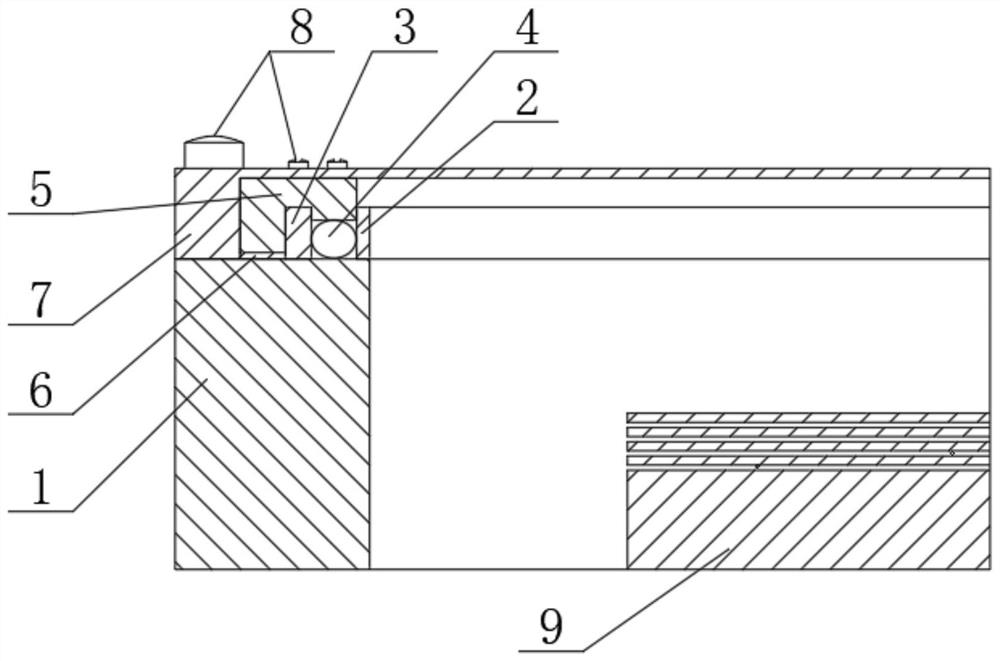

Adaptive accelerometer temperature compensation method for inertial navigation

ActiveCN110823216AHigh precisionImprove effectivenessNavigation by speed/acceleration measurementsAccelerometer dataMathematical model

The invention discloses an adaptive accelerometer temperature compensation method for inertial navigation. The method comprises the following steps: S1, testing multiple groups of accelerometer data output by inertial navigation in a full temperature range; S2, calculating and analyzing the plurality of groups of accelerometer data obtained in the step S1 to obtain output characteristics of the plurality of groups of accelerometers; S3, establishing a plurality of groups of mathematical models according to the output characteristics of the accelerometers in the step S2; and S4, selecting an optimal mathematical model from the multiple groups of mathematical models as a temperature compensation model of a current working state to perform temperature compensation according to working state parameters of inertial navigation startup. The method has the advantages that the characteristic of the accelerometers changing along with temperature is analyzed by using big data by collecting outputdata of the accelerometers in a full temperature range for multiple times, various mathematical models fitted by segmented straight lines or curves are obtained, different mathematical models are utilized to match data output characteristics under different working conditions, and the measurement precision of the accelerometers and the effectiveness of the temperature compensation method are improved.

Owner:SHANGHAI AEROSPACE CONTROL TECH INST

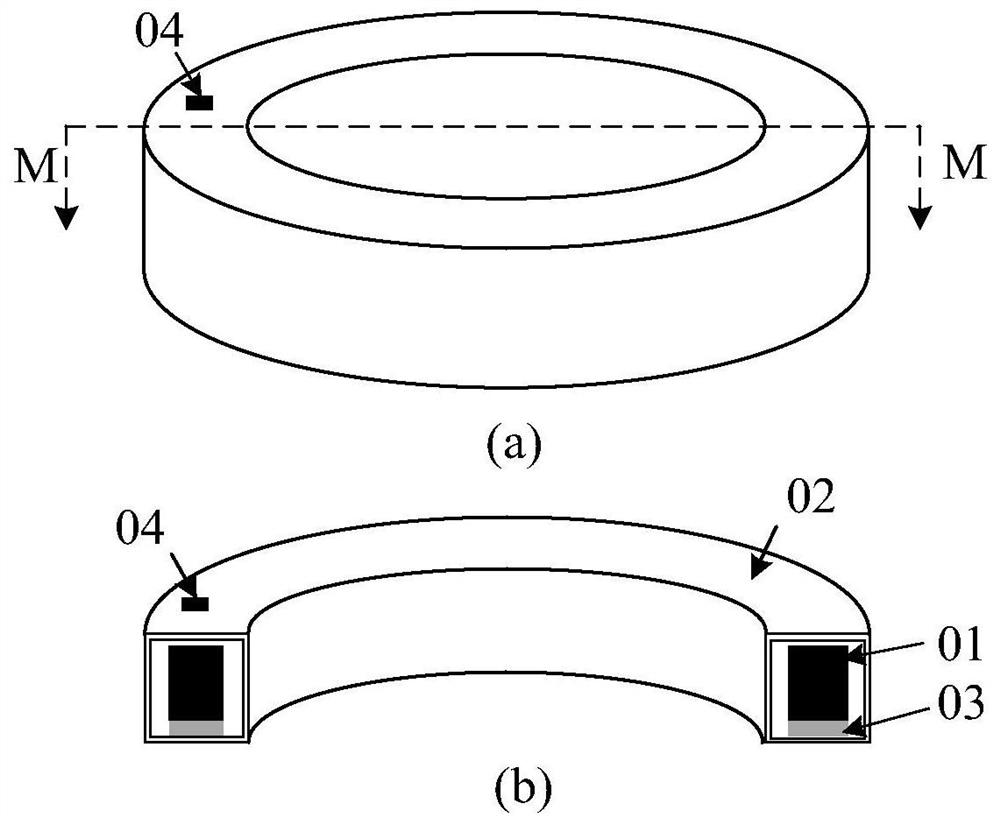

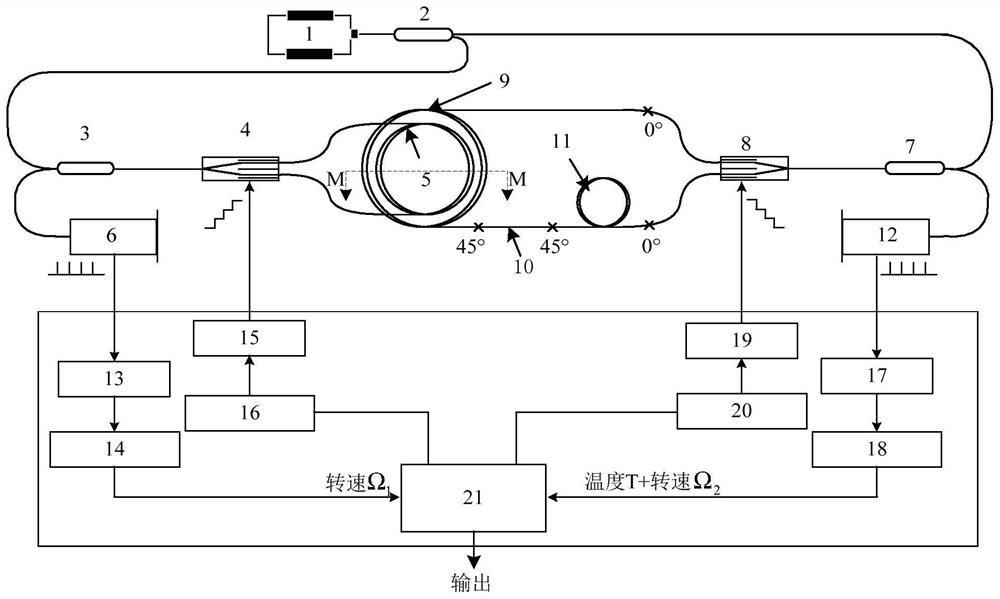

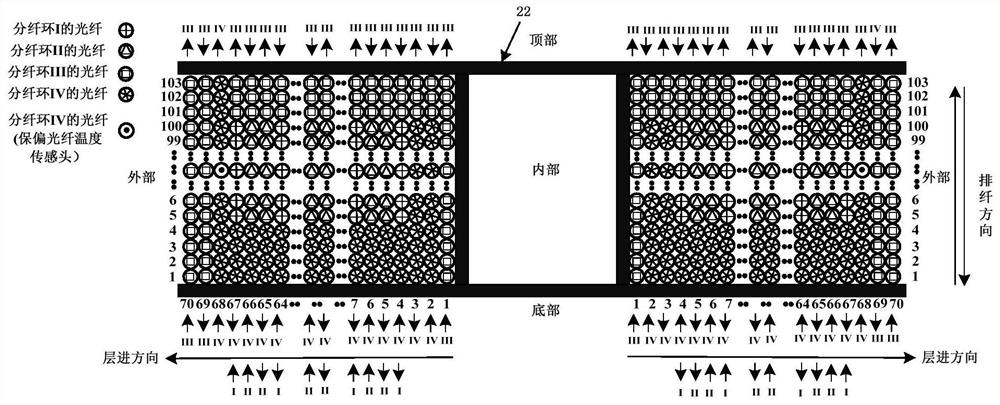

High-precision fiber-optic gyro system based on optical fiber temperature measurement and optical fiber loop structure

PendingCN111829499AAccurate measurementHigh measurement accuracyThermometers using physical/chemical changesSagnac effect gyrometersPolarization-maintaining optical fiberMaterials science

The invention relates to the technical field of fiber-optic gyroscopes, in particular to the technical field of high-precision inertial navigation under harsh environmental conditions such as vibration and temperature. The invention discloses a high-precision fiber-optic gyroscope system based on optical fiber temperature measurement, which comprises a fiber-optic gyroscope and a fiber-optic temperature sensor, wherein the fiber-optic gyroscope comprises a first optical fiber loop; and the fiber-optic temperature sensor comprises a second optical fiber loop composed of a first polarization-maintaining optical fiber delay ring, a polarization-maintaining optical fiber temperature sensing head and a second polarization-maintaining optical fiber delay ring, wherein the polarization-maintaining optical fiber temperature sensing head is in close contact with the first optical fiber loop, and the temperature of the optical fiber loop can be accurately measured in real time. According to theinvention, not only the temperature measurement precision is improved, but also the temperature compensation accuracy of the fiber-optic gyroscope is improved, and finally, the precision and the full-temperature performance of the high-precision fiber-optic gyroscope are improved.

Owner:BEIHANG UNIV

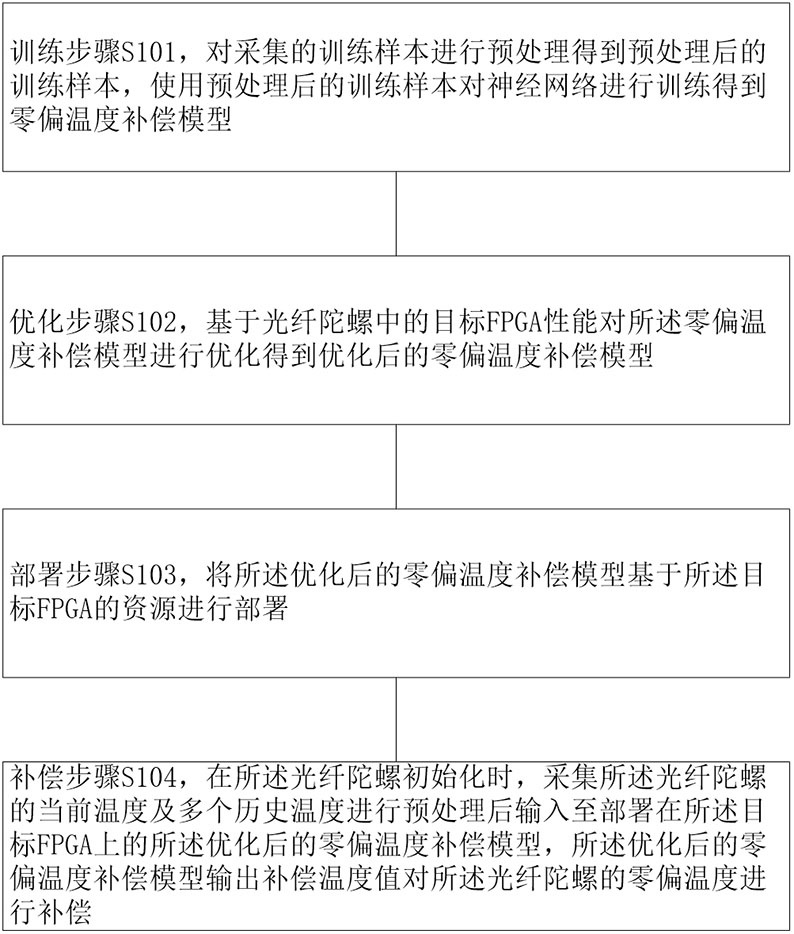

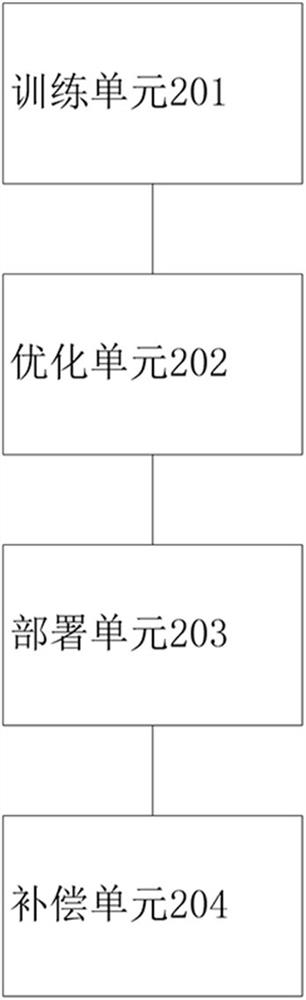

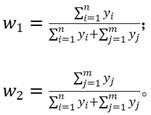

Neural network-based zero offset temperature compensation method and device for fiber-optic gyroscope and storage medium

ActiveCN114754801AImproved Temperature Compensation AccuracyImprove accuracyMeasurement devicesInternal combustion piston enginesComputational physicsEngineering

The invention provides a zero offset temperature compensation method and device for a fiber-optic gyroscope based on a neural network, and a storage medium. The method comprises the following steps: preprocessing a collected training sample to obtain a preprocessed training sample, and training the neural network to obtain a zero offset temperature compensation model; optimizing the zero offset temperature compensation model based on target FPGA performance in the fiber-optic gyroscope to obtain an optimized zero offset temperature compensation model; the optimized zero offset temperature compensation model is deployed on the basis of resources of the target FPGA; and when the fiber-optic gyroscope is initialized, collecting the current temperature and a plurality of historical temperatures of the fiber-optic gyroscope, preprocessing the current temperature and the plurality of historical temperatures, inputting the current temperature and the plurality of historical temperatures into the optimized zero offset temperature compensation model on the target FPGA, and outputting a compensation temperature value to compensate the zero offset temperature of the fiber-optic gyroscope. According to the method, the current temperature and a plurality of historical temperatures of the fiber-optic gyroscope and the specially designed loss function are used, so that the temperature compensation precision of the fiber-optic gyroscope is improved.

Owner:北京理工导航控制科技股份有限公司

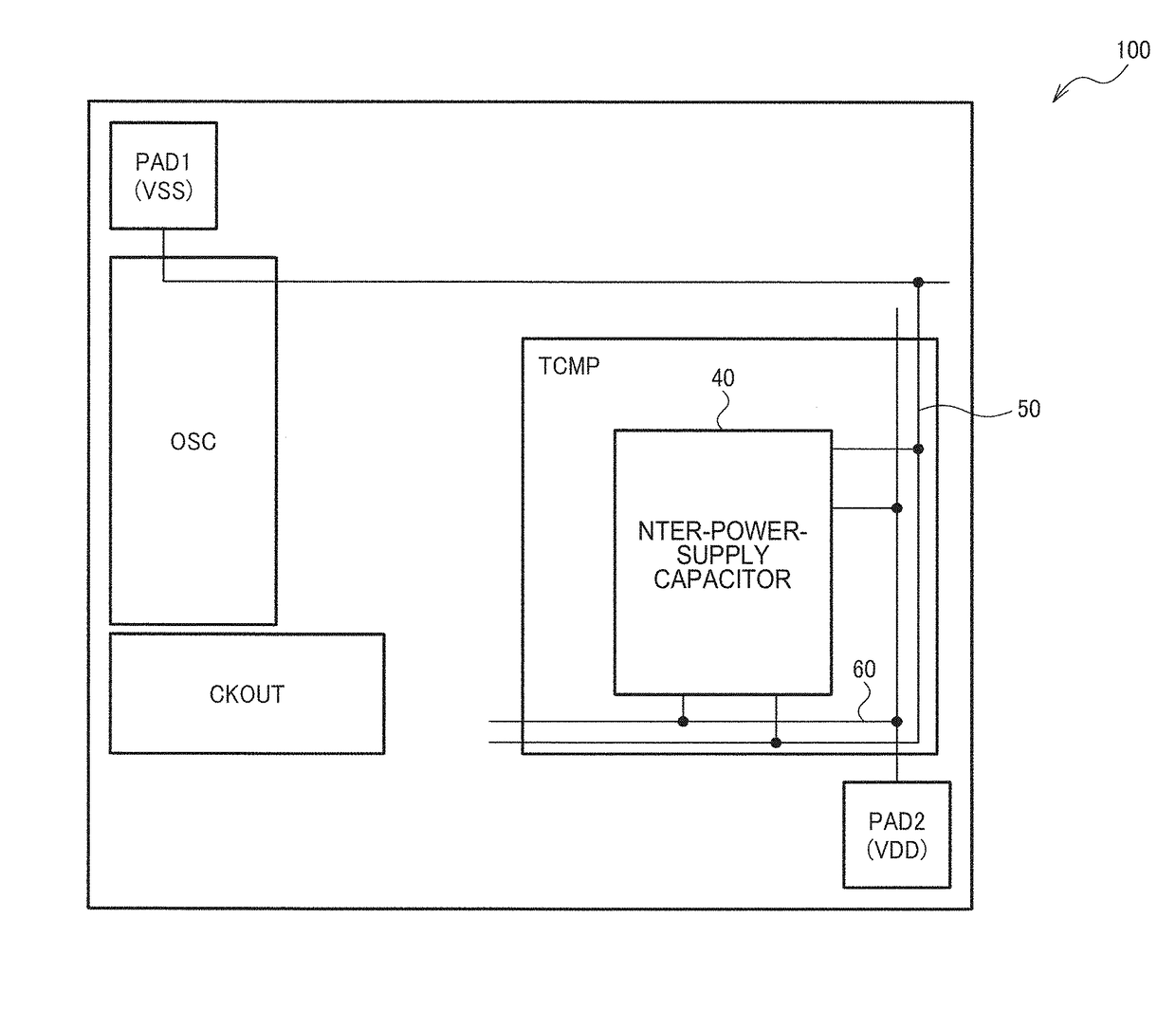

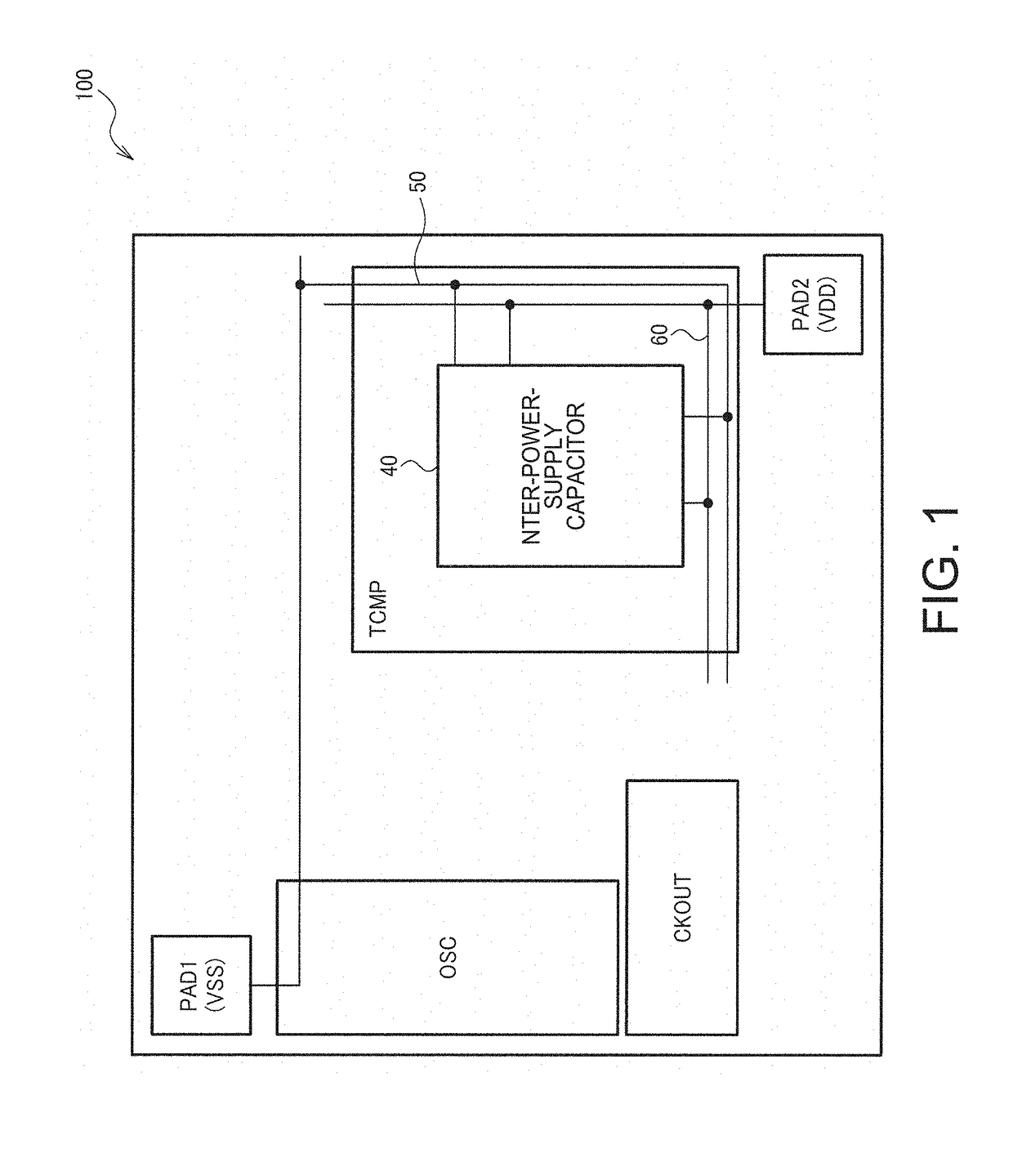

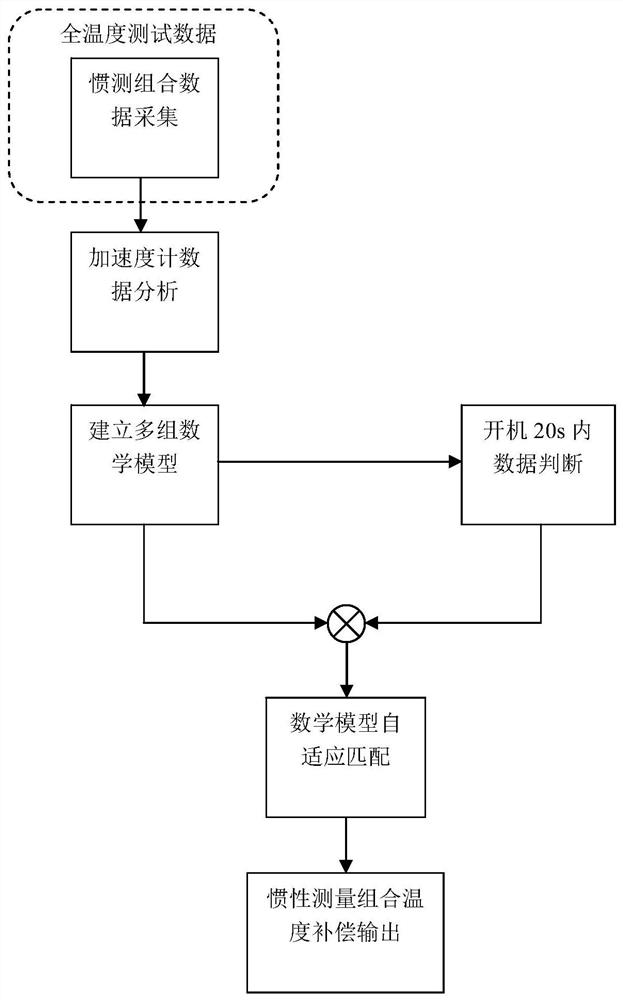

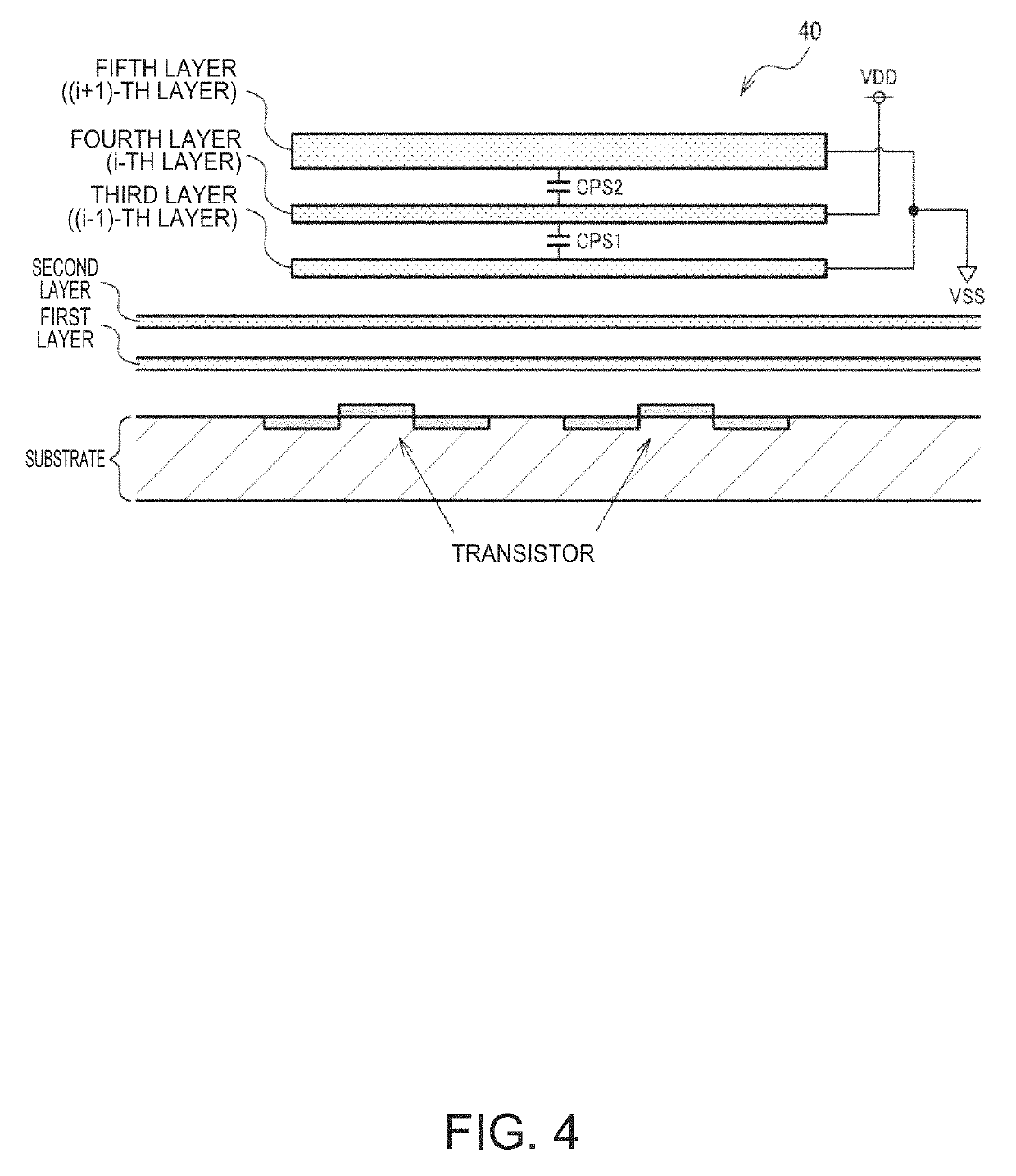

Circuit device, oscillator, electronic apparatus, and vehicle

ActiveUS20180145629A1Reduce errorsImprove accuracyGenerator stabilizationOscillations generatorsElectricityEngineering

A circuit device includes an oscillation circuit configured to cause a resonator to oscillate, a clock signal output circuit configured to output a clock signal based on an oscillation signal from the oscillation circuit, a temperature compensation circuit configured to perform temperature compensation on an oscillation frequency of the oscillation signal, a low-potential-side power supply pad to which low-potential-side electric power is supplied, a high-potential-side power supply pad to which high-potential-side electric power is supplied, and an inter-power-supply capacitor provided between a low-potential-side power supply line electrically continuous with the low-potential-side power supply pad and a high-potential-side power supply line electrically continuous with the high-potential-side power supply pad. The inter-power-supply capacitor is formed of at least two metal layers provided in a region where the temperature compensation circuit is disposed in a plan view.

Owner:SEIKO EPSON CORP

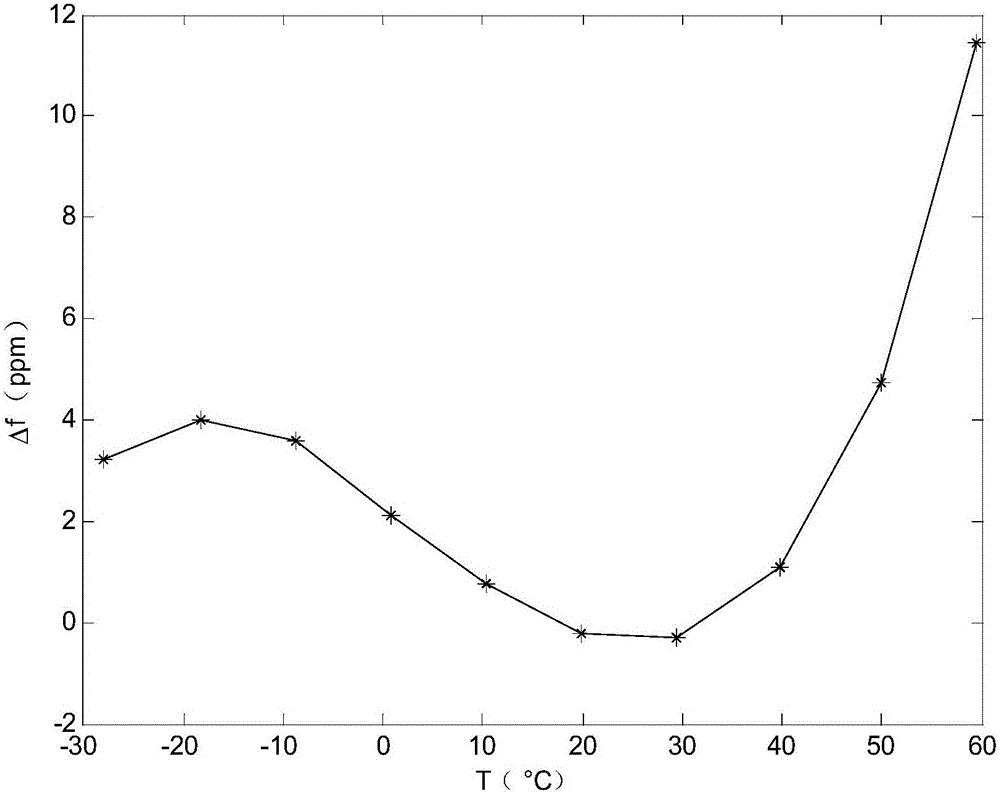

Temperature compensating system of temperature compensated crystal oscillator

InactiveCN106603068AImprove temperature stabilityImproved Temperature Compensation AccuracyGenerator stabilizationEngineeringCrystal oscillator

The invention discloses a temperature compensating system of a temperature compensated crystal oscillator. The system adopts the sum of sine functions to conduct fitting on the temperature compensating voltages. Compared with polynomial, with the same number of parameters, the sum of sine functions has abundant high-order term information. Compared with the Fourier function, though the 2 fitting methods contain high-order polynomial information, the sum of sine functions has inconsistent polynomial distribution (when n is not equal to infinite), which is to say when the number of parameters is limited, the fitted curve is inconsistent, and the sum of sine functions has higher temperature compensating precision. Also, experiments show that the sum of sine functions is more applicable to AT-cut quartz crystal.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

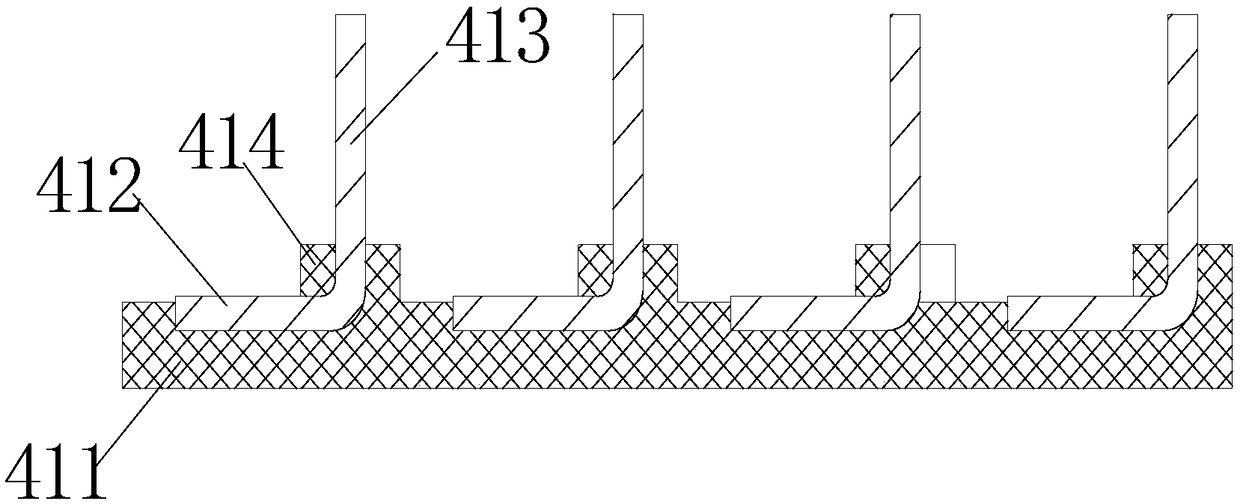

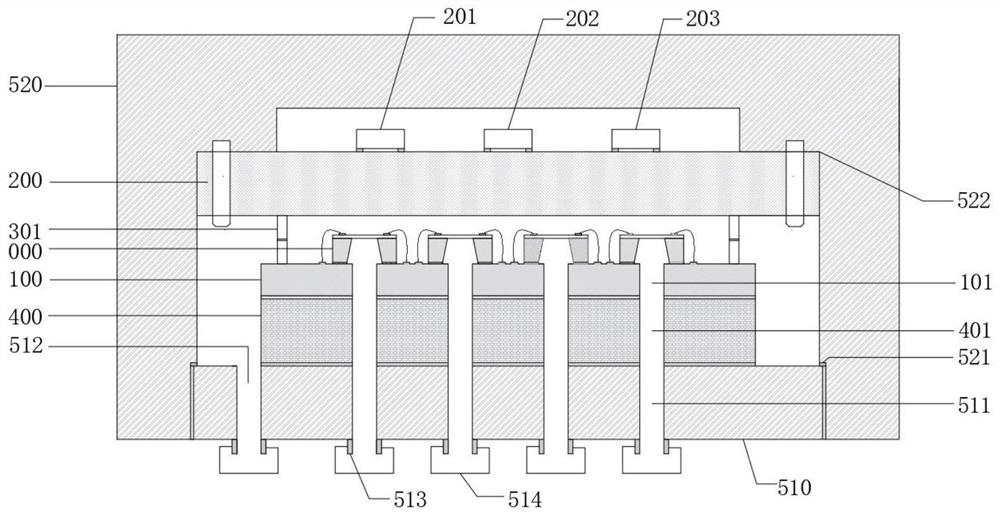

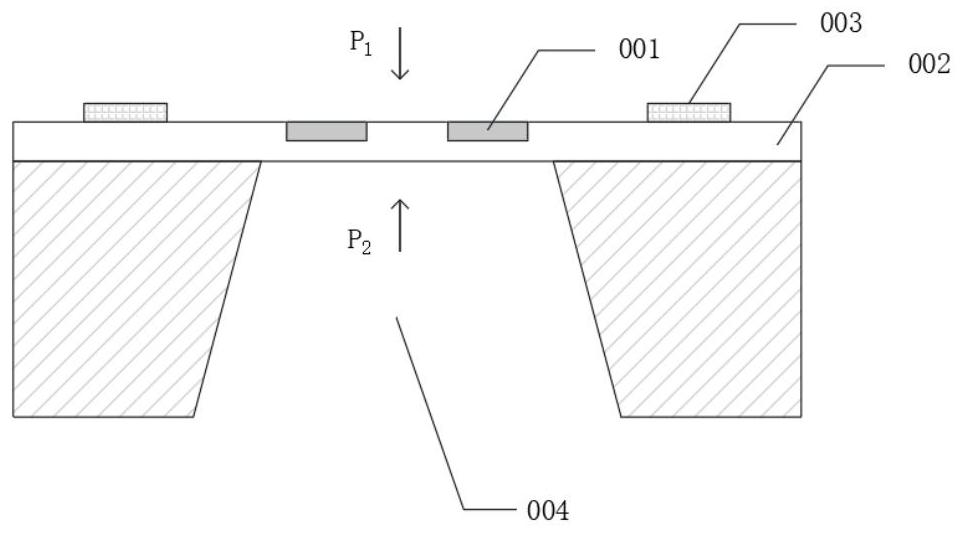

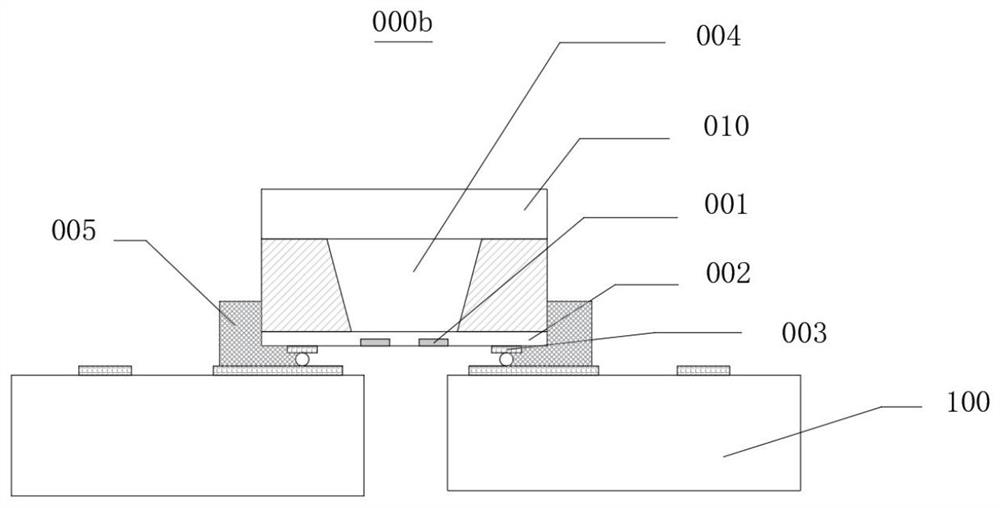

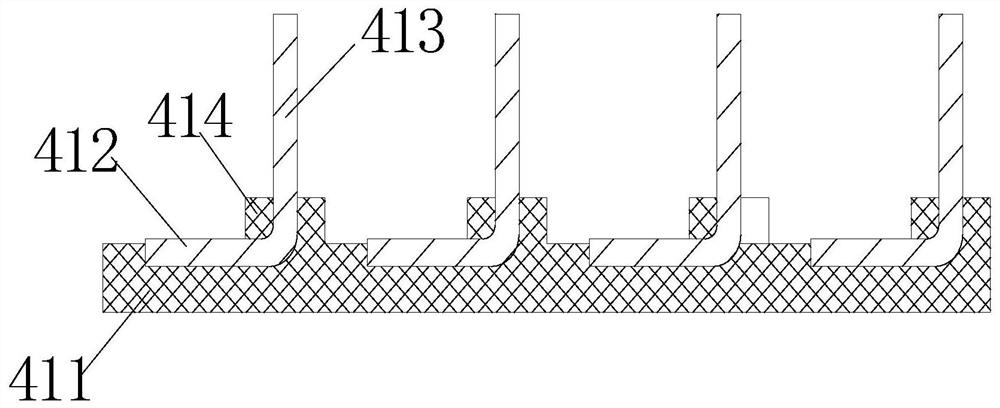

Array type pressure measuring device based on packaging substrate

PendingCN112903176AShort interconnect pathHighly integratedFluid pressure measurement using ohmic-resistance variationPressure generationMiniaturization

The invention relates to the field of microelectronic packaging, in particular to an array type pressure measuring device based on a packaging substrate, which comprises: an alloy shell and a piezoresistive sensitive chip which is arranged in the alloy shell and is used for applying reference pressure on the front surface of the piezoresistive sensitive chip and applying external gas pressure on the back surface of the piezoresistive sensitive chip to generate pressure difference; a packaging substrate which is provided with an air guide hole, is integrated with the piezoresistive sensitive chip, and is used for providing air pressure and acting on the two surfaces of the piezoresistive sensitive chip so as to generate the pressure difference; a circuit board, wherein the circuit board and the packaging substrate are stacked and arranged in parallel, the circuit board and the packaging substrate are stacked with a fixing structure through electric interconnection, and the circuit board is used for converting the generated pressure difference into an electric signal which is in direct proportion to pressure change, outputting the electric signal and processing and calculating the electric signal; and an alloy substrate which is used for sealing the piezoresistive sensitive chip, the substrate and the circuit board in the alloy shell. According to the invention, the assembly stress can be reduced, and the internal integrated gas path system facilitates the miniaturization of the whole pressure measurement device assembly.

Owner:明晶芯晟(成都)科技有限责任公司

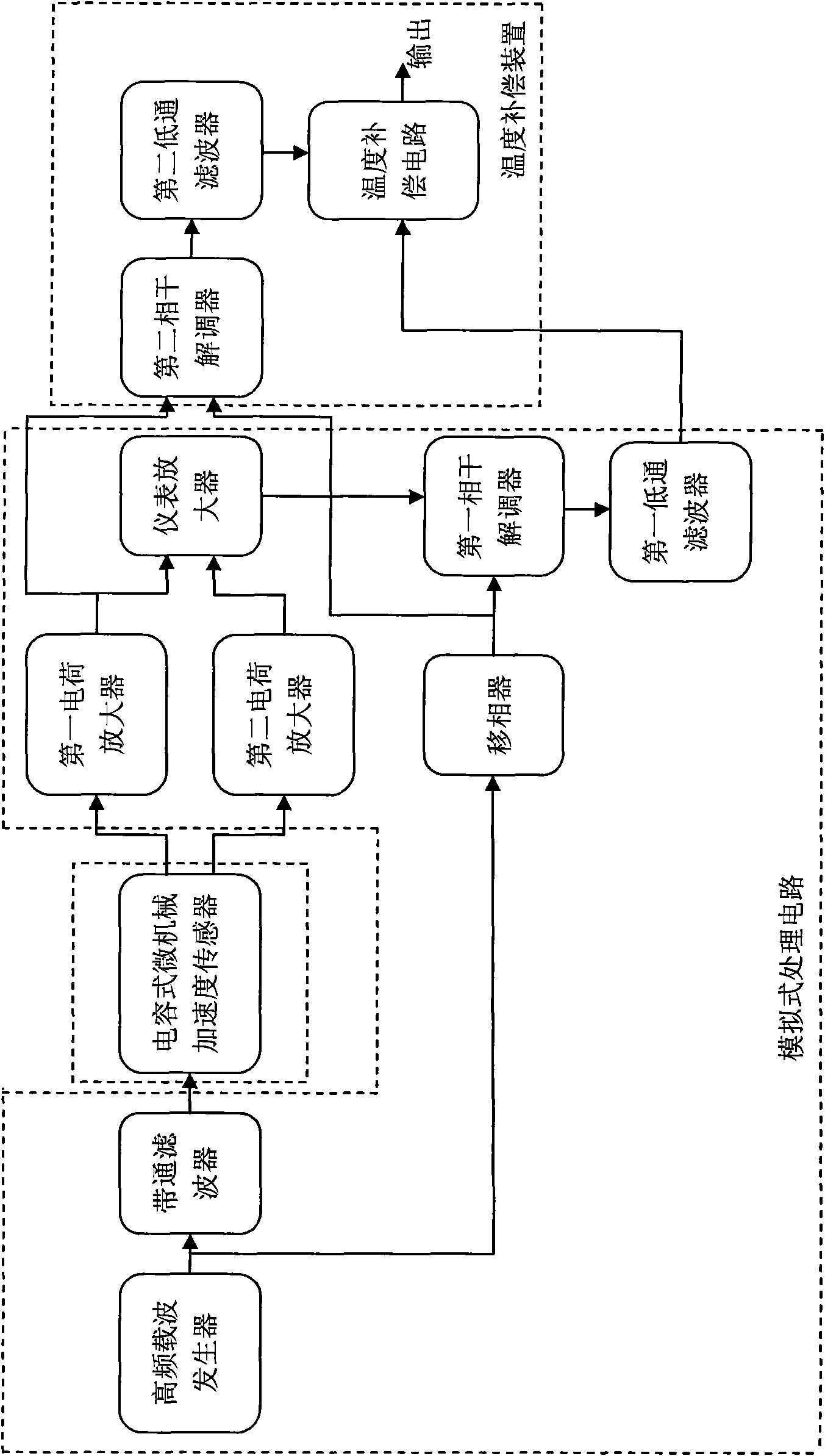

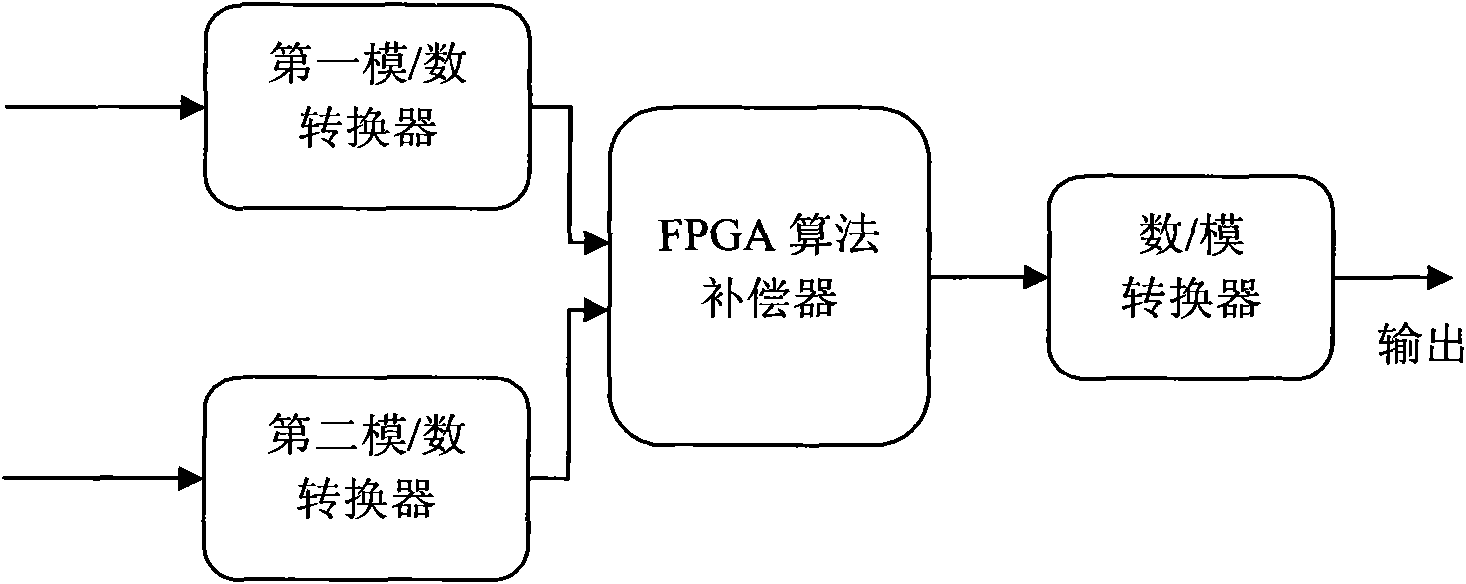

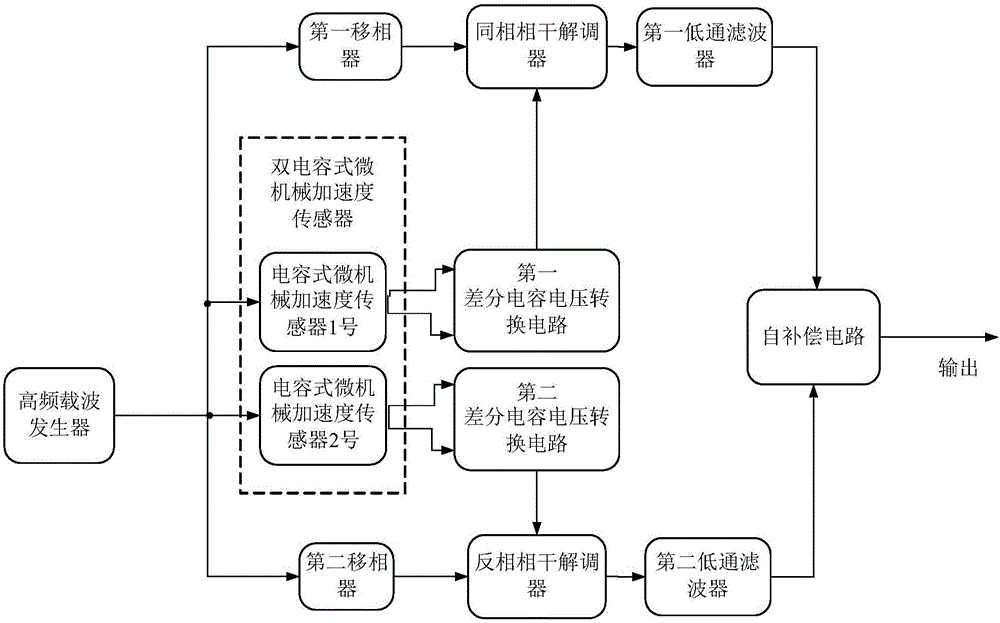

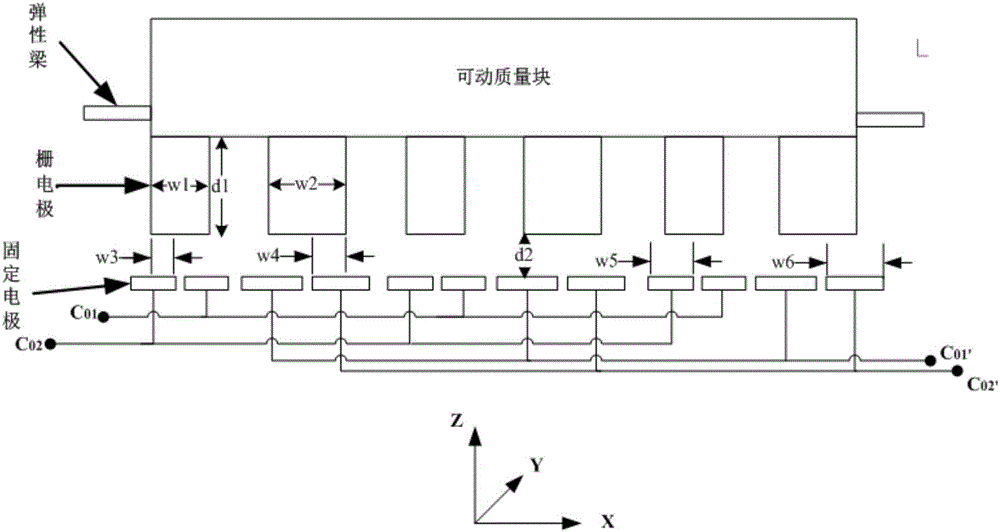

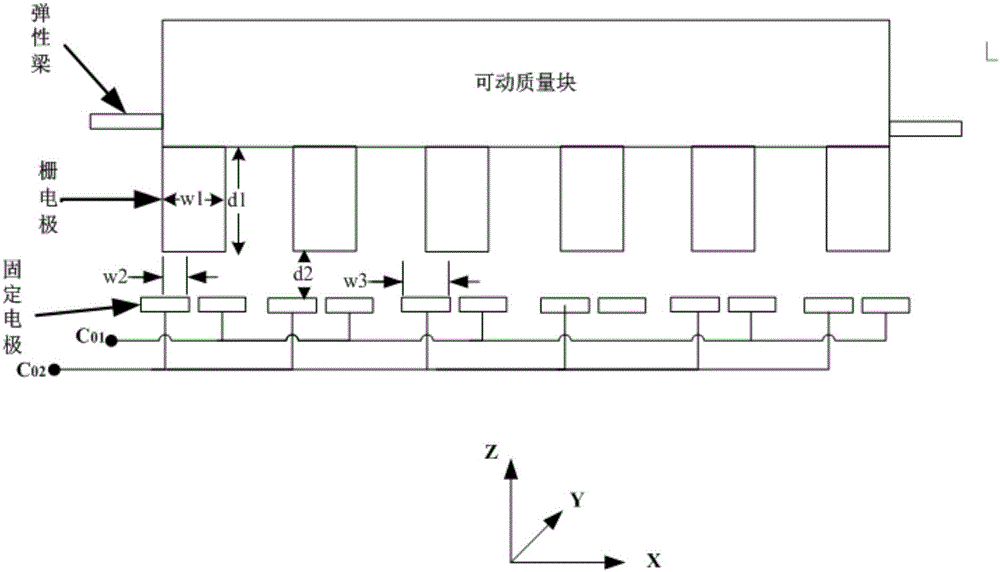

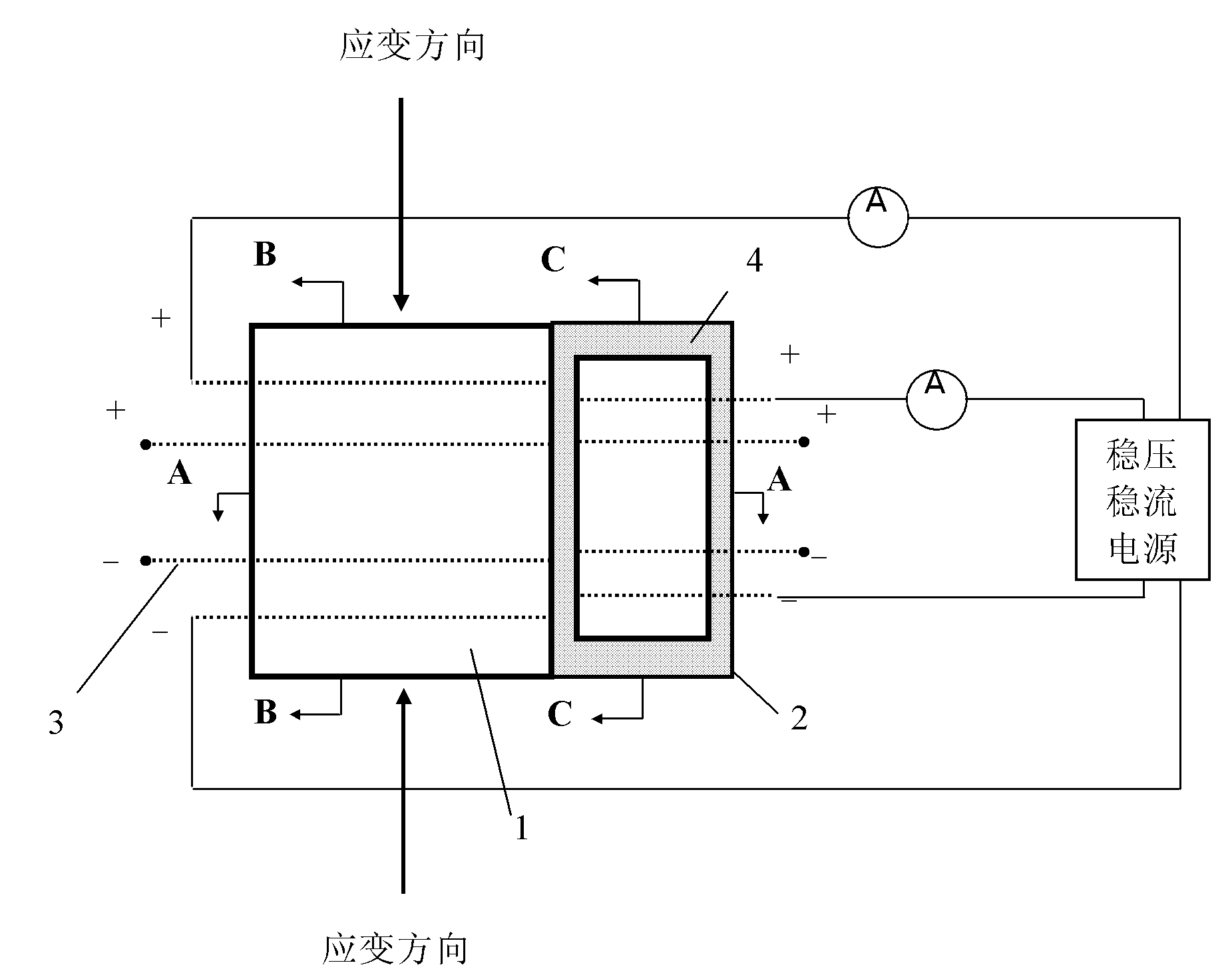

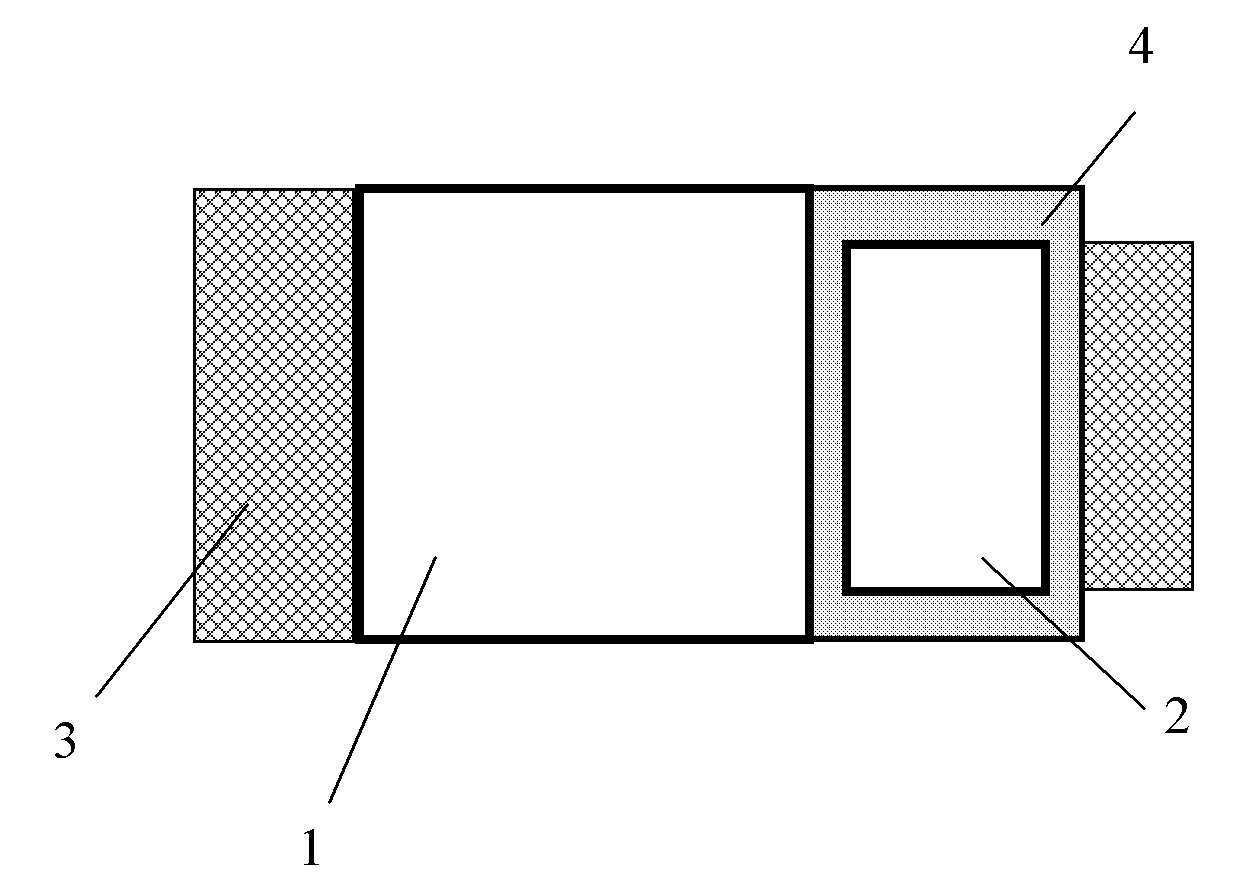

Dual-capacitance type micro-machine accelerator sensor and temperature self-compensating system based on it

ActiveCN106771361AEliminate the effects ofEliminate the influence of compensation accuracyAcceleration measurementReactive power compensationCapacitanceLow-pass filter

The invention discloses a dual-capacitance type micro-machine accelerator sensor and a temperature self-compensating system based on the dual-capacitance type micro-machine accelerator sensor; the dual-capacitance type micro-machine accelerator sensor comprises two grids and two fixing aluminum electrodes which are respectively corresponding to two output ends; the two output ends are respectively connected with input ends of two differential capacitance voltage switching circuits, and output ends of the differential capacitance voltage switching circuits are respectively connected with an output end of a high-frequency carrier wave generator and an input end of a coherent demodulator; the output end of the coherent demodulator is connected with the input end of a low pass filter, and the output end of the low pass filter is connected with the input end of the temperature self-compensating system. The system can measure temperature of the acceleration sensor instead of an additional temperature sensor, expel the influence of the temperature measurement bias caused by temperature gradient on the compensation precision, improve the temperature compensation precision while eliminate the influence of the non-linear characteristics of the temperature coefficient on the temperature compensation result.

Owner:XIAN UNIV OF POSTS & TELECOMM

Temperature-compensated crystal oscillator

InactiveUS8896388B2High sensitivityImproved Temperature Compensation AccuracyAngle modulation by variable impedenceGenerator stabilizationCapacitanceEngineering

A temperature-compensated crystal oscillator includes a crystal resonator; and an oscillator circuit for performing temperature compensation. The oscillator circuit has a temperature sensor unit that measures an ambient temperature of the crystal resonator, a temperature compensation unit that outputs a first voltage for temperature compensation based on the measured temperature, a high-temperature load capacitance adjustment unit that outputs a second voltage for temperature compensation based on the temperature measured in a high temperature area exceeding a particular temperature range, an oscillator unit having first and second variable capacitance elements used for temperature compensation within a particular temperature range, third and fourth variable capacitance elements used for temperature compensation in the high temperature area, and an oscillation integrated circuit (IC) connected to the crystal resonator to perform an oscillation operation, and a buffer that amplifies the output from the oscillator unit.

Owner:NIHON DEMPA KOGYO CO LTD

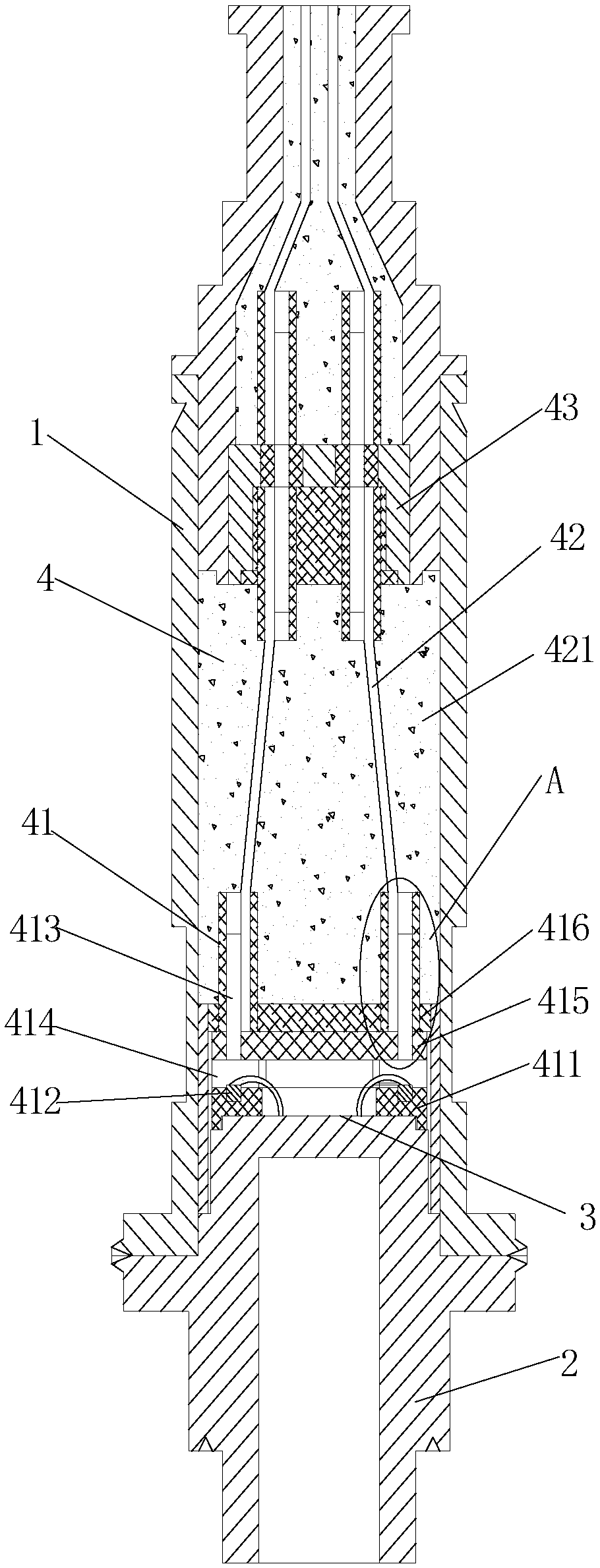

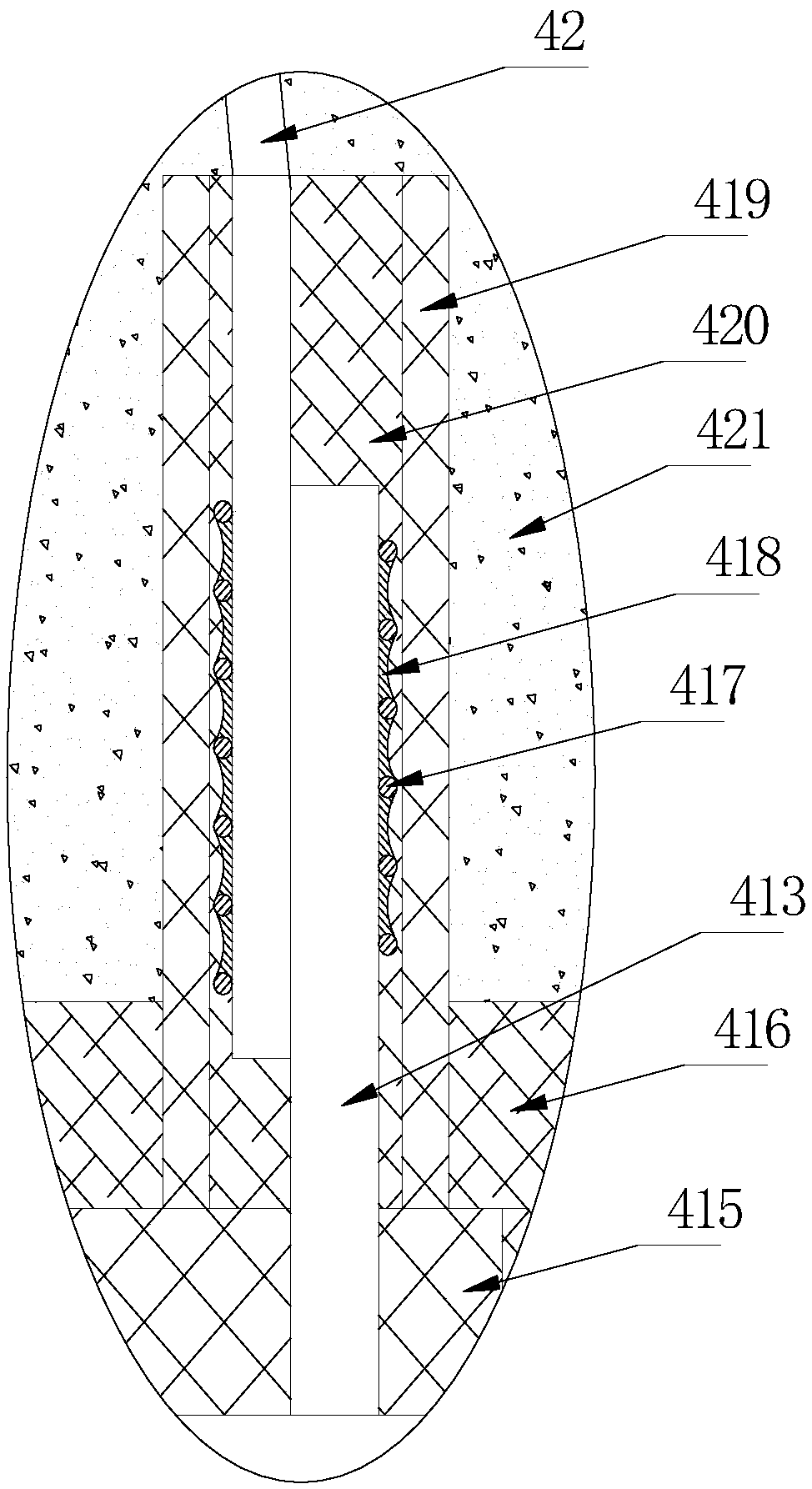

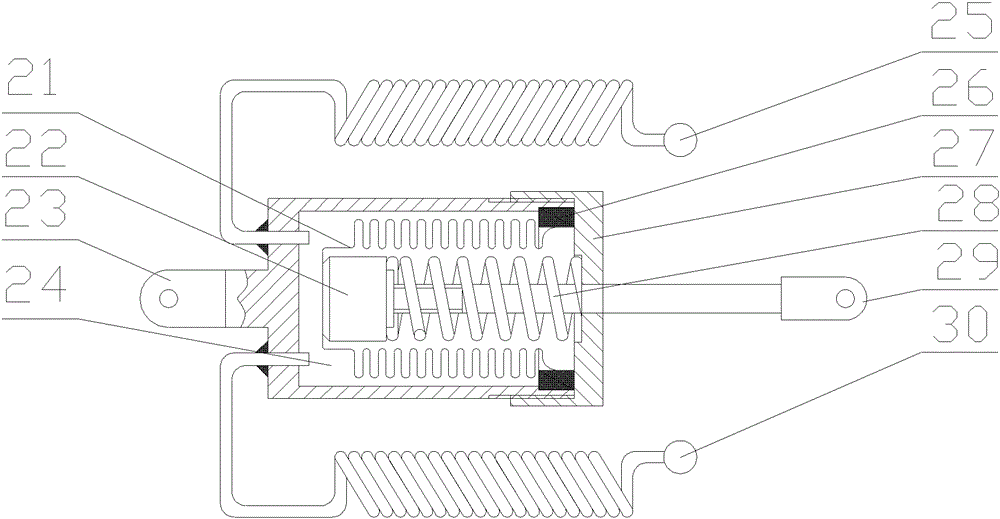

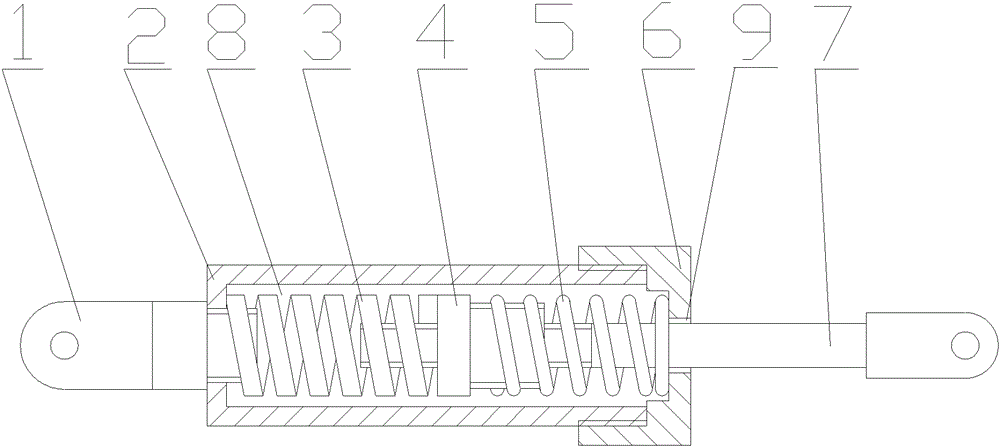

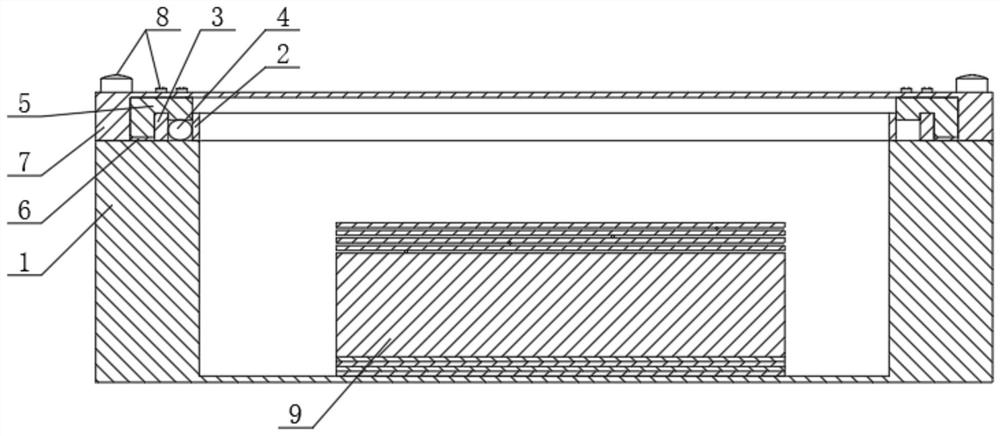

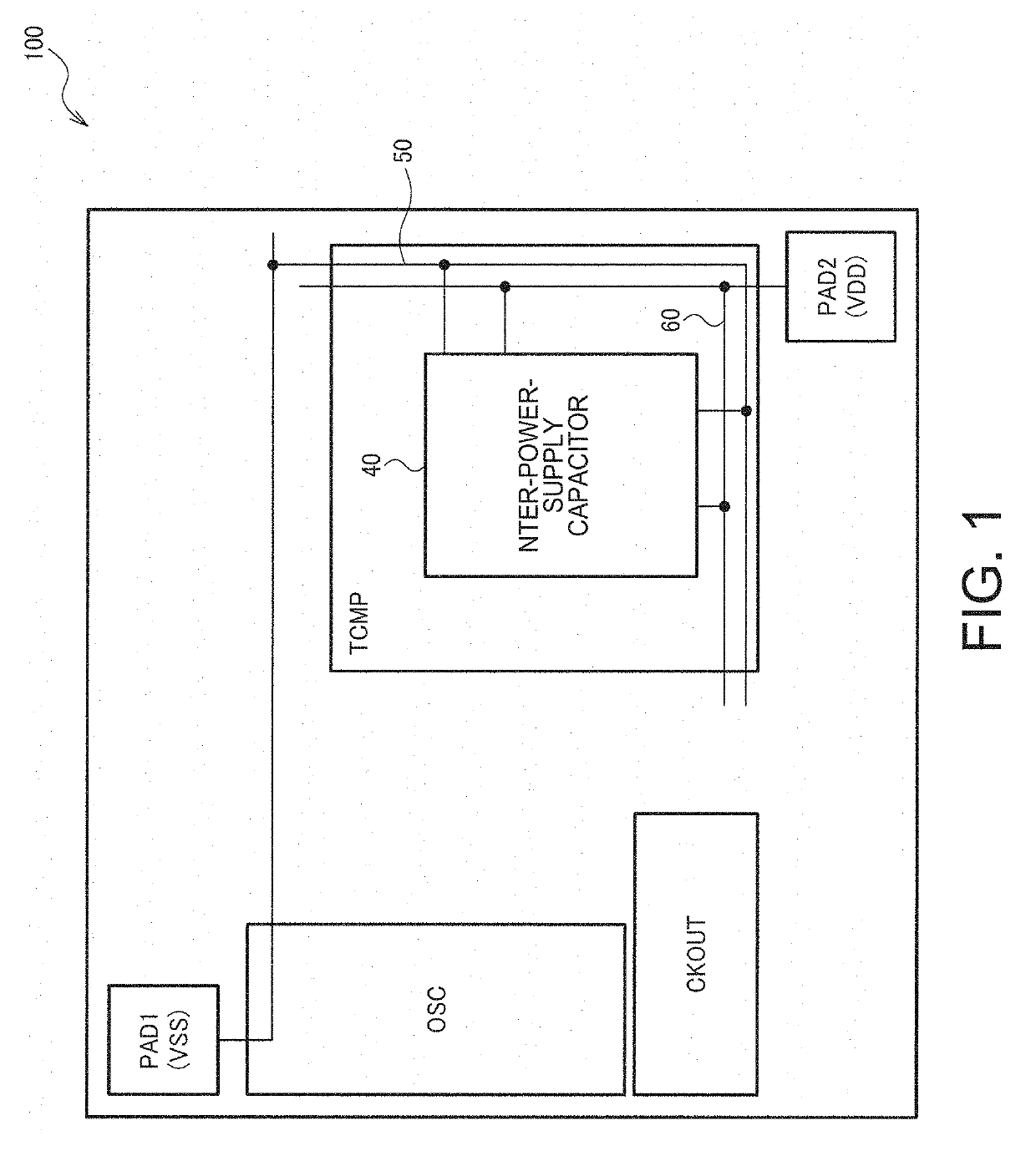

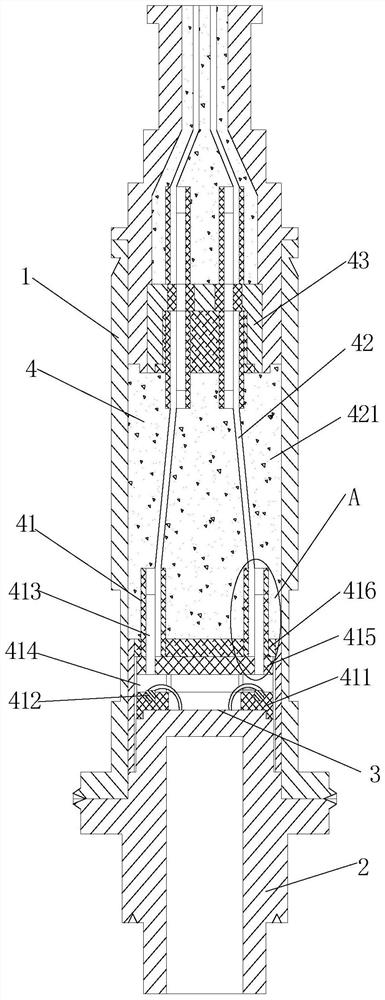

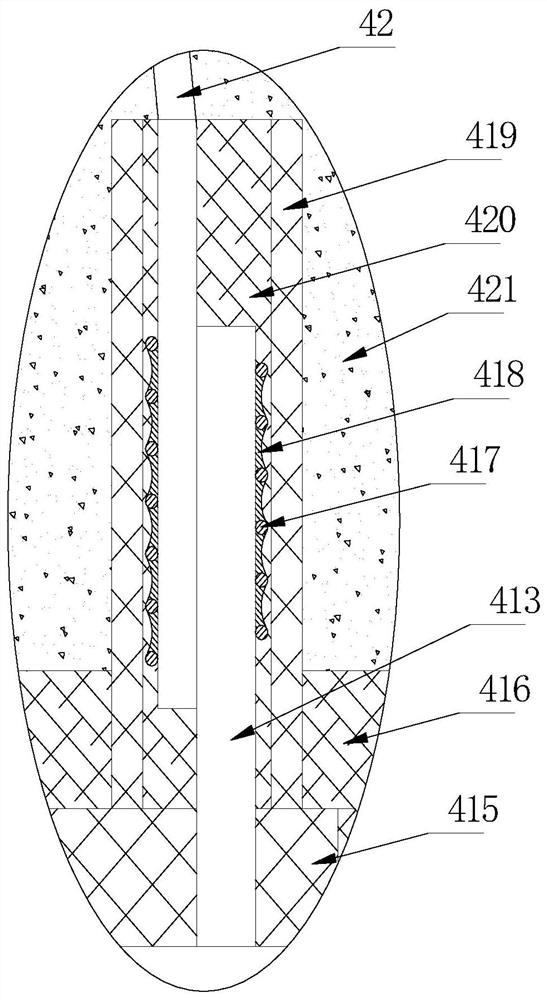

Temperature Controller Compensation Device for Large Power Transformer

InactiveCN103376167BEliminate displacement differenceTo achieve the purpose of temperature compensationThermometers using material expansion/contactionManufacturing technologyTransformer

The invention discloses a temperature controller compensation device for a large-sized power transformer. The temperature controller compensation device for the large-sized power transformer comprises a cylinder body (2), a connecting rod (1), a leaf spring (3), an adjusting nut (4), a spring (5), a cylinder body cover (6) and a push rod (7), wherein a containing groove (8) is formed in the cylinder body (2), the connecting rod (1) is arranged at the bottom of the cylinder body (2), the leaf spring (3) is arranged on the innermost portion of the containing groove (8) of the cylinder body (2), the free length of the leaf spring (3) changes along with changes of the temperature in a linear mode, one end of the adjusting nut (4) is connected with the interior of the leaf spring (3) in a sleeved mode, the spring (5) is connected with the other end of the adjusting nut (4) in a rotary mode, the cylinder body cover (6) seals the containing groove (8), a hole (9) is formed in the cylinder body cover (6), and the push rod (7) is connected with the adjusting nut (4) in a threaded mode, and penetrates out of the hole (9) of the cylinder body cover (6). Due to the fact that the free length of the leaf spring changes along with the changes of the temperature, the leaf spring pushes the adjusting nut to drive the push rod to contract or stretch out, the purpose of temperature compensation is achieved, and the temperature controller compensation device for the large-sized power transformer is simple in structure, simple in manufacturing technology, good in reliability, high in accuracy of temperature compensation, high in qualified rate and low in cost.

Owner:SHENZHEN TESTECK TECH

Temperature compensation method and apparatus for received signal strength indicator

ActiveUS9209913B2Improve accuracyReduce storage spaceReceivers monitoringElectromagentic field characteristicsReceived signal strength indicationUltimate tensile strength

Embodiments of the present invention provide a temperature compensation method and apparatus for a received signal strength indicator. The apparatus comprises a temperature sensor configured to measure a current temperature; and a digital compensation module configured to select a temperature compensation coefficient from prestored temperature compensation coefficients corresponding to a normal temperature, a low temperature and a high temperature according to the current temperature, and perform temperature compensation on output signals of the RSSI according to the selected temperature compensation coefficient. With the method and apparatus of the embodiments of the present invention, the accurate power values of the input signals of the RSSI under any temperatures can be obtained by measuring the characteristics of the RSSI under the predefined three temperatures, and using an interpolation method to compensate for the temperature characteristics of the RSSI. In comparison with the relevant art, the size of the storage is decreased and the accuracy of temperature compensation is improved.

Owner:FUJITSU LTD

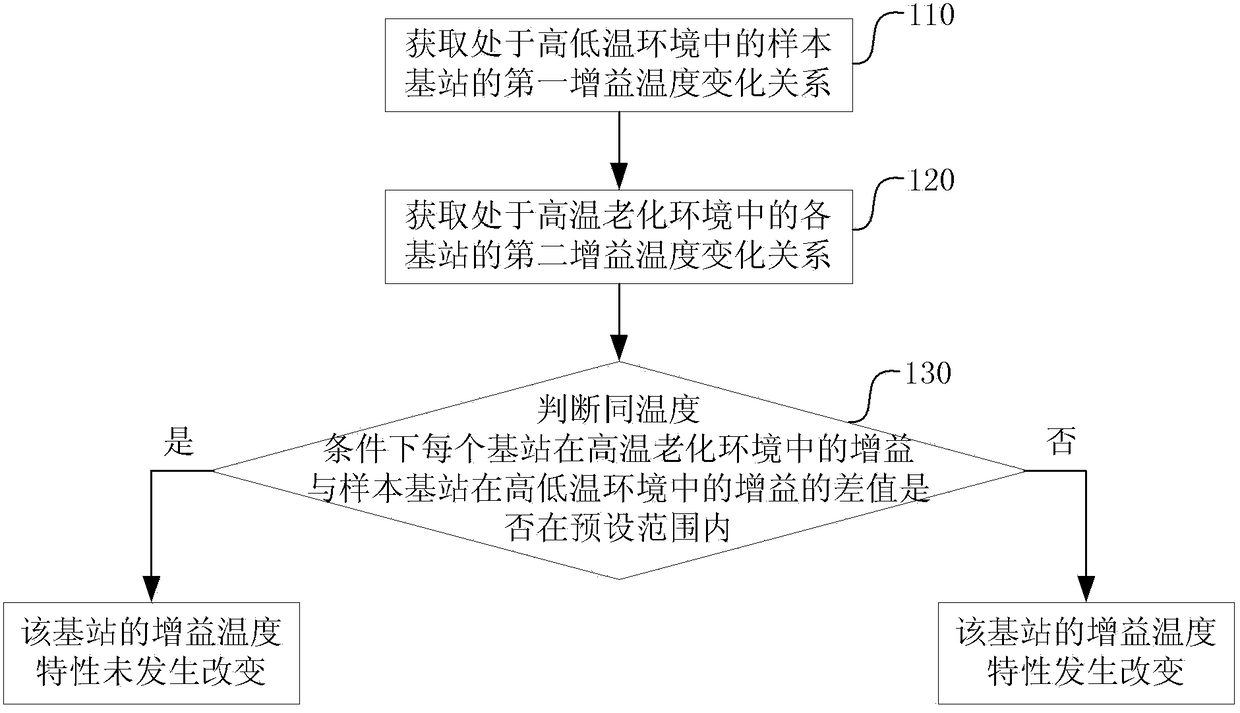

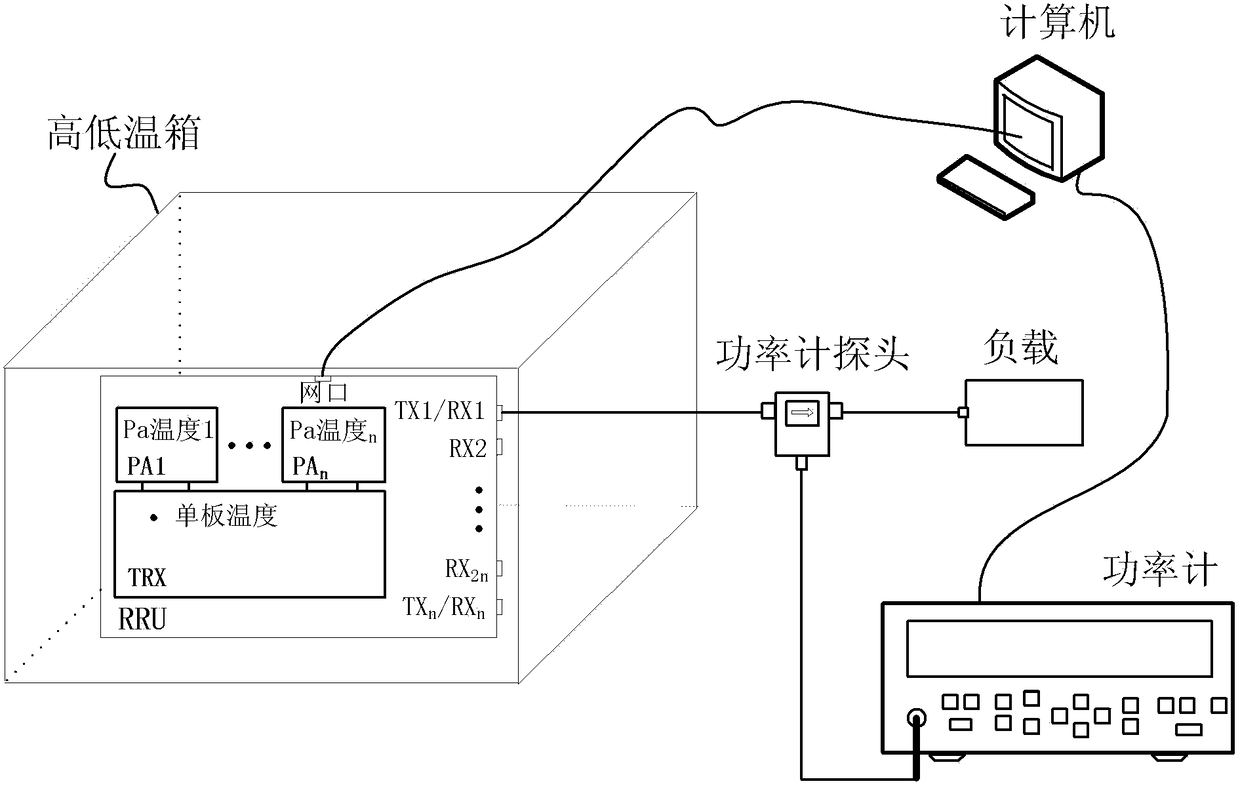

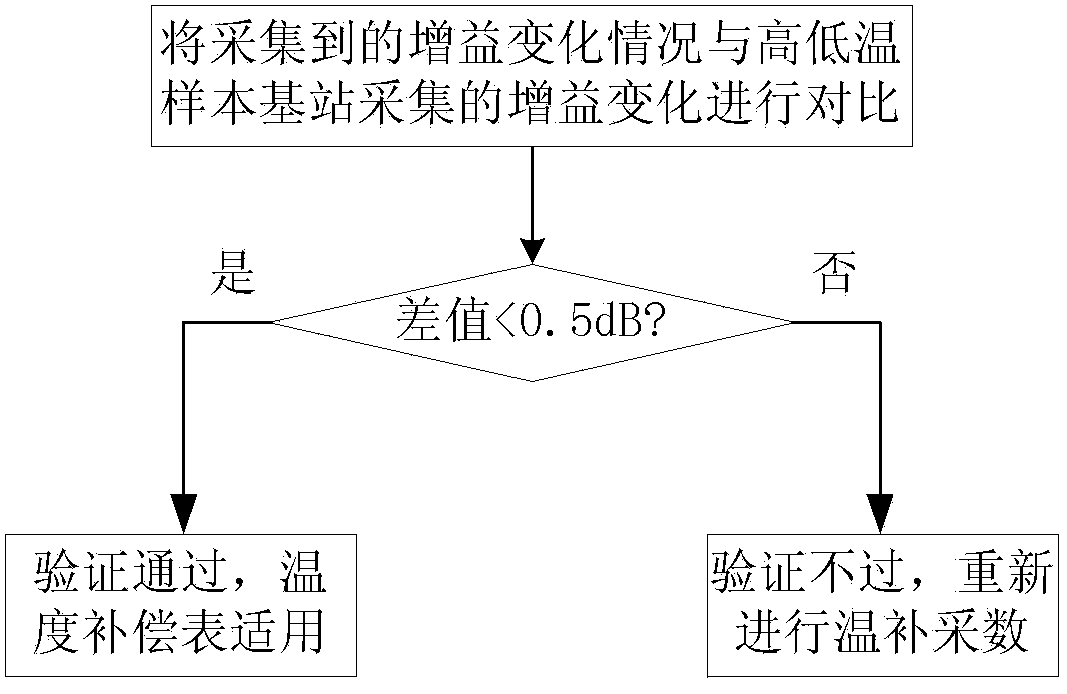

A base station gain temperature compensation, calibration and verification method and compensation device

ActiveCN103458447BImproved Temperature Compensation AccuracyAvoid Compensation BiasPower managementValidation methodsTemperature difference

The invention discloses a base station gain temperature compensation, calibration and verification method and a compensation device. The gain temperature compensation method can solve the problem that the traditional method cannot accurately compensate the gain temperature characteristics of each area of a multi-transmit and multi-receive base station, including: according to different areas of the base station Call the gain temperature compensation table corresponding to each area at the current working temperature to obtain the initial gain temperature compensation value corresponding to each area; call the gain temperature compensation table corresponding to each area according to the reference temperature of each area of the base station corresponding to the current frequency point to obtain each area The base gain temperature compensation value corresponding to the area; calculate the difference between the initial gain temperature compensation value of each area of the base station and the base gain temperature compensation value of the area, as the gain temperature compensation value of each area; the gain temperature compensation value of each area of the base station The gain temperature compensation value of the entire base station is obtained by adding the values, and the gain temperature compensation value of the base station is used to compensate the gain temperature characteristic of the base station.

Owner:ZTE CORP

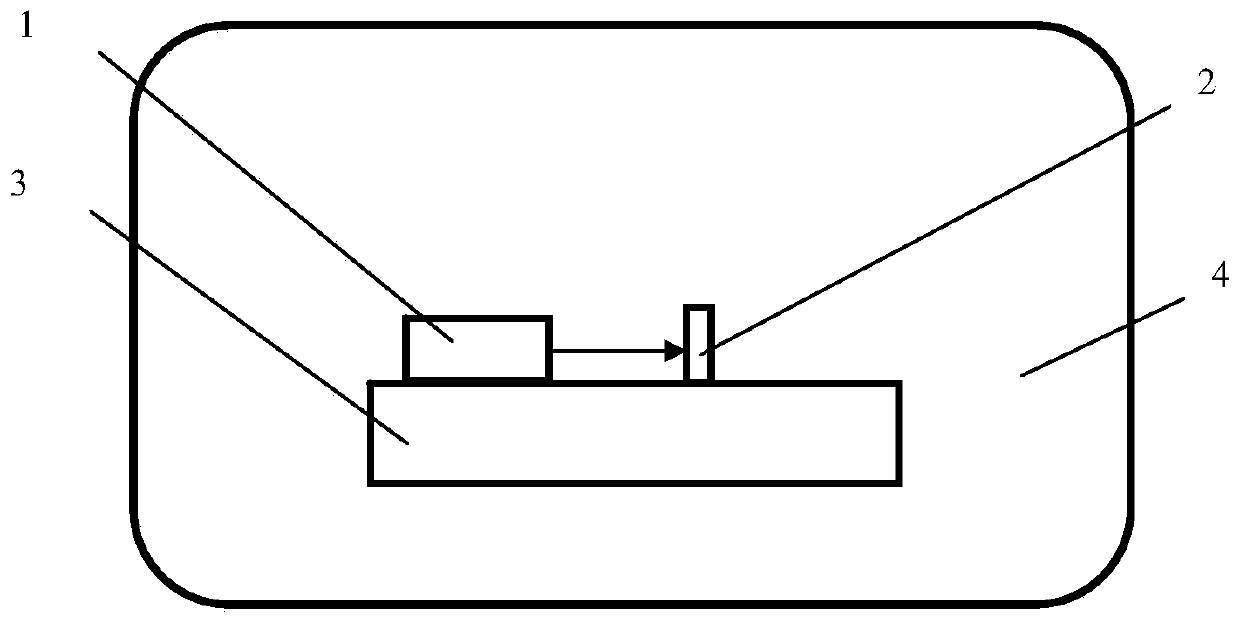

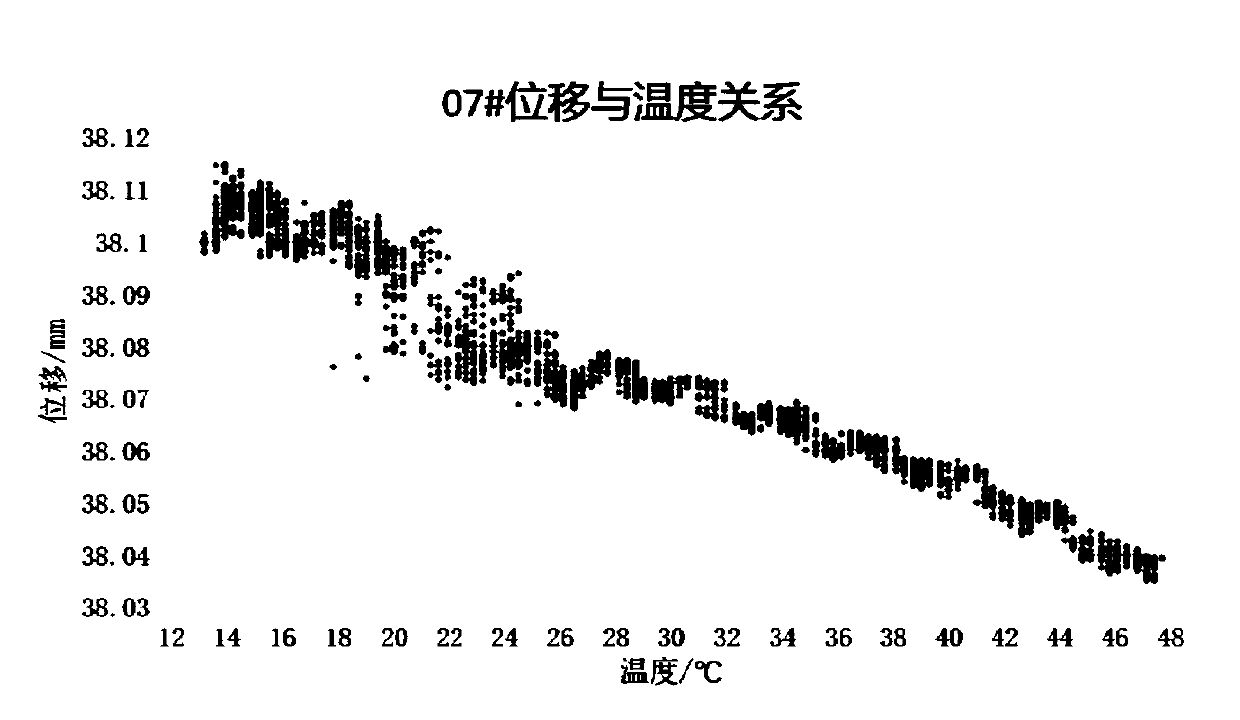

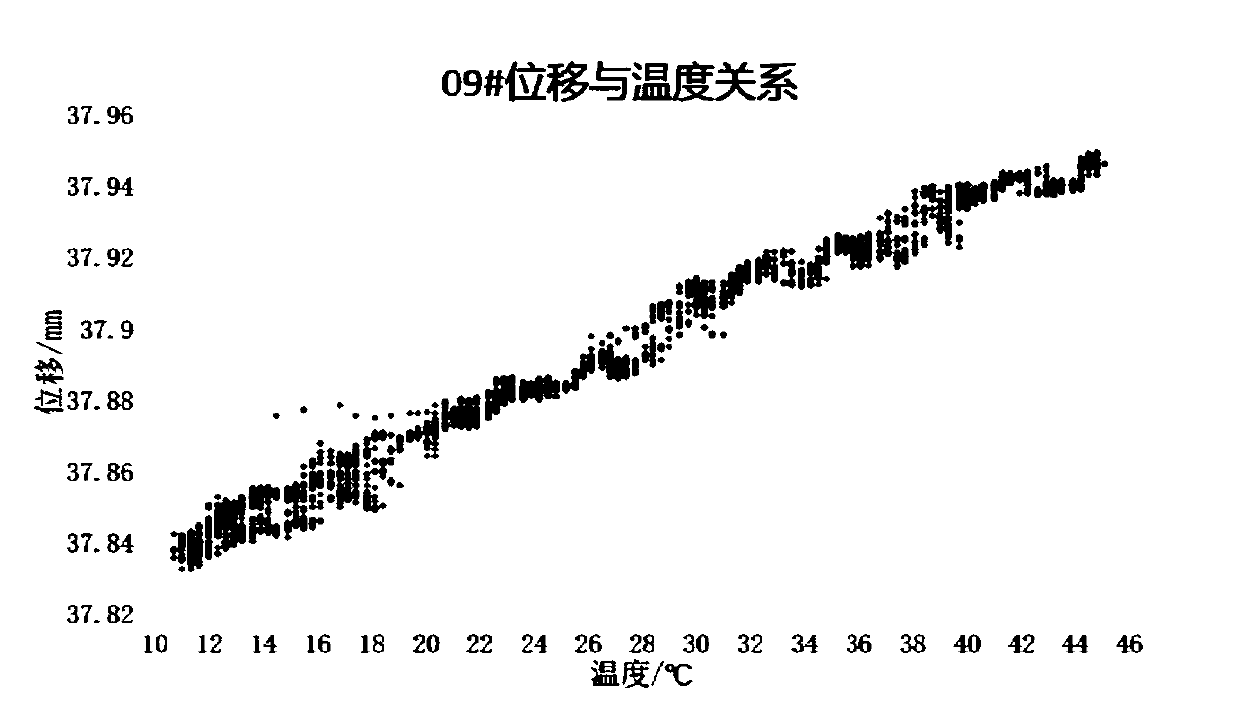

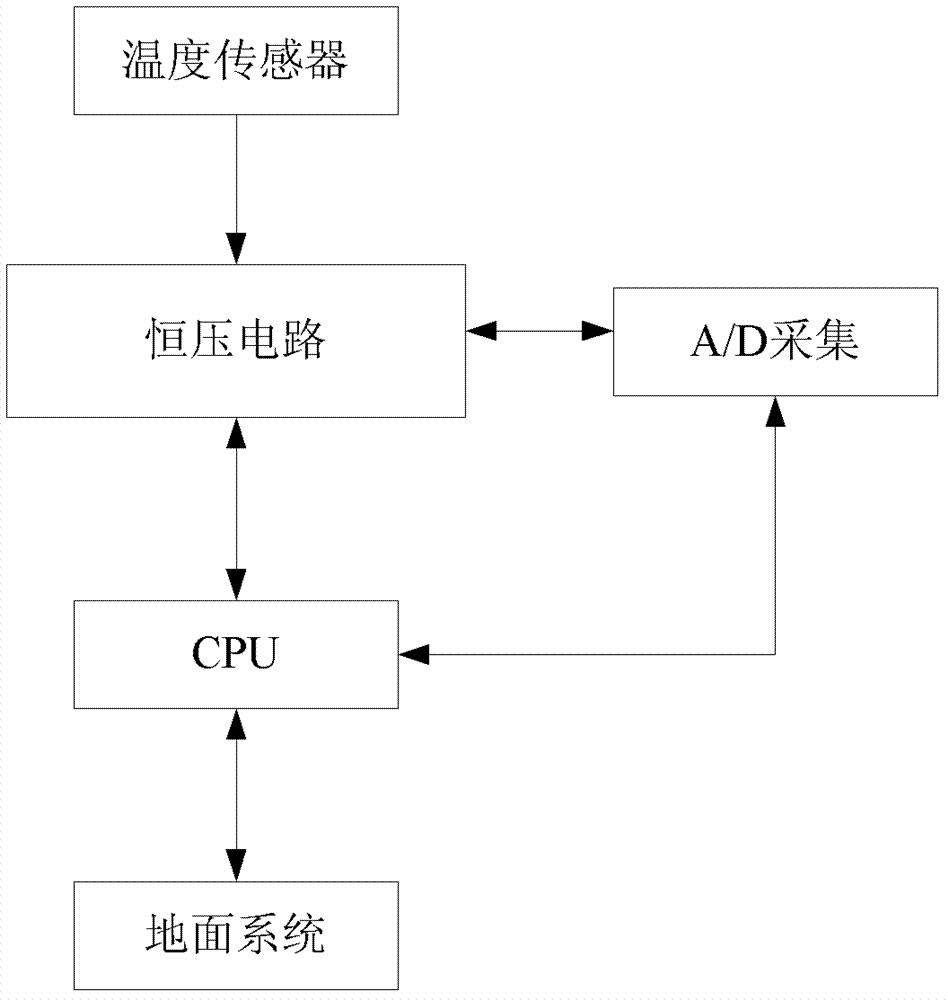

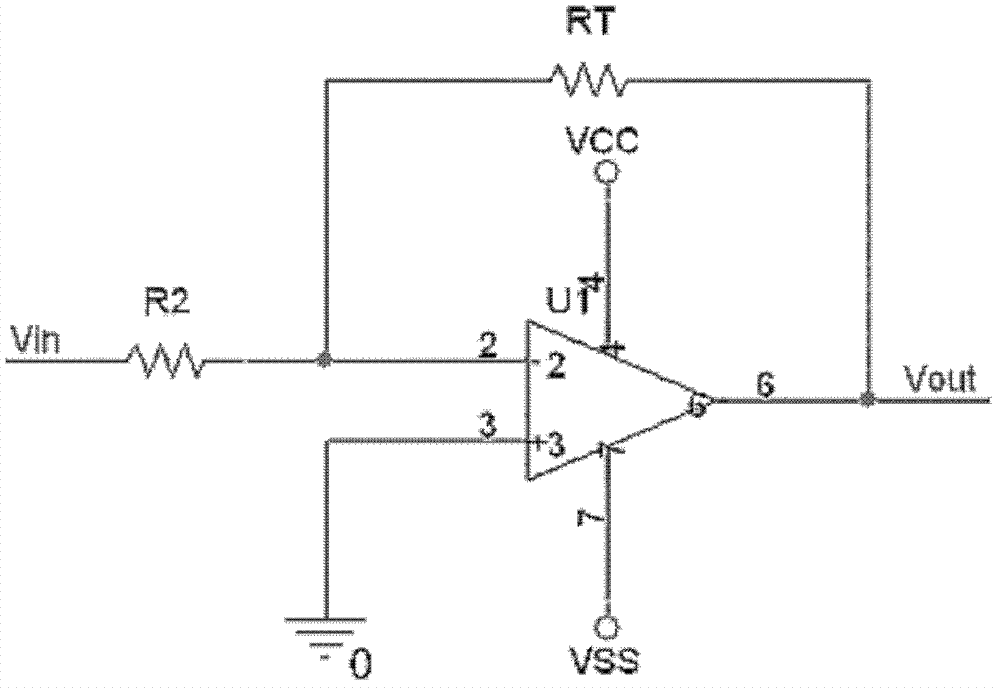

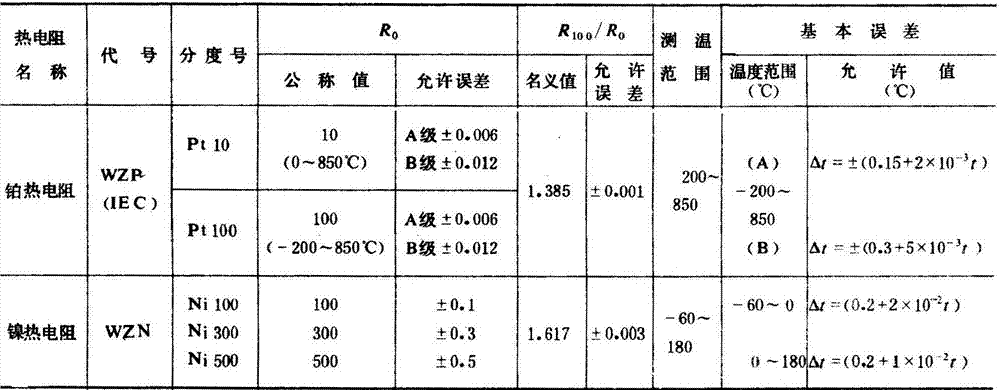

A temperature adaptive compensation method for laser displacement sensor

ActiveCN110470227BAchieving Adaptive CompensationSolve the deviation caused by differentUsing optical meansEngineeringSelf adaptive

The invention discloses a temperature self-adaptive compensation method for a laser displacement sensor, and the method comprises the following steps of respectively testing the output displacement values of the laser displacement sensor at different temperatures under different distance conditions; obtaining temperature characteristic parameter values of a displacement-temperature change curve ofthe laser displacement sensor under different distance conditions through polynomial fitting; performing polynomial fitting on the temperature characteristic parameter values at different distances to obtain calculation coefficients of the temperature characteristic parameters of the laser displacement sensor under different distance conditions; and calculating a temperature characteristic parameter corresponding to an absolute displacement value obtained in the measurement process to obtain a temperature compensation value of the displacement, and compensating the displacement value obtainedby actual measurement by using the temperature compensation value. The temperature self-adaptive compensation method for the laser displacement sensor can adapt to any position in a full range, effectively solves the deviation caused by different temperature coefficients at different distances, and not only has self-adaptive performance, but also greatly improves the temperature compensation precision.

Owner:SHANGHAI JIAO TONG UNIV

A temperature compensation method for a dual induction eight lateral logging tool and a coil system of a dual induction eight lateral logging tool

ActiveCN102505937BNo need to change the mechanical structureTo achieve the purpose of temperature compensationConstructionsReaction temperatureEngineering

The invention relates to a temperature compensation method for a dual-induction eight-side lateral logging tool and a coil system of a double-induction eight-side lateral logging tool. Temperature Sensor. The invention provides a temperature compensation method for coil systems of a double-induction eight-side logging tool that can accurately respond to probe temperature changes, has high precision, and is easy to operate.

Owner:XIAN SITAN INSTR

Cement-based intelligent composite material strain sensor with temperature compensation function

ActiveCN102506691BWith temperature compensation functionHigh sensitivity factorElectrical/magnetic solid deformation measurementFiberCarbon fibers

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

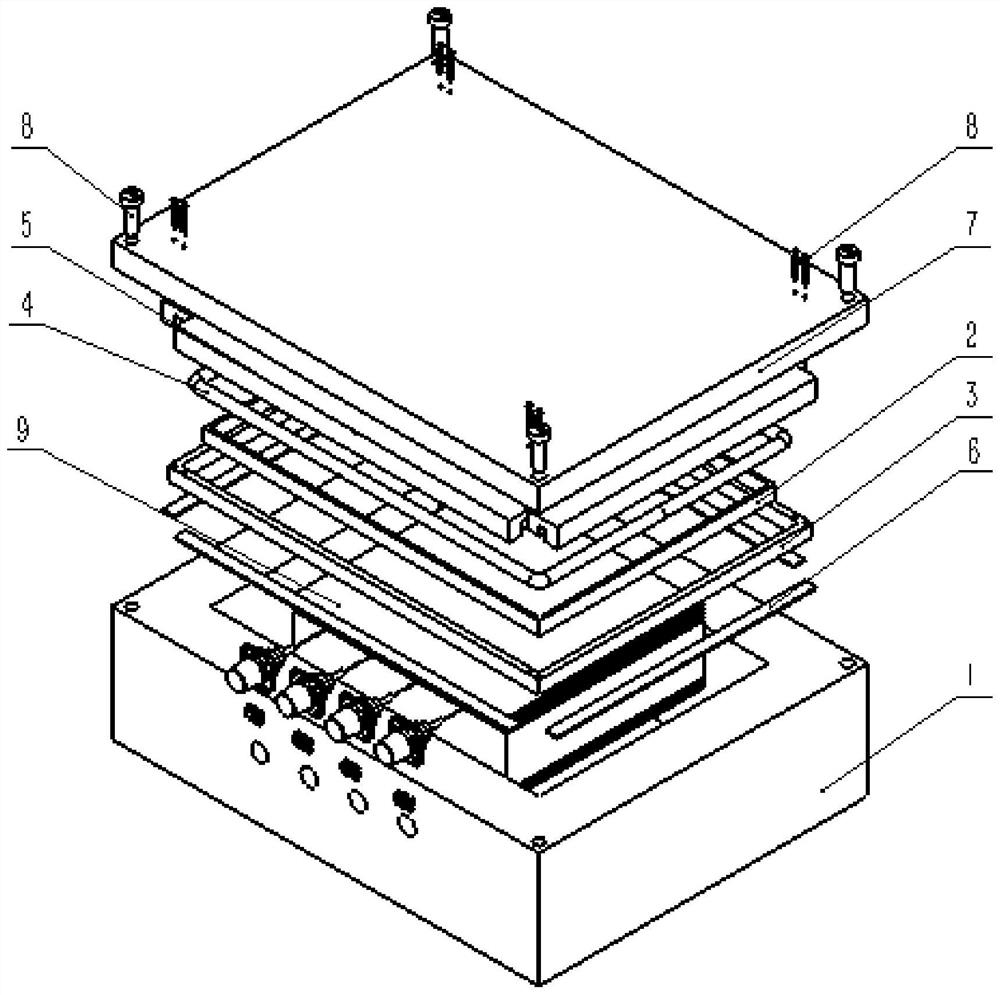

Temperature Compensation Device of Reinforced Fiber Composite Fiber Bragg Grating Strain Sensor

ActiveCN111307325BSolve the problem of wavelength drift differenceImproved Temperature Compensation AccuracyThermometer detailsThermometers using physical/chemical changesHeat-shrinkable sleeveGlass fiber

The invention relates to a temperature compensation device for a fiber grating strain sensor of reinforced fiber composite material, which comprises a base in which a fiber grating temperature compensation device is arranged: four layers of glass fiber cloth prepregs are respectively laid on the upper and lower ends of a foam core material, and Between the four layers of glass fiber cloth prepregs, between the foam core material and the glass fiber cloth prepregs, temperature compensating optical fibers are respectively embedded, and the three are integrated through the curing molding process. Lead out from one side, pass through the sleeve at the edge of the glass fiber cloth prepreg, and weld and connect with the jumper in the heat shrinkable sleeve. The jumper port is connected to the input port of the adapter, and the adapter passes through the mounting hole on the front side of the base. And it is connected to the base through fixing screws, thereby solving the problem of thermal strain differences at different lay-up positions of the composite material, which causes the center wavelength drift difference of the fiber grating temperature compensation sensor. The seal seals for an improved watertight seal.

Owner:CHINA SHIP SCIENTIFIC RESEARCH CENTER (THE 702 INSTITUTE OF CHINA SHIPBUILDING INDUSTRY CORPORATION)

An Adaptive Accelerometer Temperature Compensation Method for Inertial Navigation

ActiveCN110823216BHigh precisionImprove effectivenessNavigation by speed/acceleration measurementsAccelerometer dataMathematical model

The invention discloses an adaptive accelerometer temperature compensation method for inertial navigation, the method comprising: S1, testing multiple sets of accelerometer data output by inertial navigation within the full temperature range; S2, multiple sets of accelerometer data obtained in step S1 Accelerometer data is calculated and analyzed to obtain the output characteristics of multiple groups of accelerometers; S3, according to the output characteristics of the accelerometers in step S2, establish multiple groups of mathematical models; S4, according to the working state parameters of the inertial navigation system, from multiple groups of mathematical models Select the best mathematical model as the temperature compensation model of the current working state for temperature compensation. The advantage is that this method collects the output data of the accelerometer in the full temperature range multiple times, uses big data to analyze the characteristics of the accelerometer changing with temperature, and obtains a variety of segmented linear or curve fitting mathematical models. Different mathematical models match the data output characteristics under different working conditions, which improves the measurement accuracy of the accelerometer and the effectiveness of the temperature compensation method.

Owner:SHANGHAI AEROSPACE CONTROL TECH INST

Circuit device, oscillator, electronic apparatus, and vehicle

ActiveUS10491156B2Reduce errorsImprove accuracyGenerator stabilizationOscillations generatorsElectricityEngineering

A circuit device includes an oscillation circuit configured to cause a resonator to oscillate, a clock signal output circuit configured to output a clock signal based on an oscillation signal from the oscillation circuit, a temperature compensation circuit configured to perform temperature compensation on an oscillation frequency of the oscillation signal, a low-potential-side power supply pad to which low-potential-side electric power is supplied, a high-potential-side power supply pad to which high-potential-side electric power is supplied, and an inter-power-supply capacitor provided between a low-potential-side power supply line electrically continuous with the low-potential-side power supply pad and a high-potential-side power supply line electrically continuous with the high-potential-side power supply pad. The inter-power-supply capacitor is formed of at least two metal layers provided in a region where the temperature compensation circuit is disposed in a plan view.

Owner:SEIKO EPSON CORP

High-precision sputtering thin-film pressure sensor with wide temperature range and its manufacturing method

ActiveCN109238524BHigh precisionSolving Electrical Connection Reliability IssuesForce measurementElectrical connectionHemt circuits

Owner:XIAN AEROSPACE PROPULSION INST

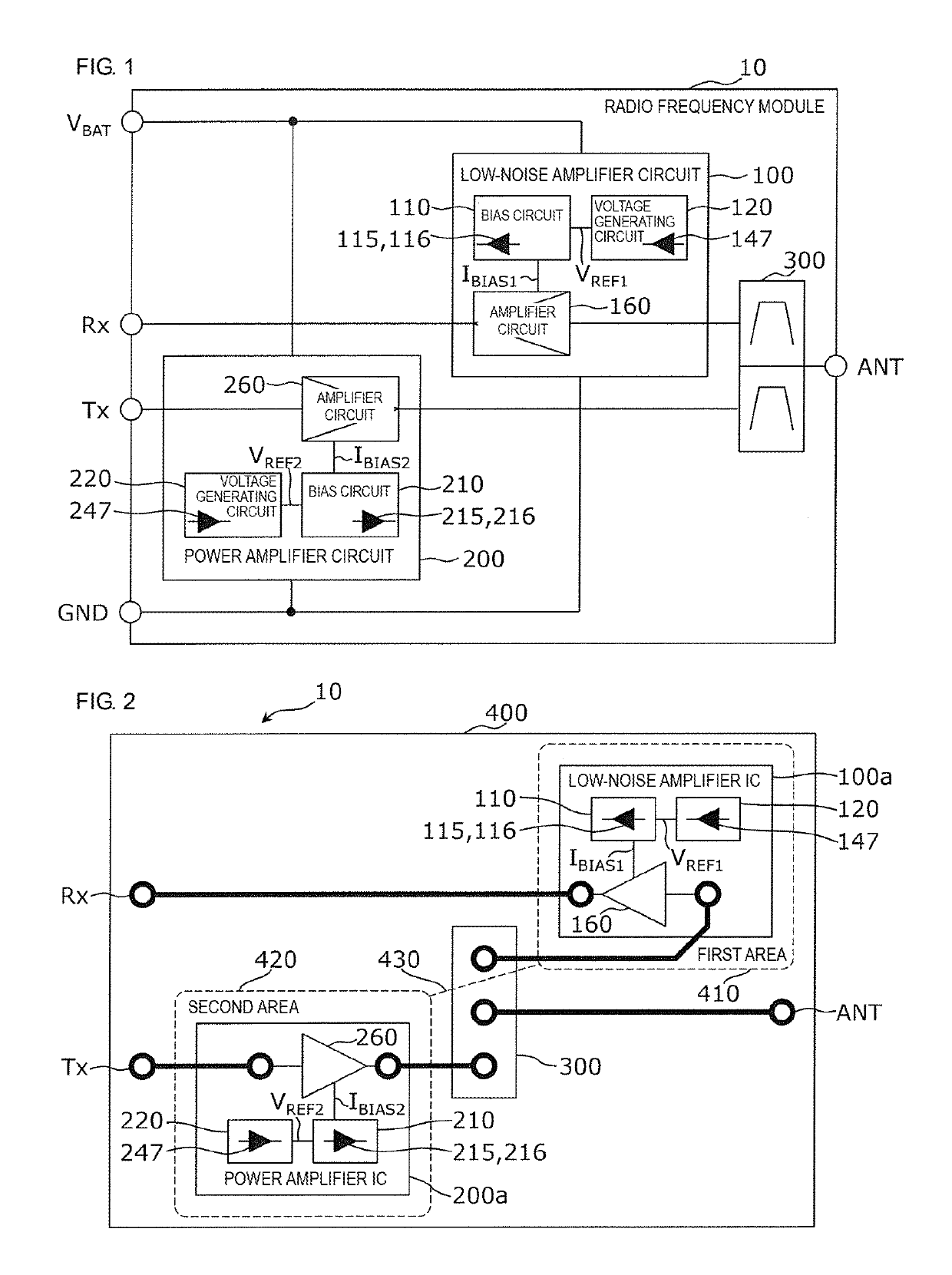

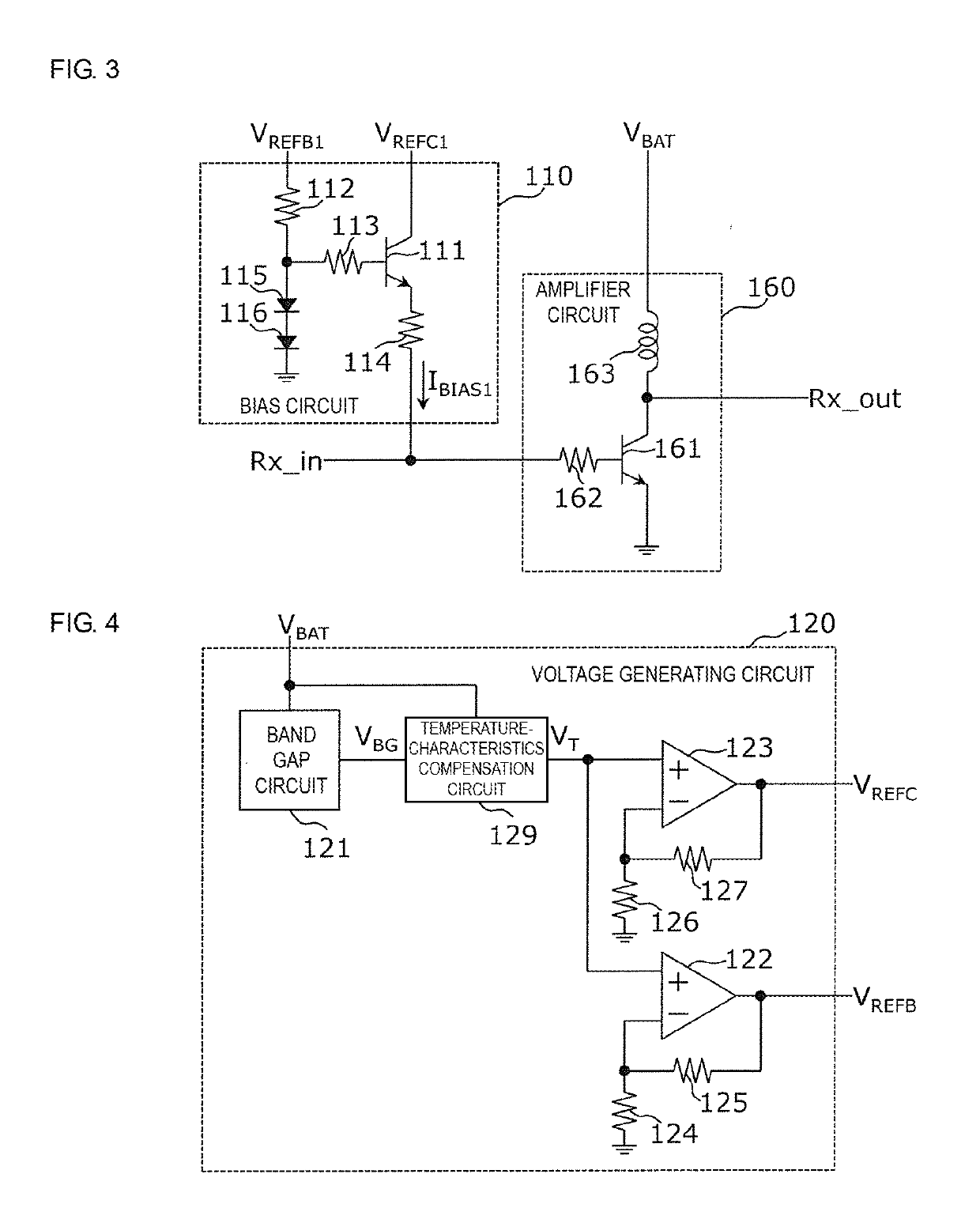

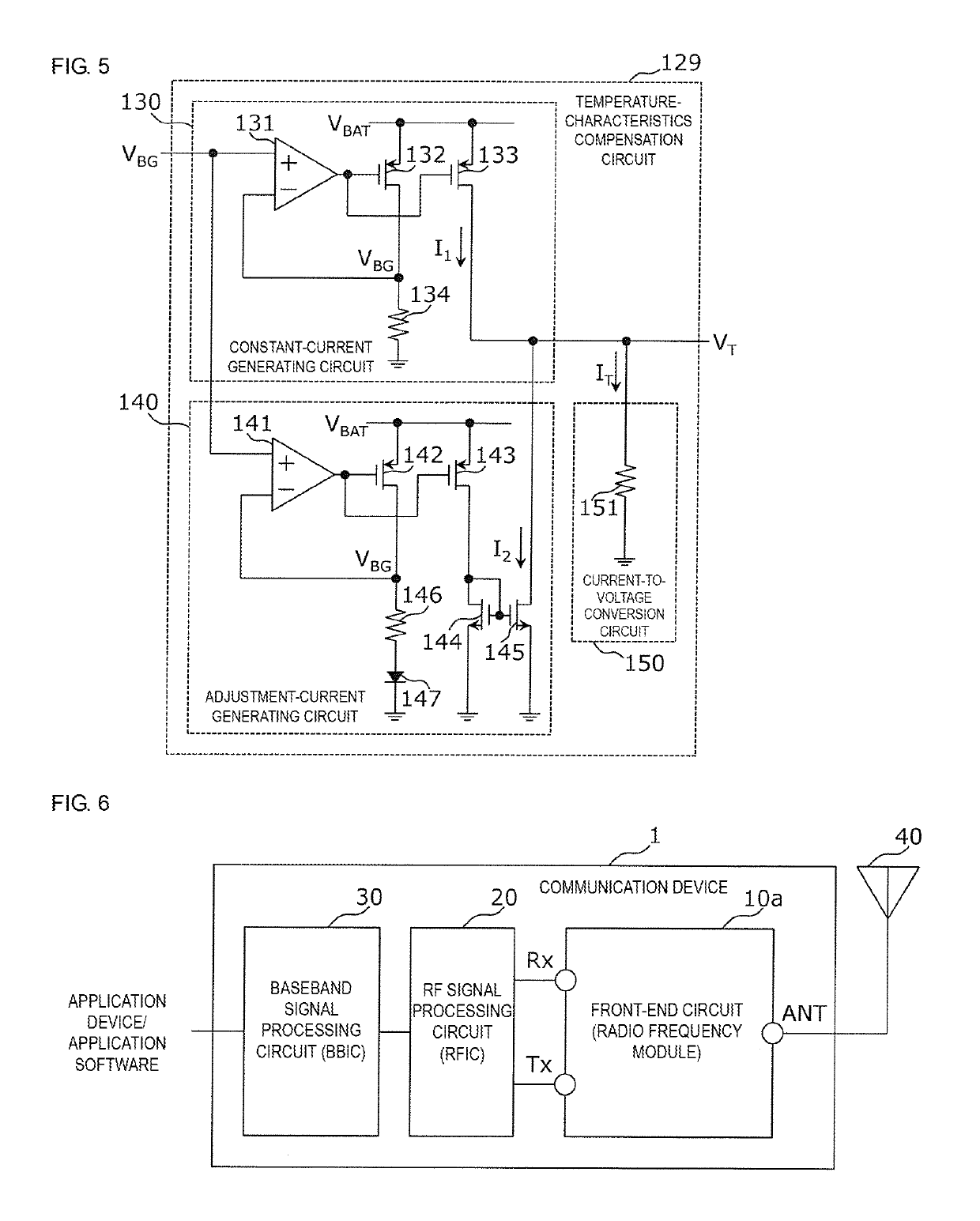

Radio frequency module and communication device

ActiveUS10348253B2Improved Temperature Compensation AccuracyReduce impactHigh frequency amplifiersAmplifier modifications to reduce temperature/voltage variationOperating pointPower flow

A radio-frequency module includes a substrate, a low-noise amplifier circuit being a first amplifier circuit arranged in a first area in the substrate, a power amplifier circuit being a second amplifier circuit arranged in a second area in the substrate, and a duplexer being a component arranged between the first area and the second area in the substrate and having a heat generating property lower than that of the power amplifier circuit. The low-noise amplifier circuit includes a bias circuit configured to generate a bias current dependent on temperature characteristics of a first diode, a voltage generating circuit configured to generate a voltage dependent on temperature characteristics of a second diode as an operating voltage for the bias circuit, and an amplifier circuit configured to operate at an operating point determined by the bias current.

Owner:MURATA MFG CO LTD

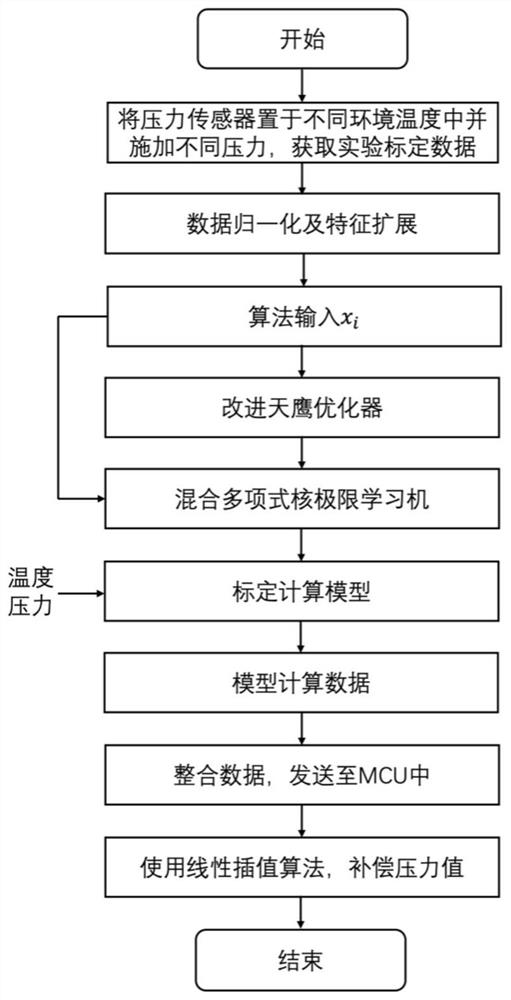

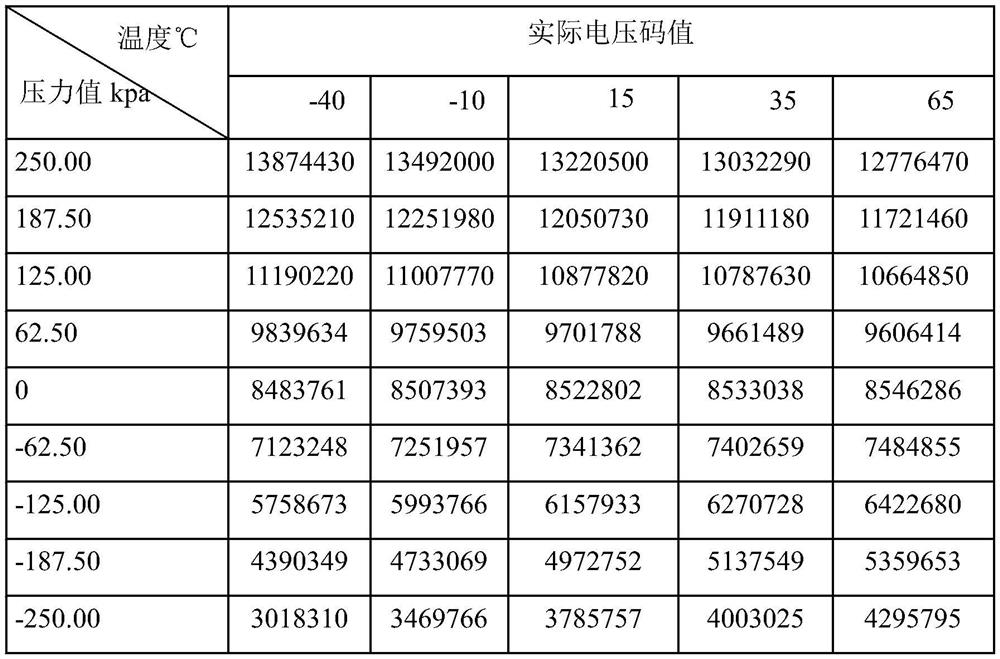

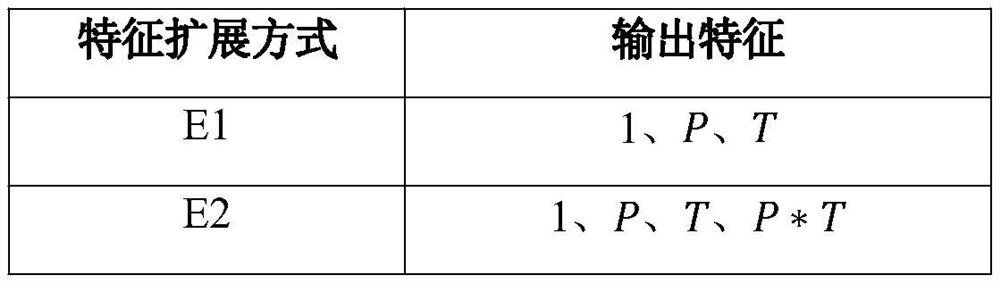

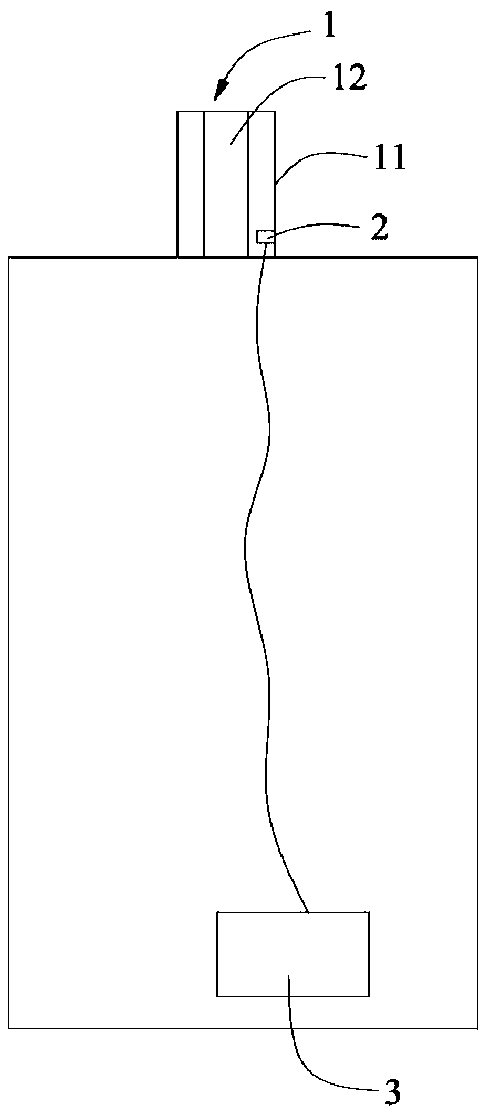

Simplified calibration method of pressure sensor

ActiveCN114791334AReduce consumptionScale upFluid pressure measurement using ohmic-resistance variationForce measurement using piezo-resistive materialsLearning machineDatasheet

The invention discloses a calibration simplification method of a pressure sensor. The method comprises the following steps: 1) placing a pressure sensor in a corresponding temperature environment, applying different pressures to obtain experimental calibration data, and sending the experimental calibration data to an upper computer; 2) performing normalization processing and feature expansion on the calibration data; 3) using a hybrid polynomial kernel extreme learning machine optimized by an improved eagle optimizer to learn calibration data to obtain a calibration calculation model; 4) inputting the values of the uncalibrated temperature points and pressure points into the trained calibration calculation model to obtain model calculation data; and 5) integrating experimental calibration data and model calculation data to form an online compensation data table, sending the online compensation data table to the MCU, and performing online temperature compensation on the pressure sensor by using a linear interpolation method. Through a small amount of calibration data, calculation data of the whole temperature zone can be inferred, temperature and pressure points needing to be calibrated are reduced, calibration work efficiency is improved, energy consumption is reduced, and temperature compensation precision is improved.

Owner:ZHEJIANG UNIV

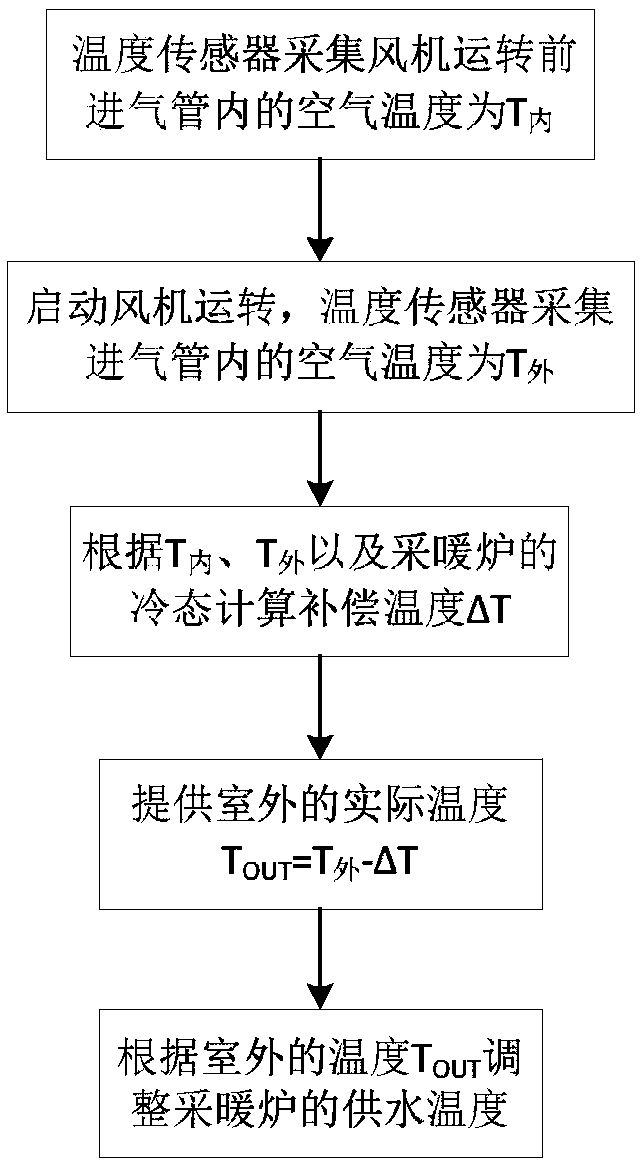

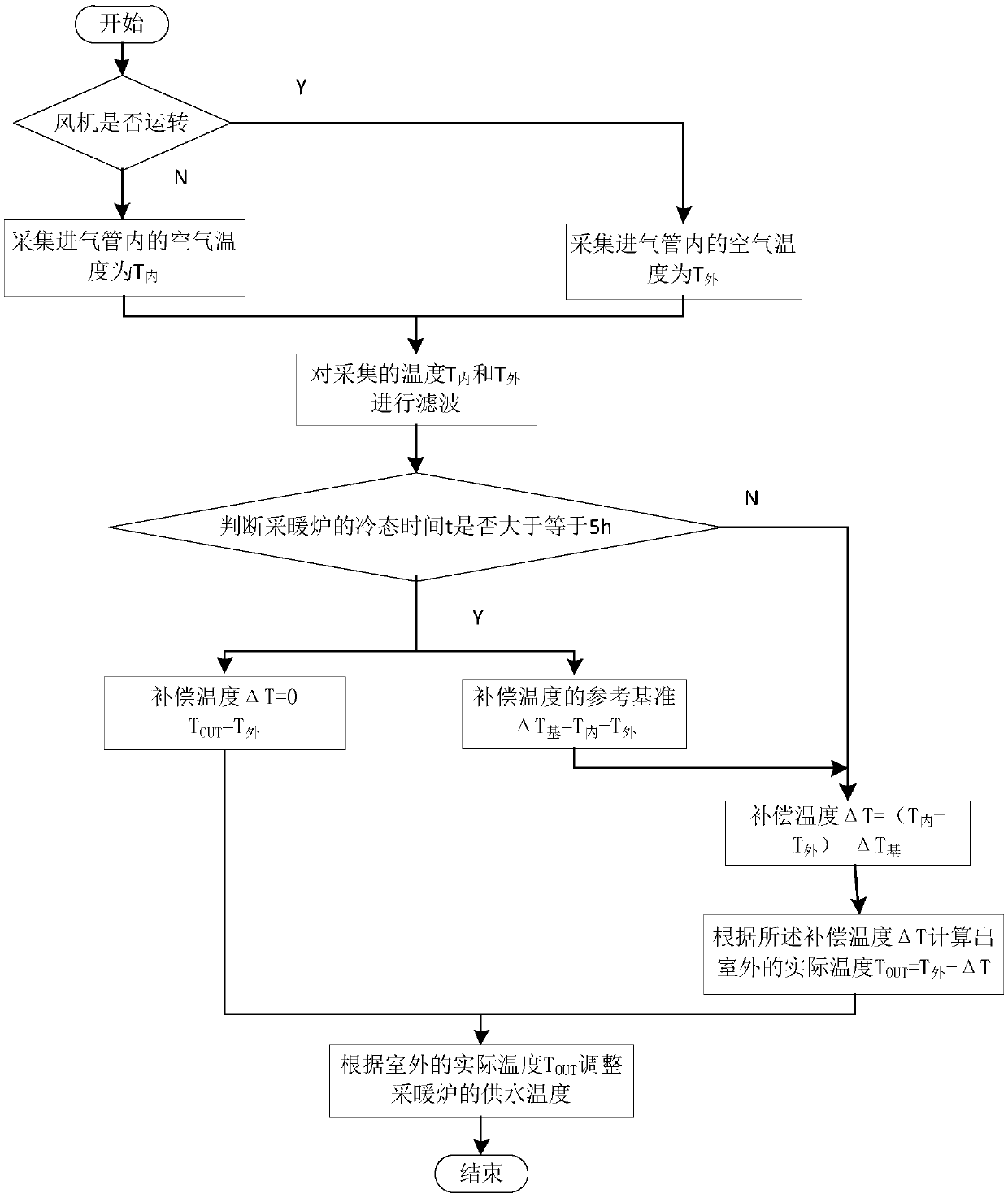

Outdoor temperature detection device for heating furnace, automatic temperature control method and heating furnace

ActiveCN110873467AIssues Affecting Acquisition Temperature ReliabilityHigh Acquisition AccuracyFluid heatersTemperature controlProcess engineering

The invention relates to the technical field of heating furnaces, and discloses an outdoor temperature detection device for a heating furnace, an automatic temperature control method and a heating furnace. According to the outdoor temperature detection device for the heating furnace, a temperature sensor detecting the outdoor temperature is installed on the pipe wall of the inner side of an air inlet pipe, the problem of additional drilling is solved, the installation cost is lowered, the problem that the reliability of temperature collection of the temperature sensor is affected by outdoor factors is further effectively solved, and the collection accuracy of the temperature sensor is improved. The automatic temperature control method is applied to the outdoor temperature detection device,and the temperature compensation accuracy is high. The heating furnace can adjust the water supply temperature according to an outdoor temperature value in real time, and energy consumption of the heating furnace is reduced to achieve the purposes of energy conservation and environmental protection. The heating furnace adopts the automatic temperature control method, use is convenient, the energyconsumption is reduced, and energy conservation and environmental protection are achieved.

Owner:QINGDAO ECONOMIC & TECHN DEV ZONE HAIER WATER HEATER

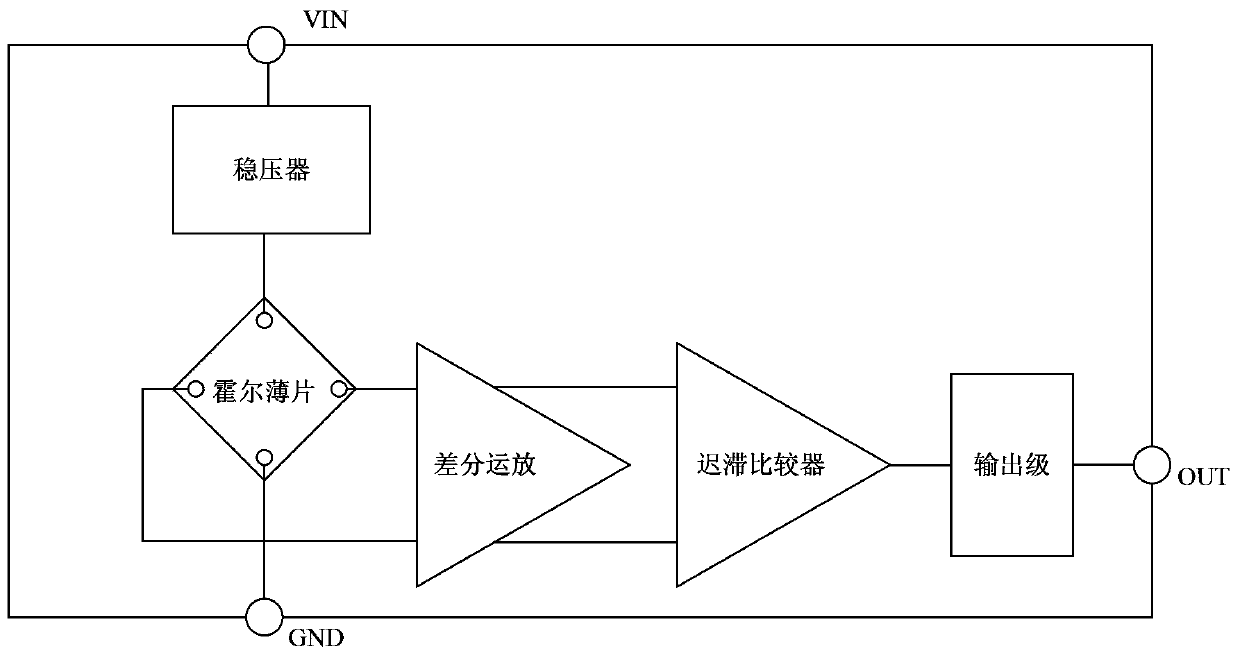

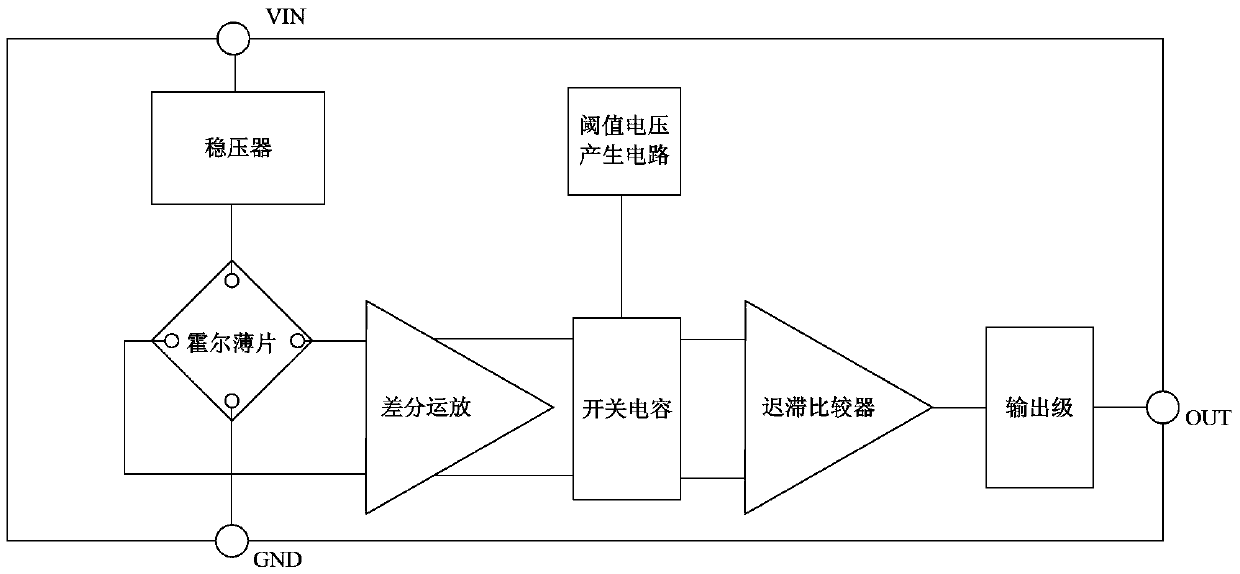

A temperature compensation circuit and temperature compensation method for a switch-type Hall sensor

ActiveCN103248345BLower requirementIncrease selectionElectronic switchingCapacitanceReference current

The invention discloses a temperature compensation circuit and a temperature compensation method of a switch-type Hall sensor, comprising: a Hall sheet, a differential amplifier, a switched capacitor circuit, a voltage stabilizer, and a hysteresis comparator, between the voltage stabilizer and the switched capacitor circuit A reference current generation circuit and a threshold voltage generation circuit are connected in series, and the reference current and threshold voltage are generated and supplied to the hysteresis comparator. The hysteresis comparator compares the amplified Hall induced voltage with the threshold voltage, and outputs the discrimination result to the output stage. The invention adds a reference current generation circuit module, changes the threshold voltage generation method, has higher temperature compensation accuracy, and is not affected by the non-linearity of the resistance temperature coefficient, and can realize indiscriminate high-precision compensation at each temperature value , which reduces the requirements on the used process lines, does not require specific positive and negative temperature coefficient resistors, and relaxes the selection of process lines for design engineers.

Owner:CROSSCHIP MICROSYST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com